Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

180results about How to "Good acid corrosion resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Composite acupuncture filter bag used for smoke treatment of ceramic kiln

ActiveCN101695615AShort production processHigh porosityDispersed particle filtrationFiltration separationYarnAlkali free

The invention discloses a composite acupuncture filter bag used for smoke treatment of a ceramic kiln. Short fibers and base fabrics are acupunctured by adopting non-woven acupuncture technology to form a composite acupuncture plain felt, the plain felt is soaked and coated by adopting a surface chemical treatment agent, and then the plain felt is dried and cured at a high temperature and is tailored and sewn to form the filter bag, wherein the base fabrics adopt 30-count alkali-free glass fiber woven fabrics; the short fibers for acupuncture comprise polypropylene fibers, polyphenylene sulfide fibers and 80-count short glass fiber yarns; and the surface chemical treatment agent comprises polytetrafluoroethylene emulsion, polyacrylic ester emulsion, coupling agent, antistatic agent and water. The invention provides the composite acupuncture filter bag used for the smoke treatment of the ceramic kiln, which has the advantages of moisture resistance, good acid corrosion resistance, long service life, high strength of the base fabrics and lower production cost. The problems of poor moisture resistance, poor corrosion resistance, low strength, short service life and high production cost of the filter bag in the prior art are solved. The filter bag is suitable for dust removal and purification treatment for the smoke of the ceramic kiln.

Owner:山东兴国新力环保科技股份有限公司

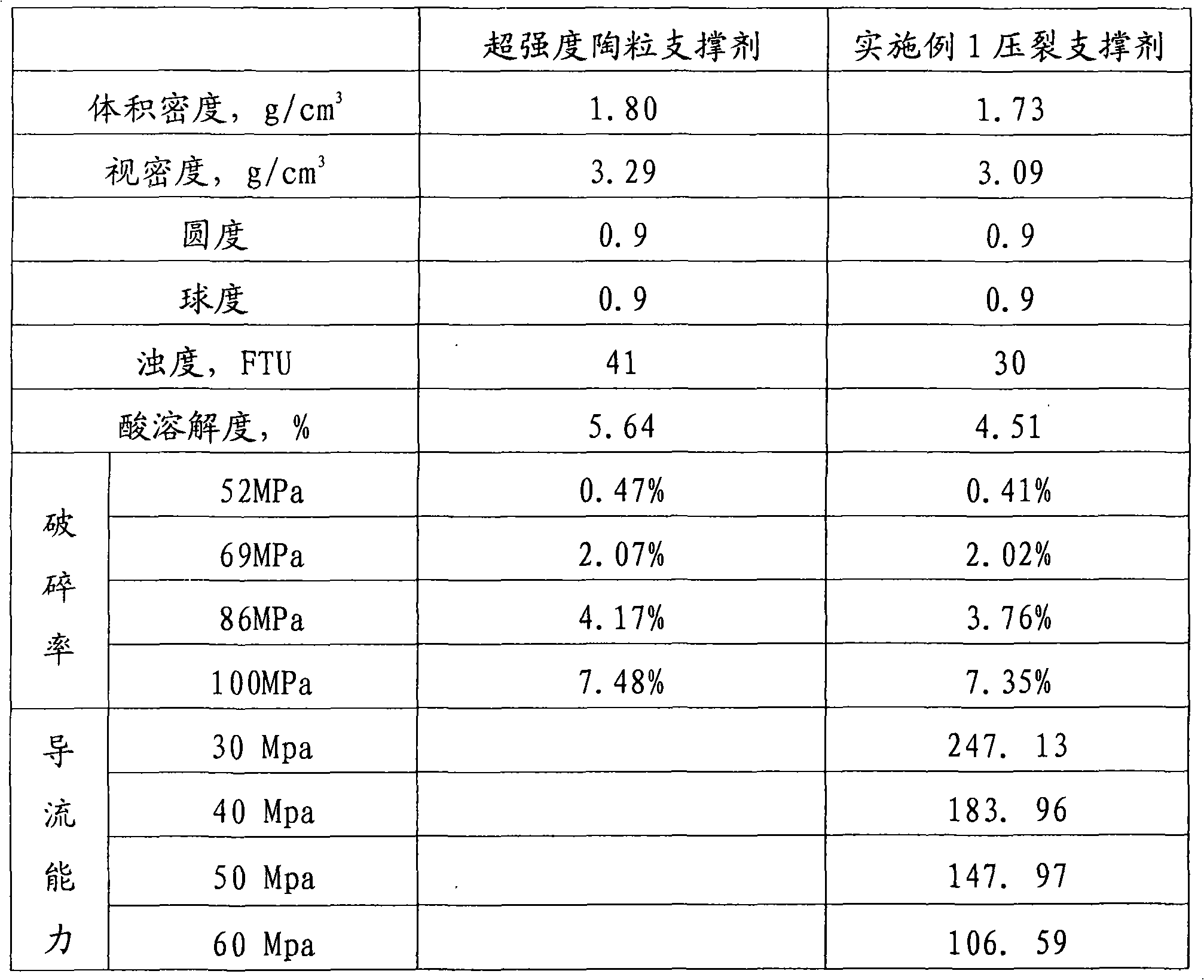

Fracturing propping agent for oil gas well and preparation method thereof

ActiveCN101270280AImprove product qualityHigh breakage resistanceFluid removalSoluble glassAcid corrosion

The invention relates to a fracturing proppant used for oil and gas wells, which is prepared with the following materials by weight: 80 to 88 portions of low content bauxite, 1 to 4 portions of manganese ore, 2 to 3 portions of potash feldspar, 2 to 4 portions of solid soluble glass, 1 to 5 portions of calcium mountain meal, and 1 to 5 portions of French chalk. The quality of the fracturing proppant is stable; the break resistance is high; the acid corrosion resistance is high; the volume density is low; the fracturing proppant can effectively prop up fracture, and significantly improve the permeability in the fracture so that oil and gas flow smoothly, and the oil productivity is improved. In addition, the raw materials and the preparation method are simple, and low requirements are proposed about the raw materials, and the fracturing proppant is prepared simply.

Owner:XINMI WANLI IND DEV

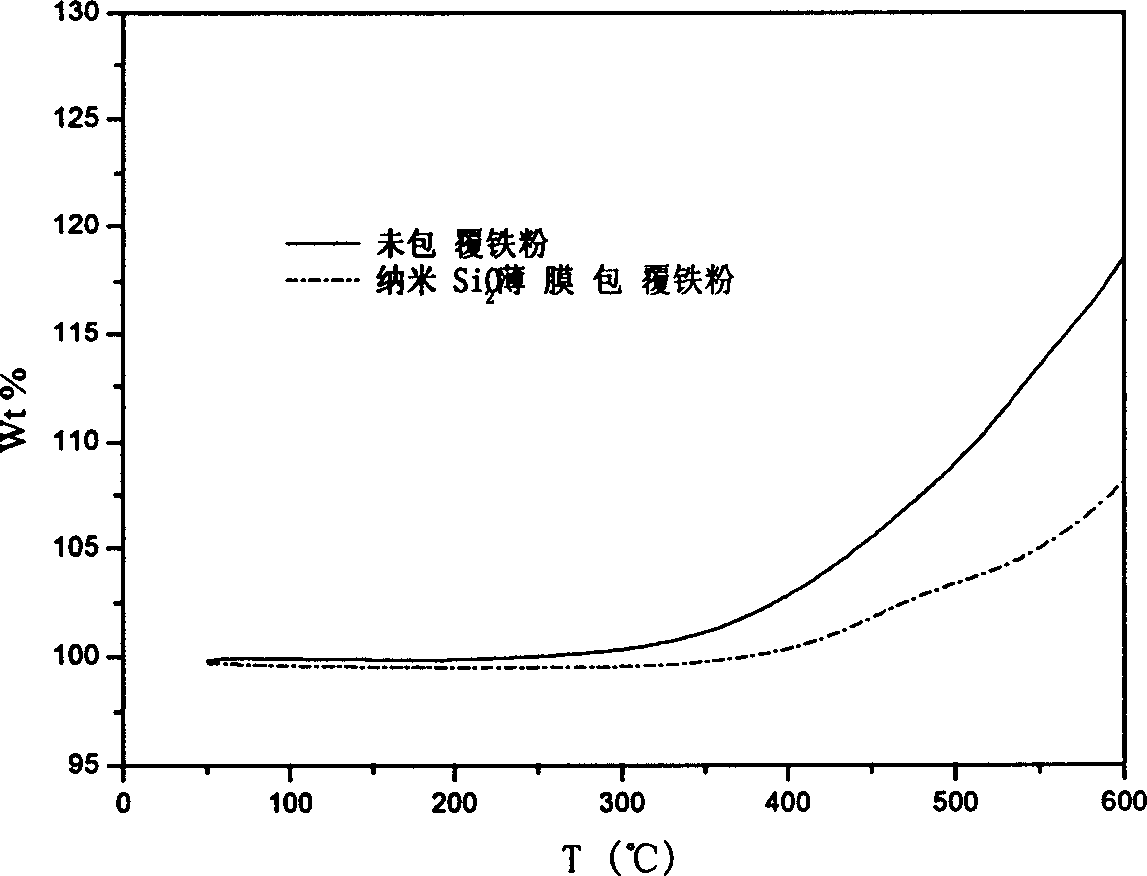

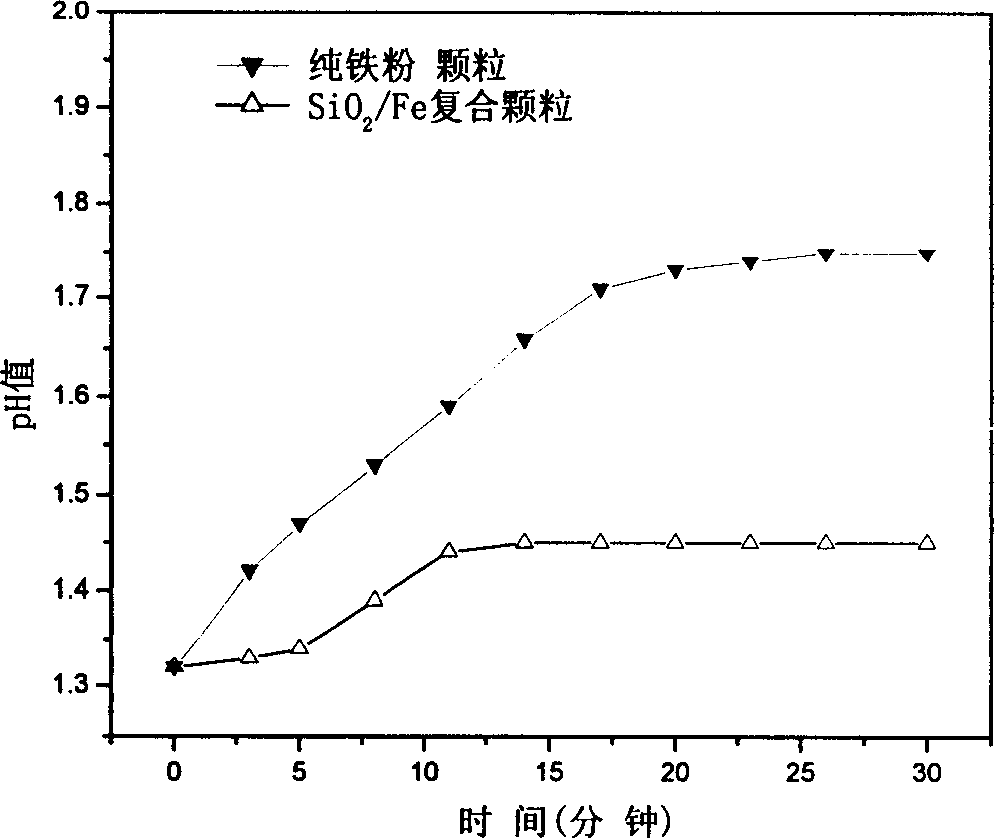

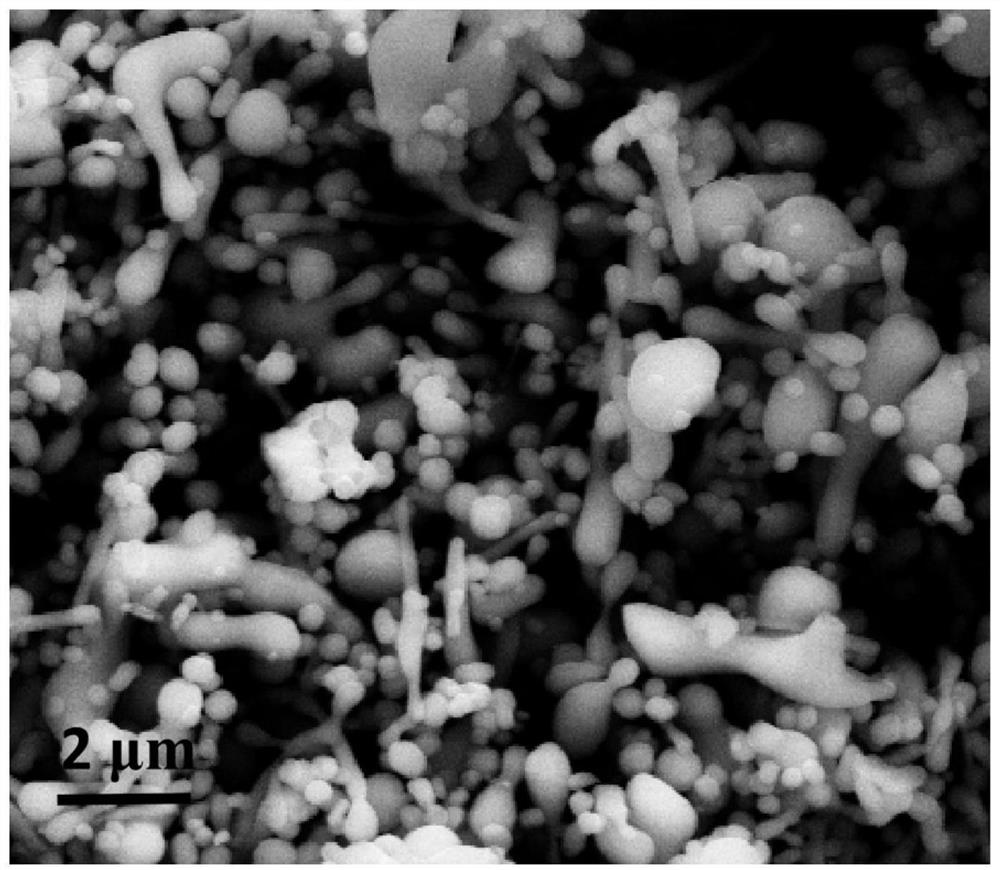

Magnetic particle with high antioxidant for magnetic flow liquid and preparation method thereof

InactiveCN1725388AImprove antioxidant capacityGood acid corrosion resistanceMagnetic liquidsAntioxidantAcid corrosion

This invention relates to iron-base soft magnetic particles with high non-oxidation used in magnetic rheological liquid and its preparation method, which utilizes TEOS hydrolytic condensation reaction to cover a layer of SiO2 film on the magnetic particle surface to prepare magnetic composite particles, which have good non-oxidation performance, acid corrosion resistance and rather high magnetic strength.

