Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

32 results about "N-Methylpyrrolidinone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

N-Methylpyrrolidinone Pharmasolve. Identifiers CAS Number. ... N-Methyl-2-pyrrolidone (NMP) is an organic compound consisting of a 5-membered lactam. It is a colorless liquid, although impure samples can appear yellow. It is miscible with water and with most common organic solvents.

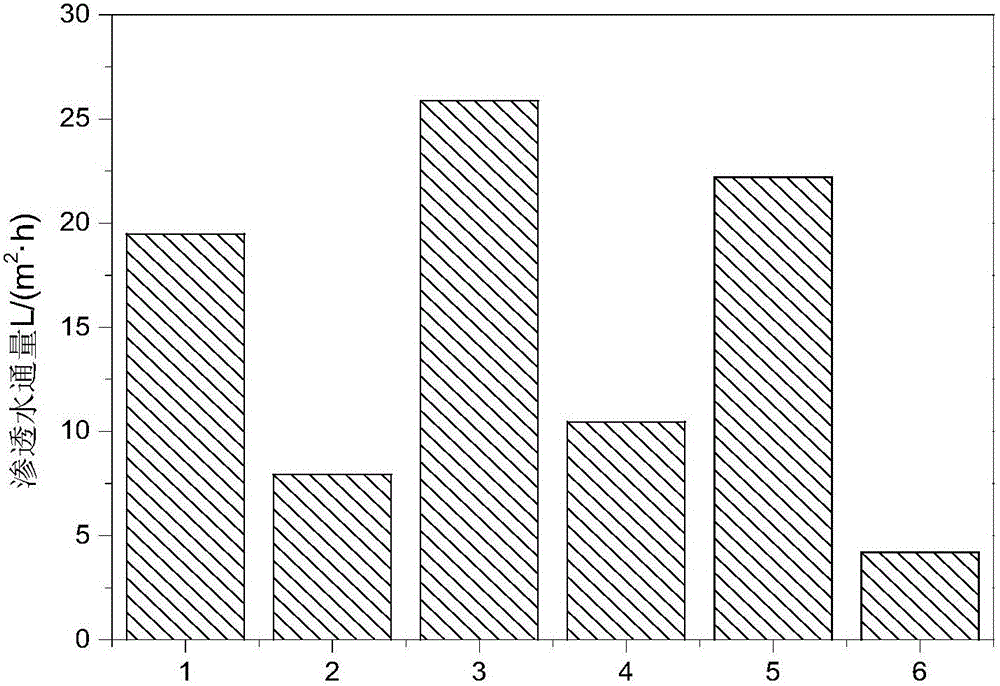

Cross-linked polyimide membranes

InactiveCN101678286AGuaranteed permeabilityGood solvent resistanceMembranesDispersed particle separationCross-linkFiltration

The present invention provides a method for improving the performance of polyimide membranes as used in solvent-resistant nanofiltration. More specifically the method of the present invention allows to imrove the solvent stability of the polyimide membranes to solvents or solvent mixtures that would dissolve polyimide under the conditions applied during the filtration, such as dimethylforrnamide (DMF), N-methylpyrrolidinone (NMP), dimethylacetamide (DMAC), tetrahydrofuran (THF), y-butyrolacton (GBL), dimethylsulphoxide (DMSO) and chlorinated solvents.

Owner:EVONIK FIBERS

Cross-linked polyimide membranes

InactiveUS20100181253A1Maintain permeabilityGood solvent resistanceMembranesDispersed particle separationCross-linkFiltration

The present invention provides a method for improving the performance of polyimide membranes as used in solvent-resistant nanofiltration. More specifically the method of the present invention allows to improve the solvent stability of the polyimide membranes to solvents or solvent mixtures that would dissolve polyimide under the conditions applied during the filtration, such as dimethylforrnamide (DMF), N-methylpyrrolidinone (NMP), dimethylacetamide (DMAC), tetrahydrofuran (THF), y-butyrolacton (GBL), dimethylsulphoxide (DMSO) and chlorinated solvents.

Owner:EVONIK FIBERS

Solvent Composition and Process for Removal of Asphalt and Other Contaminant Materials

ActiveUS20150267152A1Cationic surface-active compoundsOrganic detergent compounding agentsMETHYL SOYATEN-Methylpyrrolidinone

A method and composition for removing contaminant material from industrial equipment are disclosed herein. The method includes providing a solvent composition having methyl soyate, N-methylpyrrolidinone, an additional solvent, and a cationic surfactant. The method also includes contacting the contaminant material with the solvent composition and allowing the solvent composition to react with the contaminant material such that at least a portion of the contaminant material is no longer attached to the industrial equipment.

Owner:UNITED LAB INT LLC

Hydrogen sulfide leakage emergency removing dry powder, and preparation method thereof

InactiveCN103949140AGood dispersionConvenient secondary processingDispersed particle separationSulfolanePoly(ethylene glycol) dimethyl ether

The invention relates to a hydrogen sulfide leakage emergency removing dry powder, and a preparation method thereof. The hydrogen sulfide leakage emergency removing dry powder is mainly used for solving problems of existing technology that environmental pollution is caused, and removing efficiency is low. The hydrogen sulfide leakage emergency removing dry powder mainly comprises, by mass, 65 to 99% of a removing agent, 0.5 to 15% of a moisture-proof agent, and 0.5 to 20% of an additive; the additive is at least one selected from polyethylene glycol dimetyl ether, N-methylpyrrolidinone, propylene carbonate, tributyl phosphate, N-methylcaprolactam, methyl alcohol, alkyl alkylol amine, sulfolane, bentonite, carboxymethyl cellulose, and sodium carboxymethylcellulose. The hydrogen sulfide leakage emergency removing dry powder is capable of solving the above problems preferably, and can be used for hydrogen sulfide leakage emergency removing.

