Biofuel and chemical production by recombinant microorganisms via fermentation of proteinacious biomass

A technology for recombining microorganisms and biomass, applied in biofuels, biochemical equipment and methods, fermentation, etc., can solve problems such as storage and distribution systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

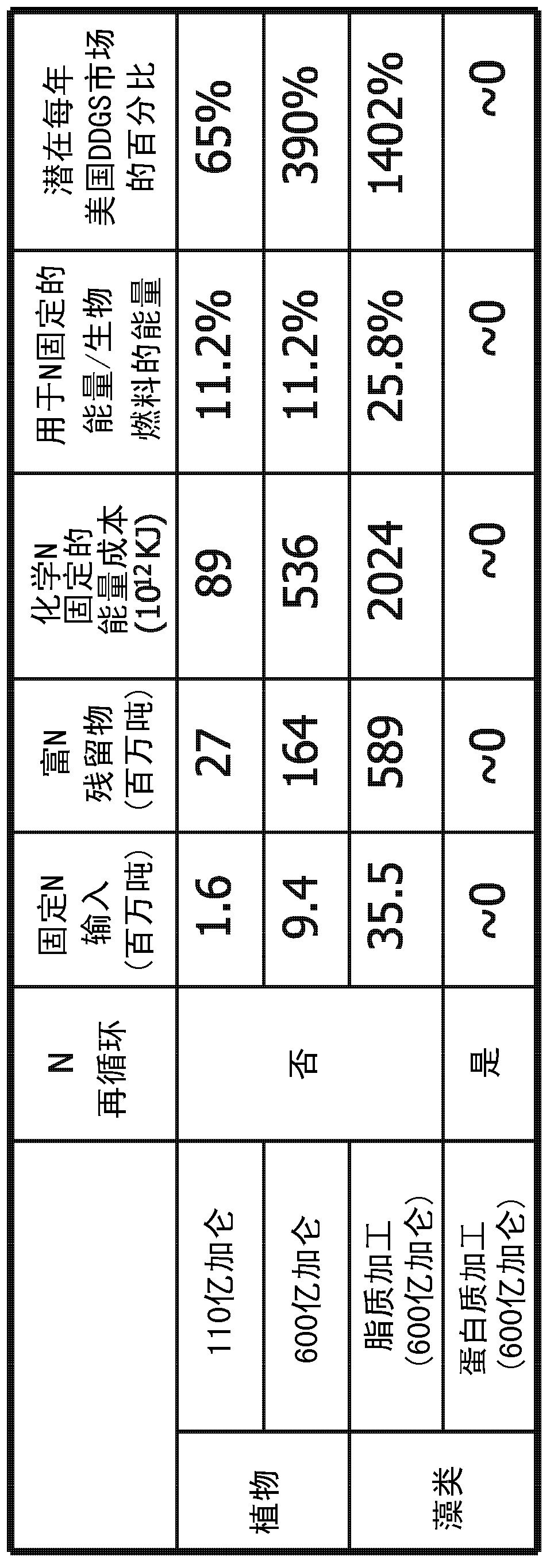

[0186] Escherichia coli was chosen as the engineered host organism because of the versatility shown by this organism. To test the efficiency of algal amino acid utilization by E. coli, the indicated cells were grown on yeast extract or a mixture of 20 amino acids (used to mimic algal extract). E. coli grew well on these enriched media, as expected. However, amino acid utilization is incomplete, possibly due to amino acid imbalance and lack of branched-chain amino acid (BCAA) degradation pathways. Wild-type E. coli will each utilize only four of the amino acids (Ala, Asp, Pro, and Gln) as a single carbon source to form colonies. When the isobutanol synthesis pathway (overexpression of alsS, ilvC, ilvD, KivD and AdhA genes) was introduced into E. coli, the cells could produce only 0.17 g / L isobutanol (Table 4 below), representing a theoretical yield of 2.3%.

[0187] Table 4: Production of higher alcohols (C≥4) in Escherichia coli in yeast extract medium containing 21.6 g / L a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com