Owner:TONGJI UNIV

Strong acid resistant and inner corrosion-resistant paint and its manufacturing method

InactiveCN1621464AGood acid corrosion resistanceGood flexibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyCyclohexanone

The present invention relates to one kind of strong acid resistant inner anticorrosive paint and its production process. The paint is produced through adding epoxy resin into mixed solvent one xylene, diacetone alcohol and cyclohexanone; adding phenolic resin, chrome green, precipitated barium sulfate, graphite, PTFE, polyacrylate copolymer solution, polymethyl alkyl siloxane solution and polyamdie wax via mixing; and grinding. The paint may be coated to inner wall of acid gas pipeline and high sulfur matter conveying pipeline for preventing corrosion.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

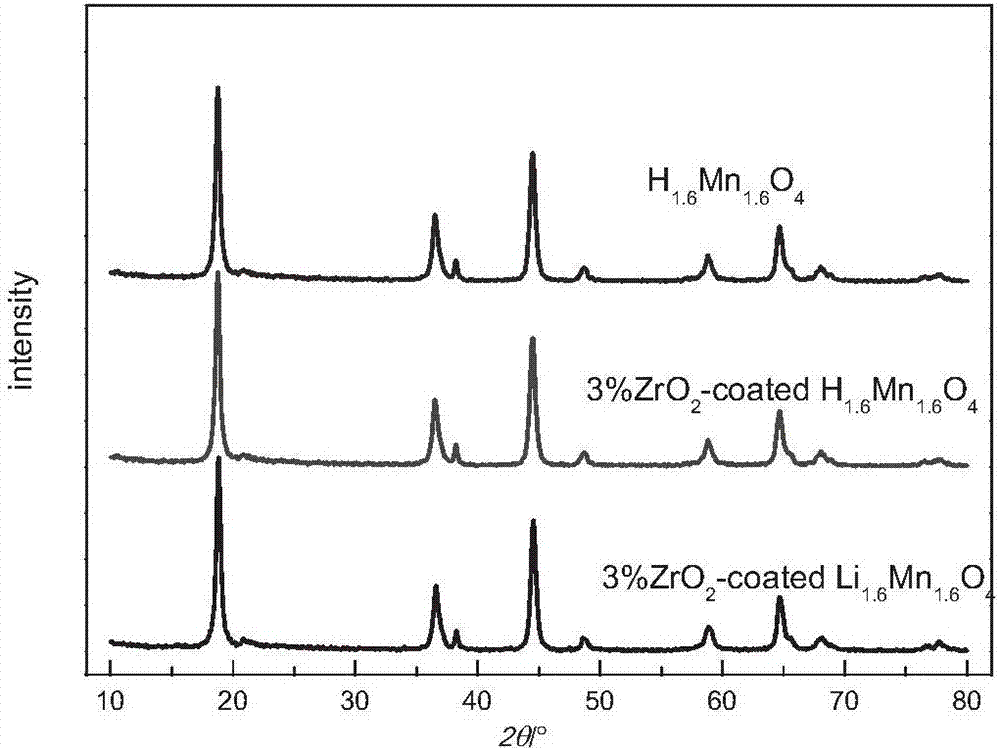

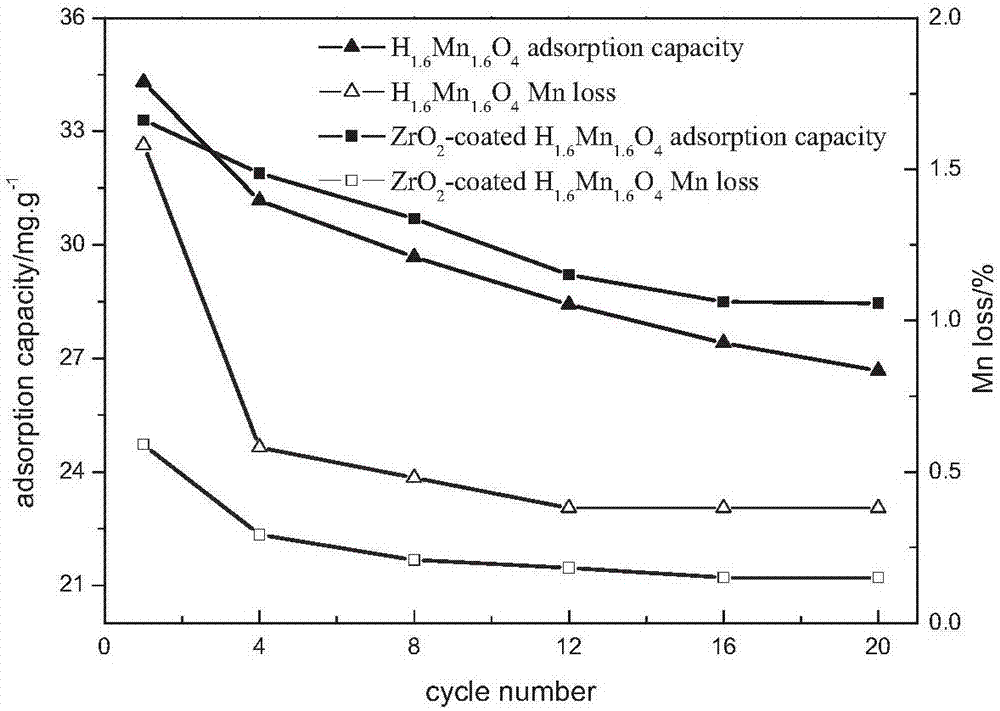

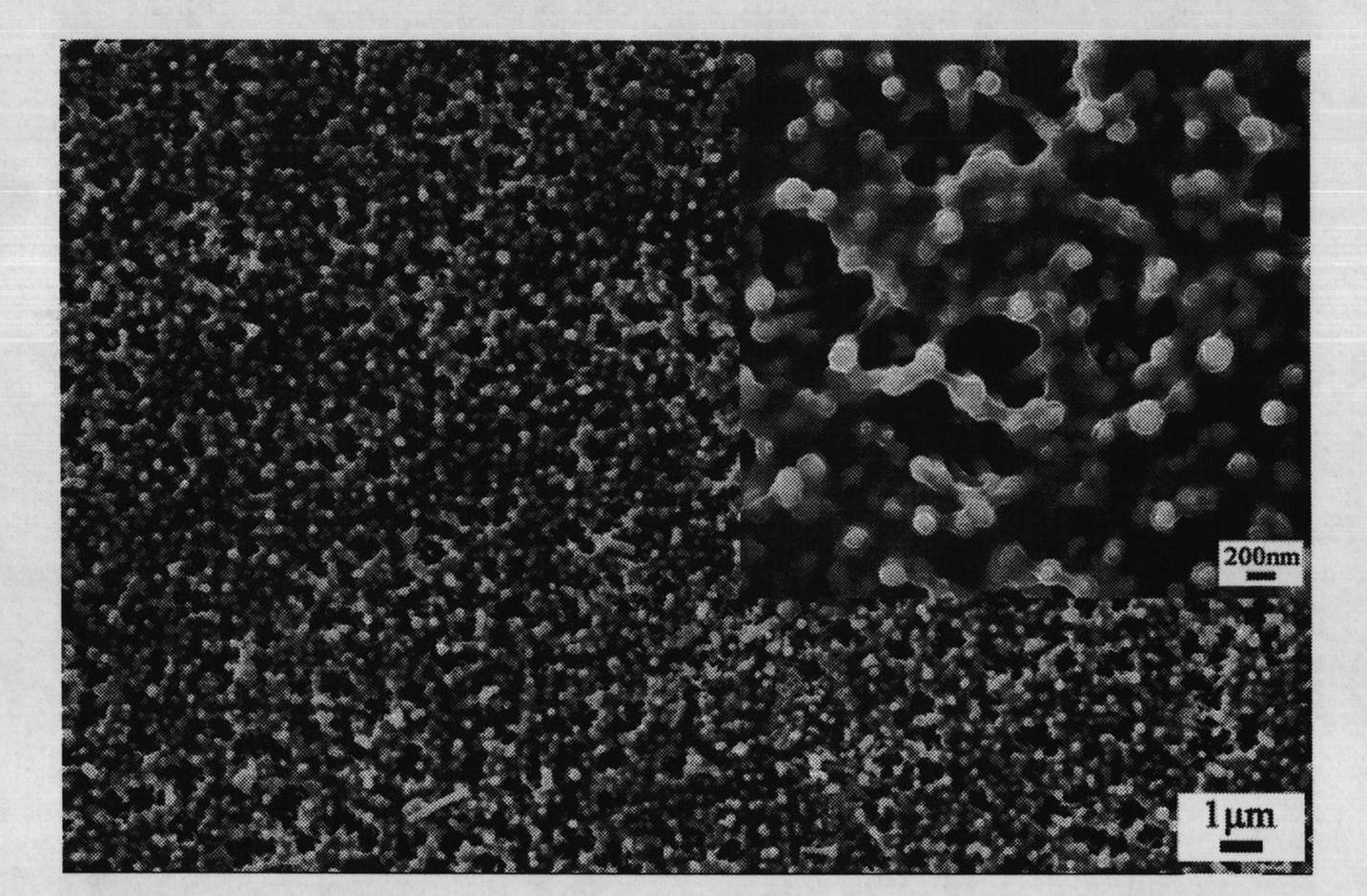

Zirconium dioxide-coated manganese lithium ion sieve as well as preparation method and application thereof

InactiveCN107376827AGuaranteed adsorption effectGood acid corrosion resistanceOther chemical processesWater/sewage treatment by sorptionSorbentManganese

The invention provides a zirconium dioxide-coated manganese lithium ion sieve which has a core-shell structure, wherein a core is made of H1.6Mn1.6O4, and a shell layer is made of ZrO2. In addition, the invention further discloses a preparation method which comprises the following steps: dispersing Li1.6Mn1.6O4 into solution containing a Zr source, removing a solvent and roasting, so as to obtain a ZrO2 lithium ion sieve precursor; removing Li from the ZrO2 lithium ion sieve precursor, then performing solid-liquid separation, washing and drying, so as to obtain the zirconium dioxide-coated manganese lithium ion sieve. According to the zirconium dioxide-coated manganese lithium ion sieve, the problems that a manganese lithium ion sieve is poor in acid corrosion resistance, large in manganese solution loss, unstable in structure and poor in cycling performance are solved. The obtained lithium ion sieve product is high in adsorption capacity of lithium ions, stable in structure and long in service life, so that the lithium ion sieve provided by the invention is an efficient lithium extraction adsorbent of salt lake brine or sea water. The zirconium dioxide-coated manganese lithium ion sieve is simple and clean in preparation processes, free of side reaction in a preparation process and good in product performance, thereby being suitable for industrial production.

