Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

33results about How to "Reduce early heat of hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-shrinkage crack self-compacting concrete

The invention discloses low-shrinkage crack self-compacting concrete which is prepared from cement, gravels, sand, a mineral admixture and an anti-shrinkage crack compound additive. By adopting the low-shrinkage crack self-compacting concrete disclosed by the invention, on the basis of overcoming the defects of bleeding, segregation, poor viscosity and great gradual loss of self-compacting concrete, the early shrinkage crack of the self-compacting concrete after hardening is greatly reduced so as to guarantee good durability and volume stability of the self-compacting concrete to satisfy the practical construction application of large-area engineering and the like; and moreover, the cement is saved at least by 40kg / m<3> through proportion optimization on the basis of meeting the requirements of fundamental norms for materials.

Owner:CENT SOUTH UNIV

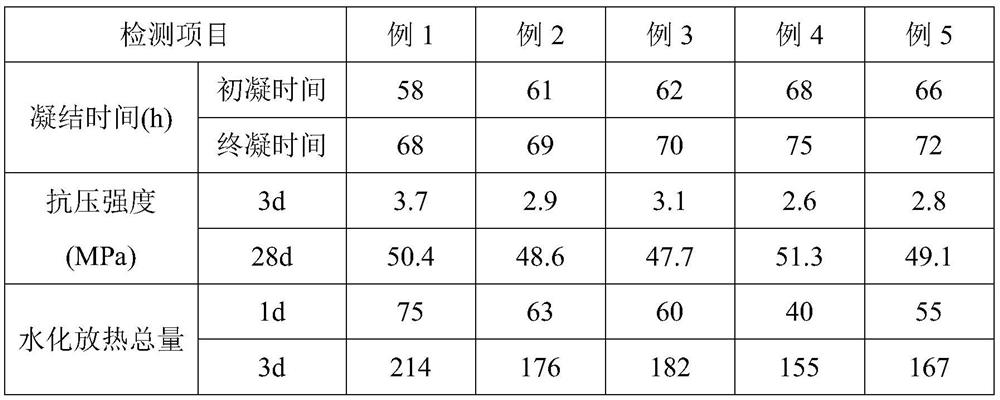

Method for preparing large-admixture-amount wet-milled phosphorus solid waste super-retarding cementing material

The invention discloses a method for preparing a large-admixture-amount wet-milled phosphorus solid waste super-retarding cementing material. The method comprises the following steps: putting phosphorus slag and desulfurized fly ash into a wet-milling machine, and performing mixing and wet milling so as to obtain mixed slurry A; grinding caustic dross, ardealite and coal ash in a dry-milling machine so as to obtain a mixed powder material B; and mixing the mixed slurry A with the mixed powder material B so as to obtain a mixed material C, adding cement, a water reduction agent, a retarder, tailing sand and macadam into the mixed material C, and performing stirring for 4 minutes, so as to obtain super-retarding concrete. Wastes such as the phosphorus slag, desulfurized fly ash, caustic dross, ardealite, coal ash and tailings are adopted to prepare concrete, wastes are turned into wealth, and the amount of cement can be also reduced; due to a mixed wet-milling mode of the phosphorus slagand the desulfurized fly ash, phosphorus dissolution of the phosphorus slag can be promoted, the initial setting time and the final setting time of the concrete can be greatly prolonged, early-stagehydration heat can be reduced, cracks can be reduced, later strength can be ensured, and large-admixture-amount efficient application of the phosphorus slag can be achieved; and the prepared super-retarding concrete can be applied to large-size concrete, drilling bitten piles, and the like.