Owner:CHINA PETROLEUM & CHEM CORP +1

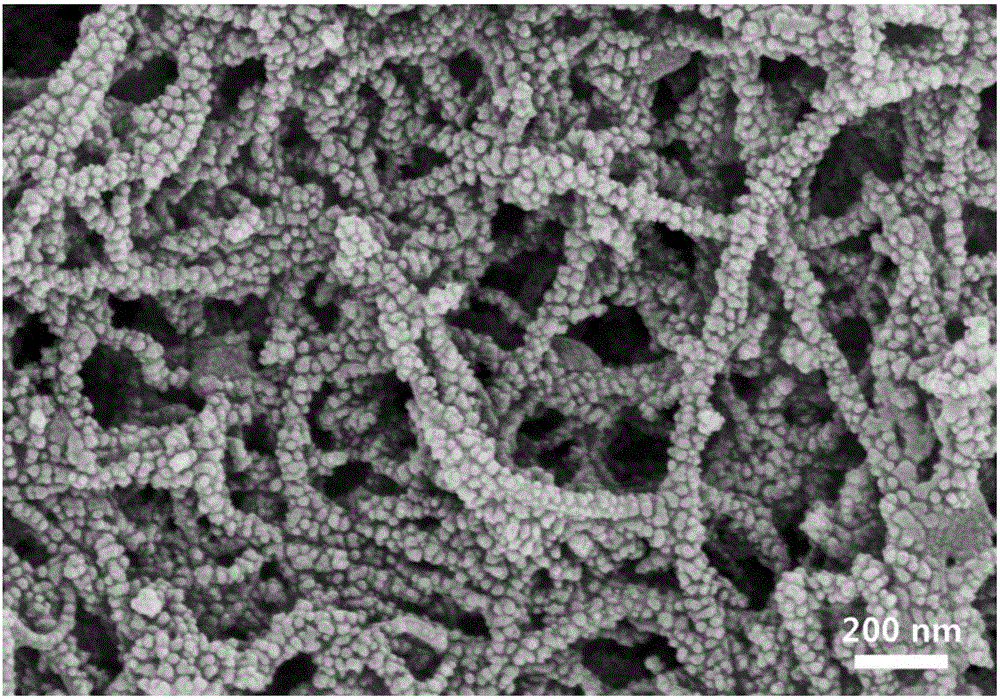

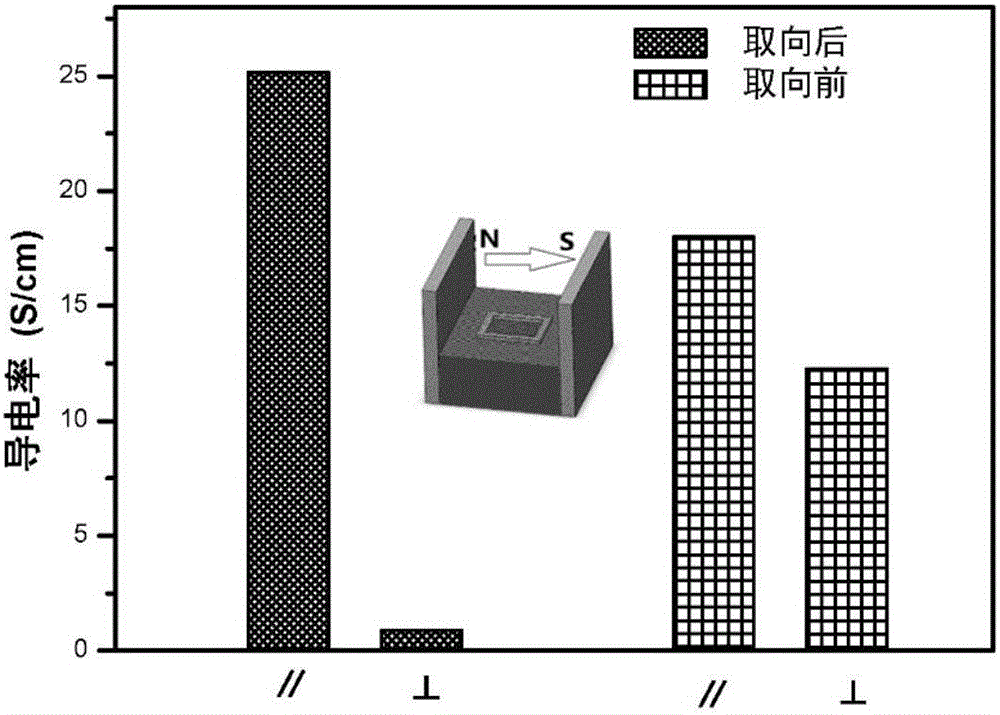

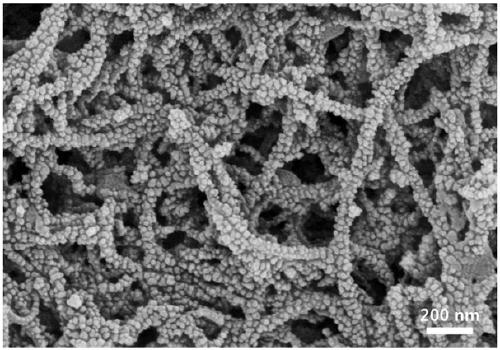

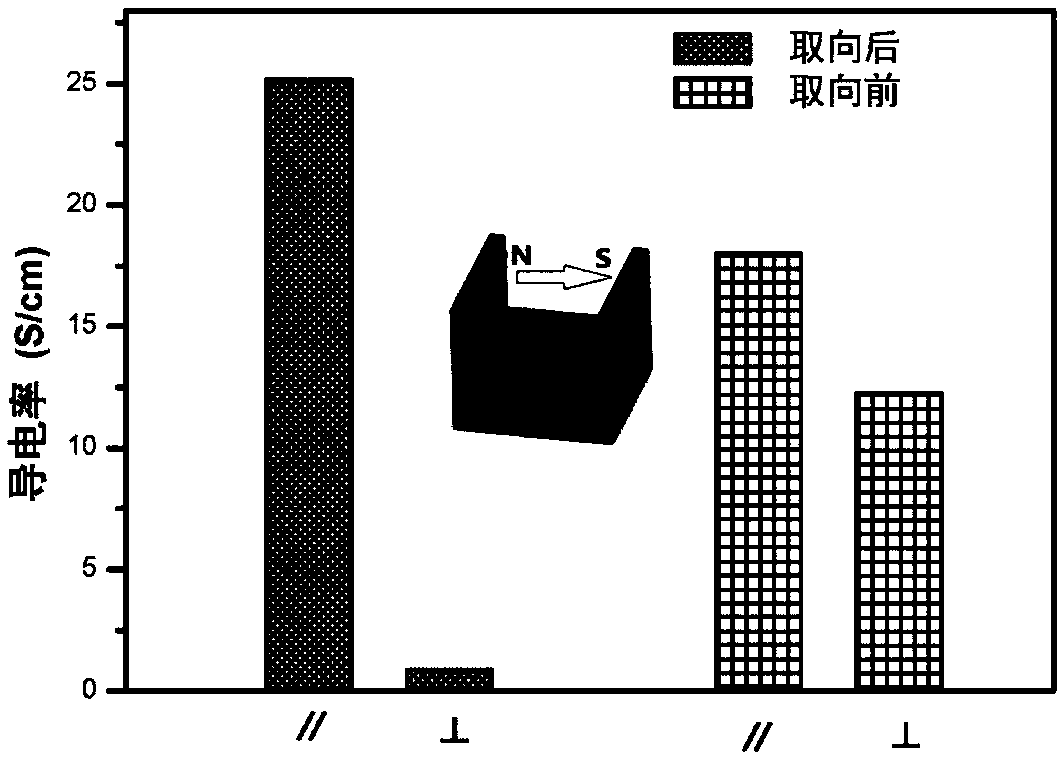

Preparation method of anisotropic conductive macromolecule composite thin film

The invention discloses a preparation method of an anisotropic conductive macromolecule composite thin film. The preparation method includes following steps: 1), uniformly adding carbon nanotubes coated with nano ferroferric oxide magnetic particles into a polyaniline-N-methylpyrrolidinone solution according to a mass percentage of 0.5-15%, and stirring well to obtain a carbon nanotube / ferroferric oxide-polyaniline solution; 2), adding the nanotube / ferroferric oxide-polyaniline solution into a polyurethane solution, and stirring well to obtain a carbon nanotube / ferroferric oxide-polyaniline-polyurethane solution; 3), dropping the carbon nanotube / ferroferric oxide-polyaniline-polyurethane solution onto a glass sheet for casting to form a thin film, putting the obtained thin film in a magnetic field for magnetic orientation, and drying at high temperature to obtain the anisotropic conductive macromolecule composite thin film. The preparation method is simple and easy to implement, high in result repeatability and easy to control.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

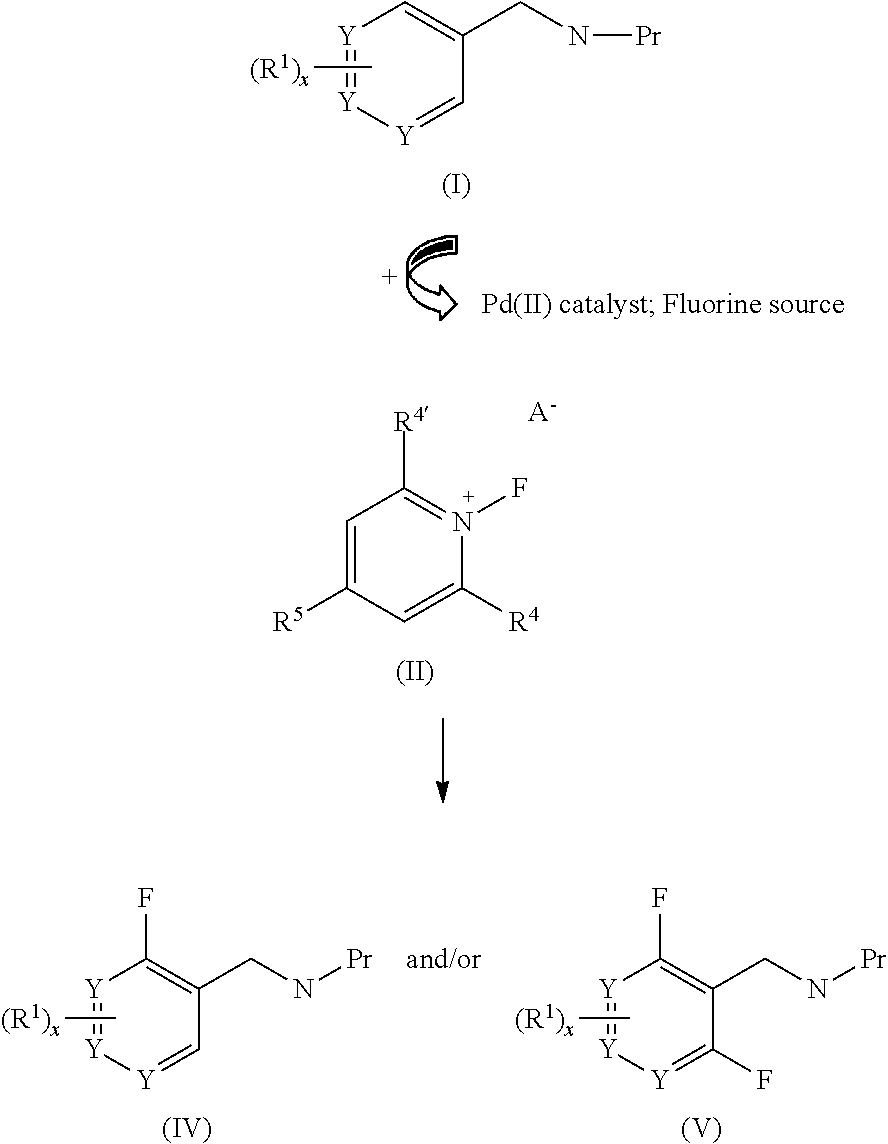

Palladium-catalyzed ortho-fluorination

InactiveUS20120059179A1Improve versatilityIncrease displacementCarboxylic acid nitrile preparationOrganic compound preparationArylOrtho position

