Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

598 results about "Gamma-Butyrolactone" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

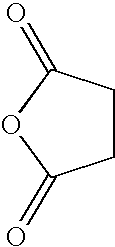

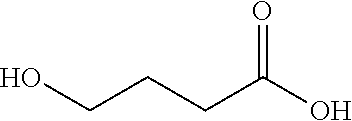

Γ-Butyrolactone (GBL) is a hygroscopic colorless, water-miscible liquid with a weak characteristic odor. It is the simplest 4-carbon lactone. It is mainly used as an intermediate in the production of other chemicals, e.g. methyl-2-pyrrolidone. In humans GBL acts as a prodrug for γ-hydroxybutyric acid (GHB), and it is used as a recreational CNS depressant with effects similar to barbiturates.

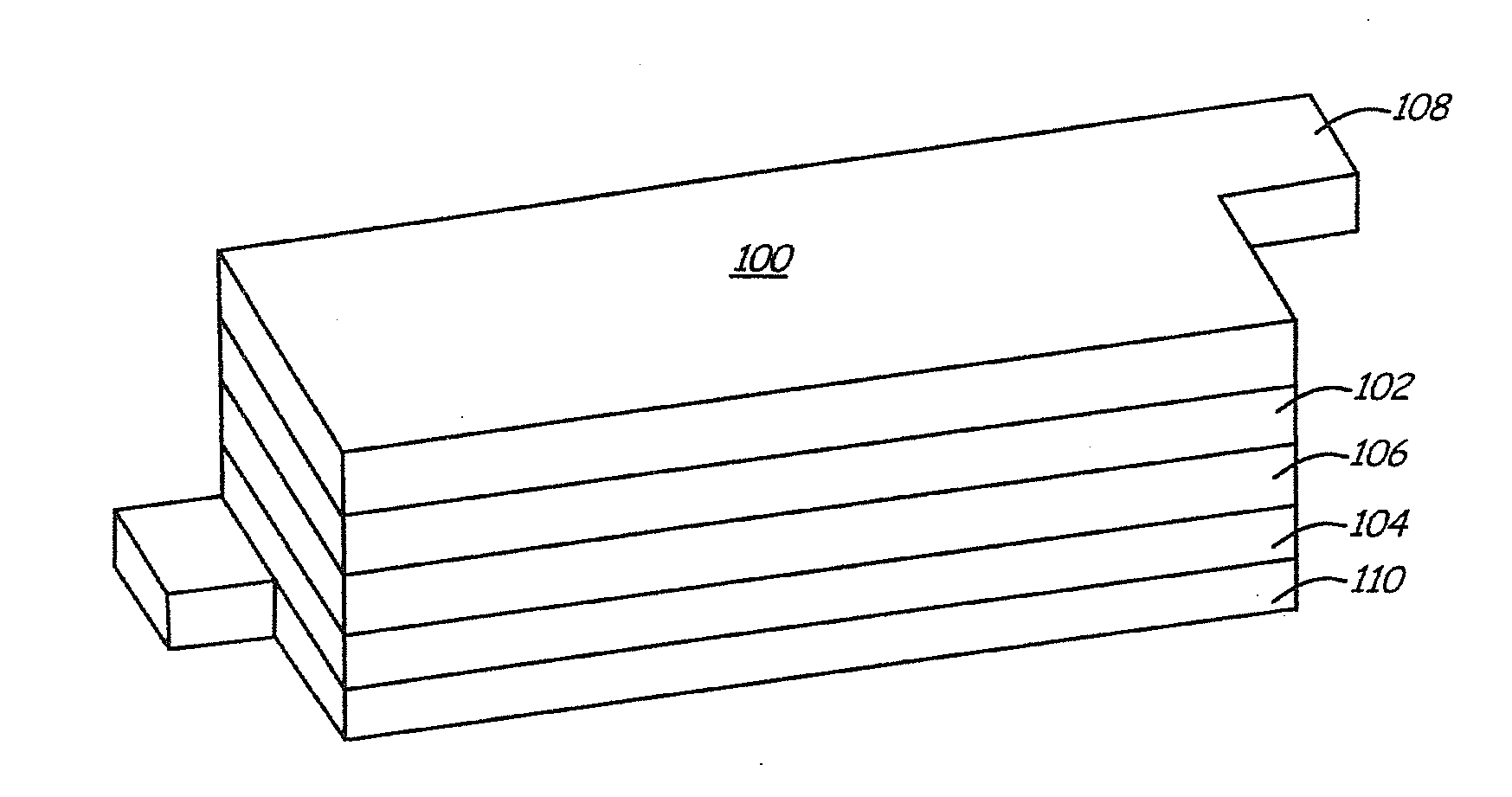

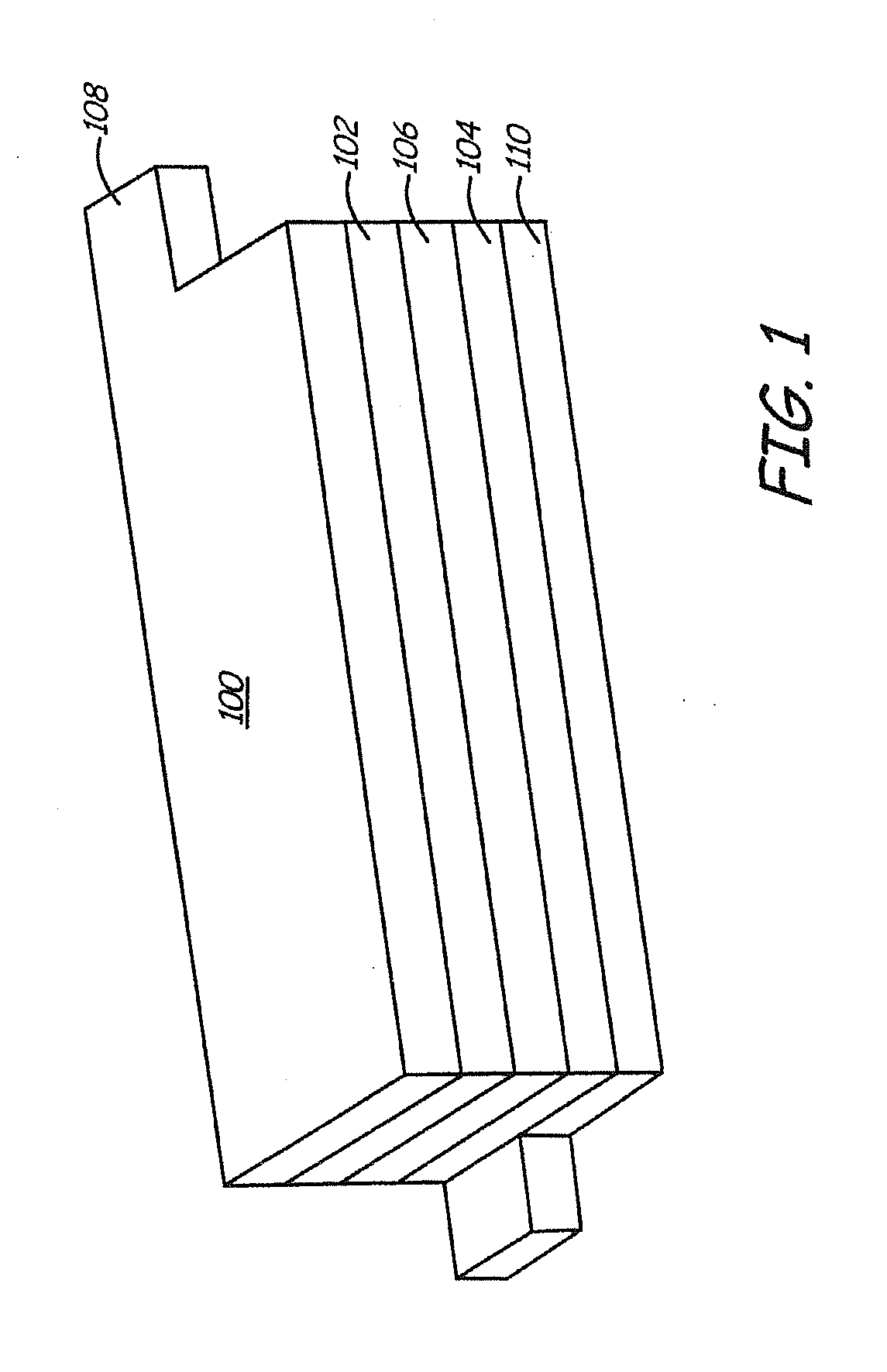

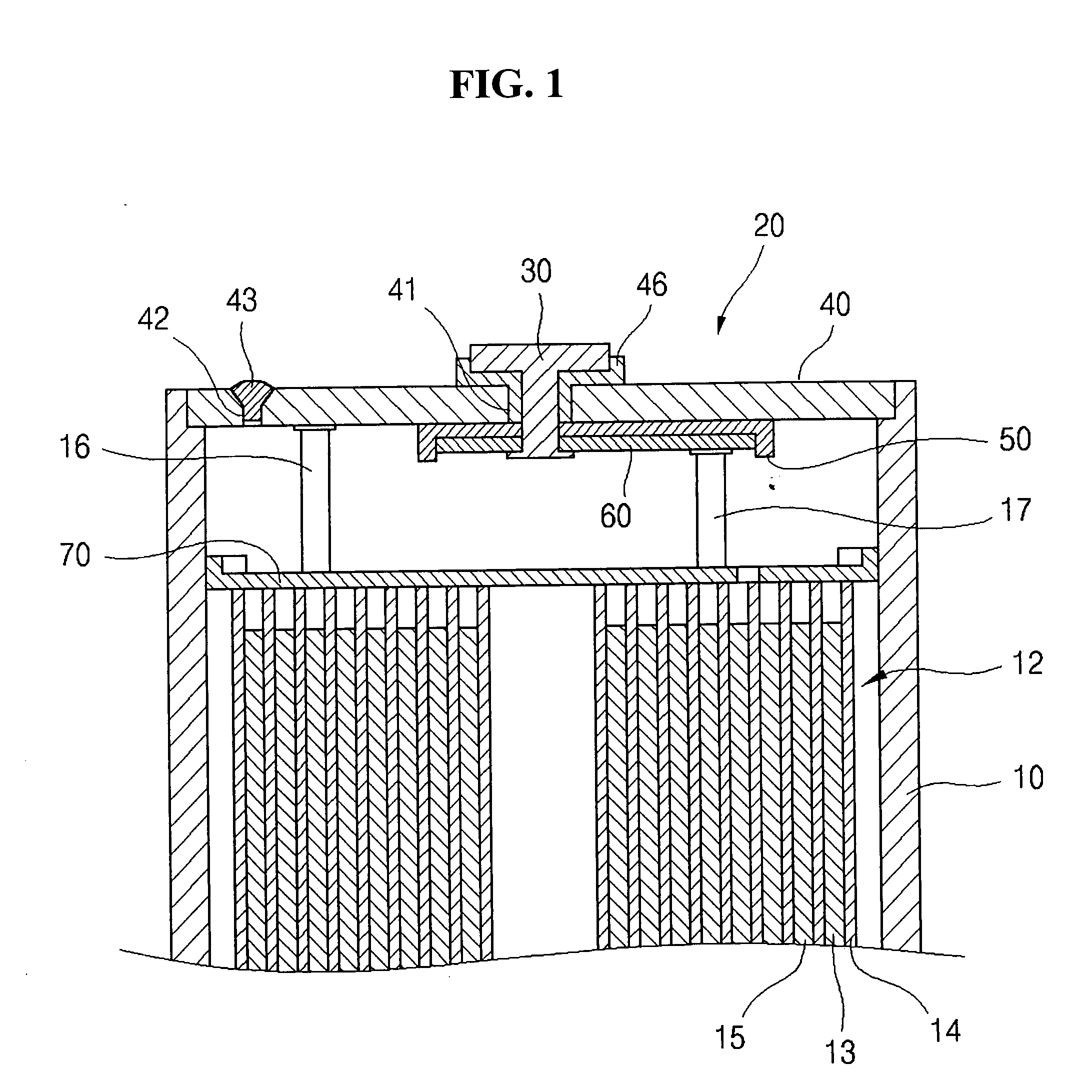

Lithium ion battery with high voltage electrolytes and additives

ActiveUS20110136019A1Final product manufactureElectrode carriers/collectorsMethyl carbonateHigh pressure

Desirable electrolyte compositions are described that are suitable for high voltage lithium ion batteries with a rated charge voltage at least about 4.45 volts. The electrolyte compositions can comprise ethylene carbonate and solvent composition selected from the group consisting of dimethyl carbonate, methyl ethyl carbonate, γ-butyrolactone, γ-valerolactone or a combination thereof. The electrolyte can further comprise a stabilization additive. The electrolytes can be effectively used with lithium rich positive electrode active materials.

Owner:IONBLOX INC

High surface area sol-gel route prepared hydrogenation catalysts

InactiveUS6686310B1Good dispersionImprove uniformityCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsRheniumSilicon oxide

This invention concerns novel compositions, useful as hydrogenation catalyst, said compositions comprising metals and metal ions such as ruthenium (Ru) or palladium (Pd) dispersed in and distributed throughout a matrix comprising an inorganic or silicon oxide network. The catalyst may be prepared by the sol-gel method; a solution of at least one catalytic metal compound is added to a solution of at least one metal alkoxide selected from Al, Ti, Nb, Zr, Ta, Si and other inorganic alkoxides, and then gelling the mixture. Promotors such as rhenium (Re), molybdenum (Mo) and tin (Sn) may be added. The catalyst may be used in the reduction of metallic acid or gamma-butyrolactone to tetrahydrofuran (THF) and 1,4-butanediol (BDO).

Owner:EI DU PONT DE NEMOURS & CO

Electrolyte for lithium secondary battery and a lithium secondary battery including the same

ActiveUS20070009806A1Improve battery performanceInhibit swellingElectrolytic capacitorsCell electrodesOrganic solventPhysical chemistry

An electrolyte for a lithium secondary battery and a lithium secondary battery having the electrolyte, the electrolyte including a lithium salt; a non-aqueous organic solvent including γ-butyrolactone-; and a succinic anhydride.

Owner:SAMSUNG SDI CO LTD

Pigment-based non-aqueous ink-jet inks

The present invention is drawn to ink compositions and methods for ink-jet recording. The ink compositions can include a milled pigment, a surfactant, a non-aqueous co-solvent system, and at least 2 wt % resin solubilized in the ink composition. The non-aqueous solvent system comprises a main co-solvent system, where each co-solvent of this system has a surface tension less than 32 dynes / cm at 25° C. The co-solvent system also includes gamma butyrolactone and a second co-solvent system. The second co-solvent system includes one or more co-solvent(s), each having a surface tension of greater than 32 dynes / cm at 25° C. The second co-solvent system or other components can optionally act to increase the overall surface tension of the ink composition as a whole.

Owner:HEWLETT PACKARD DEV CO LP

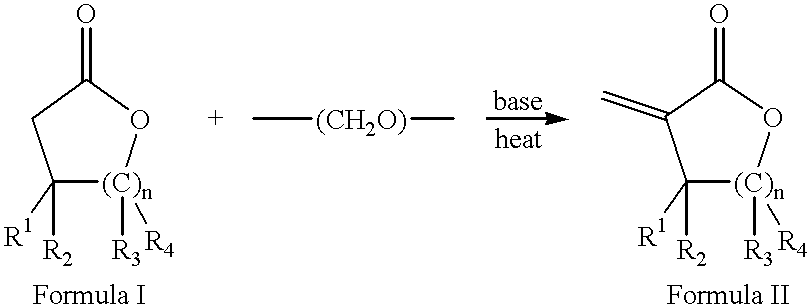

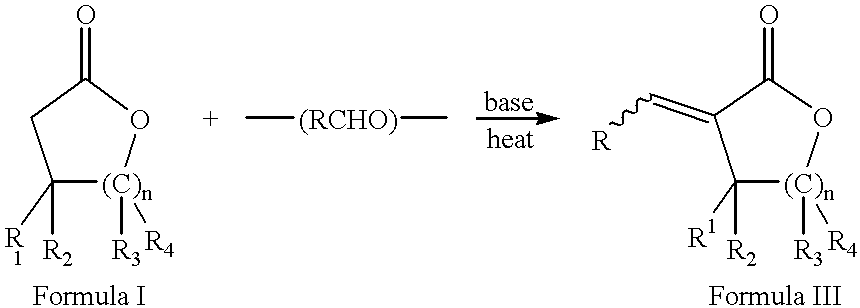

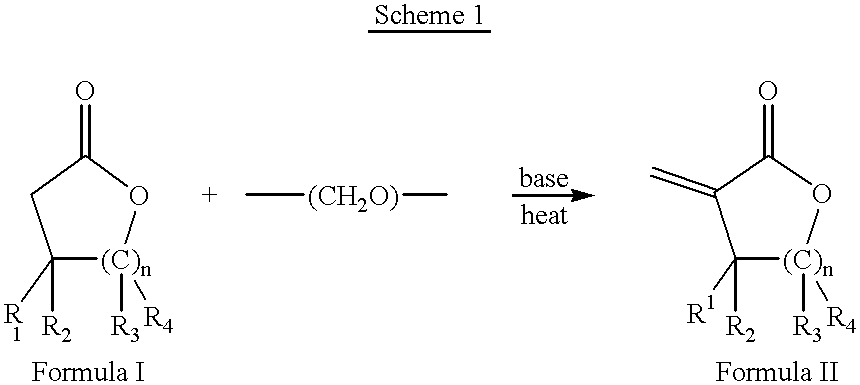

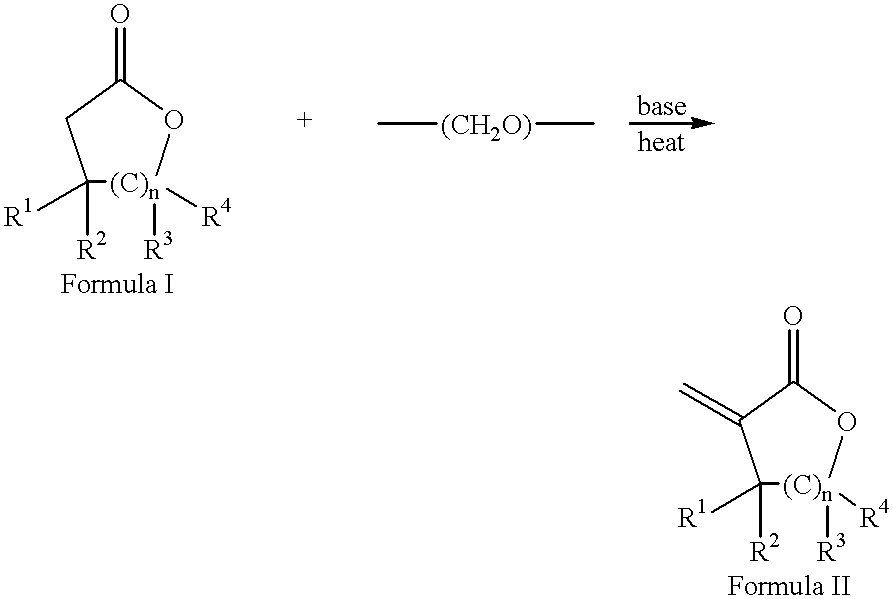

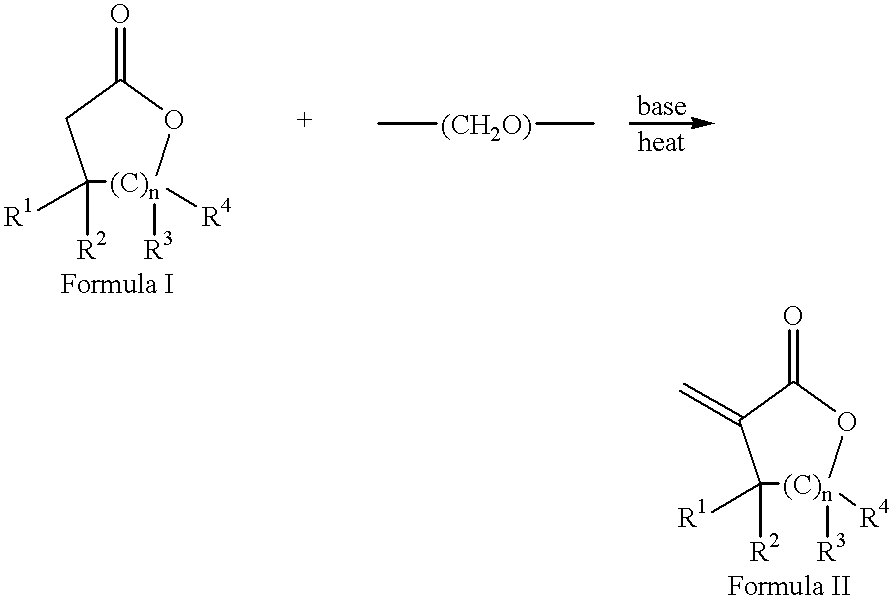

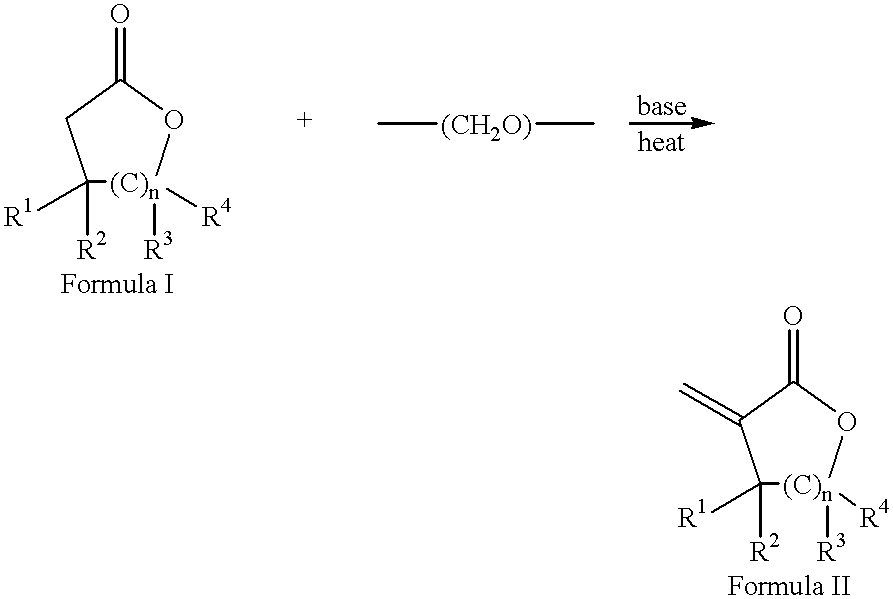

Process for the preparation of alpha-methylenelactones and alpha-substituted hydrocarbylidene lactones

This invention pertains to a process for making alpha-methylenelactones and alpha-substituted hydrocarbylidene lactones. The present invention obtains high yields of alpha-methylene-gamma-butyrolactone by heating gamma-butyrolactone and formaldehyde in the presence of a base.