Owner:CENT SOUTH UNIV

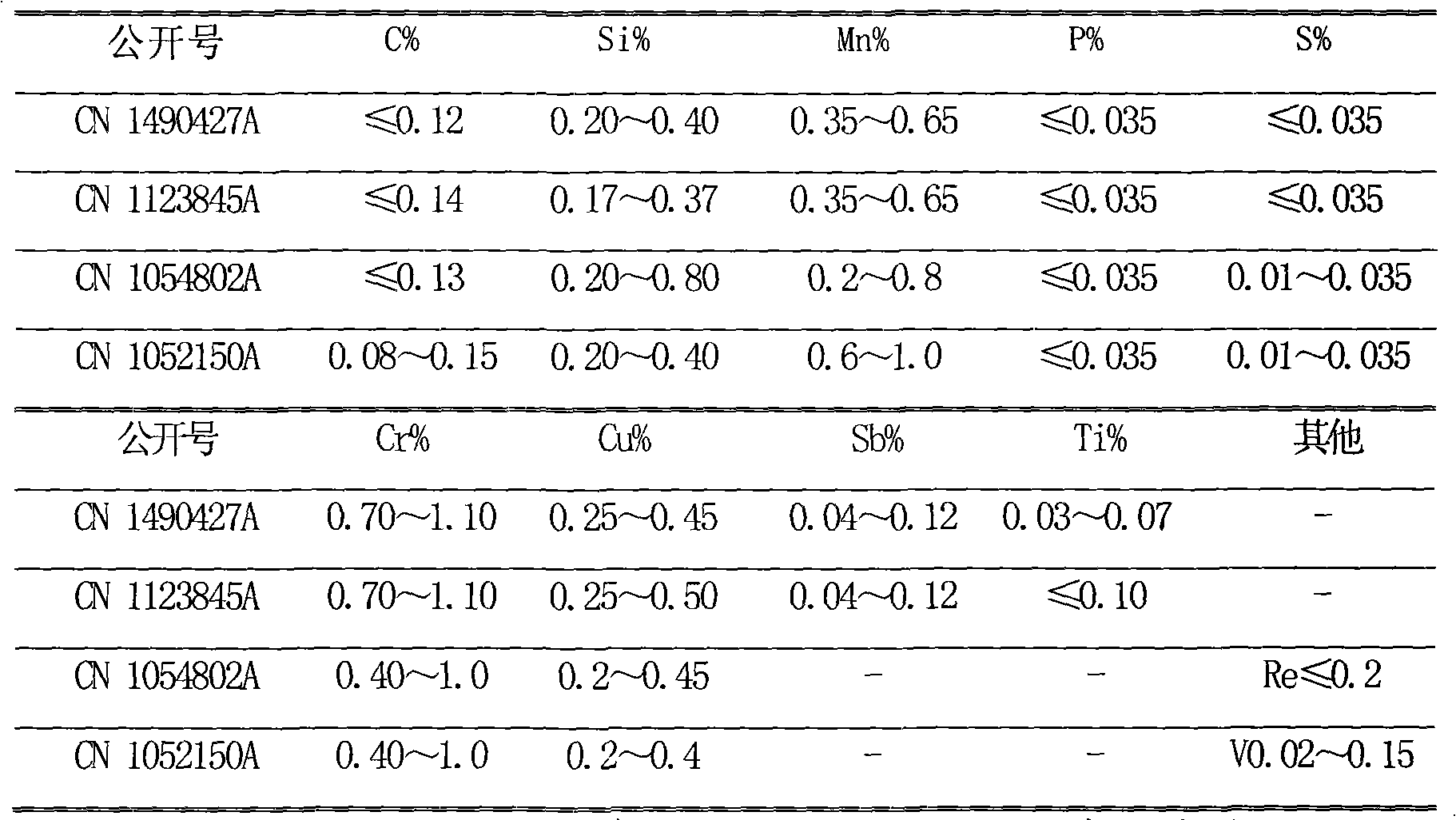

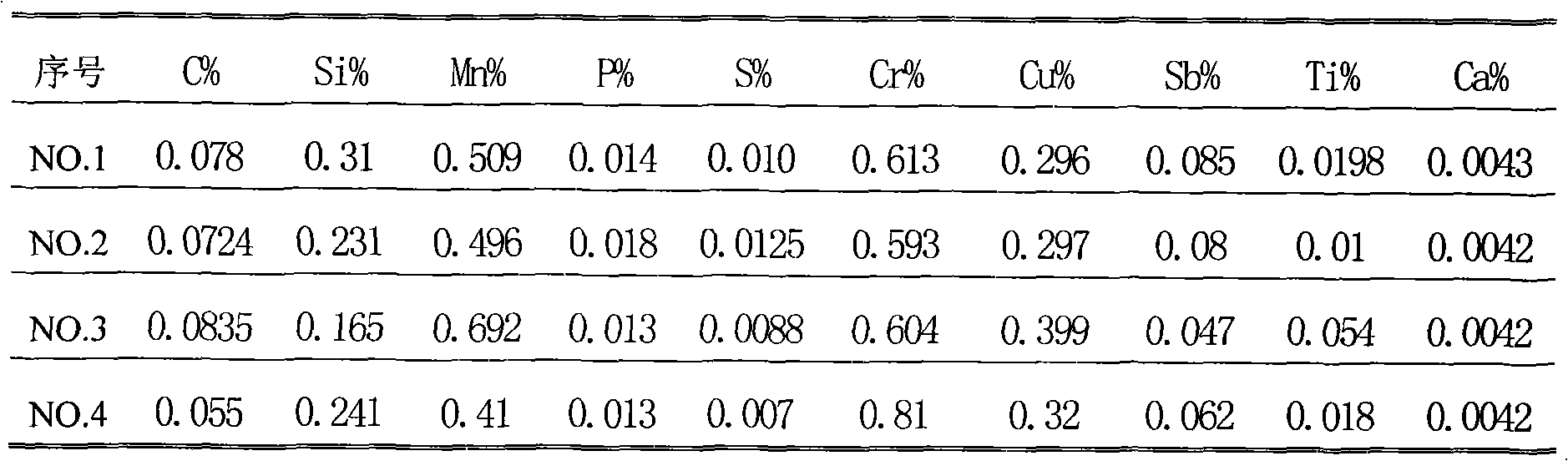

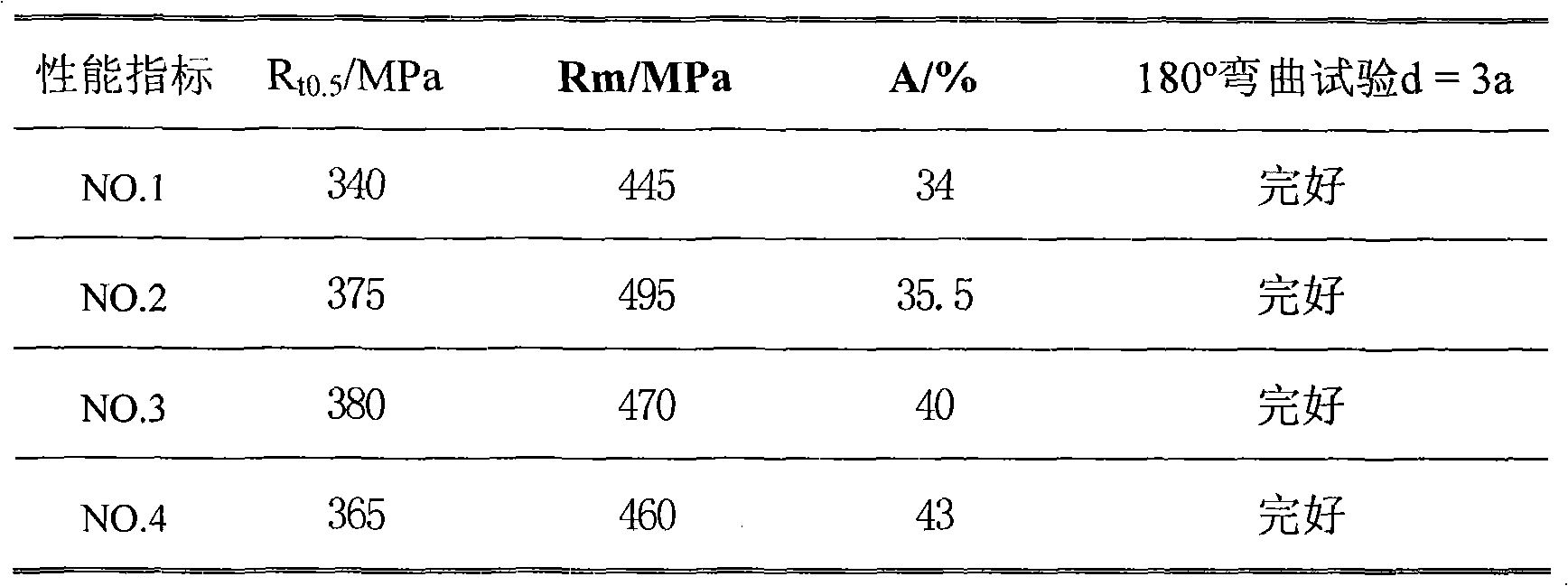

Sulfuric acid dew point corrosion resistant steel

InactiveCN101892439AGuaranteed mechanical propertiesHighlight substantiveAcid corrosionMetallic materials

The invention relates to sulfuric acid dew point corrosion resistant steel, belonging to the technical field of metal materials. The steel comprises the following components by mass: 0.05-0.1% of C, 0.1-0.35% of Si, 0.3-0.8% of Mn, 0-0.02% of P, 0-0.01% of S, 0.5-1.0% of Cr, 0.2-0.5% of Cu, 0.04-0.1% of Sb, 0.01-0.06% of Ti, 0.0004-0.001% of Ca and the balance Fe. The steel obviously improves the acid corrosion resistance under the premise of ensuring mechanical property of the steel, not only resists sulfuric acid dew point corrosion but also resists atmospheric corrosion and has obvious substantial characteristics and prominent progress compared with the prior art.

Owner:SHANGHAI MEISHAN IRON & STEEL CO LTD

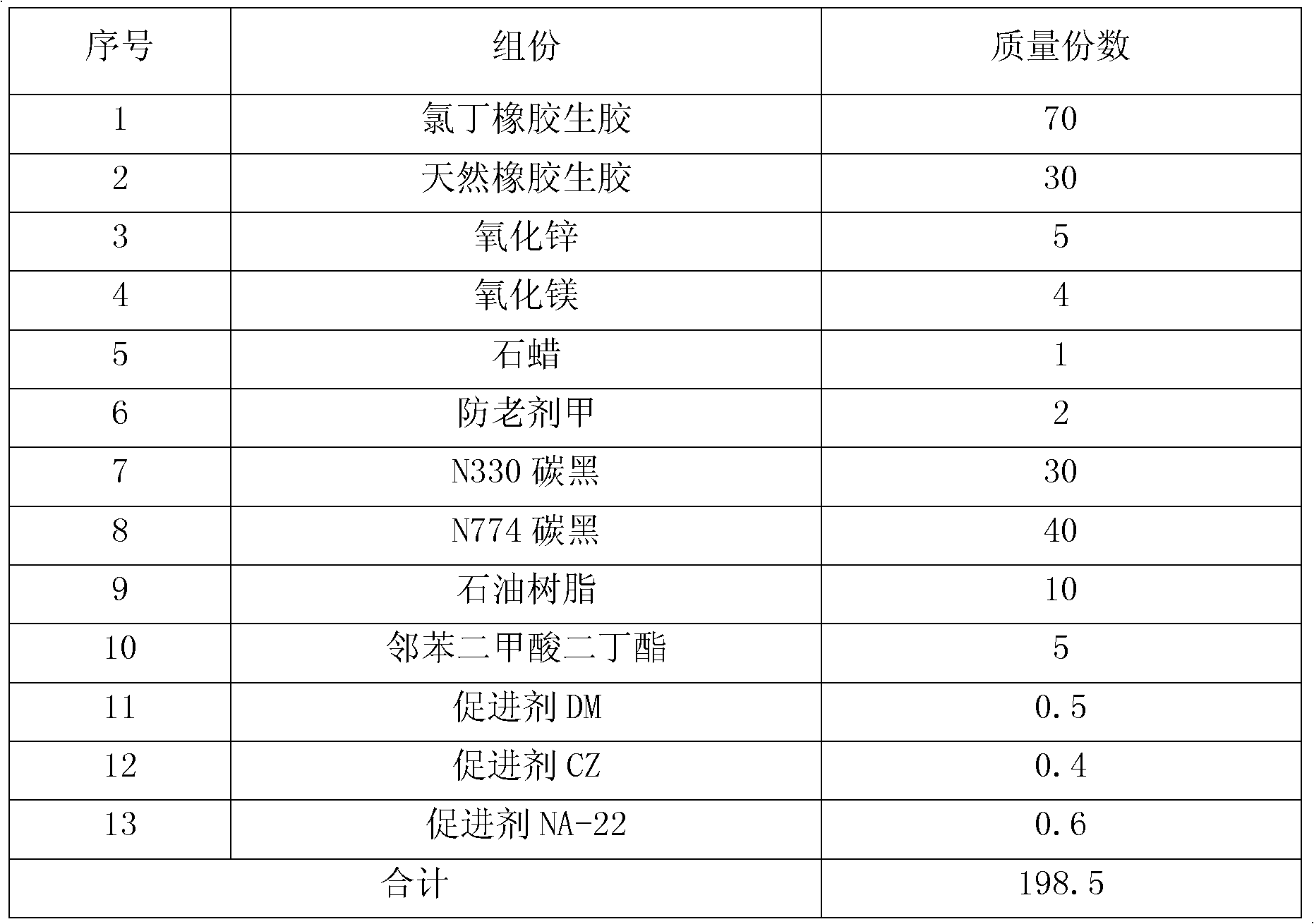

Acid corrosion resistant chloroprene rubber

The invention relates to an acid corrosion resistant chloroprene rubber which is completely made of crude chloroprene rubber so as to greatly enhance the acid corrosion resistance of the sizing material. Barium sulfate and kaolin are added to enhance the acid corrosion resistance of the sizing material. Plasticizer SUNDEX790 is added to replace the traditional ester plasticizer to improve the acid resistance of the sizing material because the plasticizer SUNDEX790 has good compatibility with the chloroprene rubber and can not be easily extracted by acid corrosion. In addition, because the plasticizer SUNDEX790 has a flash point higher than 230 DEG C and superior high-temperature aging performance, so that the thermal aging performance of the chloroprene rubber is enhanced. The rubber stopper produced from the chloroprene rubber can meet the requirements for production and using, and the durability of the rubber stopper is three times better than that of the product made according to the traditional formula, thus prolonging the service life of the product so as to lower the production cost. The chloroprene rubber can also be used for producing rubber tubes, rubber strips, rubber plates, rubber linings and other relevant acid resistant rubber products.

Owner:TIANJIN PENGYI GRP CO LTD

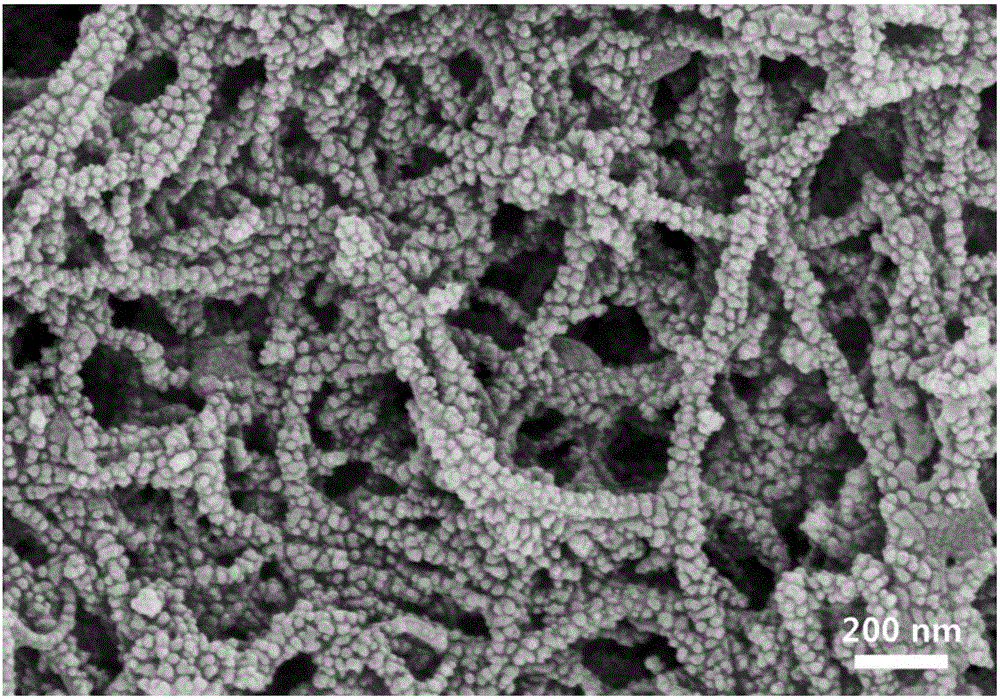

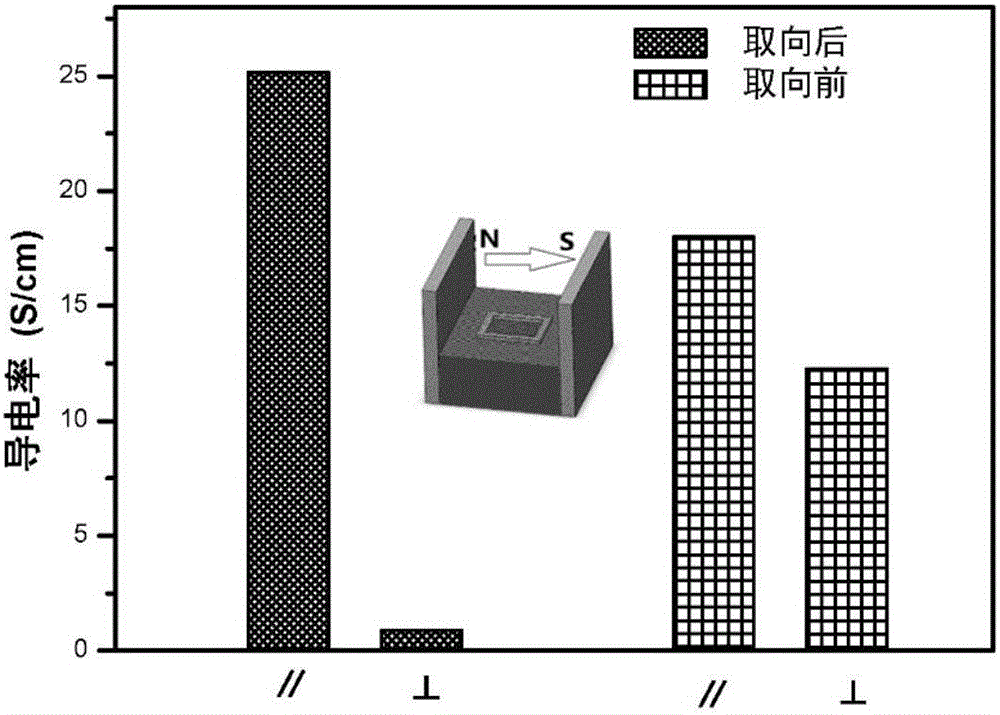

Preparation method of anisotropic conductive macromolecule composite thin film

The invention discloses a preparation method of an anisotropic conductive macromolecule composite thin film. The preparation method includes following steps: 1), uniformly adding carbon nanotubes coated with nano ferroferric oxide magnetic particles into a polyaniline-N-methylpyrrolidinone solution according to a mass percentage of 0.5-15%, and stirring well to obtain a carbon nanotube / ferroferric oxide-polyaniline solution; 2), adding the nanotube / ferroferric oxide-polyaniline solution into a polyurethane solution, and stirring well to obtain a carbon nanotube / ferroferric oxide-polyaniline-polyurethane solution; 3), dropping the carbon nanotube / ferroferric oxide-polyaniline-polyurethane solution onto a glass sheet for casting to form a thin film, putting the obtained thin film in a magnetic field for magnetic orientation, and drying at high temperature to obtain the anisotropic conductive macromolecule composite thin film. The preparation method is simple and easy to implement, high in result repeatability and easy to control.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Damage tolerant medium-strength titanium alloy

The invention discloses a damage tolerant medium-strength titanium alloy which is composed of, by mass, 5.5-7% of aluminum, 2.0-3.5% of zirconium, 2.0-3.5% of molybdenum, 2.0-3.5% of niobium and the balance of titanium and unavoidable impurities. Room-temperature tensile strength in an annealing state is 900-1000 MPa, room-temperature fracture toughness KIC is greater than or equal to 70 MPa.m1 / 2, and room-temperature fatigue crack propagation rate is da / dN is less than 3.5x10-5mm / cycle when R=0.1 and delta K=11 MPa.m1 / 2. The damage tolerant medium-strength titanium alloy does not contain element vanadium harmful to human body, element niobium difficult to being oxidized is added, raw material cost is not obviously increased generally while material performance is more stable, and safety and reliability of material application are improved.