A new method of ortho-fluorination where an aryl C—H bond is directly replaced by an aryl C-F bond in a palladium-catalyzed reaction is provided. The method includes the ortho-fluorination of a triflamide protected benzylamine, a palladium catalyst, such as Pd(OTf)2, a fluorinating reagent such as N-fluoro-2,4,6-trimethylpyridinium triflate, and a ligand to promote the reaction such as N-methylpyrrolidinone (NMP).

Owner:THE SCRIPPS RES INST

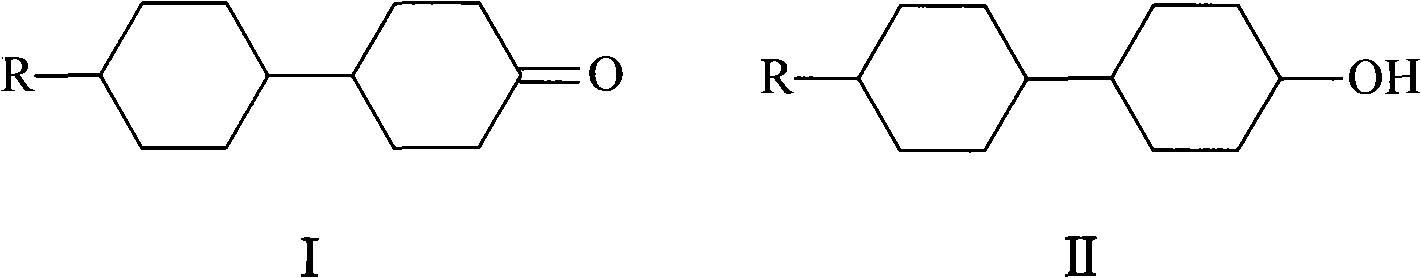

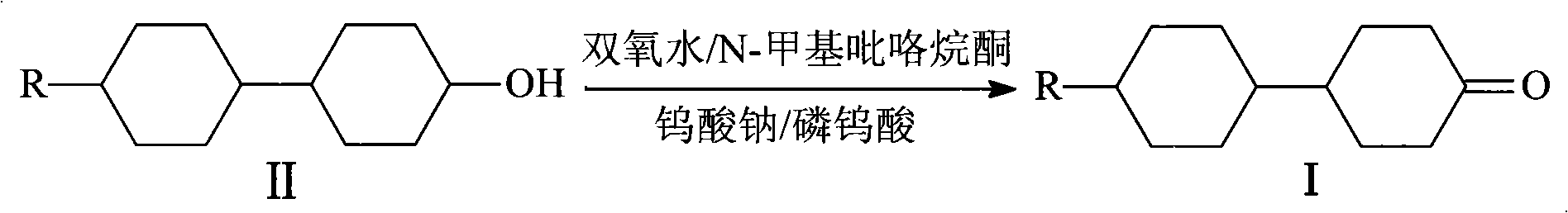

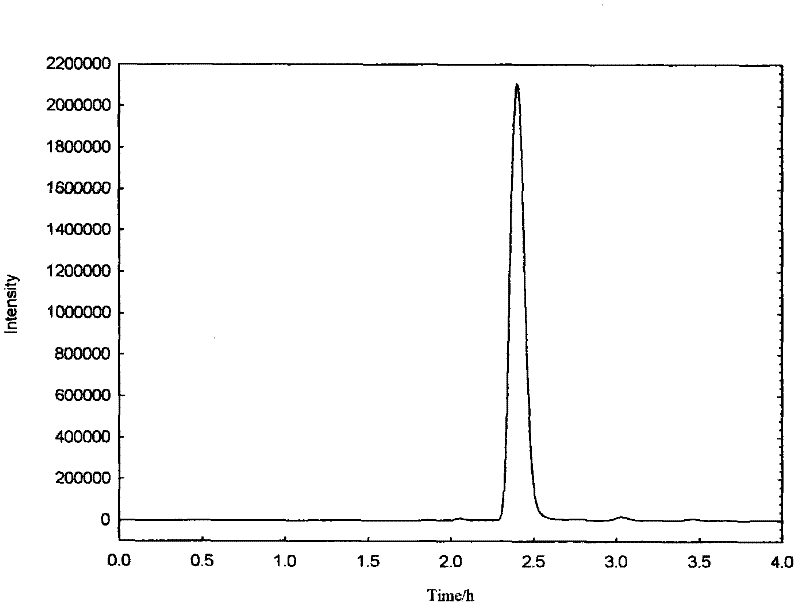

Method for synthesizing 4-(4'-n-alkyl cyclohexyl)cyclohexanone

ActiveCN101337870ALow priceNothing producedOrganic compound preparationCarbonyl compound preparationCyclohexanoneN-Methylpyrrolidinone

The invention relates to a synthesis method of 4-(4'-n-alkyl cyclohexyl) cyclohexanone, which comprises the following steps: mixing and stirring sodium tungstate dehydrate and phosphotungstic acid; adding hydrogen peroxide to obtain an oxidant; adding reactant 4-(4'-n-alkyl cyclohexyl) chclohexanol and a solvent N-methylpyrrolidinone in the oxidant; and reacting to obtain 4-(4'-n-alkyl cyclohexyl) cyclohexanone. The hydrogen peroxide is an ideal clean oxidant, and the byproduct of the reaction is water. The synthesis method has simple process and high yield. The synthesis method is a green 4-(4'-n-alkyl cyclohexyl) cyclohexanone synthesis method.

Owner:XIAN RUILIAN NEW MATERIAL CO LTD

High-performance electrospinning/electret composite fiber filtering material and preparation method thereof

InactiveCN106192062AGood storage stabilityImprove filtration efficiencyDispersed particle separationElectro-spinningFiberSilicon monoxide

The invention discloses a high-performance electrospinning / electret composite fiber filtering material. The high-performance electrospinning / electret composite fiber filtering material is prepared from the following raw material components in parts by weight: 75 to 90 parts of polythioetherimide, 5 to 10 parts of silicon monoxide, 8 to 15 parts of powdered activated carbon, 1 to 2 parts of 3-aminopropyltriethoxysilane coupling agent, 0.8 to 2 parts of glacial acetic acid, a proper amount of deionized water, 2 to 6 parts of metatitanic acid, a proper amount of 0.6mol / L AgNO3 solution, a proper amount of N-methylpyrrolidinone, 2 to 5 parts of organically modified montmorillonite, 18 to 30 parts of dimethylbenzene and 35 to 40 parts of ethanol. According to the high-performance electrospinning / electret composite fiber filtering material disclosed by the invention, silicon nanowires containing alpha-quartz are prepared; the electrospinning / electret composite fiber filtering material is prepared by an electrospinning technique and has excellent charge storage stability, and the filtering efficiency of the filtering material is greatly improved; besides, nano silver is added and nano titania is loaded, so that the antibacterial durability of the filtering material is improved, and a long-term and high-efficiency filtering effect is realized.

