Acid-corrosion-resistant repair mortar and preparation method thereof

An acid corrosion-resistant and mortar technology is applied in the field of acid-resistant repair mortar and its preparation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

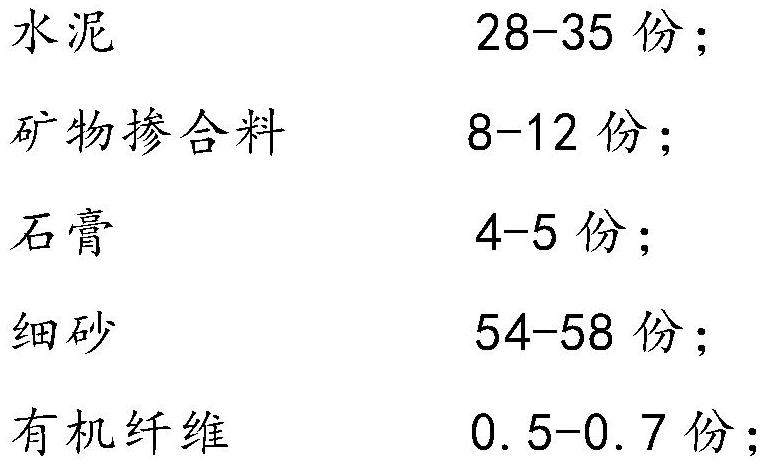

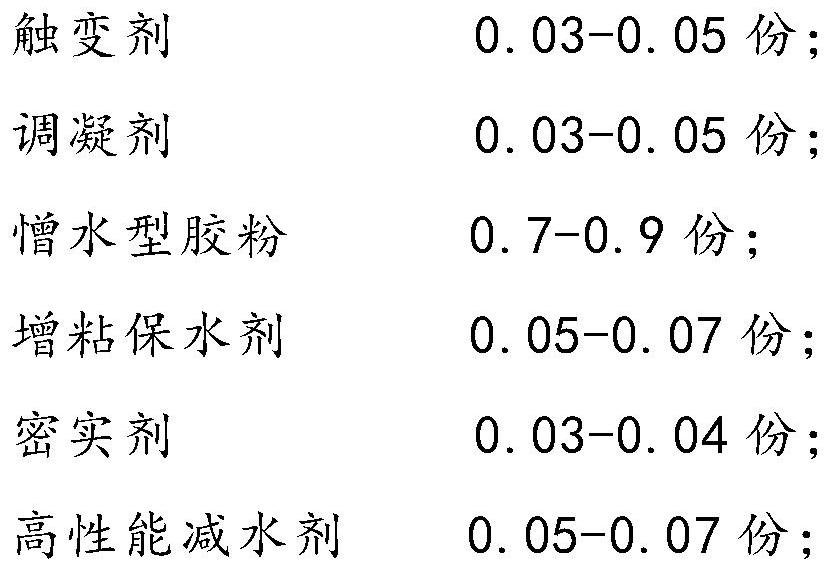

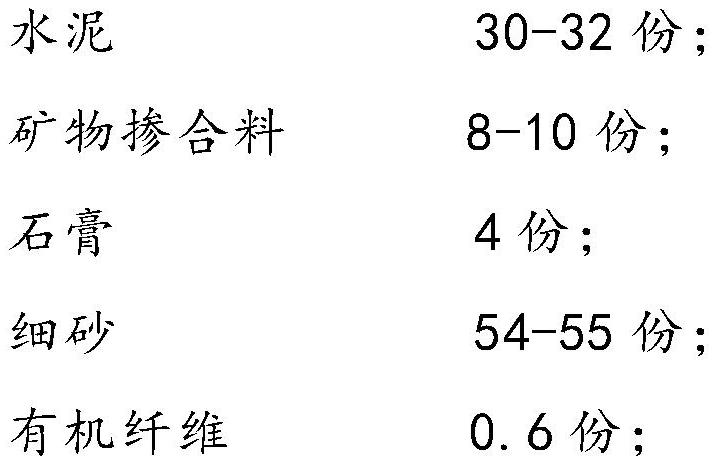

Examples

Embodiment 1

[0055] Step 1: Prepare raw materials according to the components and parts by weight of the A compound and the B compound in Table 1, the ratio of the weight part of water to the total weight parts of the A compound and the B compound is 0.14;

[0056] Step 2: Mix A mixture and B mixture evenly;

[0057] Step 3: Pour the uniformly mixed material A in step 2 into water while stirring, and then continue stirring for 3 minutes to form a mixed solution;

[0058] Step 4: Pour the B mixture evenly mixed in step 2 into the mixed liquid in step 3, and keep stirring for 5 minutes to form a repair mortar;

[0059] Step 5: Let the repair mortar prepared in step 4 stand for 3 minutes.

Embodiment 2

[0061] Step 1: Prepare raw materials according to the components and parts by weight of the A compound and the B compound in Table 1, and the ratio of the weight part of the water to the total weight parts of the A compound and the B compound is 0.15;

[0062] Step 2: Mix A mixture and B mixture evenly;

[0063] Step 3: Pour the uniformly mixed material A in step 2 into water while stirring, and then continue stirring for 3 minutes to form a mixed solution;

[0064] Step 4: Pour the B mixture evenly mixed in step 2 into the mixed liquid in step 3, and keep stirring for 5 minutes to form a repair mortar;

[0065] Step 5: Let the repair mortar prepared in step 4 stand for 3 minutes.

Embodiment 3

[0067]Step 1: Prepare raw materials according to the components and parts by weight of the A compound and the B compound in Table 1, the ratio of the weight part of the water to the total weight parts of the A compound and the B compound is 0.13;

[0068] Step 2: Mix A mixture and B mixture evenly;

[0069] Step 3: Pour the uniformly mixed material A in step 2 into water while stirring, and then continue stirring for 3 minutes to form a mixed solution;

[0070] Step 4: Pour the B mixture evenly mixed in step 2 into the mixed liquid in step 3, and keep stirring for 5 minutes to form a repair mortar;

[0071] Step 5: Let the repair mortar prepared in step 4 stand for 3 minutes.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com