Owner:WESTERN METAL MATERIAL

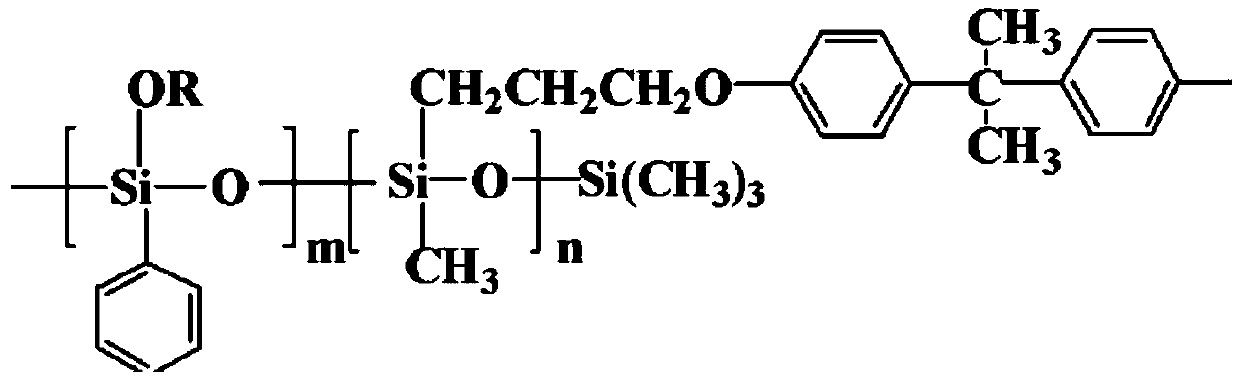

Organosilicon-modified epoxy resin, preparation method thereof and organosilicon-modified epoxy resin adhesive

ActiveCN109851759ASimple processNo pollution in the processNon-macromolecular adhesive additivesEpoxy resin adhesivesTemperature resistanceBisphenol

The invention belongs to the field of synthesis and processing of polymer materials, and particularly relates to organosilicon-modified epoxy resin, a preparation method thereof and an organosilicon-modified epoxy resin adhesive. The preparation method comprises the steps: under the protection of inert gas, mixing epoxy chloropropane with hydrogenated bisphenol A and a catalytic assistant, then adding an alkaline solution for a reaction so as to obtain a bisphenol A-epoxy resin reaction crude solution, mixing gamma-chloropropylmethyldialkoxysilane, phenyl trialkoxysilane and an organic solvent, then adding dilute hydrochloric acid for a reaction so as to obtain an organosilicon modifier intermediate, performing contact of the bisphenol A-epoxy resin reaction crude solution with the organosilicon modifier intermediate, adding alkali for a reaction, and performing separation, washing and drying so as to obtain the high temperature-resistant acid corrosion-resistant organosilicon-modifiedepoxy resin. Through the preparation method, preparation of organosilicon and blending of the organosilicon with an epoxy resin crude liquid can be completed in one step, and the operation is simpleand pollution-free; and the obtained adhesive has excellent impact resistance, high temperature resistance and acid corrosion resistance.

Owner:CHINA SHENHUA ENERGY CO LTD +1

Acidic corrosion-resistant X65 seamless steel pipeline and manufacturing method thereof

InactiveCN106319361AMeet the mechanical performance requirementsControl sulfur and phosphorus contentThermal insulationSteel pipeline

The invention discloses an acidic corrosion-resistant X65 seamless steel pipeline and a manufacturing method thereof. The acidic corrosion-resistant X65 seamless steel pipeline comprises, by weight, 0.08-0.16% of C, 0.15-0.35% of Si, 1.0-1.6% of Mn, 0.02-0.05% of Al, 0.03-0.049% of V, 0.01-0.04% of Ti, 0.20-0.30% of Cu, 0.20-0.30% of Ni, less than or equal to 0.015% of P and less than or equal to 0.005% of S. When C content is less than or equal to 0.12%, CE<Pcm> is less than or equal to 0.25 and when C content is greater than 0.12%, CE<IIW> is less than or equal to 0.42. According to the manufacturing method of the acidic corrosion-resistant X65 seamless steel pipeline, a continuous rolling method is used, a pipe blank is heated to a temperature of 1200-1300 DEG C through an annular furnace, a tube knockout temperature is in a range of 1190-1240 DEG C and a sizing temperature is in a range of 820-850 DEG C, in quenching and tempering treatment, a quenching heating temperature is in a range of 890-910 DEG C, a quenching medium is water, thermal insulation time is greater than or equal to 30min, a tempering temperature is in a range of 580-620 DEG C, thermal insulation time is greater than or equal to 50min, and heating straightening and flaw detection examination are carried out at a temperature greater than or equal to 400 DEG C.

Owner:ANGANG STEEL CO LTD

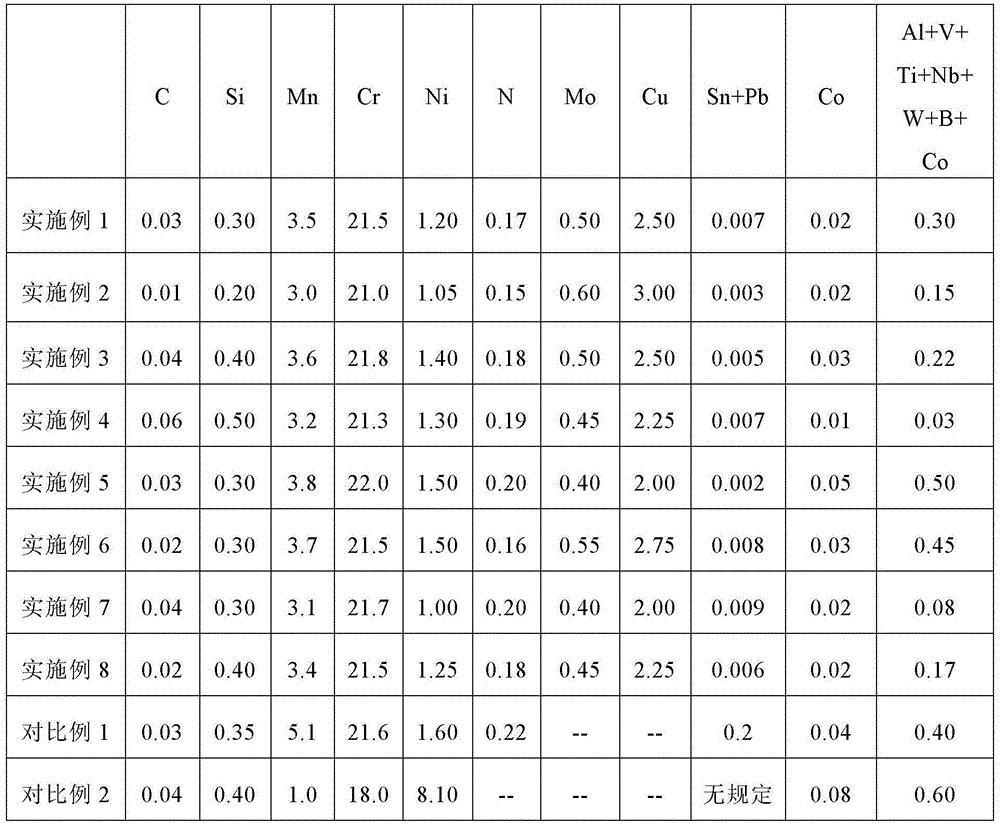

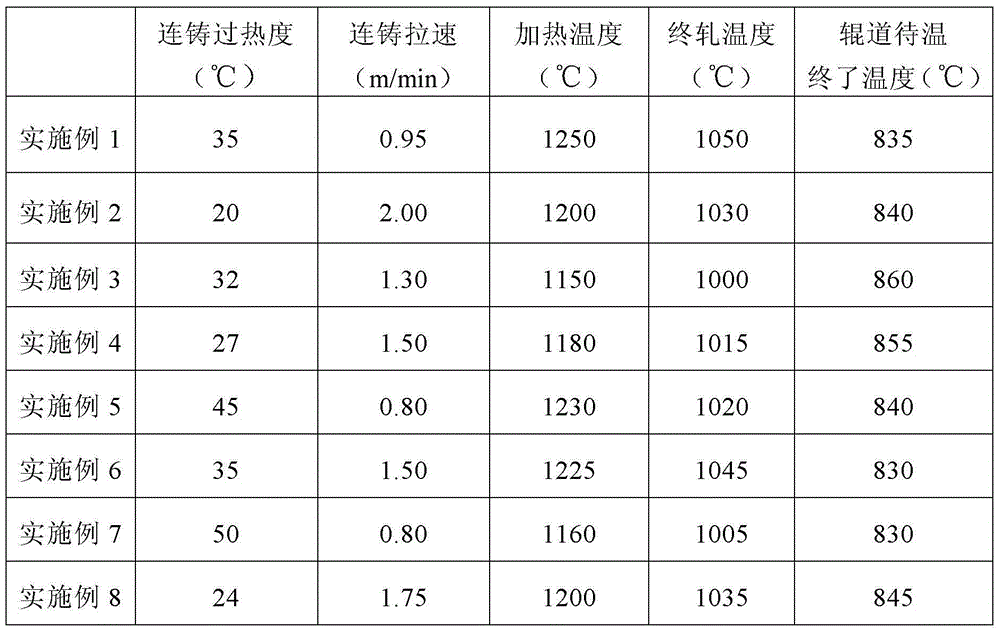

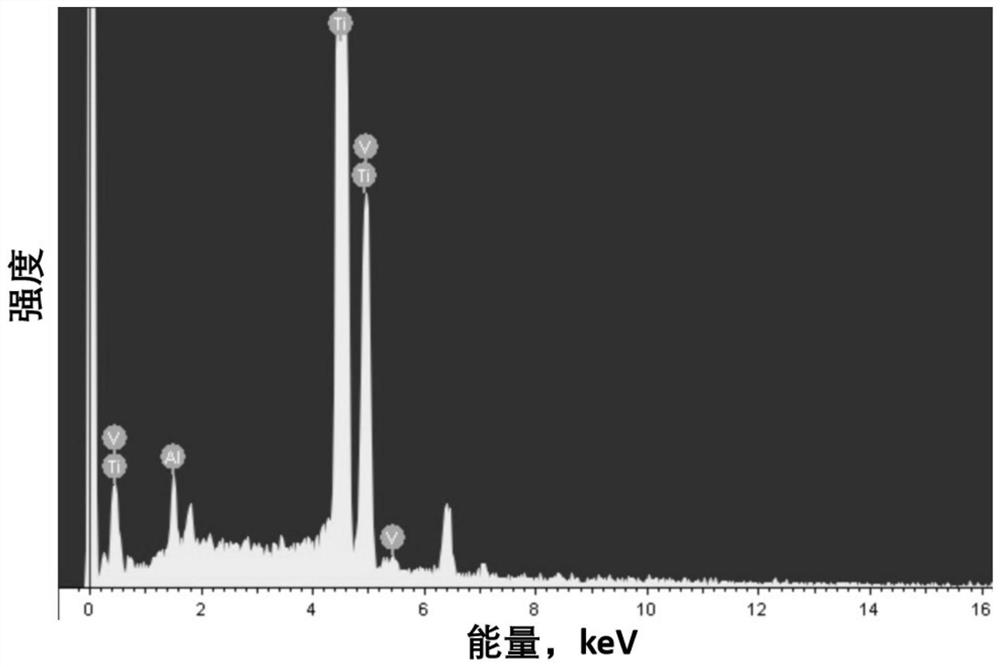

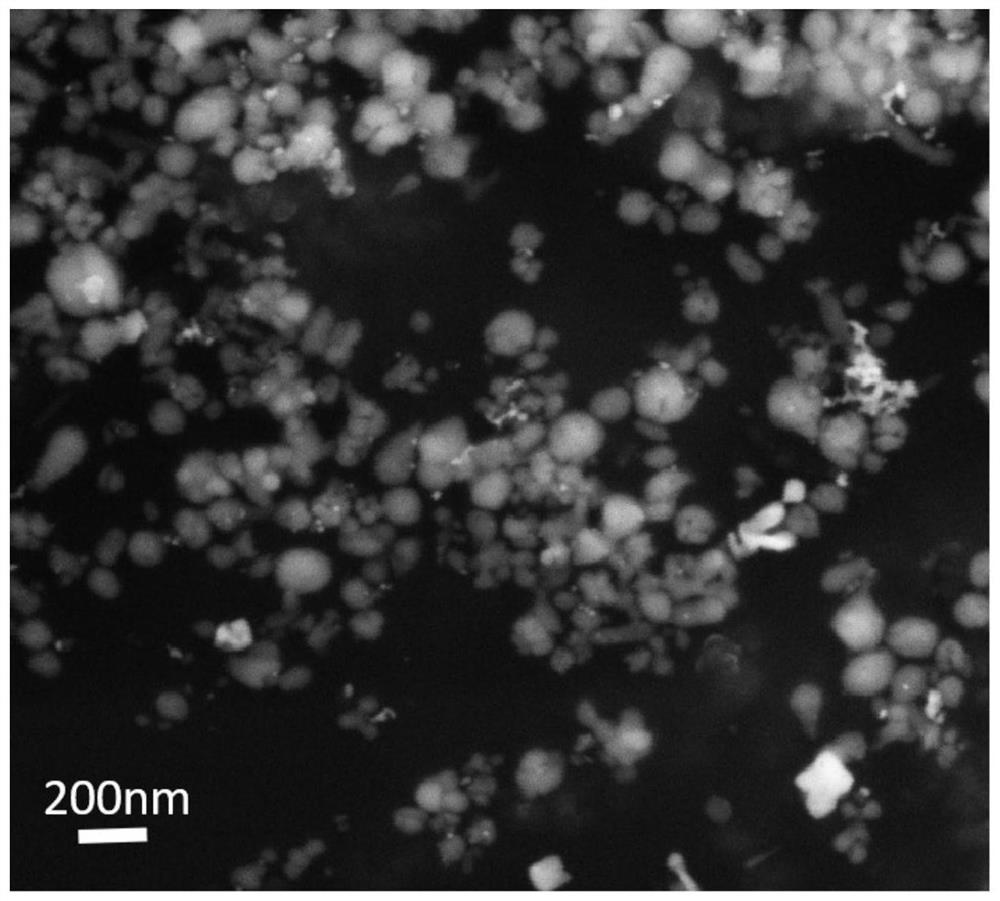

Acid-corrosion-resistant high-strength low-nickel duplex stainless steel and manufacturing method thereof

