Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

887results about How to "Good coating performance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

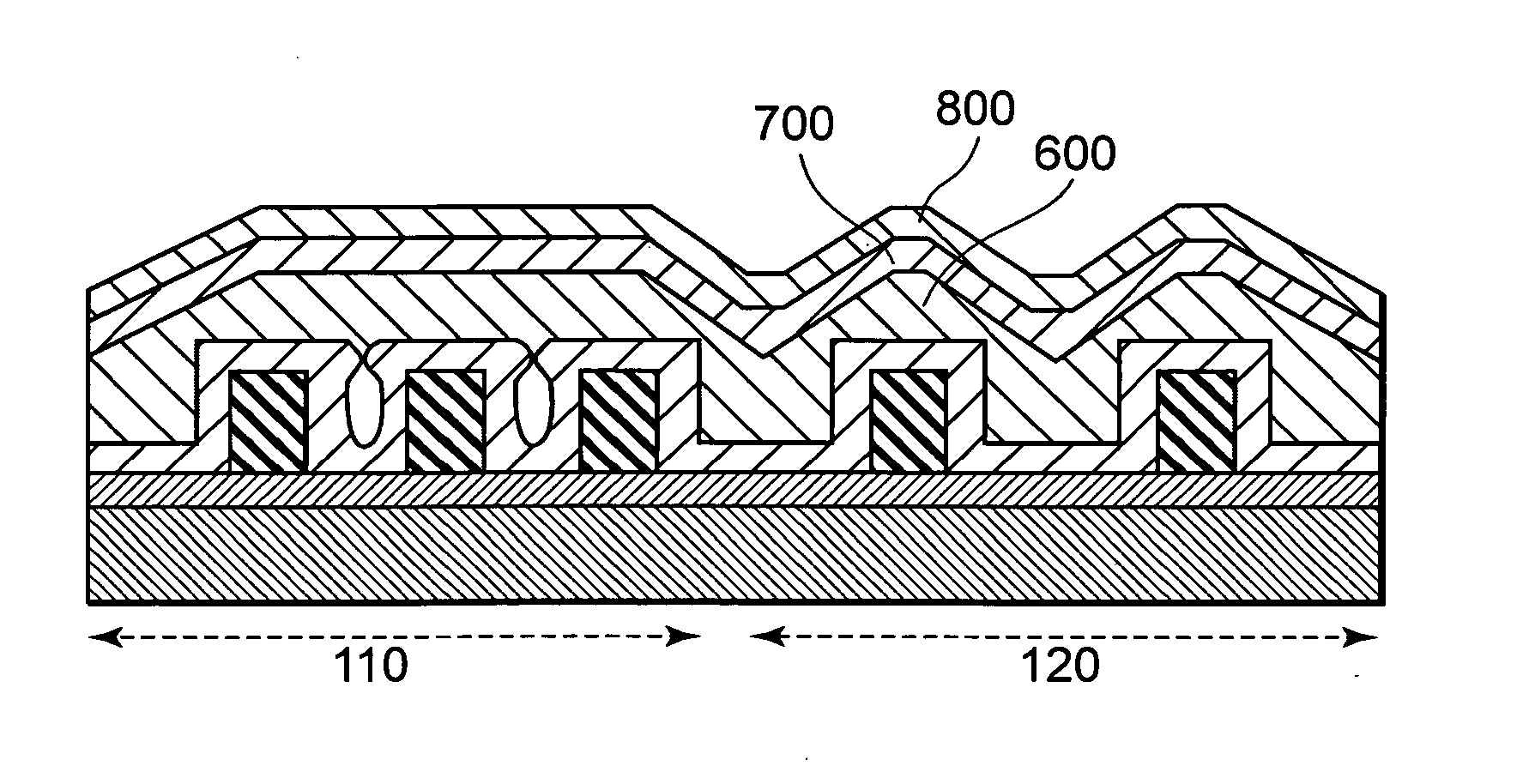

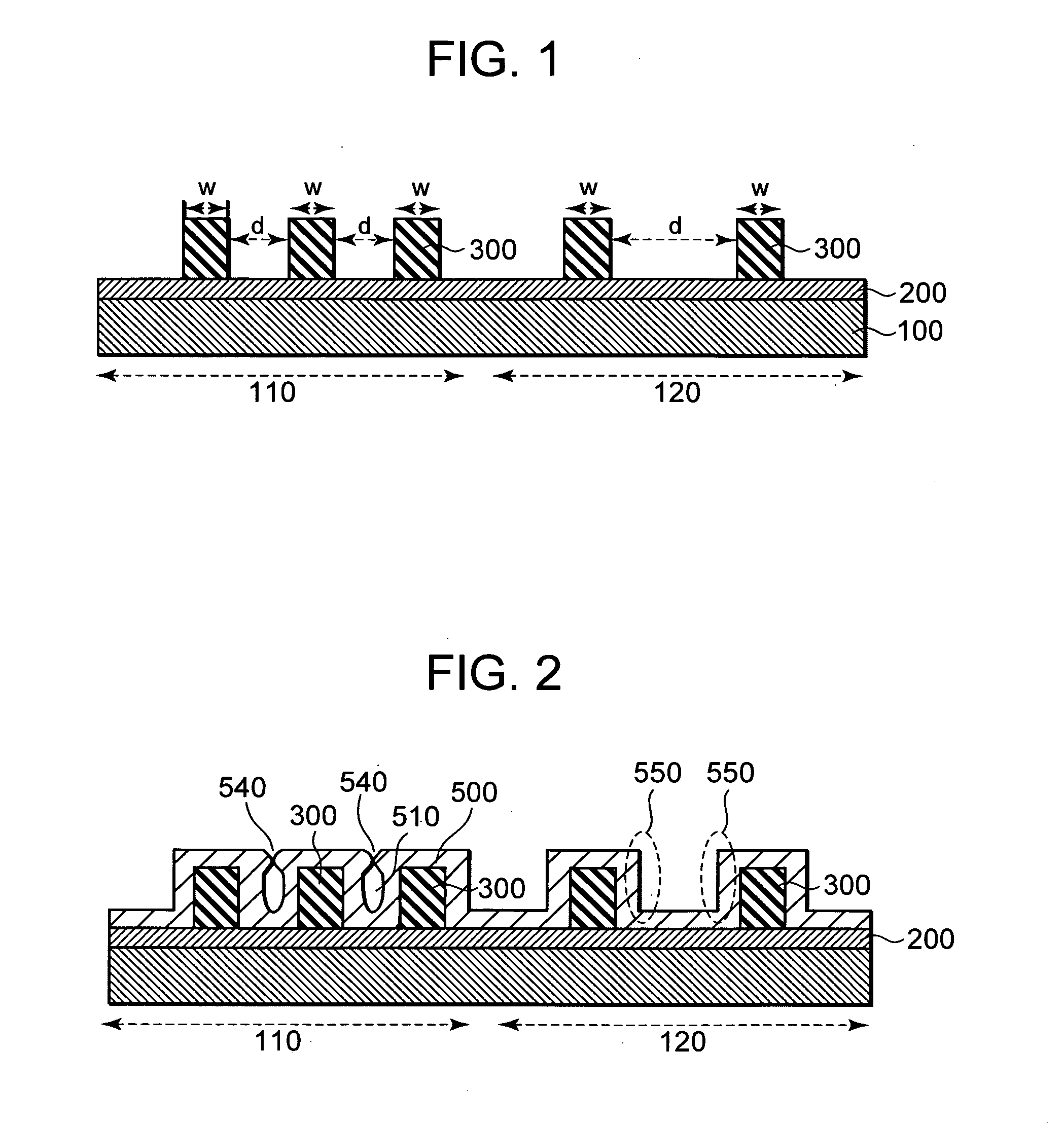

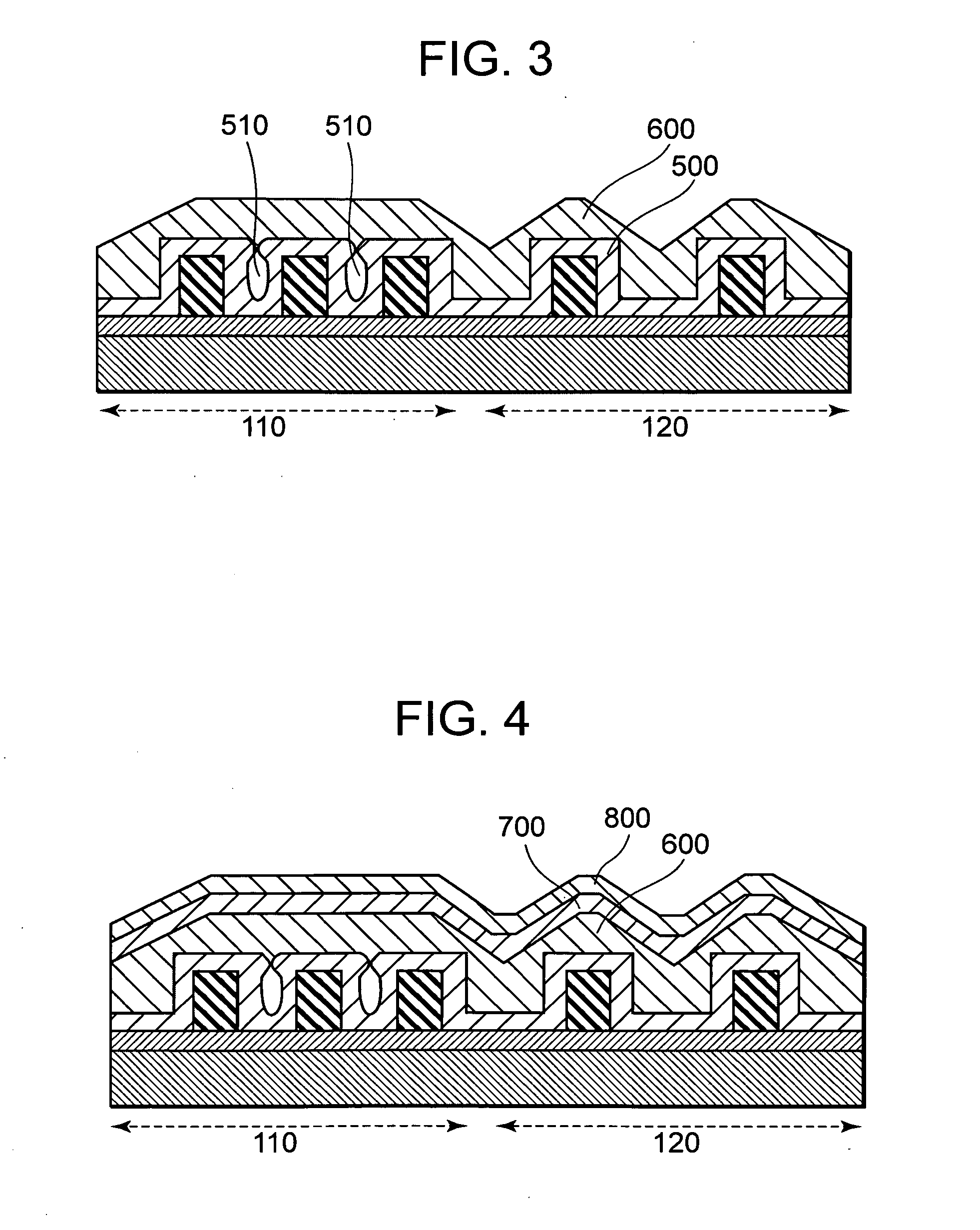