Owner:HUBEI UNIV OF TECH

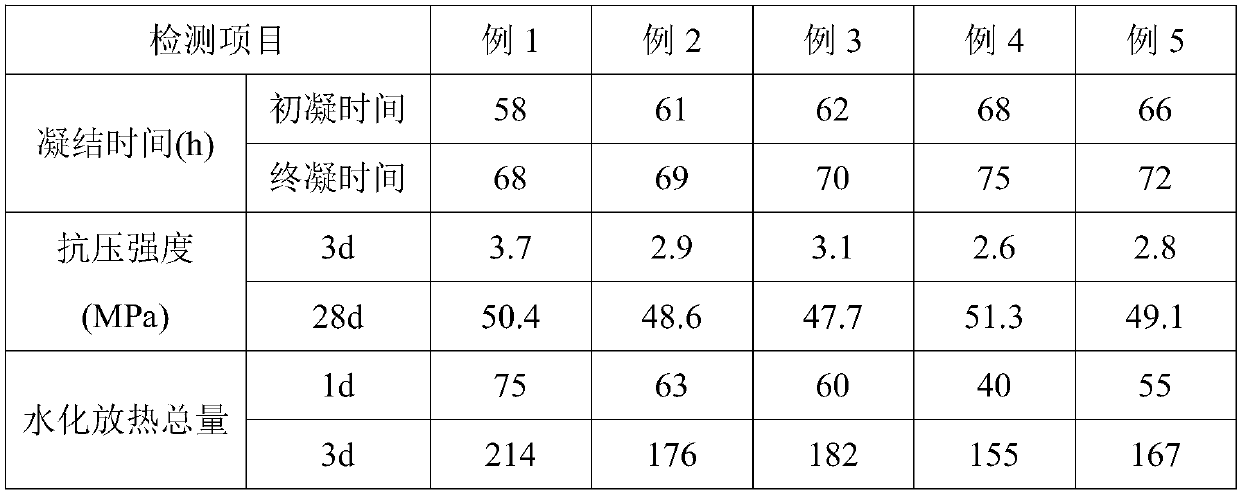

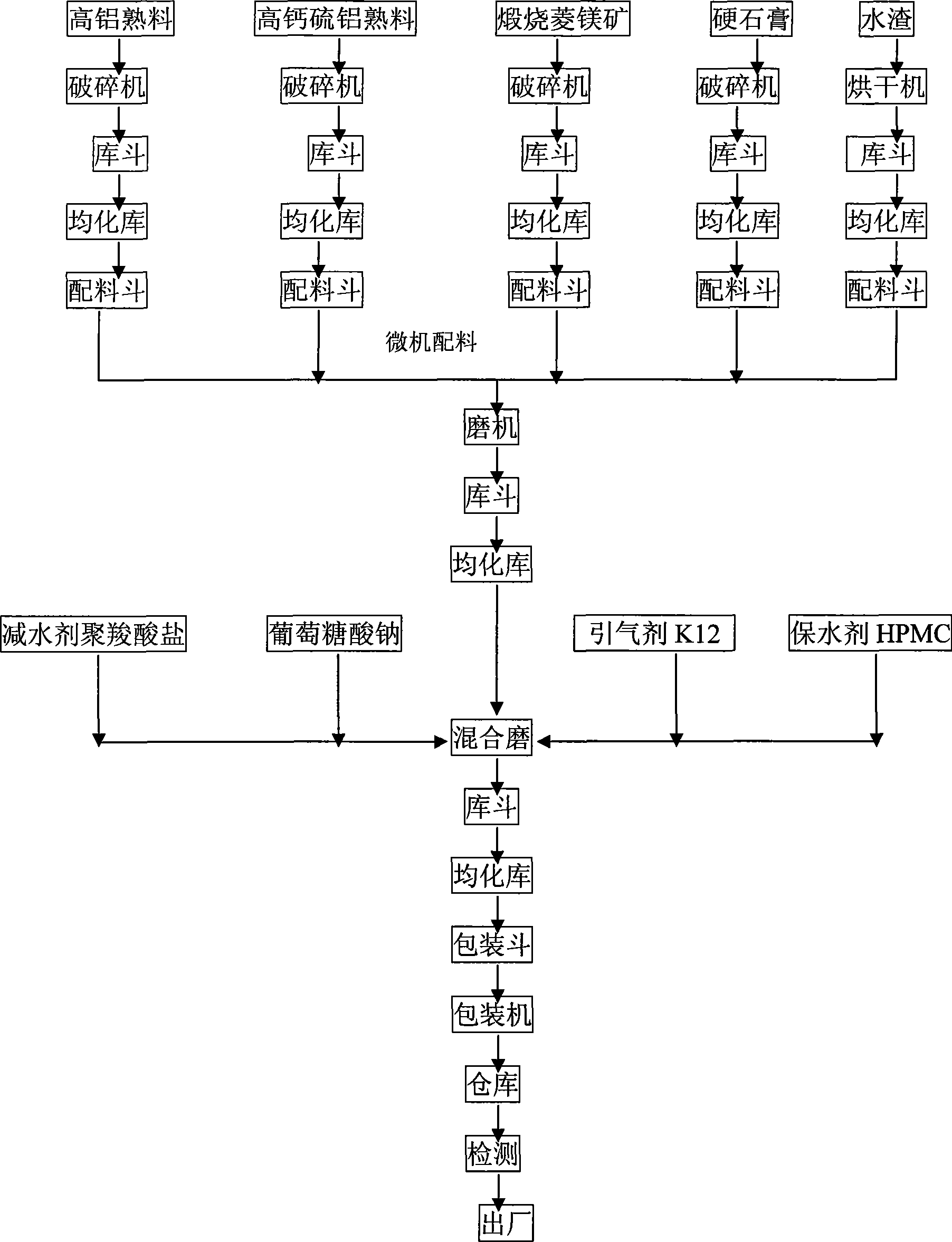

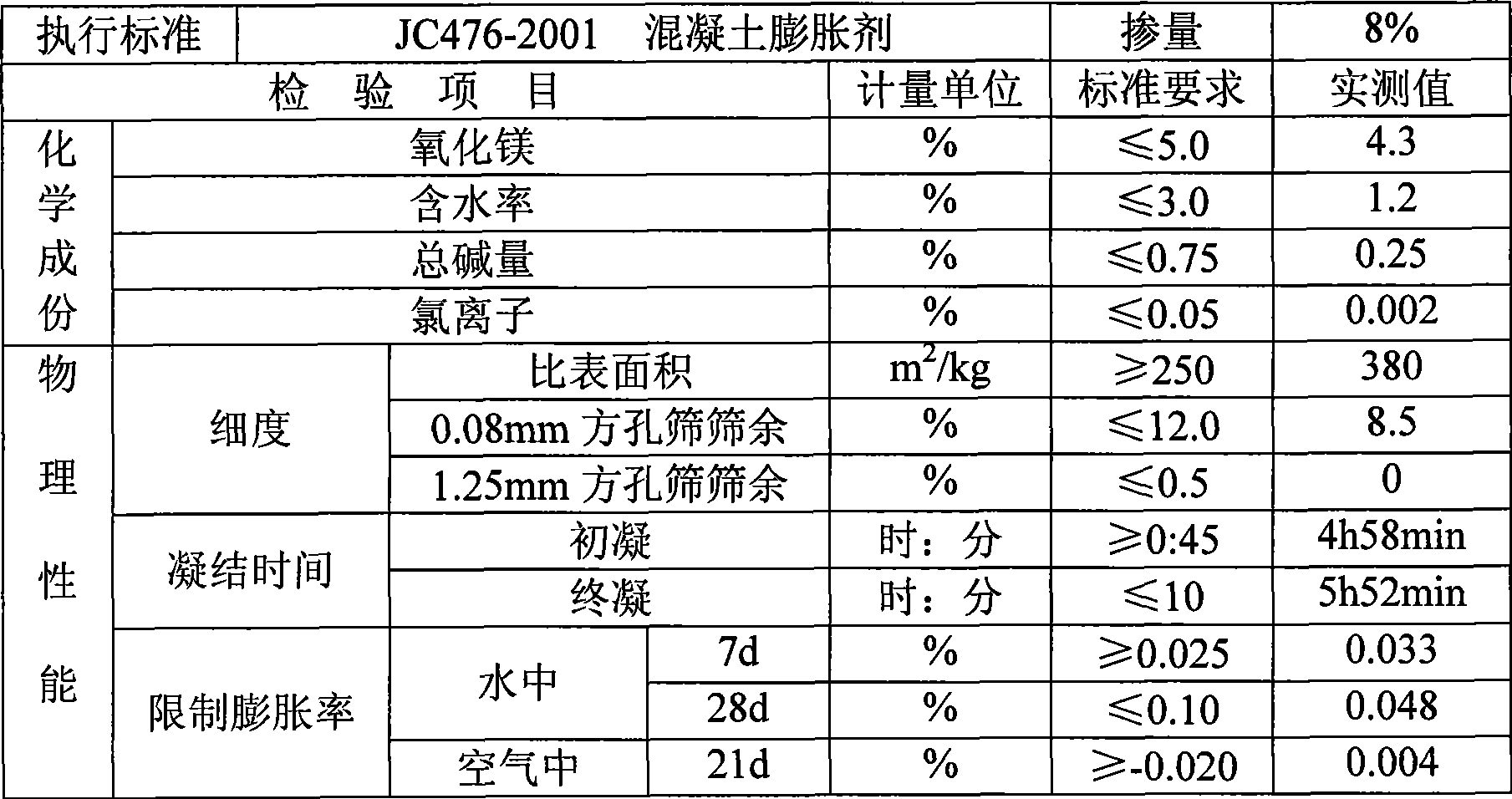

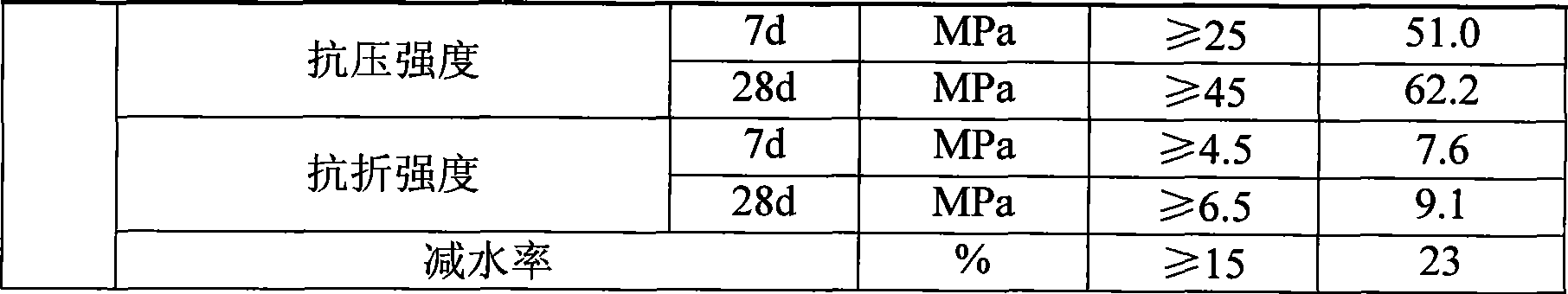

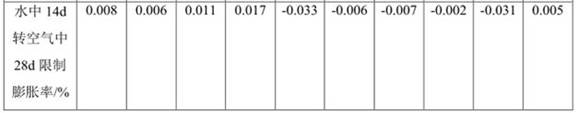

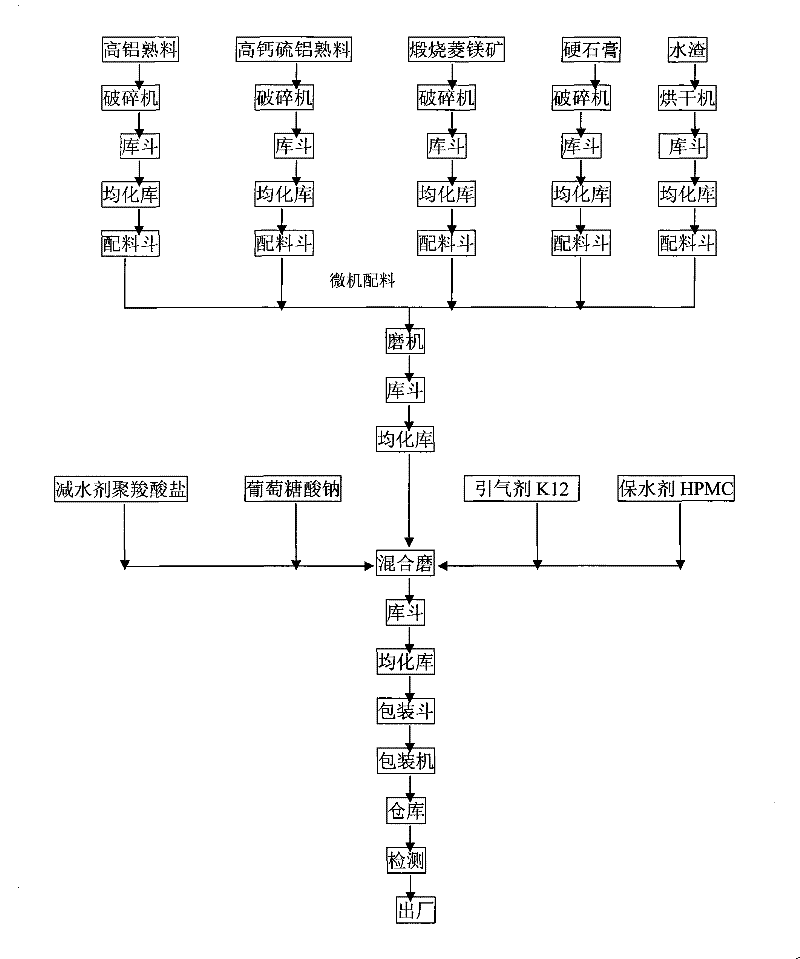

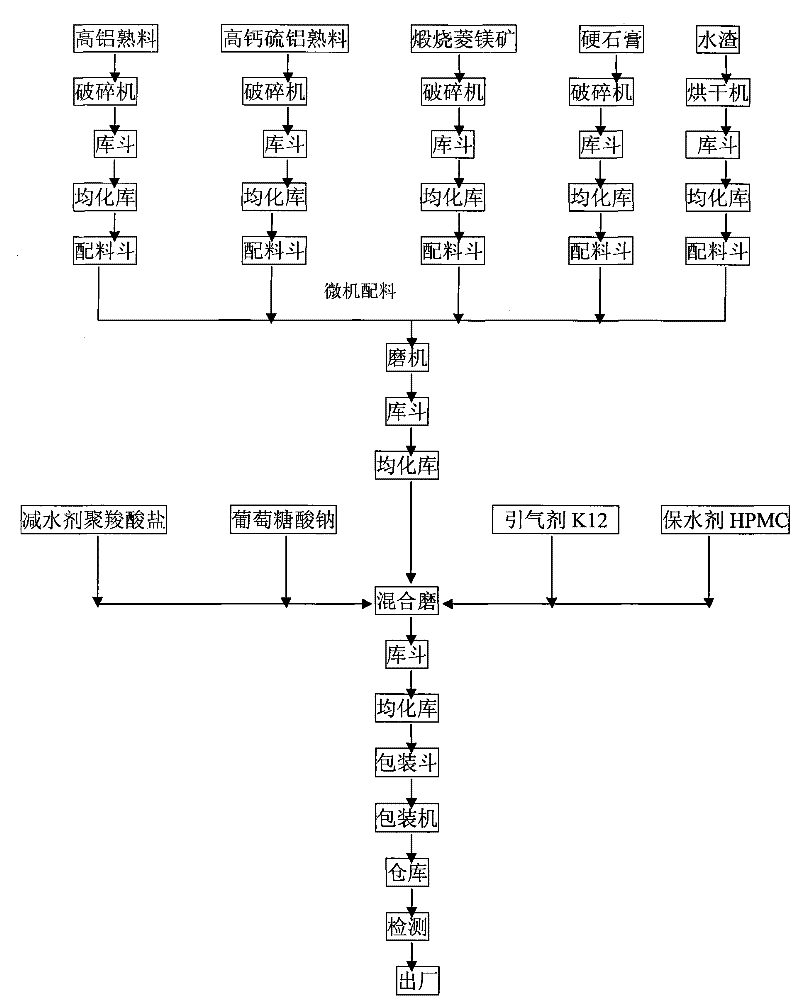

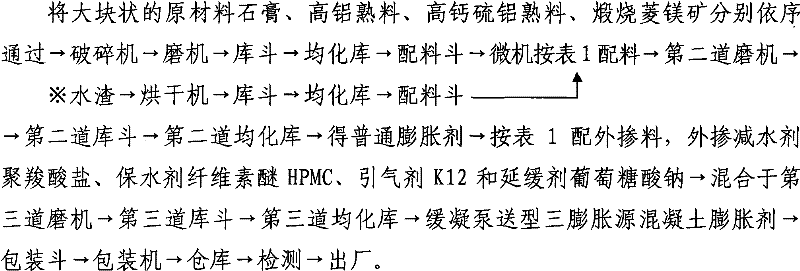

Retardation pumping type three-expansion source cement expansive material

The invention discloses a slow hardening pump deliver type three expansion source concrete expansion agent, which is characterized by comprising preparation of raw materials such as anhydrite, high alumina chamotte, high-calcium sulphoaluminate chamotte, calcined magnesite and so on by weight portion and externally doped slushing agent, water retention agent, air entraining agent and retardant. The preparation method of the expansion agent comprises steps of crushing, common mixture, mixing and grinding and external doping mixture and finish product forming. The product has low alkali content, excellent expansion performance, strong suitability with concrete, balanced mechanical property after hardening, and small gradual slump loss of concrete shrinkage compensation, contributes to improving safety and durability of reinforced concrete, obviously improves the cracking resistance, volume stability, impermeability and frost resistance, and is simple and convenient to use and easy to control quality in construction. The slow hardening pump deliver type three expansion source concrete expansion agent can meet construction use requirements of commercial concrete, long distance pump-delivering concrete and mass concrete.

