Magnetic particle with high antioxidant for magnetic flow liquid and preparation method thereof

A technology of magnetic particles and magnetorheological fluids, applied in the direction of magnetic fluids, etc., can solve the problems of high price, unfavorable magnetorheological fluids, and no public reports in domestic and foreign literatures, and achieve high acid corrosion resistance and good oxidation resistance performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The raw materials used in the embodiment are as follows:

[0033] Reduced iron powder (analytical grade) was provided by China National Pharmaceutical (Group) Shanghai Chemical Reagent Company.

[0034] Absolute ethanol (analytical grade) was provided by Shanghai Sanaisi Reagent Co., Ltd.

[0035] Ammonia water (analytical pure), China Pharmaceutical Group Shanghai Chemical Reagent Co., Ltd.

[0036] Orthoethyl silicate (TEOS), China Pharmaceutical Group Shanghai Chemical Reagent Co., Ltd.

[0037] The ratio of raw materials used is as follows:

[0038] 100 parts (weight) of reduced iron powder

[0039] Tetraethyl silicate 5 parts (weight)

[0040] 30 parts of ammonia water (weight)

[0041] 100 parts (weight) of absolute ethanol

[0042] nano-SiO 2 Preparation of film-coated magnetic particles:

[0043] Weigh 100g of iron powder, place it in 100g of absolute ethanol, add 5g of tetraethyl orthosilicate, stir and disperse fully, slowly add 30g of ammonia water wi...

Embodiment 2

[0050] The ratio of raw materials used is as follows:

[0051] 100 parts (weight) of reduced iron powder

[0052] Tetraethyl silicate 100 parts (weight)

[0053] Ammonia 15 parts (weight)

[0054] 500 parts (weight) of absolute ethanol

[0055] 30 parts of deionized water (by weight)

[0056] nano-SiO 2 Preparation of film-coated magnetic particles:

[0057] Weigh 100g of iron powder, put it in 500g of absolute ethanol, add 30g of tetraethyl orthosilicate, stir and disperse fully, slowly add 15g of 25% ammonia water and 30g of deionized water dropwise, at a stirring speed of 500rpm React at room temperature for 24 hours. After the reaction, first wash with absolute ethanol and filter, then wash with deionized water, magnetically separate, and then wash with deionized water, repeating several times to remove the remaining TEOS and SiO 2 Sol and SiO not coated on the surface of iron powder 2 particles.