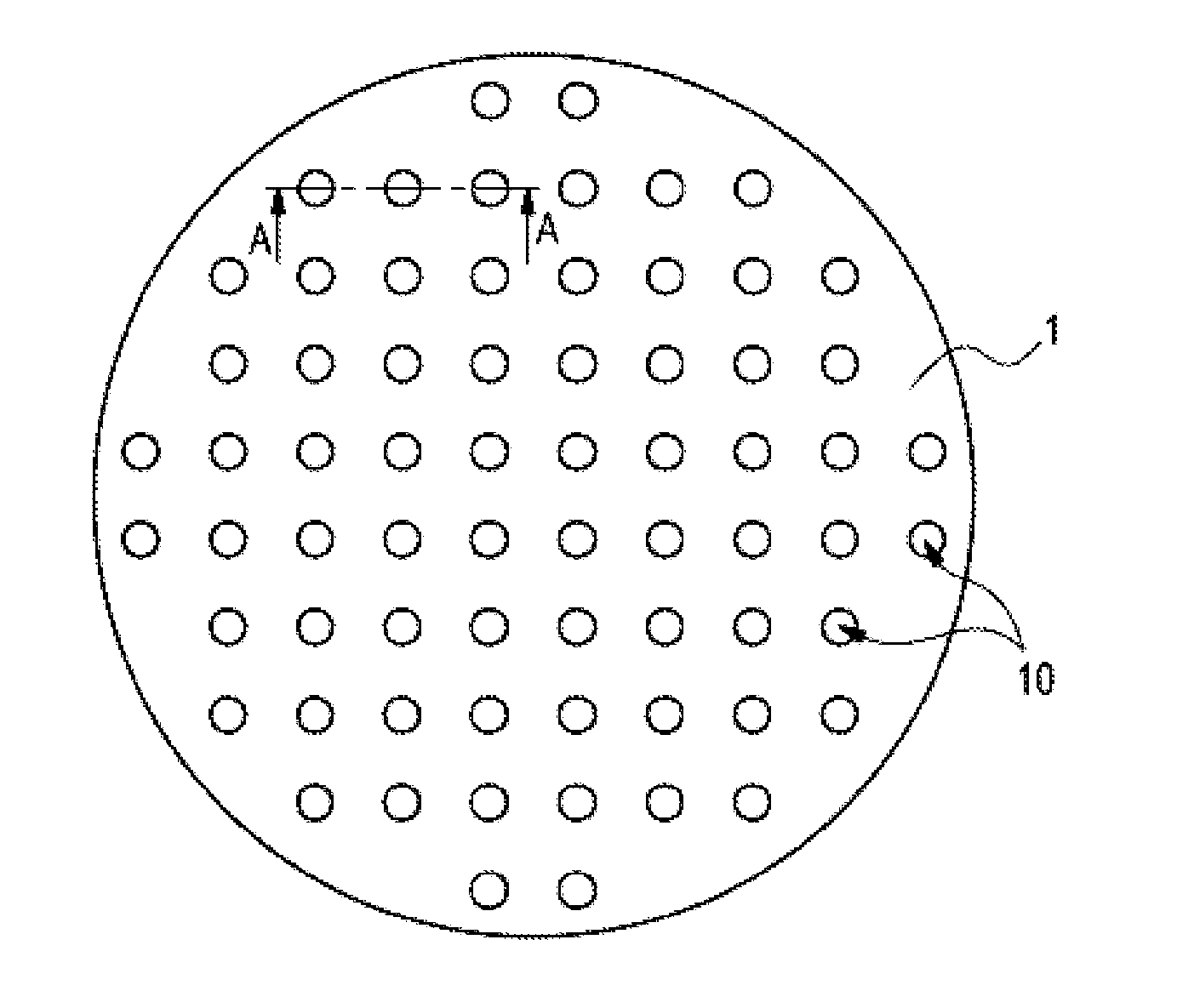

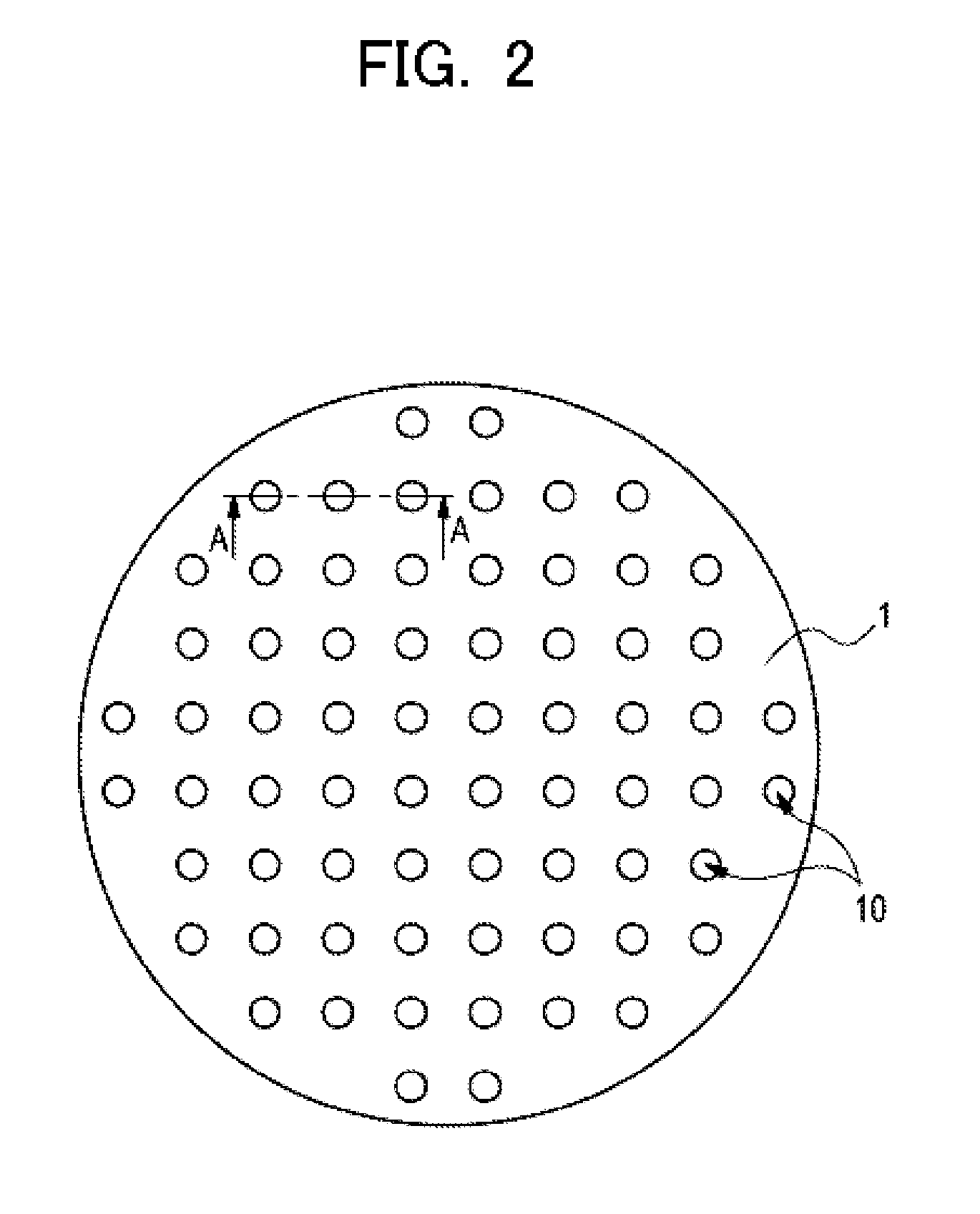

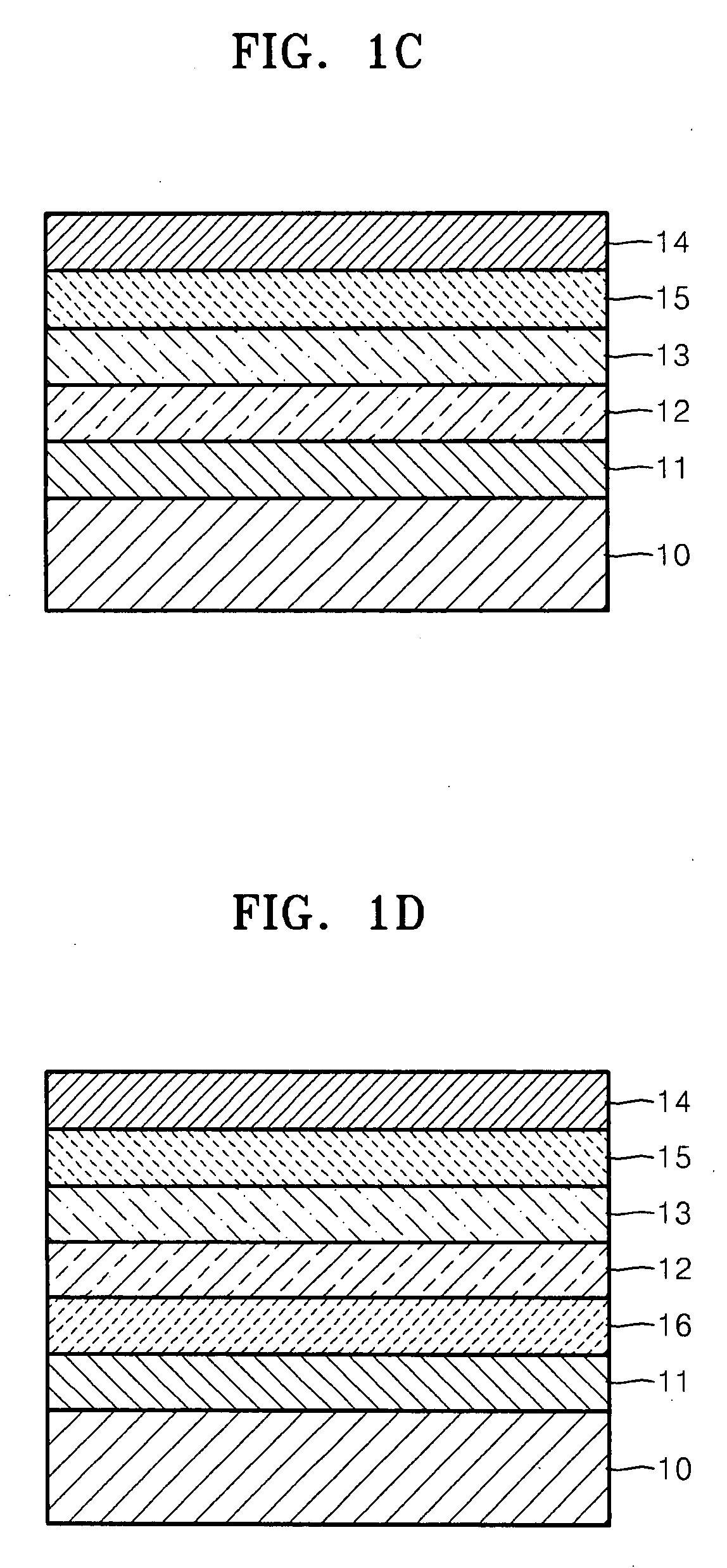

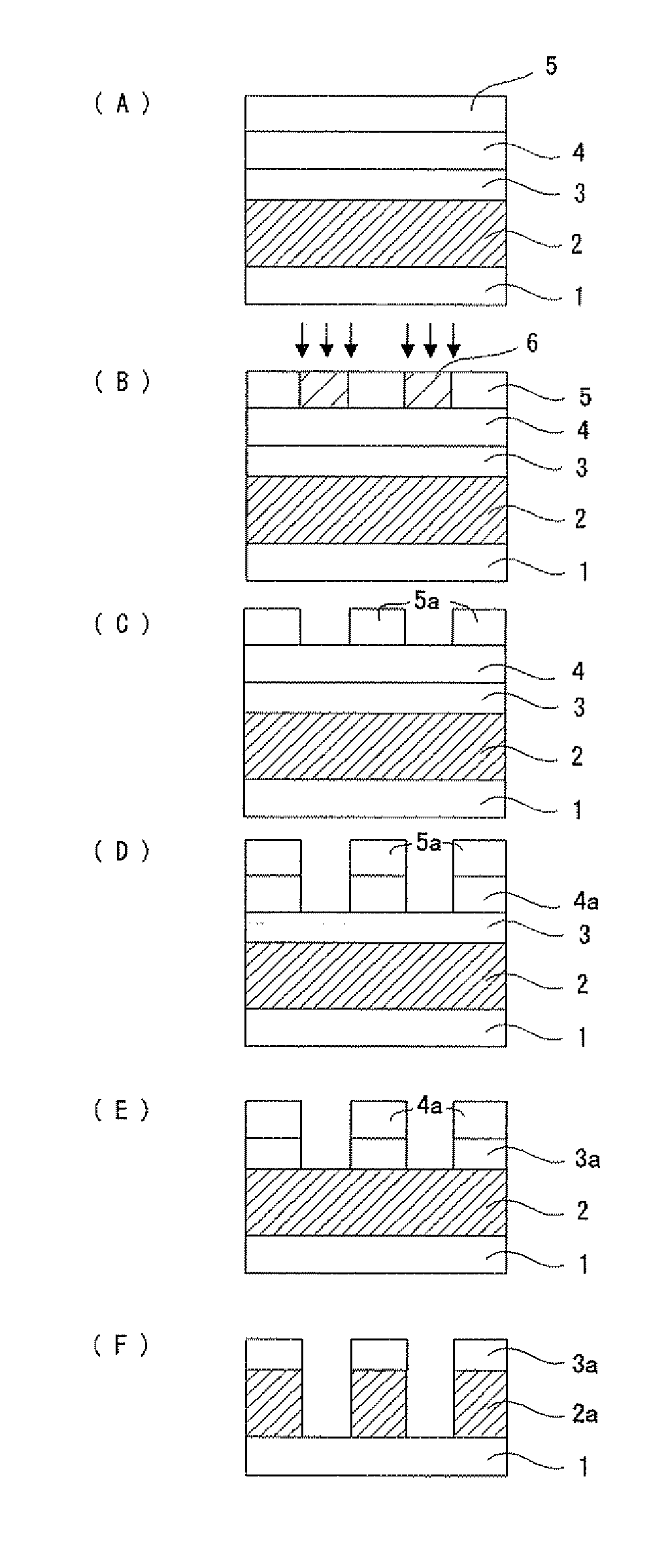

Manufacturing method of semiconductor device and semiconductor device

InactiveUS20080099876A1Good coating performanceImprove moisture resistanceSemiconductor/solid-state device detailsSolid-state devicesHigh densityDevice material

The present invention provides a method of manufacturing a semiconductor device, which comprises steps of forming a plurality of wirings on a first insulting film formed on a semiconductor substrate so as to adjoin one another, forming a second insulating film on the first insulating film by a plasma CVD method and covering the wirings with the second insulating film in such a manner that air gaps are formed between the respective adjacent wirings, forming a third insulating film on the second insulating film by a high density plasma CVD method, and forming a fourth insulating film high in moisture resistance on the third insulating film.