Owner:EI DU PONT DE NEMOURS & CO

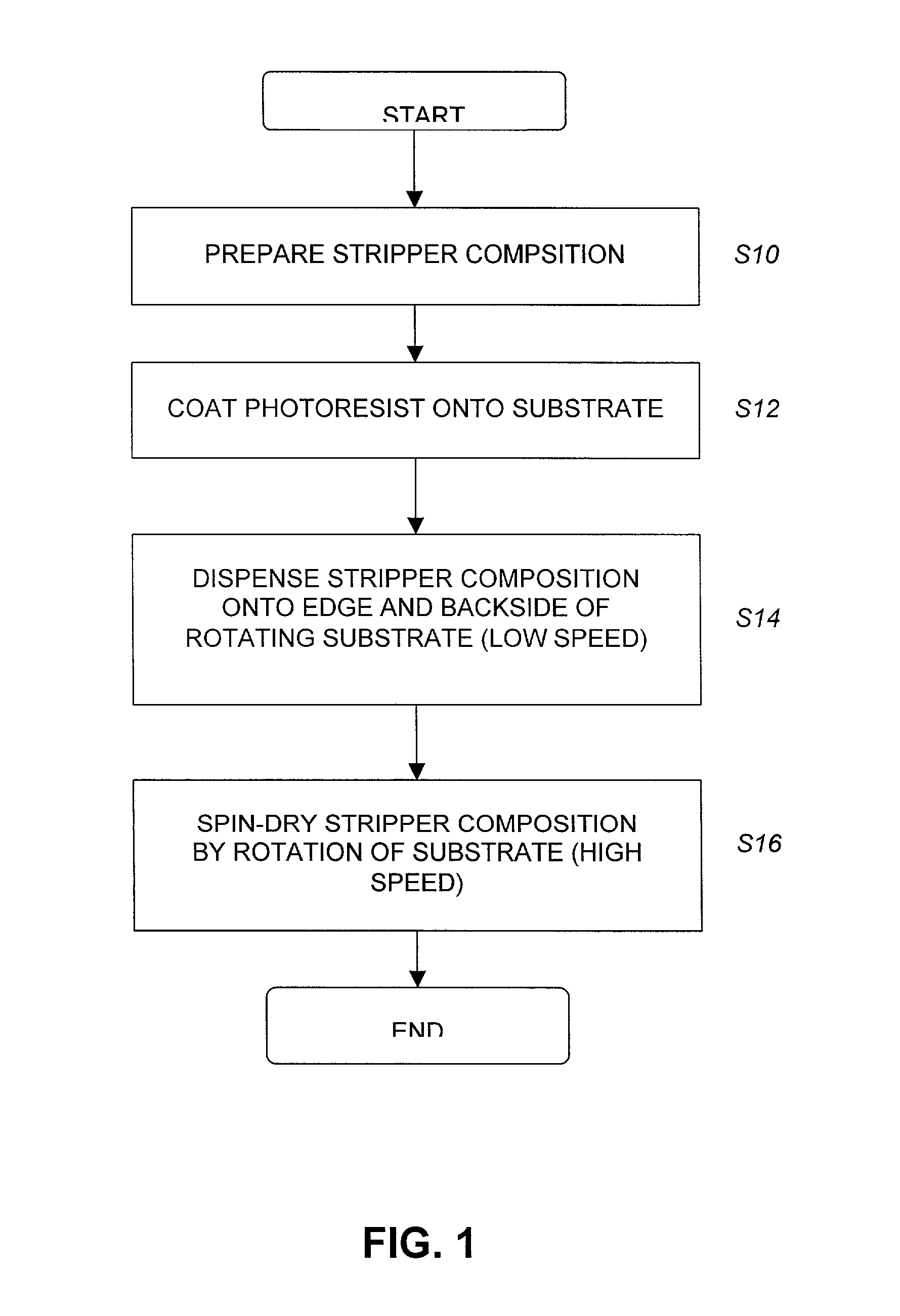

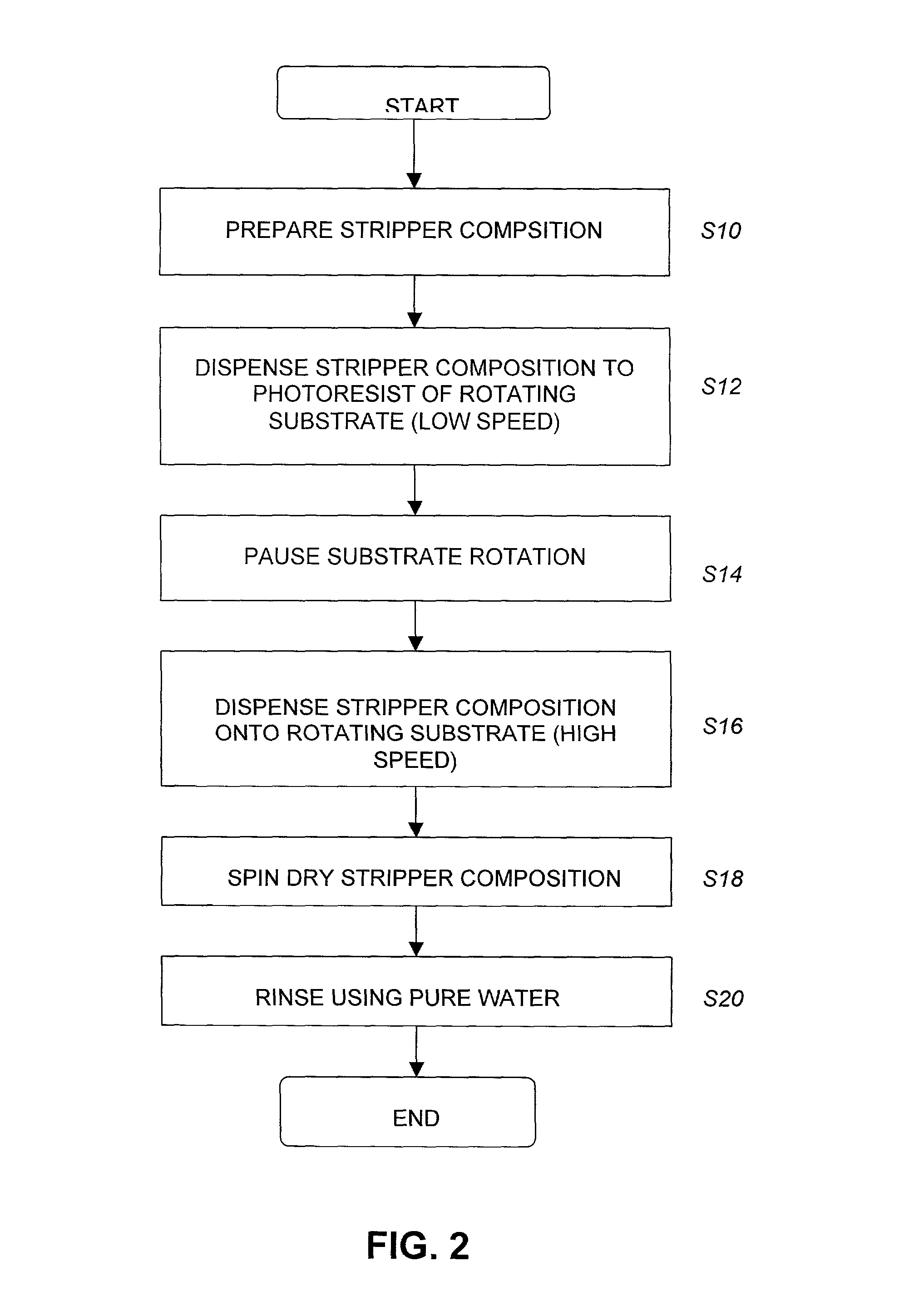

Photoresist stripper compositions

InactiveUS20030113673A1Semiconductor/solid-state device manufacturingPhotomechanical coating apparatusAmyl acetateMethyl group

A photoresist stripper composition is made up of a mixture of an acetic acid ester, gamma-butyrolactone (GBL), and a non-acetate ester or a poly alkyl alcohol derivative. The acetic acid ester may be at least one of n-butyl acetate, amyl acetate, ethyl aceto-acetate, and isopropyl acetate. The non-acetate ester may be at least one of ethyl lactate (EL), ethyl-3-ethoxy propionate (EEP) and methyl-3-methoxy (MMP). The poly alkyl alcohol derivative may be at least one of propylene glycol monomethyl ester (PGME) and propylene glycol monomethyl ester acetate (PGMEA).

Owner:SAMSUNG ELECTRONICS CO LTD

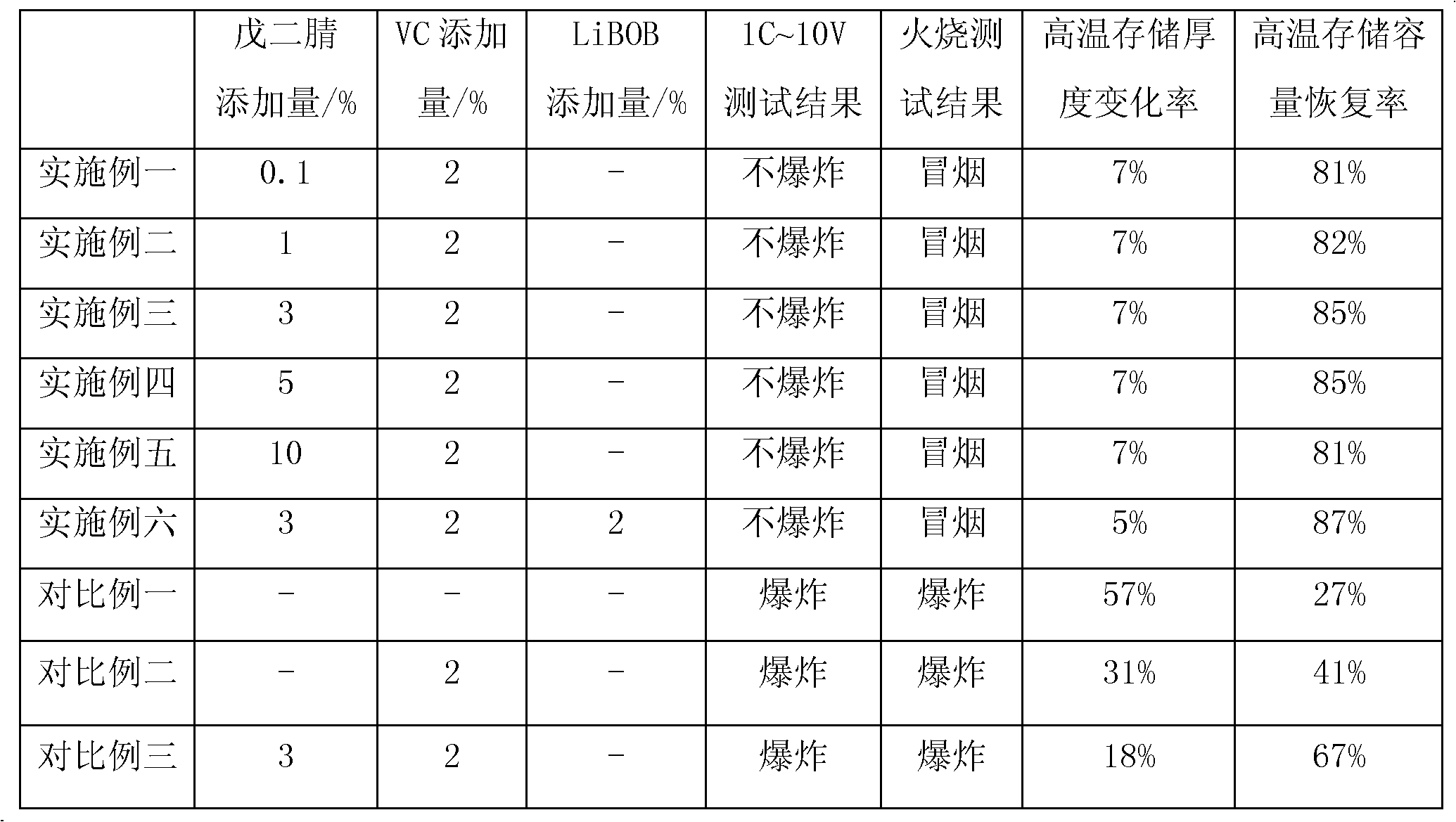

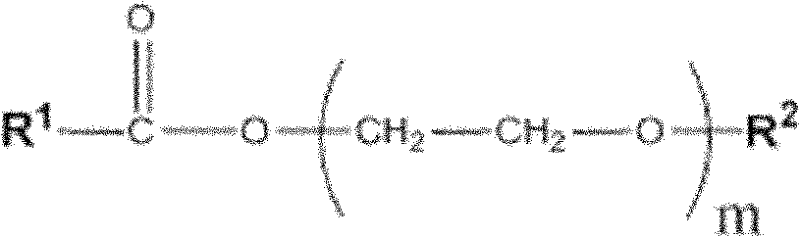

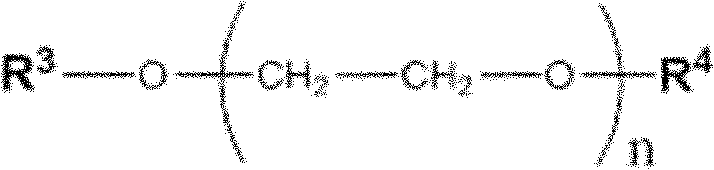

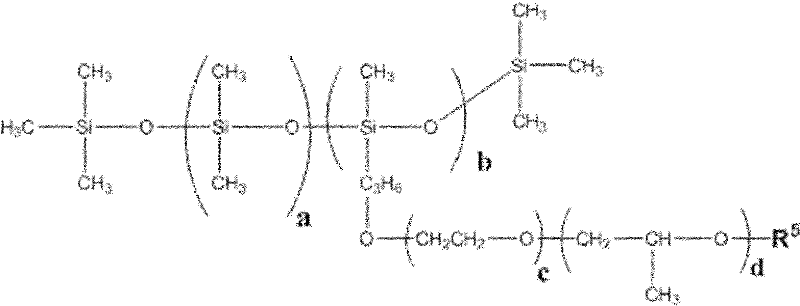

Non-aqueous organic electrolyte, lithium ion secondary battery containing non-aqueous organic electrolyte, preparation method of lithium ion secondary battery and terminal communication equipment

InactiveCN102522590AHigh energy storageIncrease energy densityFinal product manufactureCell electrodesHigh temperature storageLithium

The embodiment of the invention provides non-aqueous organic electrolyte, a lithium ion secondary battery containing the non-aqueous organic electrolyte, a preparation method of the lithium ion secondary battery and terminal communication equipment. The non-aqueous organic electrolyte comprises lithium salt, a non-aqueous organic solvent which comprises gamma-butyrolactone and a saturated cyclic ester compound shown in a formula (I), an unsaturated cyclic ester compound shown in a formula (II) and a dinitrile compound shown in a formula (III). The non-aqueous organic electrolyte has excellent chemical stability and electrochemical stability and can be used for inhibiting the decomposition of an electrolyte solvent under the high voltage and aerogenesis expansion of the lithium ion secondary battery at high temperature in the storage process and meeting the using requirement of the high-voltage lithium ion secondary battery. A cathode active material of the lithium ion secondary battery is a mixture of a spinel structure material and a laminated solid solution material. After the non-aqueous organic electrolyte is arranged in the lithium ion secondary battery, the lithium ion secondary battery has excellent high temperature storage characteristic and safety when being used under the high voltage and the full-charged condition.

