Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

38results about How to "Strong acid corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

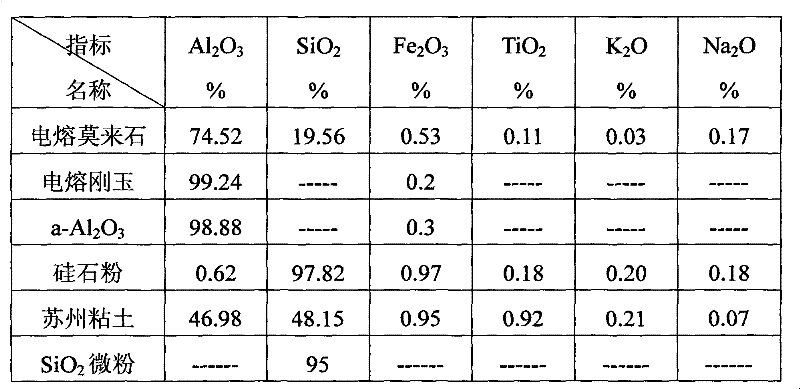

Special type fire-resistant and acid-resistant brick and preparation method thereof

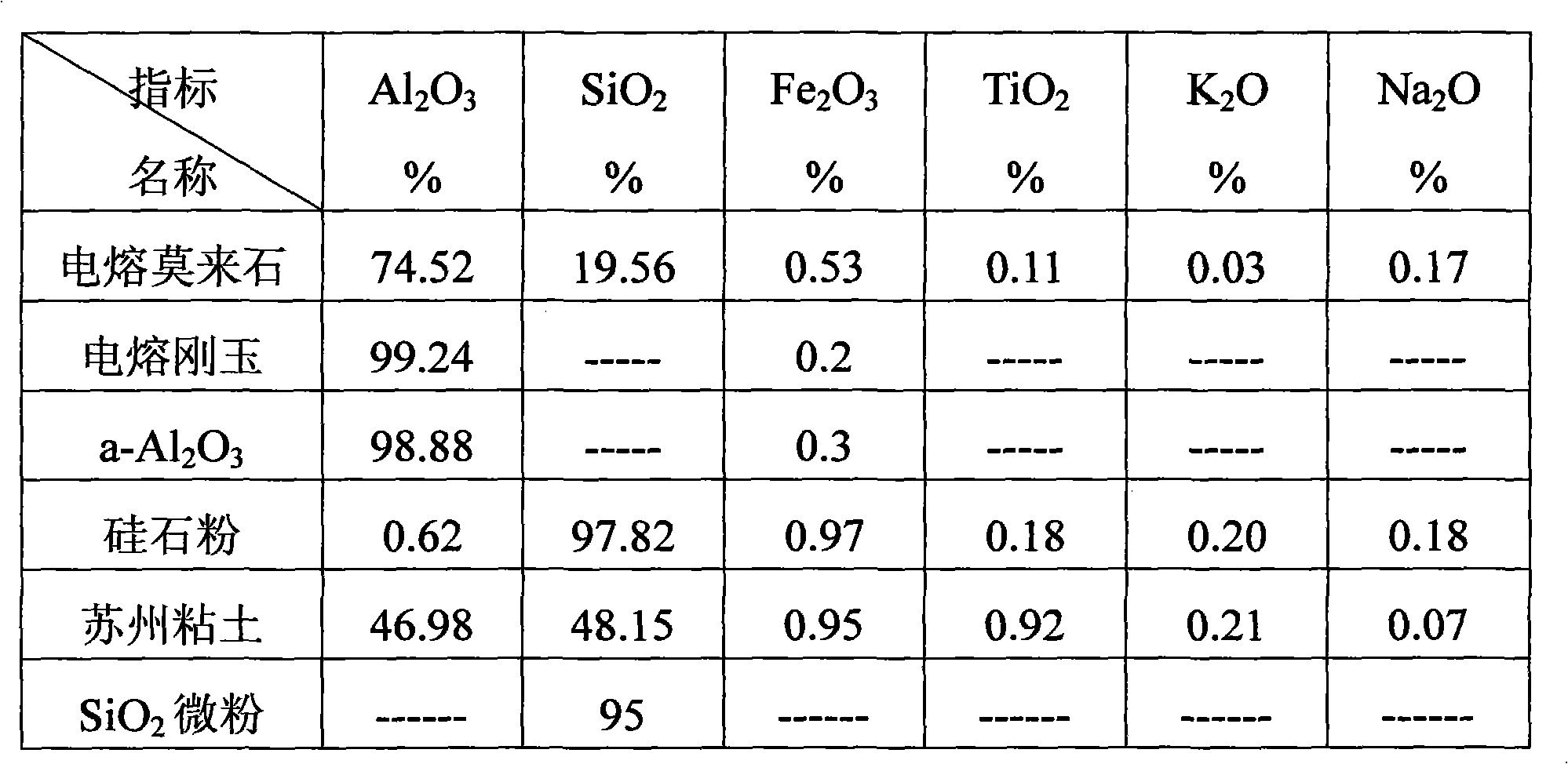

The invention discloses a special type fire-resistant and acid-resistant brick which comprises raw materials by weight percent: 20-50% of mullite, 5-20% of corundum, 5-20% of a-Al2O3, 2-12% of binding clay, 5-20% of silica powder, 3-10% of talcum powder and 2-6% of SiO2 micro powder. The raw materials are mixed together based on the mixture ratio, and then are ground in a mixing way, processed by ageing, dried and finally sintered together with bonding agent; after being naturally cooled, the special type fire-resistant and acid-resistant brick can be obtained. The special type fire-resistant and acid-resistant brick takes the mullite, the corundum and the clay as main raw materials and is introduced with part of additive, so that the prepared product has the characteristics of higher volume density, low air porosity, high compression strength, strong abrasive resistance and acid attack resistance and the like; furthermore, the special type fire-resistant and acid-resistant brick is superior to the conventional acid-resistant brick in high temperature indexes such as refractoriness under load and refractoriness, so as to be widely applied to an acid regeneration calcinatory as well as anti-corrosion engineering of petroleum, chemical engineering, metallurgy, electrical power, chemical fiber, paper making, pharmacy, fertilizer, food and the like.

Owner:GONGYI WINNA SCI & TECH DEV

Semi-silica brick for 7.63-meter coke oven

The invention relates to the fire resistance material technical field, in particular to a half silica brick of 7.63m for coke oven, which solves the problem of unstable volume, weak rusty resistance, easy expansion and easy shrink in high temperature for long time of the prior the half silica brick which is produced by adopting pyrauxite material. The raw material formulation comprises crude bauxite cribble powder which is ranged from 8 percent to 12 percent, crude bauxite medium powder which is ranged from 44 percent to 48 percent, fire resistance clay fine powder which is ranged from 22 percent to 26 percent, silex medium powder which is ranged from 18 percent to 22 percent, potassium feldspar which is ranged from 1.9 percent to 2.1 percent and pulp which is ranged from 0.45 percent to 0.55 percent. The crude bauxite cribble powder, crude bauxite medium powder, fire resistance clay fine powder and silex medium powder are mixed into a wet roller pro rata, then potassium feldspar is mixed into and pulp is mixed after grinded for 1 to 2 minutes to get mud material after grinded from 15 to 20 minutes. The mud material is mixed to uniform and even, then gets out of the roller into a mold. The invention has the advantages of more superior rationalize index of half silica brick than the national standard, stable volume, strength acidity erosion resistance, unshrinkable function in high temperature1350 DEG C for long time, higher weight soften temperature. The invention completely coincides the demands for brick of coke oven and dry quenching coke oven.

Owner:山西盂县西小坪耐火材料有限公司

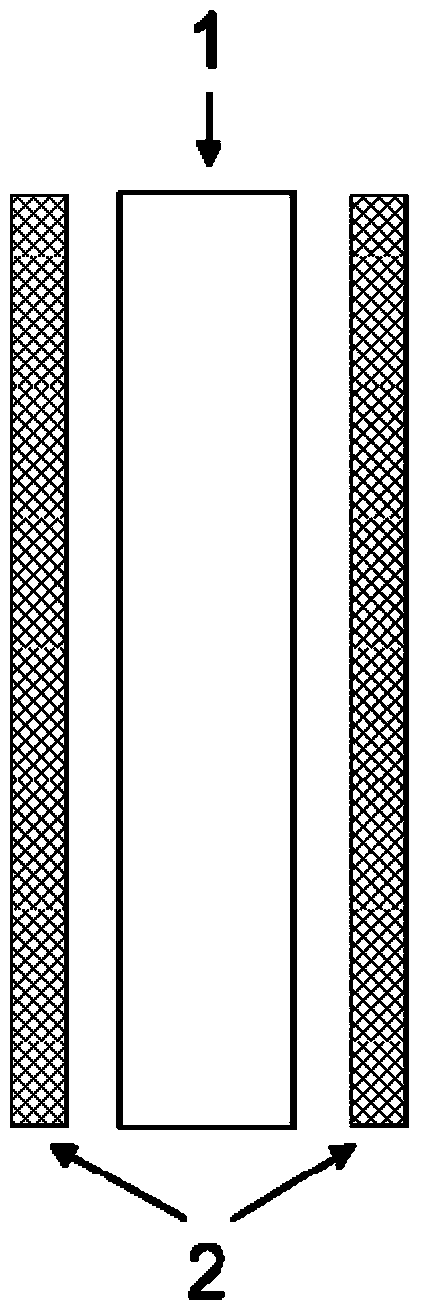

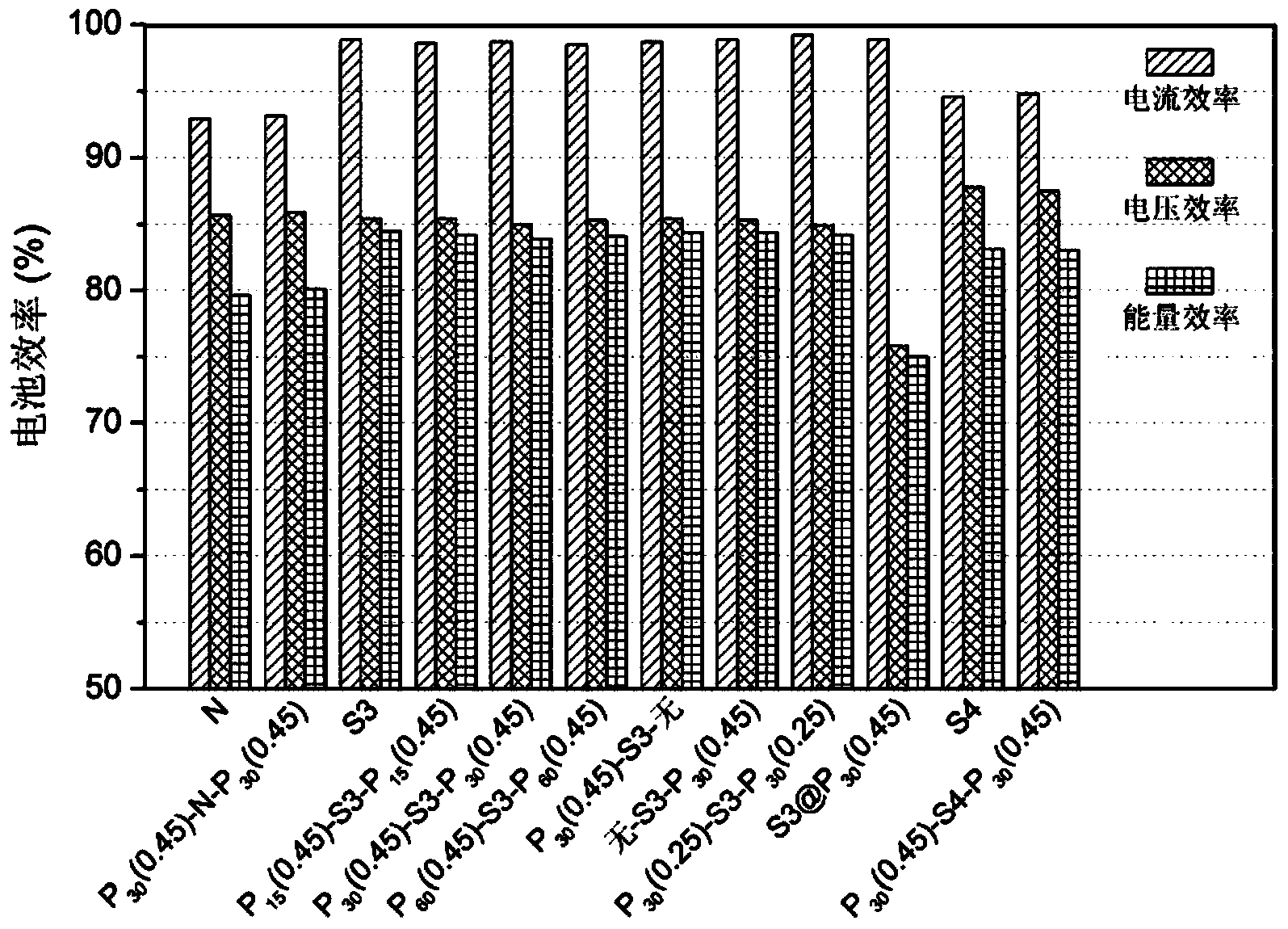

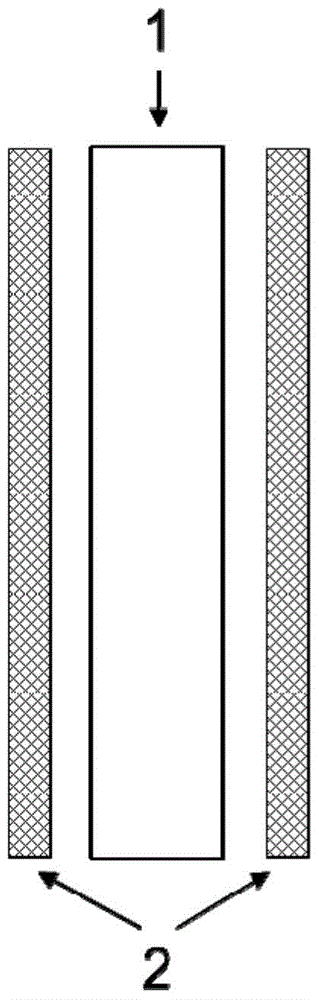

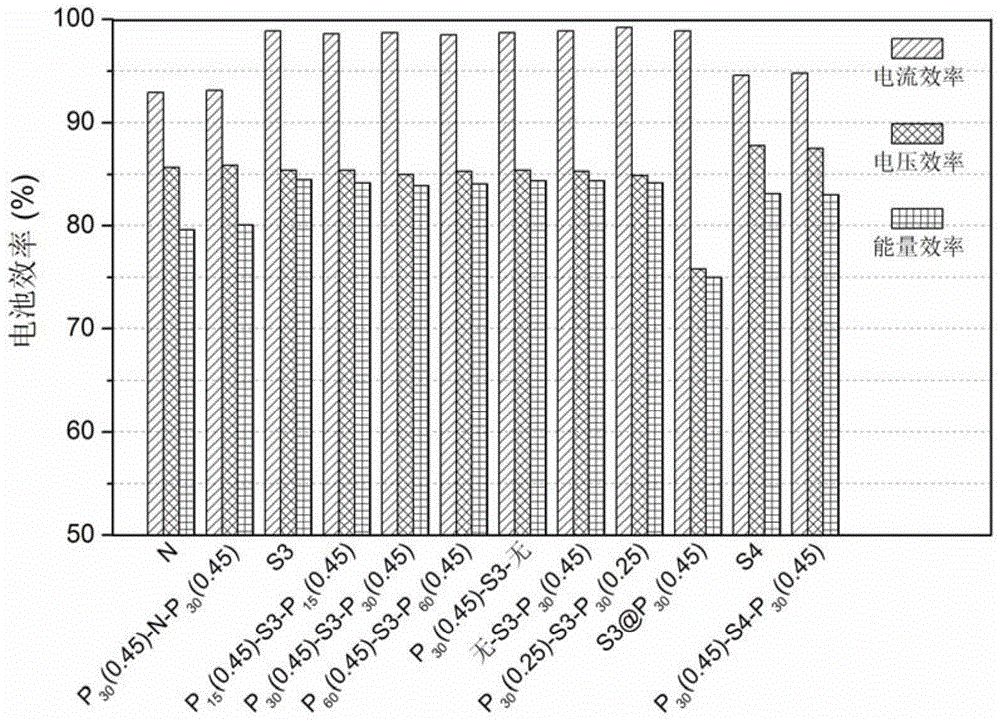

Polyfluortetraethylene sandwich layer protective ion exchange membrane, preparation method of membrane and liquid flow battery