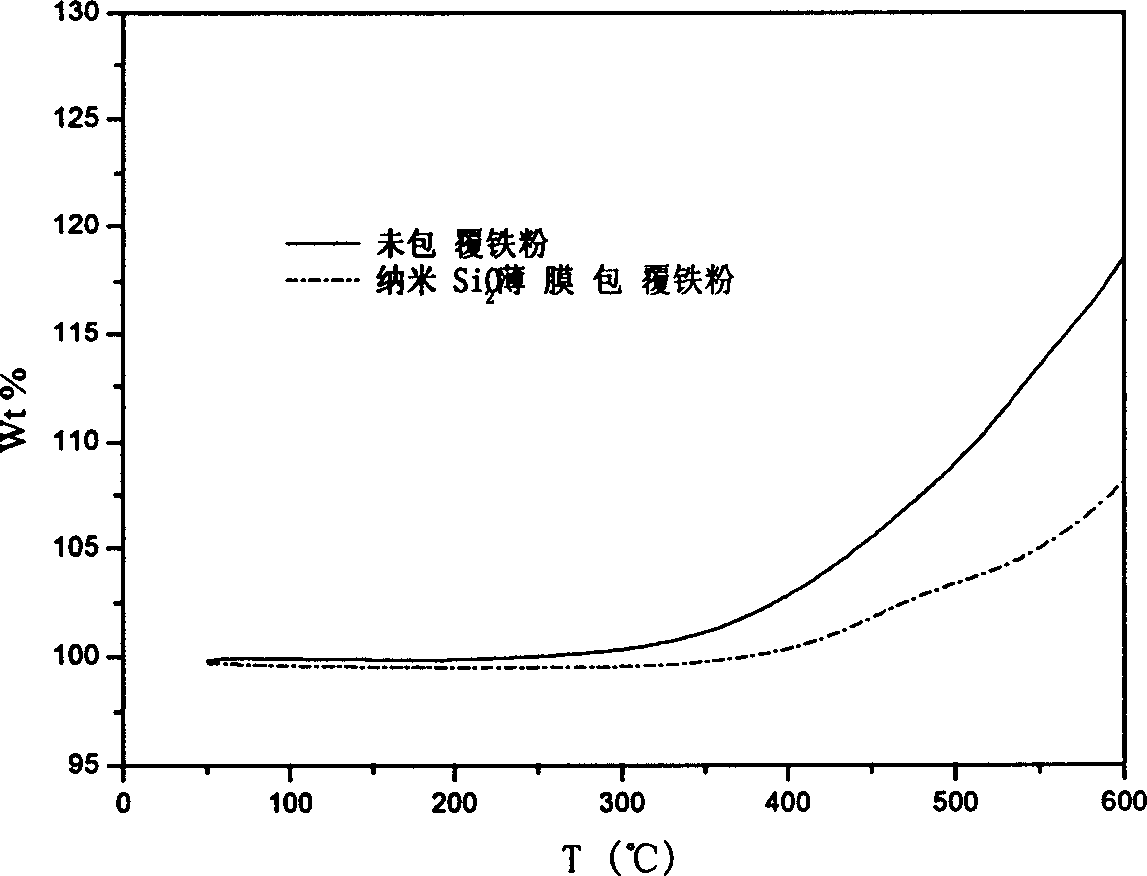

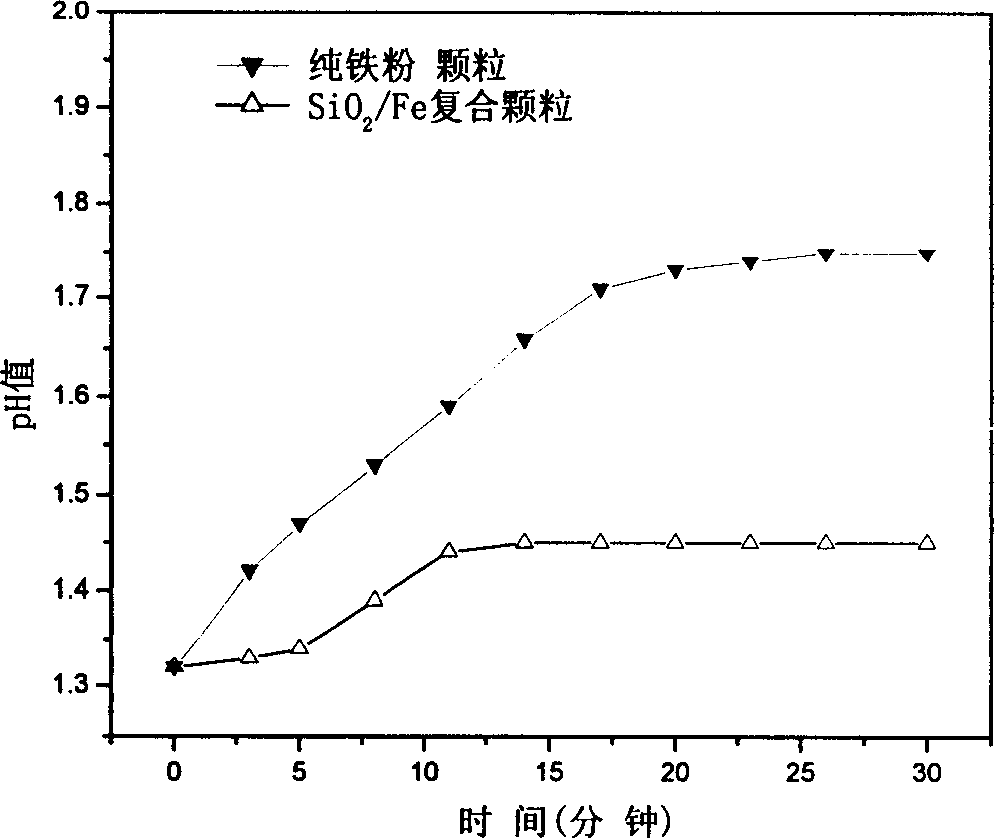

[0058] The determination of the properties of the magnetic composi...

Embodiment 3

[0060] The ratio of raw materials used is as follows:

[0061] 100 parts (weight) of reduced iron powder

[0062] Tetraethyl silicate 50 parts (weight)

[0063] 500 parts (weight) of absolute ethanol

[0064] 1000 parts (weight) of deionized water

[0065] nano-SiO 2 Preparation of film-coated magnetic particles:

[0066] Weigh 100g of iron powder, put it in 500g of absolute ethanol, add 50g of tetraethyl orthosilicate, stir and disperse fully, slowly add 1000g of deionized water dropwise, and react at room temperature at a stirring speed of 200rpm for 24 hours. After the reaction, first wash with absolute ethanol, wash with deionized water, magnetically separate, and then wash with deionized water, repeat several times to remove the remaining TEOS, SiO 2 Sol and SiO not coated on the surface of iron powder 2 particles.

[0067] The determination of the properties of the magnetic composite particles is similar to that of Example 1, and its oxidation resistance, acid cor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com