Method for producing water dispersing magnetic nano particle with high-crystallinity

A technology of magnetic nanoparticles and particles, which is applied in the direction of nanostructure manufacturing, nanotechnology, nanotechnology, etc., can solve the problems of low crystallinity and weak magnetic response, and achieve high crystallinity, strong magnetic response, and cheap raw materials. The effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

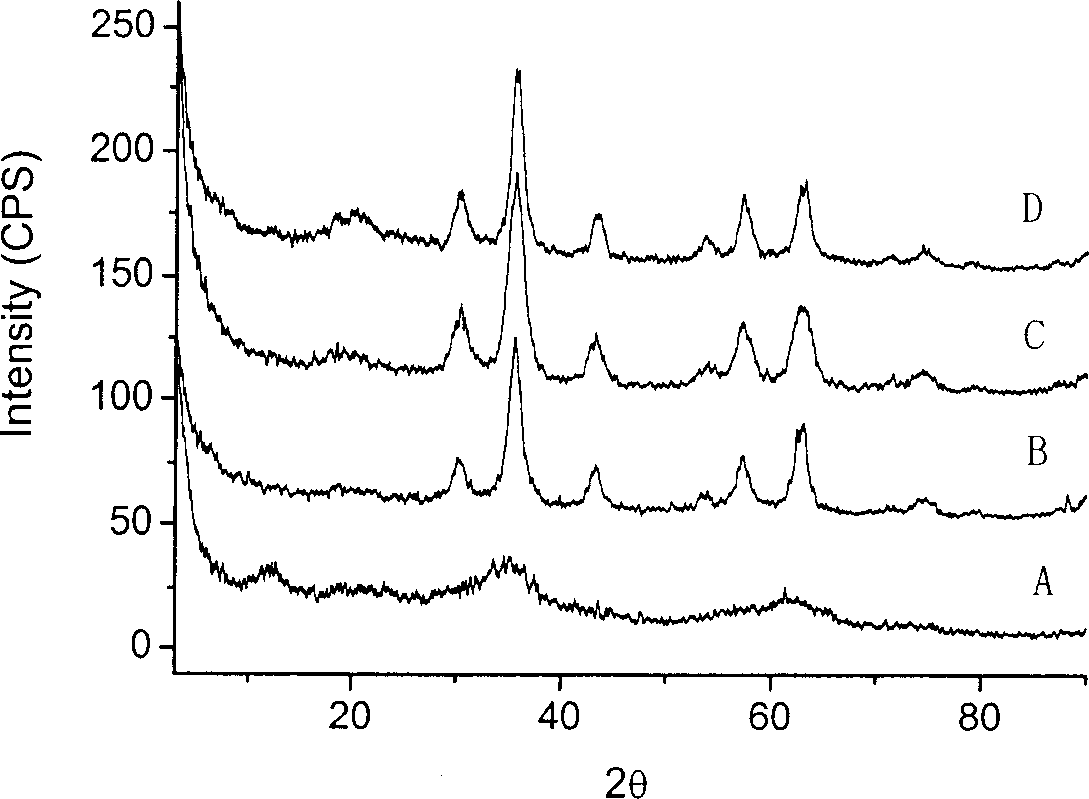

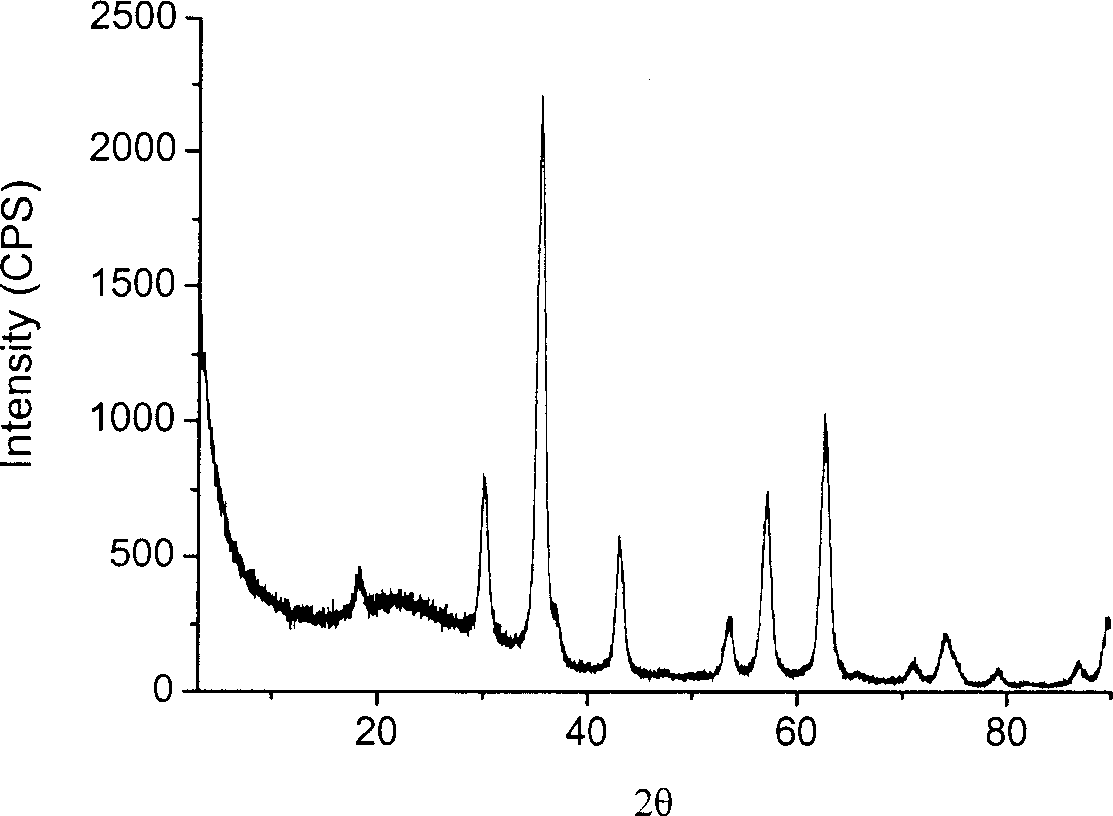

[0022] Weigh 0.43g of ferric chloride and dissolve it in 50ml of dry α-pyrrolidone, heat to reflux for 40 minutes, cool to room temperature, precipitate with a large amount of methanol (or ethanol, isopropanol, butanol, acetone), centrifuge and Precipitation of magnetic nanoparticles can be obtained. From the TEM photographs of the obtained microparticles ( figure 1 (A)) It can be seen that the particle size is 3nm, and the particle size distribution is narrow. X-ray diffraction analysis (XRD) ( figure 2 (A)) It can be seen that the obtained particles are γ-Fe 2 o 3 , but the crystallinity of the particles is low and the magnetic response is relatively weak.

specific Embodiment 2

[0023] Weigh 0.31g Fe(CO) 5 Dissolve in 50ml of α-pyrrolidone, heat to 244°C and reflux for 60 minutes, and the rest of the operations are the same as in Example 1. figure 1 (B) is a TEM photo of the obtained microparticles. It can be seen from the figure that the particle diameter is 6 nm, and the particle diameter is uniform. XRD( figure 2 (B)) shows that the obtained particles are γ-Fe 2 o 3 , and the crystallinity of the particles is higher, and the magnetic response is stronger.

specific Embodiment 3

[0024] Weigh 0.56g FeCup 3 Dissolve in 100ml of polyethylene glycol (M=400), heat and reflux for 120 minutes, and the rest of the operations are the same as in Example 1. figure 1 (C) is a TEM photograph of the obtained microparticles. It can be seen from the figure that the particle diameter is 10 nm, and the particle diameter is uniform. XRD( figure 2 (C)) shows that the obtained particles are also γ-Fe 2 o 3 , the diffraction peaks are stronger, the crystallinity is higher, and the magnetic response is also enhanced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com