ActiveCN103762375AHigh strengthUniform pore size distributionCell electrodesSynthetic resin layered productsTectorial membranePhysical chemistry

The invention discloses a polyfluortetraethylene sandwich layer protective ion exchange membrane. The polyfluortetraethylene sandwich layer protective ion exchange membrane comprises a sulfonation polymer ion exchange membrane basic membrane, and also comprises a polyfluortetraethylene microporous membrane(s) which is / are used as a sandwich layer protective membrane and attached to one side or two sides of the basic membrane. The invention also discloses a preparation method of the polyfluortetraethylene sandwich layer protective ion exchange membrane and a liquid flow battery adopting the polyfluortetraethylene sandwich layer protective ion exchange membrane. By adopting the polyfluortetraethylene sandwich layer protective ion exchange membrane, the high ion selectivity and high stability requirements can be simultaneously met, the efficiency of the liquid flow battery is improved, the cycling life is prolonged and especially the all-vanadium redox flow battery can be remarkably improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

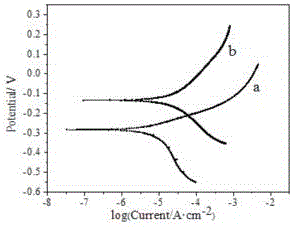

Acid resistant anode, and preparation method

This invention relates to a method for preparing acid-resistant anode. The acid-resistant anode is composed of Ti as the matrix, SnO2 + Sb2O4 + graphite fibers as the intermediate buffer layer, and PbO2 or MnO2 as the active layer. The method adds highly conductive and acid-resistant graphite fibers into the intermediate buffer layer, thus the adhesiveness between the active layer and the intermediate buffer layer is improved, and the anode has high conductivity and service life in strong acid solution. The acid-resistant anode has such advantages as high acid resistance, long service life, high catalytic activity and wide applications.

Owner:TAIYUAN UNIV OF TECH

Manufacturing process of anti-corrosion high-strength pipeline

InactiveCN106272947AMeet the mechanical performance requirementsCompact structureMouldsShaping reinforcementsFreeze thawingRebar

The invention provides a manufacturing process of an anti-corrosion high-strength pipeline. The process includes the steps that 1, aggregate and modified sulfur are adopted to prepare thermoplastic concrete; 2, a releasing agent is sprayed to a metal pipeline mold; 3, whether rebars exist in the pipeline or not is determined, and if yes, the rebars are preheated; 4, the thermoplastic concrete is poured into the metal pipeline mold; 5, hot-pressing reshaping is carried out, and the anti-corrosion high-strength pipeline is obtained after being cooled and demolded. The compressive strength of the thermoplastic concrete prepared in the process of manufacturing the anti-corrosion high-strength pipeline is larger than or equal to 30 MPa, the acid-resisting rate is larger than or equal to 95%, it is indicated that the manufactured pipeline is high in strength and resistant to corrosion, the manufacturing process is simple, and the compressive strength of the manufactured pipeline is higher than that of C30 concrete pipeline soil; the pipeline has the advantages of being resistant to corrosion and freeze thawing, free of water seepage, high in through-current capacity, long in service life and capable of being completely recovered after being discarded to pour a new pipeline, and having the advantages of a plastic pipeline and a cement reinforced concrete pipeline.

Owner:西安国蓝环保科技有限公司

Composite material containing epoxidized hydroxyl-terminated polybutadiene and preparation method thereof

The invention relates to a composite material containing epoxidized hydroxyl-terminated polybutadiene and a preparation method thereof, the composite material comprises a filler and an adhesive, the filler is based on large-particle-size silicon carbide, a fine-particle-size wear-resistant oxide is added, epoxy resin is used as a main adhesive, and the composite material with high bulk density is formed. In the preparation process, vacuum stirring and mixing are adopted, and a vacuum pouring and high-frequency vibration process is adopted during mold pouring, so that the stacking density of the filler is further improved. By adding epoxidized hydroxyl-terminated polybutadiene, the impact toughness and hydrophobicity of the composite material are improved. The prepared composite material is high in ceramic content, low in porosity, good in toughness and high in acid corrosion resistance, has excellent wear resistance and acid medium corrosion resistance, is suitable for large flow passage components of transmission equipment in various engineering fields, and is particularly suitable for being used as flow passage components of acid media.

Owner:洛阳嘉斯诺泵业制造有限公司

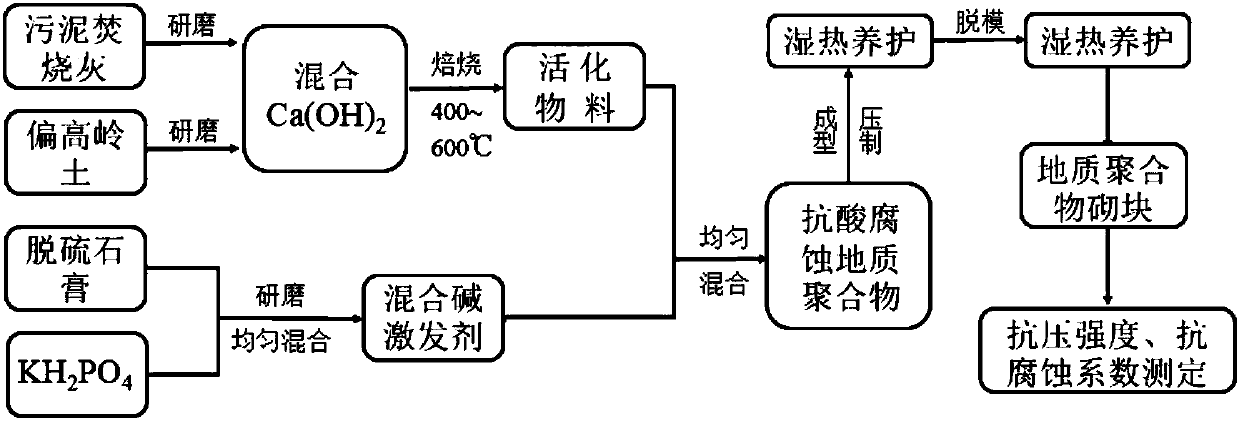

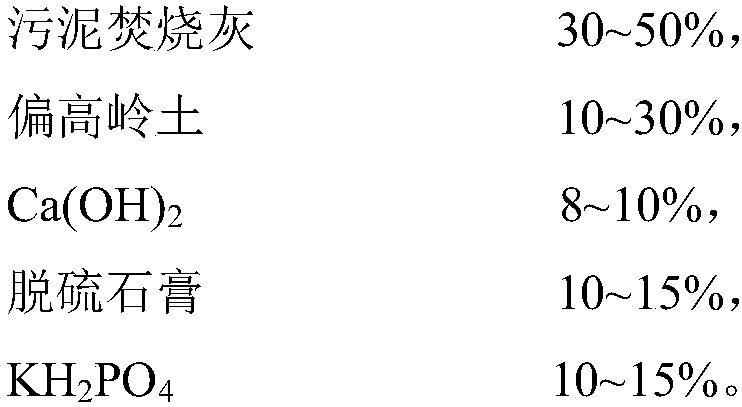

Sludge incineration ash based geopolymer and preparation method thereof

ActiveCN107867806AStrong acid corrosion resistanceExtended service lifeCement productionAluminateCalcium silicate

The invention discloses a sludge incineration ash based geopolymer which comprises the following components in percentage by weight: 30-50% of sludge incineration ash, 10-30% of metakaolin, 8-10% of Ca(OH)2, 10-20% of desulfurization gypsum and 10-20% of KH2PO4. The invention further discloses a preparation method of the sludge incineration ash based geopolymer. By utilizing co-excitation of low alkalinity sulfate and KH2PO4, the alkalinity is low, so that the prepared geopolymer has high acid corrosion resistance, and the service life can be prolonged; in order to prevent from reducing the product strength due to low alkalinity, the sludge incineration ash, the metakaolin and Ca(OH)2 are subjected to roasting activation, so that unsaturated reactive bonds are formed on the surfaces of SiO2 and Al2O3, and the SiO2 and Al2O3 are reacted with the Ca(OH)2 to produce calcium silicate hydrate (C-S-H), calcium aluminate hydrate (C-A-H) and other gelling products. Therefore, the prepared geopolymer has high acid corrosion resistance and has the ability of meeting the product strength requirement.