Owner:中安丰磊环境科技股份有限公司

Method for synthesizing 7-hydroxy-4-methylcoumarin with solvent-free catalysis of ionic liquid

InactiveCN102311414ASimple preparation processEasy to separateOrganic chemistryOrganic-compounds/hydrides/coordination-complexes catalystsAcetic acidSolvent free

The invention relates to a synthetic method of a heterocyclic compound, and concretely relates to a method for synthesizing 7-hydroxy-4-methylcoumarin with the solvent-free catalysis of an ionic liquid. The method essentially comprises that resorcinol and ethyl acetoacetate are subjected to an ester interchange reaction under the effect of a catalyst, wherein the catalyst is an ionic liquid catalyst which is N-methylimidazolium hydrogensulfate or N-methylpyrrolidinone hydrogensulfate. The ionic liquid catalyst of the present invention has the advantages of simple preparation technology, easy separation from products, recovery and utilization, less corrosion to equipment, high catalytic activity, high yield, and high purity of the preparative products.

Owner:GUANGDONG UNIV OF PETROCHEMICAL TECH

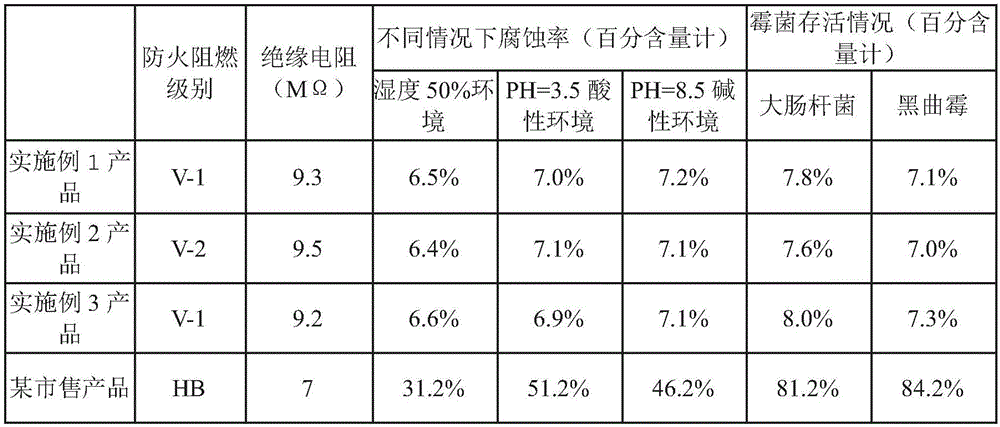

Mathematic display model surface antibiosis and flame retardation coating layer

InactiveCN105925040AExcellent flame retardantGood acid and alkali resistanceFireproof paintsAntifouling/underwater paintsNitrocellulosePhosphate

The invention relates to a mathematic display model surface antibiosis and flame retardation coating layer. The mathematic display model surface antibiosis and flame retardation coating layer comprises phenyltriethoxysilane, dibasic lead phosphite, sodium sulfhydrate, lithium phosphate powder, asphalt, porcelain powder, hydroxyethyl cellulose ether, calcium acetate, Artemisia argyi extract, titanium nitride powder, phenolic resin, methyl methacrylate, melamine copolycondensation resin, amidinourea phosphate, zinc phosphate, diethyl ethanephosphonate, parachlorometaxylenol, sodium dihydrogen phosphate, disodium hydrogen phosphate, barium sulfate powder, barite powder, N-methylpyrrolidinone, ethylene oxide, lemon oil, oleate, sodium dodecyl sulfate, nitrocellulose, sodium bisulfate, 2-mercaptobenzothiazole and cetyl trimethyl ammonium bromide. The mathematic display model surface antibiosis and flame retardation coating layer has superior flame, acid-alkali, mildew and bacterium resistance, and improved performances.

Owner:王根夫

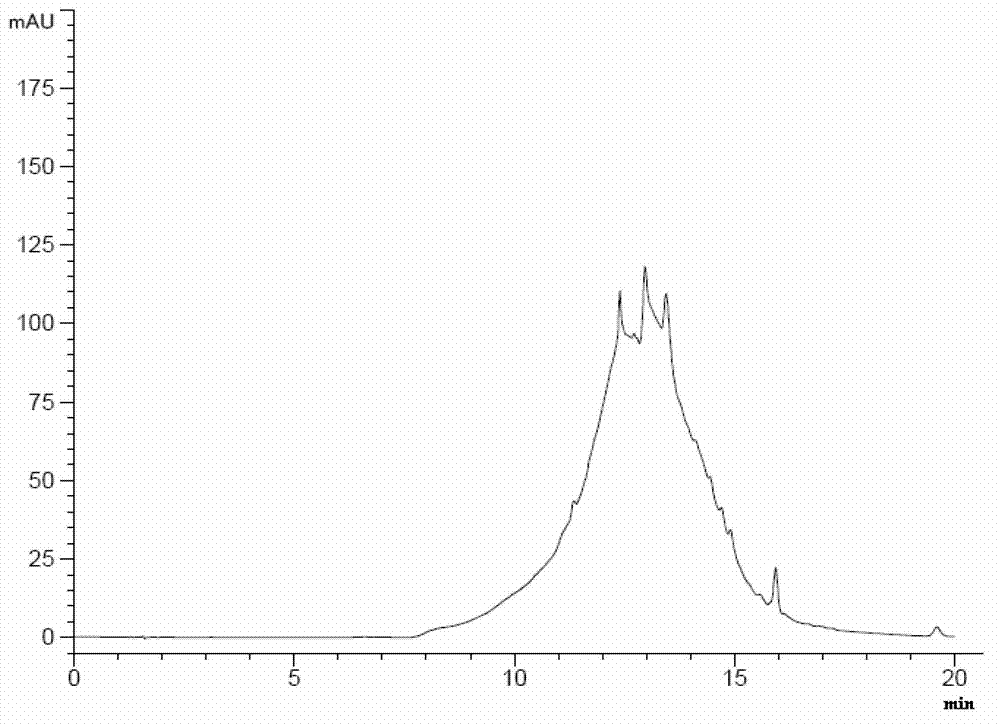

Method for detecting residual organic solvents in medicines by high performance liquid chromatography

InactiveCN103926334AReduce concentrationHigh detection sensitivityComponent separationN dimethylformamideOrganic solvent

The invention discloses a method for detecting residual organic solvents in medicines by high performance liquid chromatography (HPLC). The method comprises a step of performing HPLC detection on a to-be detected sample subjected to pretreatment. Gradient elution is employed during detection, the mobile phase A is a buffer salt with a cut-off wavelength of 210 nm or less, and the mobile phase B is acetonitrile. Gradient elution is performed, specifically elution is performed for 5 min under the condition that the volume ratio of the mobile phase A to the mobile phase B is (90:10)-(98:2); then elution is performed under the condition that the volume ratio of the mobile phase A to the mobile phase B is (20:80)-(10:90), or linear elution is performed until the volume ratio of the mobile phase A to the mobile phase B is (20:80)-(10:90); and elution is finished until impurities are removed. The organic solvents are N,N-dimethylformamide, N,N-dimethylacetamide and N-methylpyrrolidinone. The method is capable of precisely detecting the above organic solvents, is convenient and rapid and high in sensitivity, and is capable of detecting low-concentration samples with high accuracy.

Owner:CHENGDU CHEMPARTNER

High-gloss aqueous woodenware paint

The invention discloses a highly-waterproof high-gloss aqueous woodenware paint. The paint comprises 80-85 parts of an acrylic emulsion, 2-5 parts of N-methylpyrrolidinone, 0.2-1 part of an organic polar compound antifoaming agent, 0.3-0.5 parts of BYK-346, 1-2 parts of propylene glycol, 0.2-0.8 parts of BYK301, 2-4 parts of OK607, 0.5-1.5 parts of water-soluble polyacrylate and 0.1-0.5 parts of a nanosilver solution, and the acrylic emulsion is synthesized from 33 parts of butyl acrylate, 17 parts of methyl methacrylate, 1 part of methacrylic acid, 63 parts of deionized water, 1.5 parts of sodium alkyl benzene polyether sulfonate and 0.2 parts of ammonium persulfate. The high-gloss aqueous woodenware paint has the advantages of low cost, reasonable ratio and excellent waterproof property.