Owner:HUAWEI TECH CO LTD

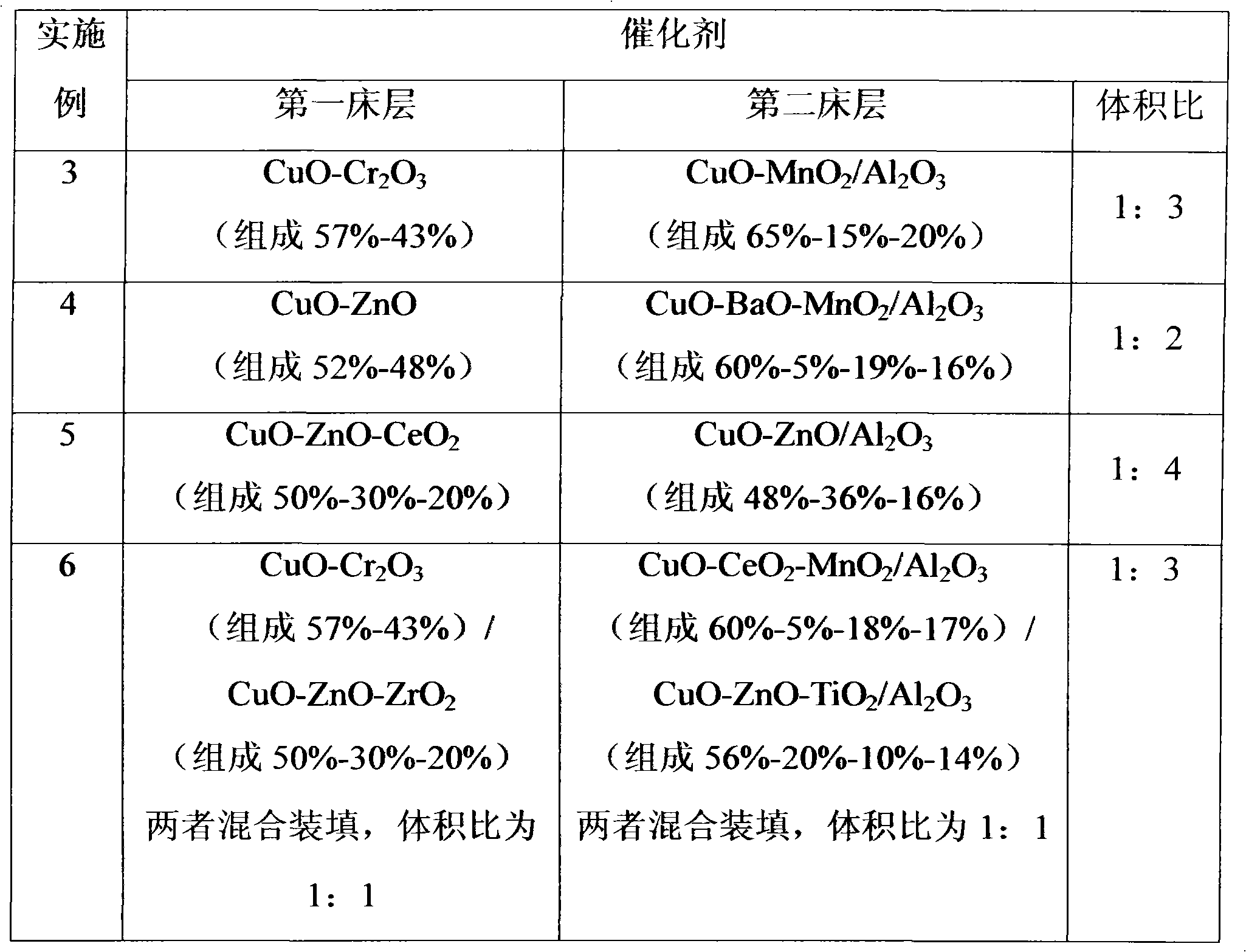

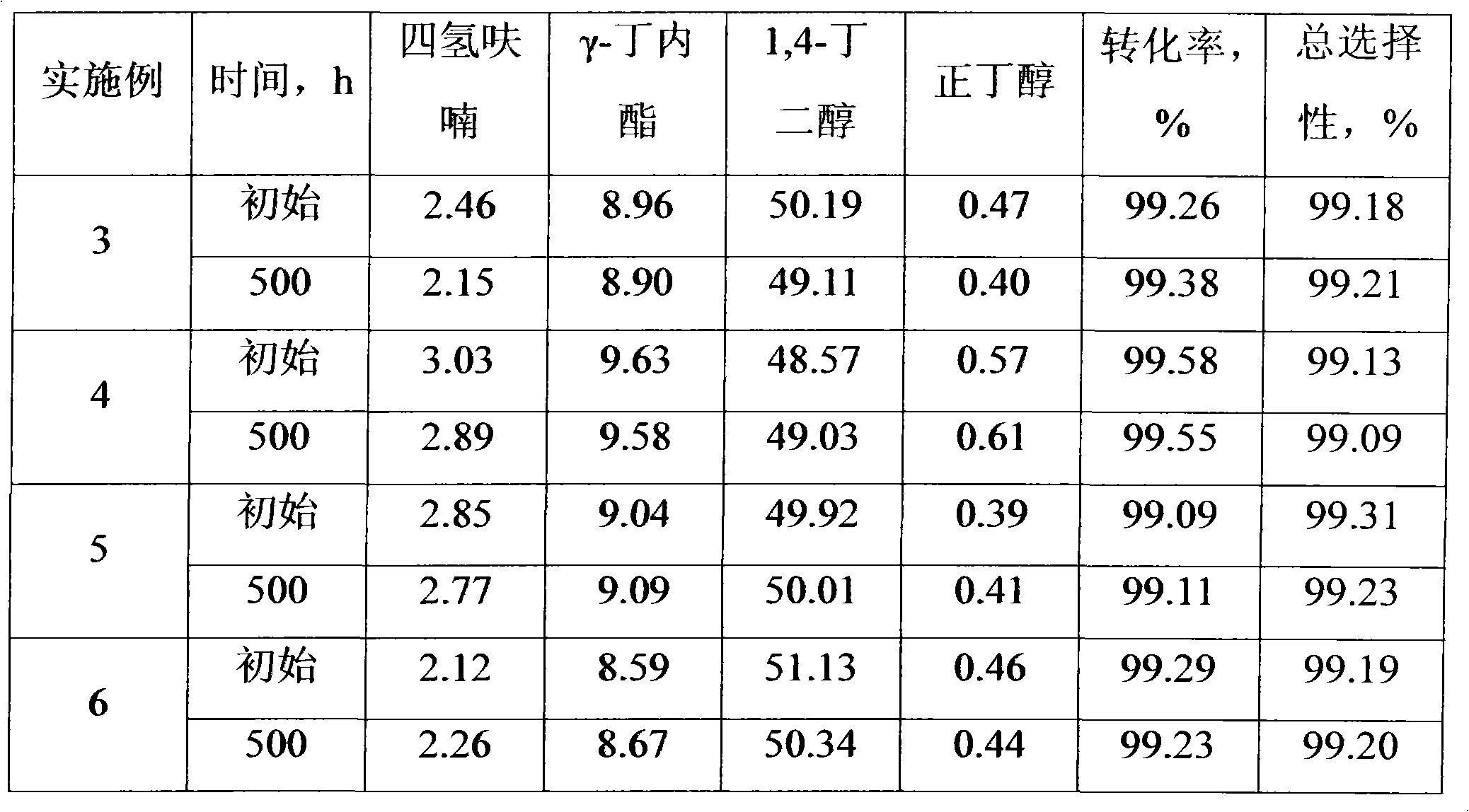

Method for producing 1,4-butanediol and coproducing tetrahydrofuran, and gamma-butyrolactone

The invention relates to a method for producing 1, 4-butanediol and co-producing tetrahydrofuran and gamma-butyrolactone. The method comprises the following steps that: maleic dialkyl ester and / or succinic acid dialkyl ester are / is used as raw material; under hydrogen existence and reaction conditions, reaction material passes through a first catalyst bed layer of CuO-AO-BO, wherein AO is Cr2O3 and / or ZnO, and BO is one or a plurality of Ba, Mg, Ti, Ce, Si, Zr and Mn oxides; then the reaction material passes through a second catalyst bed layer of CuO-MO-Al2O3, wherein MO is one or a plurality of Mn, Zn, Ba, Mg, Ti, Ce, Si and Zr oxides. Compared with the prior art, the method has the advantages that: the raw material conversion rate is more than 99 percent; the total selectivity of 1, 4-butanediol, tetrahydrofuran and gamma-butyrolactone is more than 99 percent; the catalyst stability is good.

Owner:CHINA PETROLEUM & CHEM CORP +1

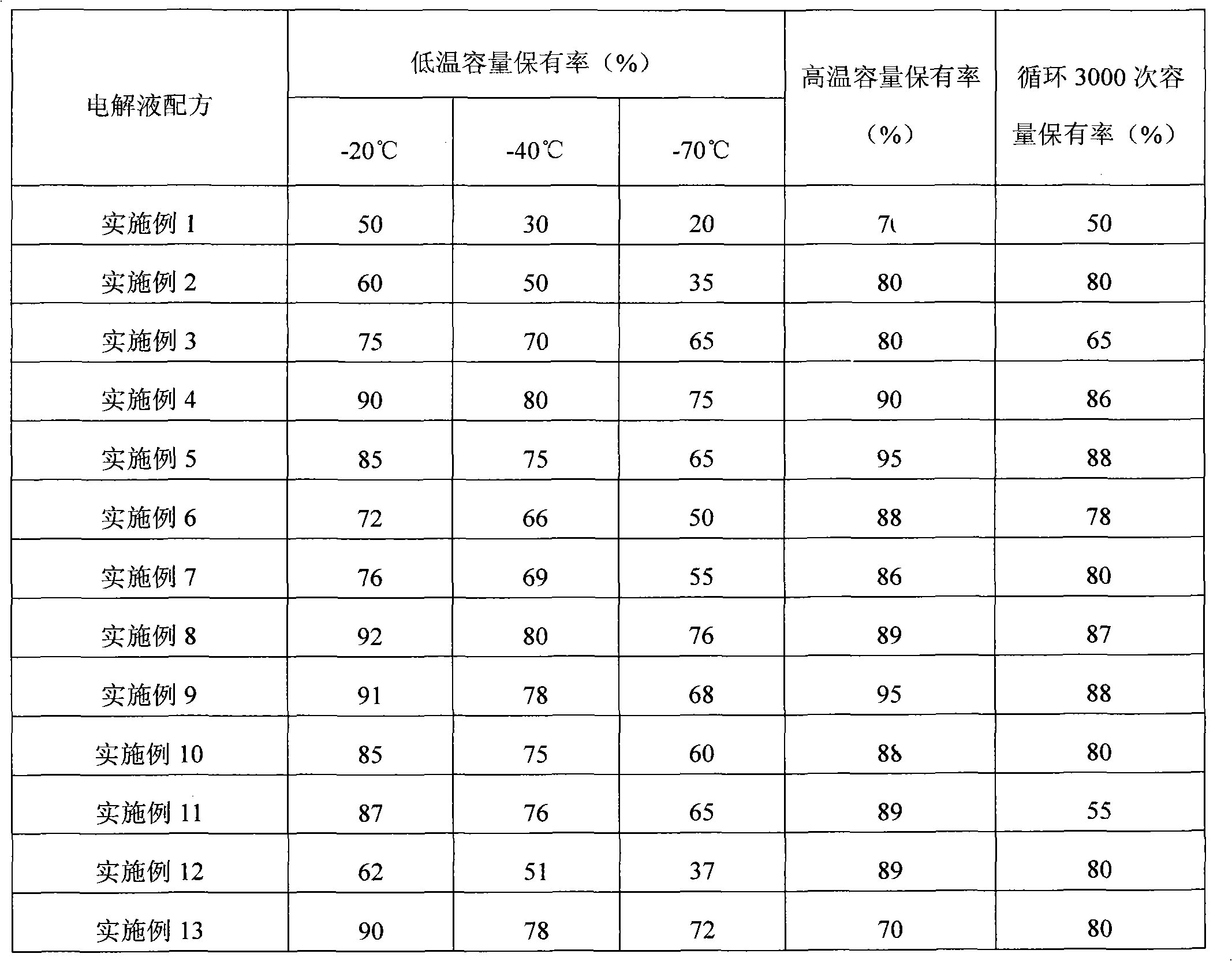

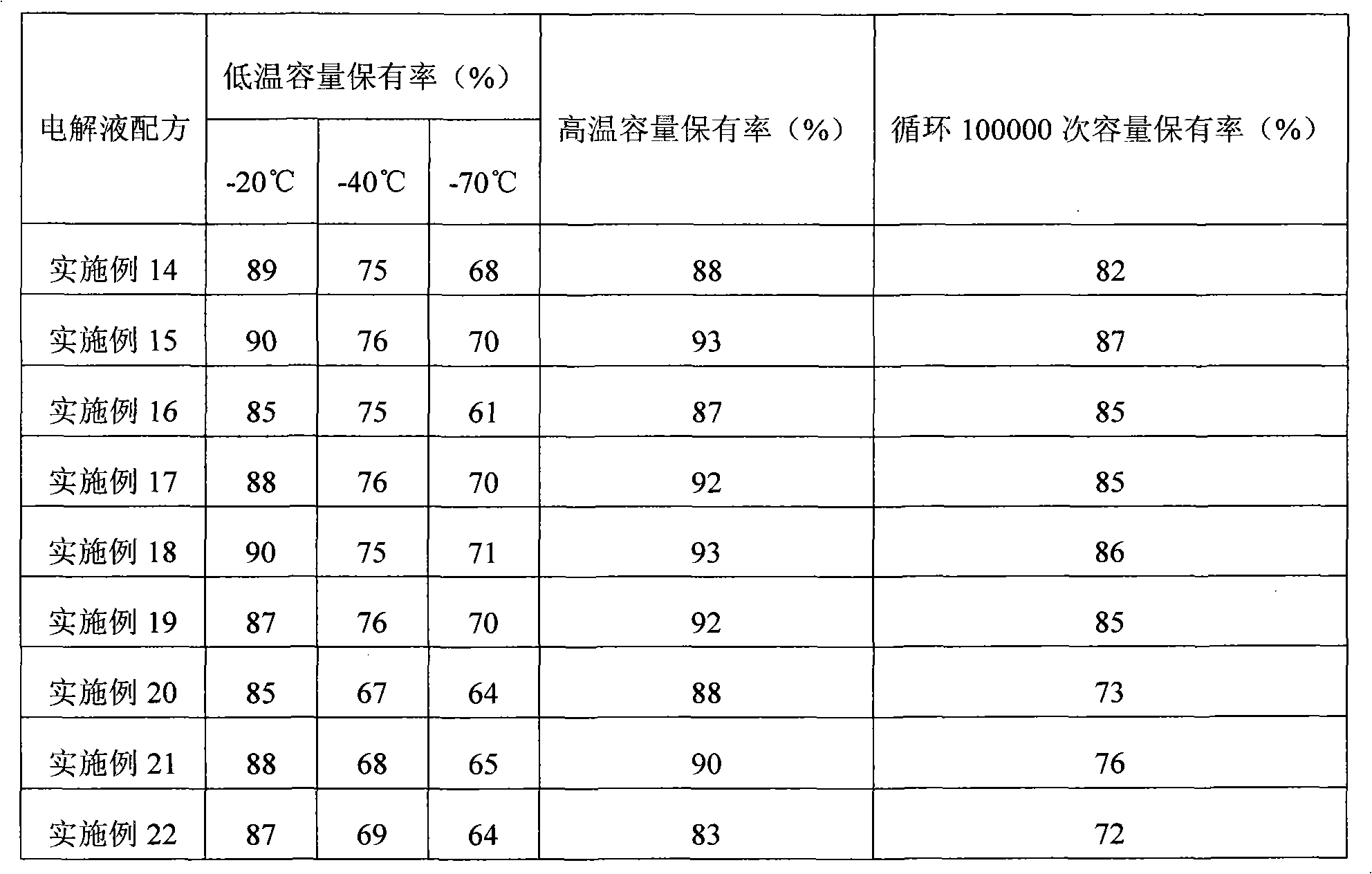

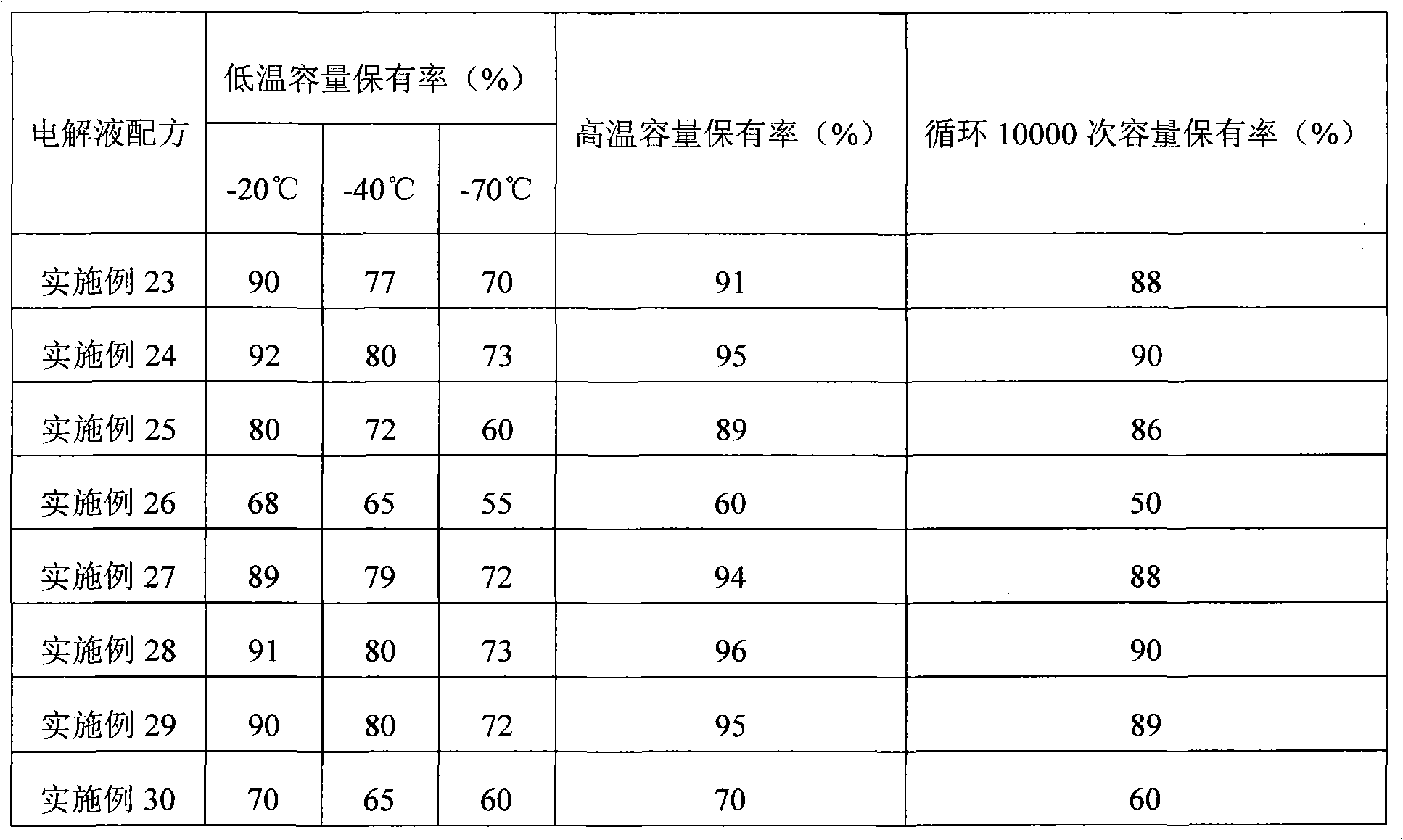

Low-temperature organic electrolyte taking gamma-butyrolactone as base solvent and application thereof

ActiveCN101916878AImprove low temperature performanceImprove cycle lifeHybrid capacitor electrolytesElectrolytic capacitorsCapacitanceGraphite

The invention discloses low-temperature organic electrolyte taking gamma-butyrolactone as a base solvent and a preparation method thereof. The organic electrolyte comprises a solvent and lithium tetrafluoroborate (LiBF4), wherein the solvent is a mixture of cyclic gamma-butyrolactone, chain carbonic ester and chain carboxylic ester. The organic electrolyte is suitable to be used by a non-graphite-based cathode lithium ion capacitor, a non-graphite-based cathode lithium ion battery and a non-graphite-based cathode lithium ion system. Compared with the formula of the traditional electrolyte, the organic electrolyte greatly improves the low-temperature performance of an electrochemical device and prolongs the cyclic service life of the electrochemical device on the basis of ensuring the electrochemical performance, and meanwhile is favorable for the safety of the electrochemical device; and the formula of the electrolyte is suitable for the non-graphite-based cathode lithium ion capacitor, the non-graphite-based cathode lithium ion battery and the non-graphite-based cathode lithium ion capacitance battery.

Owner:SHANGHAI AOWEI TECH DEV

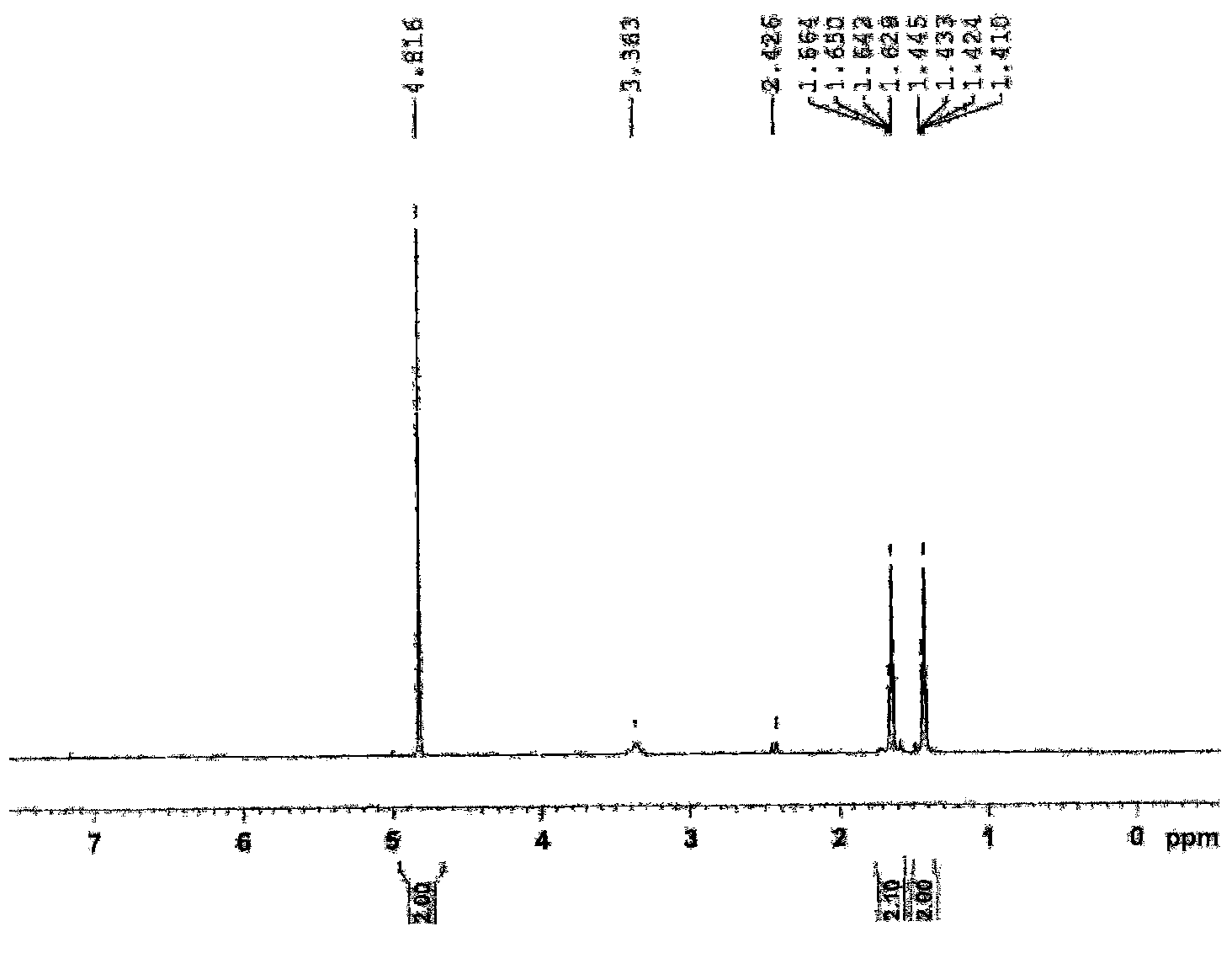

Process for the preparation of alpha-methylene lactones

This invention concerns a process for the addition of formaldehyde to the alpha carbon atom of lactones for the production of alpha-methylenelactones, and specifically alpha-methylene-gamma-butyrolactone.