Owner:YANCHENG INST OF TECH

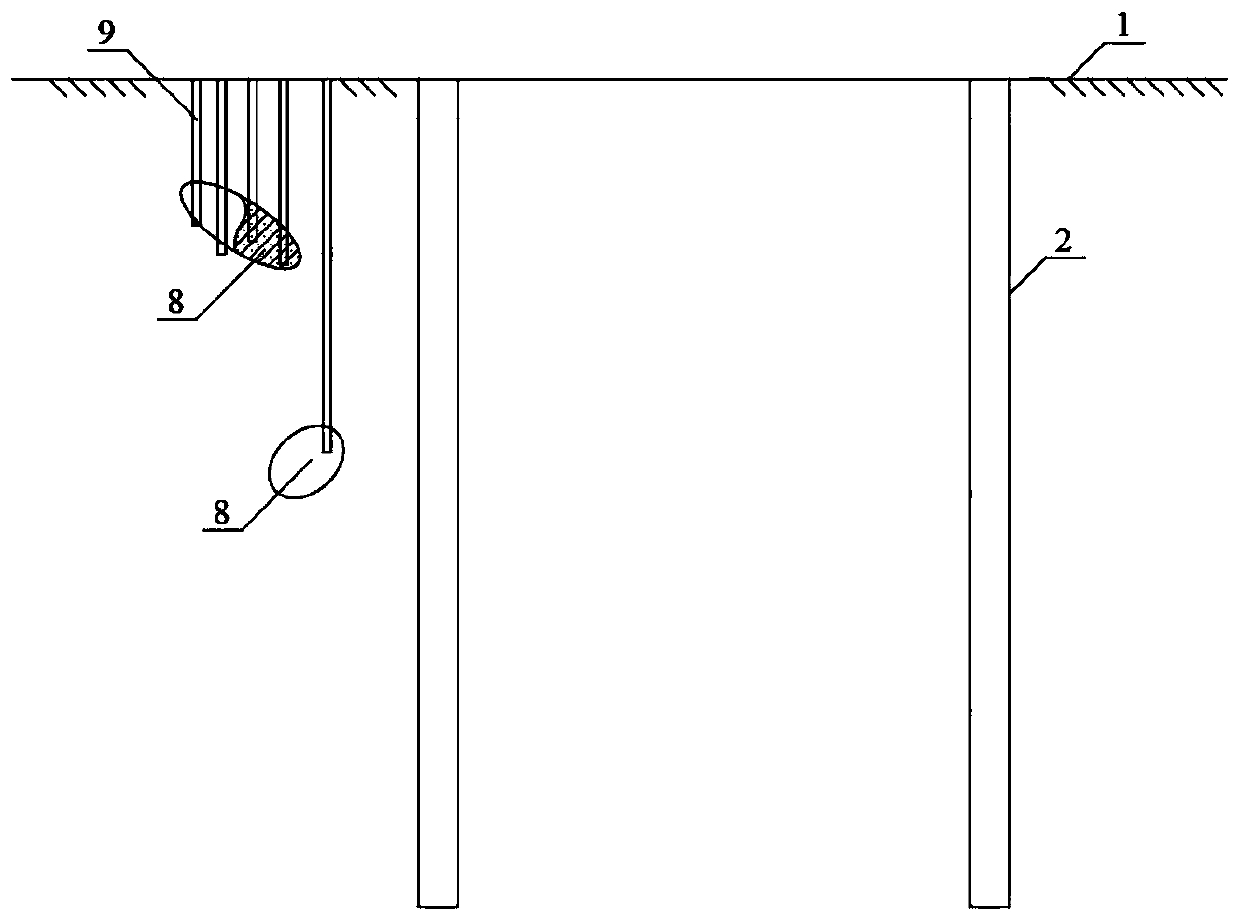

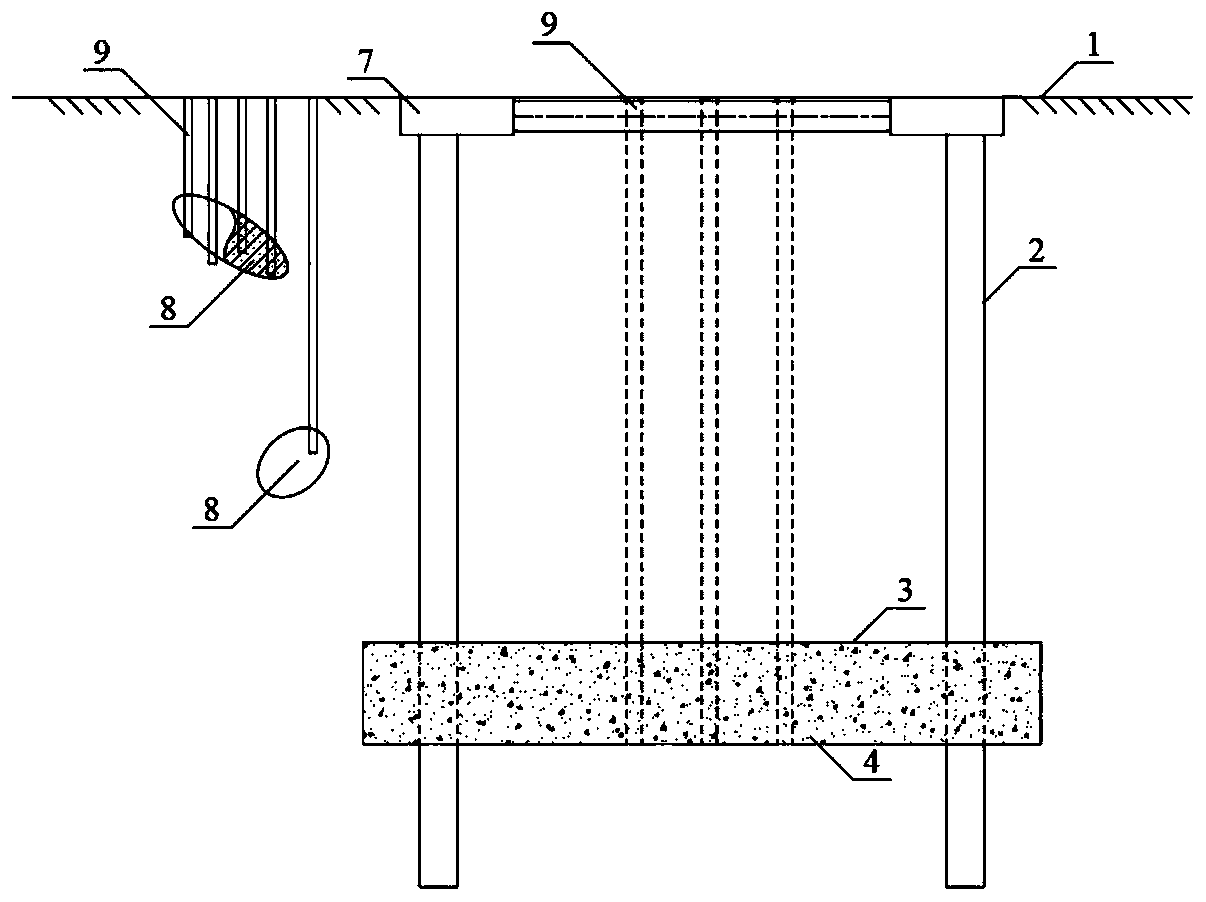

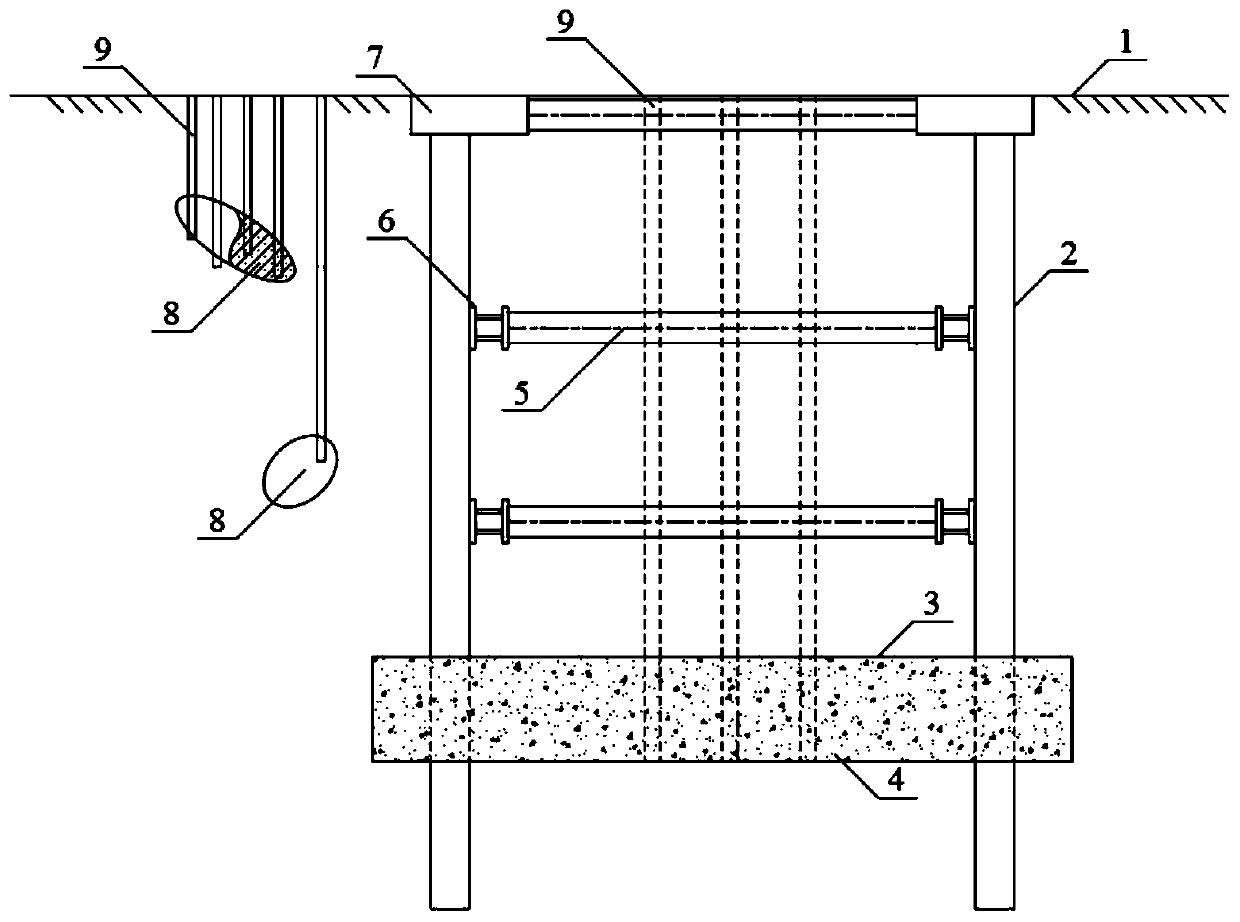

Construction method of deep foundation pit supporting anti-seepage system of coastal karst stratum

InactiveCN111042146APreventing Rapidly Evolving RisksPrevent collapseExcavationsBulkheads/pilesConfined waterKarst

The invention discloses a construction method of a deep foundation pit supporting anti-seepage system of a coastal karst stratum. The deep foundation pit supporting anti-seepage system of the coastalkarst stratum comprises a supporting structure, a karst cave treatment structure and a horizontal waterproof curtain. According to the karst cave treatment measure, the risk that the karst cave develops rapidly under the action of underground water can be prevented, the risk that a supporting structure collapses during construction and a foundation pit suddenly surges under the action of high-water-head karst confined water is avoided, and the karst local collapse resistance of the foundation is improved. The drilling secant pile and inner support combined supporting system is good in supporting effect and small in deformation capacity of the supporting structure, waterproof measures such as a waterproof curtain do not need to be additionally taken, and the situation of water seepage rarely occurs to the side wall of the foundation pit. According to the horizontal waterproof curtain, the bottom area of the foundation pit is subjected to waterproof treatment in a grouting mode, an effective channel of karst fissure water at the pit bottom can be effectively cut off, and the problem of water burst at the pit bottom is thoroughly solved.

Owner:THE SECOND ENG CO LTD OF CHINA RAILWAYSEVENTH GRP PRC +2

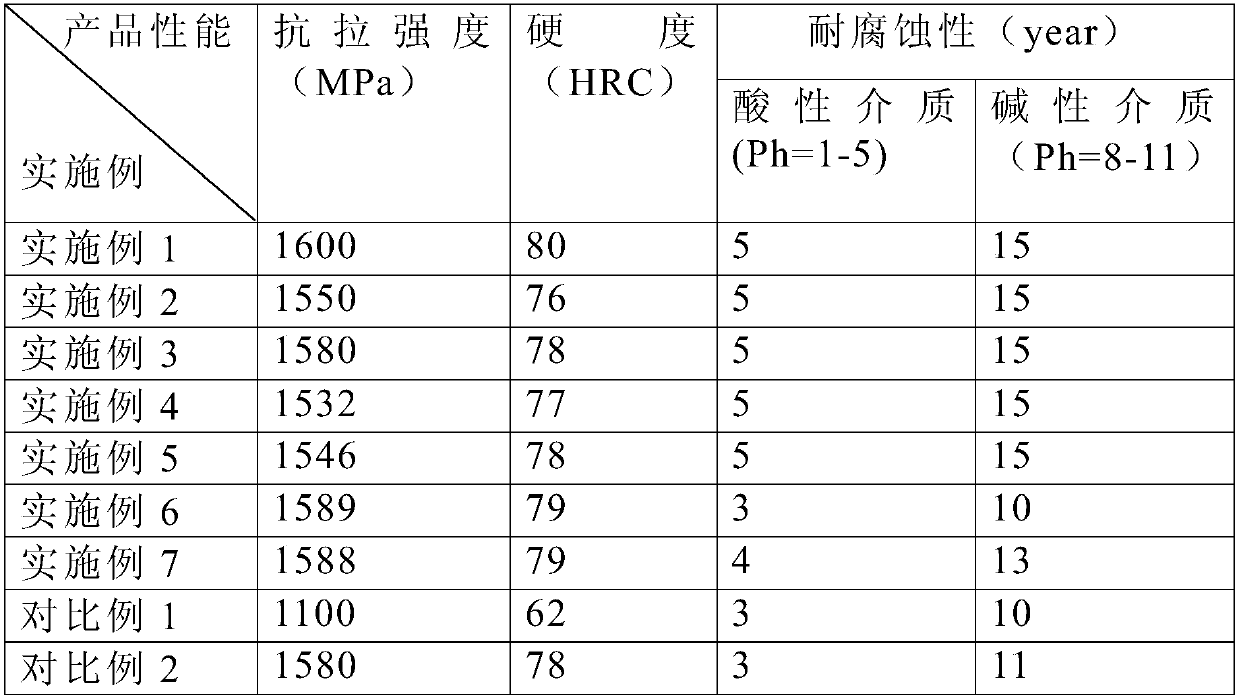

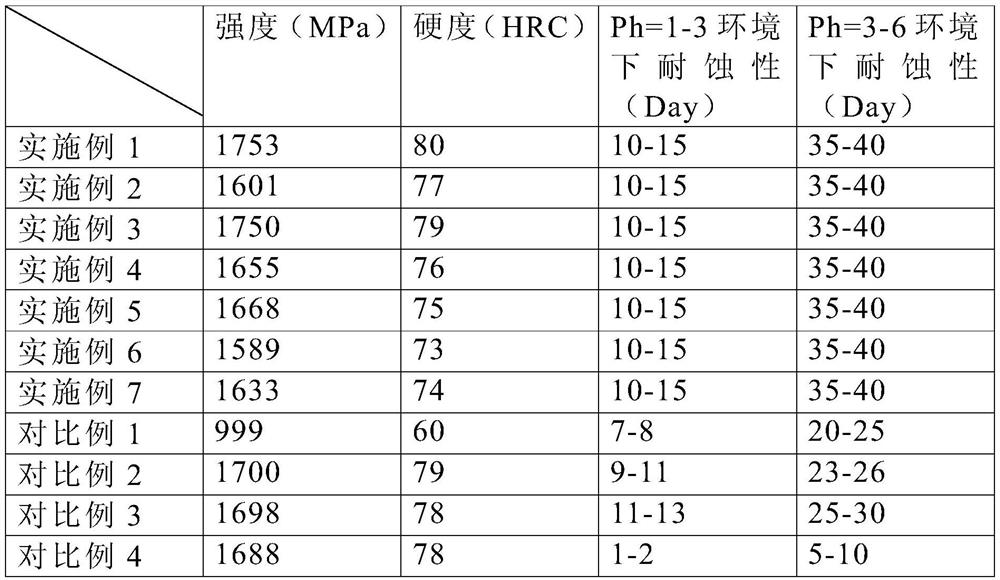

Acid-resisting, high-toughness and high-wear-resisting cast ball and preparing method thereof

ActiveCN111074143AHigh hardnessImprove toughnessFurnace typesProcess efficiency improvementTemperingIngot

The invention discloses an acid-resisting, high-toughness and high-wear-resisting cast ball and a preparing method thereof. The preparing method includes the following steps that S1, smelting is conducted in a smelting furnace, and iron liquid is obtained; S2, an aluminum ingot is added into the iron liquid for deoxygenation before the iron liquid is discharged out of the furnace, then the iron liquid is transferred into a transferring ladle, after slagging off is conducted, the iron liquid is poured into a pouring ladle for pouring, and a cast blank is obtained after cooling; and S3, the castblank is heated to 500 DEG C to 510 DEG C for heat insulation for 2 h to 3 h, the temperature is then increased to 780 DEG C to 790 DEG C for heat insulation for 2 h to 3 h, then the temperature is increased to 940 DEG C to 950 DEG C for heat insulation for 2 h to 3 h, then the temperature is then increased to 1015 DEG C to 1030 DEG C for heat insulation for 2 h to 3 h, quenching oil is used forquenching for 10 min to 15 min, finally, tempering treatment is conducted after heat insulation is conducted for 6 h to 8 h at the temperature of 260 DEG C to 280 DEG C, and the cast ball is obtained.The cast ball prepared through the method has good acid-resisting and corrosion-resisting performance, in addition, the hardness is high, the wear-resisting performance is good, and economic benefitsare better increased.

Owner:宁国东方碾磨材料股份有限公司

Method for preparing silvery white chemical conversion coating on brass surface

InactiveCN106283027AUniform colorStrong acid corrosion resistanceMetallic material coating processesPhysical chemistryAcid corrosion

The invention discloses a method for preparing a silvery white chemical conversion coating on a brass surface. The method is characterized in that the brass surface reacts with a conversion solution to generate colored ions deposited on the surface, thereby forming the silvery white chemical conversion coating. The method comprises the following steps: carrying out deoiling, polishing, activation and cleaning on the brass matrix, putting into an antimony-salt-containing acidic solution, reacting with the solution until a uniform-stable-color silvery white coating is generated on the brass surface, and carrying out related subsequent treatment to prevent the coating surface from being contaminated. The method has the advantages of simple technical process and low cost. The prepared coating has the advantages of high acid corrosion resistance and favorable binding force, and can simultaneously perform the functions of decoration and corrosion resistance.

