Organosilicon-modified epoxy resin, preparation method thereof and organosilicon-modified epoxy resin adhesive

An epoxy resin and organosilicon technology, applied in the field of organosilicon modified epoxy resin, its preparation, and organosilicon modified epoxy resin adhesive, can solve the problem of harsh synthesis conditions, cumbersome preparation process, and inability to carry out continuous Operation and other problems, to achieve the effect of improved elongation at break, simple process, and obvious effect of high and low temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

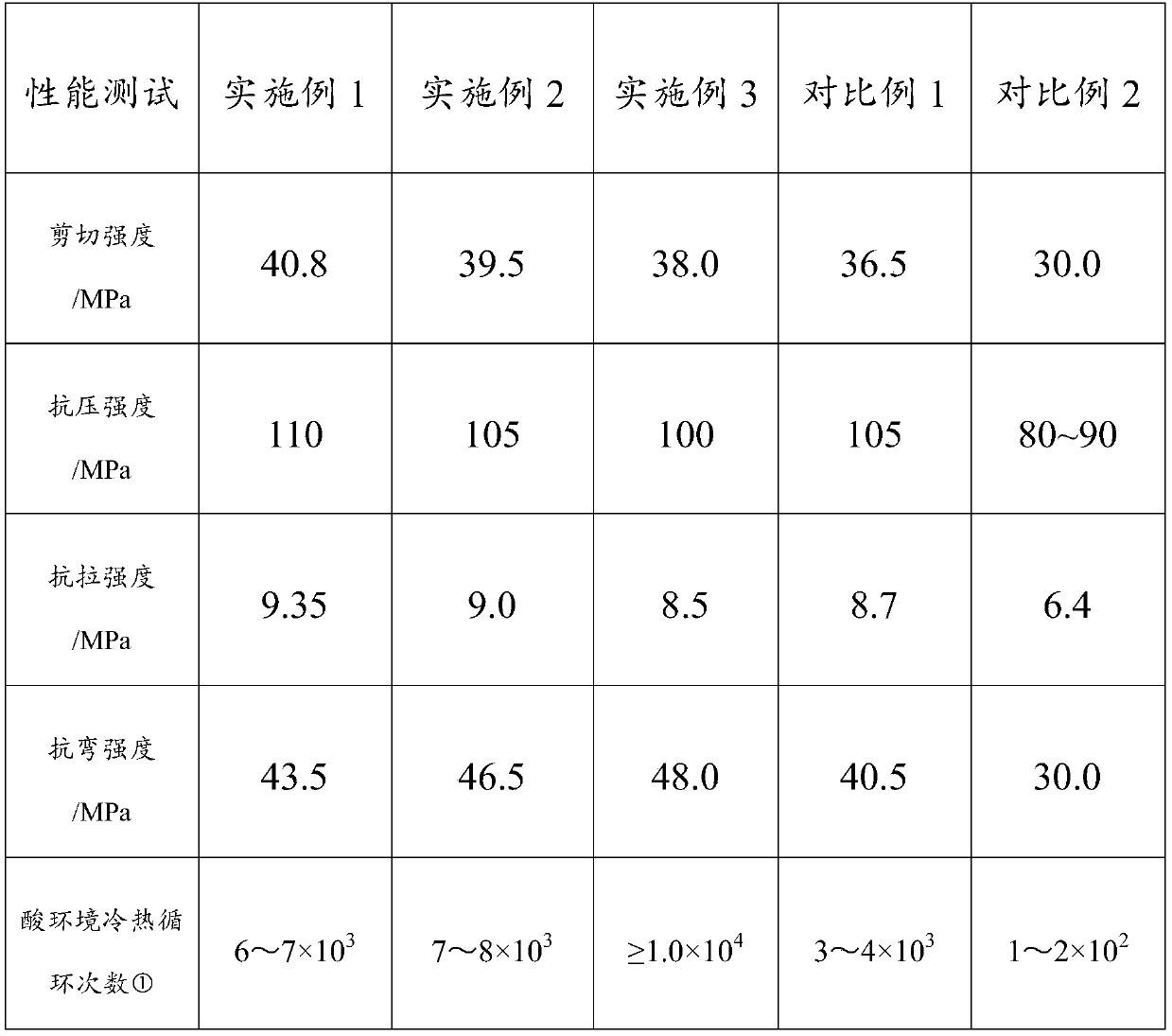

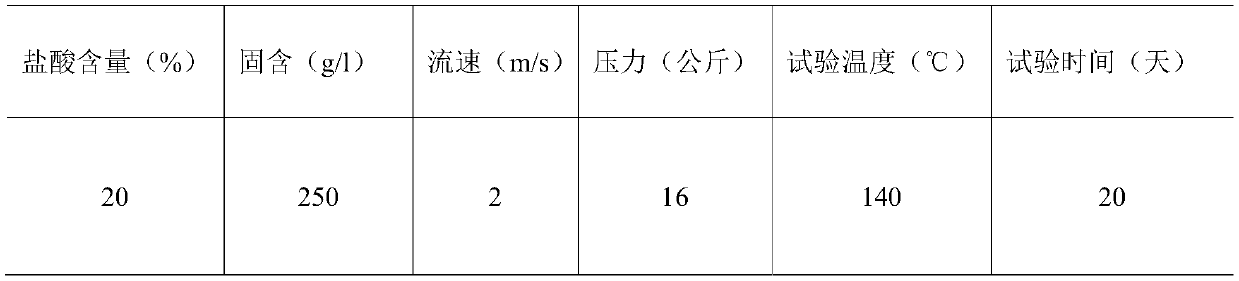

Examples

preparation example Construction

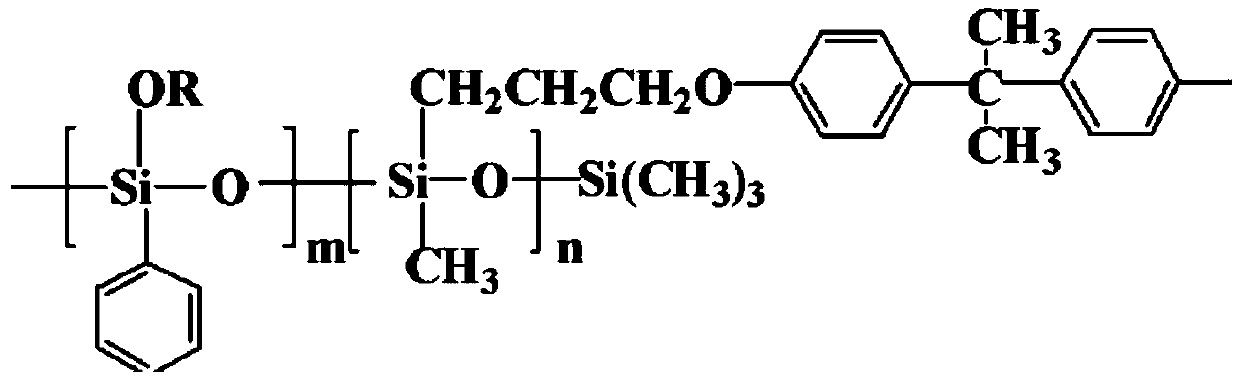

[0042] A preparation method of organosilicon modified epoxy resin, comprising the steps of:

[0043] (1) Under the protection of an inert gas, mix epichlorohydrin with hydrogenated bisphenol A and a catalyst promoter to form a mixed solution; Oxygen resin reaction crude liquid;

[0044] (2) Mix γ-chloropropylmethyldialkoxysilane, phenyltrialkoxysilane and organic solvent at 80-90°C, add dilute hydrochloric acid and react for 4-6 hours, remove the water layer to obtain organic Silicon modifier intermediate;

[0045](3) The bisphenol A epoxy resin reaction crude liquid is contacted with the organic silicon modifier intermediate, and an alkaline solution is added to react, and after separation, washing and drying, a high temperature-resistant and acid-resistant organic silicon modifier is obtained. permanent epoxy resin;

[0046] The alkaline solution described in step (1) and step (3) is an alkali metal hydroxide solution.

[0047] According to the preparation method provide...

Embodiment 1