Owner:EI DU PONT DE NEMOURS & CO

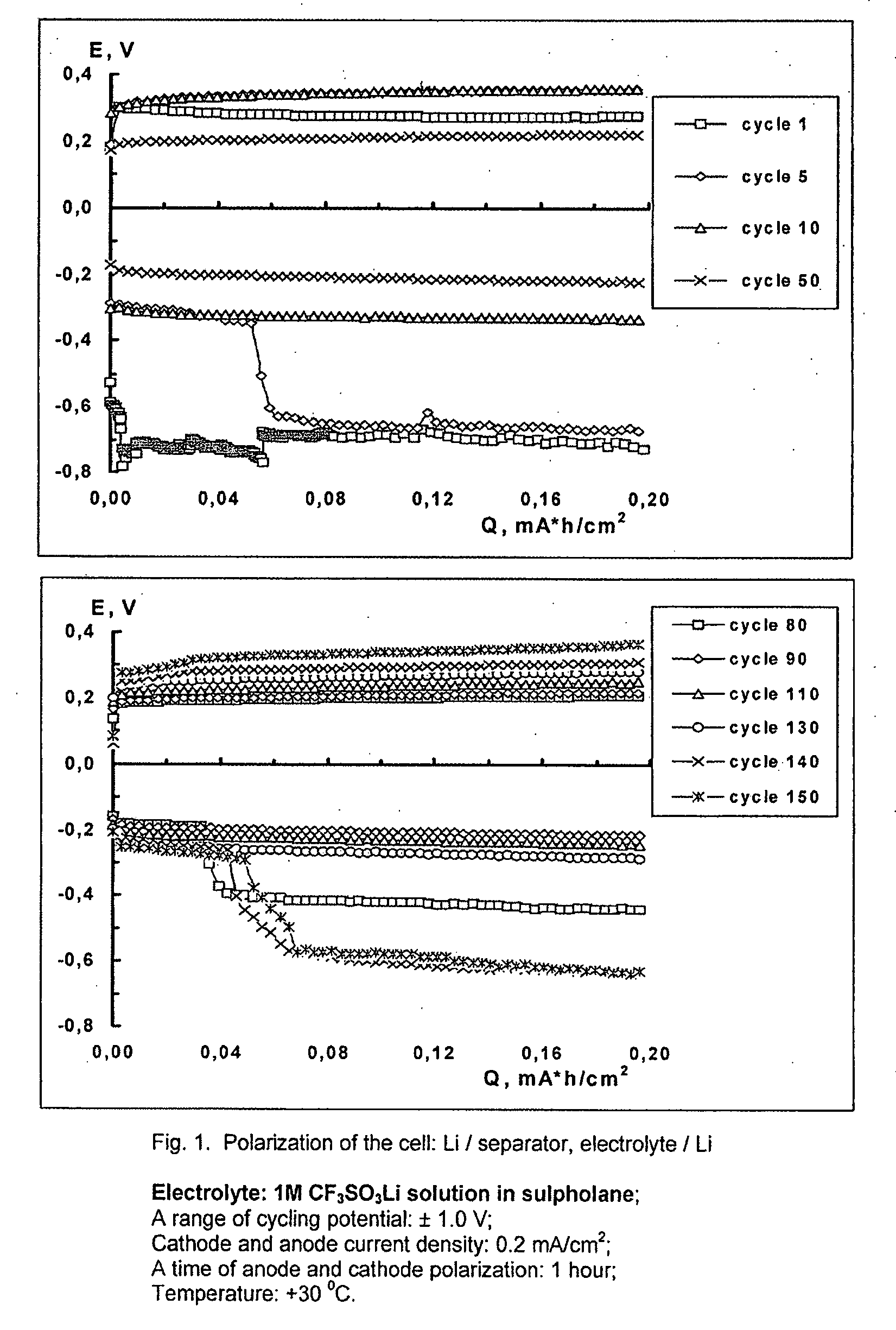

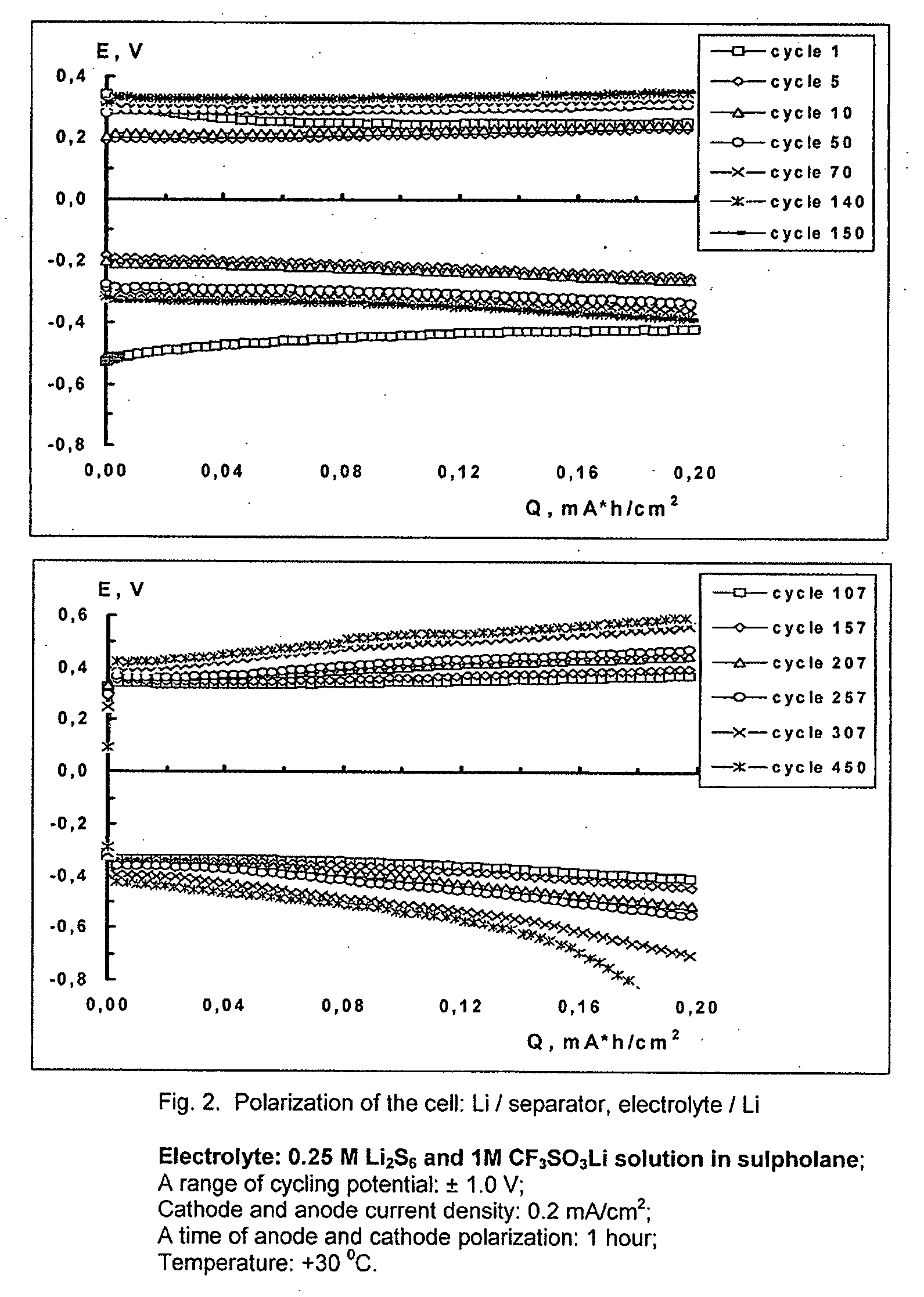

Cell or battery with a metal lithium electrode and electrolytes therefor

InactiveUS20080038645A1Improve cycle lifeOrganic electrolyte cellsLi-accumulatorsSulfolaneMetallic lithium

An electrolyte for rechargeable batteries with a negative electrode of lithium or lithium containing alloys comprising: one or several non-aqueous organic solvents, one or several lithium salts and one or several additives increasing the cycle life of the lithium electrode. The electrolyte solution may comprise one or several solvents selected from the group comprising: tetrahydrofurane, 2-methyltetrahydrofurane, dimethylcarbonate, diethylcarbonate, ethylmethylcarbonate, methylpropylcarbonate, methylpropylpropyonate, ethylpropylpropyonate, methylacetate, ethylacetate, propylacetate, dimetoxyethane, 1,3-dioxalane, diglyme (2-methoxyethil ether), tetraglyme, ethylenecarbonate, propylencarbonate, γ-butyrolactone, and sulfolane. The electrolyte solution may further comprise at least one salt or several salts selected from the group consisting of lithium hexafluorophosphate (LiPF6), lithium hexafluoroarsenate (LiAsF6), lithium perchlorate (LiClO4), lithium sulfonylimid trifluoromethane (LiN(CF3SO2)2)) and lithium trifluorosulfonate (CF3SO3Li) or other lithium salts or salts of another alkali metal or a mixture thereof. Also disclosed is an electrochemical cell or battery with an anode of metallic lithium or a lithium-containing alloy, and such an electrolyte.