Owner:LAPIS SEMICON CO LTD

Dispersion composition, polymerizable composition, light-shielding color filter, solid-state image pick-up element, liquid crystal display device, wafer level lens, and image pick-up unit

ActiveUS20110124824A1Good shading effectGood dispersionPhotomechanical apparatusNon-linear opticsLiquid-crystal displayTitanium

A dispersion composition is provided in which the dispersibility of titanium black is high, the sedimentation of titanium black over time is suppressed, and overall dispersibility and storage stability are high. Further, a polymerizable composition is provided in which favorable coating property on a substrate and even film thickness can be obtained, generation of residue in an unexposed region when a pattern is formed can be suppressed, and favorable pattern shape having any steps after exposure / development can be obtained. The dispersion composition contains (A) titanium black, (B) a graft copolymer and (C) a solvent.

Owner:FUJIFILM CORP

Conducting polymer composition, conductive film formed using the conducting polymer composition, and electronic device including the conductive film

InactiveUS20080020208A1Increase hole injectionEnhance transport capabilityNanostructure manufactureSynthetic resin layered productsOrganic solventAlcohol

Provided is a conducting polymer composition including a conducting polymer and an ionic conjugated polymer. The conducting polymer composition includes the ionic conjugated polymer having a conjugated structure, in addition to the conducting polymer, and thus, can enhance hole injection and transport capability. Furthermore, ionization potential and work function can be easily adjusted by chemically tuning the backbone of the ionic conjugated polymer. In addition, the conducting polymer composition can be dissolved in water, alcohol, or a polar organic solvent, thereby enabling a solution process and rendering spin-coating easier.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