ActiveCN105441830AGood acid corrosion resistanceExcellent pickling corrosion resistanceNuclear powerAcid corrosion

Provided are acid-corrosion-resistant high-strength low-nickel duplex stainless steel and a manufacturing method thereof. The duplex stainless steel comprises the chemical components by the weight percentage: 0.01-0.06% of C, 0.20-0.50% of Si, 3.0-3.8% of Mn, 21.0-22.0% of Cr, 1.0-1.5% of Ni, 0.15-0.20% of N, 0.40-0.60% of Mo, 2.0-3.0% of Cu, less than or equal to 0.05% of Co, less than or equal to 0.01% of Sn, less than or equal to 0.01% of Pb, less than or equal to 0.5% of the total amount of W, B, Nb, Ti, Co, Al and V, and the balance Fe and inevitable impurities, wherein the ratio of Cu% to Mo% is 5 to 1. The duplex stainless steel has pitting corrosion resistance equivalent to that of S32101 and has acid corrosion resistance superior to that of the S32101, the corrosion resistance in boric acid and other acidic conditions is further improved, the risk of corrosion occurrence is reduced, and the yield strength is increased by 20% or more than that of the conventional S32101; the alloy cost is equivalent to that of the S32101; and ordinary raw materials can be used for smelting products satisfying nuclear power material standards.

Owner:BAOSTEEL DESHENG STAINLESS STEEL

Preparation method and application of aluminum-containing alloy powder and alloy strip

ActiveCN112143926AGood acid corrosion resistanceGood removal effectAdditive manufacturing apparatusTransportation and packagingMicron scalePtru catalyst

The invention relates to a preparation method and application of aluminum-containing alloy powder. The preparation method utilizes the characteristic that an initial alloy solidification structure contains a matrix phase and a dispersed particle phase, and removes the matrix phase through reaction of an acid solution, so that the dispersed particle phase is separated out, and the aluminum-containing alloy powder is obtained. The preparation method is simple in process, can be used for preparing nano-scale, sub-micron-scale, micron-scale and millimeter-scale aluminum-containing alloy powder with different morphologies, and can be applied to the fields of photoelectronic devices, wave-absorbing materials, catalysts, 3D metal printing, metal injection molding, anticorrosive coatings and the like.

Owner:赵远云

Waterproof concrete and preparation method thereof

The invention discloses waterproof concrete and a preparation method thereof, wherein the waterproof concrete is prepared from the following components in parts by weight: 300 to 350 parts of cement,600 to 700 parts of fine aggregate, 900 to 1000 parts of coarse aggregate, 100 to 120 parts of an admixture, 8 to 10 parts of an additive, 25 to 30 parts of a waterproof agent and 130 to 150 parts ofwater, wherein the preparation method of the waterproof agent comprises: taking 40-60 parts by weight of modified basalt fiber and 5-7 parts by weight of disproportionated potassium rosinate, uniformly stirring, adding 30-40 parts by weight of a UEA expanding agent, 3-5 parts by weight of sodium dodecyl sulfate and 3-5 parts by weight of ferrous sulfate, and uniformly stirring to obtain the waterproof agent. The waterproof concrete provided by the invention has excellent water resistance, excellent permeability resistance and excellent acid corrosion resistance.

Owner:成都新豪鼎盛建材有限公司

Metallic luster glaze and preparation method thereof

InactiveCN106587624AOptimize chemical compositionVenus-like metallic glazed effectTalcMaterials science

The invention discloses metallic luster glaze and a preparation method thereof. The metallic luster glaze consists of the following components in parts by mass: 10 to 20 parts of albite, 8 to 10 parts of boron frit, 10 to 12 parts of perlite, 15 to 17 parts of calcined kaolin, 40 to 50 parts of argil, 16 to 18 parts of vermiculite, 15 to 25 parts of sandy loam soil, 5 to 7 parts of zinc oxide, 6 to 8 parts of cristobalite, 10 to 20 parts of calcined talc, 6 to 7 parts of aluminium oxide, 14 to 18 parts of gypsum powder and 1 to 2 parts of a catalyst. According to the metallic luster glaze and the preparation method thereof, the chemical composition of the formula is optimized, a plurality of superfine ferric oxide crystallization grains are separated out of the glaze when the glaze is condensed at the high-temperature sintering later period, and a plurality of isolated single lamelliform crystal flowers which glitter like small gold foils are formed, so that the Venus-like metallic glaze effect is played.

Owner:钦州市高新技术产业服务中心

Preparation method of high-strength waterproof color ardealite brick

The invention discloses a preparation method of a high-strength waterproof color ardealite brick, which comprises the steps of selecting materials by a conventional method and mixing to obtain a mixed raw material of an ardealite brick; adding pigment and stirring; adding water and stirring; making the mixed slurry into a brick blank by a hydraulic vibration forming machine; curing with saturated steam to obtain a finished product. The color ardealite brick prepared by the method disclosed by the invention has the advantages of uniform tone, low cost, high strength, good water resistance and corrosion resistance and good durability and is suitable for wall construction and pavement construction. In the method disclosed by the invention, by improving the raw materials and method, the problems that the utilization rate of the ardealite brick is low in the prior art, the cost of the color brick is high and the color brick is not strong enough and not durable and the raw materials of the ardealite brick are not easily mixed with the pigment and consequently the tone is not uniform and the strength is not high are solved; meanwhile, the problems of unsatisfactory water resistance and durability of the ardealite brick are solved unexpectedly, a new path of ardealite utilization is created, and the problems of high cost and quality defect of color bricks are solved.

Owner:GUIZHOU KAILIN GRP CO LTD

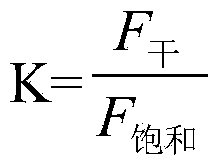

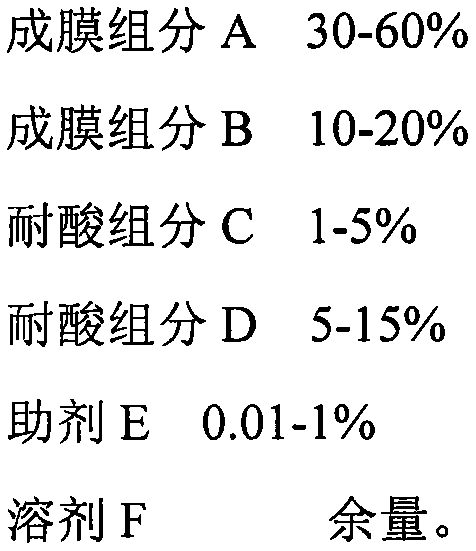

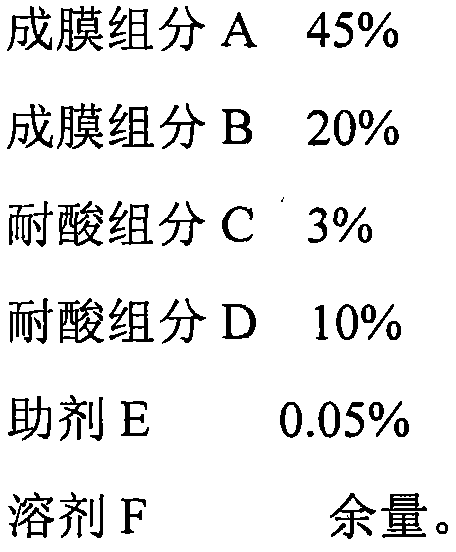

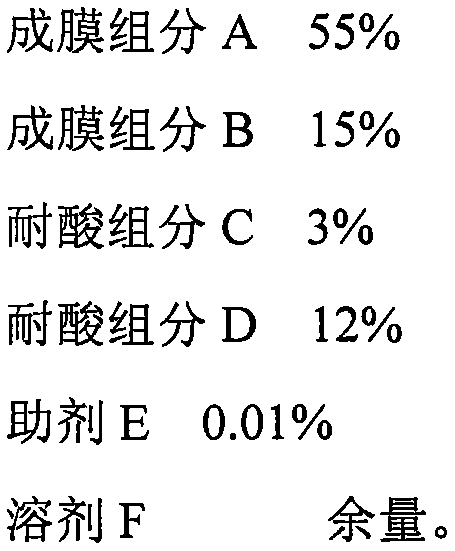

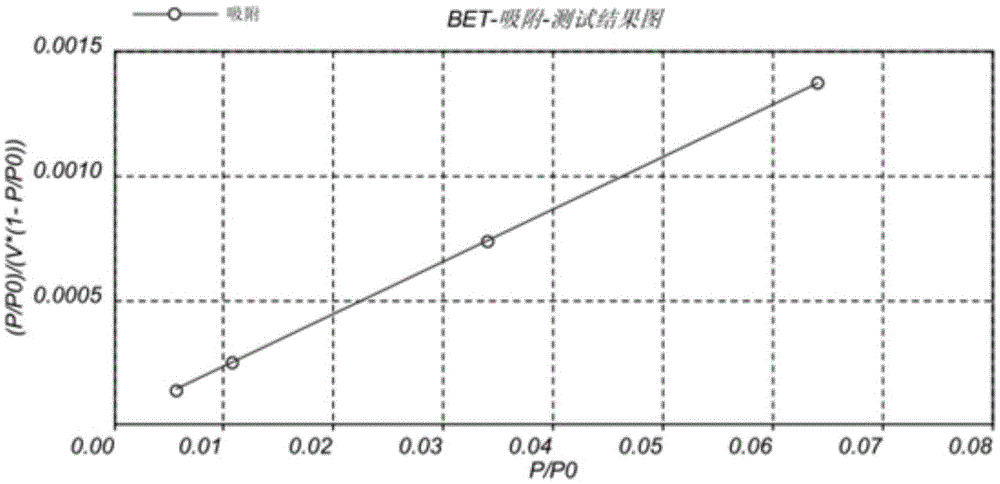

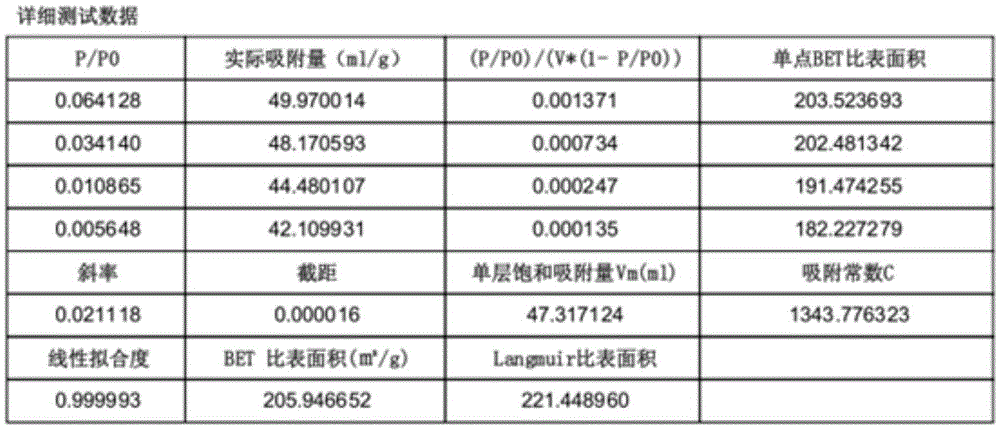

Acid-proof ink for protecting integrated touch screen and preparation method of acid-proof ink

The invention discloses acid-proof ink for protecting an integrated touch screen and a preparation method of the acid-proof ink. The acid-proof ink comprises components A to F. The component A contains polystyrene-polyurethane-unsaturated polyester resin; the polystyrene-polyurethane-unsaturated polyester resin is synthesized by virtue of a molecular design, and a controllable design of the structure and properties of a material is realized. A three-dimensional network structure is formed by virtue of chemical reaction between the film-forming components A and B, so that the acid resistance and the high temperature resistance of the ink, and the strippability of a film can be improved, and the protection effect of the ink to a substrate can be enhanced; (2) the acid corrosion resistance of the ink is further improved. The protective ink is excellent in acid resistance, excellent in film-forming property and excellent in film adhesion, and can be stripped completely after use; besides, the ink is excellent in high temperature resistance.

Owner:SHENZHEN GLITER PRINTING MATERIALS & EQUIP

Chemical anticorrosion teflon coating

InactiveCN105295590AIncrease crosslink densityImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyShock resistance

A chemical anticorrosion teflon coating is prepared from the following materials in parts by weight: 32 to 36 parts of silicon oxide sol, 10 to 16 parts of zirconia sol, 20 to 30 parts of teflon, 10 to 15 parts of epoxy resin, 10 to 15 parts of phenolic resin, 5 to 8 parts of kieselguhr, 5 to 10 parts of ultrafine ceramic powder, 5 to 10 parts of glass powder, 1 to 3 parts of carbon black, 20 to 30 parts of modified amine hardener, 10 to 20 parts of xylene, 10 to 20 parts of n-butyl alcohol and 1 to 3 parts of defoamer. The coating is used for chemical equipment inner wall anticorrosion, is convenient for construction, effectively resists the corrosion of strong corrosive exhaust gases (such as gases of SO2, NOx, HF and HCL) to a steel inner wall, and also effectively resists the corrosion of strong corrosive liquids (strong corrosive materials such as H2SO4, HCL and HF); meanwhile a paint film formed by the coating has higher abrasive resistance, temperature tolerance and heat and cold shock resistance.

Owner:无锡大塘复合材料有限公司

Sound absorbing material with tail gas clean-up function and preparation method thereof

The invention relates to a sound absorbing material with tail gas clean-up function and a preparation method thereof. The preparation method comprises the following step: by using continuous basalt fibers as a raw material, carrying out acid etching and high-temperature activation to modify the continuous basalt fibers. The method is simple and easy to operate. The sound absorbing material prepared by the preparation method has the advantages of high impact resistance, high temperature resistance, high acid resistance, favorable sound absorbing property and the like, and has the tail gas clean-up function.

