Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

103results about How to "Reduce autogenous shrinkage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength super-toughness resin concrete and preparing method thereof

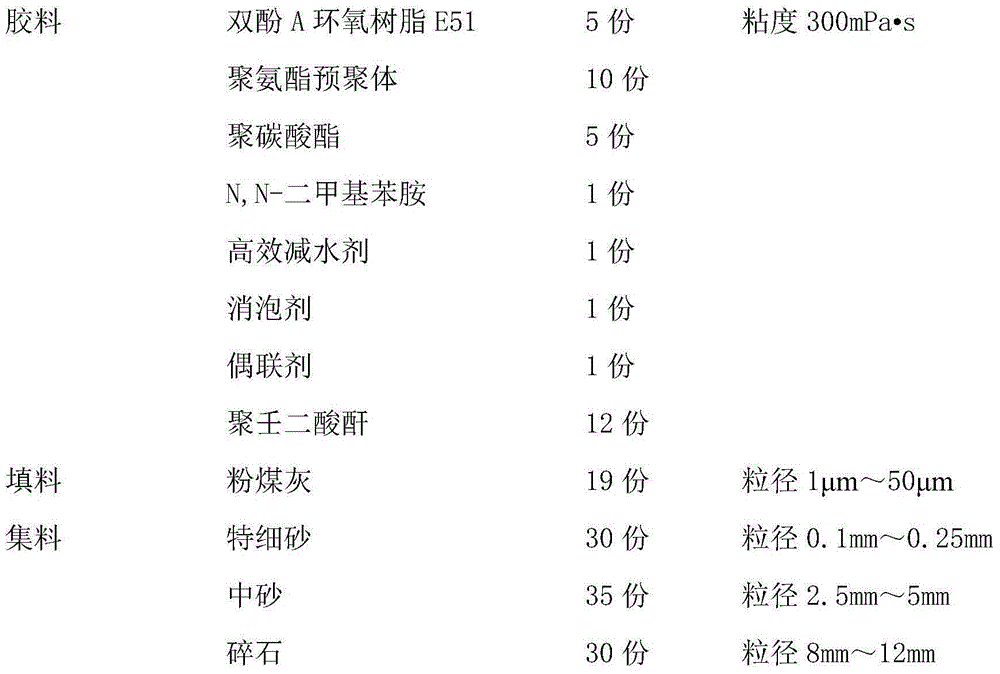

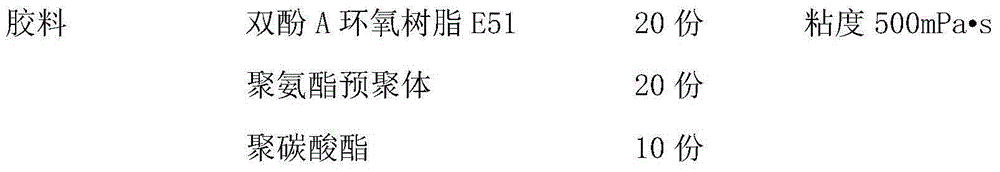

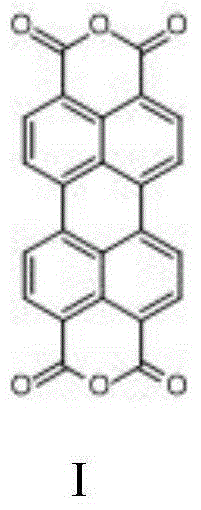

The invention discloses high-strength super-toughness resin concrete which is composed of aggregate, packing and a sizing material. The high-strength super-toughness resin concrete is characterized in that the sizing material is composed of resin A and a curing agent B. The resin A is composed of epoxy resin, polyurethane prepolymer, polycarbonate and a functional agent. The weight percentage of the resin A and the curing agent B is 1:1-2:1, and the packing is inorganic powder. The aggregate is composed of super-fine sand, coarse sand and gravel. The epoxy resin is bisphenol A epoxy resin. The functional agent comprises accelerant, a water reducing agent, a defoaming agent and a coupling agent. The curing agent is long-chain aliphatic series anhydride. The high-strength super-toughness resin concrete has the advantages that strength is high and even, cracking and breaking do not happen, the deformation capability is good, the elasticity recovery rate is high, and the high-strength super-toughness resin concrete is not prone to permanent deformation at a high temperature.

Owner:NANJING ROAD KEEPER TECH

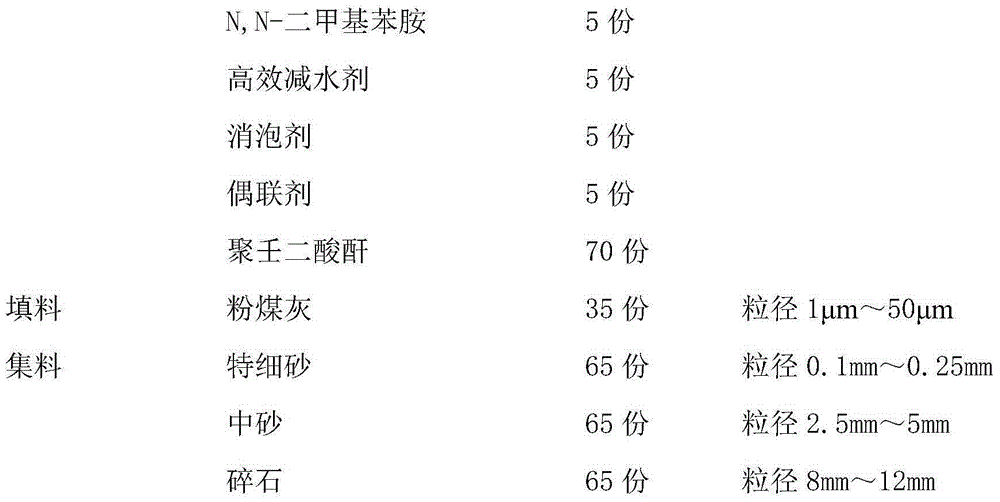

Ultrahigh-strength concrete and preparation method thereof

The invention discloses ultrahigh-strength concrete which comprises the following components in parts by weight: 300-350 parts of cement, 270-315 parts of composite mineral admixture, 30-35 parts of composite expanding agent, 96-112 parts of water, 680-720 parts of river sand, 1012-1080 parts of gravel, 13.2-14.0 parts of polycarboxylic acid high-efficiency water reducing agent, 4.4-4.7 parts of plastic retaining agent and 0.18-0.21 part of defoaming agent, wherein the composite mineral admixture is prepared from 42-49 parts of ore powder, 150-175 parts of fly ash, 30-35 parts of silica fume, 18-21 parts of zeolite powder and 30-35 parts of wollastonite powder. The invention is characterized in that the 60d concrete compression strength is 140-160 MPa, the 60d splitting tensile strength is 9.2-10.2 MPa, extruded concrete can achieve self-compaction effect within 3 hours, and the 14d self-shrinkage value is less than 0.05%.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD