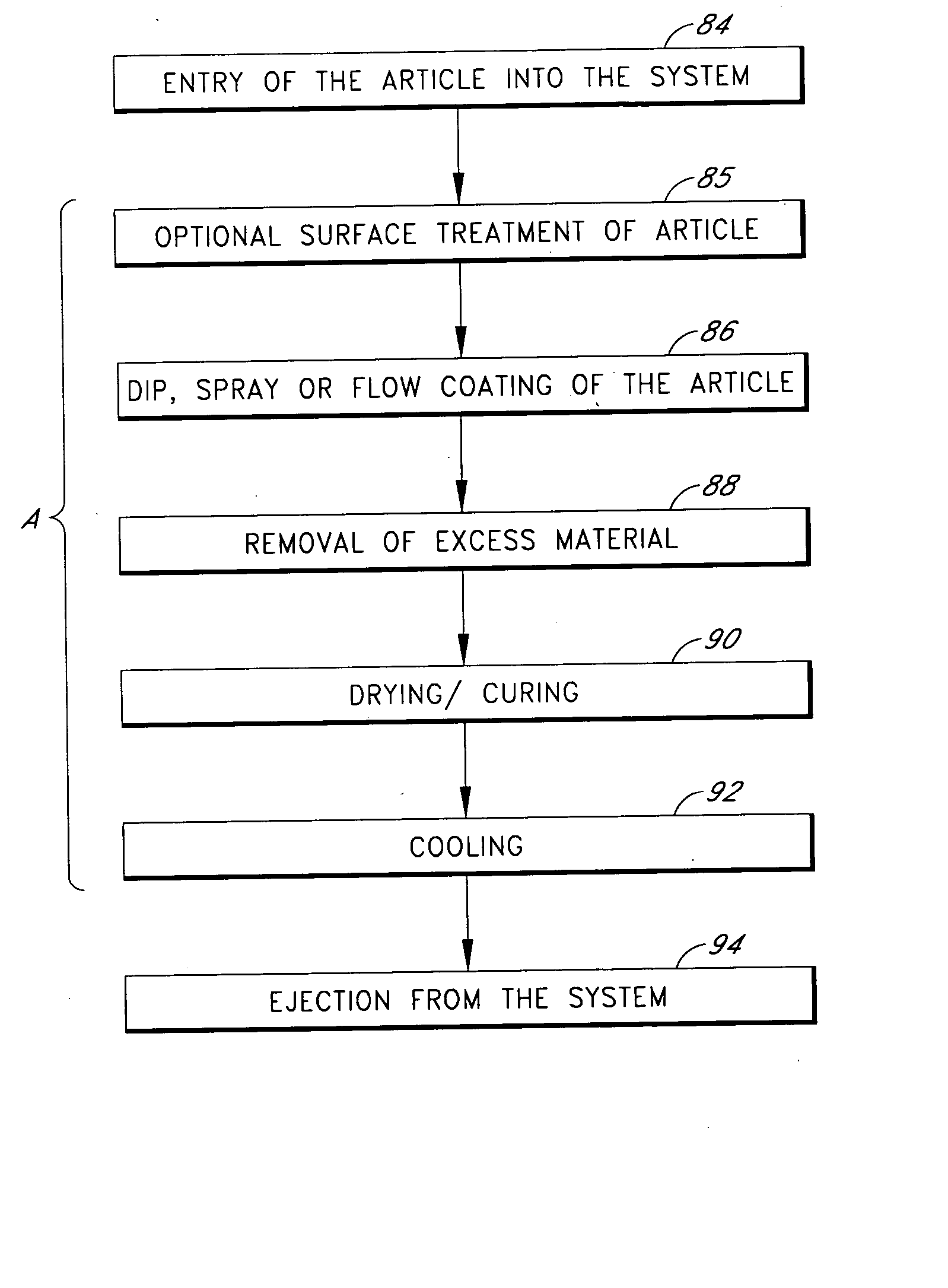

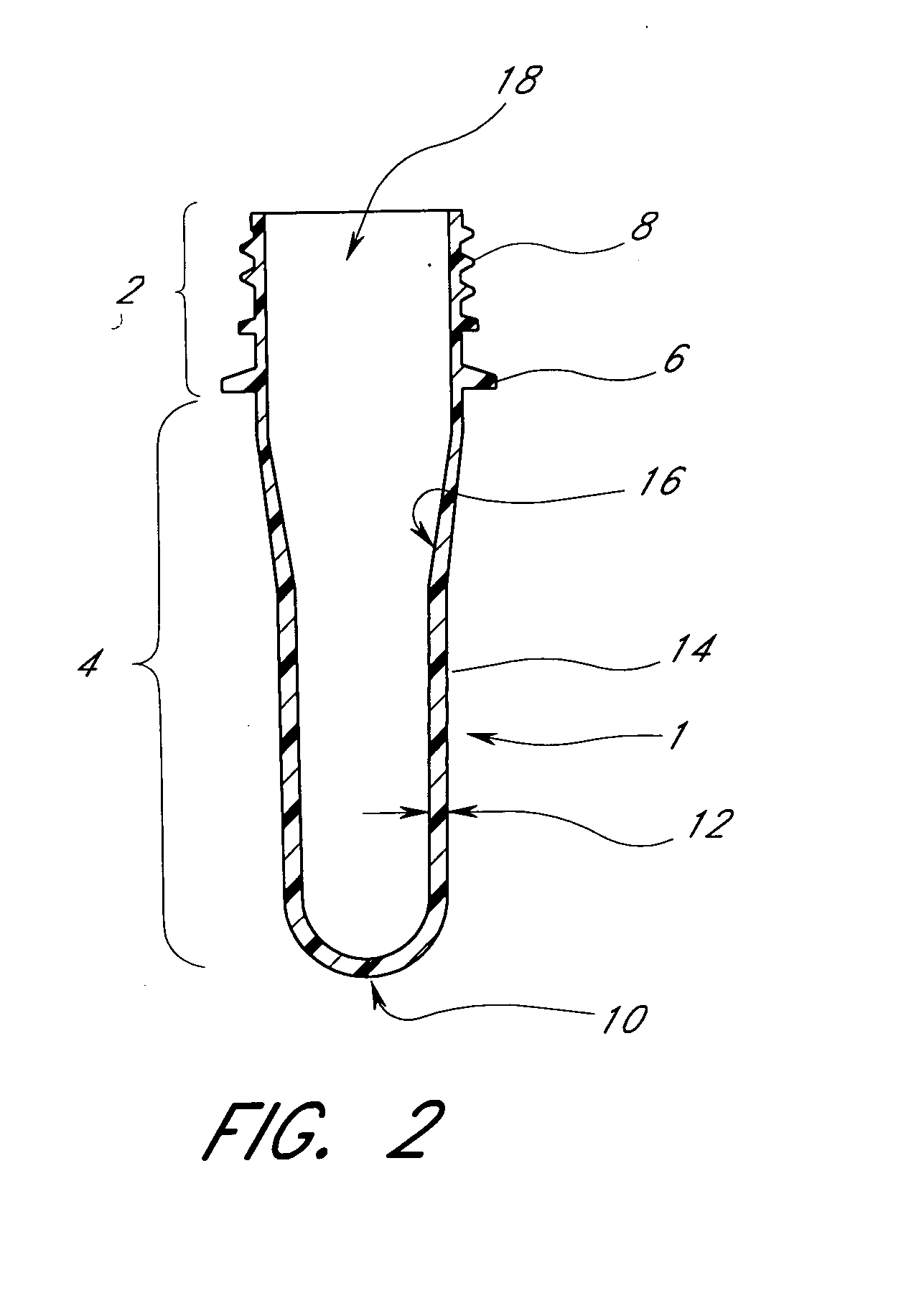

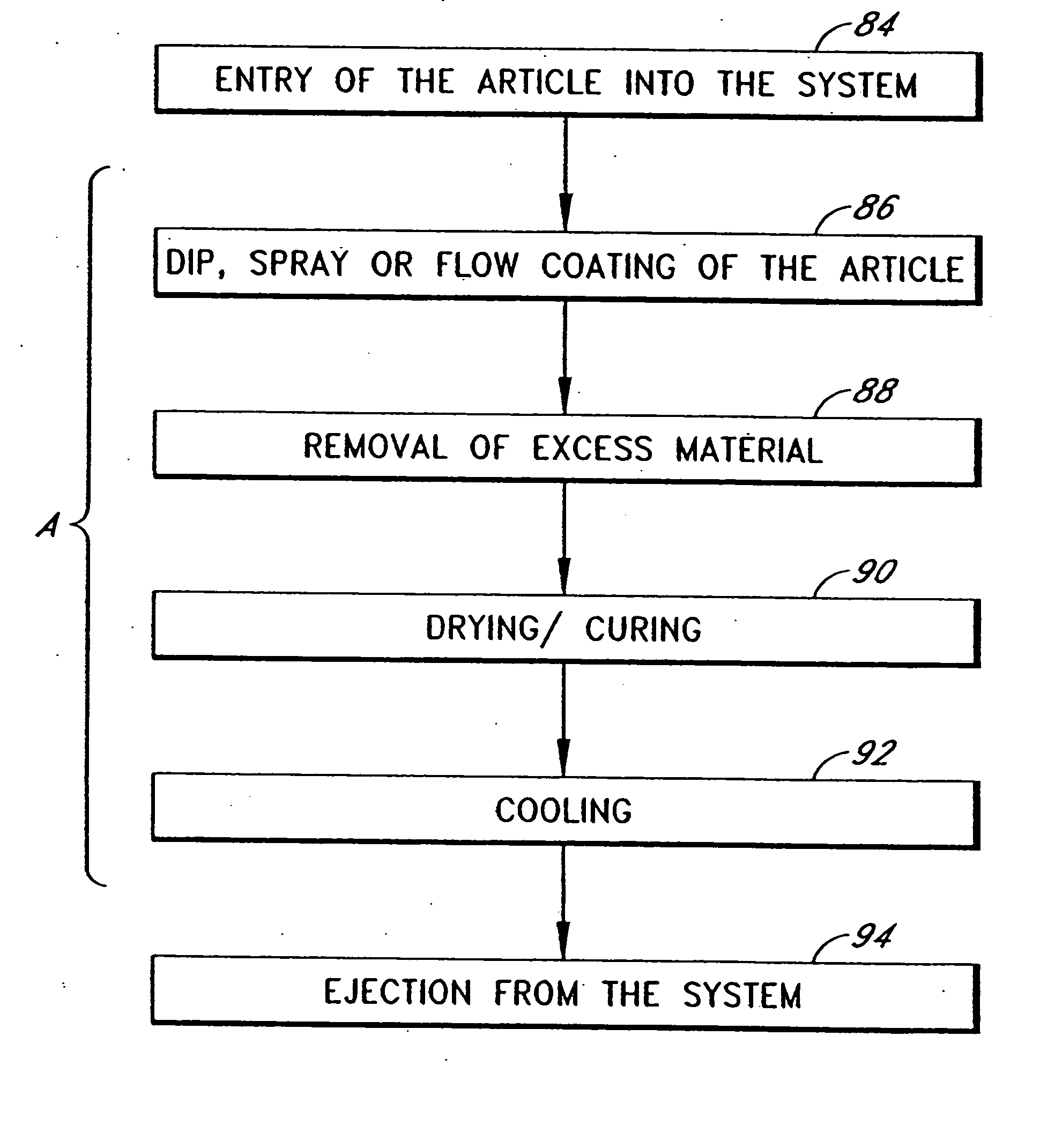

Methods of forming multilayer articles by surface treatment applications

InactiveUS20070087131A1Low water vapor transmission rateImprove adhesionPretreated surfacesCoatingsAir treatmentFlame treatment

Coated articles may comprise one or more coating layers, including water resistant coatings. A method comprises applying such coating layers by treating the article substrate by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment and dip, spray or flow coating. Additionally, a method comprises injection molding a first substrate material to form an article, treating the article surface by one or more methods selected from flame treatment, corona treatment, ionized air treatment, plasma air treatment and plasma arc treatment, and overmolding the article substrate with one or more barrier materials.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

Gas barrier film

InactiveUS20050084686A1Maintain good propertiesPackaging material to expandSynthetic resin layered productsPolyurea/polyurethane coatingsDiamineUrea

A gas barrier film exhibiting a superior gas barrier property and simultaneously provided with an excellent coating property, a polyurethane resin obtained by adding a polyisocyanate compound containing at least one of an aromatic, aromatic aliphatic, and alicyclic polyisocyanate in an amount of at least 30 wt % of the total polyisocyanate compound, a polyhydroxyalkane carboxylic acid, as necessary a polyol compound containing a C2 to C8 