Owner:广西云燕特种水泥建材有限公司

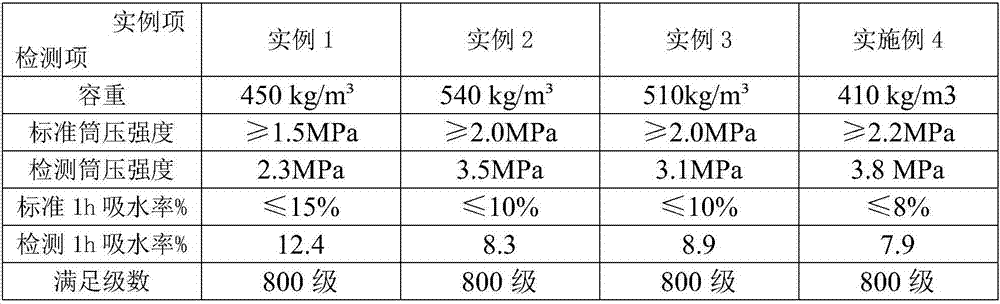

Method for producing novel light-weight wall material by mixing coal slag

The invention discloses a method for producing a novel light-weight wall material by mixing coal slag. The coal slag produced by a thermal power plant replaces 20-100% of sand. On the one hand, the consumption of the sand is reduced, the production cost is lowered greatly, resources are saved, waste materials are recycled, and the environmental pollution is relieved. On the other hand, early hydration heat of concrete mixed with the coal slag is reduced, the sulfate resistance of the concrete is improved, and the impermeability has the direct bearing on the carbonization resistance, freezing resistance and erosion resistance of the concrete and further has an important effect on shrinkage and creepage of the concrete. In addition, the coal slag is lighter than the sand, so that the volumetric weight of the concrete mixed with the coal slag is reduced; a wall is light in deadweight; the mounting efficiency is improved; for mechanical properties, compression resistance and a suspension force of the light-weight wall material mixed with the coal slag are greatly higher than those of a light-weight wall material used for construction and produced by mixing no coal slag; and the method has very good economic and social benefits.

Owner:江苏建华新型墙材有限公司

Cement concrete for wet connection seam of system sequentially comprising simply-supported bridge and continuous bridge, and preparation method thereof

The present invention discloses a cement concrete for the wet connection seam of a system sequentially comprising simply-supported bridge and continuous bridge, and a preparation method thereof, wherein the cement concrete comprises cement, river sand, water, a polycarboxylic acid-based efficient water reducer, rice hull ash, apatite, sericite, sepiolite, a sodium polyacrylate high water absorption resin, talc powder, nanometer calcium carbonate, polyethylene fibers and polyester fibers, and with the synergistic effect among the mineral components such as the apatite, the sericite and the sepiolite and the two fibers, the toughening can be achieved, the impact resistance and the extension ability of the concrete can be improved, and the problems that the wet connection seam concrete is damaged and the bridge surface cracks can be effectively solved. According to the present invention, the cement concrete has advantages of high compressive strength, good toughness, impact resistance, permeation resistance, self-leveling, and the like.

Owner:CHANGAN UNIV

Secondary ettringite type expanding agent and preparation method and application thereof

ActiveCN102167536AReduce shrinkage cracksImprove stress statusSolid waste managementAluminitePolymer science

The invention discloses a secondary ettringite type expanding agent and a preparation method and application thereof. The preparation method comprises the following steps of: stirring a pozzolanic material, a calcium material, plaster and water, forming into a blank or spheres, naturally curing, performing dry heating curing in a curing cell for 0.5 to 10 hours, raising the temperature to 100-170DEG C, and keeping the temperature for 0.5 to 10 hours for dehydration and ettringite decomposition reaction, or standing the formed blank or spheres for 2 to 10 hours, curing under steam pressure, and dehydrating for 0.5 to 10 hours, or dehydrating the thermally synthesized aluminosilicate material and wastes thereof at the temperature of higher than 100DEG C for 0.5 to 10 hours; and mixing and grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum, or respectively grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum and uniformly mixing to obtain powder of which the specific surface area is more than 200m<2> / kg, namely the secondary ettringite type expanding agent. The secondary ettringite type expanding agent can endow mortar and concrete with micro-expansion property, and improve the volume stability of the mortar and concrete.

Owner:HOHAI UNIV +1

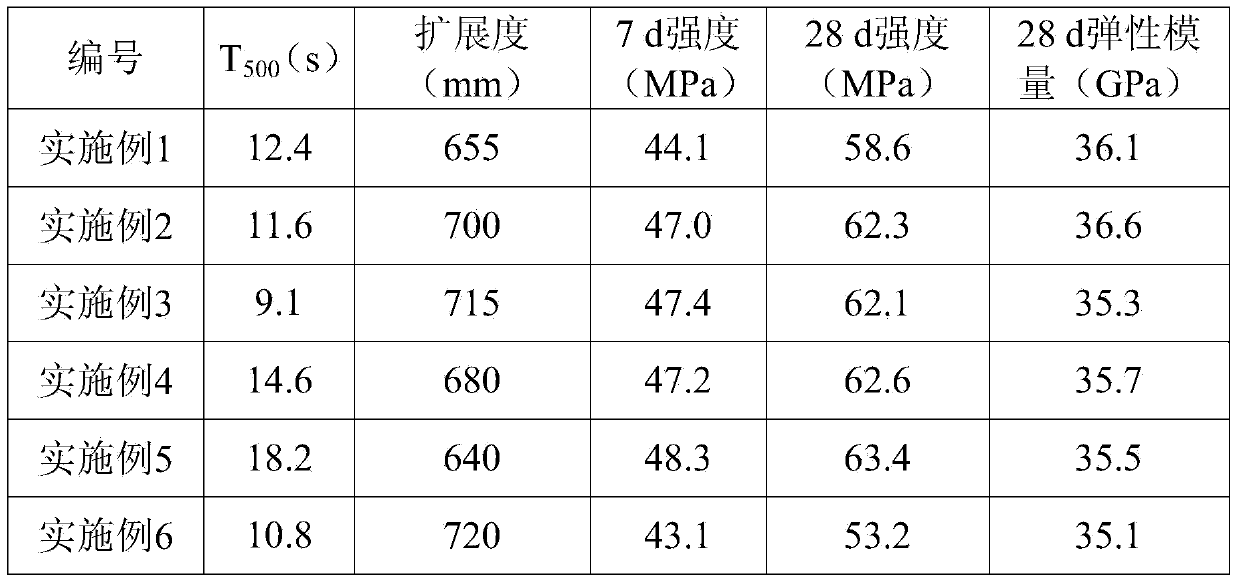

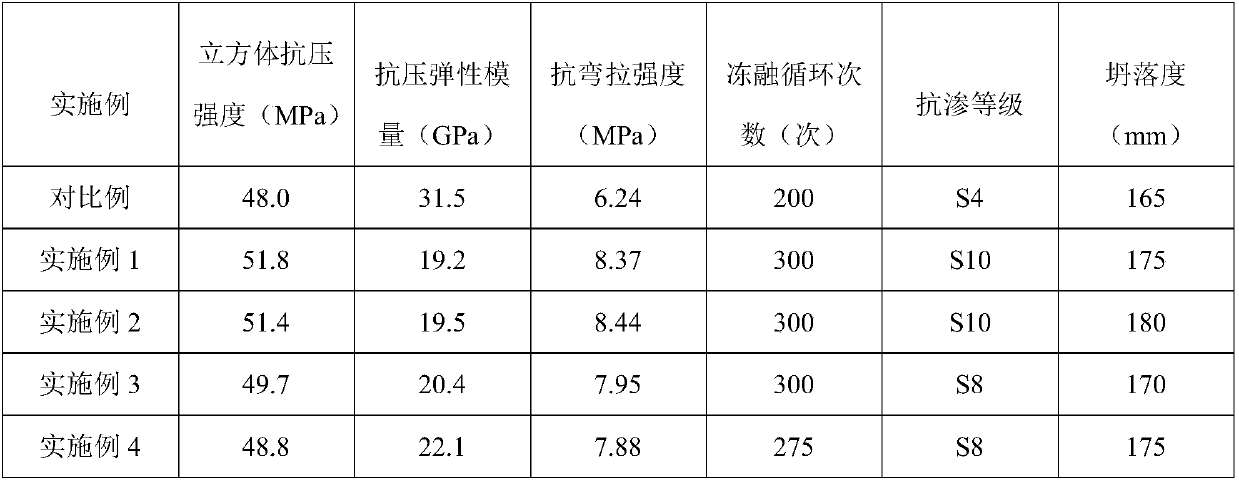

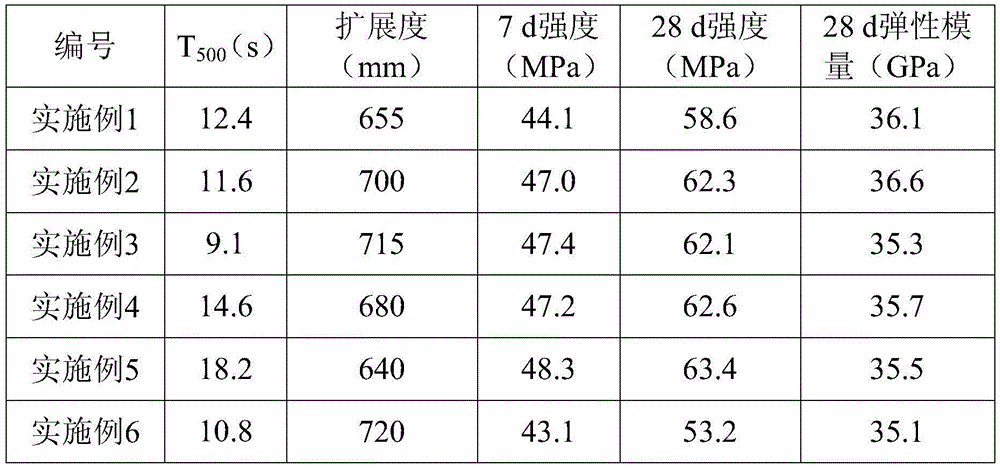

C50 self-compacting concrete for bridge and preparation method thereof

ActiveCN104177019AImproves durability and compactnessReduce vibration costsSolid waste managementElastic modulusSelf-consolidating concrete

The invention relates to a C50 self-compacting concrete for a bridge. The C50 self-compacting concrete comprises the following components per cubic meter by weight: 340-430kg of cement, 100-200kg of fly ash, 700-780kg of sand, 900-950kg of detritus, 5-7.7kg of high-performance polycarboxylic acid water reducer and160-180kg of water. The preparation method of the C50 self-compacting concrete for the bridge comprises the following steps of mixing cement, fly ash and sand at a ratio, stirring for 0.5 minute, adding the high-performance polycarboxylic acid water reducer, stirring for 1 minute, and then putting detritus, stirring for 2 minutes and shaping. The elastic modulus and 7d strength of the C50 self-compacting concrete for the bridge reach the requirement on the concrete for the bridge, and the cost is lower as compared with the original C50 ordinary concrete for the bridge; and meanwhile, due to adoption of the self-compacting concrete, the vibrating process can be also eliminated, the continuous construction can be carried out, the vibrating cost is reduced, the construction period is shortened and the significant economic benefits are achieved.

Owner:JIANGMEN XINHUI DISTRICT TIANHAI

Light energy-saving heat-insulating wall material

The light energy-saving heat insulating wall material is produced with light aggregate in 1.2-2.6 wt%, gelating material in 72-76 wt% and sand in 22-26 wt%, as well as water in 35-88 wt% of gelating material, bulking agent in 13 wt% of gelating material and water reducing agent in 1 wt% of gelating material. The light energy-saving heat insulating wall material has the advantages of saving in land, low power consumption, light weight, easy construction, high heat insulating performance, etc. and may be used in network structure building system and non-bearing wall building system.