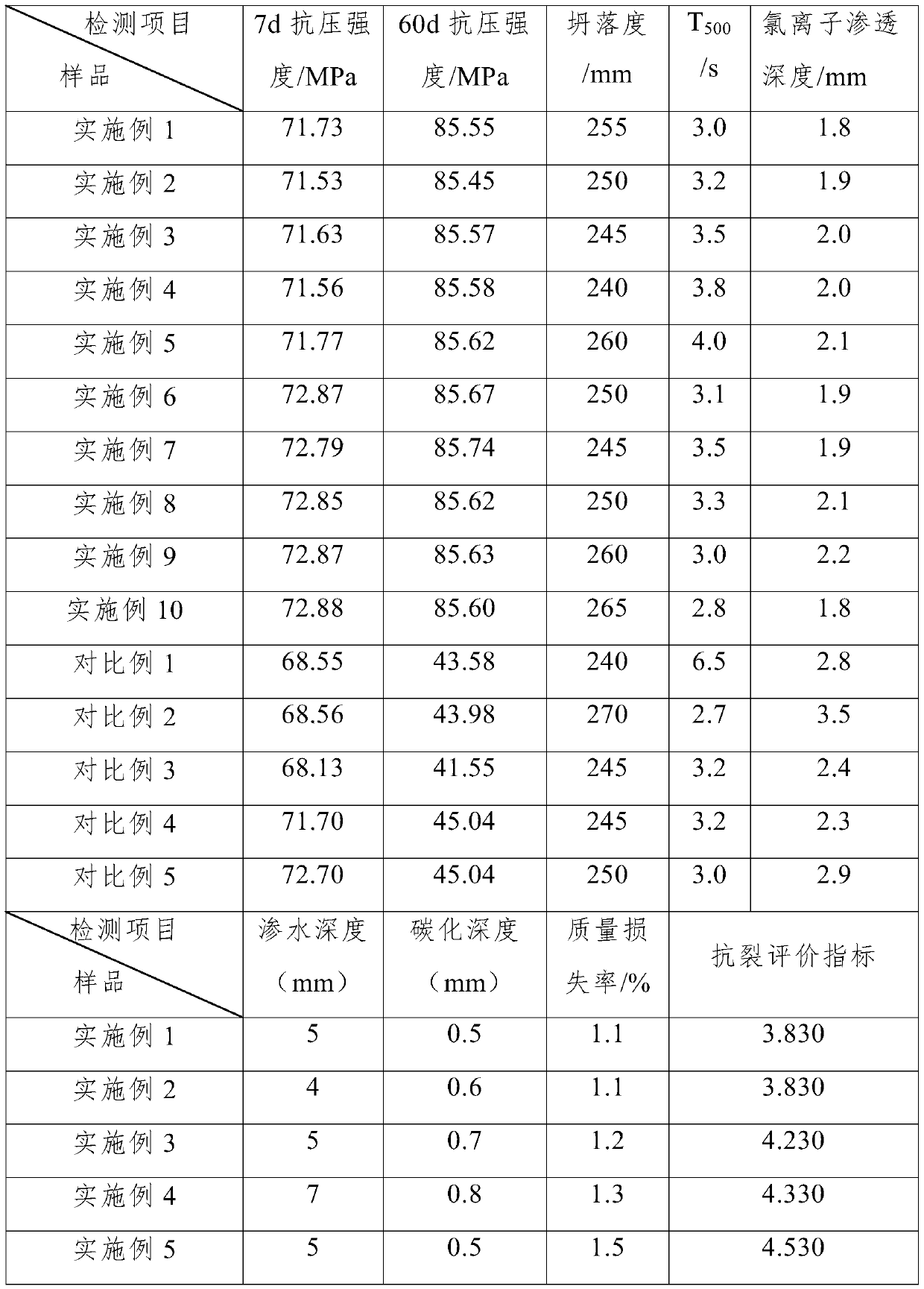

Low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensating and toughening, and preparation method thereof

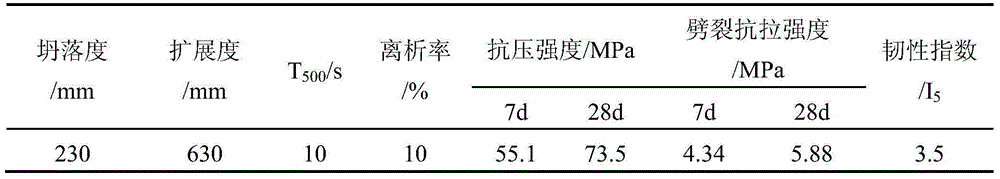

The present invention discloses a low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete based on internal curing, shrinkage compensating and toughening, wherein the low shrinkage anti-cracking C60 grade self-compacting bridge tower concrete is prepared from the following raw materials: cement, fly ash, mine powder, an expander, an AN-ICA internal curing agent, crushed stone, river sand, polyacrylonitrile fibers, micro-scale modified degreasing cotton cellulose, a cement slurry microstructure regulation agent, water and an ultra-dispersed water-reducing and shrinkage-reducing superplastic admixture. According to the present invention, the initial slump is more than or equal to 230 mm, the expansion degree is more than or equal to 630 mm, the 28 d compressive strength is more than or equal to 70 MPa, the 28 d splitting tensile strength is more than or equal to 5.8 MPa, the toughness index I5 is more than or equal to 3.0, the 28 d self-shrinkage is less than 100*10<-6>, the 28 d dry shrinkage rate is less than 150*10<-6>, the carbonization grade achieves T-IV, the anti-cracking grade achieves L-V, the product has characteristics of excellent mechanical property, excellent cracking resistance and excellent durability, and the difficult problems of high cement and cementing material material consumption, large shrinkage and easy cracking of the bridge tower concrete at the current stage can be solved.

Owner:WUHAN UNIV OF TECH +2

Polycarboxylic acid series concrete composite water-proof agent and its preparing method

InactiveCN101024566APenetration height ratio is smallReduce autogenous shrinkageAcid waterUltimate tensile strength

The invention relates to a manufacture method for polyocarboxy acid series concrete compound water proof agent that includes polyocarboxy acid water reducing agent 20-80 portions, multihydroxyl carboxyl compounds 1-10 portions, air entraining agent 0.1-1.0 portions. The advantages of the invention are that: it decreases self contraction and dry contraction inner concrete, increasing degree of compaction, decreasing concrete capillary fissure, achieving the ability of water proof and anti-leaking function; the anti-leaking grade is over the other water proof agent; it has slushing pumping, water poof, and constration anticracking function; and has high quality and low price.

Owner:郭震

Semi-flexible anti-rut pavement material and preparation method thereof

The invention relates to a semi-flexible anti-rut pavement material which comprises the following components in percentage by weight: 65-88% of big-void cement-base mixture and 12-35% of flexible grouting material. The big-void cement-base mixture comprises 1 part of cement, 4-6 parts of coarse aggregate, 0.4-1.0 part of fine aggregate, 0.1-0.3 part of water and 0-0.006 part of water reducing agent. The flexible grouting material comprises 1 part of cement, 0.65-1 part of modified emulsified asphalt, 0.1-0.35 part of water-based epoxy resin emulsion, 0-0.03 part of ground tire, 0.0025-0.007 part of water reducing agent, 0.05-0.2 part of expanding agent and 0.05-0.15 part of water. The semi-flexible anti-rut pavement material has the characteristics of high rut resistance, favorable flexibility and toughness, no seam, fewer cracks, low carbon, environmental protection and the like, can be constructed at room temperature, and is suitable for road rut treatment.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Ultra-high performance concrete mixed with seawater and prepared from full coral aggregate and preparation method thereof

InactiveCN111620620AIncrease densityReduce early heat of hydrationSolid waste managementPolyvinyl alcoholSuperplasticizer

The invention discloses ultra-high performance concrete mixed with seawater and prepared from full coral aggregate. The concrete comprises cement, silica fume, slag, micro-beads, coral fine sand, coral medium sand, coral coarse sand, polyvinyl alcohol fiber, polypropylene fiber, a polycarboxylate superplasticizer and seawater in a weight ratio of 1: (0.38-0.41): (0.23-0.26): (0.092-0.13): (0.38-0.42): (0.99-1.13): (0.2-0.22): (0.008-0.01): (0.026-0.028): (0.038-0.041): (0.38-0.41). The invention further discloses a preparation method of the ultra-high performance concrete mixed with seawater and prepared from full coral aggregate. The concrete provided by the invention not only has good mechanical properties and durability, but also has the characteristics of low self-contractibility and high compactness.

