Preparing method for corrosion prevention organic silicon binding agent for desulfurization chimney liner of thermal power plant

A chimney lining and adhesive technology, applied in the direction of adhesives, adhesive types, polyurea/polyurethane adhesives, etc., can solve the problems of high hardness, high cost, and long curing time of silicone resin, and achieve strong acid resistance Strong alkali corrosion performance is excellent, high and low temperature alternating performance is good, and the effect of improving bonding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

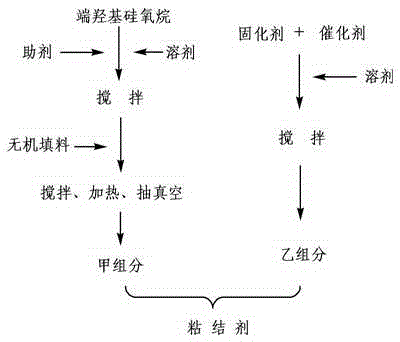

Method used

Image

Examples

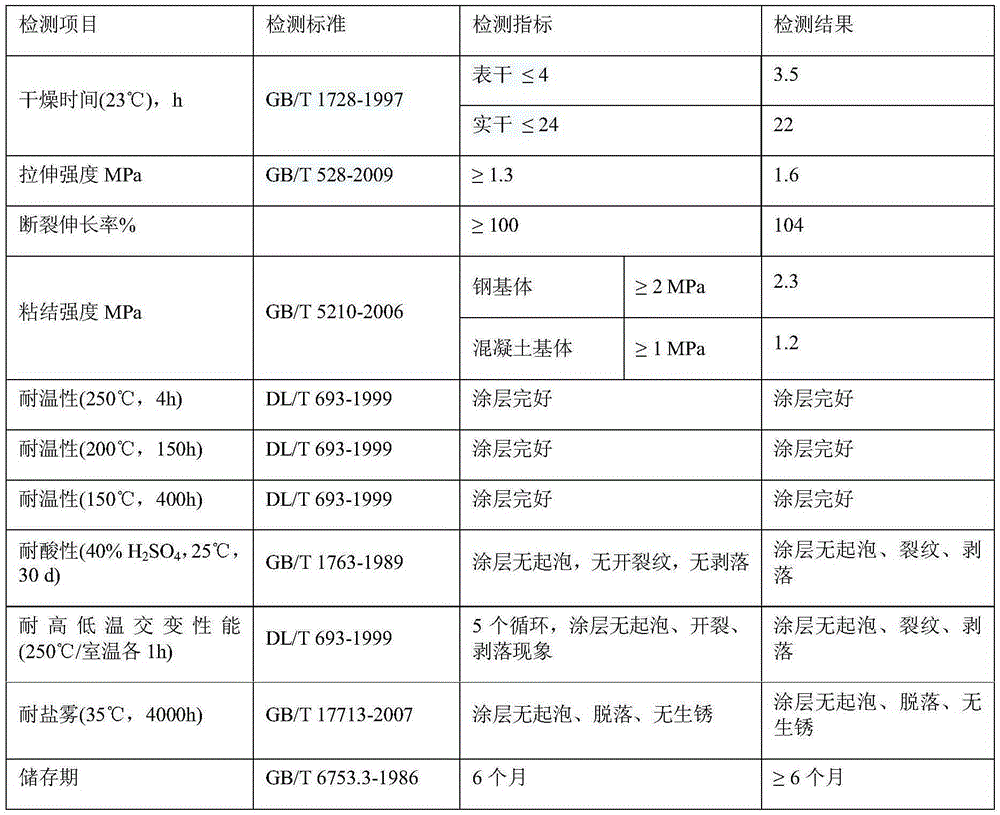

Embodiment 1

[0022] Prepare a kind of anti-corrosion organic silicon binder that is used for the lining of desulfurization chimney of thermal power plant, this binder comprises A component and B component, specifically comprises the following steps:

[0023] 1) Preparation of component A: In parts by weight, weigh 100 parts of 107 glue, 6 parts of PEG600 and 3 parts of simethicone oil into the reactor and mix and stir for 10 minutes, then add 48 parts of Inorganic filler, the mass ratio of fumed silica, glass flakes, carbon black, and calcium sulfate whiskers in the inorganic filler is 15:2:6:25. After stirring evenly, add 15 parts of solvent a and 2.5 parts of KH-550, solvent a is a mixture of toluene and acetone with a volume ratio of 5:1, stirred in vacuum for 60 minutes at a vacuum degree of 0.08 MPa to obtain component A of the binder, and set aside.

[0024] 2) Preparation of component B: In parts by weight, 1 part of TDI, 0.4 parts of dibutyltin dilaurate and 10 parts of solvent b a...

