Method for preparing Al2O3-ZnO nanorod array composite electrode

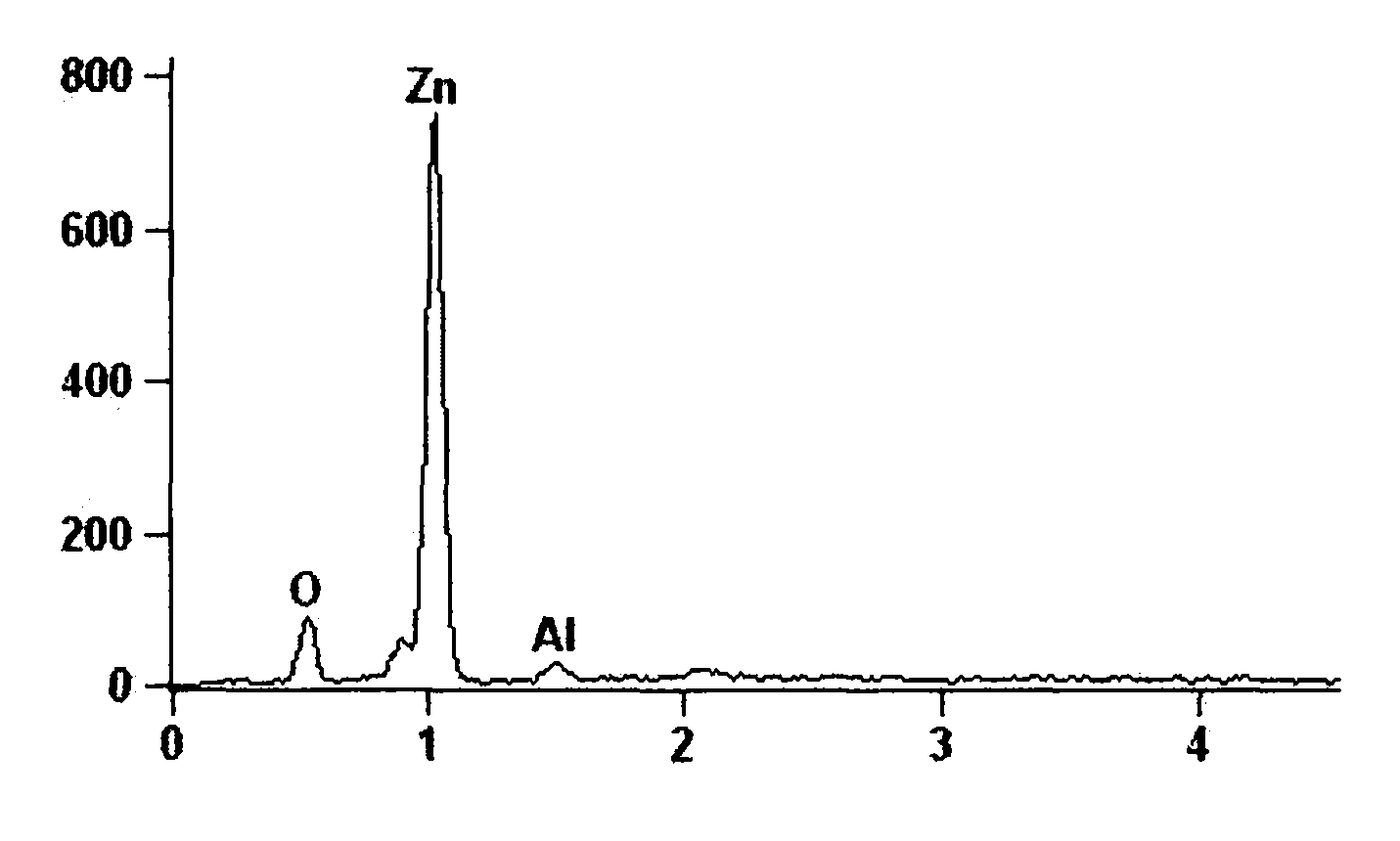

A nanorod array and composite electrode technology, applied in the field of nanomaterials, can solve the problems that affect the conversion efficiency of dye-sensitized solar cells and have not achieved significant improvement, and achieve the effects of simple process, uniform surface and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0023] 1. Dissolve equimolar chemically pure zinc nitrate and hexamethylenetetramine with ionized water to prepare a reaction solution with a molar concentration of 0.05mol / L.

[0024] 2. Cut 5 pieces of FTO conductive glass coated with a 100nm thick ZnO film as a seed layer into 2cm×1cm as a growth substrate, put them directly into the above solution, and seal and react at 95°C for 24 hours.

