Manufacturing method of lead-acid storage battery cover with strong corrosion resistance

A lead-acid battery and a manufacturing method technology, applied in the direction of battery cover/end cover, battery box/jacket, etc., can solve the problems of structural and mechanical damage, reduce weather resistance, etc., and achieve simple operation, excellent sealing performance, and uniform color. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] A strong corrosion-resistant lead-acid battery cover prepared by the present invention, a certain model is 500mm long, 300mm wide, and 30mm thick. The battery cover has 6 pole holes with a diameter of Φ70; 4 water-cooling tube holes with a diameter of Φ25 ; 4 threaded holes with a diameter of Φ40. The steps of the manufacturing method are mold preparation, insert preparation, sheet material preparation, sheet material laying, molding, mold lifting, parts repairing and post-curing in sequence.

[0024] This product uses SMC sheet of vinyl resin / glass fiber system as raw material, and adopts SMC molding process to manufacture lead-acid battery cover. The battery cover has good appearance, uniform color, no defects such as pores and cracks, and has strong acid corrosion resistance. 3 ) The service life in the steam environment is more than 5 years.

[0025] A method for manufacturing a battery cover, comprising the steps of:

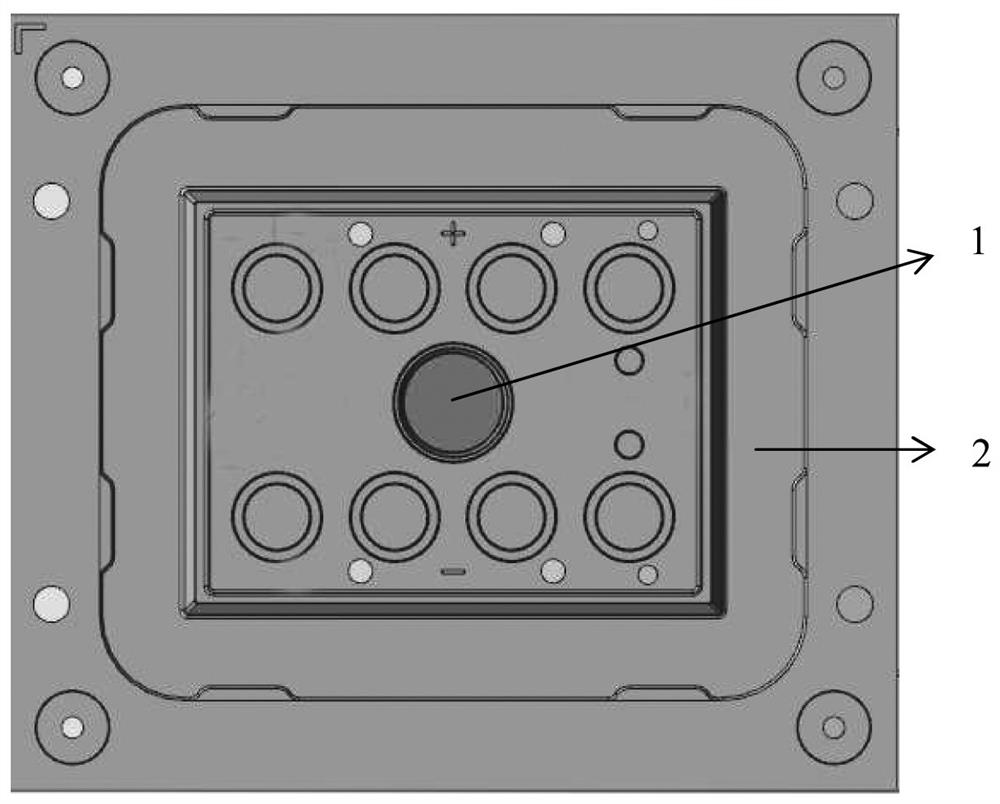

[0026] Step 1, install the female mold 2 an...

Embodiment 2

[0035] A strong corrosion-resistant lead-acid battery cover prepared by the present invention. A certain type of lead-acid battery cover is 600mm long, 300mm wide, and 30mm thick. The battery cover has 12 pole holes with a diameter of Φ50; 4 water-cooling tube holes , the aperture is Φ15; 3 threaded holes of different sizes, the aperture is Φ60, Φ30, Φ25. The steps of the manufacturing method are mold preparation, insert preparation, sheet material preparation, sheet material laying, molding, mold lifting, parts repairing and post-curing in sequence.

[0036] This product uses SMC sheet of vinyl resin / glass fiber system as raw material, and adopts SMC molding process to manufacture lead-acid battery cover. The battery cover has good appearance, uniform color, no defects such as pores and cracks, and has strong acid corrosion resistance. 3 ) The service life in the steam environment is more than 5 years.

[0037] A method for manufacturing a battery cover, comprising the step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com