Owner:OXIS ENERGY

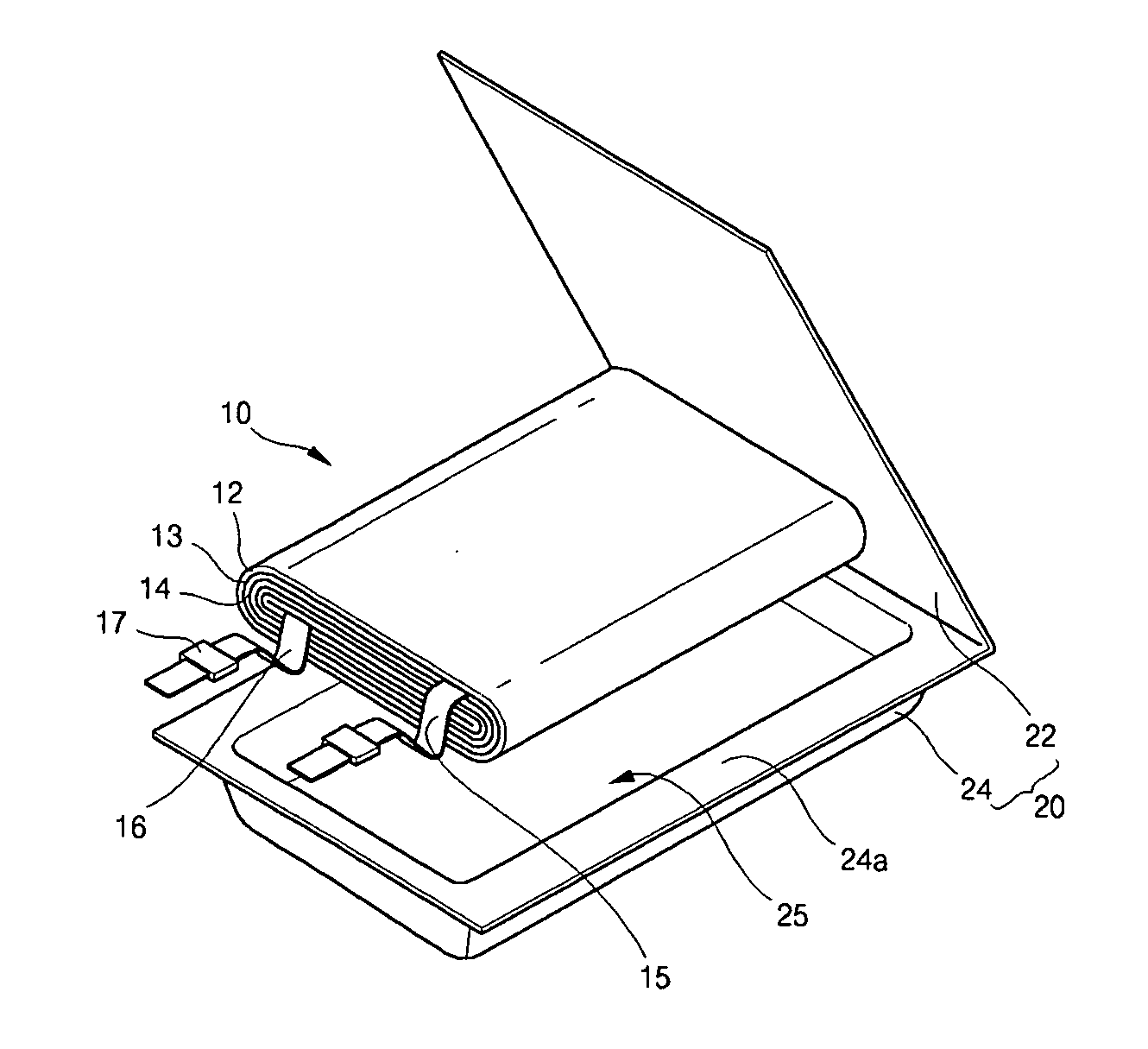

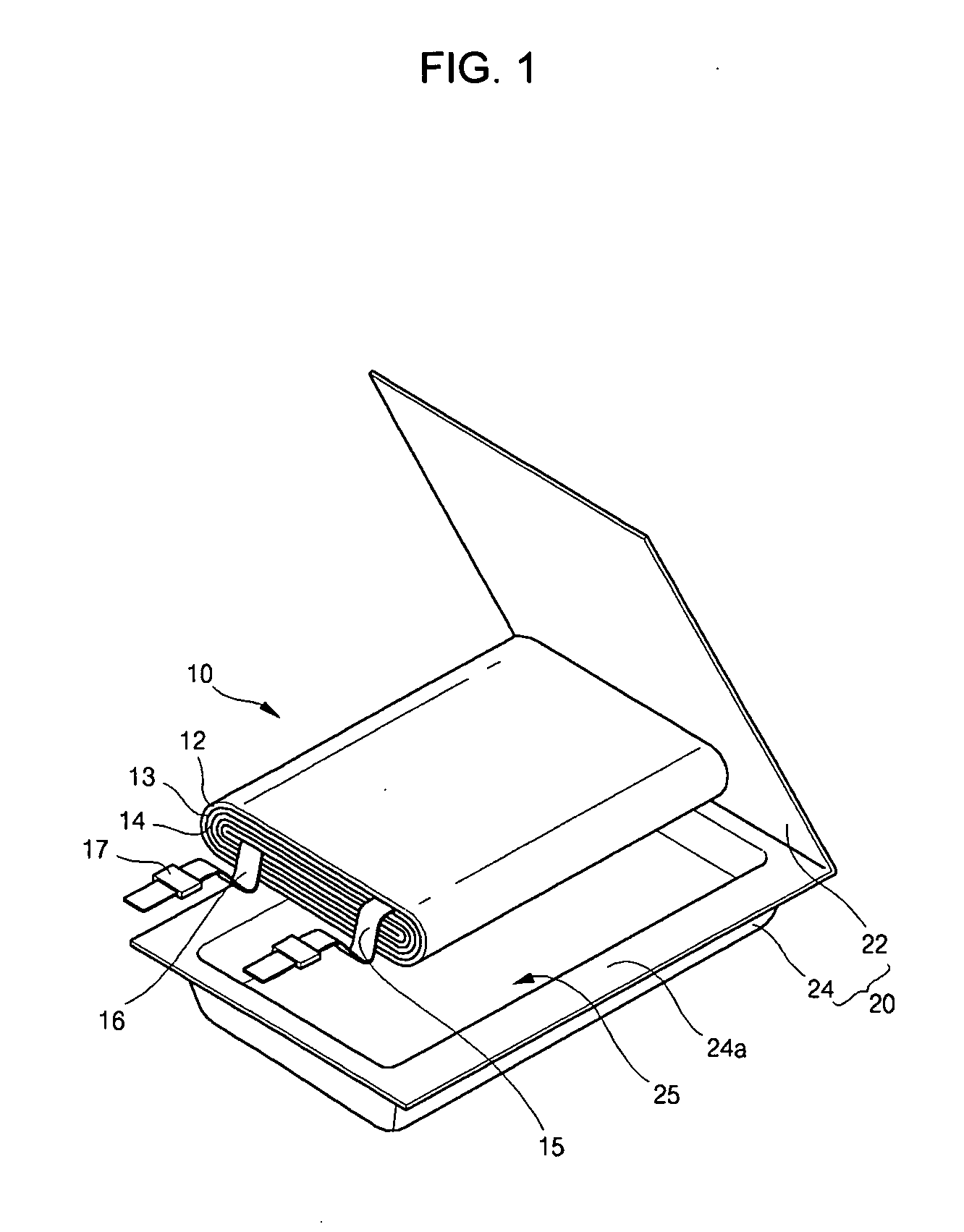

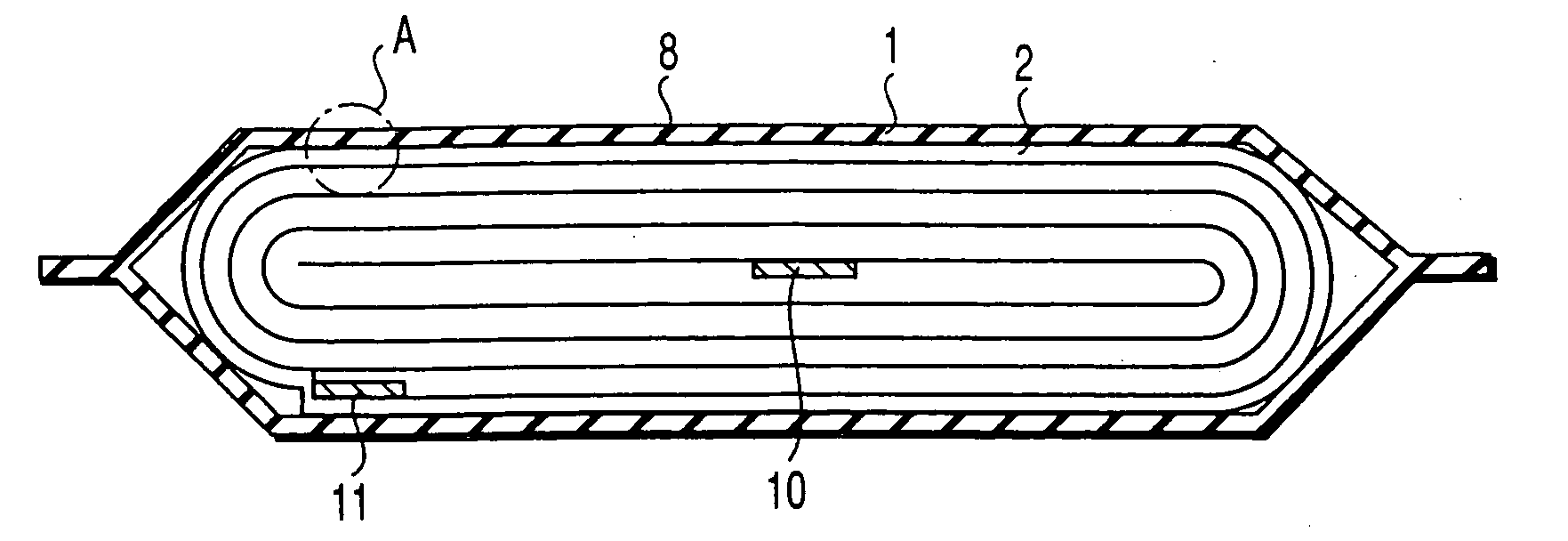

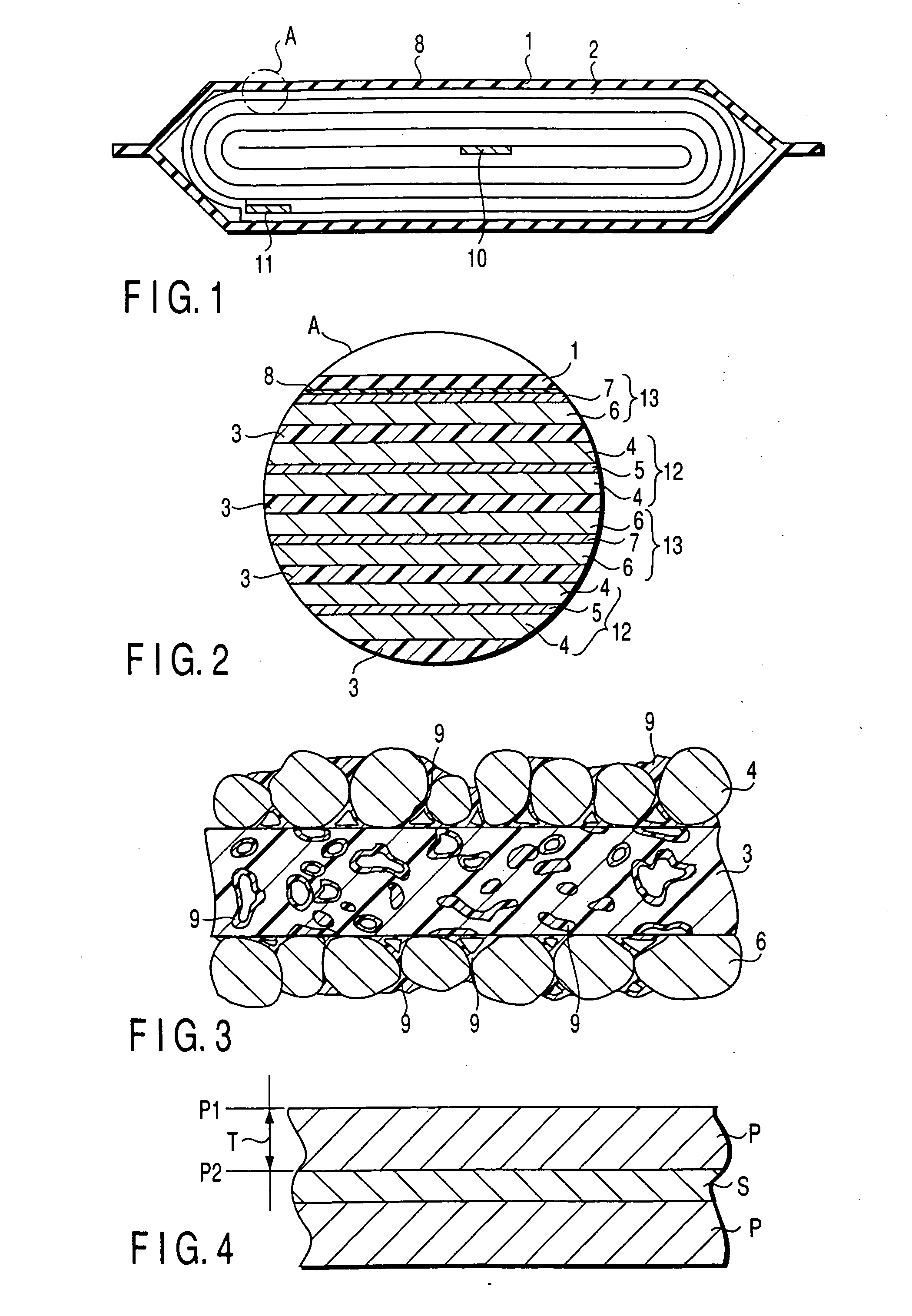

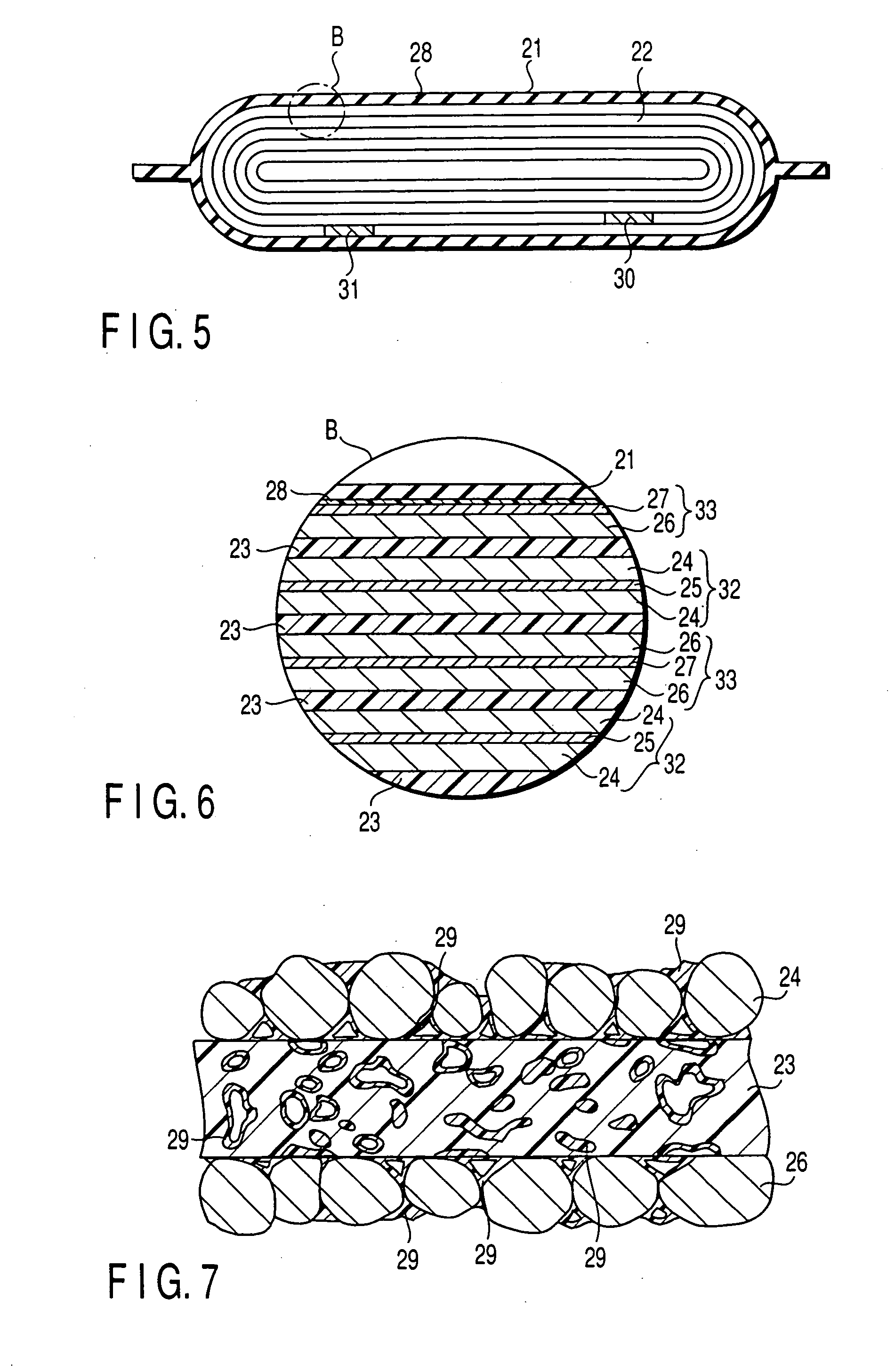

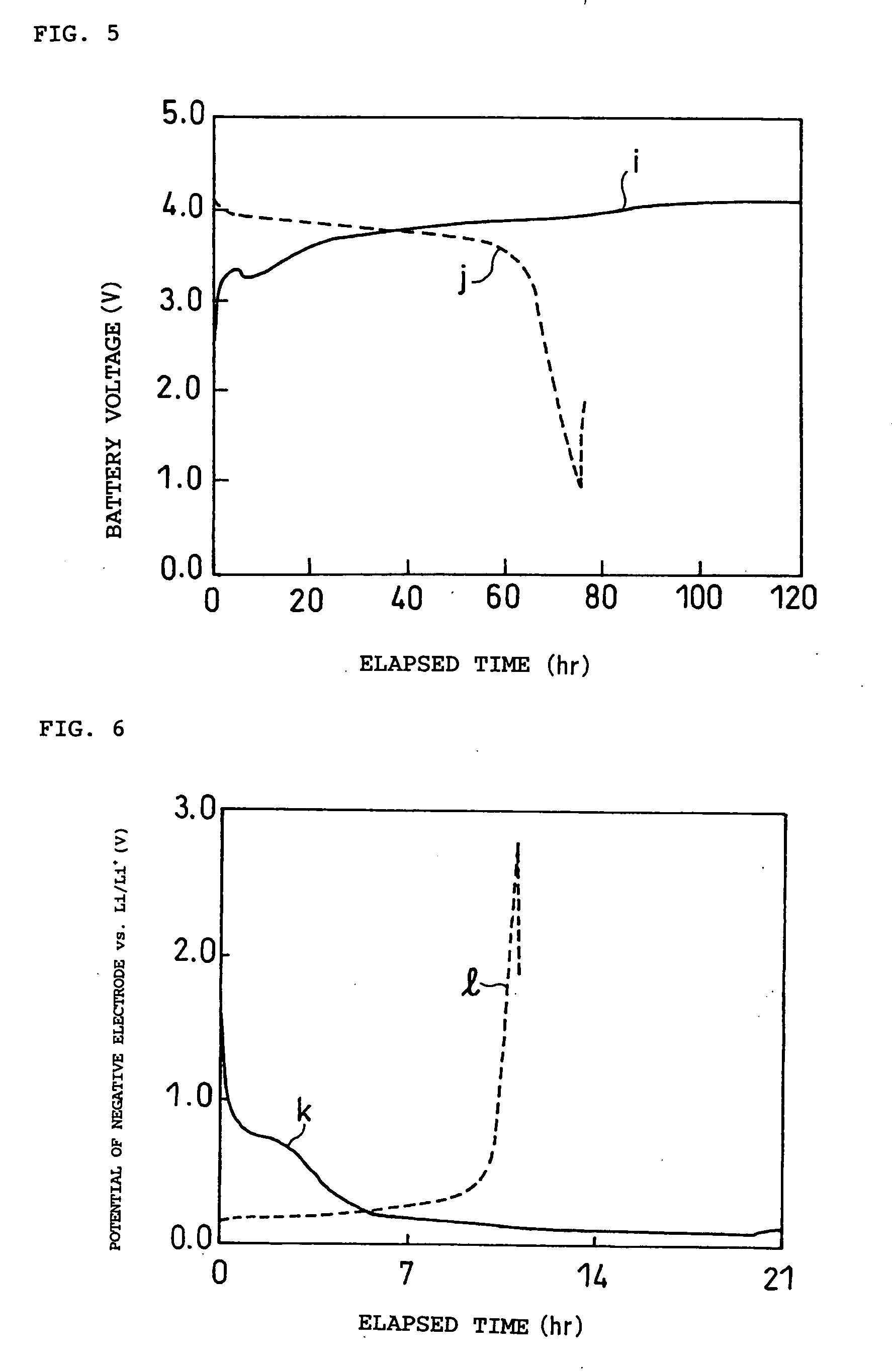

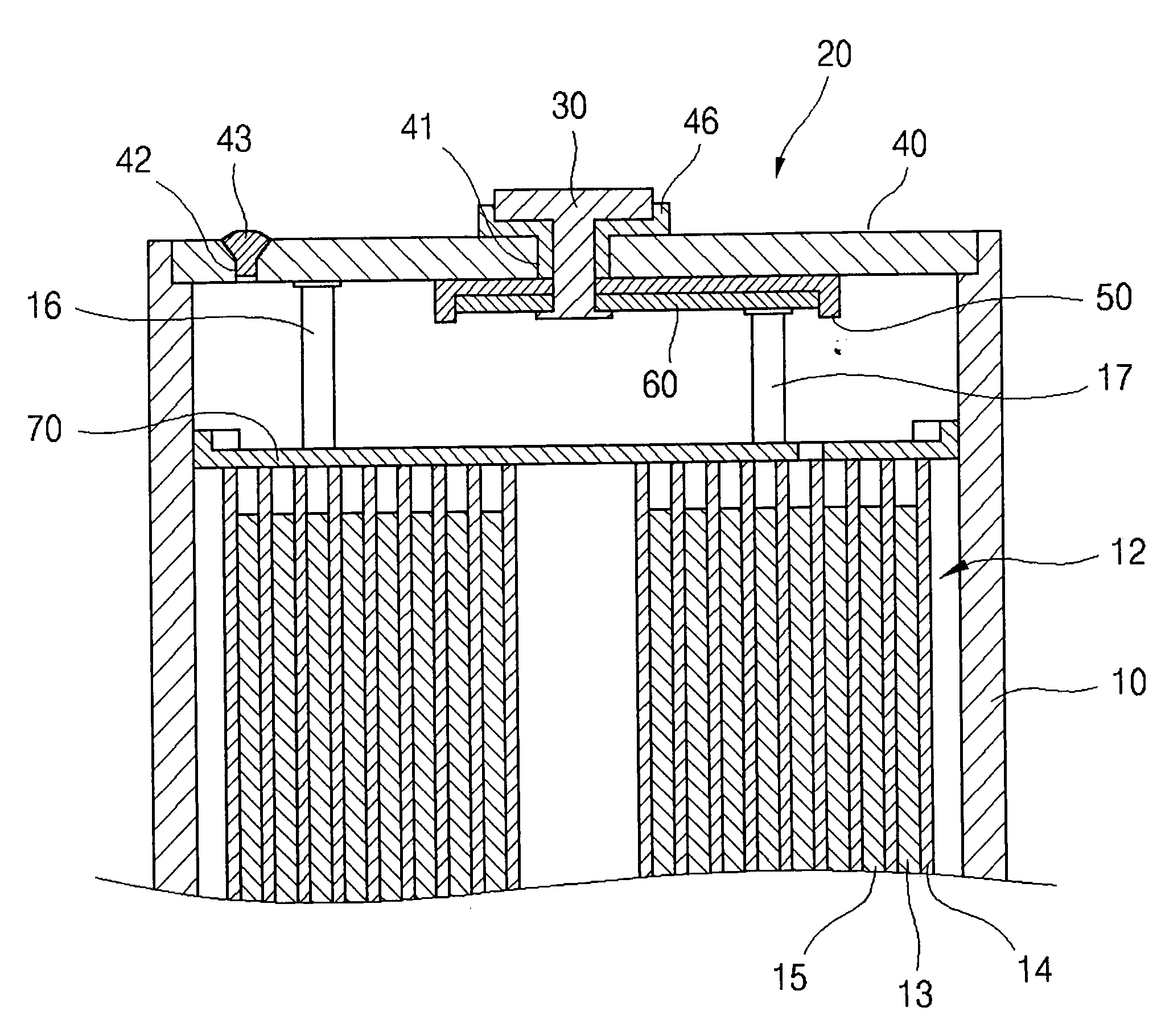

Nonaqueous electrolyte secondary battery

InactiveUS20060234131A1Improve large discharge characteristicImprove characteristic charge-discharge cycleFinal product manufactureElectrode carriers/collectorsLithiumSolvent

The present invention provides a nonaqueoxus electrolyte secondary battery, comprising an electrode group including a positive electrode, a negative electrode including a material for absorbing-desorbing lithium ions, and a separator arranged between the positive electrode and the negative electrode, a nonaqueous electrolyte impregnated in the electrode group and including a nonaqueous solvent and a lithium salt dissolved in the nonaqueous solvent, and a jacket for housing the electrode group and having a thickness of 0.3 mm or less, wherein the nonaqueous solvent γ-butyrolactone in an amount larger than 50% by volume and not larger than 95% by volume based on the total amount of the nonaqueous solvent.

Owner:KK TOSHIBA

Polyurethane urea solutions

InactiveUS20060189234A1Synthetic resin layered productsLiquid repellent fibresOrganic solventGamma-Butyrolactone

This invention relates to solutions of polyurethaneureas in γ-butyrolactone or mixtures of γ-butyrolactone with toxicologically acceptable organic solvents. A process for coating substrates using these polyurethaneurea solutions, and substrates coated by said process are also provided. The substrates coated according to the invention are preferably textile products or leather, but materials such as wood or concrete can also be coated according to the invention.