Owner:HARBIN ENG UNIV

Method for firing ceramsite from coal mixed slag and sludge

InactiveCN107129270ASmall footprintReduce pollutionCeramic materials productionCeramicwareMetallurgySlag

The invention discloses a method for firing ceramsite from coal mixed slag and sludge. The method comprises the following steps: grinding coal slag and clay, drying for later use, and dewatering sludge; uniformly mixing and stirring the coal slag, the clay and the dewatered sludge according to a certain ratio; weighing the various materials according to the volume, wherein the amount of the coal slag is 20-60%, the amount of the clay is 20-30%, and the amount of the dewatered sludge is 20-50%; preparing spheres with the particle sizes of 0-40mm from the uniformly stirred and mixed materials in the step b; drying the prepared spheres in a thermostat at the temperature of 105+ / -5 DEG C; preheating the spheres dried in the thermostat in a preheating tank at the temperature of 350-500 DEG C for 10-30 minutes; and finally, roasting the spheres in the preheating tank in a roasting box at the temperature of 1050-1150 DEG C for 5-15 minutes, and cooling, thereby obtaining the lightweight ceramsite. The ceramsite fired by the method disclosed by the invention is controllable in operation and high in reproduction ratio; and moreover, more than 70% of solid wastes serve as raw materials, so that the resources are saved, and the cost is reduced.

Owner:江苏建华新型墙材有限公司

WHDF-S type inorganic mortar anti-cracking waterproof agent

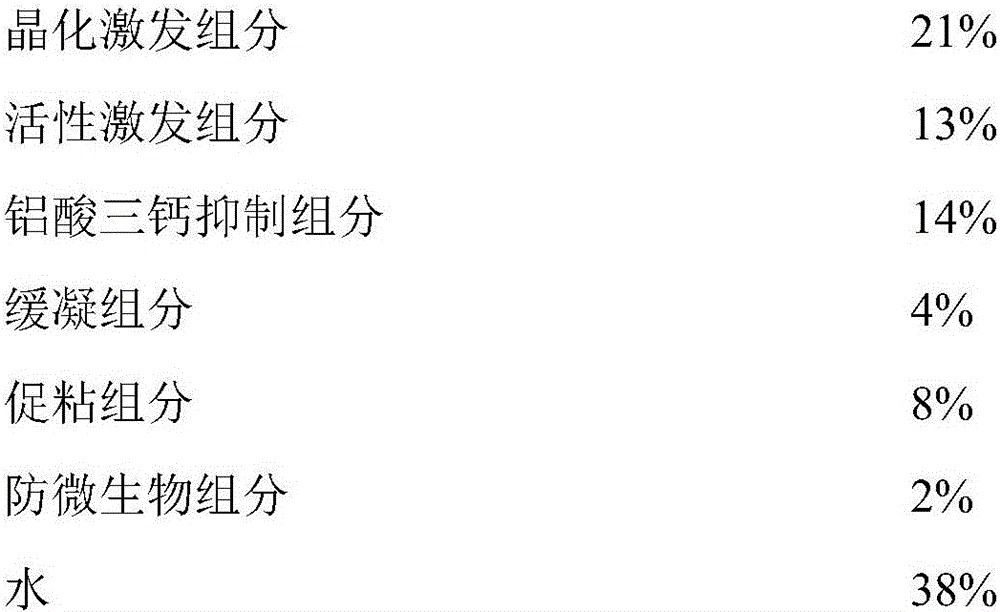

The invention provides a WHDF-S type inorganic mortar anti-cracking waterproof agent. The WHDF-S type inorganic mortar anti-cracking waterproof agent comprises, by weight, 18-28% of crystallization stimulated components, 12-18% of active stimulated components, 7-15% of tricalcium aluminate suppression components, 3-6% of retarder components, 6-13% of viscidity promoting components, 2-6% of anti-microorganism components, and 30-40% of water. The WHDF-S type inorganic mortar anti-cracking waterproof agent has excellent anti-cracking and waterproof performance, belongs to inorganic materials, is environmentally friendly, not prone to aging and low in cost, and the construction technique is simplified. The innovativeness of the WHDF-S type inorganic mortar anti-cracking waterproof agent lies in the technical path that three agents are combined into one, the inorganic materials are used boldly to solve the problems of cement hydration degree and the amount of gel products, the interior is more compact, and the problems that materials are aged and decorative surfaces are repaired frequently are solved. The WHDF-S type inorganic mortar anti-cracking waterproof agent has the advantages that construction is convenient, and the economic cost and comprehensive cost are reduced.

Owner:武汉天衣新材料有限公司

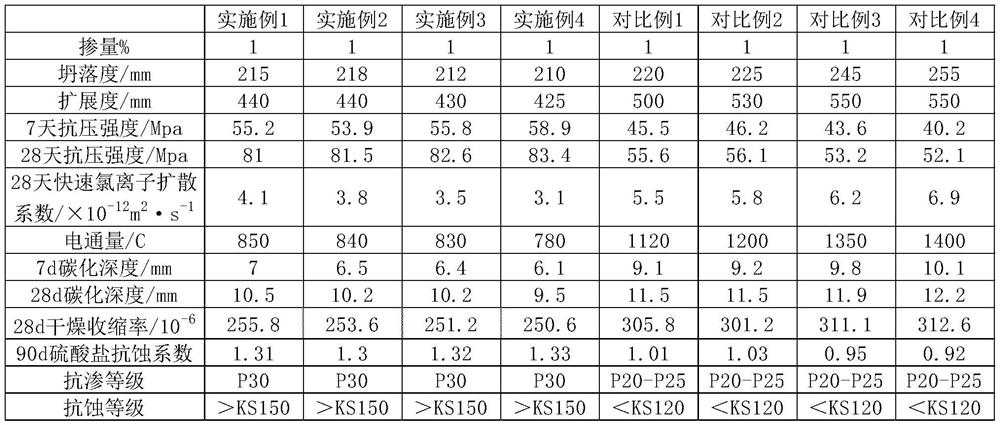

Anti-corrosion anti-cracking permeability reducing agent for marine concrete and preparation method of anti-corrosion anti-cracking permeability reducing agent

ActiveCN114634325AImprove compactnessImprove corrosion resistanceSolid waste managementFiberPhosphate

The invention discloses an anti-corrosion anti-cracking permeability reducing agent for marine concrete and a preparation method of the anti-corrosion anti-cracking permeability reducing agent, and belongs to the technical field of concrete admixtures. The anti-seepage agent is prepared from the following raw materials in parts by weight: 5 to 10 parts of a water reducing agent, 4 to 10 parts of a micro-nano anti-seepage component, 1.5 to 3.5 parts of an air entraining agent, 3 to 9 parts of anti-crack fiber, 1 to 3 parts of inositol hexaphosphate, 1 to 5 parts of polypropylene glycol, 0.5 to 1 part of hydroxy propyl distarch phosphate, 0.5 to 1.5 parts of chitosan and 20 to 30 parts of water. According to the anti-seepage agent disclosed by the invention, nano silicon dioxide is modified in two steps and then is mixed with the anti-cracking fiber, two isolated strength enhancing substances are organically combined and jointly act with other raw materials, the anti-seepage and anti-cracking properties of a concrete material are remarkably improved, and the obtained admixture does not contain substances harmful to a human body, is chlorine-free, green and environment-friendly, and has a good application prospect. The durability of the concrete in the marine environment can be greatly improved, the service life is prolonged, and the safety is improved.

Owner:日照海工研新材料有限公司

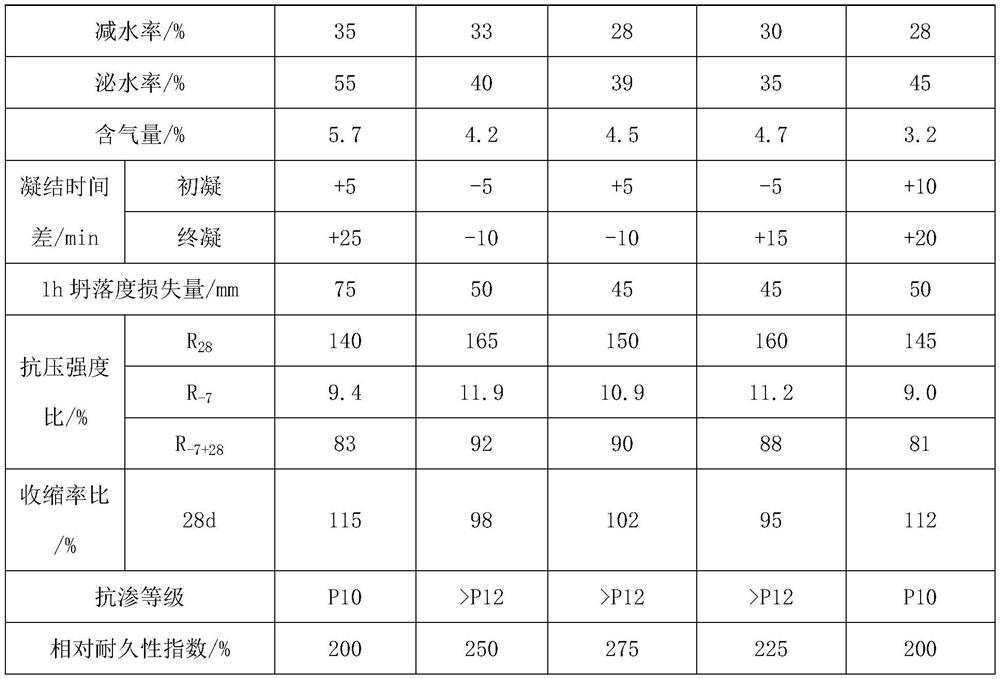

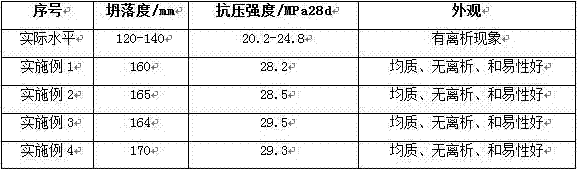

WHDF-N type viscosity modifier applicable to self-compacting concrete

InactiveCN106517856AIncreased hydrationInhibit early rapid hydrationCrack resistanceTricalcium aluminate

The invention provides a WHDF-N type viscosity modifier applicable to self-compacting concrete. The WHDF-N type viscosity modifier comprises components in percentage by weight as follows: 15%-25% of a crystallization excitation component, 7%-13% of an activity excitation component, 10%-15% of a tricalcium aluminate inhibition component, 6%-14% of a workability regulation component, 2%-6% of an anti-microbe component and 30%-40% of water. Under actions of promoting cement hydration degree, optimizing a hydration product, inhibiting early rapid hydration of tricalcium aluminate, reducing early hydration heat and the like, the WHDF-N type viscosity modifier has the advantages that gel of a system is increased, pores are reduced, an aggregate interface structure and early hydration heat are improved, and the workability and self-compacting performance of a concrete mixture are improved effectively while the crack resistance, impermeability and durability of the concrete are improved remarkably.