Owner:XUZHOU JUYEXIANG FURNITURE

Method of ultrasonic combining microwave for preparing graphene quantum dots

InactiveCN108033443ALess edge defectsReduce usageGrapheneNanotechnologyStrong acidsN-Methylpyrrolidinone

The invention discloses a method of ultrasonic combining microwave for preparing graphene quantum dots. The method includes steps of: adding graphite and NaOH to N-methylpyrrolidinone, and successively performing ultrasonic stripping, crushing and microwave irradiation heating to obtain the graphene quantum dots having uniform size. In the method, with the graphite as raw material, the graphene quantum dots are prepared through ultrasonic wave and microwave in the NaOH / N-methylpyrrolidinone, so that usage of strong acid and strong oxidants is avoided. The graphene quantum dots have less edge defects and have important researching and application value in the fields of biology, medical and the like. Meanwhile, the method has simple processes and low consumption and is high in yield, whereinthe N-methylpyrrolidinone, as a dispersant of graphite, can be recycled. The method supplies a new way for synthesis of the graphene quantum dots and is beneficial to industrial large-scale production.

Owner:SOUTH CHINA UNIV OF TECH

Preparation technology of poly(p-phenylene terephthalamide)

InactiveCN106496547AIncrease the relative molecular massRaw materials are easy to obtainN-MethylpyrrolidinoneNitrogen

The invention discloses a preparation technology of poly(p-phenylene terephthalamide). The steps include: adding 15g-20g of N-methylpyrrolidinone and 20g-30g of CaCl2 into a reaction kettle to prepare an N-methylpyrrolidinone-calcium chloride solution; adding 16g-18g of p-phenylenediamine powder into the N-methylpyrrolidinone-calcium chloride solution, introducing dry nitrogen and performing stirring continuously until the powder is completely dissolved; cooling the solution, then adding 12g-15g of paraphthaloyl chloride powder, carrying out reaction for 15min-17min to obtain a paraphthaloyl chloride-p-phenylenediamine-CaCl2 solution; preparing a paraphthaloyl chloride solution with a concentration of 25%-30%; adding the paraphthaloyl chloride-p-phenylenediamine-CaCl2 solution and paraphthaloyl chloride solution according to a ratio of 2:1 into a double-screw reactive extruder to carry out reaction for 5min-6min, and extruding poly(p-phenylene terephthalamide) powder; washing the powder with cold water several times to neutral, and performing drying at 120DEG C-130DEG C for 4.5h-5.5h, thus obtaining a light yellow poly(p-phenylene terephthalamide) polymer. The method is accurate in measurement, and can realize continuous preparation of polymers with high relative molecular mass.

Owner:杨磊

Preparation method of high-performance cellulose triacetate forward osmosis membrane

InactiveCN105749765AImprove hydrophilicityEasy accessSemi-permeable membranesMembranesFiberGlass sheet

The invention relates to a preparation method of a high-performance cellulose triacetate forward osmosis membrane. The preparation method comprises the following steps: (1) preparing membrane casting fluid which is prepared from cellulose triacetate, N-methylpyrrolidinone, acetone and lactic acid: adding the lactic acid into a binary mixed solvent of the acetone and the N-methylpyrrolidinone, performing ultrasonic treatment for 1-10min to ensure that the lactic acid and the binary mixed solvent are sufficiently and uniformly mixed, then adding a membrane material, namely the cellulose triacetate, controlling the temperature to 30-60 DEG C, and performing mechanical stirring for dissolving so as to obtain the uniform membrane casting fluid; (2) performing sufficient deaeration on the membrane casting fluid at 30-60 DEG C, and performing membrane scraping on a glass plate; (3) immersing the glass plate with a thin layer of the membrane casting fluid in a gel coagulation bath of 10-50 DEG C, performing phase separation and membrane formation, then soaking the glass plate in deionized reclaimed water for 3-8d, after surplus solvents are removed, taking out the glass plate, and performing natural airing so as to obtain the cellulose triacetate forward osmosis membrane. Compared with the prior art, the preparation method disclosed by the invention has the advantages that the technological process is simple, requirements on equipment are low, preparation conditions are easy to control, and besides, mass production is easy to perform.

Owner:SHANGHAI INST OF TECH

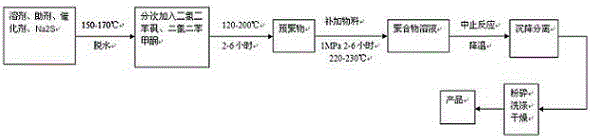

Preparation method of polyphenylene sulfide sulphone ketone with high molecular weight

The invention discloses a preparation method of polyphenylene sulfide sulphone ketone with high molecular weight. The polyphenylene sulfide sulphone ketone comprises raw materials of sodium sulfide, 4,4'-dichlorodiphenyl sulfone and 4,4'-dichlorobenzophenone, a solvent of N-methylpyrrolidinone, and additives of sodium hydroxide, a catalyst and sodium benzoate. The preparation method is mainly characterized by comprising the following steps of enabling the raw materials, the solvent, the additives and the catalyst to be subjected to a polyreaction for the first time so as to obtain a prepolymer; performing a polyreaction for the second time so as to obtain a polymer solution, wherein the polyreaction temperature of the raw materials, the solvent, the additives and the catalyst is 170-270 DEG C, the pressure condition is 0MPa-1MPa, and the required time is 3-8h; and after the polymer solution stops the reaction, reducing the temperature, performing sedimentation, performing separation, performing crushing, performing washing, and performing drying so as to obtain a macromolecule material. The resin synthesized by the preparation method disclosed by the invention is good in stability, the high temperature resistance and the corrosion resistance of the resin are improved, mechanical properties are improved, and the cost is moderate.

Owner:四川金和成科技有限公司

High-compactability heat-conduction adhesive film

ActiveCN106118517AImprove biaxial tensile propertiesAvoid local overheatingCarbon compoundsFilm/foil adhesivesHeat conductingAdhesive

The invention discloses a high-compactability heat-conduction adhesive film. The heat-conduction adhesive film is jointed to the surface of a heating component, and comprises a graphite layer, a heat-conduction gluing layer locating on the surface of the graphite layer, and a release material layer. The graphite layer is obtained through the following technological method comprising the following steps of coating a layer of a graphite modifying agent on the upper surface and the lower surface of a polyimide thin film so as to obtain a treated polyimide thin film, wherein the graphite modifying agent is made from the following components in parts by weight: 28 parts of pyromellitic dianhydride, 13.5 parts of BTDA, 25 parts of diaminodiphenylmethane, 24 parts of dimethyl formamide, 9 parts of N-methylpyrrolidinone, 2.2 parts of glycol and 2.2 parts of polydimethylsiloxane; and raising the temperature of the treated polyimide thin film to 1200 DEG C, performing heat preservation, and performing cooling so as to obtain a prefiring carbonization film. According to the high-compactability heat-conduction adhesive film disclosed by the invention, puckers and volume shrinkage in the graphitization sintering process are avoided, the compactability and the crystalinity are improved, and the heat-conducting properties in a perpendicular direction and in a horizontal direction are further improved.

Owner:JIANGSU SIDIKE NEW MATERIALS SCI & TECH CO LTD

Electrostatic spun/electret composite fiber filter material comprising sodium tartrate intercalated hydrotalcite and preparation method of filter material

InactiveCN106512553AGood storage stabilityImprove filtration efficiencyMembrane filtersFiltration separationFiberPolyetherimide

The invention discloses an electrostatic spun / electret composite fiber filter material comprising sodium tartrate intercalated hydrotalcite. The filter material is prepared from components in parts by weight as follows: 75-90 parts of polyetherimide, 6-12 parts of silicon monoxide, 9-15 parts of powdered activated carbon, 1-3 parts of a 3-aminopropyl triethoxy silane coupling agent, 0.8-2 parts of glacial acetic acid, a proper amount of deionized water, 3-6 parts of metatitanic acid, a proper quantity of 0.6 mol / L of an AgNO3 solution, a proper amount of N-methylpyrrolidinone, 1-2 parts of sodium tartrate, 7-14 parts of a 4.0 M magnesium chloride aqueous solution, 7-14 parts of a 1.0 M aluminum chloride aqueous solution and a proper quantity of a 20% NaOH solution. Silicon nanowires containing alpha-quartz are prepared, the electrostatic spun / electret composite fiber filter material is prepared with the electrostatic spinning technology and has excellent charge storage stability, and the filter efficiency of the filter material is greatly improved; besides, nano silver is added to support nano titanium dioxide, and the antibacterial endurance property of the filter material is improved.

