Low-heat micro-expansion composite cement and preparation method thereof

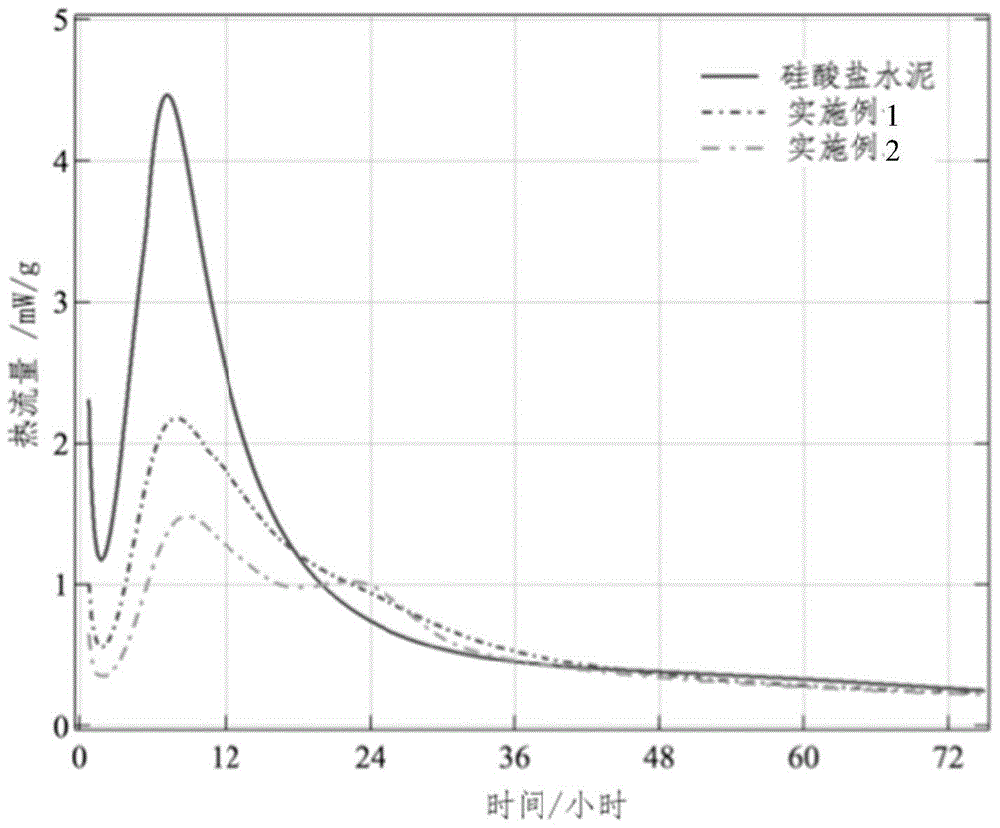

A composite cement and micro-expansion technology, which is applied in the field of building materials, can solve the problems that magnesium oxide cannot be effectively compensated, the dispersion uniformity of concrete is difficult to ensure, and the shrinkage cannot be fully compensated, so as to optimize the gradation of cement and waste slag particles and improve water quality. Improve the hydration efficiency and reduce the effect of hydration heat release