Owner:BAYER MATERIALSCIENCE AG

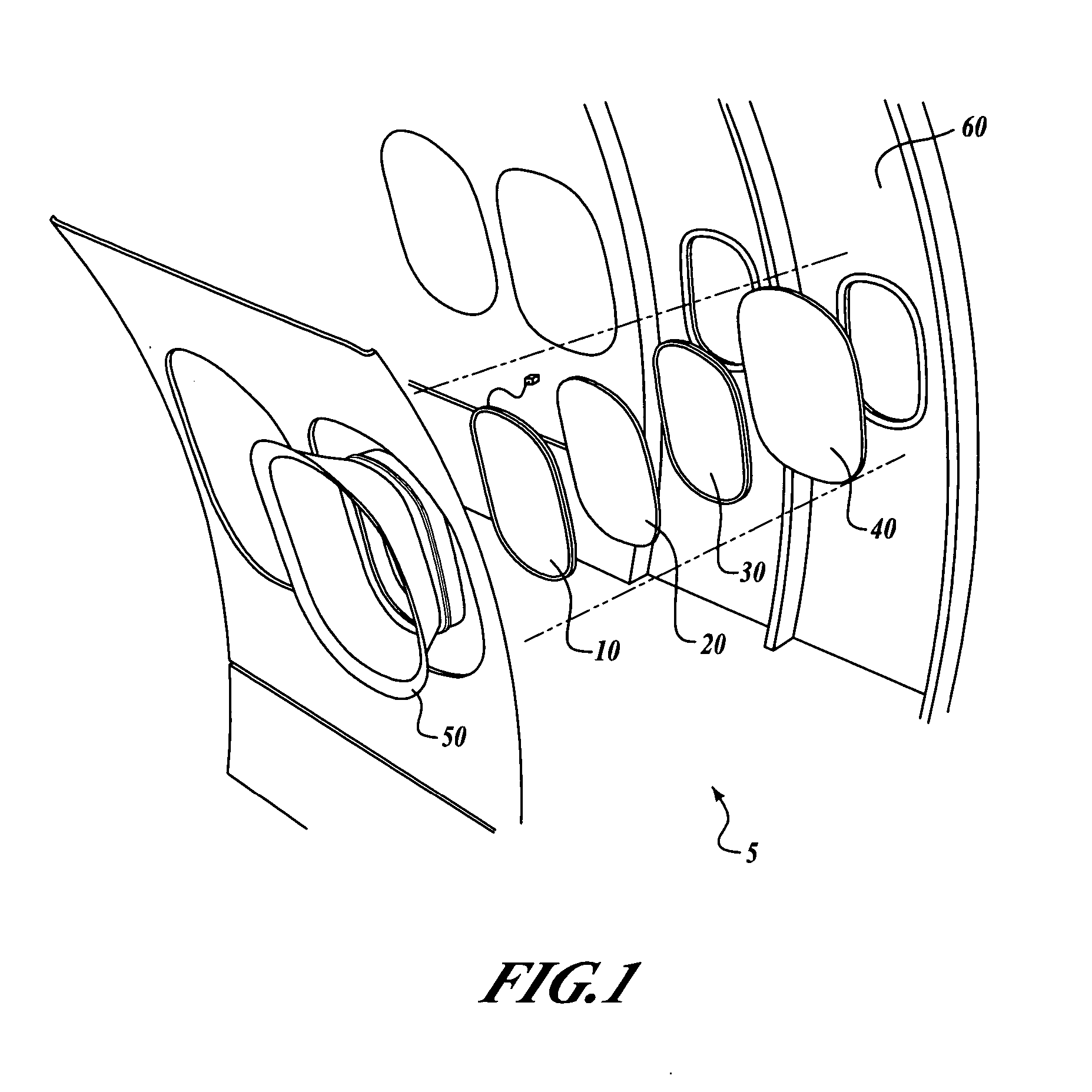

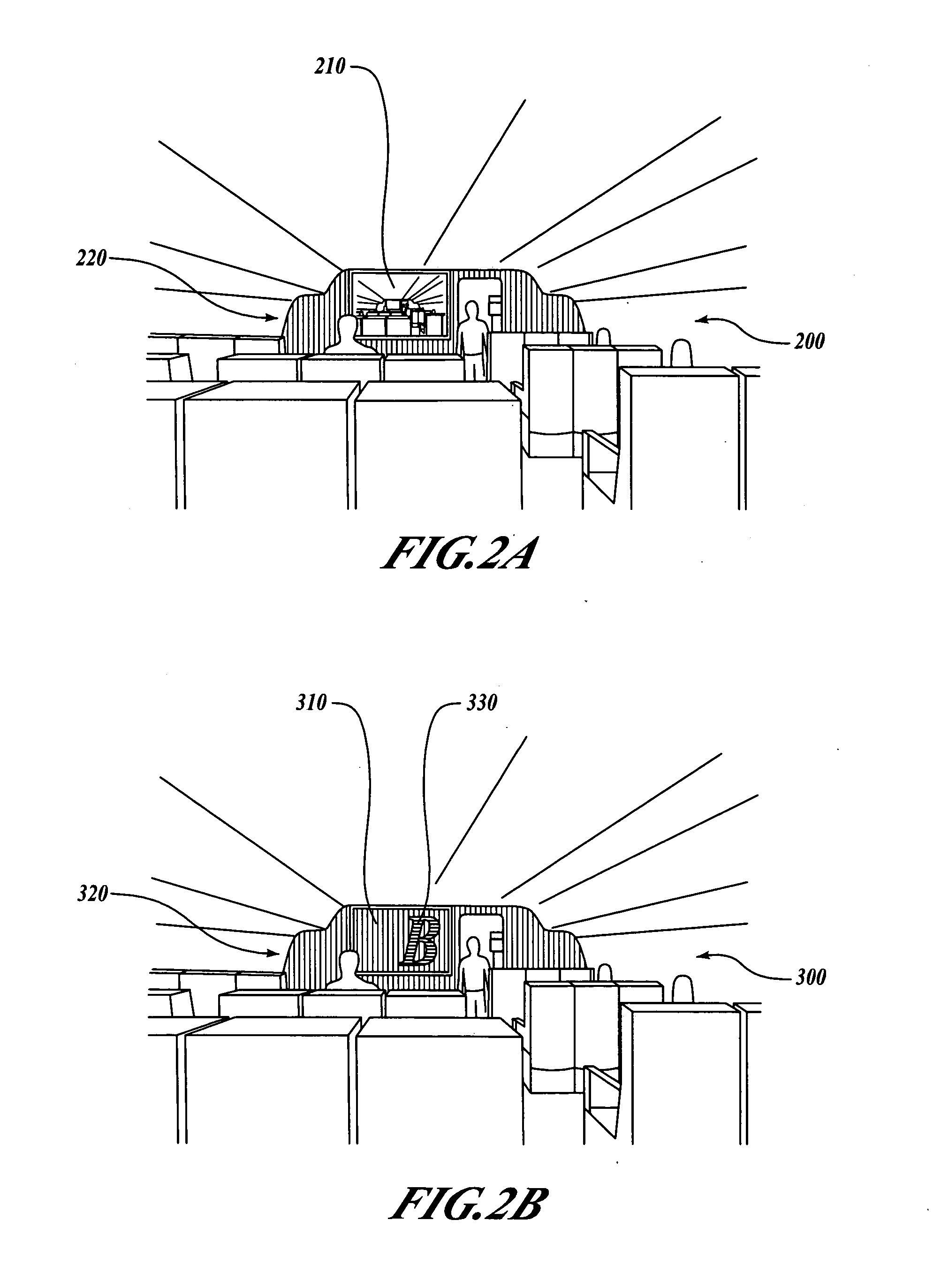

Low vapor pressure solvent for electrochromic devices

The present invention provides an electrolyte for electrochromic devices, the substance comprising γ-butyrolactone (gamma-butyrolactone or GBL). The electrolyte may include polymethylmethacrylate. The electrolyte may further include a salt, such as a salt that includes lithium perchlorate or trifluorosulfonimide. In accordance with further aspects to the invention, the electrolyte may include propylene carbonate.

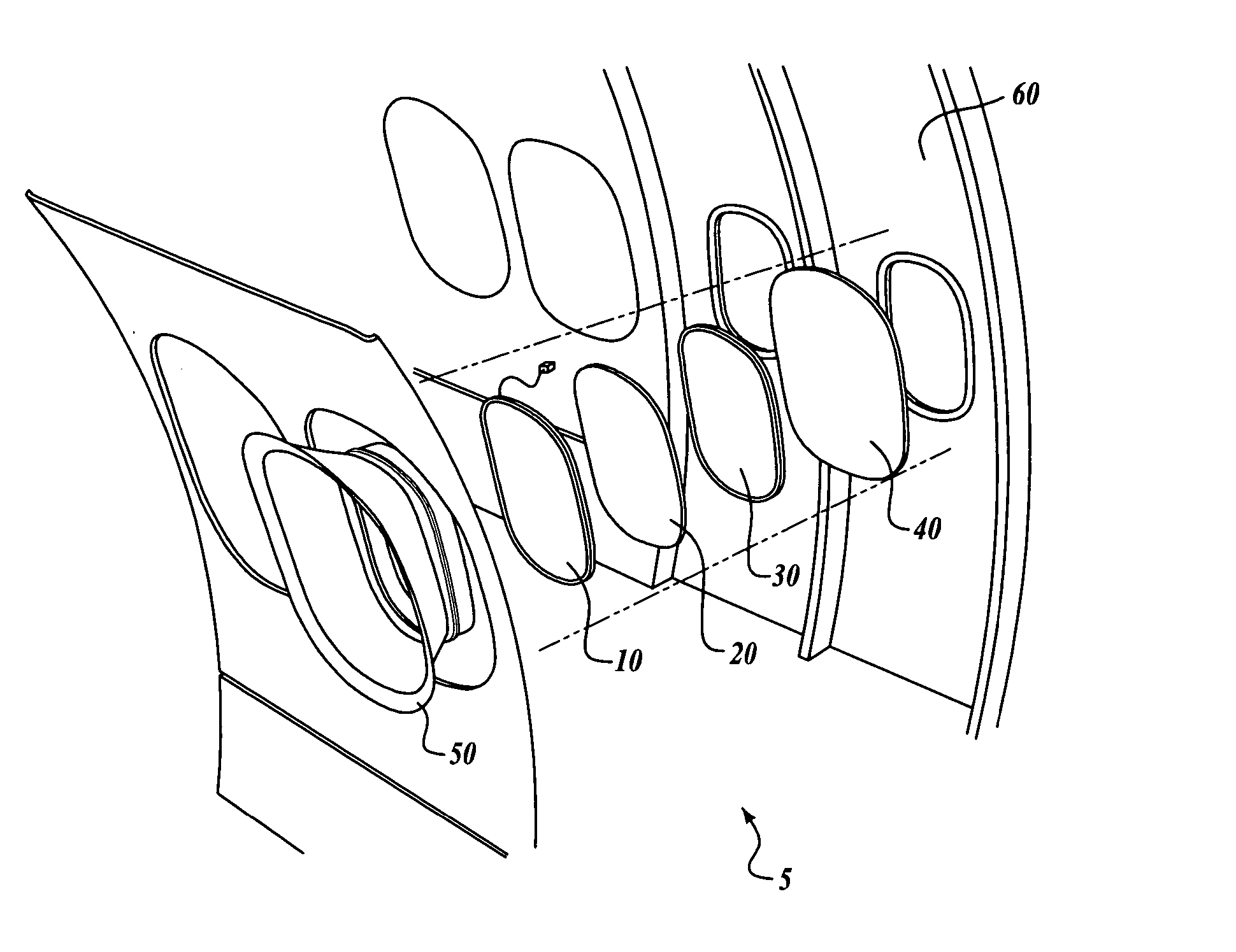

Owner:THE BOEING CO

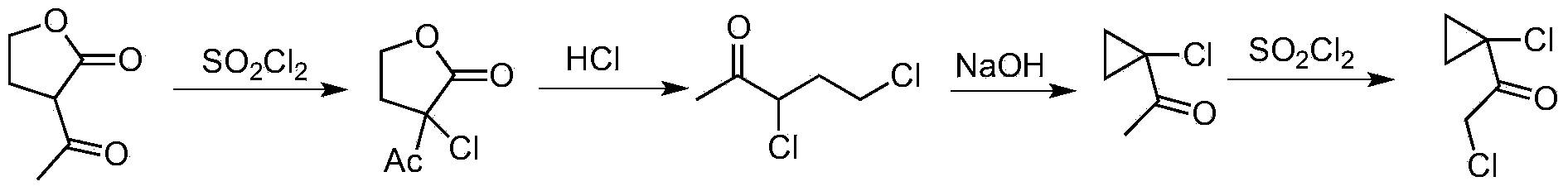

Synthetic process of 1-chloro-cyclopropanecarbonyl chloride

ActiveCN104292089ASmooth process connectionReduce unit operationsOrganic compound preparationPreparation from heterocyclic compoundsSulfonyl chlorideChloride

The invention discloses a synthetic process of 1-chloro-cyclopropanecarbonyl chloride, which belongs to the technical field of fine chemical processes. The process is implemented by taking alpha-acetyl-gamma-butyrolactone and sulfonyl chloride as raw materials through the steps of chlorinating, ring cleavage, cyclization, and re-chlorinating, so that a target product is obtained. The synthetic process is implemented by taking cheap industrial chemicals as raw materials and reaction reagents, and by using a single solvent system, a smooth process connection is achieved, so that the reaction yield is improved, the process operation is simplified, the cost of raw materials is reduced, and the cost of production is lowered.

Owner:DALIAN JOIN KING FINE CHEM CO LTD

Method of preparing gamma-butyrolactone and/or 1,4-butanediol using chromium less catalyst

InactiveCN1493569AHigh activityEnsure safetyOrganic compound preparationHydroxy compound preparationCis-Butenedioic AcidButanediol

A process for preparing gamma-butyrolactone and / or 1,4-butanediol by use of Cr-free catalyst includes making the the dialkyl maleate and / or dialkyl succinate in contact with hydrocatalyst, reacting at 170-300 deg.c and 0.1-15 hr under 0.1-7 Mpa, and collecting products. Said hydrocatalyst is CuMnaAlbOc, where a=0.01-1.5, b=0.1-2 and c is number of necessary oxygen atoms. Its advantage is controllable ratio between both products.

Owner:CHINA PETROLEUM & CHEM CORP +1

Electrolyte for power lithium ion battery

InactiveCN102544582AImprove wettabilityStable electrochemical propertiesSecondary cellsPolyolefinSolvent

The invention discloses high-wettability and high-pourability electrolyte for a power lithium ion battery. The electrolyte comprises a wetting additive, a lithium salt, a non-aqueous organic solvent and other additives, wherein the wetting additive is a nonionic surfactant, and the wetting additive accounts for 0.001 to 5 percent of the mass of the electrolyte; the non-aqueous solvent is one or a mixture of more of ethylene carbonate, propylene carbonate, methyl ethyl carbonate, dimethyl carbonate, diethyl carbonate and gamma-butyrolactone, and the non-aqueous solvent accounts for 50 to 90 percent of the mass of the electrolyte; the lithium salt at the concentration of 0.6 to 1.5 mol / L is at least one of lithium hexafluorophosphate, lithium tetrafluoroborate, lithium bis(oxalato)borate and lithium trifluoromethanesulfonate; and the other additives accounts for 0.5 to 8 percent of the mass of the electrolyte. The electrolyte has high wettability for a polyolefin diaphragm and electrode active materials, and has long cycle life.

Owner:DONGGUAN SHANSHAN BATTERY MATERIALS

Novel catalyst used in maleic anhydride liquid phase hydrogenation for preparing gamma-butyrolactone, and preparation method thereof

InactiveCN102335611AHigh activityHigh yieldOrganic chemistryCatalyst activation/preparationActivated carbonActive component

The invention discloses a novel catalyst used in maleic anhydride liquid phase hydrogenation for preparing gamma-butyrolactone. The catalyst is characterized in that: the catalyst is composed of a carrier, a main active component, and an auxiliary agent. The main active component is metal nickel, the auxiliary agent is molybdenum, and the carrier is active carbon. The product provided by the invention is advantaged in that: according to the invention, when the 20% Ni-Mo / AC catalyst prepared by using a co-impregnation method is used in a maleic anhydride hydrogenation, a result shows that the activity of the novel catalyst prepared with the co-impregnation method is high, and a gamma-butyrolactone yield reaches 97.6%. The invention also provides a preparation method for the novel catalyst used in the maleic anhydride hydrogenation for preparing gamma-butyrolactone, such that the product can be obtained.

Owner:JIANGSU KANGHENG CHEM

Method for producing succinic acid

ActiveCN102311332AHigh purityHigh selectivityPreparation from carboxylic acid anhydridesButanedioic acidHydrogenation reaction

The invention discloses a method for producing succinic acid. The method comprises the following steps of: performing hydrogenation reaction by taking 5 to 90 weight percent of a maleic anhydride gamma-butyrolactone solution as a raw material at the reaction temperature of between 50 and 100 DEG C under the pressure of between 0.2 and 2 MPa in the presence of a hydrogenation catalyst, hydrolyzing a hydrogenation product, crystallizing and separating to obtain succinic acid. The method is can be operated flexibly; reaction conditions are mild and controllable; and products are easy to separate and have good quality.

Owner:CHINA PETROLEUM & CHEM CORP +1

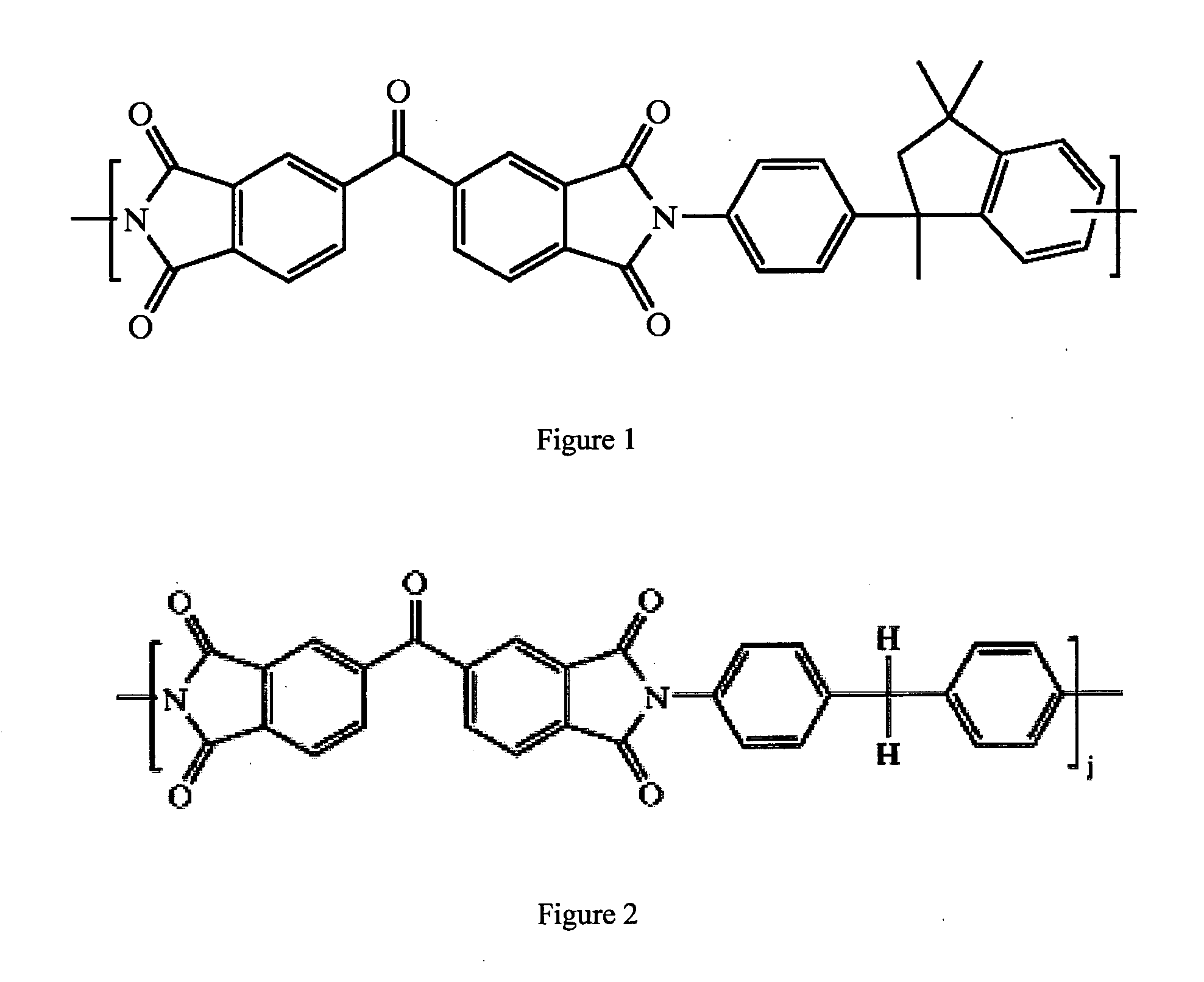

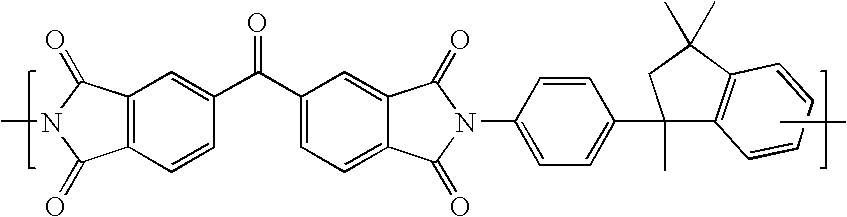

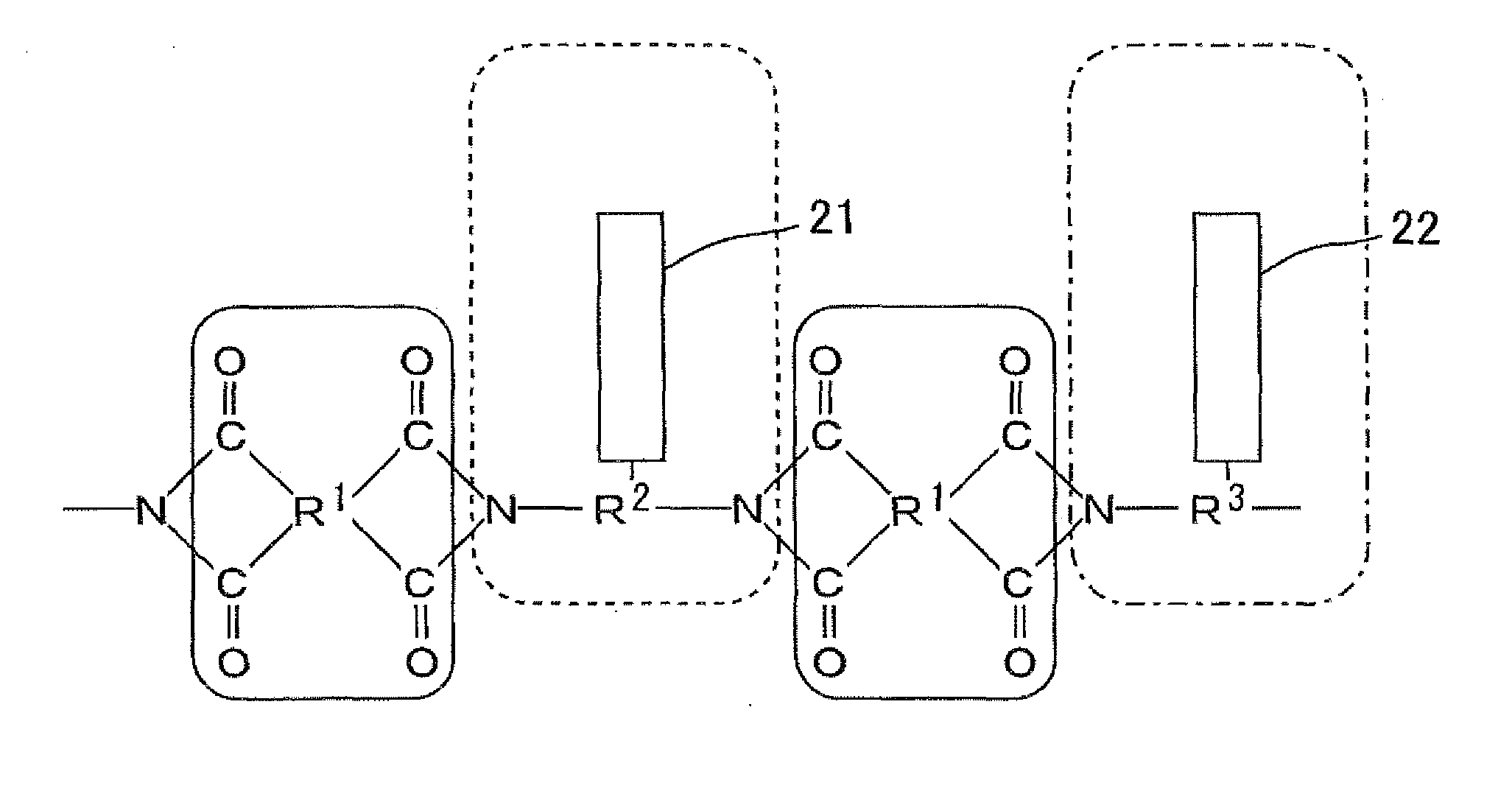

Cross-linked polyimide membranes

InactiveUS20100181253A1Maintain permeabilityGood solvent resistanceMembranesDispersed particle separationCross-linkFiltration

The present invention provides a method for improving the performance of polyimide membranes as used in solvent-resistant nanofiltration. More specifically the method of the present invention allows to improve the solvent stability of the polyimide membranes to solvents or solvent mixtures that would dissolve polyimide under the conditions applied during the filtration, such as dimethylforrnamide (DMF), N-methylpyrrolidinone (NMP), dimethylacetamide (DMAC), tetrahydrofuran (THF), y-butyrolacton (GBL), dimethylsulphoxide (DMSO) and chlorinated solvents.