Owner:安徽名杰净化科技有限公司

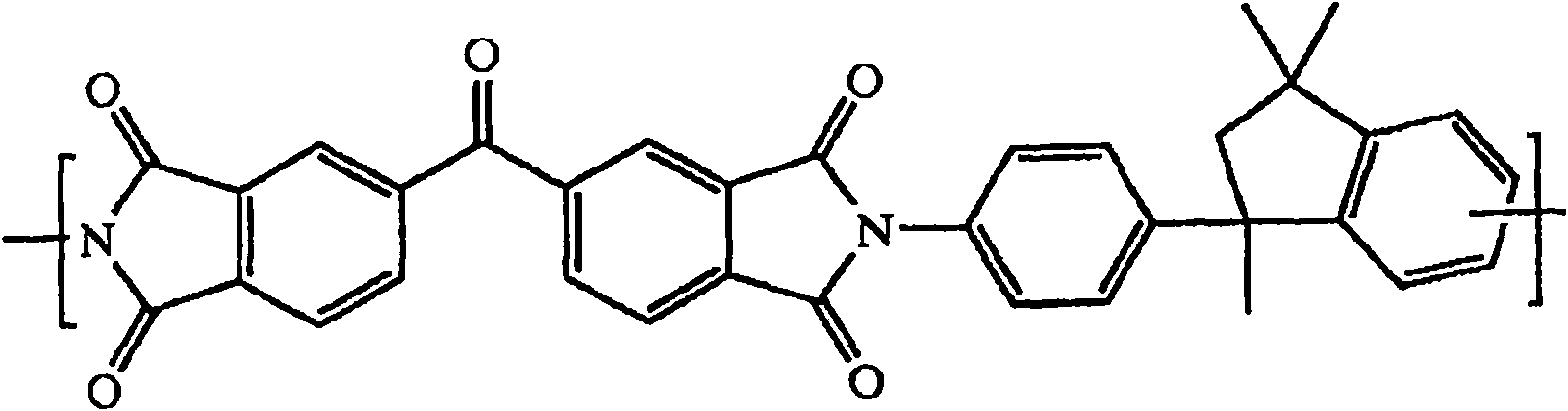

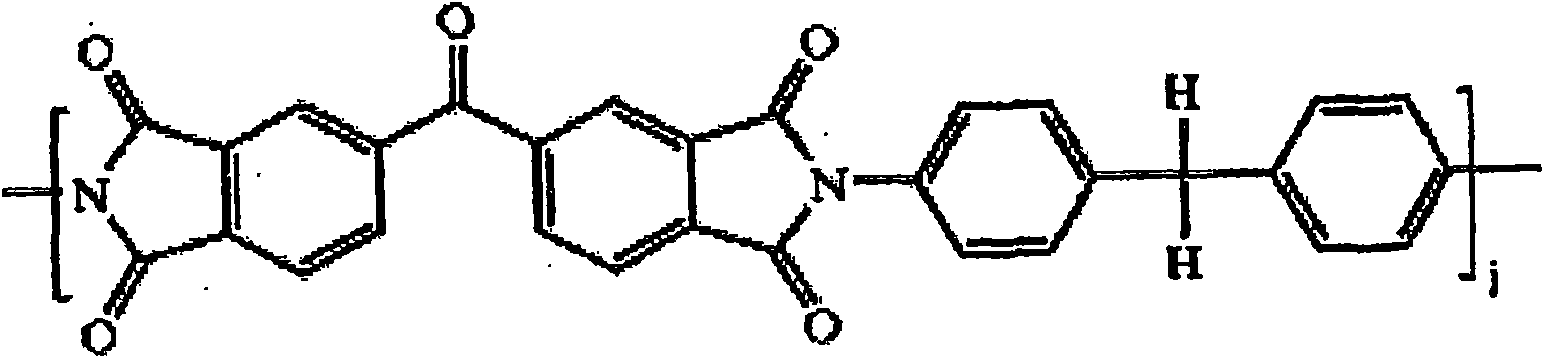

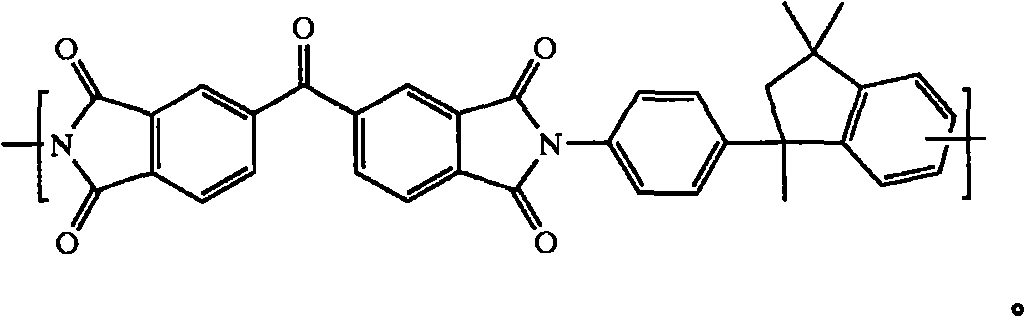

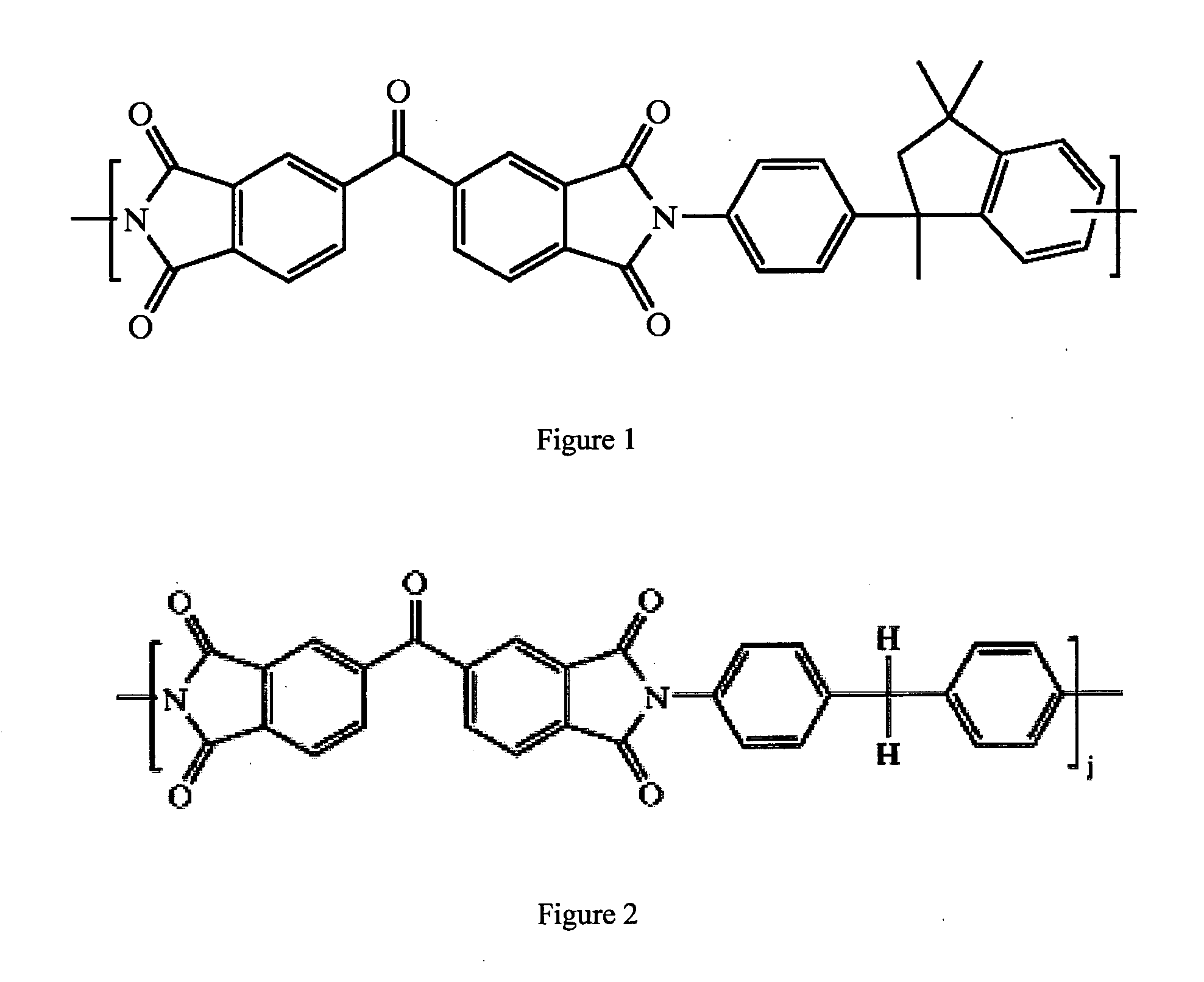

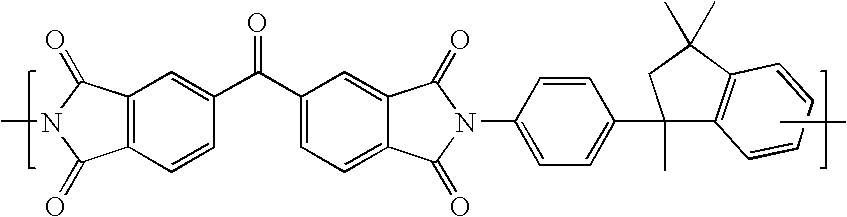

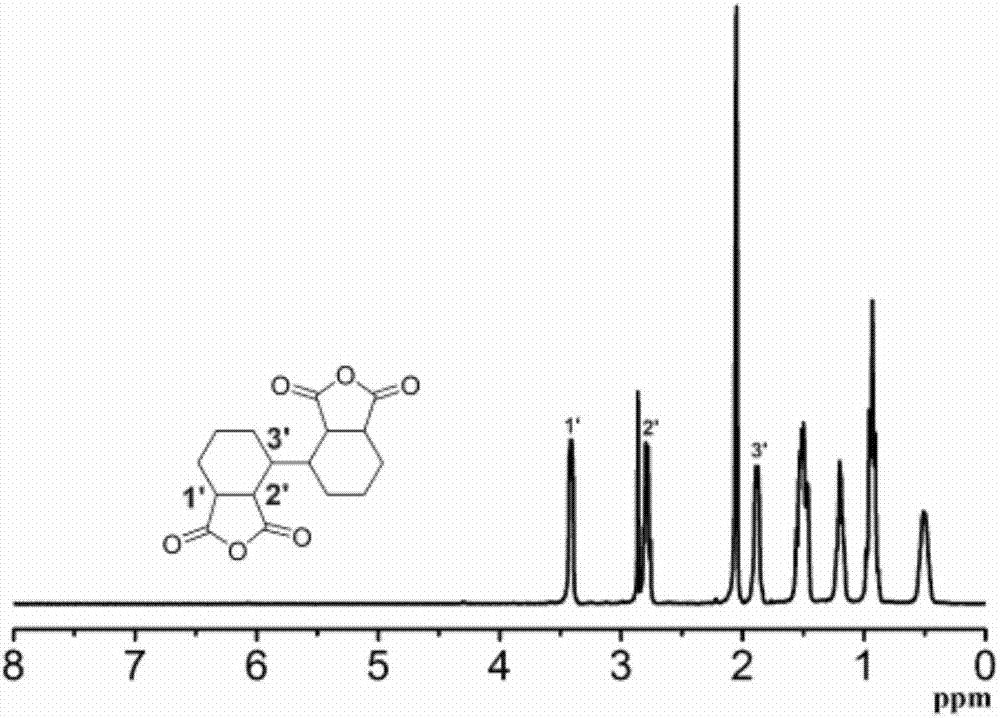

Polyimide as well as preparation method and application thereof

The invention belongs to the field of high molecular materials, and particularly relates to polyimide as well as a preparation method and application thereof. The polyimide provided by the invention comprises a repetitive unit having a structure as shown in the formula (I) (as shown in the description), wherein in the formula (I), R1 is one of following structures( as shown in the description), and R2 is a residue after removing two aminos from a diamine compound. Experimental results indicate that the polyimide provided by the invention is transparent, the ultraviolet absorption cut-off wavelength of the polyimide is 291-320nm, and the optical transmissivity of the polyimide at 450nm is 75-90%; the polyimide has favorable solubility in resorcinol, N-methylpyrrolidinone, N,N-dimethylacetamide and the like, and the polyimide can partially dissolve in chloroform and the like; besides, the vitrification transition temperature of the polyimide is 200 DEG C or above, and the 5% hot zero gravity of the polyimide is 400 DEG C or above; and besides, the inherent viscosity of the polyimide is more than 0.30dL / g, and the film forming property of the polyimide is good.

Owner:CHANGCHUN INST OF APPLIED CHEMISTRY - CHINESE ACAD OF SCI

Lithium manganate storage battery special for hybrid vehicles and preparation method thereof

InactiveCN105845888AImprove thermal stabilityReduced oxidation capacityCell electrodesAlloyTemperature resistance

The invention provides a lithium manganate storage battery special for hybrid vehicles. A positive electrode material comprises a lithium manganate-containing positive active substance, a conductive agent accounting for 5-15% of the mass of the positive active substance, and an N-methylpyrrolidinone dissolved binder accounting for 5-10% of the mass of the positive active substance. A negative electrode material is composed of 85-95% of a negative active substance, 3-10% of a conductive agent and 2-10% of the N-methylpyrrolidinone dissolved binder. The positive active substance is a mixture of layered lithium manganate and more than one of lithium cobaltate, spinel type lithium manganate and lithium iron phosphate in a mass ratio of 1-2:0-1; the negative electrode material is mixture of more than one of natural graphite, artificial graphite, mesocarbon microbeads, hard carbon, lithium titanate, tin-based alloy and silicon-based alloy. The lithium manganate storage battery special for hybrid vehicles provided by the invention makes full use of the superiorities of the lithium manganate positive electrode material and polymer li-ion batteries, and has the advantages of smaller volume, lighter weight, longer life, better high temperature resistance, easier maintenance, more stable performance, and more environmental protection, etc.