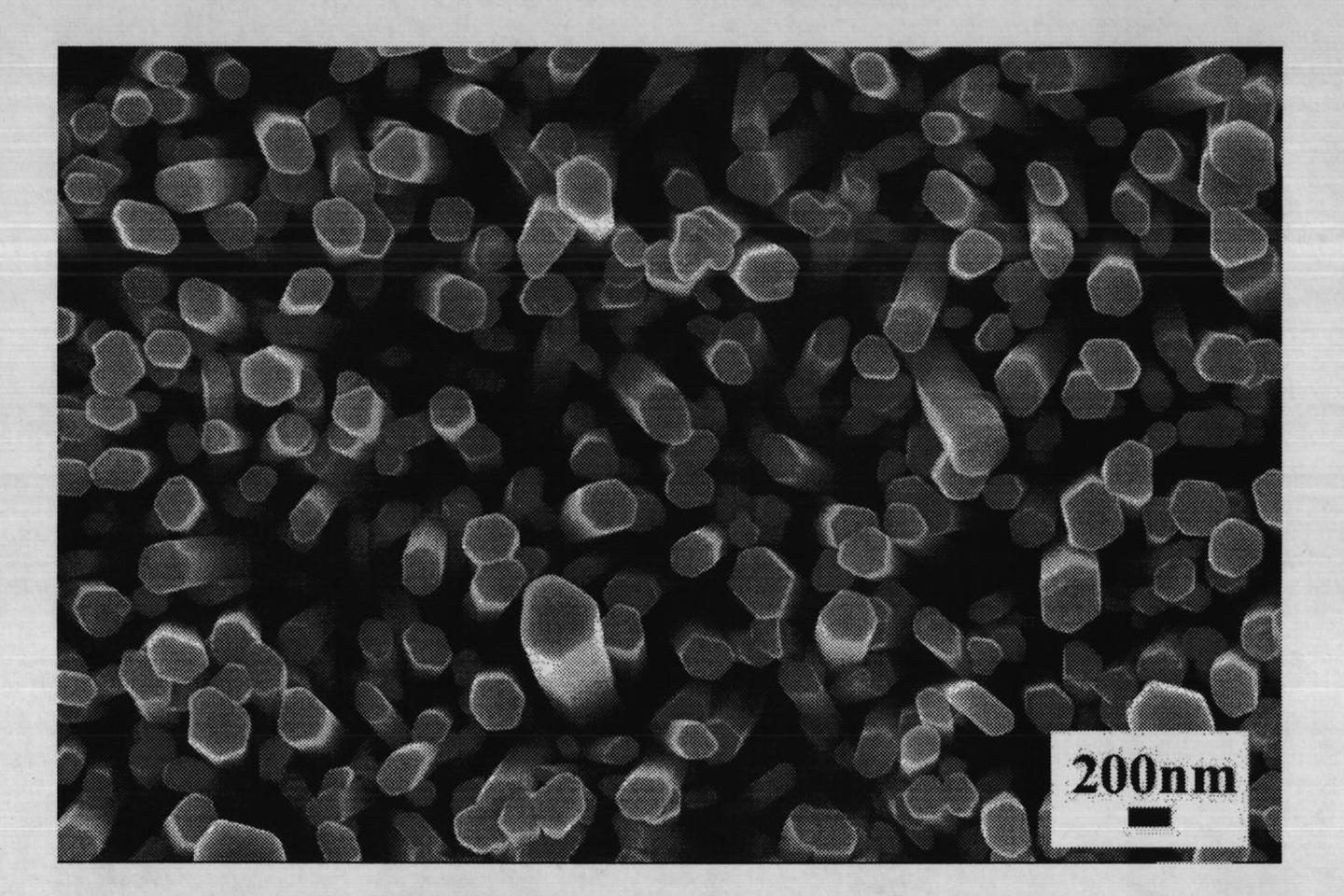

[0025] 3. After the reaction is over, take out the substrate. Rinse repeatedly with deionized water first, and after drying, it can be seen that a uniform white translucent film is formed on the substrate, and this film is the prepared ZnO nanorod array.

[0026] 4. Aluminum isopropoxide and distilled water are configured into an alumina sol with a molar ratio of 1:200.