Owner:SHENYANG LIGONG UNIV

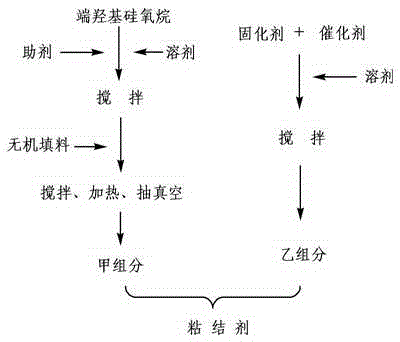

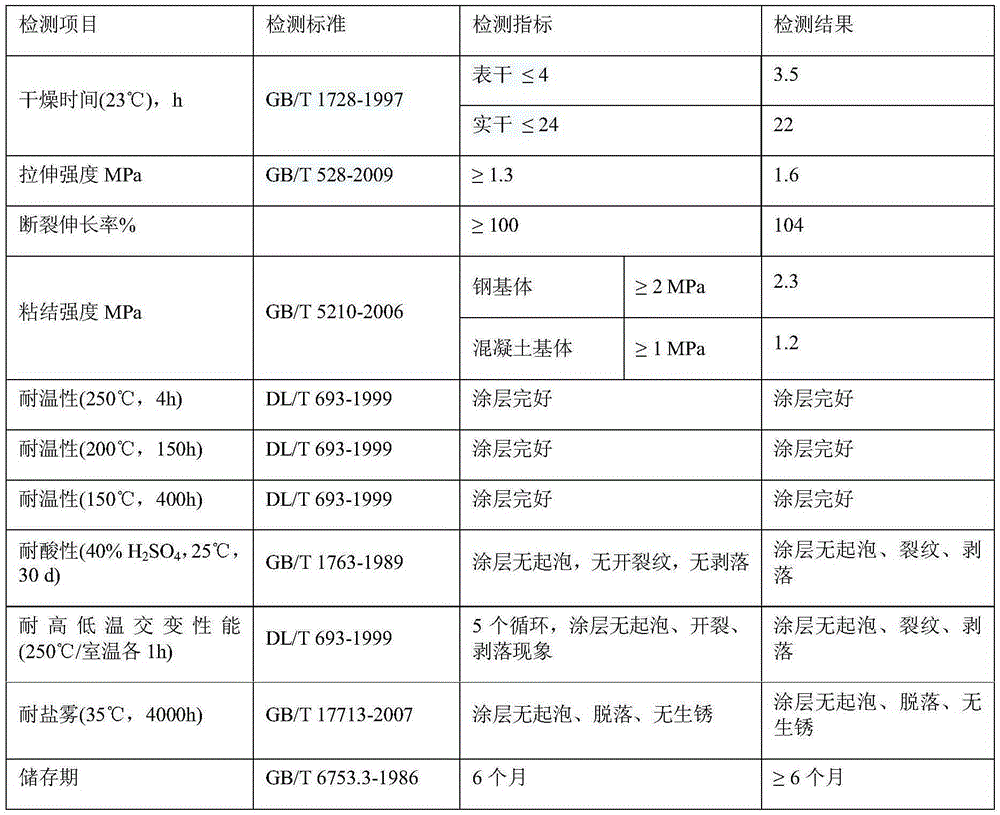

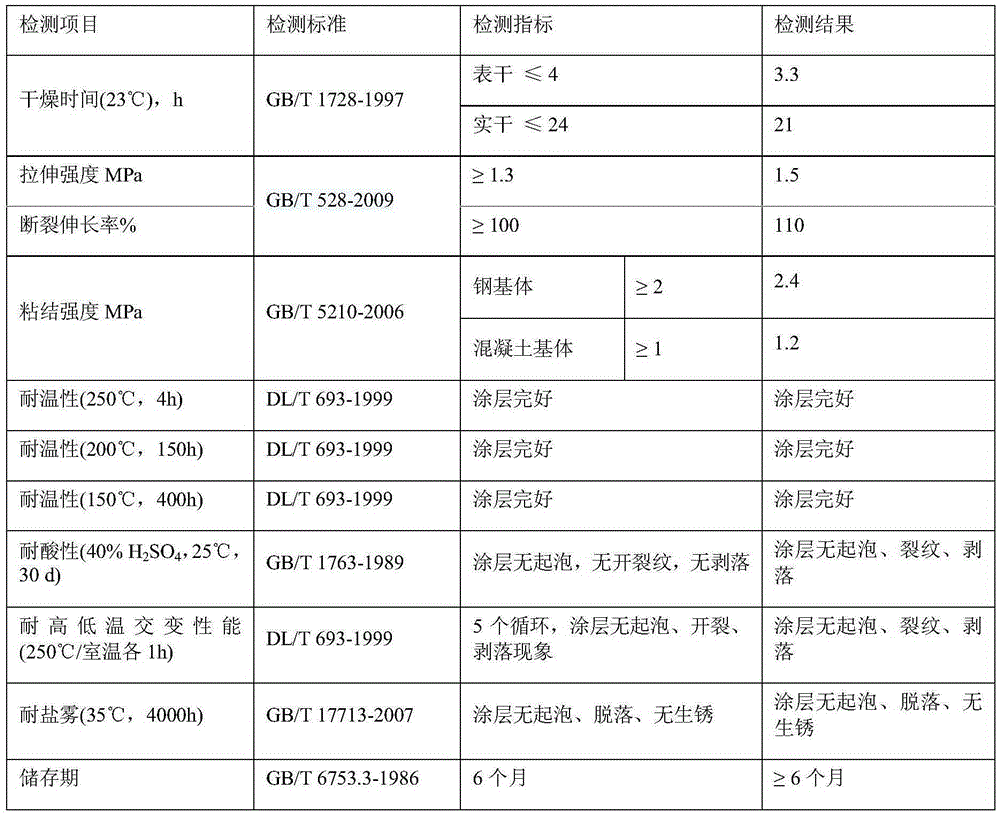

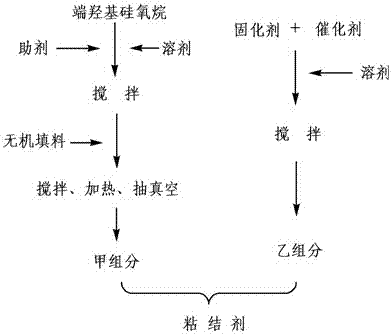

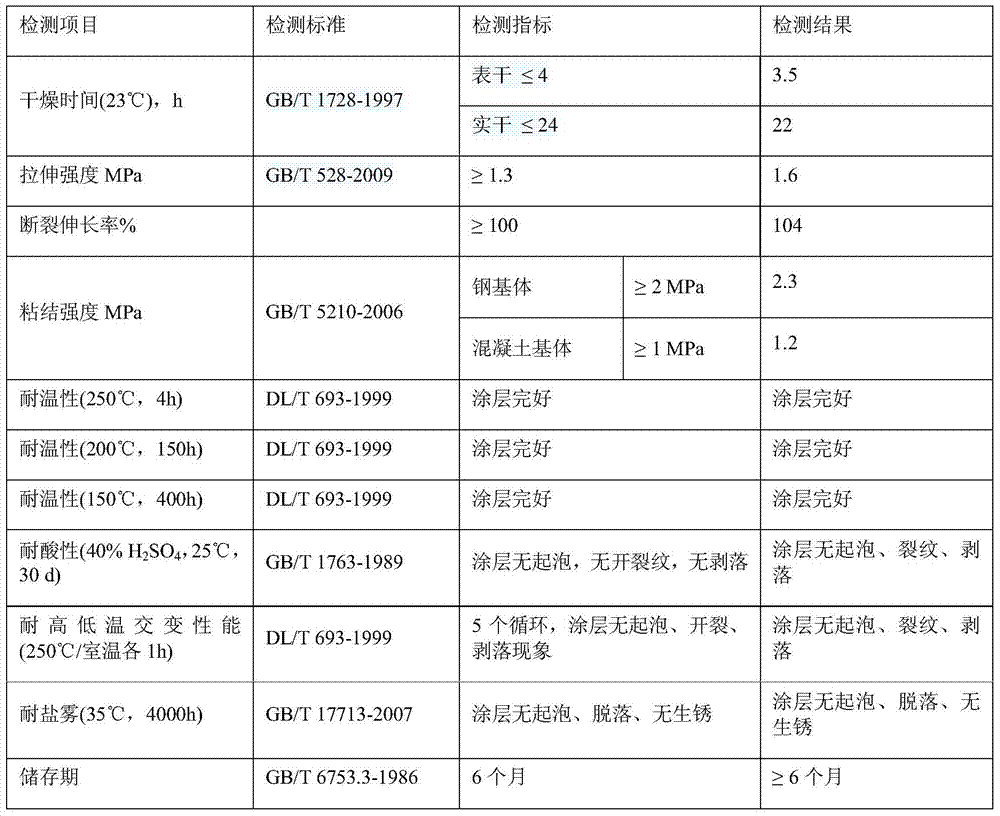

Preparing method for corrosion prevention organic silicon binding agent for desulfurization chimney liner of thermal power plant

InactiveCN105400478AImprove adhesionExcellent resistance to strong acid and alkali corrosionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesStrong acidsPolyethylene glycol

The invention relates to a preparing method for a corrosion prevention organic silicon binding agent for a desulfurization chimney liner of a thermal power plant. The preparing method comprises the following steps that firstly, a first component is prepared, wherein hydroxyl-terminated polydimethylsiloxane, polyethylene glycol PEG 600, a defoaming agent, a coupling agent and a solvent a are added into a reaction kettle according to a certain proportion and stirred evenly, then inorganic filler is added multiple times with a small amount, vacuum stirring is carried out for 60 minutes under the condition of the vacuum degree of 0.08 MPa, and the first component of the binding agent is obtained; secondly, a second component is prepared, wherein the curing agent polyisocyanate, a catalyst and a solvent b are added into a reaction kettle according to a certain proportion and stirred evenly, and the second component of the binding agent is obtained; thirdly, the first component and the second component are blended at the mass ration of 20:1 at the room temperature and stirred evenly, and the organic silicon binding agent is obtained. The organic silicon binding agent prepared through the method is high in binding performance, excellent in strong acid and strong base corrosion resistance, and good in high-temperature aging resistance and high-low temperature alternating resistance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +2

Machining method of high-strength metal shelf

InactiveCN107779745AStrong acid corrosion resistanceExtended service lifeLiquid surface applicatorsMetallic material coating processesCrystalliteSurface finishing

The invention discloses a machining method of a high-strength metal shelf, and belongs to the technical field of metal machining. The machining method of the high-strength metal shelf includes the steps: raw material smelting; forging; forming; surface treatment. The raw material components of the metal shelf comprise, in weight percent, 5-10% of Tl, 1-2% of Si, 0.1-0.2% of Ba, 0.4-0.8% of C, 4-8%of Co, 3-5% of Pb, 1-4% of Sn, 2-3% of Te and the balance Fe and impurities. The impurities comprise, in weight percent, less than 0.055% of P, less than 0.065% of S and less than 0.01% of O. According to the machining method, deformation process is performed in a forged manner, so that grain refinement is facilitated, so that comprehensive performances of the metal shelf are improved, a uniformand compact protection film is formed in a laser surface alloying manner, and the anti-rust capability of the metal shelf is enhanced by sprayed paint.

Owner:NINGBO CITY XINGUANG SHELF

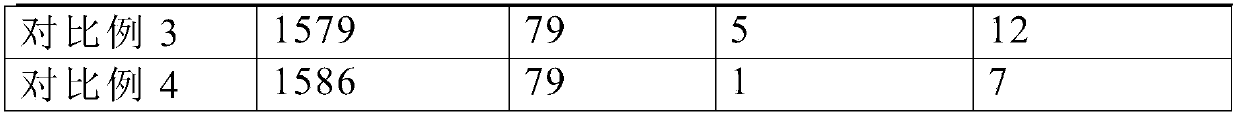

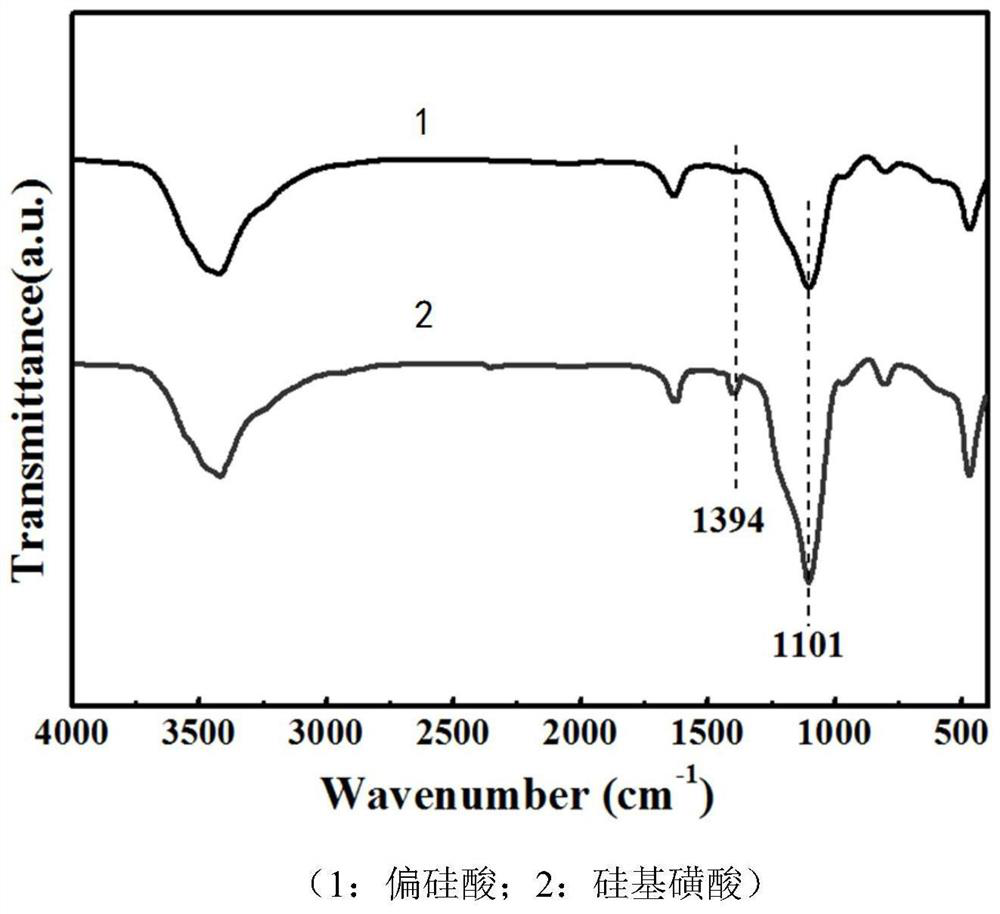

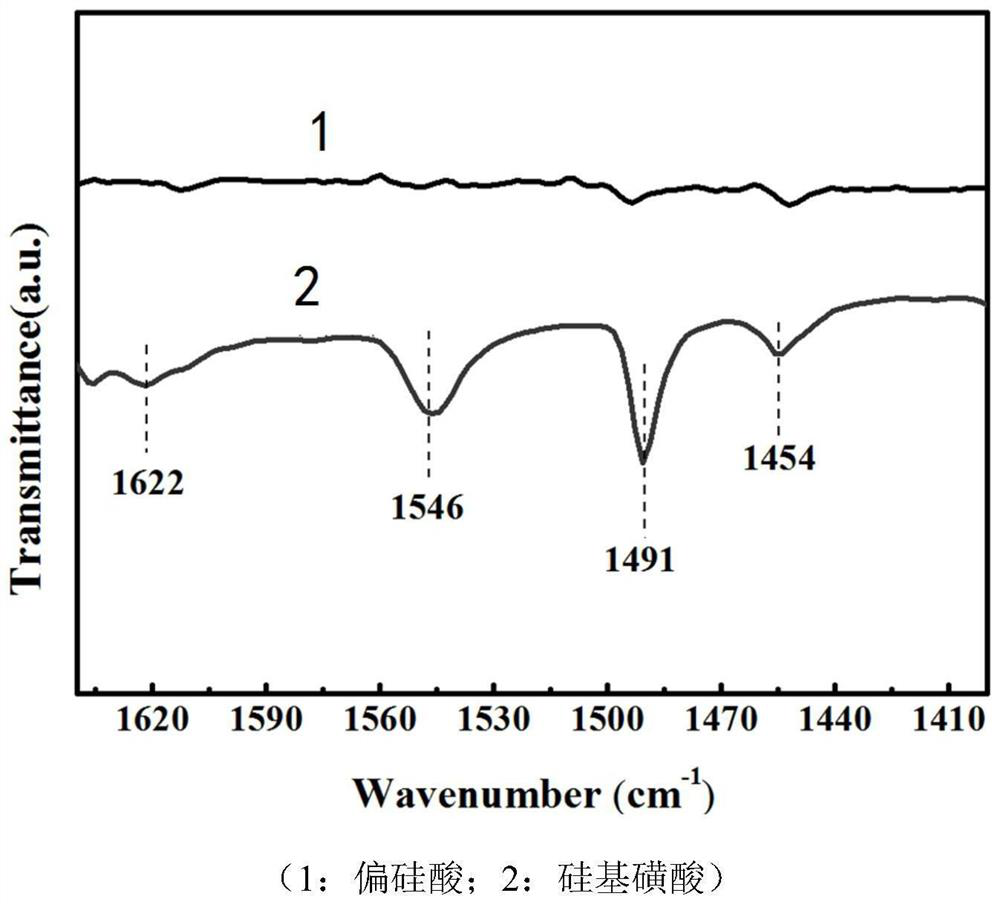

Inorganic solid silicon-based sulfonic acid and/or phosphoric acid catalyst, and preparation method and application thereof

ActiveCN113385191AIncrease acidityHigh activityOrganic chemistryCatalyst activation/preparationO-Phosphoric AcidIsomerization

The invention discloses a preparation method and application of a novel pure inorganic solid silicon-based sulfonic acid and / or phosphoric acid catalytic material. The pure inorganic solid silicon-based sulfonic acid and / or phosphoric acid catalytic material is obtained by taking metasilicic acid rich in hydroxyl groups on the surface as a raw material and bonding a sulfonic acid group and / or a phosphoric acid group to an inorganic silicon material by using a sulfonating reagent and / or phosphoric acid through a chemical bonding method. The catalytic material can be widely applied to many acid-catalyzed organic reaction fields such as isomerization reaction, esterification reaction, alkylation reaction, olefin hydroamination reaction, condensation reaction, nitration reaction, etherification reaction, multi-component reaction, oxidation reaction and the like. The inorganic solid silicon-based sulfonic acid and / or phosphoric acid catalytic material disclosed by the invention has the advantages of high acid content, high activity, good hydrothermal stability, no swelling, simple preparation process, low cost, no pollution, no corrosion, easiness in separation, reusability and the like.