Owner:深圳市索阳新能源科技有限公司

Light-weight polyvinyl chloride plastic tube and preparation method thereof

The invention discloses a light-weight polyvinyl chloride plastic tube. The light-weight polyvinyl chloride plastic tube is prepared from the following raw materials in parts by weight: 0.1-0.2 part of nonylphenol, 1-2 parts of triallyl isocyanurate, 0.2-0.3 part of linoleic acid, 3-4 parts of carbon nanotubes, 40-60 parts of 90-93% sulfuric acid, 60-70 parts of 95-97% nitric acid, 1-2 parts of acryloyl chloride, 0.01-0.02 part of 1,4-dioxane, 0.2-0.3 part of azodiisobutyronitrile, 6-10 parts of 2-hydroxyethyl acrylate, 7-8 parts of triethylamine, 10-14 parts of liquid ethylene propylene diene monomer, 1-1.2 parts of dicumyl peroxide, 100-120 parts of polyvinyl chloride, 10-14 parts of light-weight calcium carbonate, 3-5 parts of N-methylpyrrolidinone, 0.2-0.3 part of coconut diethanolamide, 3-4 parts of allyl polyethylene glycol, 0.8-1 part of zinc dialkyl dithiophosphate and 0.03-0.1 part of sp80. The light-weight polyvinyl chloride plastic tube disclosed by the invention is low in processing cost, and high in weather resistance and impact resistance.

Owner:安徽玉发塑业有限公司

Poly amic acid system for polyimides

InactiveUS20050124781A1Easy to disassembleThin material handlingCircuit susbtrate materialsN-MethylpyrrolidinonePolyamic acid

A poly amic acid precursor containing a combination of tetrahydrofuran and N-methylpyrrolidinone as cosolvents is described. Utilizing the combination of tetrahydrofuran and N-methylpyrrolidinone allows for the removal of significant portions of the solvent during the formation of the polyimide. The removal of tetrahydrofuran and N-methylpyrrolidinone can be done without the use of preheating zones so as to allow for the large scale production of polyimide articles.

Owner:MEDTRONIC INC

High-strength aging-resistant advertising board adhesive

InactiveCN109439242AEliminate flammableEliminate toxicNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesAdhesivePolystyrene

The invention discloses high-strength aging-resistant advertising board adhesive, comprising SEBS (styrene ethylene butylene styrene), coumarone resin, an antioxidant, sulfonated polystyrene, cyclohexane, rosin resin, terpene resin, potassium permanganate (5% by mass) (15% in mass percentage), N-methylpyrrolidinone, pentaerythritol, poly(aminopropylphenyl) silsesquioxane, and a filling material. The high-strength aging-resistant advertising board adhesive is given excellent mechanical properties, high tensile strength, excellent tear resistance, high strength and good aging resistance since the materials are blended for modifying.