Owner:SICHUAN AEROSPACE TUOXIN BASALT IND

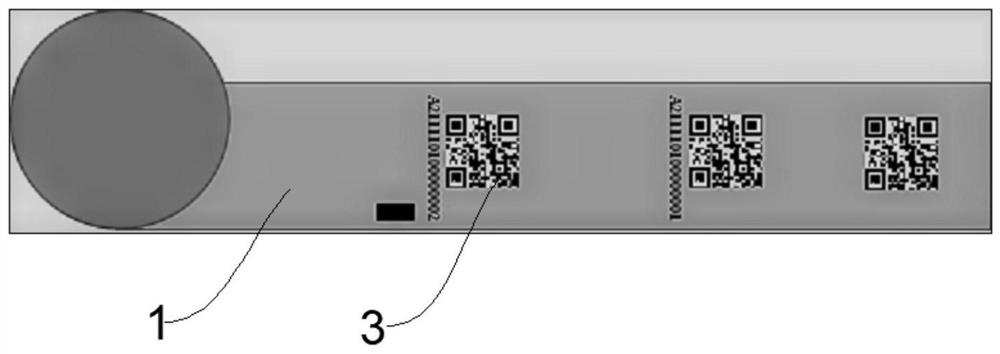

Traceable adhesive tape and preparation method thereof

PendingCN114196345AHigh precisionImprove clarityFilm/foil adhesive primer layersPolyureas/polyurethane adhesivesAdhesive beltEngineering

The invention provides a traceable adhesive tape. The traceable adhesive tape comprises a light-transmitting base material and an adhesive layer which are compounded with each other, the light-permeable base material comprises a first surface and a second surface which are arranged back to back; the first surface is a corona surface, and a digital printing marker is arranged on the corona surface; the first surface of the light-permeable base material is compounded with the adhesive layer. The traceable adhesive tape has the advantages of being high in recognition rate, simple in structure, high in adhesive layer adaptability and high in chemical resistance, and can be applied to industrial production and products, and tracing of production information of the products can be achieved.

Owner:DONGGUAN AOZON ELECTRONICS MATERIAL

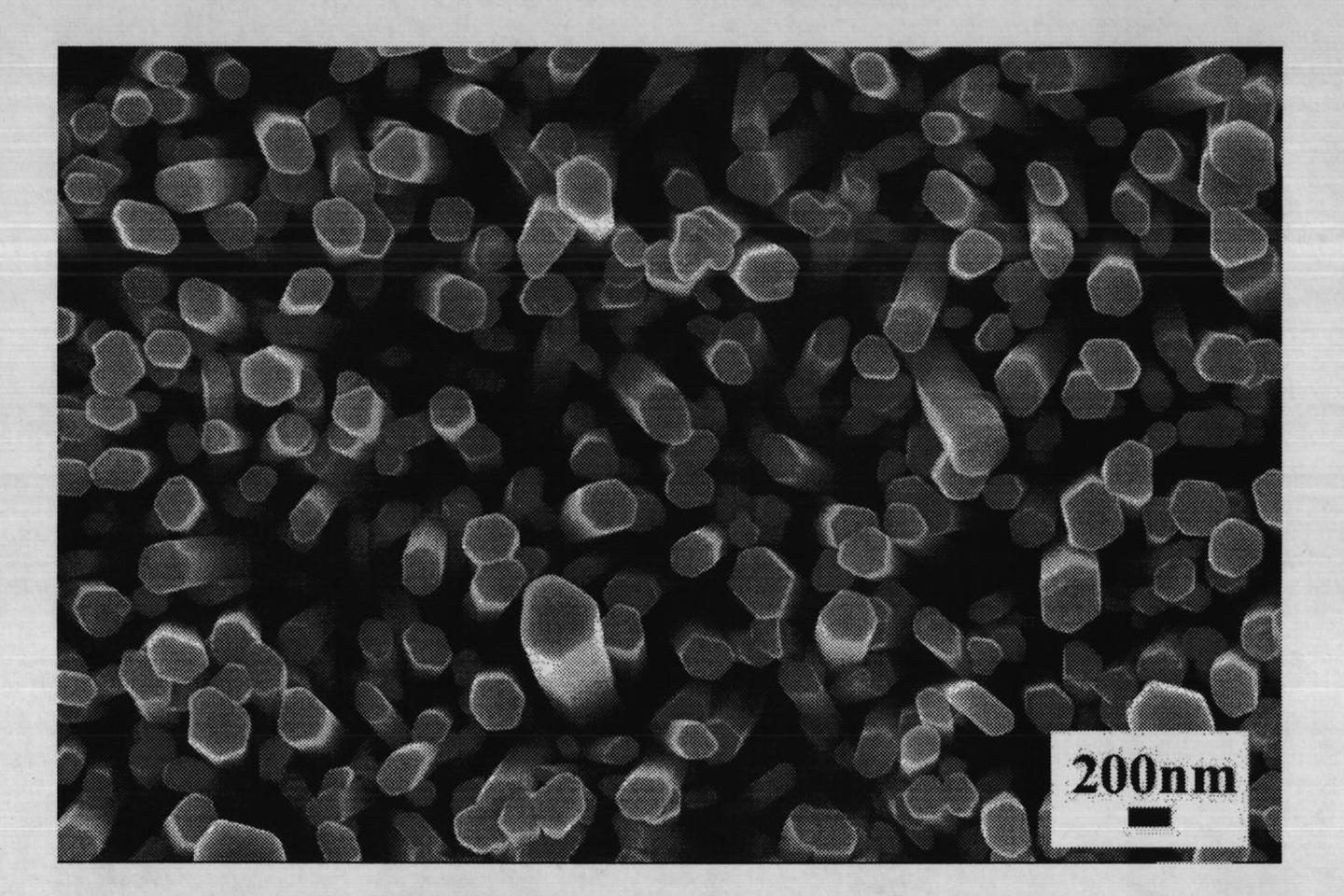

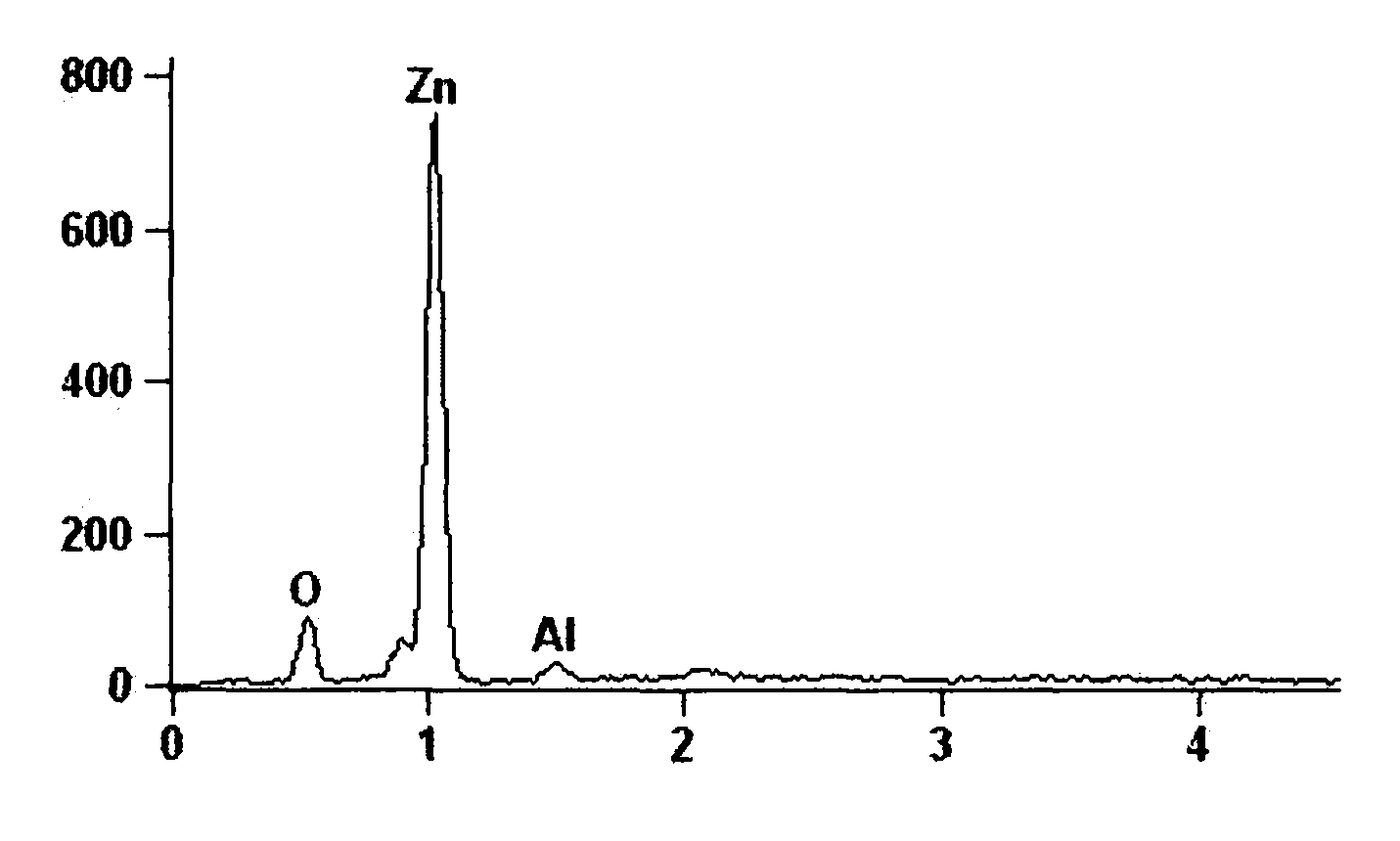

Method for preparing Al2O3-ZnO nanorod array composite electrode

InactiveCN102034612AGood acid corrosion resistanceAvoid corrosionLight-sensitive devicesSolid-state devicesComposite electrodeSeed crystal

The invention discloses a method for preparing an Al2O3-ZnO nanorod array composite electrode, which belongs to the technical field of nano materials. The method specifically comprises the following steps of: a, dissolving Zn(NO3)2 and (CH2)6N4 in the same molar weight into deionized water to prepare reaction solution at the concentration of 0.05 to 0.2 M; b, directly placing a conductive substrate serving as a growth substrate coated with a ZnO seed crystal layer into the solution, and performing reaction for 12 to 24 hours at 80 to 100 DEG C to obtain a ZnO nanorod array electrode; and c, coating alumina sol onto the surface of the ZnO nanorod array electrode by using a spin-coating method, and performing heat treatment to obtain the Al2O3-ZnO nanorod array composite electrode. The method effectively inhibits the corrosion of the surface of the ZnO electrode and the generation of a Zn<2+> / dye coordination compound; the sol spin-coating method is simple, and an Al2O3 thin film coating with a uniform surface and a large area can be obtained; and the thickness of the Al2O3 thin film coating can be rationally controlled by regulating the concentration, coating number of layers and sintering times of the sol. The performance of a dye sensitized solar cell assembled by the composite electrode is greatly stabilized.

Owner:UNIV OF SCI & TECH BEIJING

X52 seamless pipeline steel pipe with sour corrosion resistance and manufacturing method of X52 seamless pipeline steel pipe

InactiveCN106319362AMeet the mechanical performance requirementsControl sulfur and phosphorus contentRoll mill control devicesMetal rolling arrangementsPunchingSizing

The invention discloses an X52 seamless pipeline steel pipe with sour corrosion resistance and a manufacturing method of the X52 seamless pipeline steel pipe. The X52 seamless pipeline steel pipe comprises, by weight percent, 0.08%-0.16% of C, 0.15%-0.35% of Si, 1.0%-1.6% of Mn, 0.021%-0.05% of Al, 0.03%-0.049% of V, 0.21%-0.30% of Cu, 0.21%-0.30% of Ni, smaller than or equal to 0.015% of P, smaller than or equal to 0.005% of S, and the balance iron and inevitable impurities. When C is smaller than or equal to 0.12%, the carbon equivalent CEPcm is smaller than or equal to 0.25%, and when C is larger than 0.12%, CEIIW is smaller than or equal to 0.43. A continuous rolling method is adopted in the manufacturing method of the seamless pipeline steel pipe, in other words, a pipe blank obtained after continuous casting and continuous rolling is heated to 1,200 DEG C-1,300 DEG C through an annular furnace, the temperature ranges from 1,190 DEG C to 1,240 DEG C after punching, and the sizing temperature is controlled to range 820 DEG C to 850 DEG C. The seamless steel pipe is high in economical efficiency and good in corrosion resistance and can be widely applied to the fields of oil and gas well pipeline pipes in the sour corrosion environment and the like.

