Protective coating for metal bipolar plate and preparation method thereof

A metal bipolar plate and protective coating technology, used in fuel cell parts, collectors/separators, etc., can solve problems such as poor corrosion resistance and increased contact resistance, and achieve improved electrical conductivity, reduced contact resistance, The effect of strong acid corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

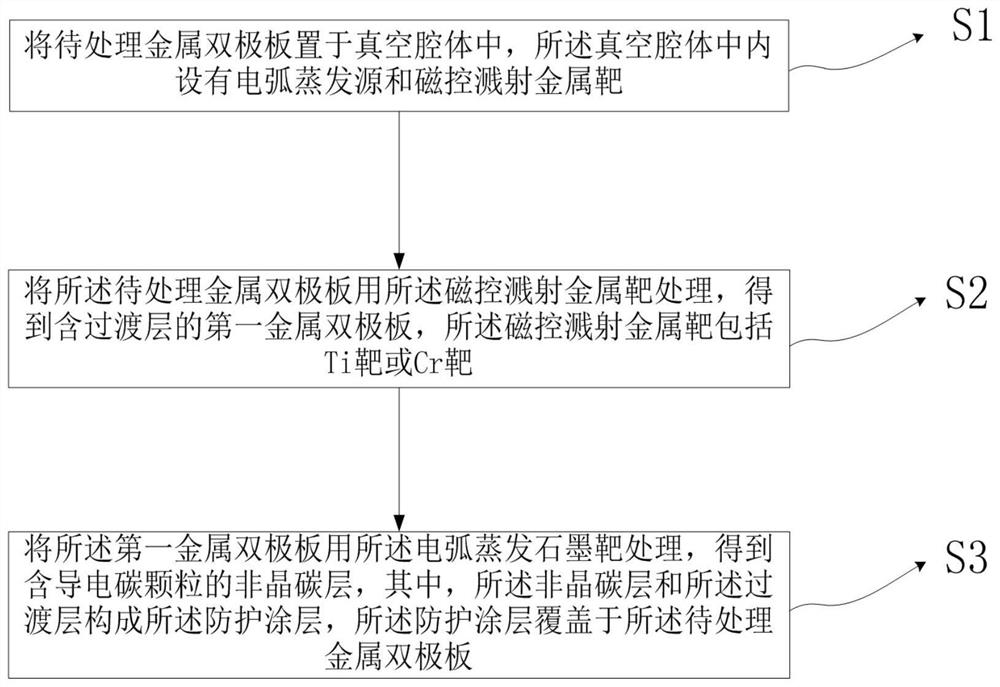

[0041] According to a typical embodiment of the present invention, the present application provides the preparation method of the protective coating, such as figure 1 As shown, the method includes the following steps:

[0042] S1. The metal bipolar plate to be treated is placed in a vacuum chamber, and the vacuum chamber is provided with an arc evaporation graphite target and a magnetron sputtering metal target;

[0043] S2. The to-be-treated metal bipolar plate is treated with a magnetron sputtering metal target to obtain a first metal bipolar plate containing a transition layer, and the magnetron sputtering metal target includes a Ti target or a Cr target;