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

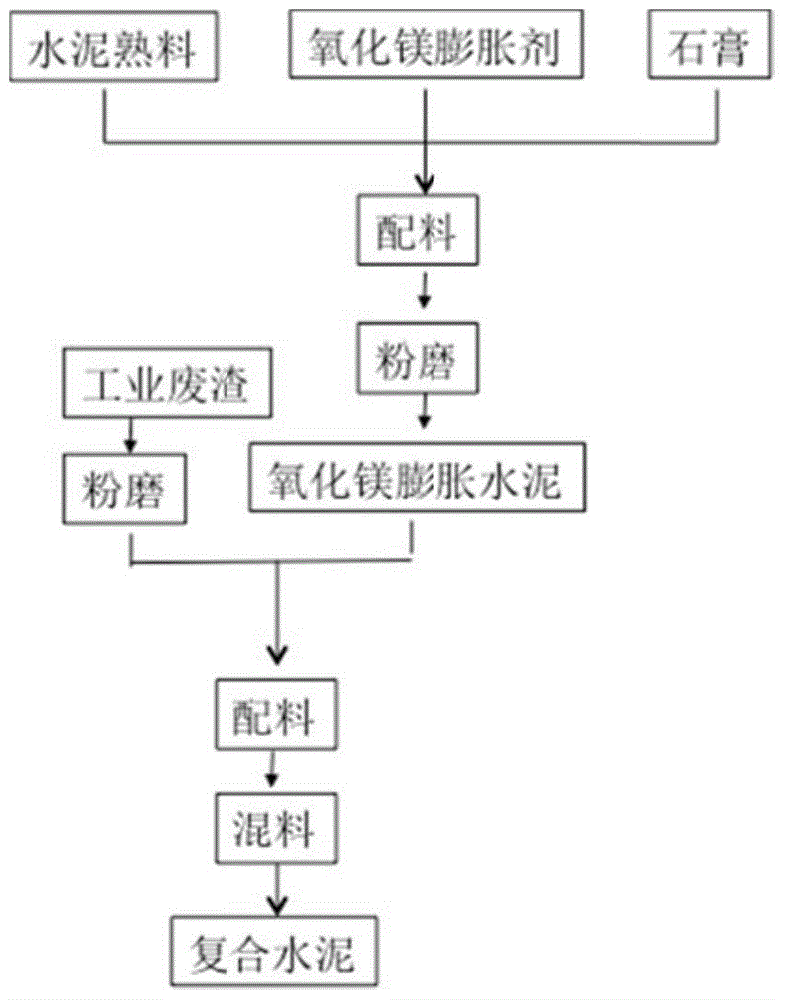

[0024] use figure 1 In the process flow shown, 53.1 parts of Portland cement clinker, 4.25 parts of magnesium oxide expansion agent (according to the citric acid method, the activity index is 50s, the magnesium oxide content is 87wt%, and the specific surface area is 25m 2 / kg. ) and 2.65 parts of gypsum are ground in a ball mill to prepare magnesium oxide expansion cement with a specific surface area greater than 400m 2 / kg. Then use the prepared magnesia expansion cement and 20 parts of slag (separately ground until the specific surface area is greater than 450m 2 / kg), 20 parts of fly ash were mixed to prepare composite cement.

Embodiment 2

[0026] use figure 1 In the process flow shown, 35.4 parts of Portland cement clinker, 2.8 parts of magnesium oxide expansion agent (according to the citric acid method, the activity index is 50s, the magnesium oxide content is 87wt%, and the specific surface area is 25m 2 / kg. ) and 1.8 parts of gypsum are ground in a ball mill to prepare magnesium oxide expansion cement, and the specific surface area of cement is greater than 400m 2 / kg. Then use the prepared magnesia expansion cement and 40 parts of slag (separately ground until the specific surface area is greater than 450m 2 / kg), 20 parts of fly ash were mixed to prepare composite cement.

Embodiment 3

[0028] use figure 1 As shown in the technological process, 35.4 parts of Portland cement clinker, 2.8 parts of magnesium oxide expansion agent (according to the citric acid method, the activity index is 400s, the magnesium oxide content is 89wt%, and the specific surface area is 7.2m 2 / kg. ) and 1.8 parts of gypsum are ground in a ball mill to prepare magnesium oxide expansion cement, and the specific surface area of cement is greater than 400m 2 / kg. Then use the prepared magnesia expansion cement and 40 parts of slag (separately ground until the specific surface area is greater than 450m 2 / kg), 20 parts of fly ash were mixed to prepare composite cement.

PUM

| Property | Measurement | Unit |

|---|---|---|

| activation index | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com