Owner:武汉天衣新材料有限公司

Concrete anti-seepage and anti-freezing admixture for plateau complex environment and preparation method thereof

ActiveCN114014581AImprove mechanical propertiesIncreased durabilityCalcium formateStructural engineering

The invention discloses a concrete anti-seepage and anti-freezing admixture suitable for a plateau complex environment and a preparation method thereof. The concrete anti-seepage and anti-freezing admixture comprises the following raw materials in percentage by mass: 10-15% of sodium dodecyl benzene sulfonate, 7-10% of calcium nitrite, 3-6% of calcium formate, 5-8% of methanol, 4-7% of ethylene glycol, 2-5% of sodium gluconate, 1-3% of sodium polyacrylate, 11-14% of polyoxyethylene ether and the balance of deionized water. According to the anti-seepage and anti-freezing admixture disclosed by the invention, the construction of concrete under low-temperature and negative-temperature conditions can be realized, the construction period of the concrete can be prolonged, the early strength of the concrete can be improved, and the durability of the concrete and the service capacity of the concrete under complex plateau environment conditions can be effectively improved.

Owner:中交二公局第四工程有限公司

WHDF-H type anti-corrosion agent suitable for marine concrete

The invention provides a WHDF-H type anti-corrosion agent suitable for marine concrete. The WHDF-H type anti-corrosion agent comprises, by weight, 16-22% of crystallization stimulated components, 12-16% of active stimulated components, 13-17% of tricalcium aluminate suppression components, 10-15% of anti-corrosion components, 2-6% of anti-microorganism components, and 30-40% of water. According to the WHDF-H type anti-corrosion agent, by promoting the extent of hydration of cement, optimizing hydration products, suppressing early fast hydration of tricalcium aluminate, reducing early hydration heat and the like, the amount of gel of a system is increased, the porosity is decreased, interface structures of aggregates and the early hydration heat are improved, the anti-cracking performance, anti-seepage performance and durability of the concrete are remarkably improved, and meanwhile, the corrosion resistance of concrete mixtures is effectively improved.

Owner:武汉天衣新材料有限公司

Proportioning method for novel C25 concrete applied to downhole floor pouring

The invention relates to a proportioning method for novel C25 concrete applied to downhole floor pouring. The method is characterized in that the concrete is cement, gravity-separated iron tailings, yellow sand, cobblestone, water, a high-efficiency water reducer and steel fibers in a mass ratio of (394-400): (410-418): (380-385): (791-800): (220-225): (4-5): (55-60). The method can effectively reduce the usage amount of yellow sand in a reasonable range, so the cost of support production is lowered; and at the same time, the high-performance water reducer and large-proportion steel fibers areintroduced to improve the deformation resistance, compressive strength, abrasion resistance, toughness, impact strength and durability of the concrete.

Owner:NANJING MEISHAN METALLURGY DEV +1

A method for producing lightweight new wall material by mixing coal slag

ActiveCN103467013BLight weightReduce early heat of hydrationSolid waste managementSocial benefitsSlag

The invention discloses a method for producing a novel light-weight wall material by mixing coal slag. The coal slag produced by a thermal power plant replaces 20-100% of sand. On the one hand, the consumption of the sand is reduced, the production cost is lowered greatly, resources are saved, waste materials are recycled, and the environmental pollution is relieved. On the other hand, early hydration heat of concrete mixed with the coal slag is reduced, the sulfate resistance of the concrete is improved, and the impermeability has the direct bearing on the carbonization resistance, freezing resistance and erosion resistance of the concrete and further has an important effect on shrinkage and creepage of the concrete. In addition, the coal slag is lighter than the sand, so that the volumetric weight of the concrete mixed with the coal slag is reduced; a wall is light in deadweight; the mounting efficiency is improved; for mechanical properties, compression resistance and a suspension force of the light-weight wall material mixed with the coal slag are greatly higher than those of a light-weight wall material used for construction and produced by mixing no coal slag; and the method has very good economic and social benefits.

Owner:江苏建华新型墙材有限公司

High-performance sulfur concrete and preparation method thereof

The invention discloses high-performance sulfur concrete and a preparation method thereof. The high-performance sulfur concrete comprises the following raw materials in percentage by mass: 30%-37% ofcement, 38%-43% of river sand, 11%-17% of water, 0.4%-0.8% of a water reducer, 8%-15% of sulfur powder, 0.1-0.5% of an emulsifying dispersant and 0.8-1.2% of resin emulsion. By the high-performance sulfur concrete provided by the invention, sulfur can be recycled, furthermore, the bending resistance, the seepage resistance and the frost resistance of the concrete can be improved, and the durability of the concrete and the service capability of the concrete under extreme condition are improved effectively.

Owner:CHANGAN UNIV

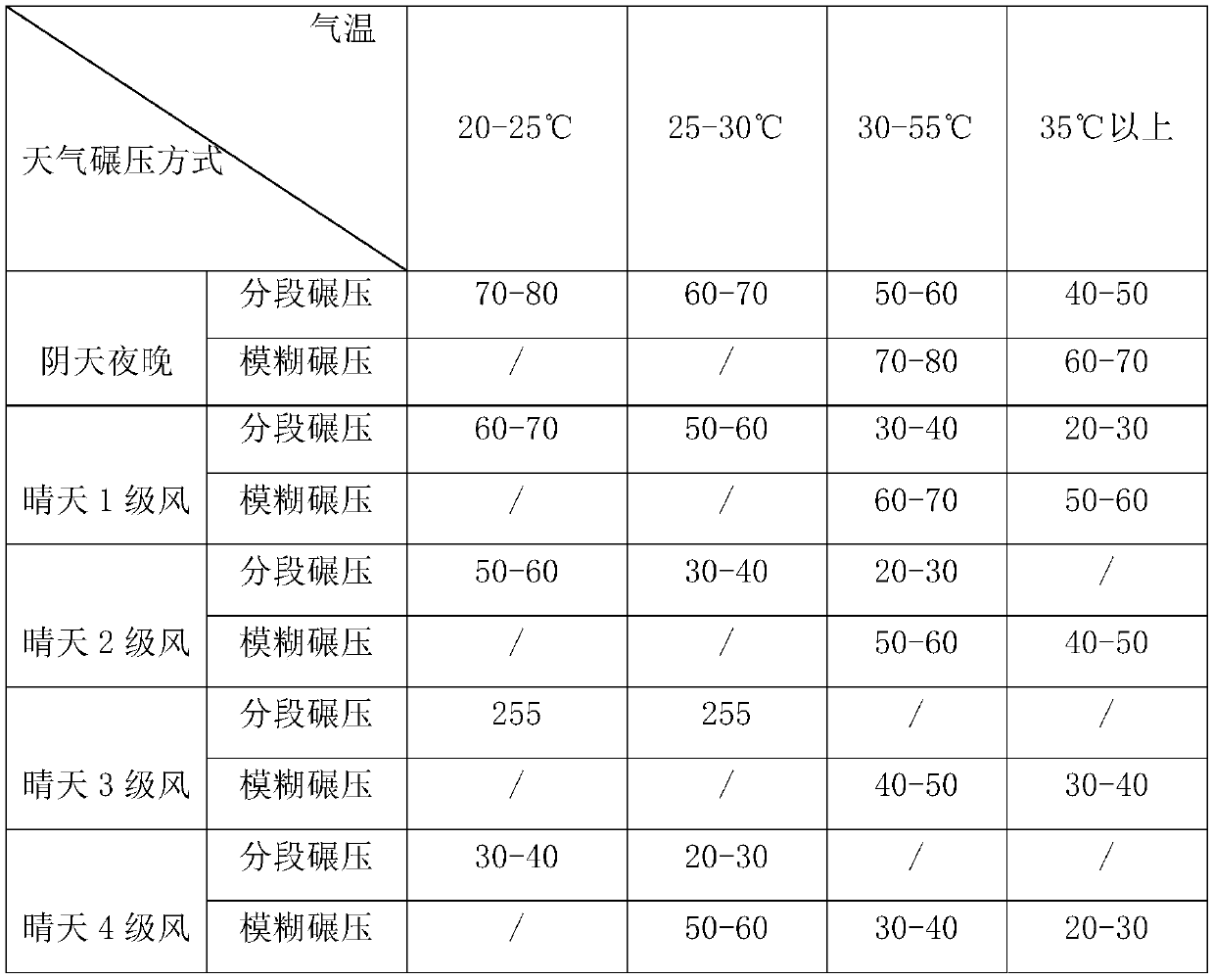

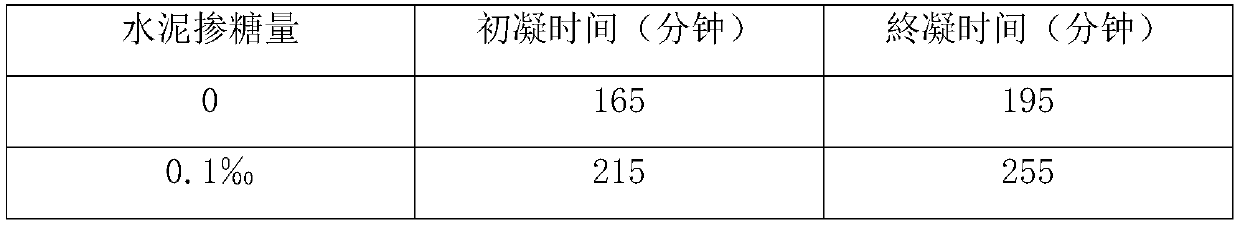

Cement stabilized macadam mixture and road base layer construction method used in high-temperature seasons

ActiveCN110714382AReduced hydrationRealize retarding effectRoadwaysCement mixing apparatusHydration reactionPolymer chemistry

The invention discloses a cement stabilized macadam mixture and a road base layer construction method used in high-temperature seasons. The mixture comprises cement, a saccharose solution, stabilizedmacadam rough aggregates and fine aggregates. Saccharose is fused in cement stabilized macadam mixed water, the cement hydration reaction can be delayed, the non-delayed-coagulation cement delayed coagulation effect is achieved, and the cement stabilized macadam mixture has sufficient construction delay time. The construction delay time can be flexibly adjusted according to the mixing amount, thesufficient construction time can be achieved for the cement stabilized macadam mixture under the situation that ordinary cement is used in the scorching summer, and accordingly the engineering qualityis ensured.