Owner:XIANGTAN UNIV

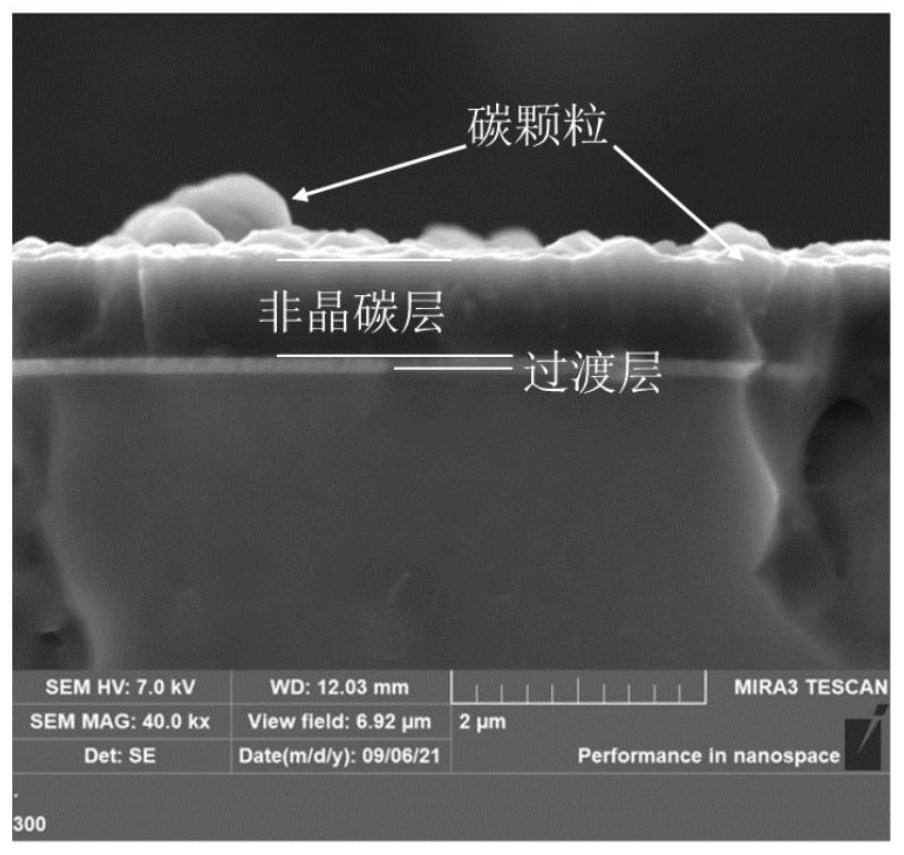

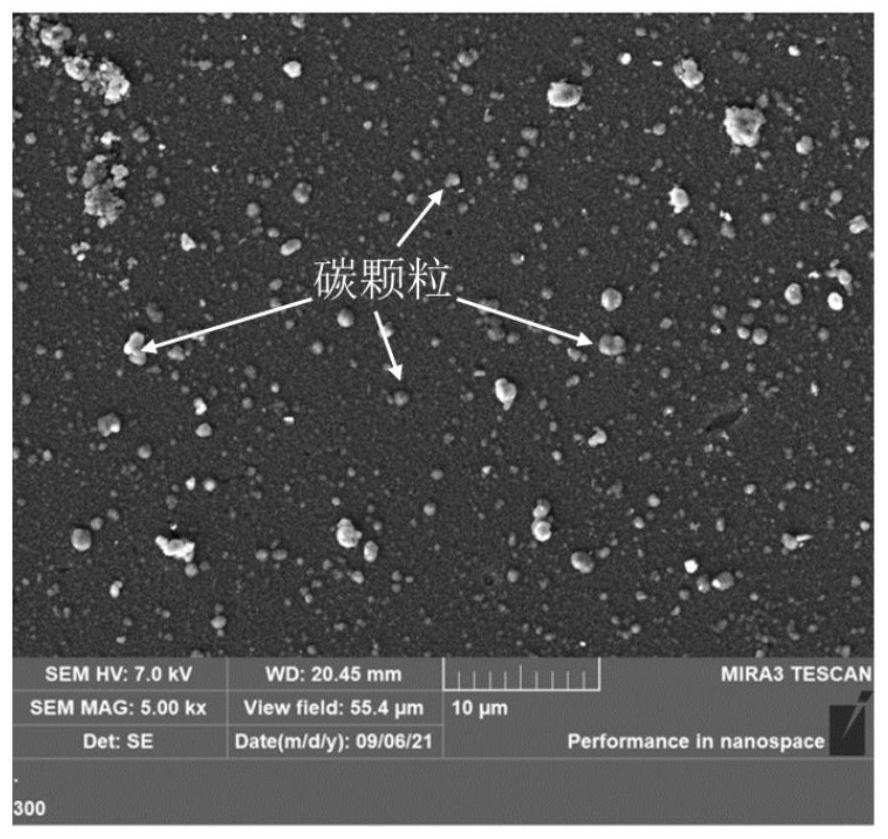

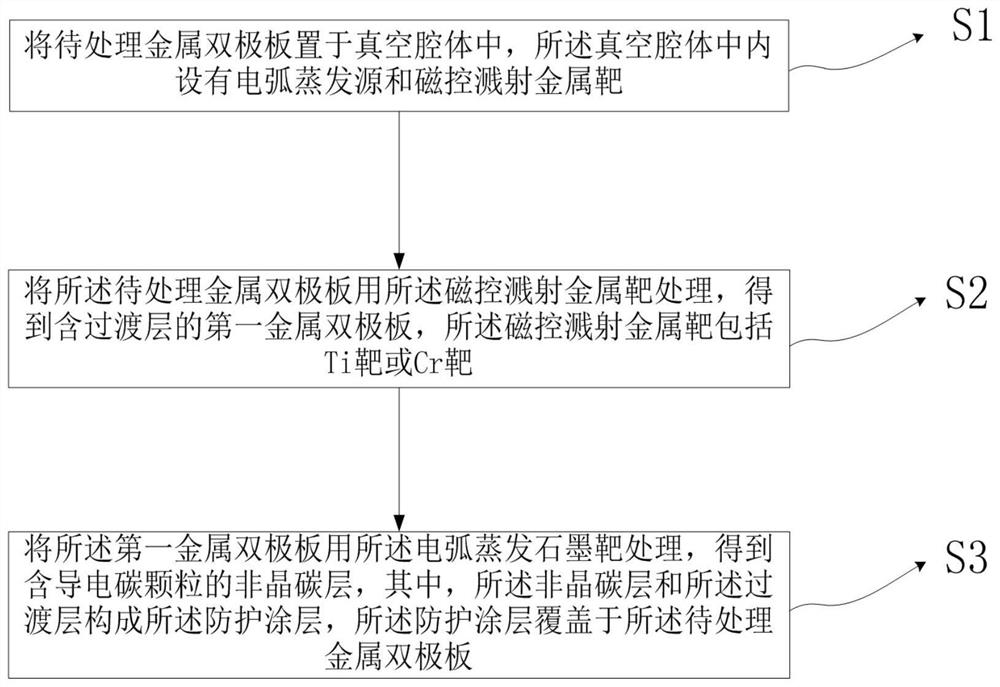

Protective coating for metal bipolar plate and preparation method thereof

ActiveCN114597436AImprove bond reliabilityImprove corrosion resistanceCollectors/separatorsCarbon layerElectrical resistance and conductance

The invention belongs to the field of fuel cell metal bipolar plates, and particularly relates to a protective coating for a metal bipolar plate and a preparation method of the protective coating. The protective coating covers the surface of a metal bipolar plate base body, the protective coating comprises a transition layer and an amorphous carbon layer, the transition layer is covered with the amorphous carbon layer, the transition layer is combined with the metal bipolar plate base body, and the transition layer comprises at least one of Ti and Cr. The design of the transition layer can improve the bonding reliability of the protective coating on the surface of the metal bipolar plate, the amorphous carbon layer has good conductivity and corrosion resistance, and the problem of poor conductivity caused by surface oxidation of the metal bipolar plate can be solved; and finally, the average corrosion current density of the metal bipolar plate can be less than 0.03 [mu] A / cm < 2 > (keeping for 24 hours under constant potential polarization of 0.6 V), and the interface contact resistance is less than 2 m omega.cm < 2 > (under 1.4 MPa).

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Acid-resistant brick for incinerator and preparation method thereof

An acid-resistant brick for an incinerator relates to the field of materials and comprises the following raw materials: an aluminum silicate material, flint clay, chrome corundum and the like. The meta-acidic aluminum silicate material has good thermal shock stability and acid corrosion resistance. The industrial chromium corundum micro-powder has very strong acid corrosion resistance, and by introducing the industrial chromium corundum micro-powder, not only can the acid substance corrosion resistance of the acid-resistant brick for the incinerator be improved, but also pore channels of the acid-resistant brick for the incinerator are micronized, and permeation of gas or liquid substances is prevented. The formula is scientific and reasonable in collocation, corrosion resistance and stripping resistance can be remarkably improved, and the service life of the incinerator is prolonged. The embodiment of the invention also provides a preparation method of the acid-resistant brick for theincinerator, which is simple and convenient to operate, has low requirements on equipment, can be quickly and efficiently used for producing the acid-resistant brick for the incinerator, and realizeslarge-scale industrial production.