Owner:EVONIK FIBERS

Non-aqueous electrolyte and electrochemical energy storage device using the same

InactiveUS20090130565A1Improve antioxidant capacityReduce resistanceHybrid capacitor electrolytesNon-aqueous electrolyte accumulatorsQuaternary ammonium cationCarbonate

A non-aqueous electrolyte of the present invention contains a lithium salt (A), a quaternary ammonium salt (B) containing a straight chain alkyl group having carbon atoms of 4 or less and a solvent (C) composed of at least one compound selected from the group consisting of ethylene carbonate, propylene carbonate, butylene carbonate, γ-butyrolactone, dimethyl carbonate, ethyl methyl carbonate, diethyl carbonate, dimethoxyethane, ethoxymethoxyethane and diethoxyethane. The molar ratio C / A of the solvent (C) to the lithium salt (A) or the molar ratio C / B of the solvent (C) to the ammonium salt (B) is 6 or less. The non-aqueous electrolyte has a single phase. Consequently, there can be obtained a non-aqueous electrolyte of a high ion concentration having an excellent oxidation resistance and reduction resistance.

Owner:PANASONIC CORP

Electrolyte for lithium ion secondary battery and lithium ion secondary battery including the same

ActiveUS20060078792A1Improve securityOrganic electrolyte cellsActive material electrodesLithiumHigh temperature storage

An electrolyte includes a lithium salt, a non-aqueous organic solvent, gamma-butyrolactone and halogenated toluene represented by the following formula 1: wherein X represents at least one element selected from the group consisting of F, Cl, Br and I, and n represents an integer of 1 to 5. The lithium ion secondary battery including the electrolyte provides improved safety under overcharge and high-temperature storage conditions.

Owner:SAMSUNG SDI CO LTD

Post plasma ashing wafer cleaning formulation

InactiveUS7534752B2Increase productionImprove adhesionDetergent mixture composition preparationSemiconductor/solid-state device manufacturingSulfolaneInorganic compound

A semiconductor wafer cleaning formulation for use in post plasma ashing semiconductor fabrication comprising at least one organic chelating agent and at least one polar solvent, wherein the chelating agent and polar solvent are in sufficient amounts to effectively remove inorganic compound residue from a semiconductor wafer. Preferably, the chelating agent is selected from the group consisting of 2,4-Pentanedione, Malonic acid, Oxalic acid, p-Toluenesulfonic acid, and Trifluoroacetic acid; and the polar solvent is selected from the group consisting of Water, Ethylene glycol, N-Methylpyrrolidone (NMP), Gamma butyrolactone (BLO), Cyclohexylpyrrolidone (CHP), Sulfolane, 1,4-Butanediol, and Butyl carbitol.

Owner:ENTEGRIS INC

Lithium secondary battery with high performance

InactiveUS20060194119A1Inhibit side effectsPad sawsOrganic electrolyte cellsInorganic saltsOrganic solvent

Disclosed is a lithium secondary battery comprising: (a) a cathode; (b) an anode; (c) a separator; and (d) a non-aqueous electrolyte comprising a lithium salt and an organic solvent, wherein the cathode comprises a cathode active material, doped with at least one element selected from the group consisting of Sn, Al and Zr, or containing the element in the form of a solid solution, and the non-aqueous electrolyte comprises a lithium-containing inorganic salt and a lithium imide salt dissociated in at least one organic solvent including gamma-butyrolactone (GBL). The lithium secondary battery can minimize side reactions between both electrodes and gamma-butyrolactone (GBL), used as a conventional electrolyte for a battery, and thus can provide high capacity, long service life and improved quality at high-temperature.

Owner:LG CHEM LTD

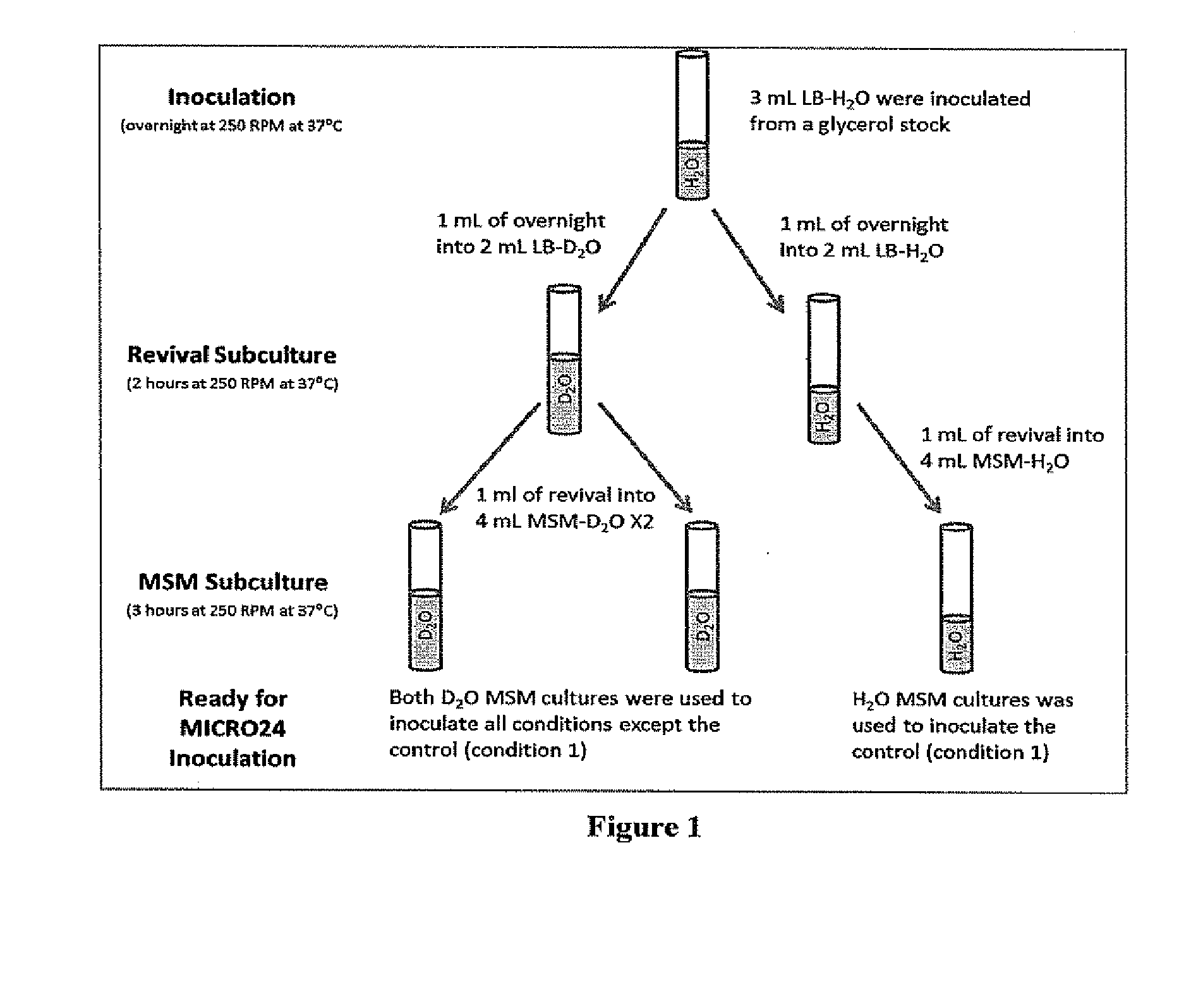

Production of salts of 4-hydroxybutyrate using biobased raw materials

Gamma-butyrolactone (“GBL”) and Gamma-hydroxybutyrate (“GHB”) having a unique carbon footprint as defined by the percent modern carbon (pmc) are described herein. The percent modern carbon can be controlled by varying the amounts of biobased, renewable starting materials and petroleum-based starting materials to prepare GBL or GHB having a defined pmc or by preparing mixtures of GBL or GHB prepared from biobased renewable starting materials and GBL or GHB prepared from petroleum-based starting materials.

Owner:CJ CHEILJEDANG CORP

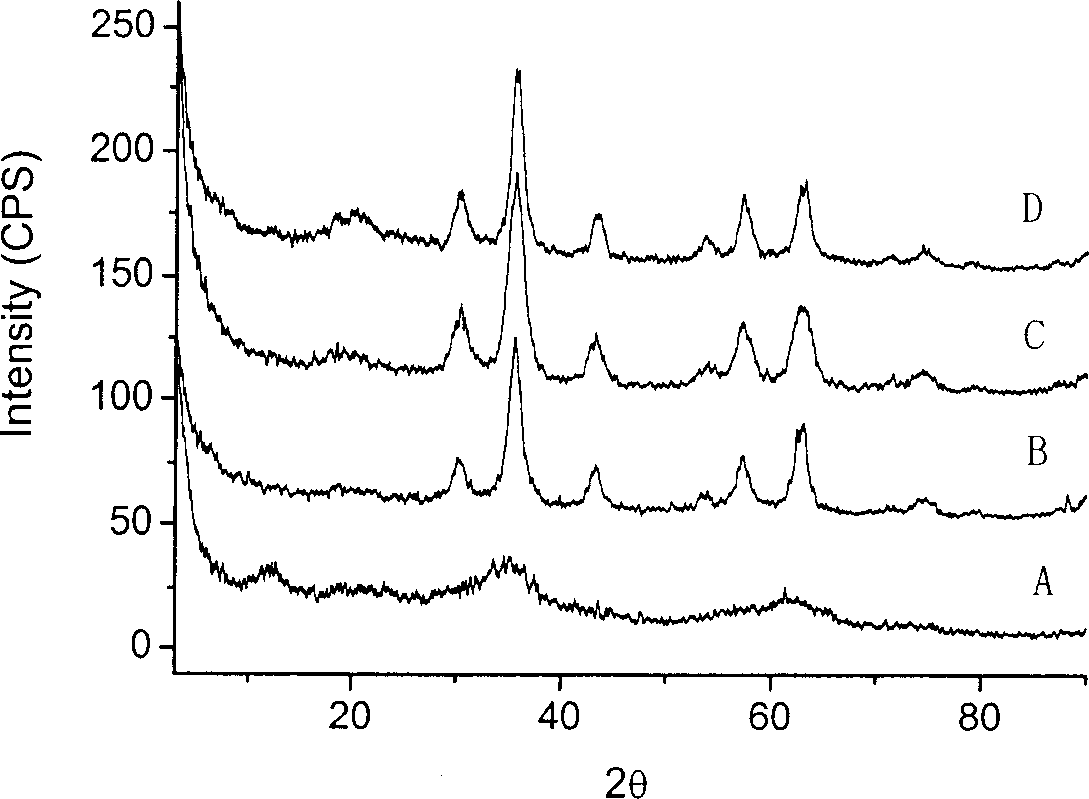

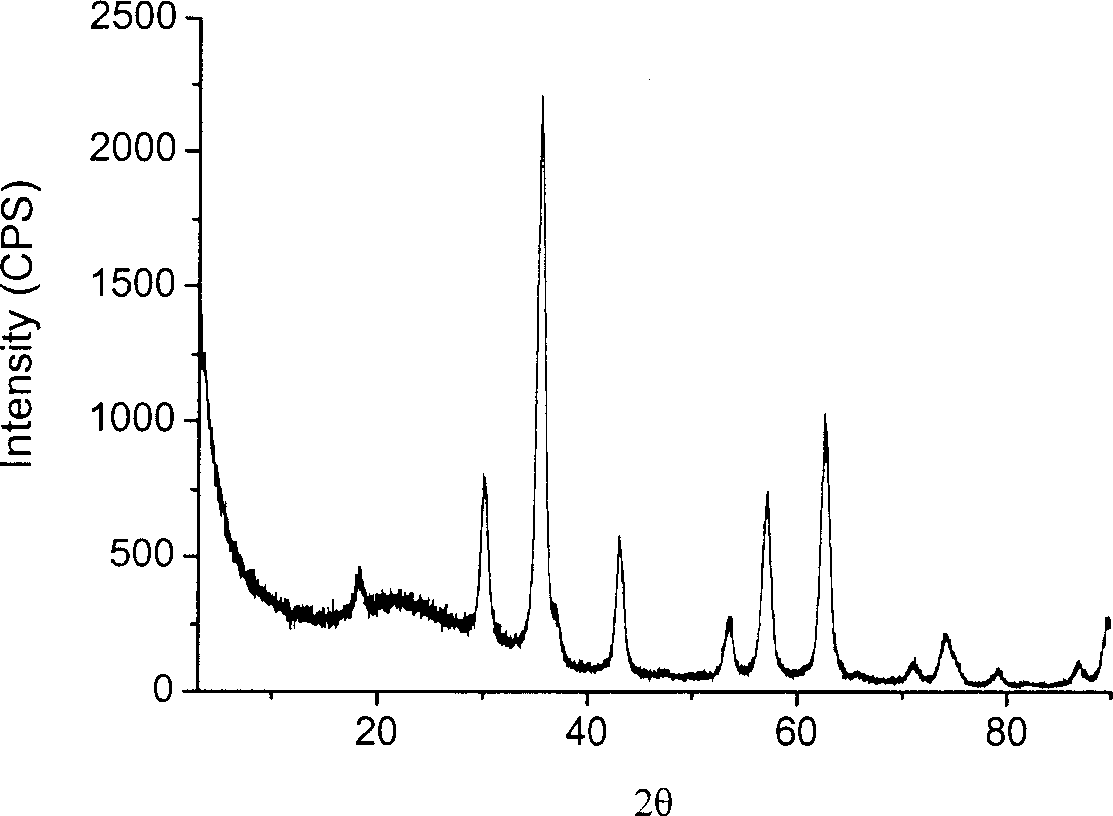

Highly dispersed CuZnTi catalyst for hydrogenation of catalytic maleic anhydride to gamma-butyrolactone and preparation method thereof

InactiveCN101940927AOrganic chemistryMetal/metal-oxides/metal-hydroxide catalystsHydrogenation reactionReaction temperature

The invention provides a highly dispersed CuZnTi catalyst for hydrogenation of catalytic maleic anhydride to gamma-butyrolactone and a preparation method thereof, belonging to the technical field of catalytic materials. The CuZnTi catalyst is prepared by properly calcining carbonate pillared copper-zinc-titanium houghite used as a catalyst precursor. In the catalyst precursor, the atomic ratio of Cu, Zn and Ti is 0.5:2:1-2.5:2:1. The CuZnTi catalyst comprises the following components in percentage by mass: 11.4-36.2 percent of Cu, 29.5-46.4 percent of Zn and 10.9-17.0 percent of Ti, and the specific surface area of the CuZnTi catalyst is 60.3-125.9m2 / g. When the CuZnTi catalyst reacts for 2 hours at the temperature of 200 DEG C under the pressure of 4.0 MPa, the conversion rate of series CuZnTi catalyst for hydrogenation of catalytic maleic anhydride is 88.2-99.6 percent, and the selectivity of the gamma-butyrolactone is 80.7-89.8 percent. The invention has the advantages of being applied to maleic anhydride liquid phase hydrogenation reaction and obtaining higher catalytic activity under lower reaction temperature and pressure.