Owner:北京城建华晟交通建设有限公司

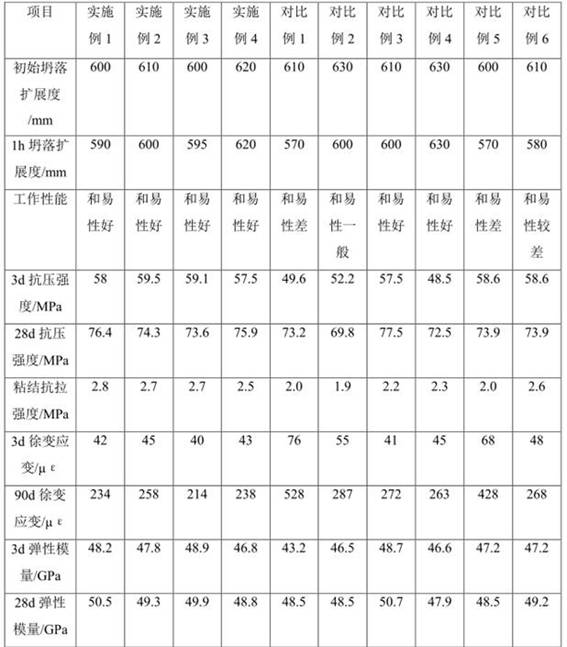

Low-shrinkage low-creep concrete composite additive suitable for early-age prestress tensioning

ActiveCN112194404AImprove early strength and elastic modulusImprove compactnessSilica fumeSilicate Cement

The invention discloses a low-shrinkage low-creep concrete composite additive suitable for early-age prestress tensioning. The composite additive is composed of anhydrous calcium sulfoaluminate clinker, calcium sulfate, silica fume, lithium carbonate, a styrene polymer, triisopropanolamine, an anti-settling agent and the like, is used in concrete taking ordinary Portland cement as a cementing material, and provides ettringite crystals through hydration reaction of anhydrous calcium sulfoaluminate and calcium sulfate. The forming speed of ettringite in a hydration product is increased by utilizing the seed crystal effect of silica fume and the early strength effect of lithium carbonate and triisopropanolamine, the purposes of micro-expansion, early strength, low shrinkage and low creep areachieved, meanwhile, the workability of concrete is improved through an anti-settling agent, and the later strength of silica fume is improved through a volcanic ash reaction; the concrete added withthe composite additive has the characteristics of early strength, micro-expansion and low creep, is suitable for concrete early-age prestress tensioning engineering, saves time and shortens the construction period.

Owner:湖南固特邦土木科技发展有限公司

Retardation pumping type three-expansion source cement expansive material

Owner:广西云燕特种水泥建材有限公司

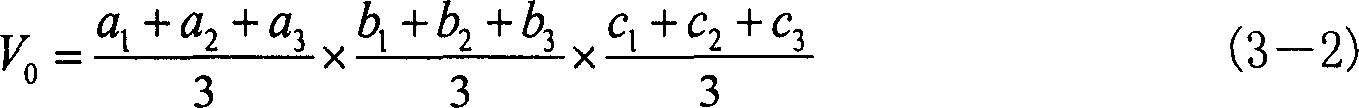

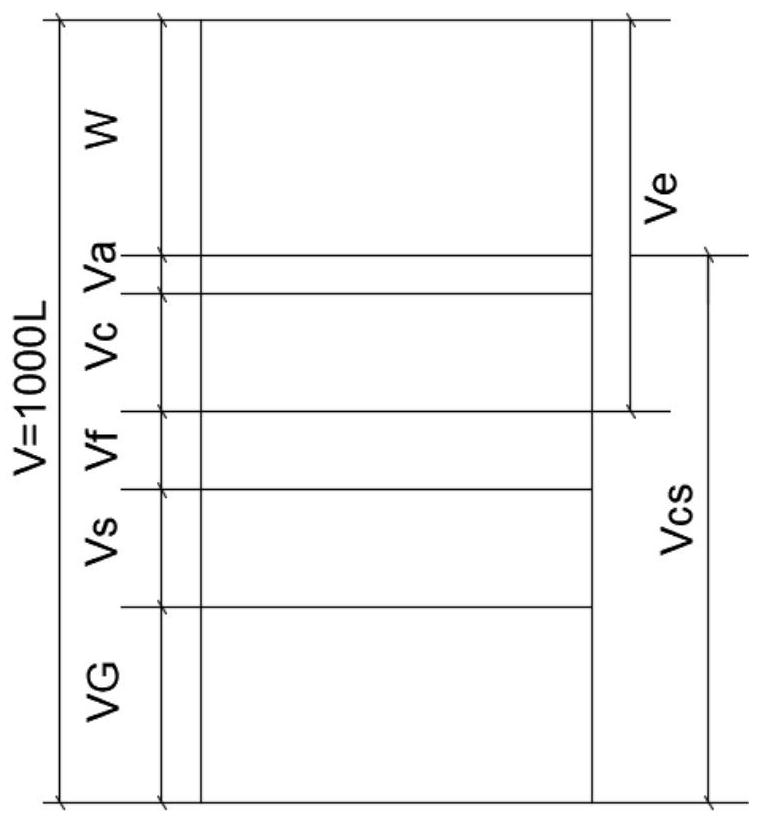

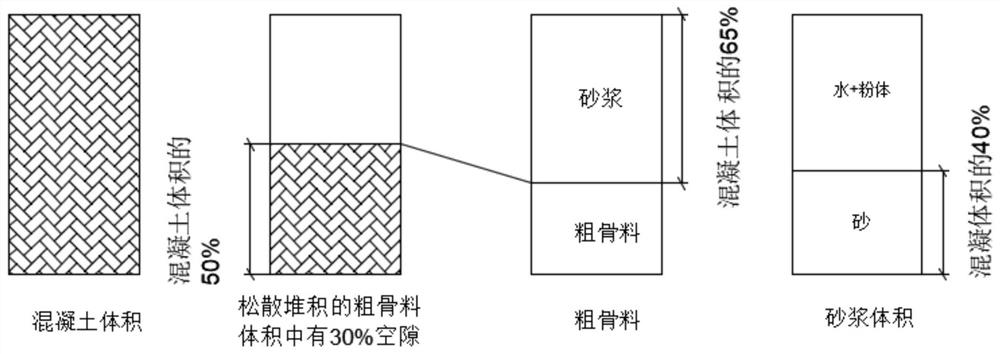

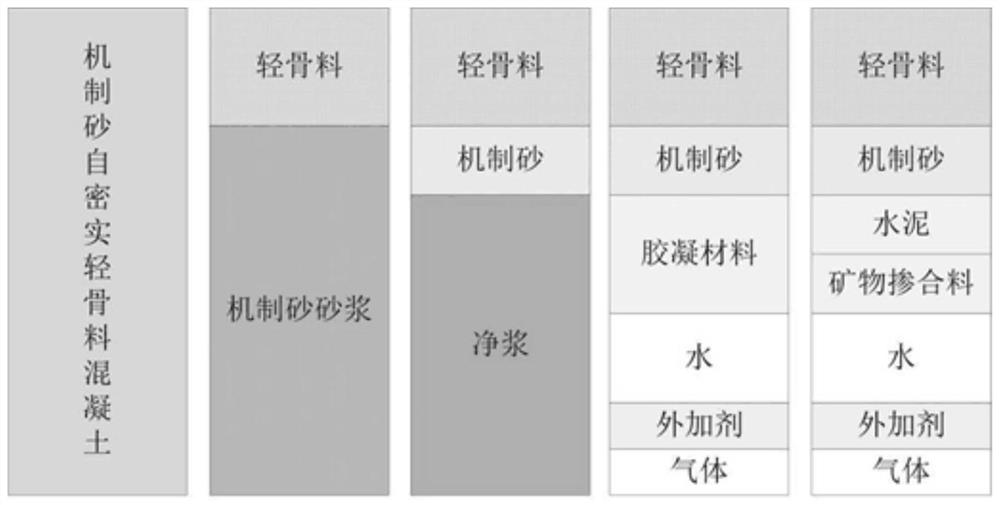

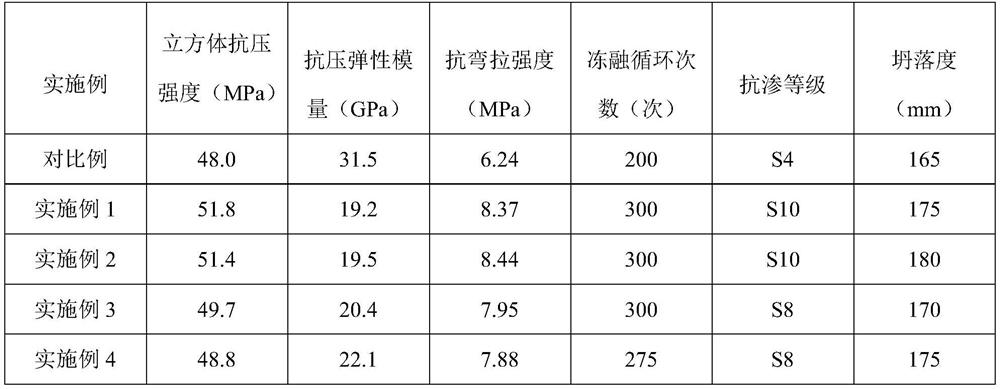

A method for mixing ratio of machine-made sand self-compacting lightweight aggregate concrete

ActiveCN113336489BGuaranteed to workGuaranteed mechanical propertiesSolid waste managementProcess engineeringSlurry

The invention discloses a method for designing the mixing ratio of machine-made sand self-compacting lightweight aggregate concrete. The method includes: (1) determining the water-cement ratio according to the configuration strength, and determining the unilateral consumption of each raw material in the clean slurry in combination with the improved water consumption formula; 2) Determine the unilateral amount of lightweight aggregate and machine-made sand according to the value of primary slump expansion; convert the initial amount of each raw material into a preliminary benchmark mix ratio; (3) use the orthogonal test method to optimize the amount of each raw material to obtain the benchmark mix ratio (4) Convert the base mixing ratio to the production mixing ratio according to the raw material index. The present invention fully considers the characteristics of machine-made sand and lightweight aggregate, improves the water consumption formula, and proposes an additional water consumption correction factor for machine-made sand γ 2 , and give the value range. Pre-wet the lightweight aggregate with additional water, and add a large amount of fly ash and some silica fume and other mineral admixtures, which can effectively inhibit the floating of the lightweight aggregate and ensure the working performance of the machine-made sand self-compacting lightweight aggregate concrete and mechanical properties.

Owner:XIAN UNIV OF SCI & TECH

A kind of high-performance sulfur concrete and its preparation method

The invention discloses high-performance sulfur concrete and a preparation method thereof. The high-performance sulfur concrete comprises the following raw materials in percentage by mass: 30%-37% ofcement, 38%-43% of river sand, 11%-17% of water, 0.4%-0.8% of a water reducer, 8%-15% of sulfur powder, 0.1-0.5% of an emulsifying dispersant and 0.8-1.2% of resin emulsion. By the high-performance sulfur concrete provided by the invention, sulfur can be recycled, furthermore, the bending resistance, the seepage resistance and the frost resistance of the concrete can be improved, and the durability of the concrete and the service capability of the concrete under extreme condition are improved effectively.