Owner:巩义市新科耐火材料有限公司

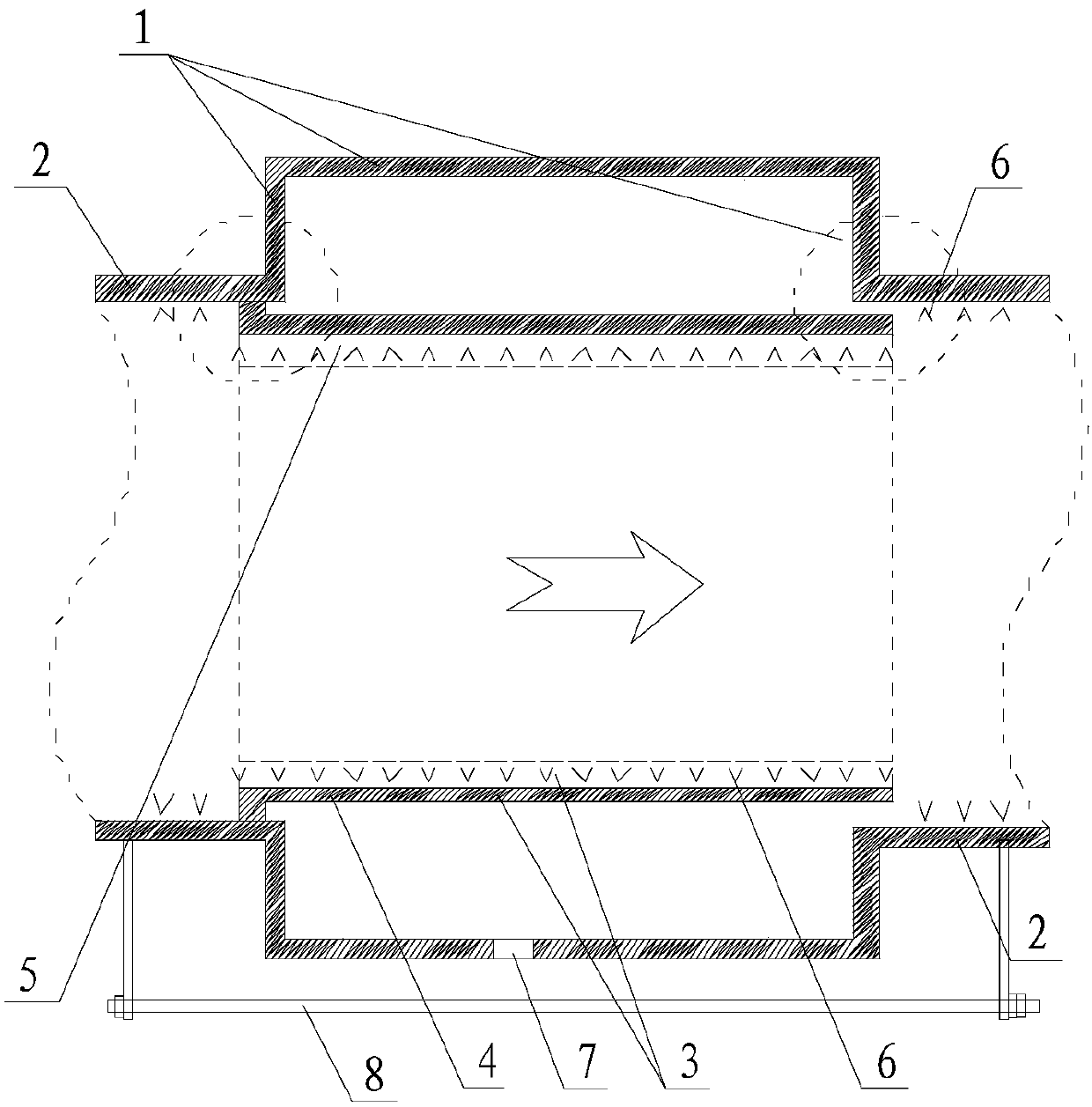

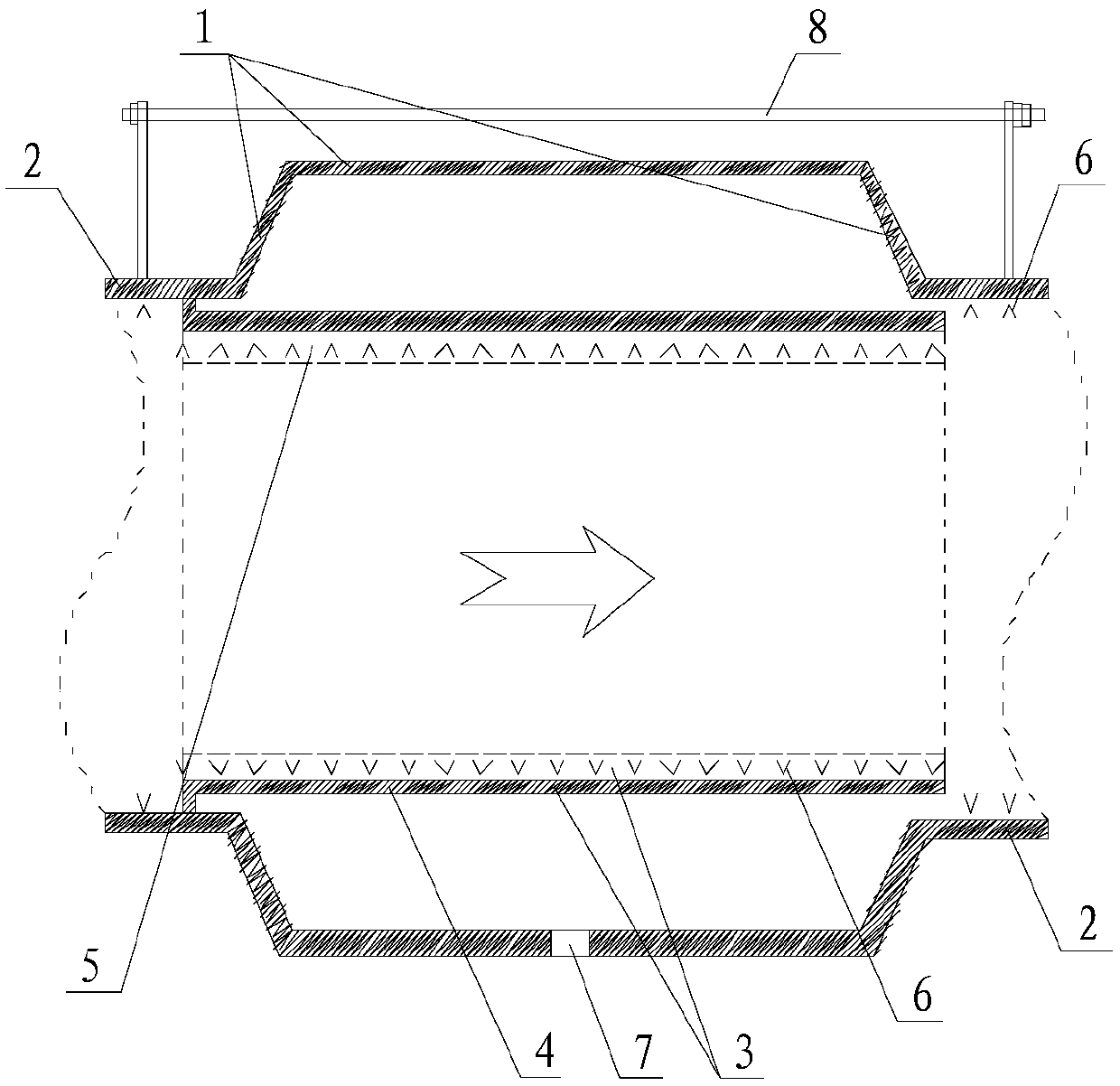

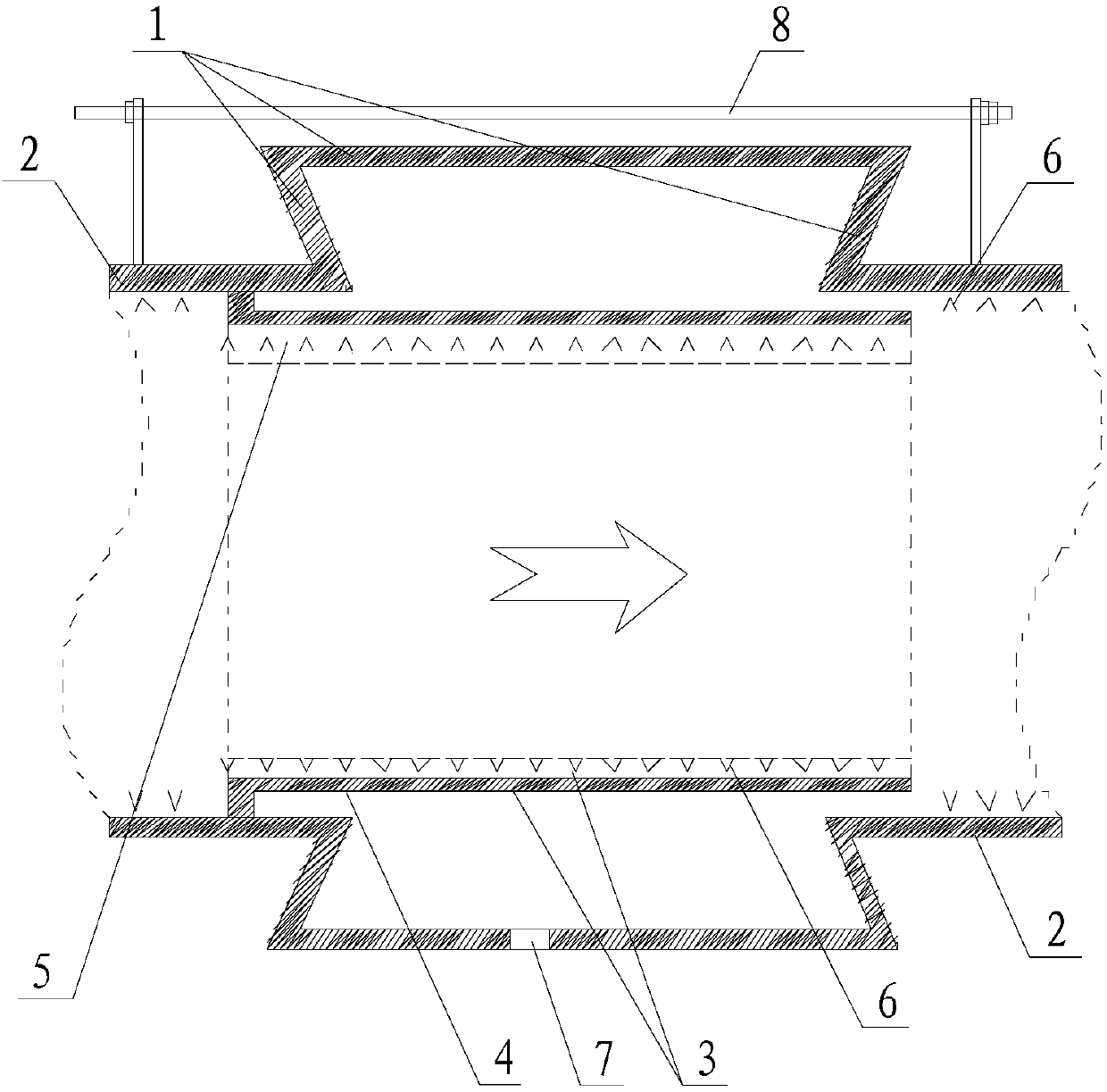

Connecting structure for SO2 flue gas pipelines and expansion joint

InactiveCN107654787AExtended service lifeImprove matchPipeline expansion-compensationEngineeringExpansion joint

The invention discloses a connecting structure, particularly discloses a connecting structure for SO2 flue gas pipelines and an expansion joint, and belongs to the technical field of metallurgy production equipment accessory design and building. According to the connecting structure for the SO2 flue gas pipelines and the expansion joint, the service life of an SO2 flue gas collecting and conveyingpipeline, especially an expansion joint pipeline, can be remarkably prolonged. The connecting structure comprises a corrugated expansion joint body. The SO2 flue gas pipelines are telescopically connected into whole in the axial direction through the corrugated expansion joint body. The connecting structure further comprises an anti-corrosion and corrosion-resisting assembly, and the anti-corrosion and corrosion-resisting assembly is arranged on the inner side of the corrugated expansion joint body. The inner side wall of the corrugated expansion joint body in the operating process is protected through the anti-corrosion and corrosion-resisting assembly.

Owner:CHINA 19TH METALLURGICAL CORP

A kind of high-strength corrosion-resistant glassware and preparation method thereof

The invention discloses high-strength and corrosion-resisting glassware and a preparation method thereof. The high-strength and corrosion-resisting glassware is prepared from the following raw materials in parts by weight: 80 to 85 parts of quartz sand, 2 to 5 parts of calcium oxide, 0.1 to 0.5 part of iron oxide, 0.3 to 0.5 part of titanium dioxide, 0.1 to 0.3 part of bismuth trioxide, 0.1 to 0.4part of magnesium oxide, 0.1 to 0.3 part of aluminum oxide, 2 to 4 parts of kaolin, 0.1 to 0.3 part of vanadium dioxide, 5 to 10 parts of sodium carbonate, 0.1 to 0.3 part of niobium dioxide, 0.1 to0.2 part of tellurium dioxide and 0.1 to 0.2 part of silver chloride. The preparation method comprises the following four steps: mixing the materials, smelting, molding, and inducing to nucleate. Theglassware prepared by the invention has the advantages of high mechanical strength and strong corrosion resistance and is suitable for being produced and applied in a large scale.

Owner:安徽晶晶玻璃制品有限公司

Manufacturing process of acid corrosion resistant foam glass

InactiveCN105461195AAccelerated corrosionImprove seismic performanceGlass shaping apparatusAcid corrosionShock resistance

The invention provides a manufacturing process of acid corrosion resistant foam glass. The manufacturing process comprises the following steps: placing a mixture of both basic ingredients of borosilicate glass and a foamer into a ball milling tank, and performing ball-milling to obtain specified fineness, wherein the mass of the foamer is 0.5-0.8% of the total mass of the basic ingredients; placing the ground powder into a grinding tool, then placing the grinding tool into a melting furnace, and firing at the temperature of being lower than 1,000 DEG C. The manufactured foam glass has the favorable characteristics of high corrosion resistance, relatively low thermal expansion coefficient and heat conductivity, and relatively high heat and shock resistance and closed pore rate, and can achieve special purposes.

Owner:TIANJIN CITY CENTSTAGE TECH INCUBATOR COMPANY

Polytetrafluoroethylene interlayer protective ion exchange membrane, its preparation method and flow battery

ActiveCN103762375BHigh strengthUniform pore size distributionCell electrodesSynthetic resin layered productsTectorial membranePhysical chemistry

The invention discloses a polyfluortetraethylene sandwich layer protective ion exchange membrane. The polyfluortetraethylene sandwich layer protective ion exchange membrane comprises a sulfonation polymer ion exchange membrane basic membrane, and also comprises a polyfluortetraethylene microporous membrane(s) which is / are used as a sandwich layer protective membrane and attached to one side or two sides of the basic membrane. The invention also discloses a preparation method of the polyfluortetraethylene sandwich layer protective ion exchange membrane and a liquid flow battery adopting the polyfluortetraethylene sandwich layer protective ion exchange membrane. By adopting the polyfluortetraethylene sandwich layer protective ion exchange membrane, the high ion selectivity and high stability requirements can be simultaneously met, the efficiency of the liquid flow battery is improved, the cycling life is prolonged and especially the all-vanadium redox flow battery can be remarkably improved.

Owner:SHENZHEN GRADUATE SCHOOL TSINGHUA UNIV

Semi-silica brick for 7.63-meter coke oven

The invention relates to the fire resistance material technical field, in particular to a half silica brick of 7.63m for coke oven, which solves the problem of unstable volume, weak rusty resistance, easy expansion and easy shrink in high temperature for long time of the prior the half silica brick which is produced by adopting pyrauxite material. The raw material formulation comprises crude bauxite cribble powder which is ranged from 8 percent to 12 percent, crude bauxite medium powder which is ranged from 44 percent to 48 percent, fire resistance clay fine powder which is ranged from 22 percent to 26 percent, silex medium powder which is ranged from 18 percent to 22 percent, potassium feldspar which is ranged from 1.9 percent to 2.1 percent and pulp which is ranged from 0.45 percent to 0.55 percent. The crude bauxite cribble powder, crude bauxite medium powder, fire resistance clay fine powder and silex medium powder are mixed into a wet roller pro rata, then potassium feldspar is mixed into and pulp is mixed after grinded for 1 to 2 minutes to get mud material after grinded from 15 to 20 minutes. The mud material is mixed to uniform and even, then gets out of the roller into a mold. The invention has the advantages of more superior rationalize index of half silica brick than the national standard, stable volume, strength acidity erosion resistance, unshrinkable function in high temperature1350 DEG C for long time, higher weight soften temperature. The invention completely coincides the demands for brick of coke oven and dry quenching coke oven.

Owner:山西盂县西小坪耐火材料有限公司

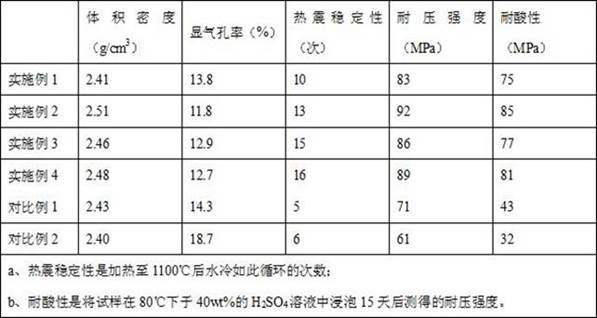

Special refractory and acid-resistant brick and its preparation method

The invention discloses a special fire-resistant and acid-resistant brick, which is represented by weight percentage. The raw material of the fire-resistant and acid-resistant brick contains 20-50% of mullite, 5-20% of corundum, 35-20% of a-Al2O, and 2% of bonded clay. ~12%, silica powder 5~20%, talcum powder 3~10% and SiO2 fine powder 2~6%. The materials are configured according to the proportioning ratio, then mixed and milled with a binder, trapped, dried, finally fired, and cooled naturally to obtain the special refractory and acid-resistant brick of the present invention. The product of the present invention uses mullite, corundum and clay as the main raw materials, and introduces some additives, so that the prepared product has high bulk density, low porosity, high compressive strength, strong wear resistance, and acid erosion resistance. Strong and other characteristics, and the high temperature index load softening temperature and refractoriness of the product of the present invention are far superior to conventional acid-resistant bricks, and can be widely used in acid regeneration roasters, petroleum, chemical industry, metallurgy, electric power, chemical fiber, papermaking, pharmaceuticals, chemical fertilizers, food And other anti-corrosion works.

