Fracturing propping agent for oil gas well and preparation method thereof

A technology for fracturing proppants and oil and gas wells, which is applied in earthwork drilling, wellbore/well components, and production fluids, etc. It can solve problems such as unsuitable preparation and production, high proppant density, and complicated raw material formulations, and achieve anti-fragmentation High efficiency, high acid corrosion resistance, low raw material requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

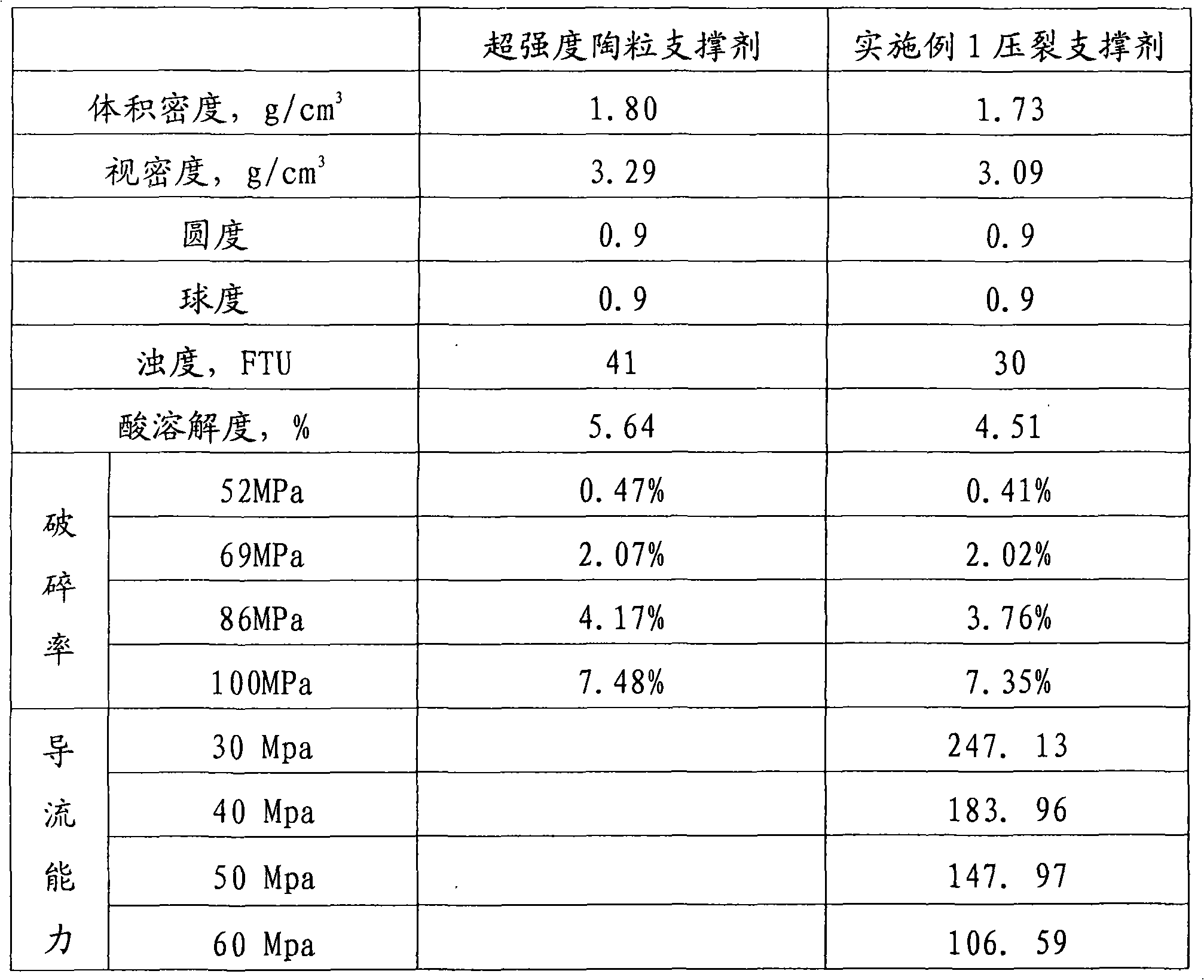

Embodiment 1

[0032] Raw material weight composition is as follows: low-content bauxite (Al 2 o 3 Content is 60-65%) 86 parts, manganese ore (MnO 2 Content 40-50%) 3 parts, potassium feldspar (SiO 2 68%, Al 2 o 3 18%, K 2 O 14%) 3 parts, solid water glass (Na2O.3SiO2) 3 parts, calcium stone powder (CaO content 57%) 4 parts, talcum powder (Mg 3 [Si 4 o 10 ](OH) 2 ) 2 copies.

[0033] Grind the above-mentioned mineral components by weight into fine powders with an ultra-fine Raymond mill, pass through a 325-mesh sieve, mix and stir evenly, enter the ball mill for grinding, and then add to the rolling granulator for granulation, and at the same time Add atomized water vapor, and stop atomizing after 50 minutes. At this time, the mixture has formed round particles of different sizes; continuously and evenly add talcum powder for planing. Rotate further and pass through a 140-mesh sieve to obtain a semi-finished product, put the semi-finished product into a sagger, send it into a tun...

Embodiment 2

[0038] The weight composition of raw materials is as follows: 88 parts of low-content bauxite, 4 parts of manganese ore, 3 parts of potassium feldspar, 4 parts of solid water glass, 5 parts of calcium stone powder, and 4 parts of talcum powder.

[0039] The preparation method is the same as in Example 1.

Embodiment 3

[0041] The weight composition of raw materials is as follows: 82 parts of low-content bauxite, 2 parts of manganese ore, 2 parts of potassium feldspar, 2 parts of solid water glass, 3 parts of calcium stone powder, and 2 parts of talcum powder.

[0042] The preparation method is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| bearing capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com