Owner:马鞍山和春文化传媒有限公司

A kind of titanium nano polymer alloy coating material and application method thereof

ActiveCN103881563BNo chemical reactionStable storageConjugated diene hydrocarbon coatingsPretreated surfacesEpoxyPolymer alloy

Owner:IANGSU JINLING SPECIAL PAINT CO LTD

Chemical equipment cleaning agent

The invention provides a chemical equipment cleaning agent including the composition by weight: 1-4 parts of triethanolamine, 3-6 parts of hydroxypropyl methyl cellulose, 3-6 parts of a metal ion chelating agent, 8-12 parts of N-methylpyrrolidinone, 5-9 parts of aluminum-magnesium silicate, 5-9 parts of maleic acid diisooctyl ester sodium sulfonate, 1-2 parts of bentonite, 5-9 parts of arginine, 3-6 parts of tetrasodium ethylenediamine tetraacetate, and 1-2 parts of fatty alcohol polyoxyethylene ether. The chemical equipment cleaning agent has the beneficial effects that the chemical equipment degreasing cleaning agent is provided and is suitable for cleaning and degreasing chemical equipment, a surface after cleaning and degreasing is glossy but not blackened, and the cleaning agent has no erosion on the surface of metal equipment; the degreasing cleaning agent is little affected by acids and alkalis, soft and hard water and seawater, and has the advantages of strong degreasing ability and good cleaning effect; the cleaning agent is non-toxic and non-flammable; and the cleaning agent is simple and convenient to use, the pollution is reduced, and the cost of cleaning is reduced.

Owner:JIANGSU JIHUA CHEMICAL CO LTD

Low-temperature-resistant and crack-resistant synthetic leather applied to baseballs

InactiveCN106633819AImprove adhesionImprove toughnessTextiles and paperCrack resistanceDodecylsulfonic acid

The invention discloses low-temperature-resistant and crack-resistant synthetic leather applied to baseballs. The synthetic leather comprises a base cloth and a polyurethane composition, wherein the polyurethane composition comprises the following raw materials in parts by weight: 80-120 parts of modified polyurethane emulsion, 10-15 parts of water, 8-10 parts of N-methylpyrrolidinone, 20-30 parts of organized montmorillonite, 10-12 parts of talcum powder, 18-22 parts of lignocelluloses, 0.4-0.6 part of a high-carbon alcohol fatty acid ester compound, 0.2-0.3 part of silicone emulsion, 7-9 parts of a pigment, 1-1.5 parts of a mildew preventive and 2-3 parts of sodium dodecyl sulfate. The synthetic leather has high low-temperature resistance, high low-temperature crack resistance and high low-temperature impact resistance.

Owner:天长市良文运动器材有限公司

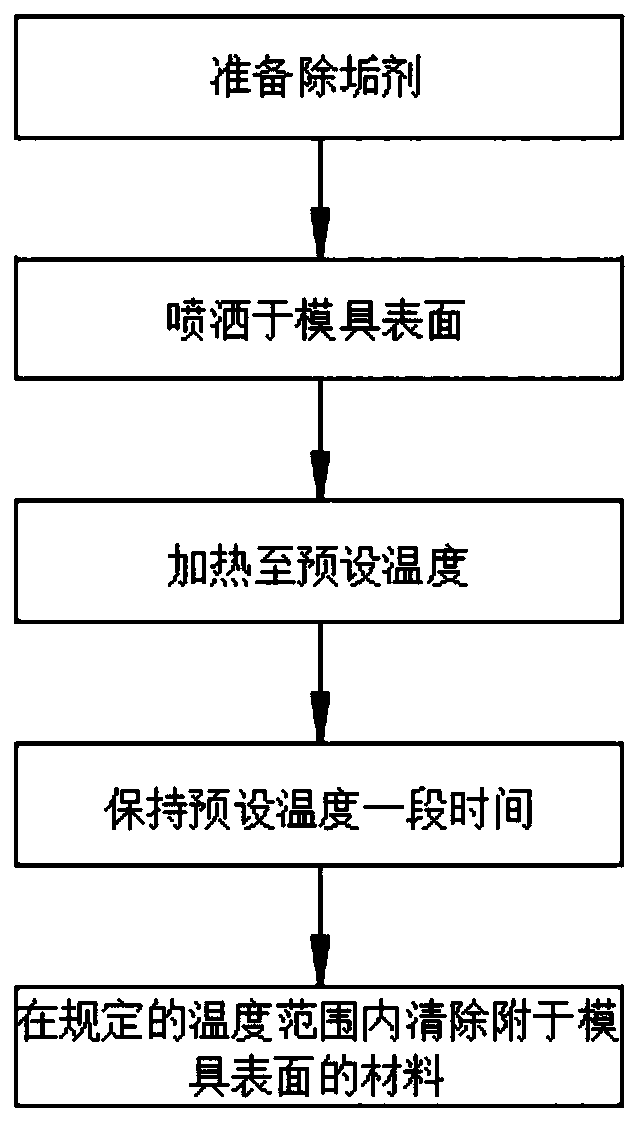

A method for descaling pressure gel molds

The invention discloses a method for removing scale from a pressure gel mold. The method comprises a scale remover, wherein the scale remover comprises an organic solvent; and the organic solvent comprises N-methylpyrrolidinone and triethylene glycol. The method comprises the following steps of sprinkling the scale remover on the surface of the mold to be cleaned; heating the mold to a pre-set temperature; maintaining the pre-set temperature for some time; and removing materials adhered to the surface of the mold in a set temperature range. The method disclosed by the invention can be operatedon a mold locking machine, and discharging is not needed, so that the method is simple and quick, and time for cleaning is short; and in the treating process, the mold is not damaged, so that the life of the mold is not influenced, renewedly performing surface oxidation or electroplating treatment is not needed, and the cost is saved.

Owner:GUANGDONG SIHUI INSTR TRANSFORMER WORKS

A kind of preparation method of anisotropic conductive polymer composite film

ActiveCN106497048BConductiveGood acid corrosion resistanceConductive polymer compositeComposite film

The invention discloses a preparation method of an anisotropic conductive macromolecule composite thin film. The preparation method includes following steps: 1), uniformly adding carbon nanotubes coated with nano ferroferric oxide magnetic particles into a polyaniline-N-methylpyrrolidinone solution according to a mass percentage of 0.5-15%, and stirring well to obtain a carbon nanotube / ferroferric oxide-polyaniline solution; 2), adding the nanotube / ferroferric oxide-polyaniline solution into a polyurethane solution, and stirring well to obtain a carbon nanotube / ferroferric oxide-polyaniline-polyurethane solution; 3), dropping the carbon nanotube / ferroferric oxide-polyaniline-polyurethane solution onto a glass sheet for casting to form a thin film, putting the obtained thin film in a magnetic field for magnetic orientation, and drying at high temperature to obtain the anisotropic conductive macromolecule composite thin film. The preparation method is simple and easy to implement, high in result repeatability and easy to control.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

High-temperature-resistant anticorrosion waterborne polyurethane adhesive and preparation method thereof

InactiveCN110305613ACorrosion resistantGood flexibilityNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesEnvironmental resistancePropanoic acid

A high-temperature-resistant anticorrosion waterborne polyurethane adhesive is characterized by being made from, by weight, 25-35 parts of isophorone diisocyanate, 40-50 parts of polytetrahydrofuran,2-8 parts of 2,2-bis(hydroxymethyl)propionic acid, 0.05-0.15 part of a catalyst, 5-15 parts of N-methylpyrrolidinone, 2-2.4 parts of potassium hydroxide, 110-130 parts of water, 0.5-1.5 parts of isophorone diamine, 1.3-1.8 parts of a flame retardant, 3.2-3.5 parts of nano-montmorillonite, 2.3-2.8 parts of a silane coupling agent, and 6.5-7.8 parts of fluorine-bearing oligomeric diol. The inventionalso provides a preparation method of the high-temperature-resistant anticorrosion waterborne polyurethane adhesive. The high-temperature-resistant anticorrosion waterborne polyurethane adhesive hasa low quantity of a solvent and is suitable for food packaging bags; a film layer of one packaging bag is pasted to a paper layer through the high-temperature-resistant anticorrosion waterborne polyurethane adhesive, the cost is saved, no toxicity is caused, and good environmental friendliness is present; the high-temperature-resistant anticorrosion waterborne polyurethane adhesive has the good properties of resistance to low and high temperatures, corrosion resistance, good flexibility, high adhesive strength, and good waterproof property.

Owner:SHANTOU XINYUAN CHEM TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com