[0085] (1) In a helium atmosphere protection, add 3mol epichlorohydrin, 0.8mol hydrogenated bisphenol A, and 0.2g glycerol into a vacuum reactor, heat and stir at 40°C to dissolve completely; Concentration is that 35% potassium hydroxide aqueous solution is joined in the reactor, and reaction temperature is 45 ℃, and reaction duration is 2h; Reactor is evacuated to 100KPa, and 70g concentration is added for the second time and is 35% potassium hydroxide solution, and reaction temperature 55°C, the reaction time is 5h;

[0086] (2) Add 0.07mol of γ-chloropropylmethyldiethoxysilane, 0.1mol of phenyltriethoxysilane and 110g of toluene organic solvent into the reaction kettle, heat up to 80°C and stir to mix, drop Add 18 g of dilute hydrochloric acid with a mass concentration of 7%, react for 6 hours, and remove the water layer after cooling to obtain the intermediate of the organosilicon modifier;

[0087] (3) the bisphenol A epoxy resin reaction crude liquid that 50g step (1) m...

Embodiment 2

[0091] (1) In a helium atmosphere protection, add 2.6mol epichlorohydrin, 0.5mol hydrogenated bisphenol A, and 0.2g glycerol trimethyl ether into a vacuum reactor, heat and stir at 45°C to dissolve completely; 50g of sodium hydroxide solution with a mass concentration of 40% was added to the reactor, the reaction temperature was 55°C, and the reaction duration was 1.5h; the reactor was evacuated to 100KPa, and 50g of hydrogen with a mass concentration of 40% was added for the second time Sodium oxide solution, the reaction temperature is 60°C, the reaction time is 4.5h; the reaction kettle is evacuated to 22KPa;

[0092] (2) Add 0.03mol of γ-chloropropylmethyldiethoxysilane, 0.1mol of phenyltriethoxysilane and 100g of toluene organic solvent into the reaction kettle, heat up to 85°C, stir and mix, drop Add 15.5 g of dilute hydrochloric acid with a mass concentration of 6%, react for 5.5 hours, and remove the water layer after cooling to obtain the intermediate of the organosil...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com