Owner:CHANGAN UNIV

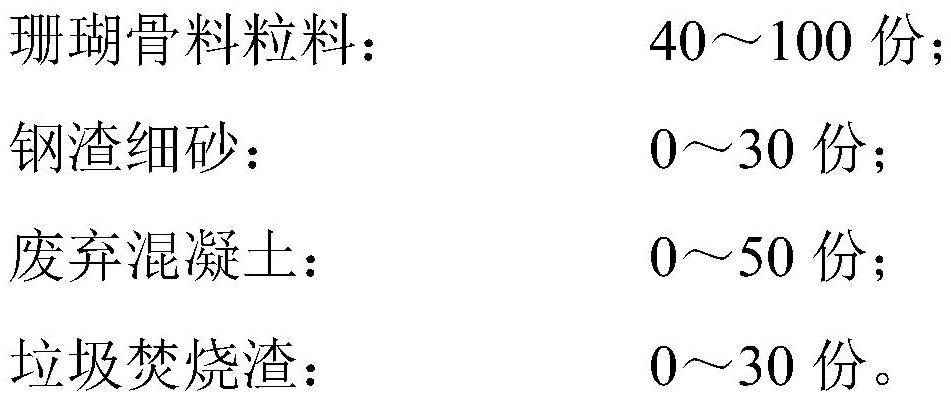

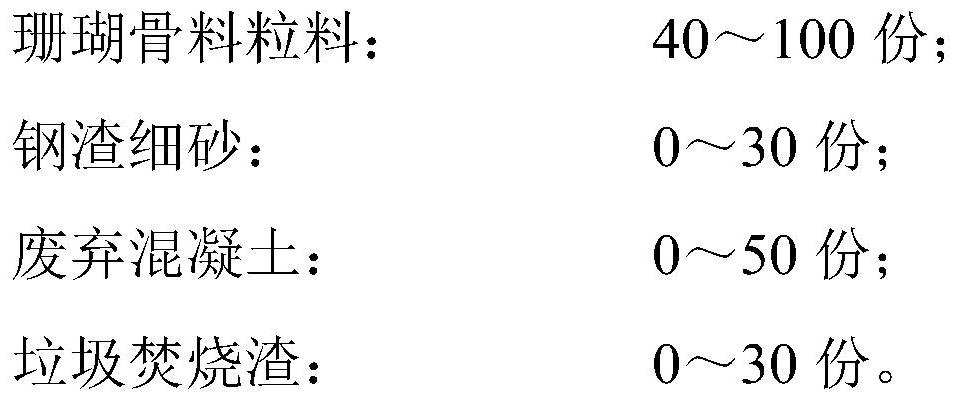

Coral aggregate aggregate base layer or cushion layer material and preparation method thereof

PendingCN112479638AImprove seawater corrosion resistanceImprove bending and tensile strengthRoadwaysCement mixing apparatusAluminateStructural engineering

The invention discloses a coral aggregate aggregate base layer or cushion layer material and a preparation method thereof. The raw materials comprise cement, aggregates and seawater, and the cement isslag aluminate cement or maritime work cement; and the aggregates comprise coral aggregate aggregates and one or more of steel slag fine sand, waste concrete and waste incineration slag. Local materials are used, the cost is low, the seawater corrosion resistance is high, the flexural-tensile strength is high, the anti-cracking performance is high, the anti-permeability performance is high, the early hydration heat is low, the construction period is short, and the material is suitable for serving as a pavement base layer or cushion layer material. A vibration stirring mode is adopted for mixing, the mixture is uniform, and the material can be applied to pavement base layer or cushion layer engineering construction of airfield runways on islands and reefs, highways, ports, wharfs and the like.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