Owner:INST OF DEFENSE ENG ACADEMY OF MILITARY SCI PLA CHINA

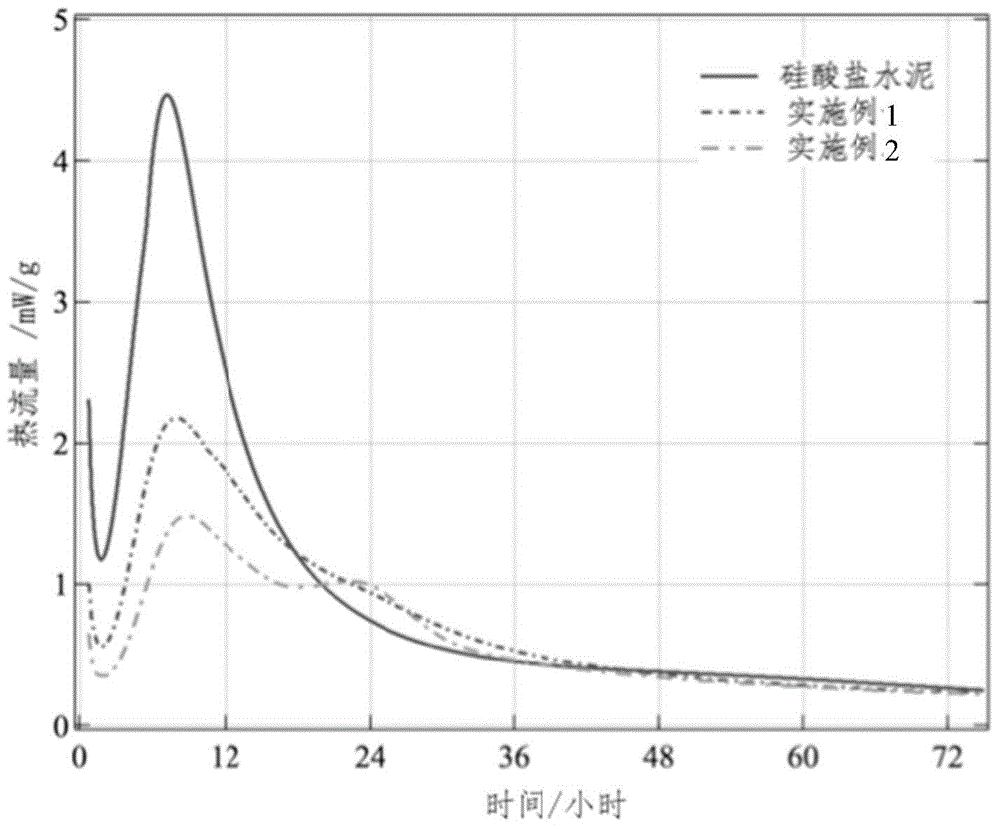

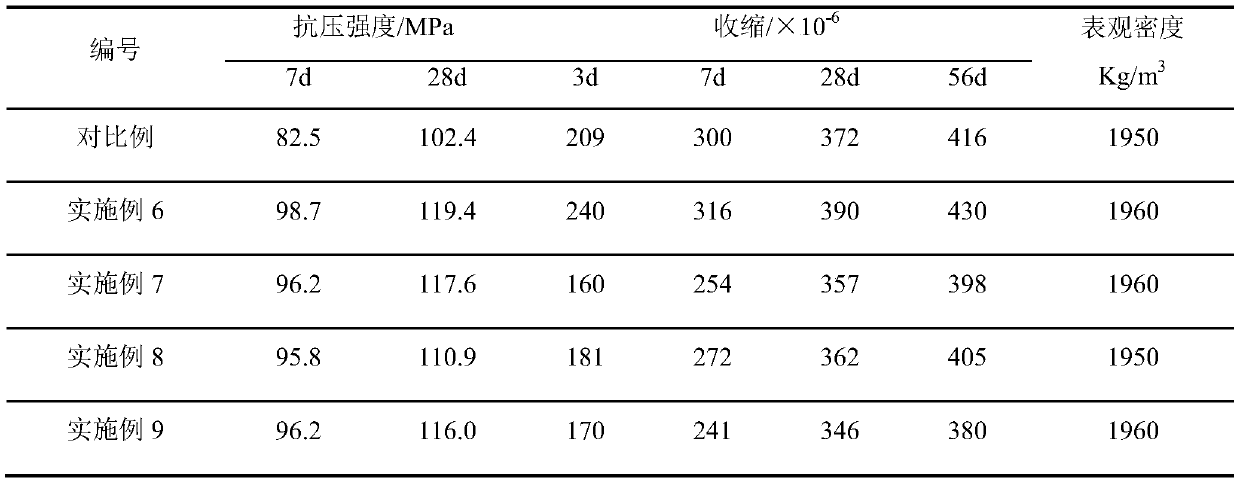

Low-heat micro-expansion composite cement and preparation method thereof

ActiveCN104529319AReduce heat of hydrationReduce autogenous shrinkageSolid waste managementGypsumIndustrial waste

