Coral aggregate aggregate base layer or cushion layer material and preparation method thereof

A technology for pellets and corals, which is applied to clay preparation devices, chemical instruments and methods, cement mixing devices, etc., can solve the problems of unfavorable road engineering durability, unconsumed solid waste of islands and reefs, low environmental benefits and economic benefits, etc. Achieve the effect of improving seawater corrosion resistance, protecting the environment, and high rate of local material collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

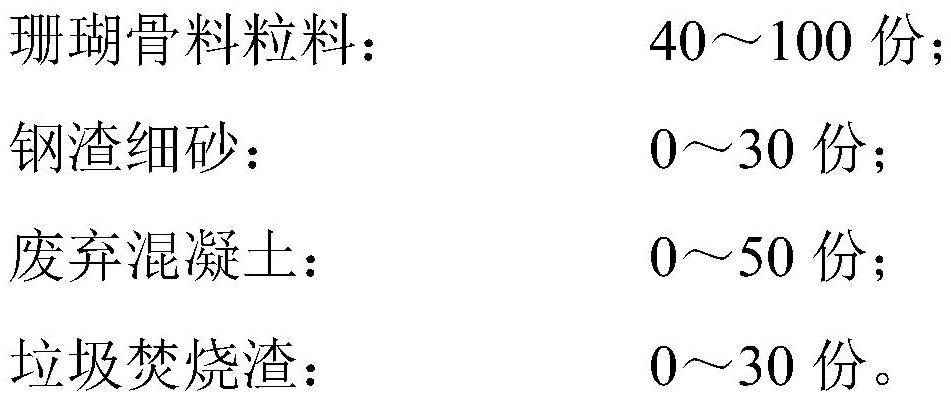

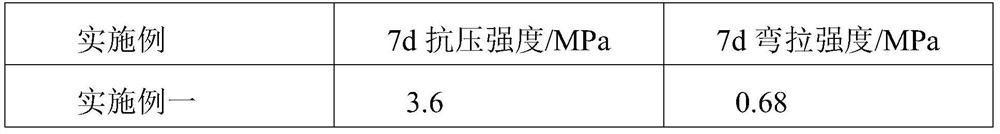

Embodiment 1

[0043] A coral aggregate granular base material, comprising: 4% slag sulphoaluminate cement, 30.5% coral aggregate pellets with a particle diameter of 0mm to 20mm, 10.6% coral aggregate pellets with a particle diameter of 0mm to 45mm, 20 % steel slag fine sand, 20% waste concrete and 14.9% seawater. The final gradation after mixing the four kinds of pellets is: the mass ratio of the particle size ranges of 0mm-4.75mm, 4.75mm-31.5mm, and 31.5mm-45mm is 40:50:10.

[0044] The preparation method of the above-mentioned base material comprises the following steps:

[0045] (1) Determination of the water content of the coral aggregate pellets is 10.5%, and the water content of the coral aggregate pellets is calculated according to the quality of the coral aggregate pellets to be 4.3%;

[0046] (2) Through the compaction test, determine the optimum water content of the base layer to be 19.2%;

[0047] (3) Subtracting the water content quality of the coral aggregate pellets from the o...

Embodiment 2

[0051] A coral aggregate granular base or subbase material, comprising: 6% slag sulphoaluminate cement, 21.4% coral aggregate pellets with a particle size of 0mm to 20mm, and 34.1% coral aggregate particles with a particle diameter of 0mm to 45mm materials, 20% waste concrete, 10% waste incineration slag and 8.5% seawater. The final gradation of the four kinds of pellets is: 0mm~4.75mm, 4.75mm~31.5mm, 31.5mm~45mm, the mass ratio of particle size range is 35:45:20.

[0052] The preparation method of the above-mentioned base material comprises the following steps:

[0053] (1) Determining the water quality of the coral aggregate pellets is 14.2%, and calculating the water quality of the coral aggregate pellets according to the quality of the coral aggregate pellets is 7.9%;

[0054] (2) Through the compaction test, it is determined that the optimum water content of the base is 16.4%;

[0055] (3) Subtracting the water content of the coral aggregate pellets from the optimal wat...

Embodiment 3

[0059] A cement-stabilized base material, comprising: 9% marine cement, 13.8% coral aggregate pellets with a particle size of 0mm to 20mm, 31.3% coral aggregate pellets with a particle diameter of 0mm to 45mm, 10% steel slag fine sand, 20% % waste concrete, 5% waste incineration slag and 10.9% seawater. The final gradation of the four kinds of pellets is: 0mm~4.75mm, 4.75mm~31.5mm, 31.5mm~45mm, the mass ratio is 30:55:15.

[0060] The preparation method of the above-mentioned base material comprises the following steps:

[0061] (1) Determining the water quality of the coral aggregate pellets is 8.9%, and calculating the water quality of the coral aggregate pellets according to the quality of the coral aggregate pellets is 4.0%;

[0062] (2) Through the compaction test, determine the optimum water content of the base layer to be 15.9%;

[0063] (3) Subtracting the water content of the coral aggregate pellets from the optimal water content of the grassroots to obtain the cons...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com