Owner:BEIJING UNIV OF CHEM TECH

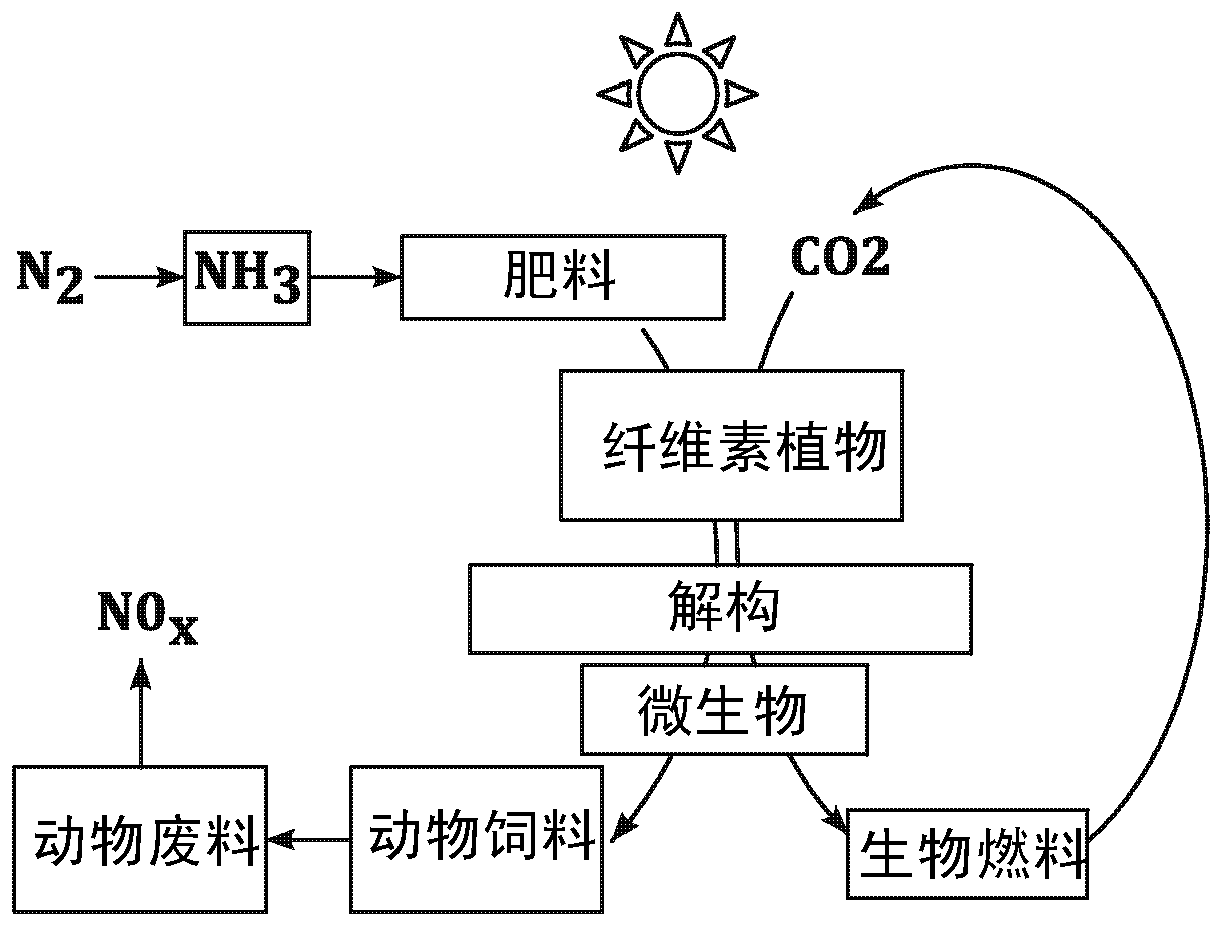

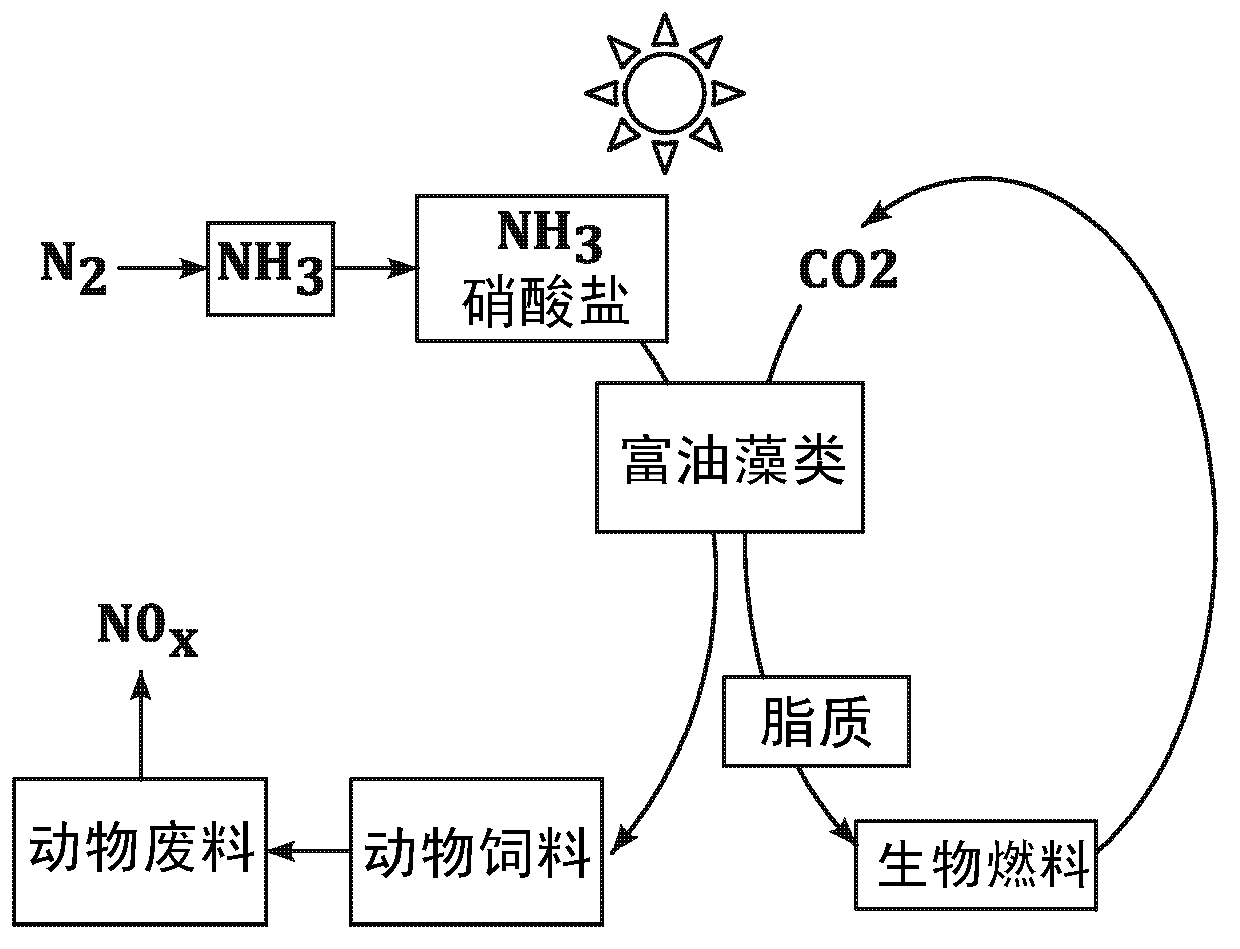

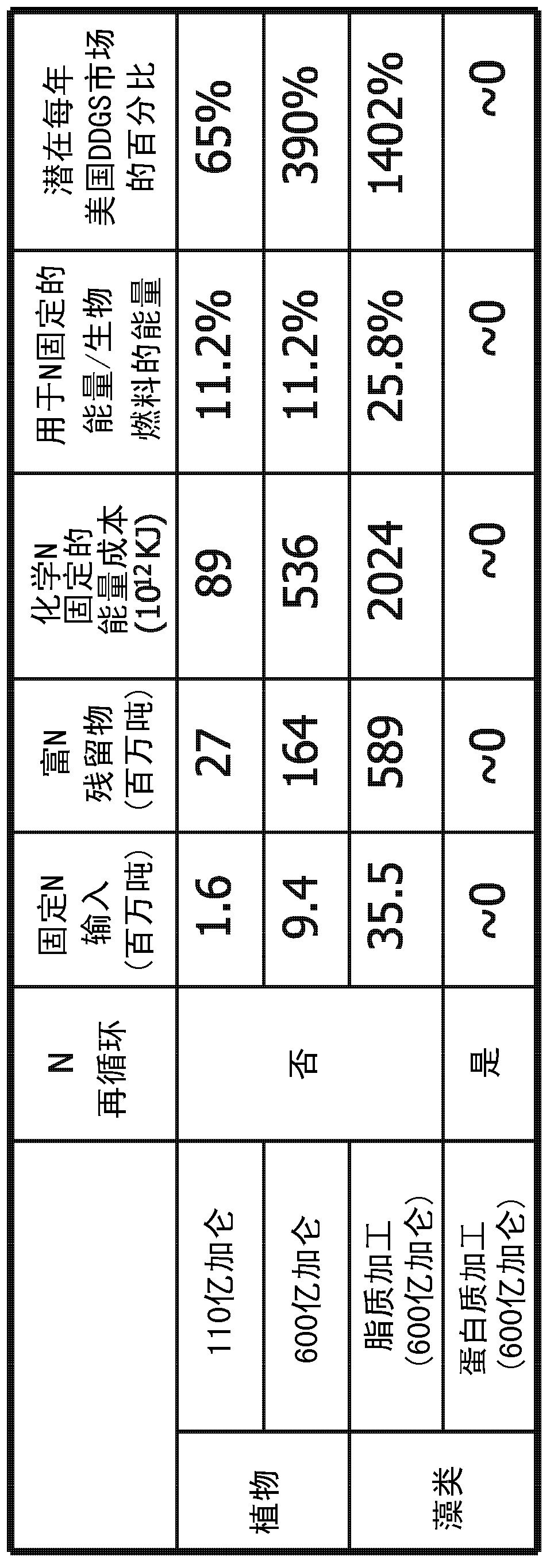

Biofuel and chemical production by recombinant microorganisms via fermentation of proteinacious biomass

Provided herein are metabolically modified microorganisms characterized by having an increased keto-acid flux when compared with the wild-type organism and comprising at least one polynucleotide encoding an enzyme, and causing the production of a greater quantity of a chemical product when compared with the wild-type organism. The recombinant microorganisms are useful for producing a large number of chemical compositions from various nitrogen containing biomass compositions and other carbon sources. More specifically, provided herein are methods of producing alcohols, acetaldehyde, acetate, isobutyraldehyde, isobutyric acid, n- butyraldehyde, n-butyric acid, 2-methyl-l-butyraldehyde, 2-methyl-l -butyric acid, 3- methyl-l-butyraldehyde, 3 -methyl- 1 -butyric acid, ammonia, ammonium, amino acids, 2,3-butanediol, 1,4-butanediol, 2-methyl-l, 4-butanediol, 2-methyl- 1,4-butanediamine, isobutene, itaconate, acetoin, acetone, isobutene, 1,5-diaminopentane, L-lactic acid, D- lactic acid, shikimic acid, mevalonate, polyhydroxybutyrate (PHB), isoprenoids, fatty acids, homoalanine, 4-aminobutyric acid (GABA), succinic acid, malic acid, citric acid, adipic acid, p-hydroxy-cinnamic acid, tetrahydrofuran, 3-methyl-tetrahydrofuran, gamma-butyrolactone, pyrrolidinone, n-methylpyrrolidone, aspartic acid, lysine, cadeverine, 2-ketoadipic acid, and / or S-adenosyl-methionine (SAM), from a suitable nitrogen rich biomass.

Owner:RGT UNIV OF CALIFORNIA

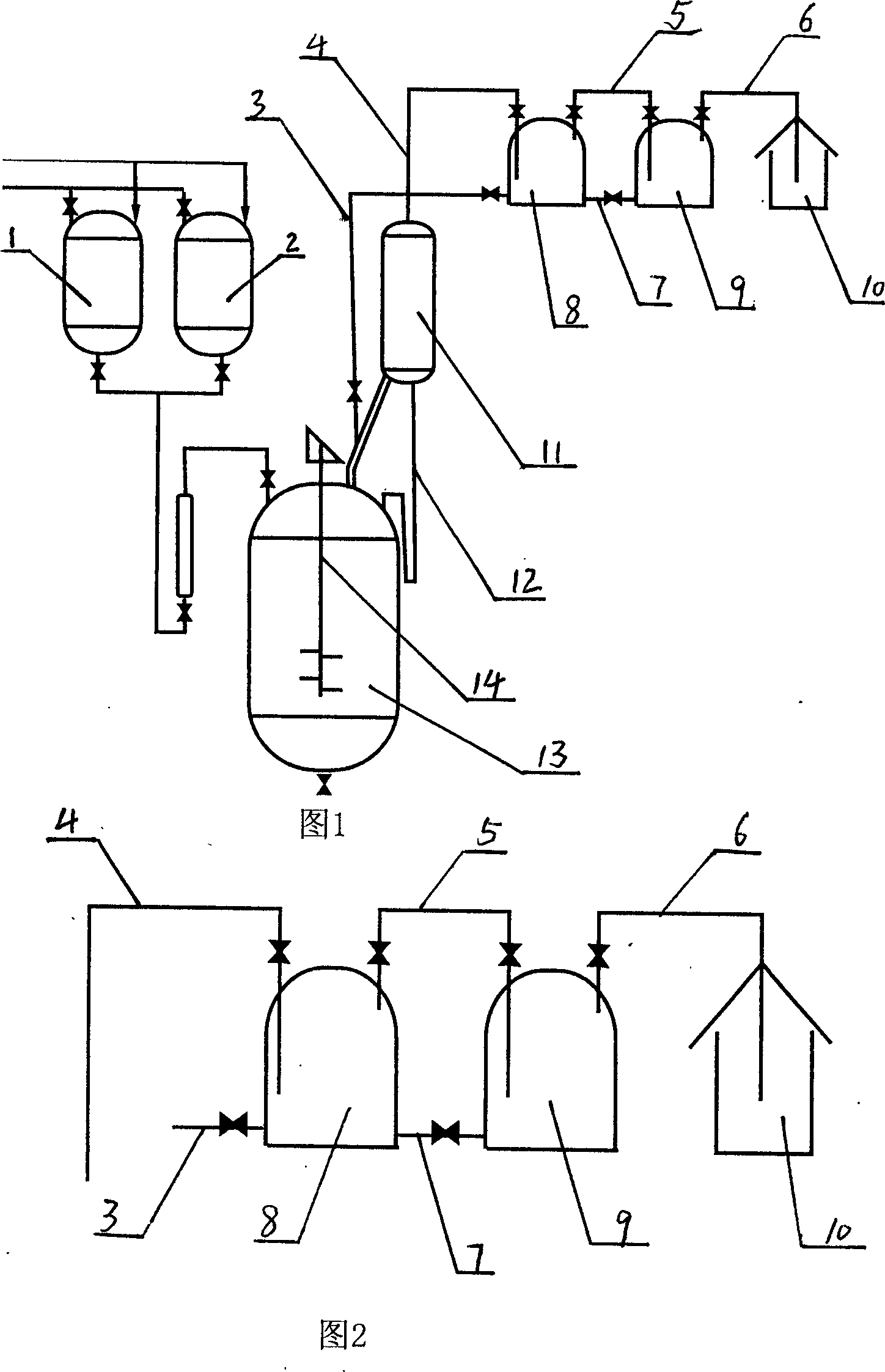

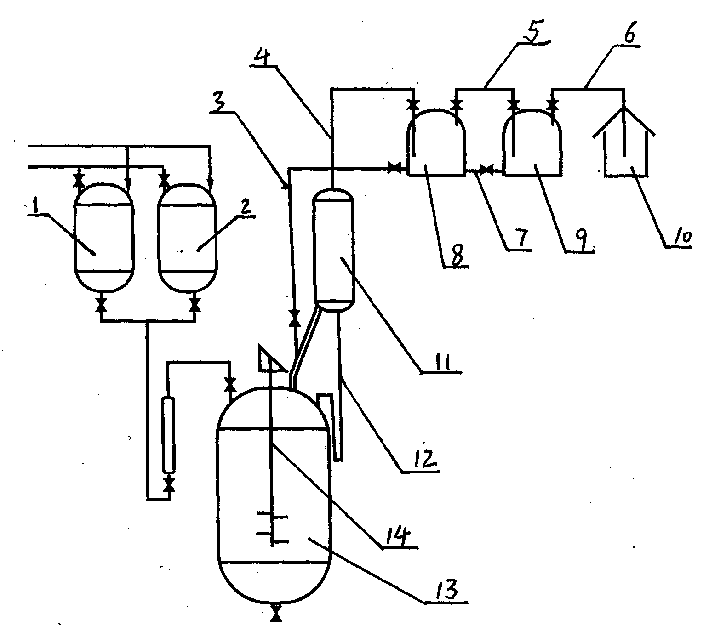

Prepn process and apparatus for alpha-acetyl-gamma-butyrolactone

InactiveCN1548427AAvoid safety hazardsEven contactOrganic chemistryAlpha-acetyl-gamma-butyrolactoneGamma-Butyrolactone

The preparation process of alpha-acetyl-gamma-butyrolactone includes reaction section, neutralization section and distillation section, and features the reaction section, which includes adding catalyst into benzene solvent, heating while stirring, fast cooling and dropping the liquid mixture of gamma-butyrolactone and acylating agent; the neutralization section before extraction; and the distillation section to prepare alpha-acetyl-gamma-butyrolactone. The present invention also relates to the reactor with one increased buffering reflux unit for preparing alpha-acetyl-gamma-butyrolactone.

Owner:LINHAI LIANSHENG CHEM

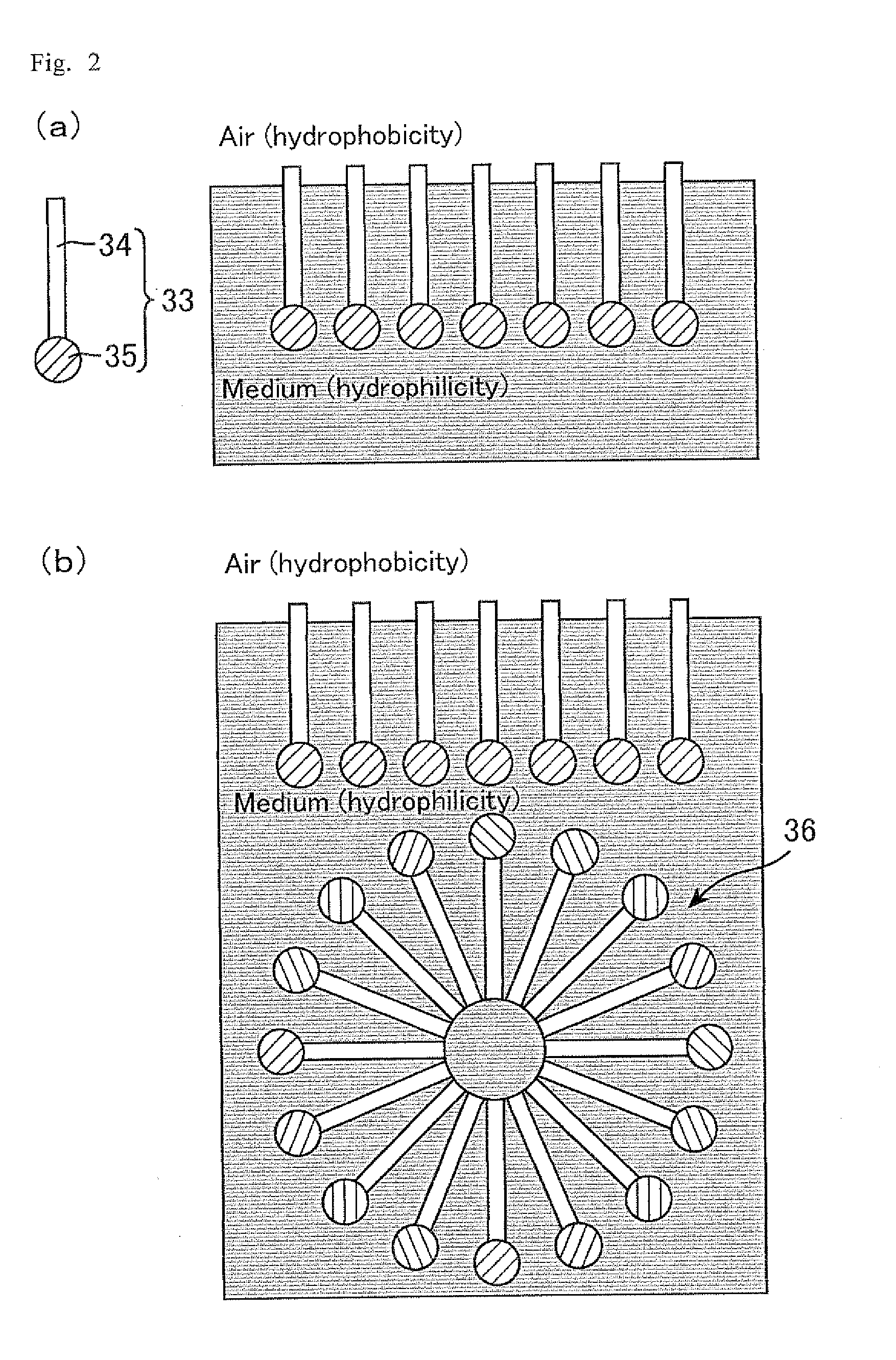

Method for producing water dispersing magnetic nano particle with high-crystallinity

InactiveCN1549283AUniform and controllable particle sizeHigh crystallinityNanostructure manufactureInductances/transformers/magnets manufactureFerric oxalateIron salts

The new method for preparing high crystallinity monodisperse water-soluble magnetic nano microparticles is characterized by that it selects the inorganic iron salts of anhydrous iron trichloride and iron chloride, etc. or metal organic iron compounds (such as iron pentacarbonyl, iron triacetylacetonate, iron biacetylacetonate, complex of cupferron and iron salt, iron octoate and ferric oxalate, etc.) as iron raw material, and utilizes high-temp. decomposition of them in high boiling point polar solvent (for example alpha-pyrrolidone and its derivatives (N-methyl-2-pyrrolidone and N-ethyl-2-pyrrolidone, etc.), N,N-dimethyl-2-imidazolone, hexametapol, gamma-butyrolactone and its derivative and low molecular weight (molecular weight M is less than or equal to 5000) polyglycol and its derivatives) to prepare magnetic nano microparticles. Said invention can adopts different iron raw materials and high boiling point polar solvents so as to obtain different types of magnetic nano microparticles (Fe, Fe2O3 and Fe3O4) with different sizes and crystallinities and different crystal structures.

Owner:苏州欣影生物医药技术有限公司

Composition for forming a liquid crystal alignment film, and liquid crystal display device

ActiveUS20110007254A1Good coating performanceSuppress display unevennessLiquid crystal compositionsPlastic/resin/waxes insulatorsDiethylene glycol diethyl etherLiquid-crystal display

The present invention provides: a composition for forming a liquid crystal alignment film capable of forming a liquid crystal alignment film excellent in evenness; and a liquid crystal display device. The present invention provides a composition for forming a liquid crystal alignment film, wherein the composition comprises: a material for forming a liquid crystal alignment film; diethylene glycol diethyl ether; diisobutyl ketone; and at least one of γ-butyrolactone and N-methyl-2-pyrrolidone as solvents.

Owner:SHARP KK +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com