Machining method of high-strength metal shelf

A processing method and high-strength technology, which is applied to devices and coatings that apply liquid to the surface. It can solve the problems of unacceptable product life, product specification impact, product performance interference, etc., and achieve refinement of internal crystal grains. , The effect of improving corrosion resistance and dense internal organization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

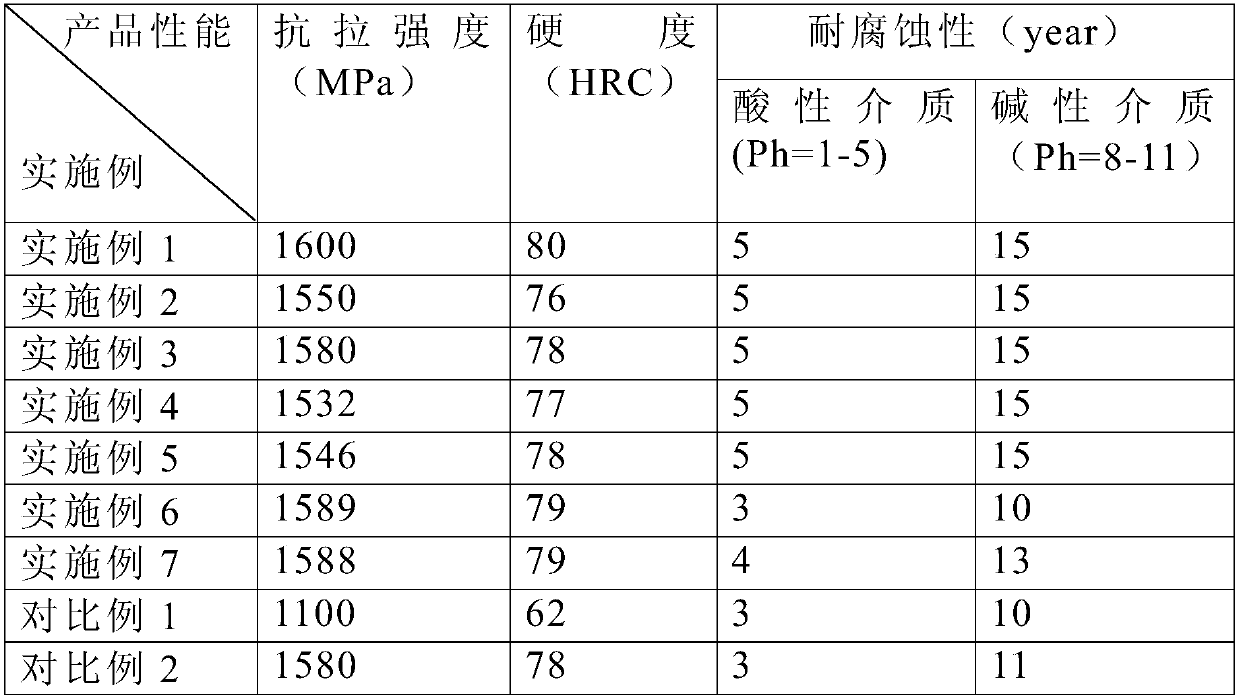

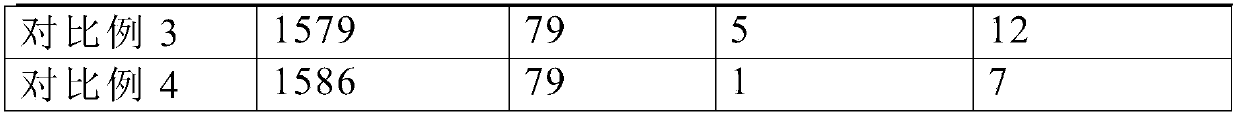

Examples

Embodiment 1

[0027] Ingredients: Weigh the raw materials according to the ingredients and mass percentages of the above-mentioned high-strength metal shelves, including Tl: 8%, Si: 1.5%, Ba: 0.15%, C: 0.6%, Co: 6%, Pb: 4%, Sn : 2.5%, Te: 2.5%, the balance is Fe and impurities, where the impurities include P<0.055%, S<0.065%, and O<0.01%.

[0028] Melting: Put the raw materials into an intermediate frequency induction furnace to form alloy steel liquid.

[0029] Forging: Injecting molten alloy steel into a mold to form alloy steel ingots, and then upsetting, elongating, shaping and cooling the alloy steel ingots at 1250°C to obtain alloy steel plates. The specific cooling is: adding 0.5% pertechnetate to the cooling water, and then pour the cooling water from top to bottom on the shaped alloy steel plate, and circulate it many times until the temperature of the steel plate drops to room temperature, during which the cooling water is replenished in time Technetate maintains its concentration.

[...

Embodiment 2

[0033] Ingredients: Weigh the raw materials according to the ingredients and mass percentages of the above-mentioned high-strength metal shelves, including Tl: 5%, Si: 1%, Ba: 0.1%, C: 0.4%, Co: 4%, Pb: 3%, Sn : 1%, Te: 2%, the balance is Fe and impurities, wherein the impurities include P<0.055%, S<0.065%, and O<0.01%.

[0034] Melting: Put the raw materials into an intermediate frequency induction furnace to form alloy steel liquid.

[0035] Forging: Injecting molten alloy steel into a mold to form alloy steel ingots, and then upsetting, elongating, shaping and cooling the alloy steel ingots at 1250°C to obtain alloy steel plates. The specific cooling is: adding 0.5% pertechnetate to the cooling water, and then pour the cooling water from top to bottom on the shaped alloy steel plate, and circulate it many times until the temperature of the steel plate drops to room temperature, during which the cooling water is replenished in time Technetate maintains its concentration.

[0036]...

Embodiment 3

[0039] Ingredients: Weigh the raw materials according to the ingredients and mass percentages of the above-mentioned high-strength metal shelves, including Tl: 10%, Si: 2%, Ba: 0.2%, C: 0.8%, Co: 8%, Pb: 5%, Sn : 4%, Te: 3%, the balance is Fe and impurities, where the impurities include P<0.055%, S<0.065%, and O<0.01%.

[0040] Melting: Put the raw materials into an intermediate frequency induction furnace to form alloy steel liquid.

[0041] Forging: Injecting molten alloy steel into a mold to form alloy steel ingots, and then upsetting, elongating, shaping and cooling the alloy steel ingots at 1250°C to obtain alloy steel plates. The specific cooling is: adding 0.5% pertechnetate to the cooling water, and then pour the cooling water from top to bottom on the shaped alloy steel plate, and circulate it many times until the temperature of the steel plate drops to room temperature, during which the cooling water is replenished in time Technetate maintains its concentration.

[0042] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com