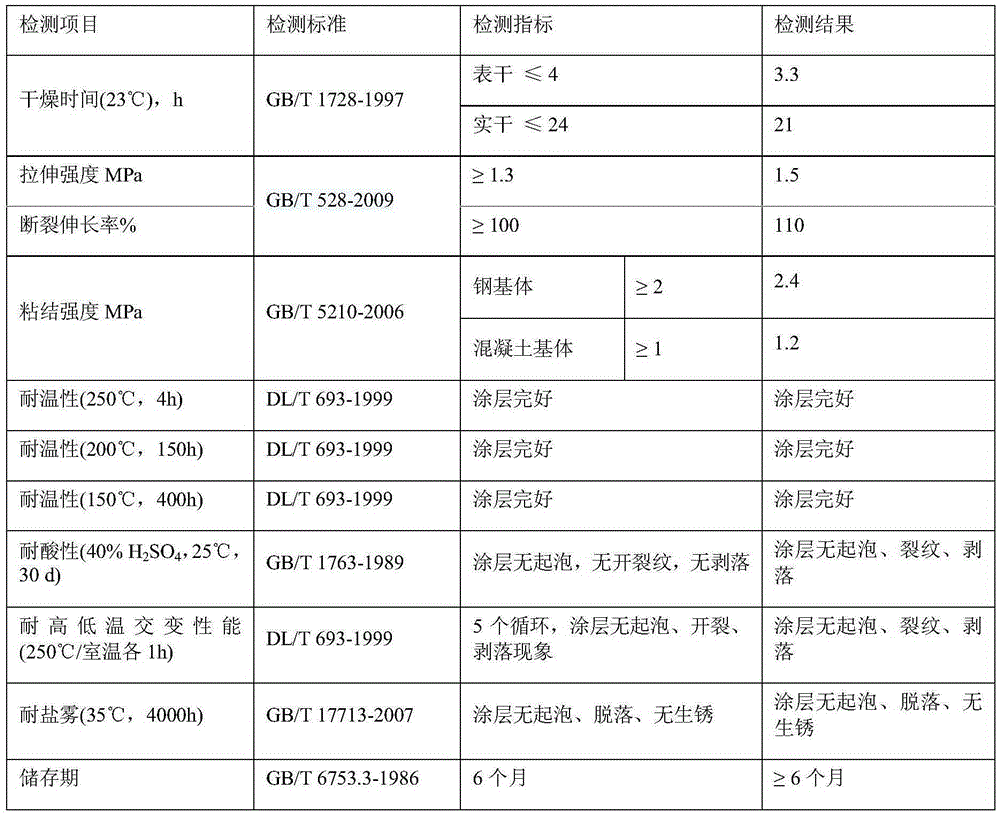

Embodiment 2

[0030] Prepare a kind of anti-corrosion organic silicon binder that is used for the lining of desulfurization chimney of thermal power plant, this binder comprises A component and B component, specifically comprises the following steps:

[0031] 1) Preparation of component A: In parts by weight, add 100 parts of 107 glue, 7 parts of PEG600 and 4 parts of simethicone into the reactor and mix and stir for 10 minutes, then add 46 parts of inorganic filler in 2 times , the mass ratio of fumed silica, glass flakes, carbon black, and calcium sulfate whiskers in the inorganic filler is 12:3:7:24. After stirring evenly, add 14.5 parts of solvent a and 3.0 parts of KH-550, solvent a is A mixture of toluene and acetone with a volume ratio of 5:1 was stirred in vacuum for 60 minutes under the condition of a vacuum degree of 0.08 MPa to obtain component A of the binder, which was set aside.

[0032] 2) Preparation of component B: in parts by weight, 1.2 parts of TDI, 0.4 parts of dibutylt...

Embodiment 3

[0038] Prepare a kind of anti-corrosion organic silicon binder that is used for the lining of desulfurization chimney of thermal power plant, this binder comprises A component and B component, specifically comprises the following steps:

[0039] 1) Preparation of component A: In parts by weight, add 100 parts of 107 glue, 8 parts of PEG600 and 5 parts of simethicone into the reactor and mix and stir for 10 minutes, then add 44 parts of inorganic filler in 2 times , the mass ratio of fumed silica, glass flakes, carbon black, and calcium sulfate whiskers in the inorganic filler is 12:3:7:22, after stirring evenly, add 14 parts of solvent a and 3.5 parts of KH-550, solvent a is A mixture of toluene and acetone with a volume ratio of 5:1 was stirred in vacuum for 60 minutes under the condition of a vacuum degree of 0.08 MPa to obtain component A of the binder, which was set aside.

[0040] 2) Preparation of component B: In parts by weight, 1.4 parts of TDI, 0.5 parts of dibutyltin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com