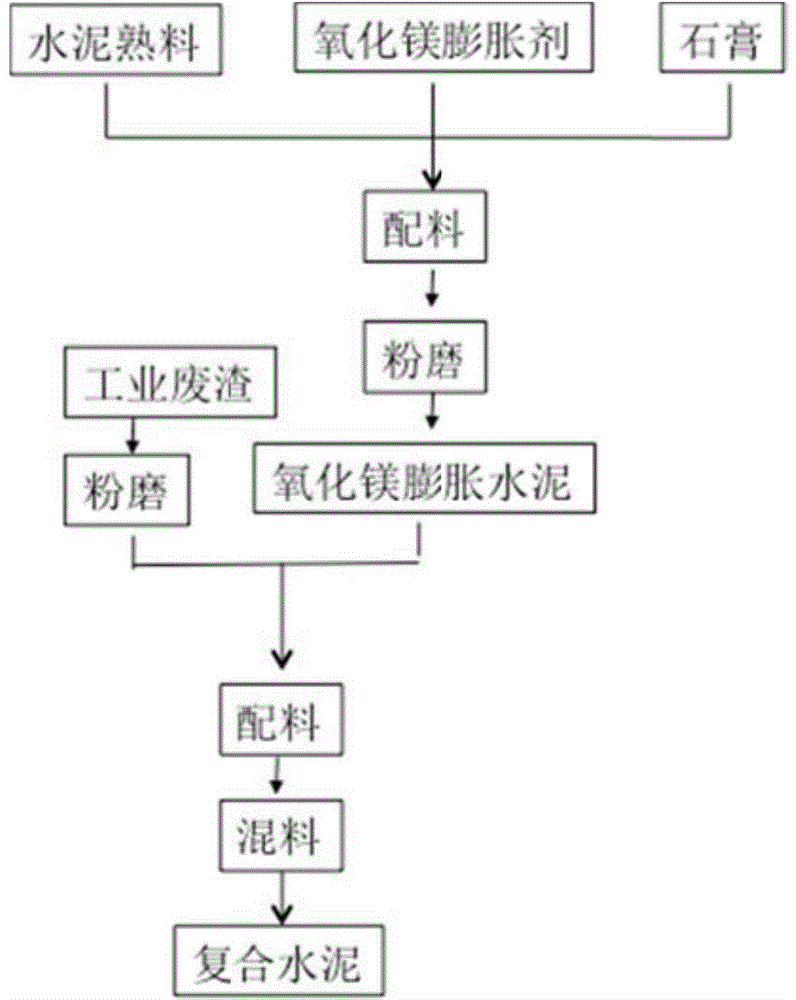

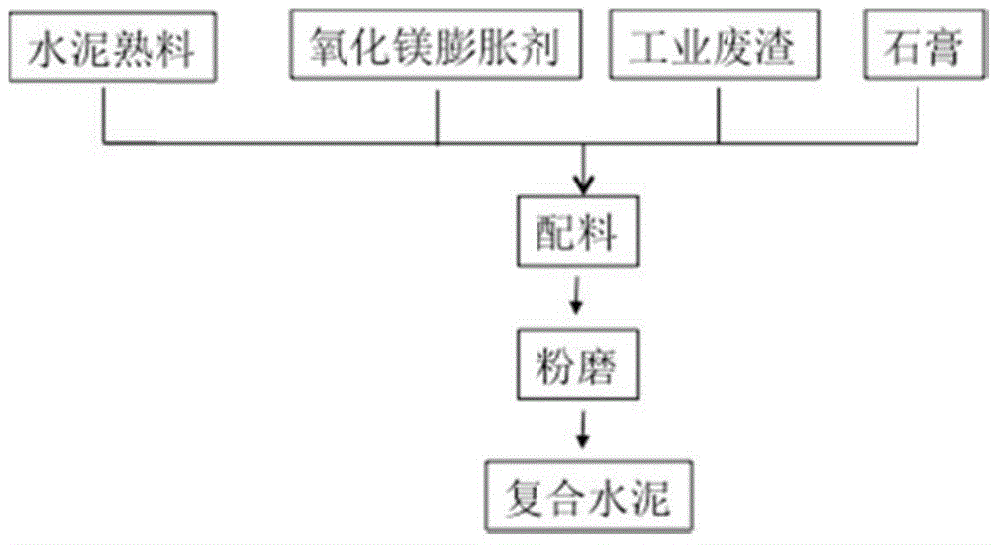

The invention relates to a low-heat micro-expansion composite cement and a preparation method thereof. The composite cement comprises the following components: 1-8 parts of a magnesium oxide expanding agent, 25-70 parts of industrial waste residue, 25-70 parts of portland cement clinker, and 1-4 parts of gypsum. The preparation method includes: mixing and grinding the magnesium oxide expanding agent, the portland cement clinker and the gypsum to prepare magnesium oxide expansive cement with a specific surface area of not lower than 300m<2> / kg, then mixing the magnesium oxide expansive cement with the industrial waste residue evenly according to the ratio to prepare composite cement; or burdening and mixing the magnesium oxide expanding agent, the cement clinker, the gypsum and the industrial waste residue in proportion, and carrying out grinding together to obtain composite cement. The composite cement prepared by the method has fineness of 80-micrometer square hole screen residue of less than 10%, and a specific surface area of not less than 300m<2> / kg. The composite cement provided by the invention can generate expansion in the early stage, also can generate expansion in the middle and late stage, simultaneously satisfies compensation of concrete shrinkage in the early stage and the middle and late stage, and prevents shrinkage crack of concrete.

Owner:NANJING UNIV OF TECH

Low-self-shrinkage high-toughness cement-based composite material and preparation method thereof

InactiveCN110734255AIncrease late strengthReduce autogenous shrinkageMicrofine cementAggregate (composite)

The invention discloses a low -self-shrinkage high- toughness cement-based composite material which is prepared from the following raw materials in percentage by mass according to the Dinger-Funk powder close packing theory: 15-22% of ultrafine cement, 20-28% of a mineral admixture, 10-14% of steel slag powder, 2-6% of gypsum, 0-10% of silica fume, 0-5% of nano-powder, 0-5% of porous powder, 15-25% of a fine aggregate, 1-2.5% of fibers, 0.3-2% of an additive, 0-0.5% of a defoaming agent, 0-1% of a water retention component and 10-18% of water. By utilizing the water absorption characteristic of the porous powder, a base material has a self-curing effect, the later strength can be improved and the self-shrinkage of the high-toughness cement-based composite material can be reduced while thecost of the raw materials is reduced, and the cracking risk of the high-toughness cement-based composite material due to shrinkage is avoided.

Owner:CHINA WEST CONSTR ACAD OF BUILDING MATERIALS CO LTD +1

Autoclave curing-free, light and ultrahigh-strength concrete and preparation method thereof

ActiveCN110563409AReduce dosageHigh shapeCeramicwareClaywaresSuper absorbentUltimate tensile strength

Belonging to the field of building materials, the invention particularly relates to an autoclave curing-free, light and ultrahigh-strength concrete and a preparation method thereof. The concrete is composed of a cementing material, interface-modified high-strength porous microspheres, natural sand, a super absorbent slow-release internal curing material, a hyper-dispersion reducing admixture and water. Based on the particle close packing theory, the method provided by the invention adopts silica fume, fly ash microspheres and ultrafine limestone powder, designs and optimizes the cementing material particle composition, fires high-strength porous microspheres, researches and develops an interface improvement emulsion, and performs treatment on the surfaces of porous microspheres to obtain the interface-modified high-strength porous microspheres, and then optimizes the concrete interfacial transition zone; and the super absorbent slow-release internal curing material is prepared, and significantly lowers the early autogenous shrinkage of concrete. The prepared concrete has the characteristics of high strength, light weight, small shrinkage and the like, can obviously reduce the self-weight of the structure, and provides a new material choice for structural design and construction innovation.

Owner:CHINA STATE CONSTR READY MIXED CONCRETE CO LTD +1

C70 mass concrete and preparation process thereof

The invention discloses C70 mass concrete. The C70 mass concrete is prepared from the following components by mass: 140 to 170 parts of water, 400 to 450 parts of cement, 1,000 to 1,200 parts of crushed stone, 550 to 650 parts of gravel, 70 to 110 parts of coal ash, 60 to 90 parts of mineral powder, 30 to 70 parts of silica fume, 8 to 10 parts of a pumping agent, 35 to 45 parts of an anti-crackingagent, and 0.3 to 0.4 part of an internal curing agent. The invention also discloses a preparation method for the C70 mass concrete. The method comprises a first step of uniformly mixing sand, graveland water and a second step of adding other components and carrying out uniform mixing under stirring. According to the composition of the mass concrete in the invention, mineral powder, silica fumeand fly ash are used as mineral admixtures and can delay the release rate of cement hydration heat and reduce the shrinkage and deformation of the concrete, and the mineral admixtures acts synergistically with the other components to inhibit the generation of cracks at the same time; and the preparation method of the invention is simple in process and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

Ultra-high performance cement-based material applied to wet spraying construction

ActiveCN110845190AEasy to sprayPlay a binding roleSolid waste managementBuilding repairsAluminum sulphateSurface-active agents

The invention discloses an ultra-high performance cement-based material applied to wet spraying construction. The ultra-high performance cement-based material comprises the following ingredients in parts by weight: 300-400 parts of cement, 50-100 parts of fly ash floating beads, 50-100 parts of silica fume, 40-70 parts of superfine limestone powder, 5-15 parts of a surfactant, 30-50 parts of a magnesium expanding agent, 300-400 parts of quartz sand, 100-200 parts of coral reef sand, 30-70 parts of microfilament steel fibers, 3-6 parts of ultra-high molecular weight polyethylene fibers, 1-5 parts of a mineral additive, 90-120 parts of mixing water, and 25-45 parts of a setting accelerator; wherein the surfactant is a naphthalene series or aliphatic series organic powder, the mineral additive is attapulgite gel powder with the average particle size of 5-15 microns, and the setting accelerator is an alkali-free accelerating agent with the total alkali content not larger than 1%, and the main components are aluminum sulfate and an organic amine. The ultra-high performance cement-based material can realize continuous wet spraying construction, and the mechanical property and durabilityof sprayed concrete are greatly improved. The ultra-high performance cement-based material can be widely applied to the field of cement-based material preparation.

Owner:CCCC SECOND HARBOR ENG +3

Composite additive improving self-contraction of concrete

InactiveCN101172803ALow costReduce autogenous shrinkageSolid waste managementDimethyl siloxaneRelative humidity

The invention relates to a compound admixture for improving the self-contraction property of concrete, and belongs to the technical field of the admixture. The prior materials used for improving the self-contraction of the concrete mainly comprise expansion agent, shrinkage reducing agent and fiber, but the materials are not effective when the materials are used solely. The invention is characterized in that the compound admixture is formed by evenly mixing I-class fly ash, milled limestone powder, dihydrate gypsum, raw alum clay and dimethyl siloxane, wherein, the weight percent of each component is showed as follows: 20 to 40 percent of the I-class fly ash, 30 to 60 percent of the milled limestone powder, 5 to 10 percent of the dihydrate gypsum, 10 to 20 percent of the raw alum clay and 3 to 5 percent of the dimethyl siloxane; the finenesses of the milled limestone powder, the dihydrate gypsum and the raw alum clay are larger than 350m2 / kg. When the invention is mixed into the concrete with high strength and large area and the self-compacting concrete, and the relative ambient humidity is less than 50 percent, the invention can obviously reduce the self contraction rate of the concrete by more than 30 percent and improve the strength, the mobility and the durability of the concrete.