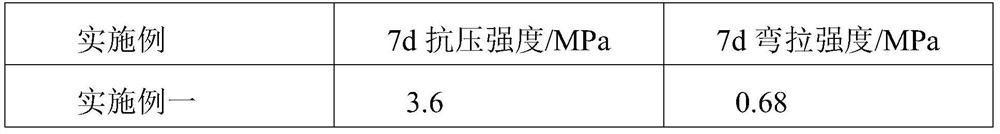

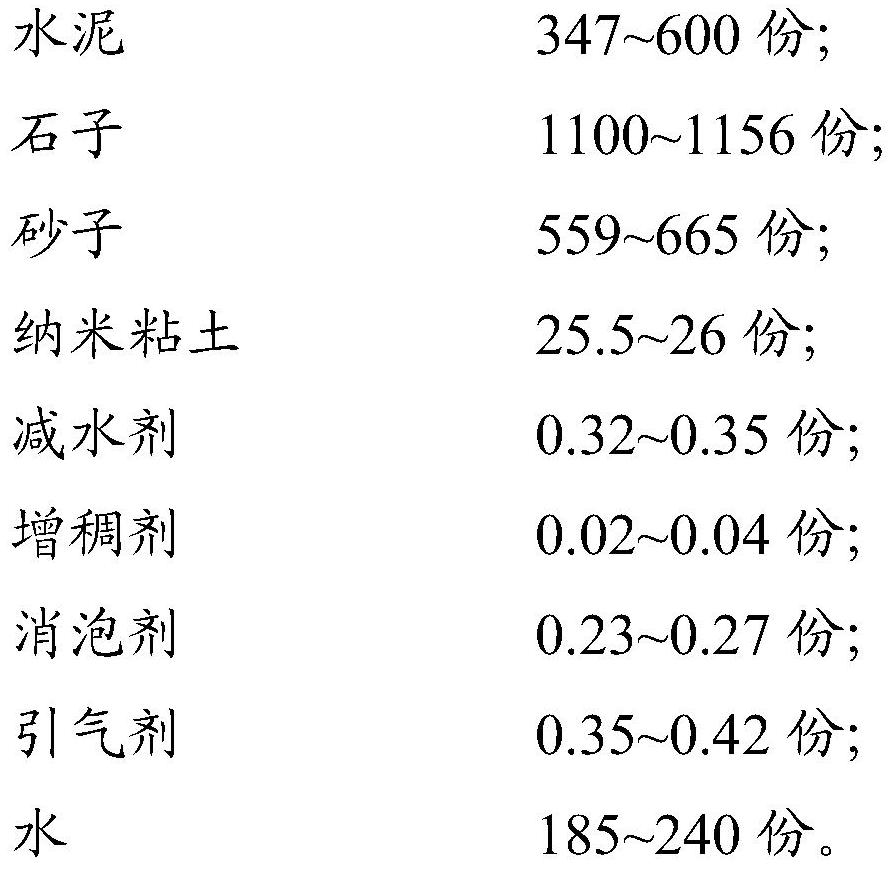

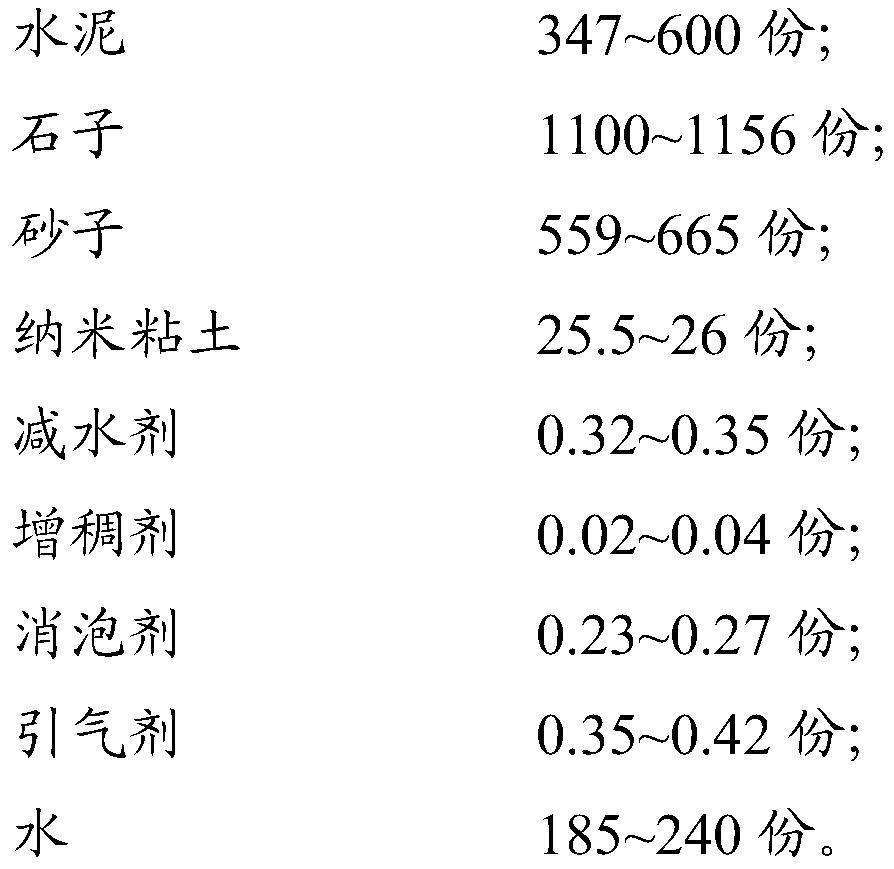

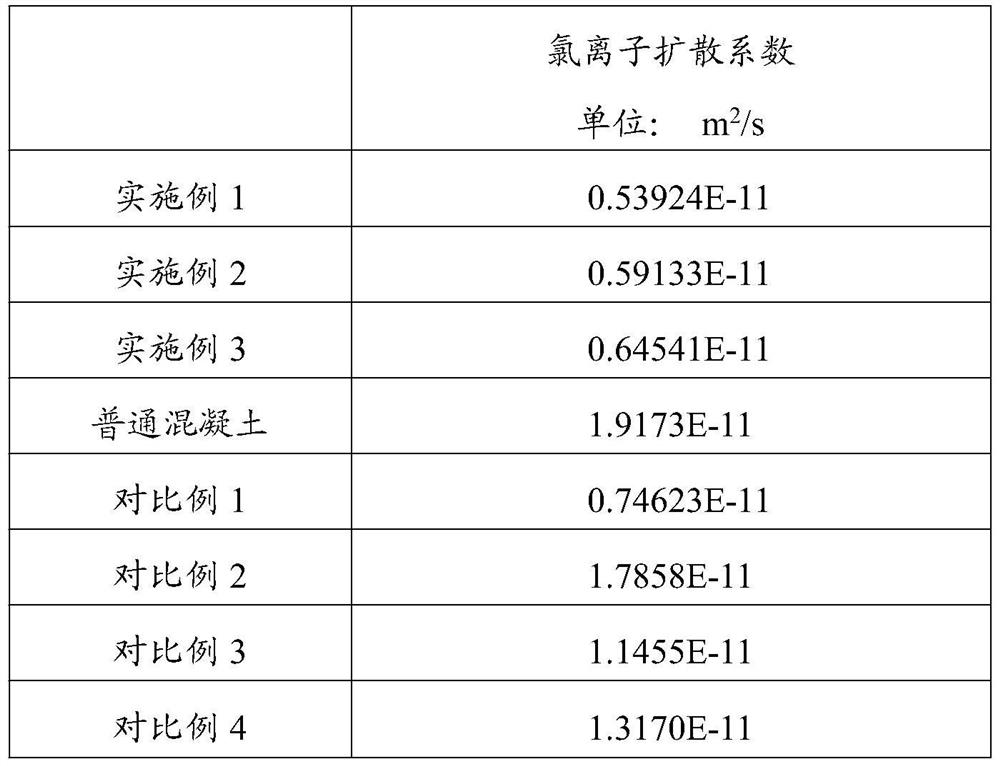

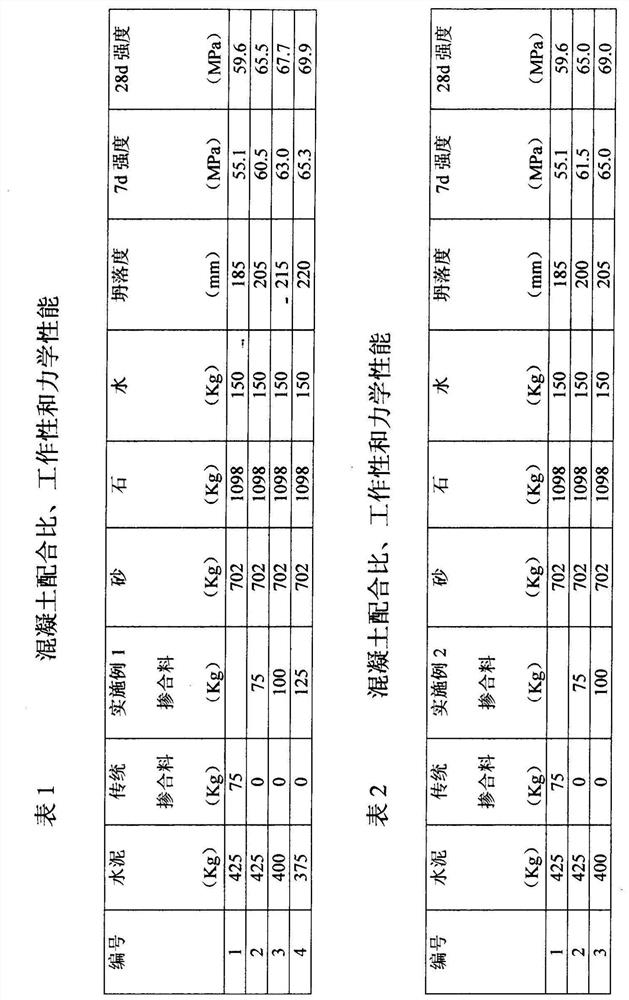

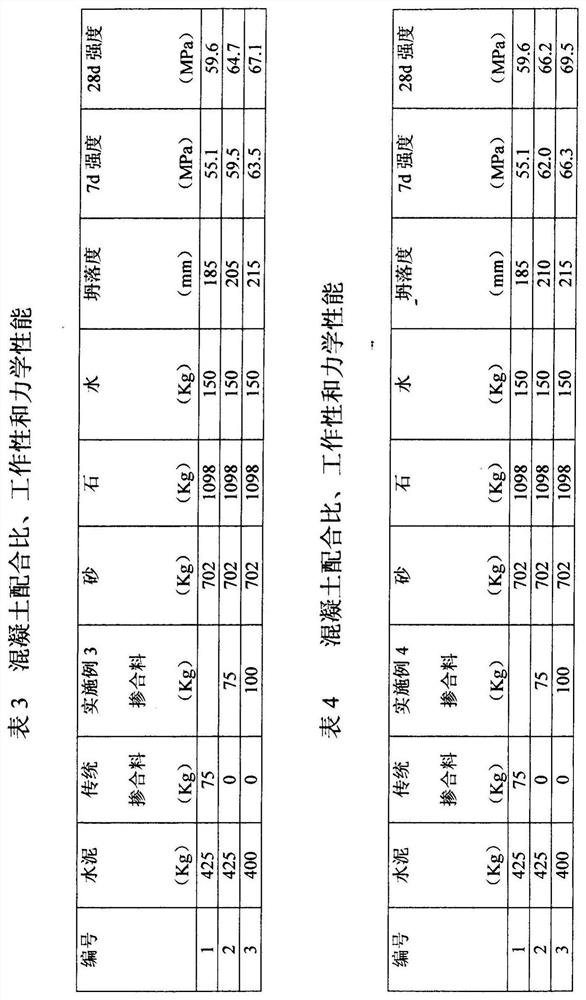

A kind of anti-salt erosion concrete and preparation method thereof

The invention provides a salt erosion-resistant concrete and a preparation method thereof, belonging to the field of concrete. The salt erosion-resistant concrete provided by the present invention comprises the following components in parts by mass: 570-600 parts of cement, 1100-1106 parts of gravel, 640-665 parts of sand, 25.5-26 parts of nanoclay, and 0.32-0.35 parts of water reducer 0.02-0.04 parts of thickener, 0.23-0.27 parts of defoamer, 0.35-0.42 parts of air-entraining agent, and 185-240 parts of water. The invention effectively improves the pore structure inside the concrete by adding the nano-clay, the incorporation of the nano-clay reduces the corrosion of the concrete to chloride and sulfate, and prolongs the service life of the concrete. The results of the examples show that the salt erosion-resistant concrete provided by the invention can effectively resist the erosion of chloride salts and sulfates.

Owner:INNER MONGOLIA UNIV OF TECH

A kind of ground rice husk ash-based composite admixture and its application

ActiveCN110041002BImprove performanceSmall shrinkage deformationSolid waste managementSlagPlasticizer

A ground rice husk ash-based composite admixture and its application. The ground rice husk ash-based composite admixture is a composite material mixed with various ultrafine powders on the basis of ground rice husk ash. The mass percentages are: ground rice husk ash 30%-40%, glass microspheres 20%-30%, metakaolin 15%-25%, superfine silica fume 5%-15%, steel slag 5%-10% , 1% to 5% of limestone powder, 0.5% to 1.0% of activator, 0.5% to 1.0% of superplasticizer, and 0.5% to 2.0% of reinforcing agent. When preparing high-performance concrete, it is mixed into the concrete cementitious material, and the cement is replaced by composite admixture, and the replacement amount is 15% to 25% of the total cementitious material. The finely ground rice husk ash-based composite admixture of the present invention has good performance, it can not only improve the working performance of concrete, but also improve the mechanical properties of cement-based composite materials, and the preparation process is simple, and it is especially suitable for the preparation of high-strength and high-performance concrete .

Owner:SHIJIAZHUANG CHANGAN YUCAI BUILDING MATERIALS

C50 self-compacting concrete for bridges and its preparation method

ActiveCN104177019BIncreased durabilityImprove compactnessSolid waste managementAcid waterEconomic benefits

The invention relates to a C50 self-compacting concrete for a bridge. The C50 self-compacting concrete comprises the following components per cubic meter by weight: 340-430kg of cement, 100-200kg of fly ash, 700-780kg of sand, 900-950kg of detritus, 5-7.7kg of high-performance polycarboxylic acid water reducer and160-180kg of water. The preparation method of the C50 self-compacting concrete for the bridge comprises the following steps of mixing cement, fly ash and sand at a ratio, stirring for 0.5 minute, adding the high-performance polycarboxylic acid water reducer, stirring for 1 minute, and then putting detritus, stirring for 2 minutes and shaping. The elastic modulus and 7d strength of the C50 self-compacting concrete for the bridge reach the requirement on the concrete for the bridge, and the cost is lower as compared with the original C50 ordinary concrete for the bridge; and meanwhile, due to adoption of the self-compacting concrete, the vibrating process can be also eliminated, the continuous construction can be carried out, the vibrating cost is reduced, the construction period is shortened and the significant economic benefits are achieved.

Owner:JIANGMEN XINHUI DISTRICT TIANHAI

Cement concrete for wet joints of simply supported and then continuous bridges and preparation method thereof

Owner:CHANGAN UNIV

A preparation method of a large amount of wet-grinding phosphorus solid waste ultra-retarded gelling material

The invention discloses a method for preparing a large-volume wet-grinding phosphorus solid waste super-slow gelling material. Phosphorus slag and desulfurization ash are added to a wet mill and mixed with water to obtain a mixed slurry A; alkali slag, Grind phosphogypsum and fly ash with a dry mill to obtain mixed powder B; mix mixed slurry A and mixed powder B to obtain mixed material C, and add cement, water reducer, retarder, Tailings sand and crushed stone were stirred for 4 minutes to obtain ultra-retarded concrete. The invention utilizes phosphorus slag, desulfurization ash, alkali slag, phosphogypsum, fly ash, tailings and other wastes to prepare concrete, turns waste into treasure, and can reduce the amount of cement; the mixed wet grinding method of phosphorus slag and desulfurization ash promotes The dissolution of medium phosphorus can greatly prolong the initial setting time and final setting time of concrete, reduce the early heat of hydration, reduce the generation of cracks, and ensure the later strength, so as to realize the high-efficiency application of large amount of phosphorus slag; the prepared ultra-retarded concrete It can be used for mass concrete, drilled occlusal piles, etc.

Owner:HUBEI UNIV OF TECH

Secondary ettringite type expanding agent and preparation method and application thereof

ActiveCN102167536BReduce shrinkage cracksImprove stress statusSolid waste managementAluminitePolymer science

The invention discloses a secondary ettringite type expanding agent and a preparation method and application thereof. The preparation method comprises the following steps of: stirring a pozzolanic material, a calcium material, plaster and water, forming into a blank or spheres, naturally curing, performing dry heating curing in a curing cell for 0.5 to 10 hours, raising the temperature to 100-170DEG C, and keeping the temperature for 0.5 to 10 hours for dehydration and ettringite decomposition reaction, or standing the formed blank or spheres for 2 to 10 hours, curing under steam pressure, and dehydrating for 0.5 to 10 hours, or dehydrating the thermally synthesized aluminosilicate material and wastes thereof at the temperature of higher than 100DEG C for 0.5 to 10 hours; and mixing and grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum, or respectively grinding 60 to 95 weight parts of material and 5 to 40 weight parts of anhydrous gypsum and uniformly mixing to obtain powder of which the specific surface area is more than 200m<2> / kg, namely the secondary ettringite type expanding agent. The secondary ettringite type expanding agent can endow mortar and concrete with micro-expansion property, and improve the volume stability of the mortar and concrete.

Owner:HOHAI UNIV +1

A low-shrinkage and low-creep concrete composite additive suitable for early-age prestressed tension

ActiveCN112194404BImprove anti-settling performanceIncrease resistance to dehydrationHydration reactionClinker (cement)

The invention discloses a low-shrinkage and low-creep concrete composite additive suitable for early-age prestressed tension. The composite additive is composed of anhydrous calcium sulfoaluminate clinker, calcium sulfate, silica fume, lithium carbonate, styrene polymer, triisopropanolamine, anti-settling agent and other components, and is used for ordinary portland cement In the concrete used as cementitious material, ettringite crystals are provided through the hydration reaction of anhydrous calcium sulfoaluminate and calcium sulfate, and the seed crystal effect of silica fume and the early strength effect of lithium carbonate and triisopropanolamine are used to accelerate The formation speed of ettringite in the hydration product achieves the purpose of micro expansion, early strength, low shrinkage and low creep. At the same time, the anti-settling agent improves the workability of concrete, and silica fume improves the later strength through pozzolanic reaction; Concrete with composite additives has the characteristics of early strength, micro-expansion, and low creep, and is suitable for prestressed tensioning projects in the early age of concrete, saving time and shortening the construction period.

Owner:湖南固特邦土木科技发展有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com