Owner:ANGANG STEEL CO LTD

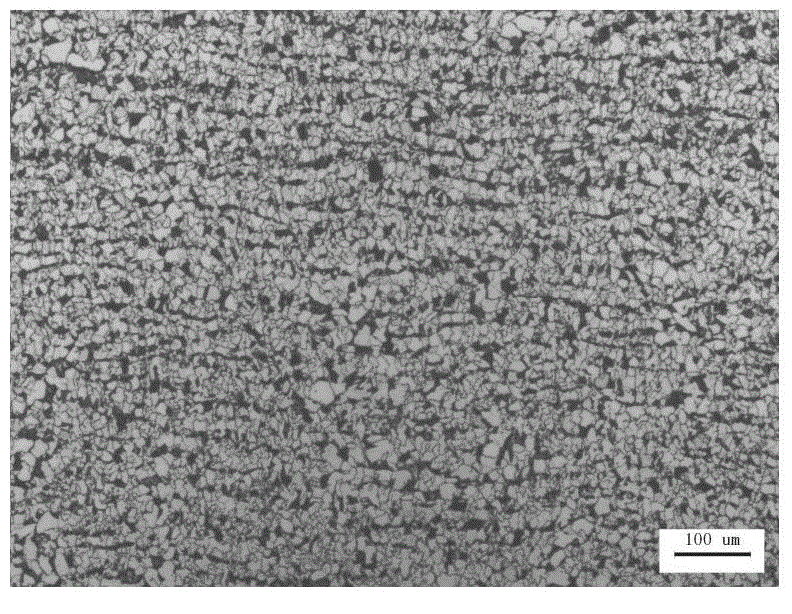

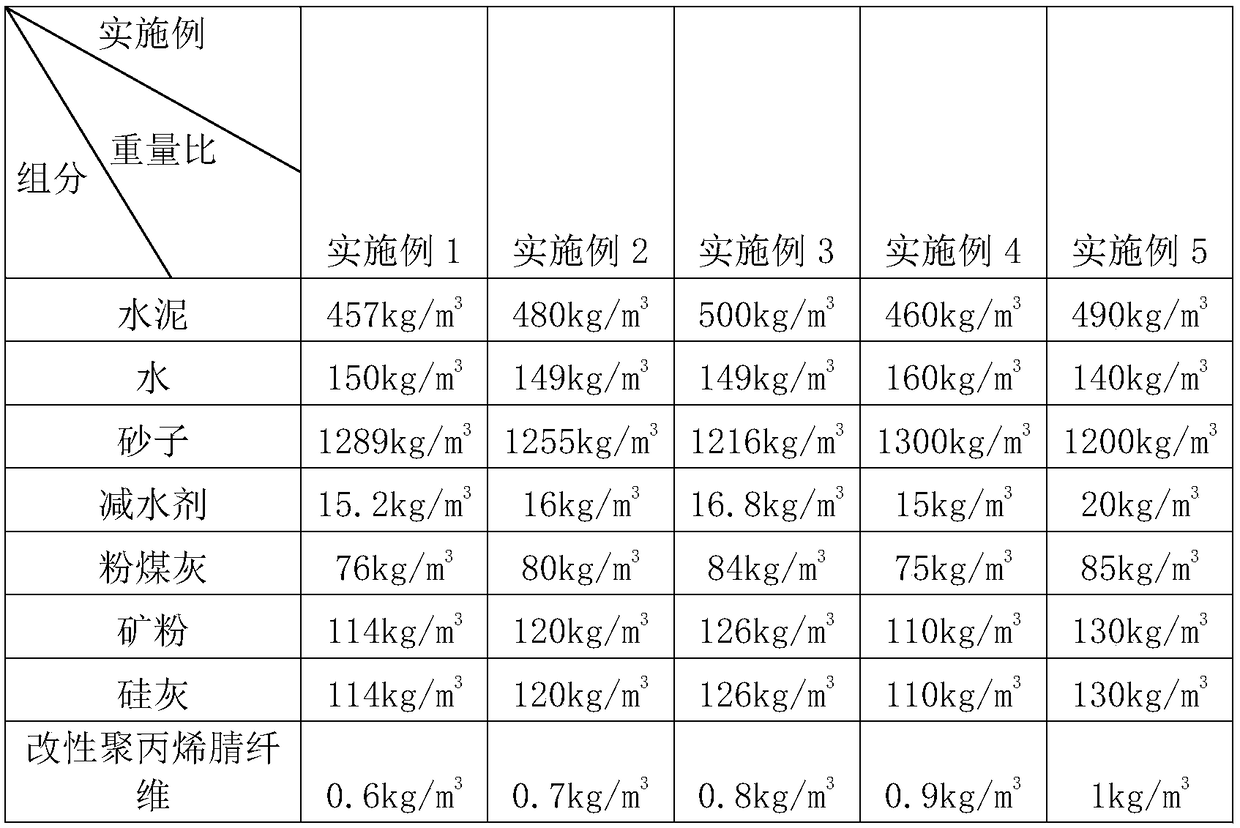

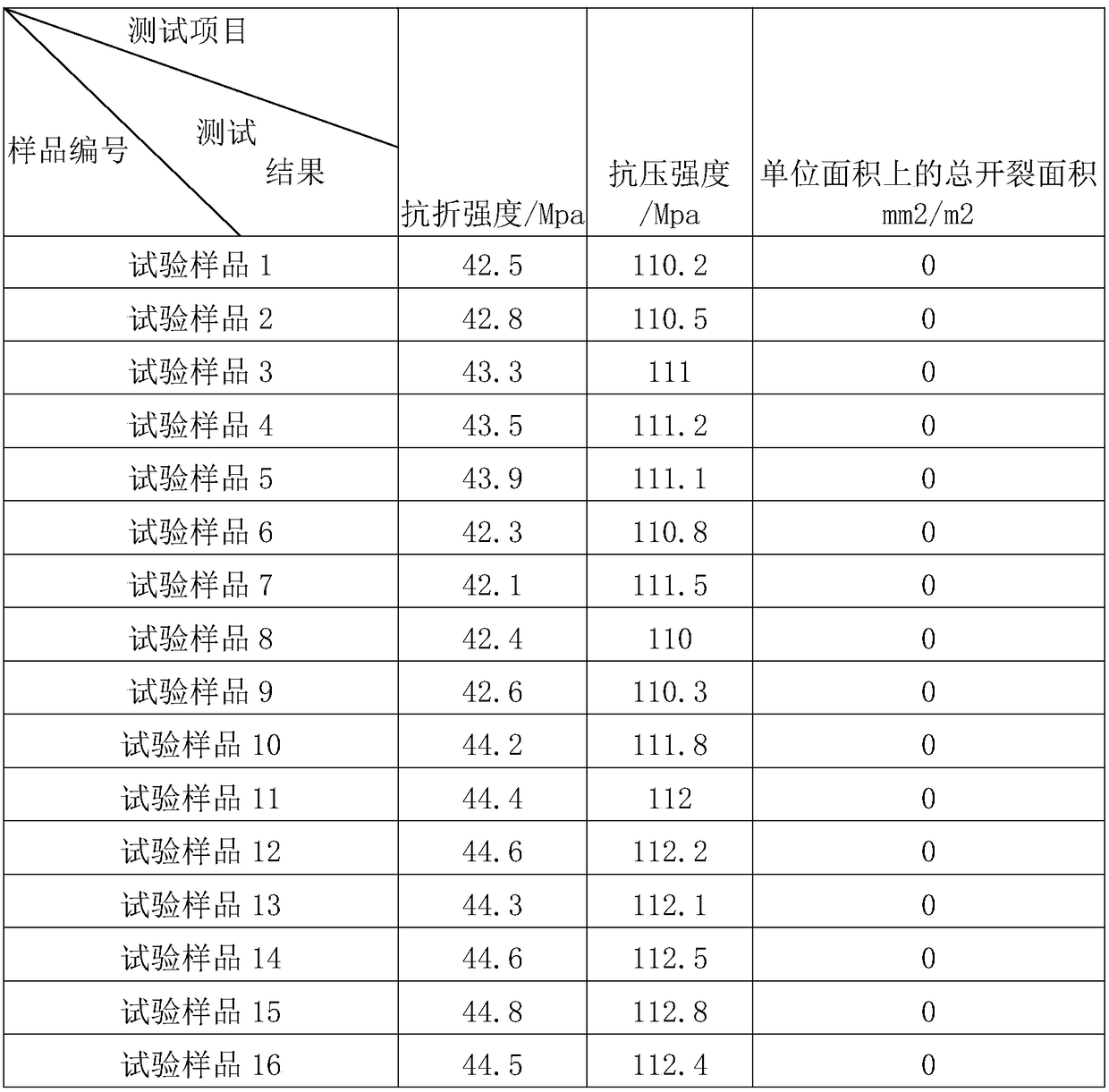

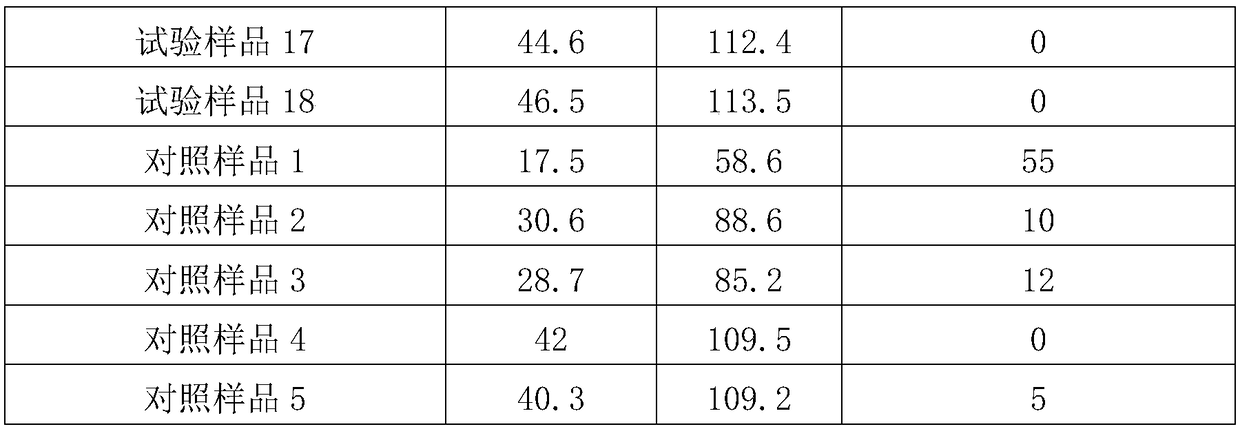

Concrete containing modified fibers and preparation method thereof

The invention discloses concrete containing modified fibers and a preparation method thereof, and relates to the technical field of concrete. A technical key point of the concrete is that the concretecontaining the modified fibers comprises the following raw materials according to a weight ratio: 450-500 kg / m<3> of cement, 140-160 kg / m<3> of water, 1200-1300 kg / m<3> of sand, 15-20 kg / m<3> of a water reducing agent, 75-85 kg / m<3> of coal ash, 110-130 kg / m<3> of mineral powder, 110-130 kg / m<3> of silica fume, and 0.6-1 kg / m<3> of modacrylic fibers, wherein the modacrylic fibers comprise polyacrylonitrile fibers and an anti-corrosion coating sprayed on the surface of the polyacrylonitrile fibers. The method is capable of improving alkali corrosion resistance of the polyacrylonitrile fibers,prolonging service life of the concrete, and improving breaking strength, anti-cracking ability, and compressive strength of the concrete.

Owner:厦门捷航工程检测技术有限公司

Processing technology for preparing high-strength concrete

InactiveCN110540390ATake advantage ofReduce processing costsSievingScreeningHigh strength concreteFiber

The invention discloses a processing technology for preparing high-strength concrete. The processing technology comprises the following steps: (1) raw material preparation: taking cement, sand, water,a water reducing agent, phenolic fiber and montmorillonite, wherein the sand is obtained by crushing construction waste by a crushing apparatus; (2) dry mixing: putting the cement, the sand, the water reducing agent, the phenolic fiber and the montmorillonite into a material mixing machine for dry material pre-mixing to obtain a mixture A after uniform mixing; and (3) wet mixing: putting the mixture A into a stirrer, adding water and a fine aggregate into the stirrer, and then performing uniform stirring to obtain the slurry-like concrete. According to the processing technology, the dry mixing operation is first performed before the wet mixing, so that a mixing uniformity degree of the dry powder materials is relatively high during mixing, and the processing technology ensures that various materials are all mixed together.