Owner:BEIJING UNIV OF TECH

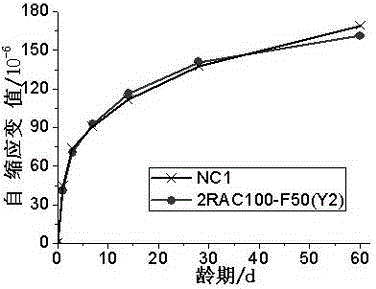

Low-autogenous shrinkage and high-performance recycled concrete

InactiveCN104628344AReduce autogenous shrinkageImprove volume stabilitySolid waste managementShrinkage rateUltimate tensile strength

The invention discloses low-autogenous shrinkage and high-performance recycled concrete which can meet pumping requirements. Each cubic meter of the high-performance recycled concrete contains 400-500kg of a cementing material, 950-1150kg of a coarse aggregate (wherein the substitution rate of the recycled coarse aggregate is 70%-100%), 660-715kg of a natural fine aggregate, 160-180kg of water and 7-9kg of an efficient water-reducing agent, and the high-performance recycled concrete is prepared by a process of enveloping stone with cement. The obtained high-performance recycled concrete has the strength grade of C30-C50 and the slump of 180-220mm, and can effectively improve the autogenous shrinkage performance of the recycled concrete, reduce the total autogenous shrinkage rate by above 25% in comparison with ordinary recycled concrete with the same mixture ratio and enable the total autogenous shrinkage rate to be close to ordinary concrete with the same mixture ratio. The high-performance recycled concrete disclosed by the invention has important theoretical value and social significance in promotion of reasonable and extensive application of the recycled concrete, recovery of construction waste resources and the like.

Owner:FUJIAN JIANGXIA UNIV

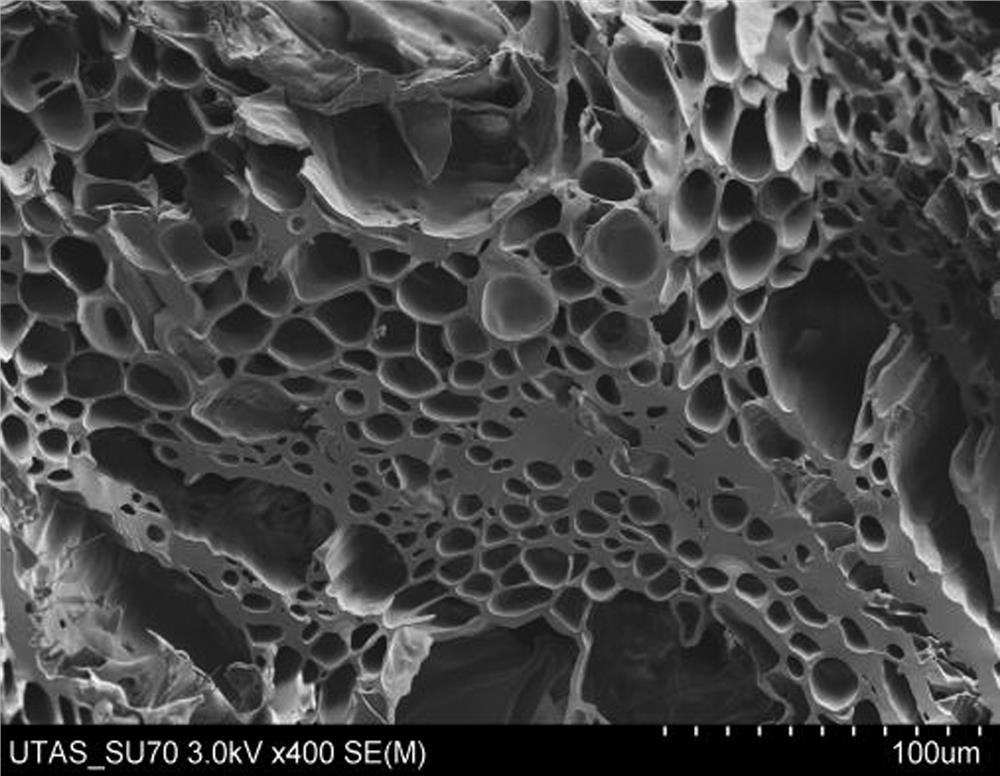

Cement-based material carbon sequestration internal curing agent as well as preparation and application thereof

ActiveCN112876119AWell-developed pore structureTo achieve the effect of internal maintenanceSolid waste managementSuper absorbentSorptivity

The invention discloses a cement-based material carbon sequestration internal curing agent as well as preparation and application thereof. The internal curing agent is modified biochar or a compound of the modified biochar and light aggregate and / or super absorbent resin; and the modified biochar is biochar powdery particles obtained by soaking biochar obtained by pyrolyzing biomass under high-temperature and oxygen-limited conditions in an alkaline solution, drying and grinding. The rich pore structure and the strong hydrophilic performance of the biochar enable the biochar to achieve the internal curing effect of the cement-based material, and the good stability can ensure the long-term and stable development of the performance of the cement-based material; the biochar is sealed in the cement-based material, so that the release of CO2 can be reduced, and the effects of carbon sequestration and emission reduction are achieved; and the biochar modified by the aqueous alkali can make the cement more fully hydrated, and when the biochar is matched with the lightweight aggregate and / or the super absorbent resin for use, the internal curing effect is stronger. After the internal curing agent provided by the invention is doped, the compressive strength and bending strength of the cement-based material at the age of 28 days are improved, and the self-constriction is effectively reduced.

Owner:HUALAN DESIGN GRP CO LTD

C60 self-compacting shrinkage-compensating anti-crack concrete suitable for steel anchor beam cable tower anchoring structure and preparation method of concrete

The invention discloses C60 self-compacting shrinkage-compensating anti-crack concrete suitable for a steel anchor beam cable tower anchoring structure. The concrete is prepared from raw materials, namely, cement, fly ash, mineral powder, an expanding agent, gravel, high-titanium heavy slag sand, polyacrylonitrile fibers, micron-sized modified absorbent cotton cellulose, a cement paste microstructure regulating agent, water and an ultra-dispersing, water-reducing, shrinkage-reducing and plasticity-maintaining additive. According to the concrete, the initial slump is higher than or equal to 230 mm, the expansion degree is higher than or equal to 630 mm, the 28 d compressive strength is higher than or equal to 70 MPa, the 28 d splitting tensile strength is higher than or equal to 5.8 MPa, the toughness index I5 is larger than or equal to 3.0, the 28 d autogenous-shrinkage ratio is smaller than 0, the 28 d dry shrinkage ratio is smaller than 0, the carbonization level reaches T-IV, the cracking resistance level reaches L-V, and the concrete has excellent mechanical properties, crack resistance and durability, can solve general problems that bridge tower concrete at the present stage is high in cement and cementing material consumption and large in shrinkage and cracks easily, and is suitable for popularization and application.