Owner:GONGYI WINNA SCI & TECH DEV

Acid resistant anode, and preparation method

Owner:TAIYUAN UNIV OF TECH

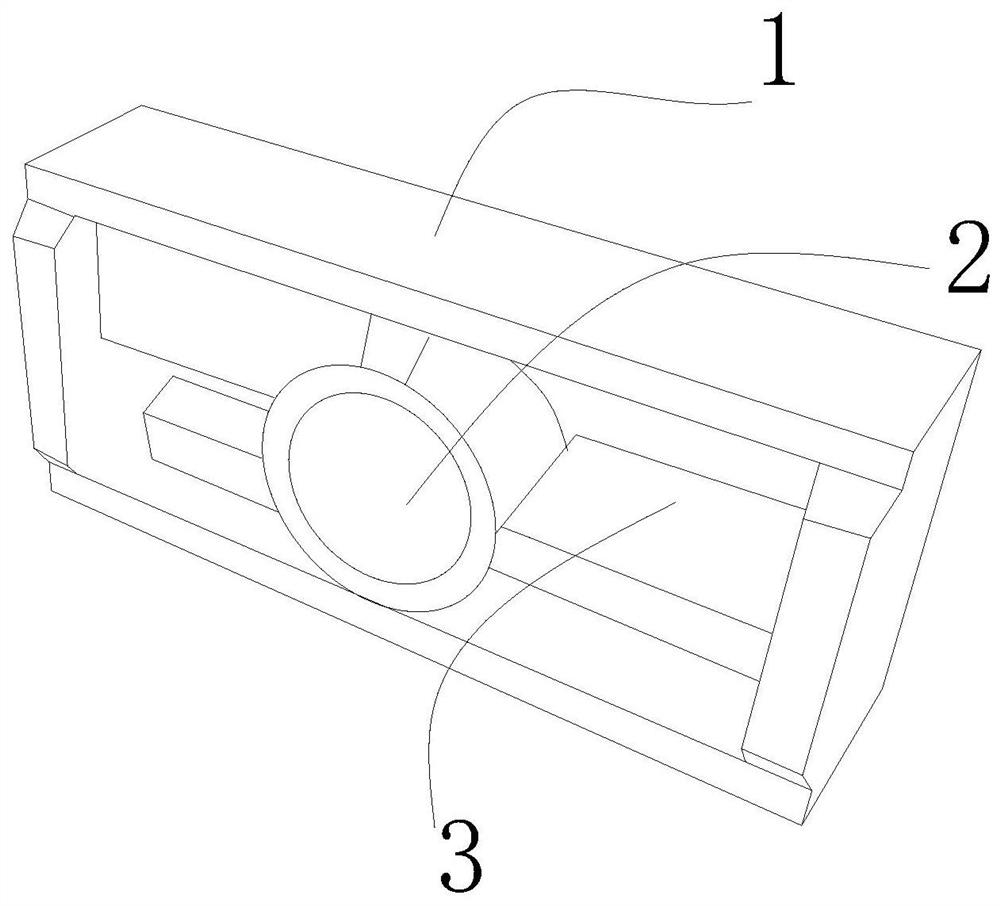

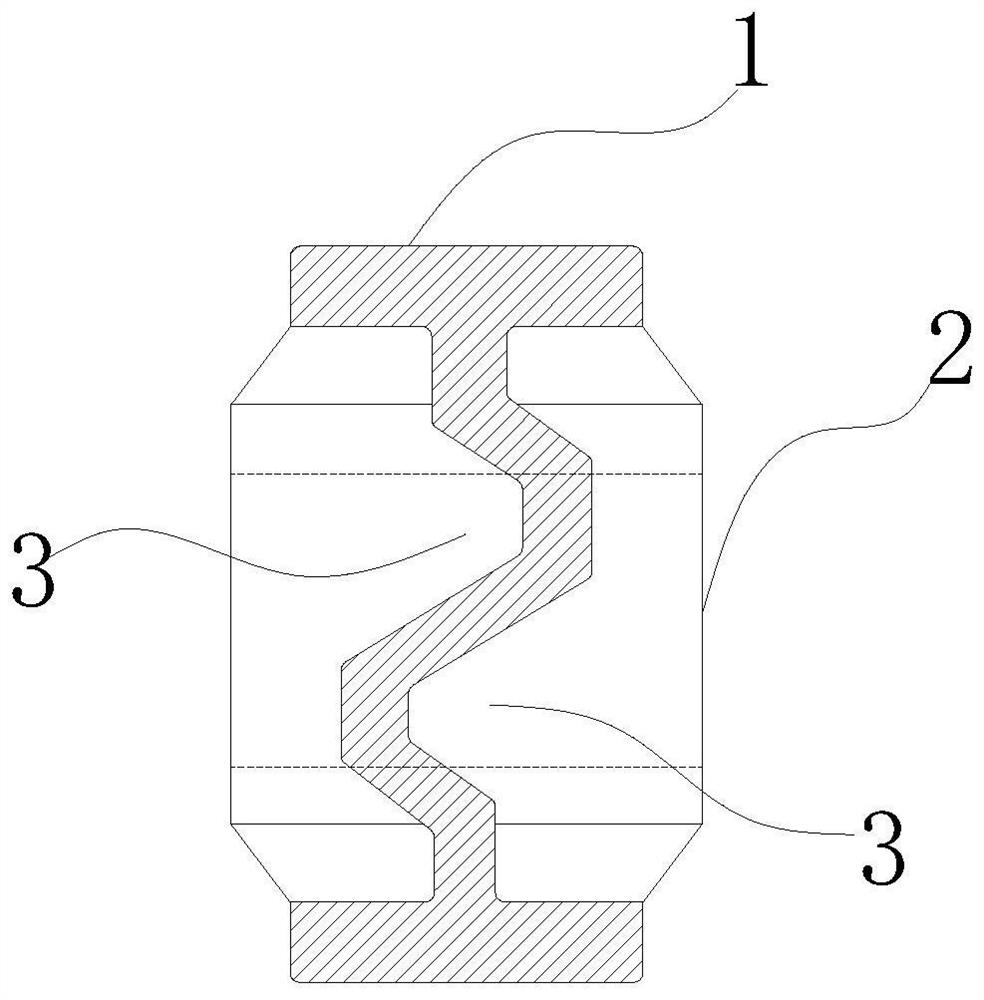

A copper alloy slider

The invention discloses a copper alloy slider and a preparation method thereof. A hollow part (3) is provided, and the hollow part (3) is located on the two surfaces through which the shaft hole (2) penetrates. The slider body (1) is a copper alloy, and the composition of the copper alloy contains 79% to 80% Copper by mass percentage, aluminum by mass percentage by 9%-10%, iron by mass percentage by 4%-5% and nickel by mass percentage by 4%-5%. The copper alloy slider of the present invention can have the advantages of high structural strength, wear resistance, and corrosion resistance, effectively improve the service life of the slider, and reduce maintenance costs; on the other hand, the invention also provides the preparation of the copper alloy slider method, this method can not only effectively guarantee the quality of the slider, but also further improve the performance of the slider.