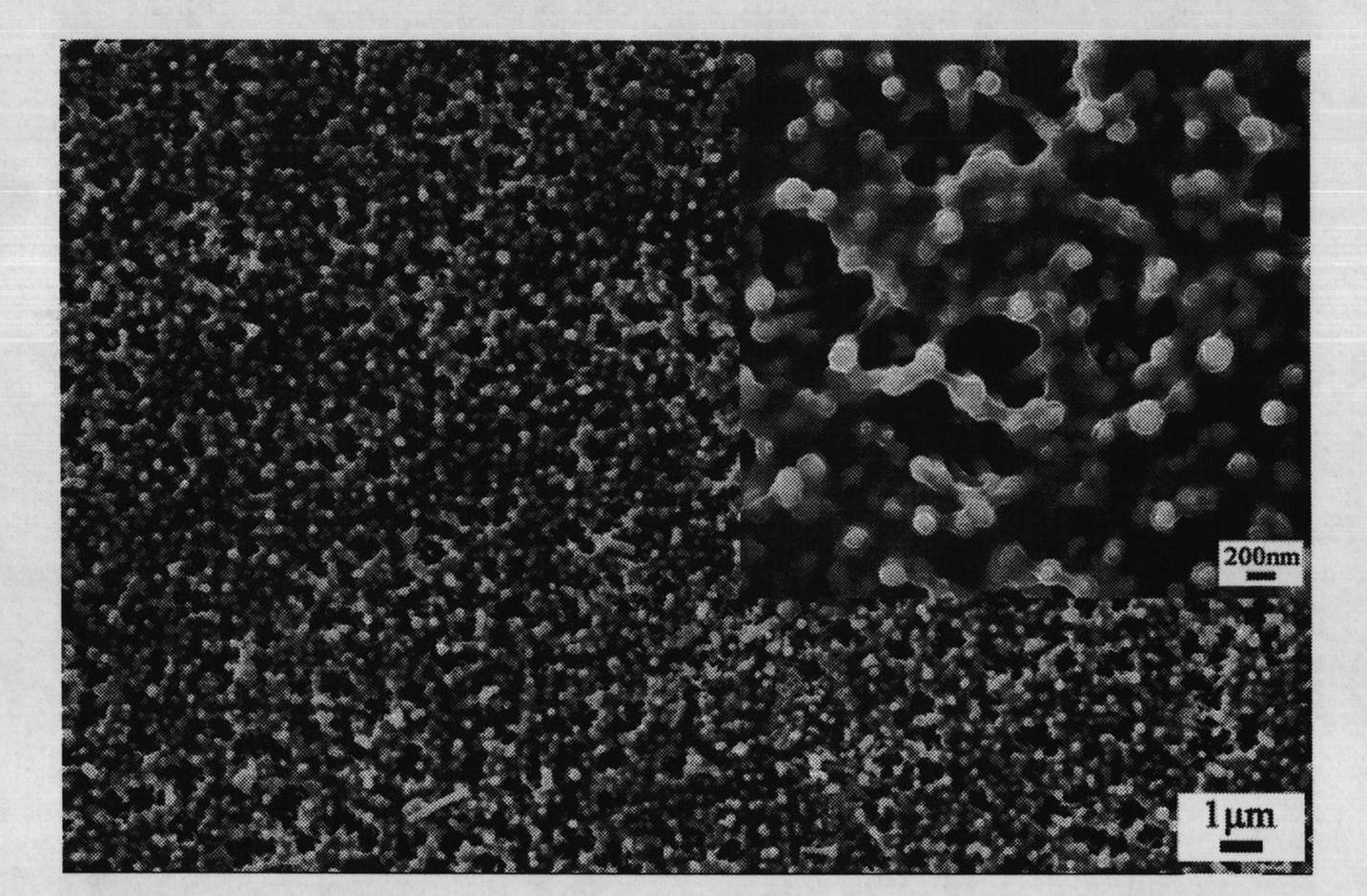

[0027] 5. Take 0.1 ml of the above-mentioned alumina sol and drop it on the surface of five ZnO nanorod array electrodes respectively. Then spin for 10 seconds at 1000 rpm in low gear and 15 seconds at 3000 rpm in hi...

example 2

[0030] 1. Dissolve equimolar zinc nitrate and hexamethylenetetramine with ionized water to prepare a reaction solution with a molar concentration of 0.15 mol / L.

[0031] 2. Cut 5 pieces of FTO conductive glass coated with a 100nm thick ZnO film as a seed layer into 2cm×2cm as a growth substrate, put them directly into the above solution, and seal and react at 80°C for 12 hours.

[0032] 3. Take out the substrate after the reaction. A uniform white translucent film can be obtained on the substrate, and the film is the prepared ZnO nanorod array.

[0033] 4. Aluminum isopropoxide and distilled water are configured into an alumina sol with a molar ratio of 1:200.

[0034] 5. Take 0.1 ml of the above-mentioned alumina sol and drop it on the surface of five ZnO nanorod array electrodes respectively. Then spin for 10 seconds at 1000 rpm in low gear and 15 seconds at 3000 rpm in high gear. And the above spin-coating process was repeated twice to obtain a uniform colloidal layer on t...

example 3

[0037] 1. Dissolve equimolar zinc nitrate and hexamethylenetetramine with ionized water to prepare a reaction solution with a molar concentration of 0.05mol / L.

[0038] 2. Cut 5 pieces of aluminum glass plated with a 100nm thick ZnO film as a seed layer into 2cm×1cm size as a growth substrate, put them directly into the above solution, and seal and react at 95°C for 24 hours.

[0039] 3. Take out the substrate after the reaction. A uniform milky white film can be obtained on the substrate, and the film is the prepared ZnO nanorod array.

[0040] 4. Aluminum isopropoxide and distilled water are configured into an alumina sol with a molar ratio of 1:200.

[0041] 5. Take 0.1 ml of the above-mentioned alumina sol and drop it on the surface of five ZnO nanorod array electrodes respectively. Then spin for 15 seconds at 1000 rpm in low gear and 15 seconds at 3000 rpm in high gear. And the above spin-coating process was repeated twice to obtain a uniform colloidal layer on the ZnO...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com