Owner:WUHAN UNIV OF TECH +2

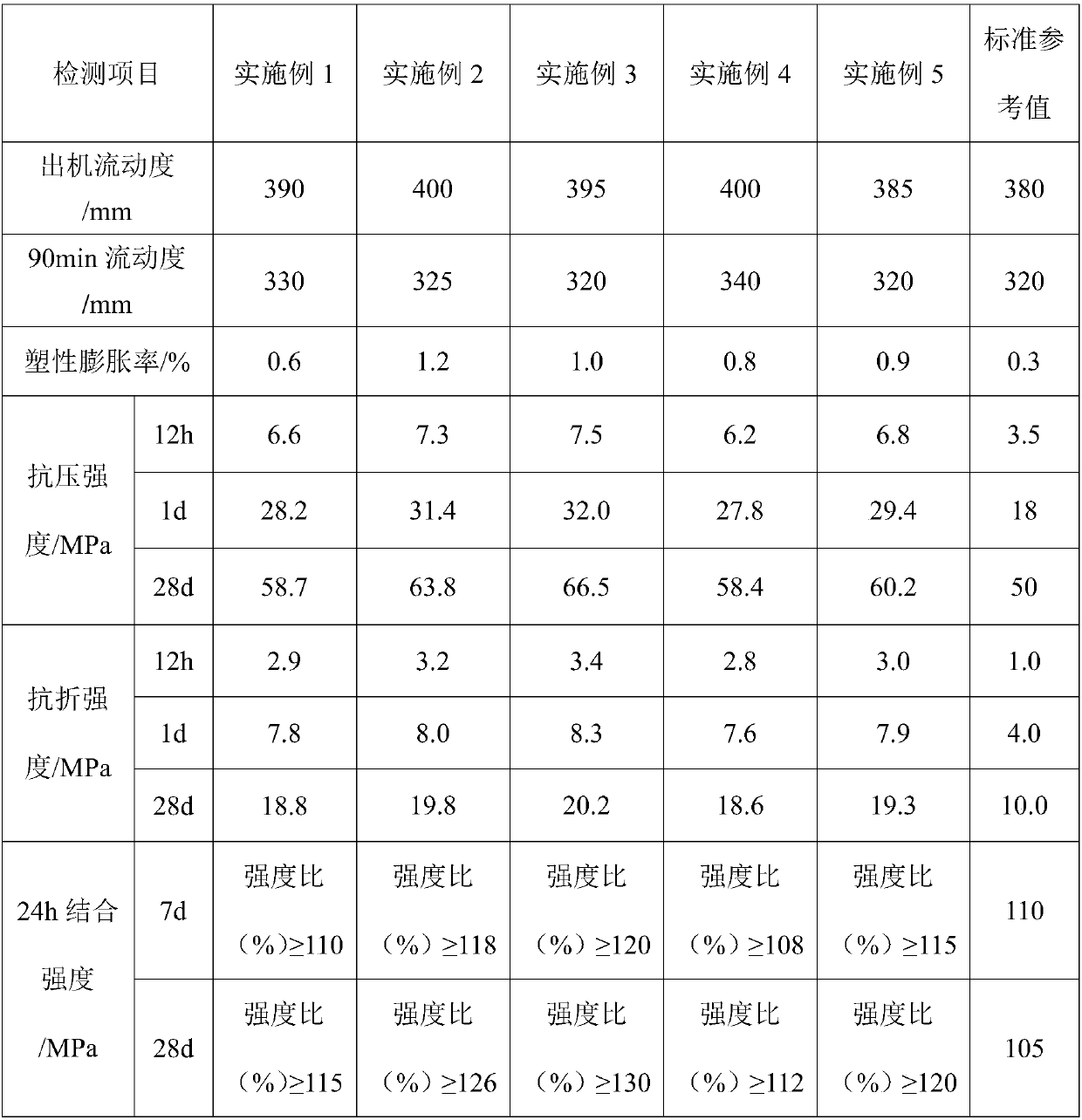

Micro-expansive grouting material for tunnel lining vault mold grouting

The invention discloses a micro-expansive grouting material for tunnel lining vault mold grouting in order to mainly solve the problems of disengaging, crack and other quality defects of tunnel vaults, caused by easy shrinkage deformation, poor compatibility and poor bonding property of existing like grouting materials. The micro-expansive grouting material is obtained through adding water to 750-800 parts of a gelling component, 900-1350 parts of compounded quartz sands, 100-150 parts of a graphene oxide modified mineral admixture, 8-10 parts of a volume stability regulator and 2-3 parts of areinforced water reducer, and mixing and stirring the above raw materials and the water, wherein a ratio of the water to the total materials is 0.16 to 0.19. The micro-expansive grouting material hasgood fluidity and good pumpability, and has a binding performance with lining concrete, and has significant economic and social benefits in the infrastructure industry.

Owner:WUHAN UNIV OF TECH

Ultrahigh-strength building concrete and preparation method thereof

The invention discloses ultrahigh-strength building concrete and a preparation method thereof. The ultrahigh-strength building concrete is prepared from the following raw materials in parts by weight: 85-100 parts of modified coating pottery clay, 20-30 parts of a sand material, 10-25 parts of a stone material, 15-35 parts of a waste calcined material, 10-15 parts of ultrafine fly ash, 18-25 parts of hollow glass beads, 10-20 parts of phenolic resin, 20-25 parts of zeolite powder, 10-15 parts of SiO2 aerogel, 10-20 parts of a polycarboxylate superplasticizer, 5-10 parts of a compound expansion agent, 8-15 parts of a stabilizer, and an appropriate amount of water. The ultrahigh-strength building concrete provided by the invention, by adopting efficient proportioning of the modified coating pottery clay, the sand material, the stone material, the waste calcined material, the ultrafine fly ash, the hollow glass beads, the phenolic resin, the zeolite powder, the SiO2 aerogel, the polycarboxylate superplasticizer, the compound expansion agent, and the stabilizer, can effectively prevent surface and internal cracks caused by non-structural reasons of temperature, dry shrinkage and the like of the concrete; and the concrete also has relatively high impact resistance and impervious performance, is suitable for mine operation, and is good in safety performance and water resistance, and long in service life.

Owner:芜湖浩权建筑工程有限公司

Method for keeping expansion of steel tube concrete

InactiveCN1562857AImprove pumping performanceReduce dosageSolid waste managementSuperplasticizerExpanded clay aggregate

The characteristic is that porous ceramsite light aggregate with grain size 1.5-5 mm, water adsorption 8-12 percent, drum pressure strength 6-12 Mpa is preprocesed by soaking and absorbing water, then to be dried in the shade, the dried porous ceramsite light aggregate is used as fine aggregate to instead of 10-20 percent of sand, the matching ratio of each compound (kg / m3) is water 182, silicate cement 460, UEA expanding agent 55, flyash 60, sand (fineness module is 2.5-3.0) 560, breakstone (continuous graded interval grain size is 5-20 mm) 1033, amidogen sulphonate high-efficiency water-reducing agent 12, which are mixed and stirred to produce C60 steel pipe concrete.

Owner:WUHAN UNIV OF TECH

Recycled concrete mixed with waste clay brick powder and brick sand

InactiveCN107021694ASimple processReduce energy consumptionSolid waste managementFlexural strengthCompressive strength

The invention relates to recycled concrete mixed with waste clay brick powder and brick sand, the waste clay brick powder is mixed into concrete for replacing part of cement, the waste clay brick sand is mixed into the concrete for replacing part of natural sandstone aggregate without reducing the performance of the concrete, the recycled concrete is prepared from the waste clay brick powder and brick sand obtained by crushing of waste clay bricks, the dosage of the cement is reduced by 0-55% not including 0, the dosage of the natural sandstone aggregate is reduced by 0-25% not including 0 without changing of concrete strength and workability, the waste clay brick powder and brick sand are obtained by crushing of the waste clay bricks in construction waste, the cost is low, the brick powder has less influence on the compressive strength and the flexural strength of the concrete, and can improve shrinkage of the concrete. The recycled concrete adopts a multi-stage preparation and multi-time feeding method for production, first cement mortar is premixed, according to the granular composition, the brick sand, small stones and large stones are in turn fed in, mixing time and energy consumption are reduced, the strength of the concrete is improved, the homogeneity and the workability of the concrete are improved, and the recycled concrete has important significance for energy conservation and emission reduction.