Owner:桐庐明晟机械科技有限公司

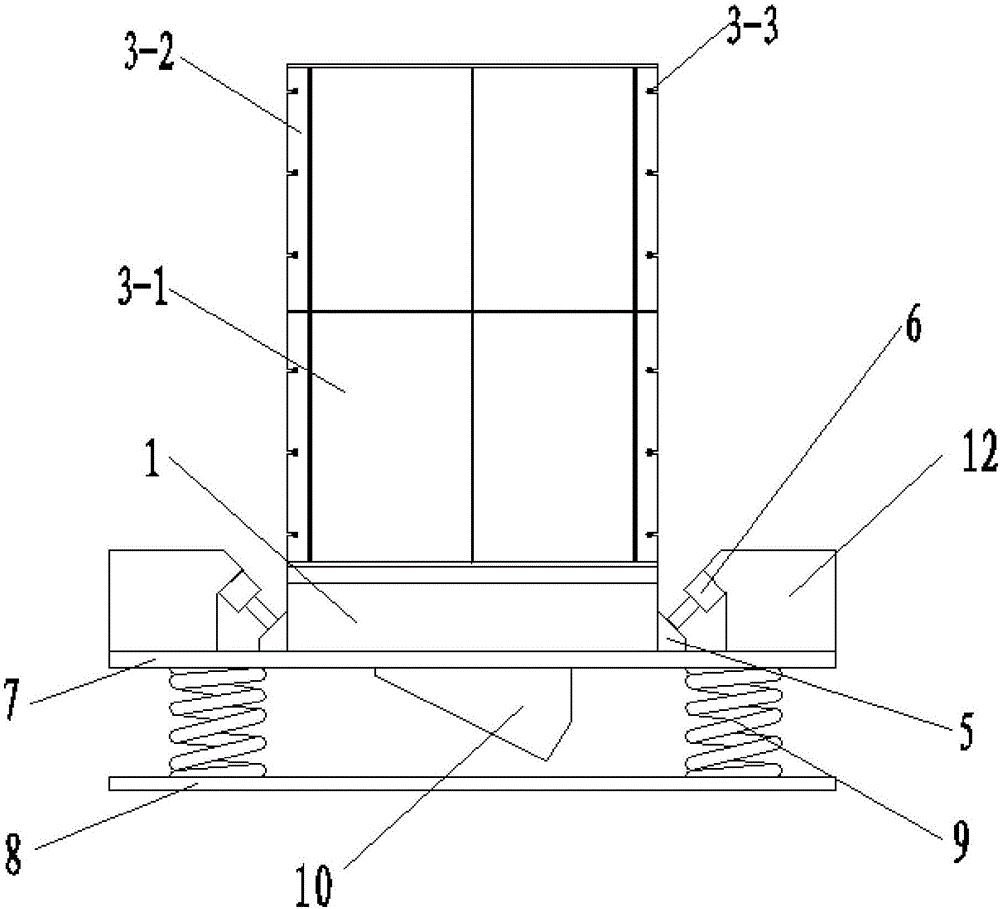

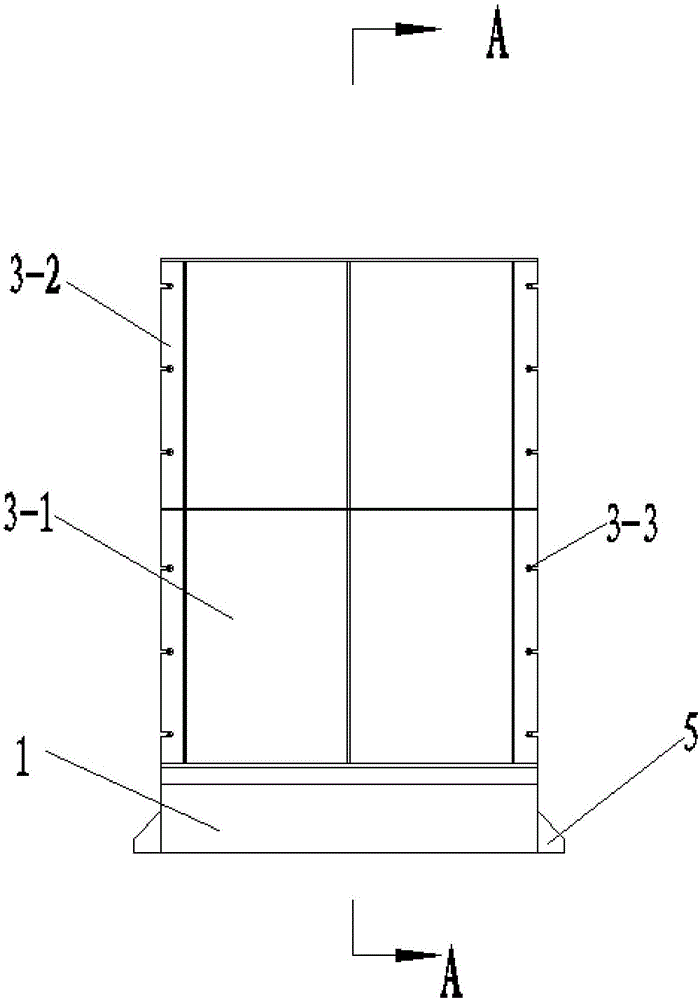

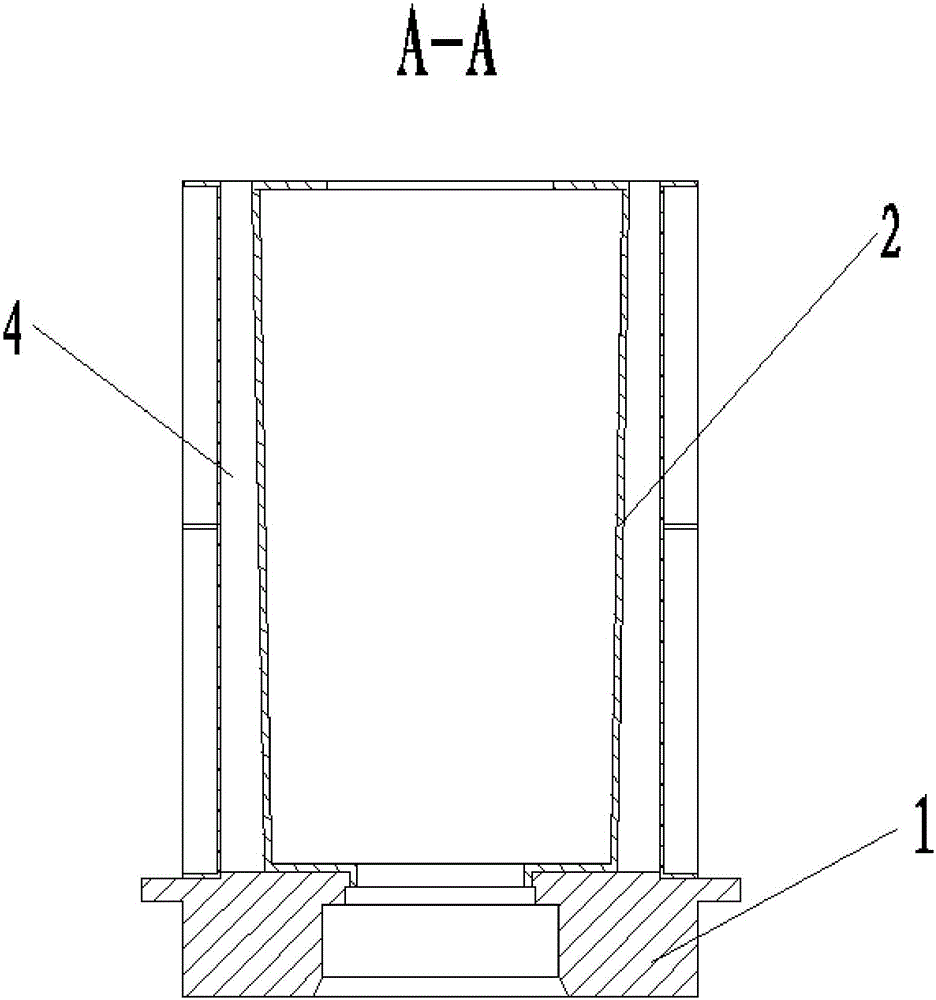

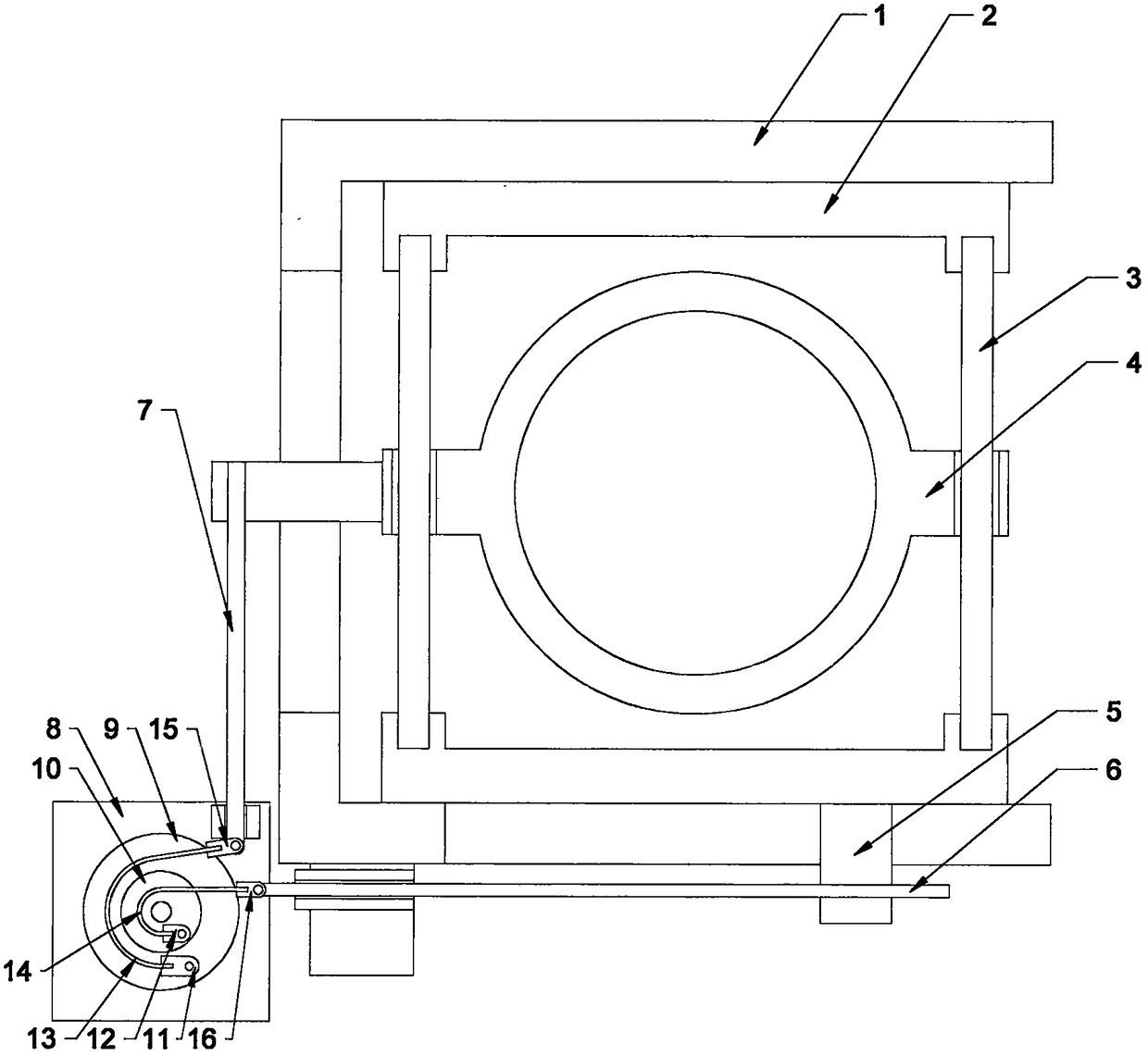

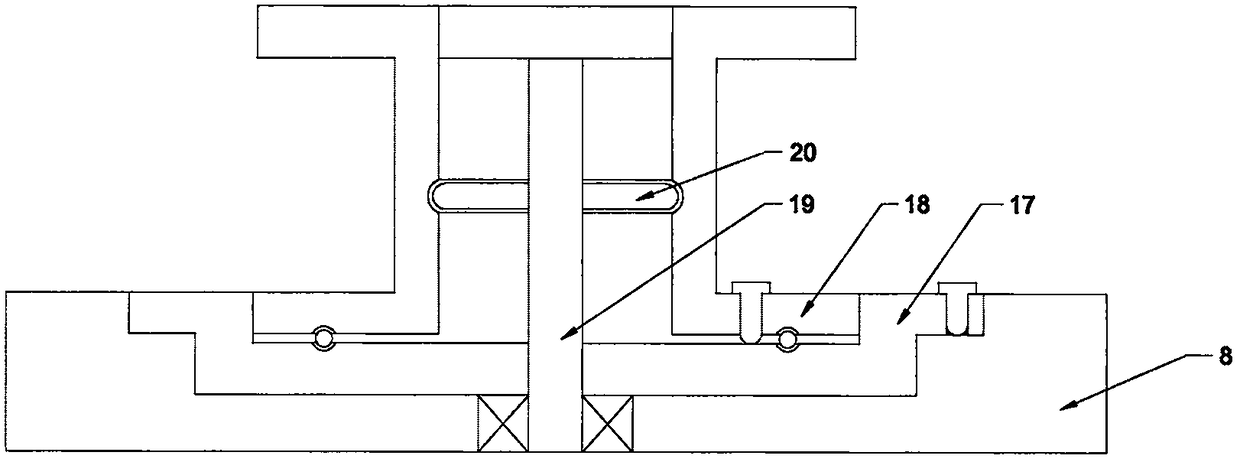

Multi-directional shock absorber

InactiveCN108361316AStrong anti-fouling abilityStrong acid corrosion resistanceNon-rotating vibration suppressionEngineeringConductor Coil

The invention relates to a multi-directional shock absorber. The multi-directional shock absorber comprises a shock absorbing frame, a moving frame and a buffering unit, wherein the moving frame and the buffering unit are arranged in the shock absorbing frame, and the moving frame and the shock absorbing frame are slidably connected; the moving frame and a fixed frame are slidably connected; one end of the fixed frame is provided with an extension arm A, and one end of the moving frame is provided with an extension arm B; the buffering unit comprises two supporting discs which are rotationallyconnected, the two supporting discs are the supporting disc A and the supporting disc B, and the supporting disc A and the supporting disc B are rotationally connected with a reed clamping seat A anda reed clamping seat B correspondingly; the extension arm A is connected to the reed clamping seat A through a connection reed A winding around the circle center of the supporting disc A, and the extension arm B is connected to the reed clamping seat B through a connection reed B winding around the circle center of the supporting disc B; and the extension arm A is rotationally connected with a reed connection seat A used for fixing the connection reed A, and the extension arm B is rotationally connected with a reed connection seat B used for fixing the connection reed B.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

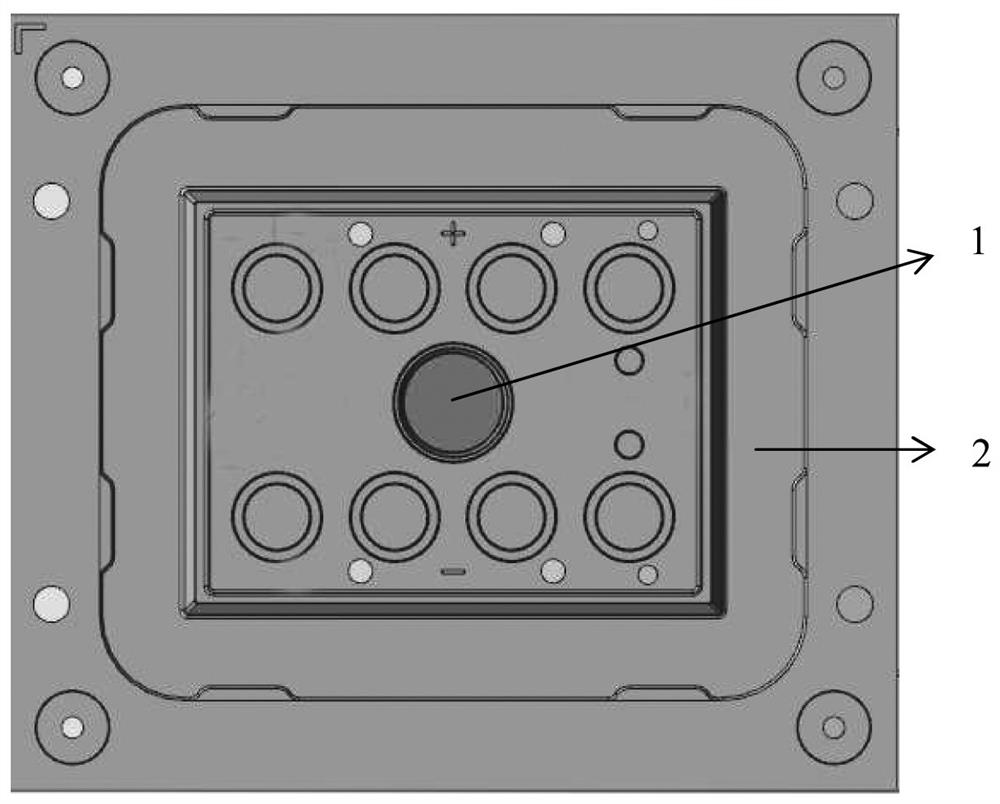

Manufacturing method of lead-acid storage battery cover with strong corrosion resistance

PendingCN114311739AGood acid corrosion resistanceFit closelyCell lids/coversCompression moldingGlass fiber

The invention discloses a manufacturing method of a high-corrosion-resistance lead-acid storage battery cover, which sequentially comprises the following steps of: preparing a mold, preparing an insert, preparing a sheet material, paving the sheet material, carrying out mold pressing, lifting the mold to take out a part, repairing a flash and carrying out post-curing. 6-12 pole holes which are uniformly distributed in two rows, 2-4 water cooling pipe holes and one or more threaded holes are formed in the storage battery cover, and at least one threaded hole is formed in the middle of the storage battery cover; the SMC sheet of the vinyl resin / glass fiber system is used as the raw material, the SMC compression molding process is adopted for manufacturing the lead-acid storage battery cover, the method is easy to operate, the prepared product is good in appearance, uniform in color and luster and free of defects such as air holes and cracks, meanwhile, the lead-acid storage battery cover has the high acid liquid corrosion resistance, and the service life of the lead-acid storage battery cover is prolonged. And the service life in a 50 DEG C sulfuric acid solution (1.32 g / cm < 3 >) steam environment is as long as more than 5 years.

Owner:WUHAN MARINE ELECTRIC PROPULSION RES INST CHINA SHIPBUILDING IND CORP NO 712 INST

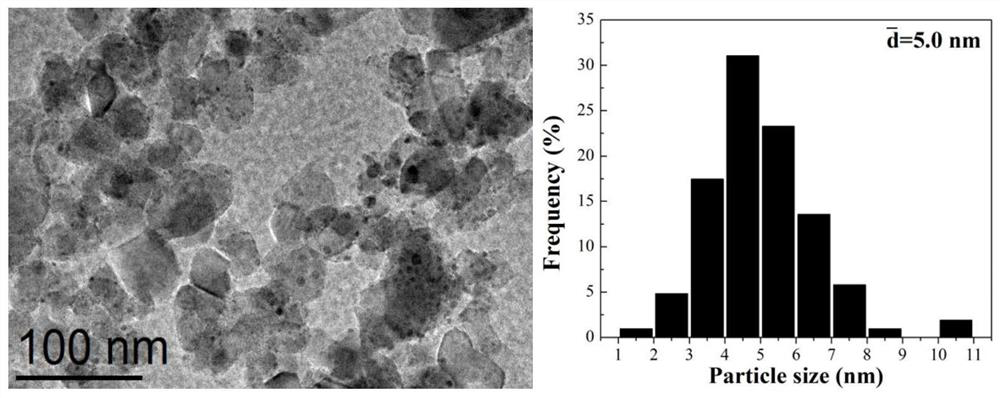

Hydrogenation catalyst for 2, 5-furandicarboxylic acid and reaction process

PendingCN114849703AStrong acid corrosion resistanceGood stabilityOrganic chemistryChemical recyclingHydrotalciteTitanium oxide

The invention discloses a hydrogenation catalyst for 2, 5-furandicarboxylic acid and a reaction process. The catalyst takes one of palladium, ruthenium or rhodium as an active component; the oxide is used as a carrier, and the carrier is one of aluminum oxide, silicon oxide, titanium oxide, zirconium oxide, attapulgite, diatomite and hydrotalcite; the catalyst is used for a reaction for preparing 2, 5-tetrahydrofurandicarboxylic acid through catalytic hydrogenation of 2, 5-furandicarboxylic acid. Due to the synergistic catalysis effect of the active metal and the oxide and the high-temperature heat treatment reduction process, the catalyst has high reaction activity and good stability. Under mild reaction conditions, 2, 5-furandicarboxylic acid can be converted into 2, 5-tetrahydrofurandicarboxylic acid with high selectivity by the catalyst, and the catalyst can be recycled.

Owner:DALIAN UNIV OF TECH

A preparation method of an anti-corrosion organic silicon binder for the inner lining of desulfurization chimneys in thermal power plants

InactiveCN105400478BImprove adhesionExcellent resistance to strong acid and alkali corrosionNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesPolyethylene glycolStrong acids

The invention relates to a preparing method for a corrosion prevention organic silicon binding agent for a desulfurization chimney liner of a thermal power plant. The preparing method comprises the following steps that firstly, a first component is prepared, wherein hydroxyl-terminated polydimethylsiloxane, polyethylene glycol PEG 600, a defoaming agent, a coupling agent and a solvent a are added into a reaction kettle according to a certain proportion and stirred evenly, then inorganic filler is added multiple times with a small amount, vacuum stirring is carried out for 60 minutes under the condition of the vacuum degree of 0.08 MPa, and the first component of the binding agent is obtained; secondly, a second component is prepared, wherein the curing agent polyisocyanate, a catalyst and a solvent b are added into a reaction kettle according to a certain proportion and stirred evenly, and the second component of the binding agent is obtained; thirdly, the first component and the second component are blended at the mass ration of 20:1 at the room temperature and stirred evenly, and the organic silicon binding agent is obtained. The organic silicon binding agent prepared through the method is high in binding performance, excellent in strong acid and strong base corrosion resistance, and good in high-temperature aging resistance and high-low temperature alternating resistance.

Owner:SICHUAN UNIVERSITY OF SCIENCE AND ENGINEERING +2

A processing method for corrosion-resistant metal shelves

ActiveCN107737933BHigh affinityHigh strengthMetallic material coating processesMetal machiningImpurity

Owner:NINGBO CITY XINGUANG SHELF

An acid-resistant tough high-wear cast ball and its preparation method

ActiveCN111074143BHigh hardnessImprove toughnessFurnace typesProcess efficiency improvementTemperingSlag

The invention discloses an acid-resistant, tough, high-wear cast ball and a preparation method thereof. The preparation method comprises the following steps: S1, smelting in a smelting furnace to obtain molten iron; S2, adding aluminum ingots to the molten iron before being released from the furnace Carry out deoxidation, then transfer the molten iron to the transfer ladle, pour the slag into the pouring ladle for pouring, and obtain the cast slab after cooling; S3, raise the temperature of the cast slab to 500-510°C for 2-3h, and then raise the temperature to 780‑790°C for 2‑3h, then heated to 940‑950°C for 2‑3h, then raised to 1015‑1030°C for 2‑3h, quenched with quenching oil for 10‑15min, and finally kept at 260‑280°C for 6‑ 8h for tempering treatment, that is. The casting ball prepared by the invention not only has excellent acid and corrosion resistance, but also has high hardness and good wear resistance, which is beneficial to improving economic benefits.

Owner:宁国东方碾磨材料股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com