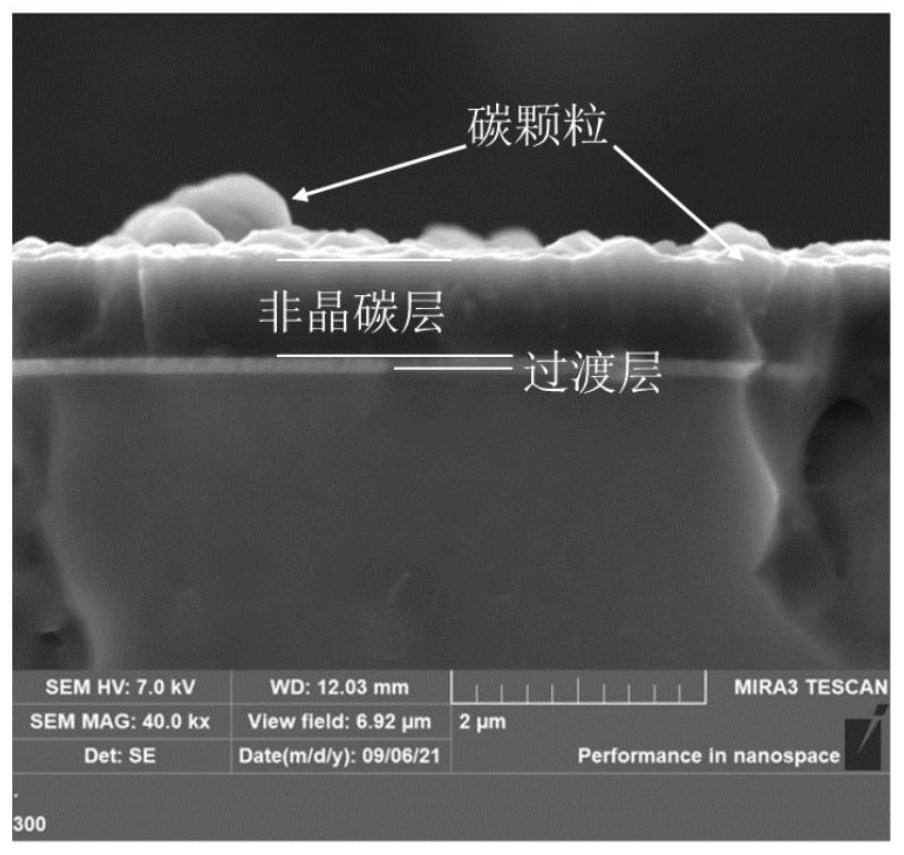

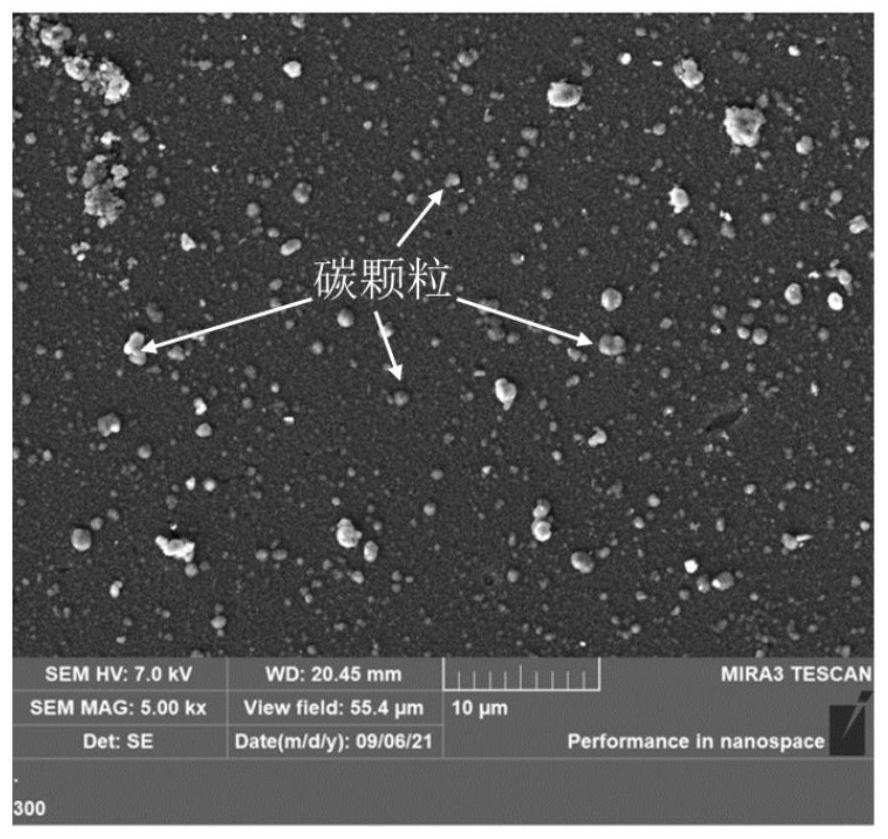

[0044] S3. The first metal bipolar plate is treated with an arc evaporation graphite target to obtain an amorphous carbon layer containing conductive carbon particles, wherein the amorphous carbon layer and the transition layer constitute the protective coating, and the protective The coating covers the to-be-treated me...

Embodiment 1

[0065] The embodiment of the present application provides a protective coating for a titanium foil bipolar plate, the protective coating covers the surface of the bipolar plate substrate, the protective coating includes a transition layer and an amorphous carbon layer, the non-crystalline carbon layer The crystalline carbon layer covers the transition layer, and the transition layer is combined with the bipolar plate base, wherein the composition of the transition layer is Ti. The thickness of the transition layer is about 120 nm, the thickness of the amorphous carbon layer is about 200 nm, and the amorphous carbon layer contains conductive carbon particles.

[0066] The preparation method of described protective coating, described method comprises the following steps:

[0067] S1. The titanium foil bipolar plate to be treated is placed in a vacuum chamber, and an arc evaporation source and a magnetron sputtering metal target are arranged in the vacuum chamber;

[0068] S2. T...

Embodiment 2

[0077] The difference between Example 2 and Example 1 is that: when an amorphous carbon layer containing conductive carbon particles is prepared by using an arc evaporation high-purity graphite target on the Ti crossing layer, the flow rate of argon gas is set to 300sccm, and the bias voltage is set to -25V. , turn on the arc cathode power supply, set the target current to 90A, and set the time to 2 minutes to obtain an amorphous carbon layer with a thickness of about 200nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com