Owner:XINJIANG JINYUXIN NEW MATERIAL CO LTD

Functional aggregate and preparation method thereof

The invention belongs to the field of concrete materials, and specifically relates to a functional aggregate and a preparation method thereof. The functional aggregate is characterized in that: the functional aggregate has a core-shell structure, and is composed of a porous core substrate and an alkaline surface active shell. Mullite is a main mineral phase of the porous core substrate, and a continuous phase is formed. Pores are distributed in the continuous phase. The pore sizes of the pores are distributed in a multilevel form. The pores are mainly micron-leveled pores. The mineral phase of the alkaline surface active shell is mainly composed of dicalcium silicate, tricalcium silicate, tricalcium aluminate, and tetracalcium iron aluminate. The functional aggregate provided by the invention has light weight and high strength. The functional aggregate can be internally cured, and has a surface active layer. When the functional aggregate is used in concrete, an interfacial transition zone (ITZ) can be completely enhanced and improved, cement stone structure formation can be regulated, and concrete overall performance can be improved. The preparation process is simple and controllable, and is easy to operate.

Owner:WUHAN UNIV OF TECH

Preparation method and application of high-performance concrete internal curing agent

InactiveCN109987875ASimple preparation conditionsSuitable water absorptioCrack resistanceWork Performances

The invention relates to a composite concrete internal curing agent. The internal curing agent is characterized by comprising the following components in parts by weight: 4-8 parts of nano silicon dioxide, 5-10 parts of a silane coupling agent, 15-30 parts of kaolin, 20-50 parts of monomers and 10-25 parts of wheat straw, wherein the monomers comprise the following components in parts by weight: 10-20 parts of acrylic acid, 5-10 parts of acrylamide and 10-25 parts of allyl polyoxyethylene ether. Through the modified internal curing agent, working performance, mechanical performance and cracking resistance of high-performance concrete are all enhanced to a certain extent.

Owner:北京瑞骞科技有限公司 +2

Hydrophobic low shrinkage lightweight cementitious matrix

ActiveCN105036666ALow densityLow hydrophobicitySolid waste managementCeramicwareCementitious matrixLow shrinkage

The present invention provides a composition for forming a lightweight, low shrinkage and hydrophobic cementitious matrix, and a method for preparing thereof. The present cementitious matrix formed by the composition is lightweight, hydrophobic (or water repelling) and with low shrinkage which is useful in building and construction industry as non-structural wall resistant to water, heat and sound entry. The present invention also provides a method of preparing the composition and the cementitious matrix formed from the composition.

Owner:NANO & ADVANCED MATERIALS INST

Low autogenous shrinkage, high-strength concrete prepared from waste pulp in concrete-mixing station

Provided is low autogenous shrinkage, high-strength concrete prepared from the waste pulp in concrete-mixing station. The concrete is a blended composition of 300-340 parts of cement, 90-130 parts of lithium slag, 70-110 parts of waste pulp from a concrete-mixing station, 696-739 parts of river sand, 1044-1109 parts of crushed stone, 8.5-10 parts of shrinkage reducing agent, 4-6 parts of water reducing agent and 80-92 parts of water. The 7d autogenous shrinkage value of the low autogenous shrinkage, high-strength concrete prepared from the waste pulp in concrete-mixing station, is <=80*10<-6>, the 28d autogenous shrinkage value is <=100*10<-6>, approaching stability. The lithium slag and shrinkage-reducing agent compositions adopted by present invention is good for lowering autogenous shrinkage; the compatibility with waste pulp is good. The roles and functions are different and achieve superposition effects, effectively lowering the autogenous shrinkage of high-strength concrete prepared from the waste pulp in concrete-mixing station.

Owner:上林县林燃建工材料有限公司

Concrete internal curing agent, preparation method and applications thereof

InactiveCN110746535AOvercome uneven heat transfer and difficult stirringThe preparation process is simple and controllableChemical synthesisPolymer science

The invention discloses a concrete internal curing agent, a preparation method and applications thereof, and belongs to the field of chemical synthesis. The preparation method comprises: 1) dispersingtwo emulsifiers in a dispersion medium at a room temperature to form an oil phase system, adjusting the neutralization degree of an anionic monomer aqueous solution, mixing the neutralized anionic monomer aqueous solution and a nonionic monomer aqueous solution, and adding a cross-linking agent and an initiator to form a water phase system; 2) under the protection of an inert gas, adding the water phase system into the oil phase system, and carrying out a reaction until a gel appears; and 3) taking the gel, washing, and drying to obtain the white powdery concrete internal curing agent. According to the invention, the concrete internal curing agent obtained by the preparation method is moderate in water absorption rate, integrates hydrophilic and alkali-resistant groups, ensures the moisture required by later hydration of cement, and reduces the negative influence on the strength of concrete after water release based on small particle size.

Owner:CHANGAN UNIV

Low-carbon green ultra-high performance concrete and preparation method thereof

InactiveCN114368953AImprove compactnessReduce autogenous shrinkageSolid waste managementBrickEnvironmental engineering

The invention provides low-carbon green ultra-high performance concrete and a preparation method thereof, and relates to the technical field of building materials. The low-carbon green ultra-high performance concrete provided by the invention is prepared from the following preparation raw materials in parts by weight: 550 to 650 parts of cement, 250 to 350 parts of regenerated red brick powder, 100 to 200 parts of fly ash, 90 to 110 parts of silica fume, 550 to 650 parts of natural sand, 450 to 550 parts of regenerated red brick sand, 40 to 50 parts of an additive, 160 to 180 parts of steel fiber and 170 to 190 parts of water. The problems of stacking and discarding of the construction waste red bricks are solved, the waste red bricks are subjected to processing of the regenerated red brick powder and the regenerated red brick sand, the problem of resource utilization is solved, and environmental protection benefits are improved. Meanwhile, the problems that existing ultra-high performance concrete is large in shrinkage, high in energy consumption, high in cost and poor in environmental protection property are solved.

Owner:建研建硕(北京)科技有限公司

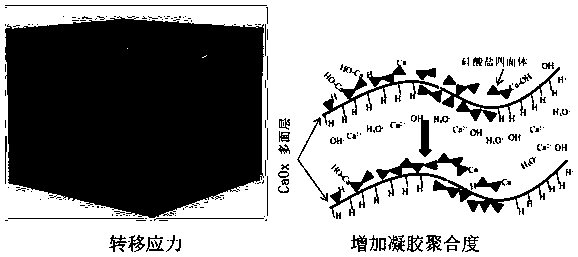

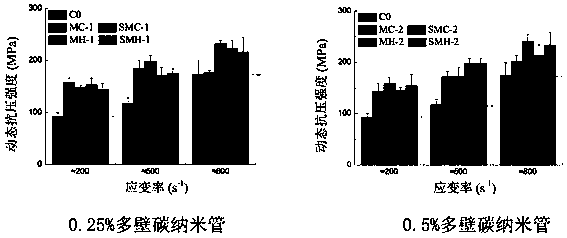

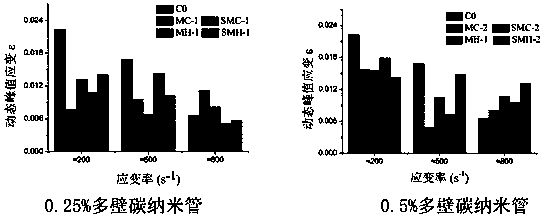

High-impact resistance surface functional group treated carbon nanotube modified reactive powder concrete

The invention discloses a high-impact resistance surface functional group treated carbon nanotube modified reactive powder concrete. The high-impact resistance surface functional group treated carbonnanotube modified reactive powder concrete is characterized in that the raw materials of the high-impact resistance surface functional group treated carbon nanotube modified reactive powder concrete comprise cement, functionalized multi-walled carbon nanotubes, silica fume, fly ash, sands, a water reducer and water; and the functionalized multi-walled carbon nanotubes are carboxylated multi-walledcarbon nanotubes or hydroxylated multi-walled carbon nanotubes. The functionalized multi-walled carbon nanotubes can significantly enhance the dynamic compressive strength, dynamic peak strain and impact toughness of the reactive powder concrete. When the strain rate is in a range of 200-800 / s and the dosage of the multi-wall carbon nanotubes is 0.25-0.5%, the dynamic compressive strength of concrete can be increased by 71.3%, the dynamic peak strain can be increased by 101. 1%, and the impact toughness can be increased by 100.8%.