Owner:鄱阳县恒基建材有限公司

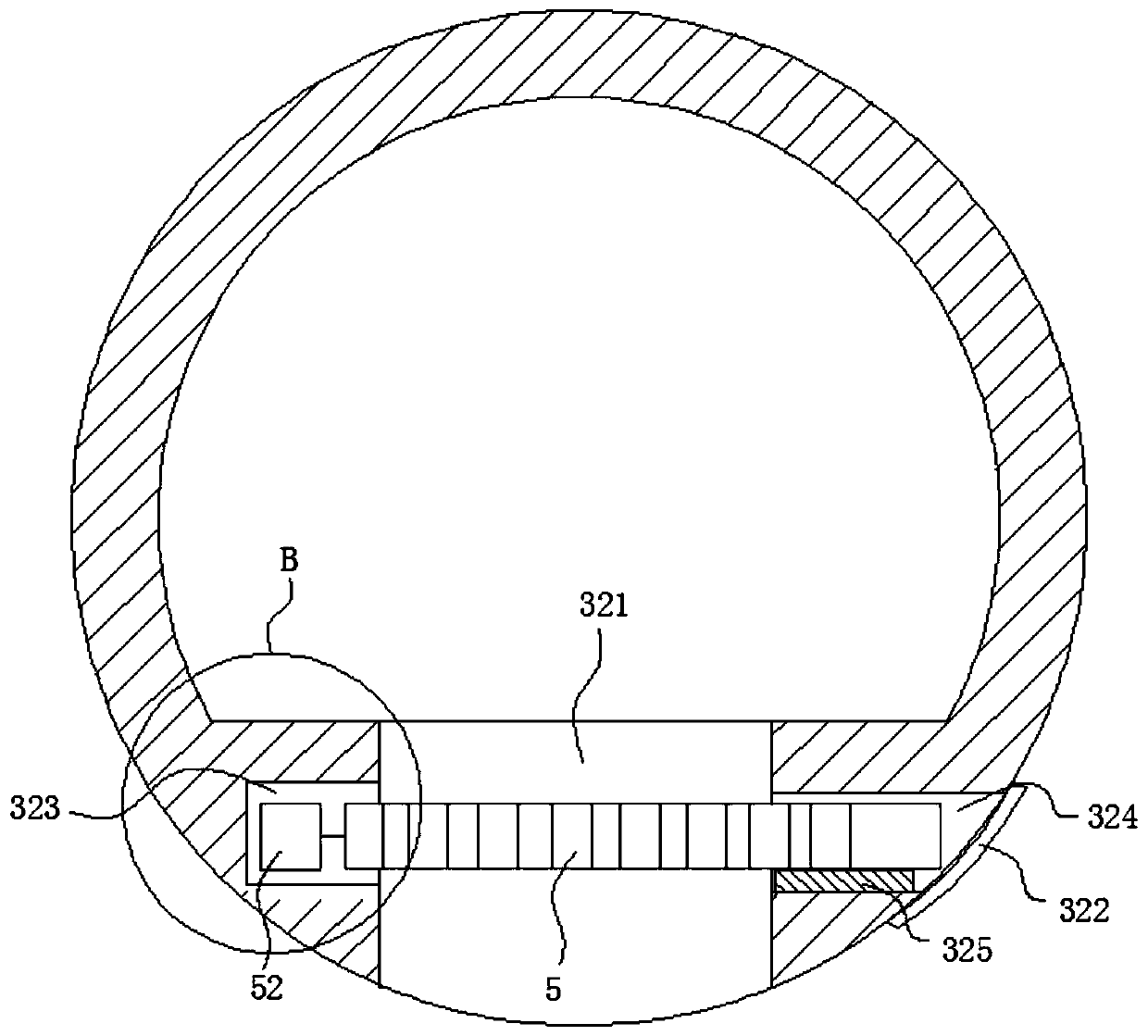

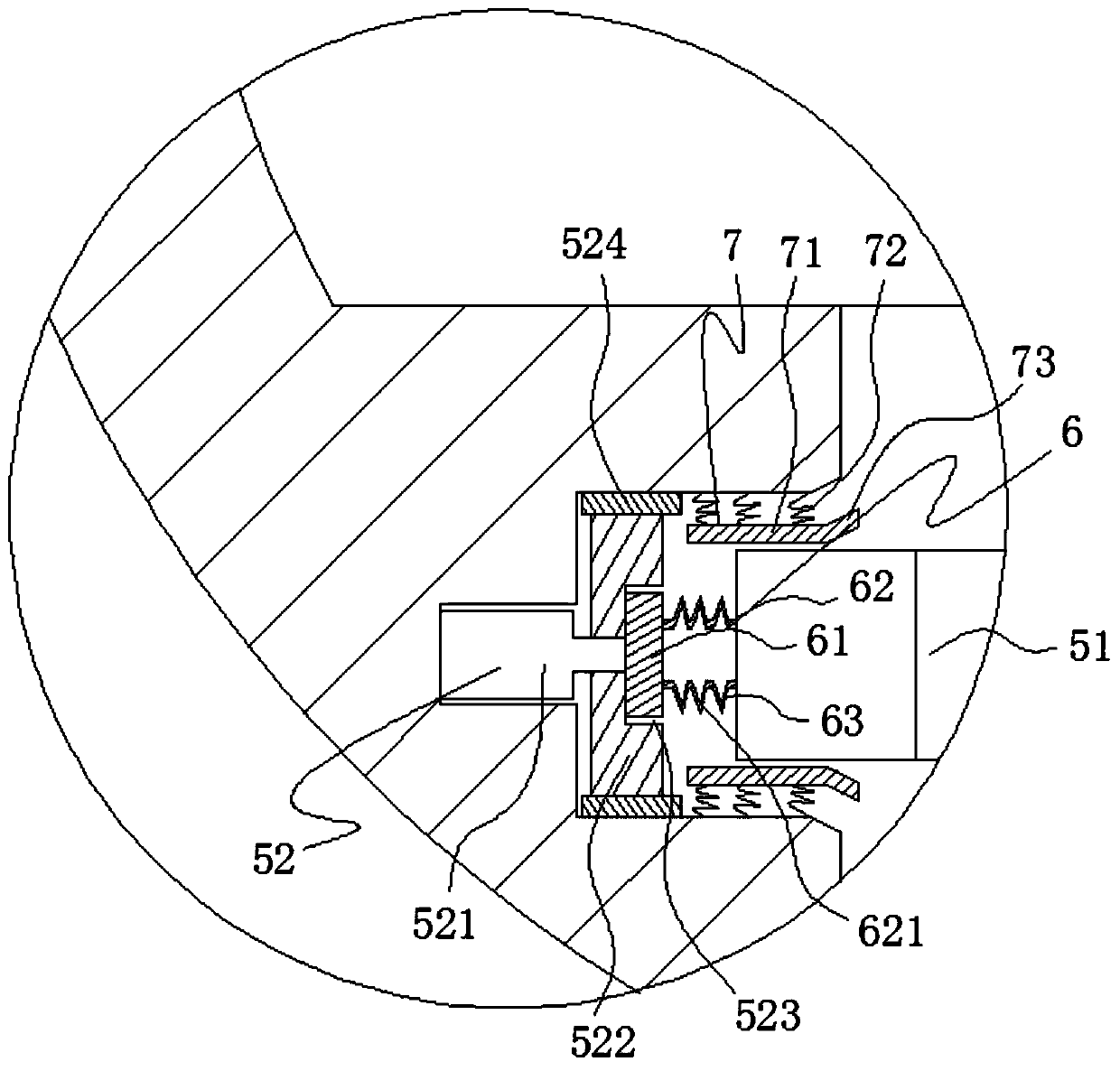

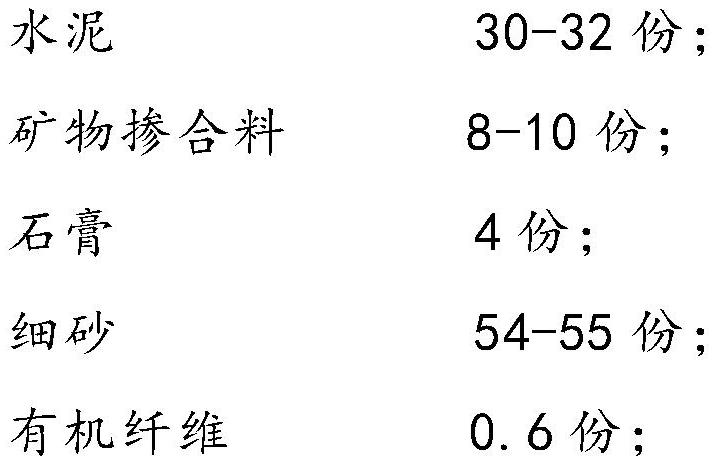

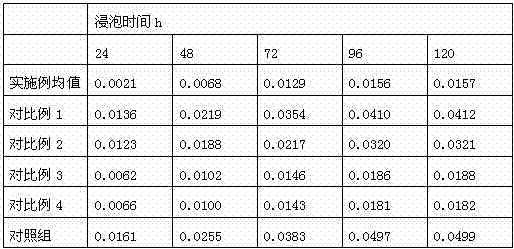

Acid-corrosion-resistant repair mortar and preparation method thereof

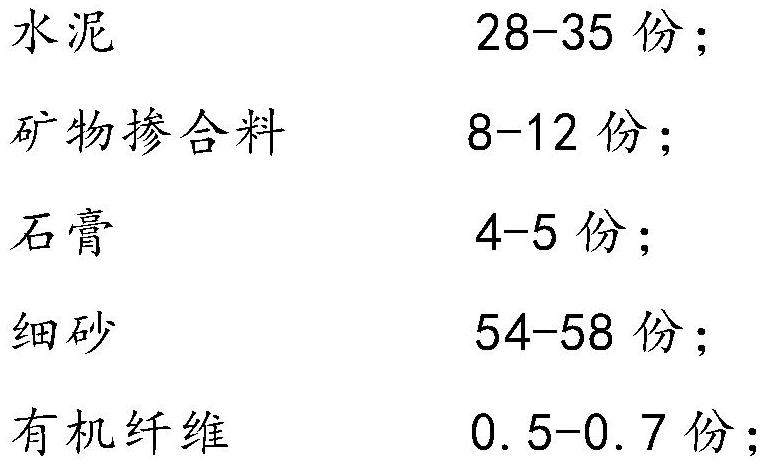

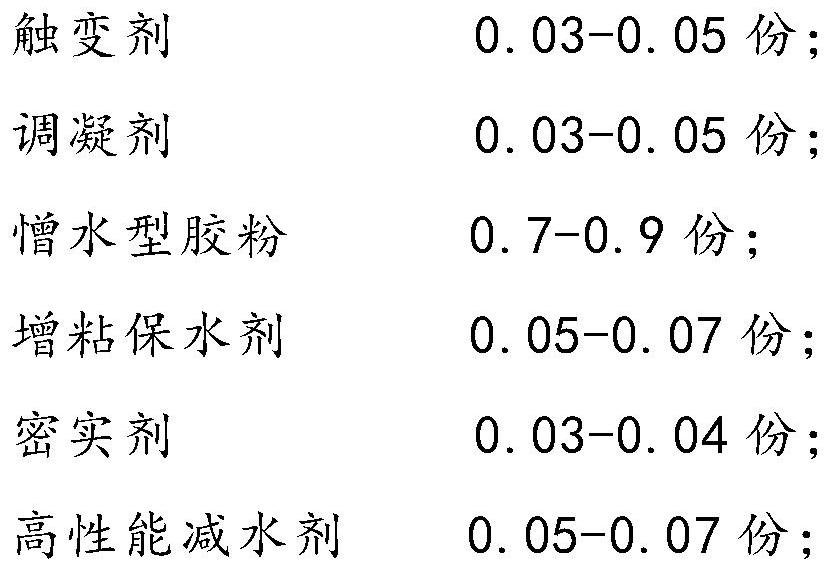

The invention discloses acid-corrosion-resistant repair mortar and a preparation method thereof. The acid-corrosion-resistant repair mortar comprises a mixture A, a mixture B and water, wherein the mixture A comprises the following components in parts by weight: 28-35 parts of cement; 8-12 parts of a mineral admixture, 4-5 parts of gypsum, 54-58 parts of fine sand, and 0.5-0.7 part of organic fiber, the mixture B is prepared from the following components in parts by weight: 0.03 to 0.05 part of a thixotropic agent, 0.03 to 0.05 part of a thickening time control agent, 0.7 to 0.9 part of hydrophobic rubber powder, 0.05 to 0.07 part of a tackifying water-retaining agent, 0.03 to 0.04 part of a compacting agent, and 0.05 to 0.07 part of a high-performance water reducing agent, the ratio of the weight part of the water to the total weight part of the mixture A and the mixture B is 0.13-0.17, and the cement is any one of aluminate cement, a mixture of aluminate cement and Portland cement and a mixture of aluminate cement and phosphate cement. According to the invention, aluminate cement is used as a main cementing material, and hydrophobic rubber powder and a compacting agent are used as auxiliary materials, so that the acid-corrosion-resistant repair mortar is prepared.

Owner:SHANGHAI MUNICIPAL SEWERAGE CO LTD

High-temperature corrosion-resistant coating and preparation method thereof, and high-temperature corrosion-resistant material

ActiveCN107903071AThe preparation process is simpleShort production cycleAcid corrosionProduction cycle

The invention discloses a high-temperature corrosion-resistant coating and a preparation method thereof, and a high-temperature corrosion-resistant material. The preparation method comprises the following steps: 1) providing the high-temperature corrosion-resistant coating so as to form a sol; 2) allowing the sol to generate a gelation reaction; 3) placing a substrate in the treated sol obtained in the step 2) so as to form a gel on the surface of the substrate; and 4) taking out the substrate with the surface formed with the gel, and subjecting the gel to drying treatment so as to form the high-temperature corrosion-resistant coating, wherein the step of drying treatment is performed in a drying box at 50 to 100 DEG C for 0.5 h to 10 h. According to embodiments of the invention, the preparation method for the high-temperature corrosion-resistant coating can form a coating with excellent wear resistance, acid corrosion resistance and high-temperature corrosion resistance on the surfaceof the substrate, has the advantages of simple and convenient preparation process, short production period, low cost and high safety, can realize large-scale production and application, and is also applicable to formation of a coating on the surface of a special-shaped part.

Owner:优澎(嘉兴)新材料科技有限公司

Treatment method for improving acid corrosion resistance of chemical pump shaft

InactiveCN107312918AImproved resistance to intergranular corrosionImprove surface qualityFurnace typesMetallic material coating processesSolution treatmentAfter treatment

The invention discloses a treatment method for improving the acid corrosion resistance of chemical pump shafts, which includes: (1) solid solution treatment and irradiation treatment; (2) phosphating treatment; (3) cleaning and drying; after being treated by the method of the invention The high-quality pump shaft can fully dissolve the carbide and ferrite in the pump shaft material structure in the austenite matrix, thereby obtaining a single austenite structure, and greatly improving the corrosion resistance of the stainless steel pump shaft.

Owner:ANHUI LUYUAN PUMP&VALVE CO LTD

Filling resin of electrolytic zinc negative plate stripping mouth and processing technology thereof

The invention discloses a filling resin of an electrolytic zinc negative plate stripping mouth and a processing technology thereof. The filling resin is prepared by mixing component A and component B at a weight ratio of 2:1; the component A comprises bisphenol-F-epoxy resin, a epoxy resin diluent, a flexibilizer, silicon carbide filling material, a hydrolytic stabilizer and an adhesion promoter; and the component B comprises polyamide 650 curing agent, polysulfide rubber flexibilizer, mica and a color paste. Optimized selection and reasonable combination of raw materials with different performances, and a double-component mixing process are employed in the preparation of the filling resin, so that the filling resin is capable of solidifying quickly at room temperature, and possesses high bonding strength and peeling resistance after solidification, and also possesses excellent acid corrosion resistance, high temperature resistance, ageing resistance, and current shock resistance. The insulativity is high, cost is low, and storage requirements are few. The filling resin is easy to produce, is non-toxic, and is appropriate to be used as the filling resin of the electrolytic zinc negative plate stripping mouth.

Owner:云南曲靖润扬商贸有限公司

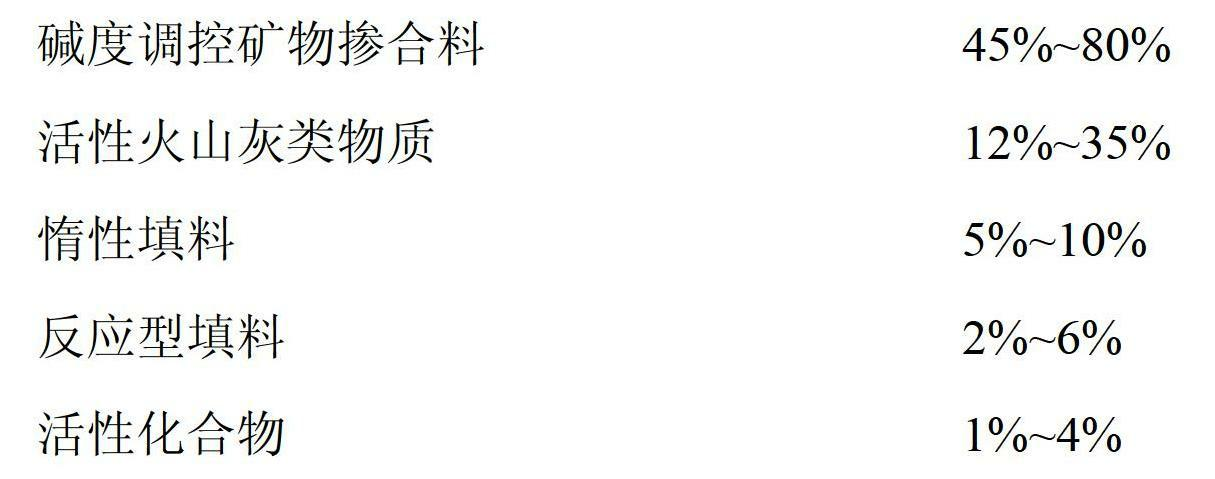

Multi-functional acid-resistant concrete gel powder

InactiveCN102674744AImprove volume stabilityGood acid corrosion resistanceEconomic benefitsAcid corrosion

The invention relates to multi-functional acid-resistant concrete gel powder. The multi-functional acid-resistant concrete gel powder comprises the following components in percentage by weight: 45 to 80 percent of mineral admixture for basicity regulation and control, 12 to 35 percent of active volcanic ash substances, 5 to 10 percent of inert filler, 2 to 6 percent of reactive filler and 1 to 4 percent of active compound. The multi-functional acid-resistant concrete gel powder can remarkably improve the acid corrosion resistance of cement concrete, reduce the risks of surface burst, peeling and strength reduction of concrete under acid environment erosion conditions, and remarkably improve the permeability resistance and volume stability of concrete matrixes, is convenient to construct, and has a remarkable economic benefit. The multi-functional acid-resistant concrete gel powder can be widely applied to concrete works such as ports, wharves, plants, sewage treatment plants, tunnels, roads, bridges and civil buildings which serve in acid environments.

Owner:JIANGSU SOBUTE NEW MATERIALS

Corrosion-resistant metal porous material and preparation method and application thereof

PendingCN111910166AGood filtration performanceLow reaction temperatureChemical vapor deposition coatingFluorhydric AcidComposite material

The invention provides a corrosion-resistant metal porous material and a preparation method and application thereof, and relates to the technical field of metal porous materials. The corrosion-resistant metal porous material comprises a metal porous material base material and a corrosion-resistant deposition layer metallurgically bonded on the surface of a porous framework of the metal porous material base material through chemical vapor deposition, wherein the corrosion-resistant deposition layer is a metal Ta layer or a metal Mo layer or an alternate composite layer of the metal Ta layer andthe metal Mo layer. The metal porous material can be bonded with Ta and Mo at a melting point far lower than that of Ta and Mo through chemical vapor deposition, and the chemical vapor deposition hashigh diffractivity, so that Ta and Mo can evenly and compactly surround the surface of the metal porous framework, and the corrosion resistance of the metal porous material is improved. The corrosion-resistant metal porous material has good corrosion resistance in sulfuric acid, hydrofluoric acid, hydrochloric acid, nitric acid and mixed acid of the sulfuric acid, the hydrofluoric acid, the hydrochloric acid and the nitric acid.

Owner:WESTERN METAL MATERIAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com