Owner:DALIAN UNIV OF TECH

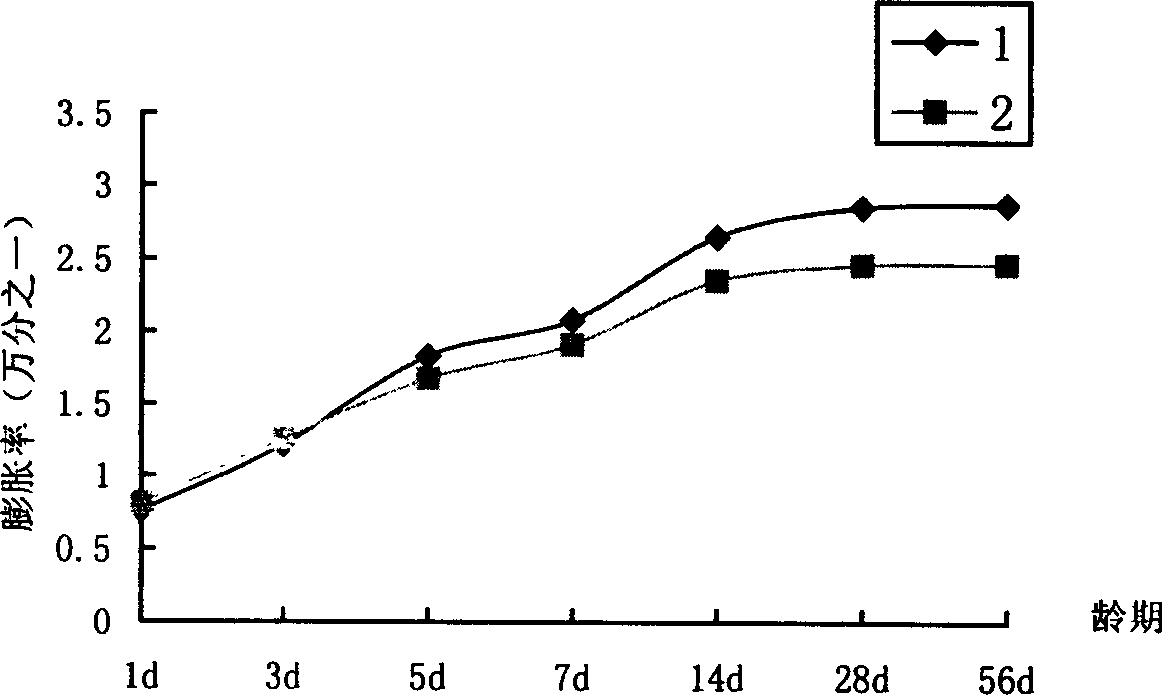

Preparation method of expansion rate-controllable steel pipe and steel-slag concrete column

ActiveCN104591643AReduce construction difficulty and project costGood economic and social benefitsSolid waste managementSteel tubeSlag

The invention discloses a preparation method of an expansion rate-controllable steel pipe and steel-slag concrete column, and belongs to the technical field of civil engineering. The method is that steel-slag sand is used for replacing all fine aggregates, and ordinary portland cement, steel-slag sand, gravels and water are utilized to prepare the expansion rate-controllable steel pipe and steel-slag concrete column. The method specifically comprises the preparation steps of selecting a steel pipe and steel-slag concrete at a certain strength grade according to the requirement of the bearing capacity of the steel pipe and steel-slag concrete column; determining self stress of the steel pipe; calculating to determine the free expansion rate of the slag-steel concrete; calculating to determine the average particle size of the steel-slag stand; selecting the steel-slag sand with reasonable graduation; calculating to determine the quantity of the used portland cement, the steel-slag sand, the gravels and the water according to a design method of a mixing ratio of ordinary concrete; and preparing the steel pipe and steel-slag concrete column, pouring the steel pipe and steel-slag concrete column and maintaining the steel pipe and steel-slag concrete column. With the adoption of the prepared steel pipe and steel-slag concrete column, the core concrete can early be in a three-directional pressing state, and therefore, the bearing capacity and ductility of the steel pipe concrete can be obviously improved.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Low-shrinkage anti-carbonization steel slag geopolymer concrete

InactiveCN111620665AAchieve re-usePlay a lubricating roleSolid waste managementCement productionSlagKaolin clay

The invention discloses low-shrinkage anti-carbonization steel slag geopolymer concrete. The steel slag geopolymer concrete comprises the following components: fly ash, mineral powder, kaolin, coarseand fine aggregates of steel slag, sodium hydroxide, sodium silicate and free water. The steel slag geopolymer concrete is characterized in that the mixing proportion of the fly ash is 271.6 kg / m<3>;the mixing proportion of the mineral powder is 38.8 kg / m<3>; the mixing proportion of a sodium hydroxide solution is 55.3 kg / m<3>; the mixing proportion of a sodium silicate solution is 138.7 kg / m<3>;the mixing proportion of the coarse aggregate of steel slag is 1200-1700 kg / m<3>; the mixing proportion of the fine aggregate of steel slag is 619.5 kg / m<3>; the mixing proportion of the kaolin is 83.7 kg / m<3>; and the mixing proportion of the free water is 13.3 kg / m<3>. Compared with the traditional slag aggregate concrete, the steel slag aggregate geopolymer concrete has higher compressive strength, can compensate shrinkage and reduce carbonization, and is enhanced in frost resistance. The mineral powder and the coal ash are mixed, so the expansibility influence of steel slag crystalline substances on the concrete is relieved and delayed. According to the invention, the used raw materials are simple, the early strength of a solidified body is improved by utilizing the waste steel slag and doping a small amount of kaolin, and the concrete has the advantages of low carbon, environmental protection performance, high strength, low shrinkage and good carbonization resistance.

Owner:XIANGTAN UNIV

Ultrahigh-performance concrete doped with steel residues and preparation method of ultrahigh-performance concrete

The invention discloses ultrahigh-performance concrete doped with steel residues and a preparation method of the ultrahigh-performance concrete. The content of each raw material in every stere of ultrahigh-performance concrete is as follows: 372.1-620.2 kg of cement, 62.0-248.1 kg of steel residues, 141.3-196.3 kg of coal ash, 87.8-131.8 kg of silica fume, 198.4-297.6 kg of quartz sand I, 793.6-1190.4 kg of quartz sand II, 78.5-235.5 kg of steel fibers, 127.8-153 kg of water and 27-45 kg of water reducing agent. The doping amount of the steel residues is large and can reach 30% of the mass ofthe cement, and 186 kg of steel residues can be doped into every stere of ultrahigh-performance concrete; and meanwhile, the ultrahigh-performance concrete is high in strength, after the cement with the mass percentage of 30% is replaced with the steel residues, the seven-day strength can reach 130 MPa, and the fourteen-day strength can exceed 150 MPa.

Owner:WUHAN UNIV OF TECH

Carbonized foam light soil and preparation method thereof

The invention belongs to the technical field of civil construction engineering materials, and particularly relates to green and low-carbon foam light soil prepared by using carbon dioxide and magnesium oxide as raw materials. The carbonized foam light soil is prepared from the following raw materials in parts by weight: 10 to 200 parts of magnesium oxide, 10 to 100 parts of a filler, 2 to 45 parts of CO2 bubble group and 20 to 400 parts of water. According to the invention, based on the problems of large carbon emission and serious energy consumption caused by a cement curing agent used by traditional bubble mixed light soil, the invention aims to provide a novel bubble mixed light soil operation method, so that a foundation treatment technology is promoted to be converted from high pollution and high energy consumption to low carbon, environmental protection and sustainable conversion, and the light soil is prepared by taking magnesium oxide as a curing agent and carbon dioxide gas as a raw material of bubbles.

Owner:SOUTHEAST UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com