polyol ingredient in an amount of at least 90 wt % of the total polyol compound, a chain extender selected from the group comprised of at least one of ammonia, an ammonia derivative, diamine, hydrazine, and a hydrazine derivative, and a neutralization agent and having a total of a urethane group concentration and urea group concentration of 25 to 60 wt % and an acid value of 5 to 100 mgKOH·g−1, a swellable inorganic layer compound, and a polyamine compound having an amine value of 100 to 1900 mgKOH·g−1 formed on one side or both sides of a thermoplastic resin base.

Owner:FUTAMURA KAGAKU INDS

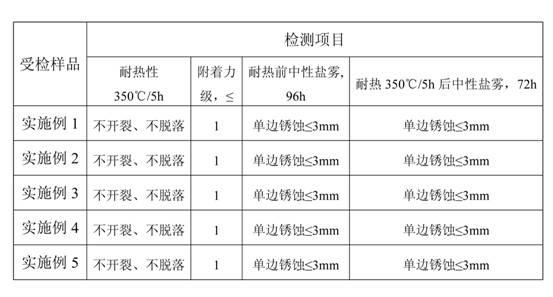

Heat-resisting organic silicon antiseptic inner tank coating

InactiveCN101935498AGood high temperature resistanceGood adhesionAnti-corrosive paintsEpoxy resin coatingsSolventFilling materials

The invention discloses a heat-resisting organic silicon antiseptic inner tank coating which comprises the following components in part by mass: 5-30 parts of organic silicon resin, 5-15 parts of modified organic silicon resin, 1-5 parts of amino resin, 0-18 parts of epoxy resin, 0-8 parts of phenolic resin, 11-43 parts of antiseptic pigment, 8-20 parts of filling material and 4-22 parts of solvent. The heat-resisting organic silicon antiseptic inner tank coating has good heat resistance and can work for long term at the high temperature of 350 DEG C; the coating has good adhesion force, good corrosion resistance and excellent performance; and a coating film still has good corrosion resistance after working at high temperature.

Owner:JIANGMEN PAINT FACTORY

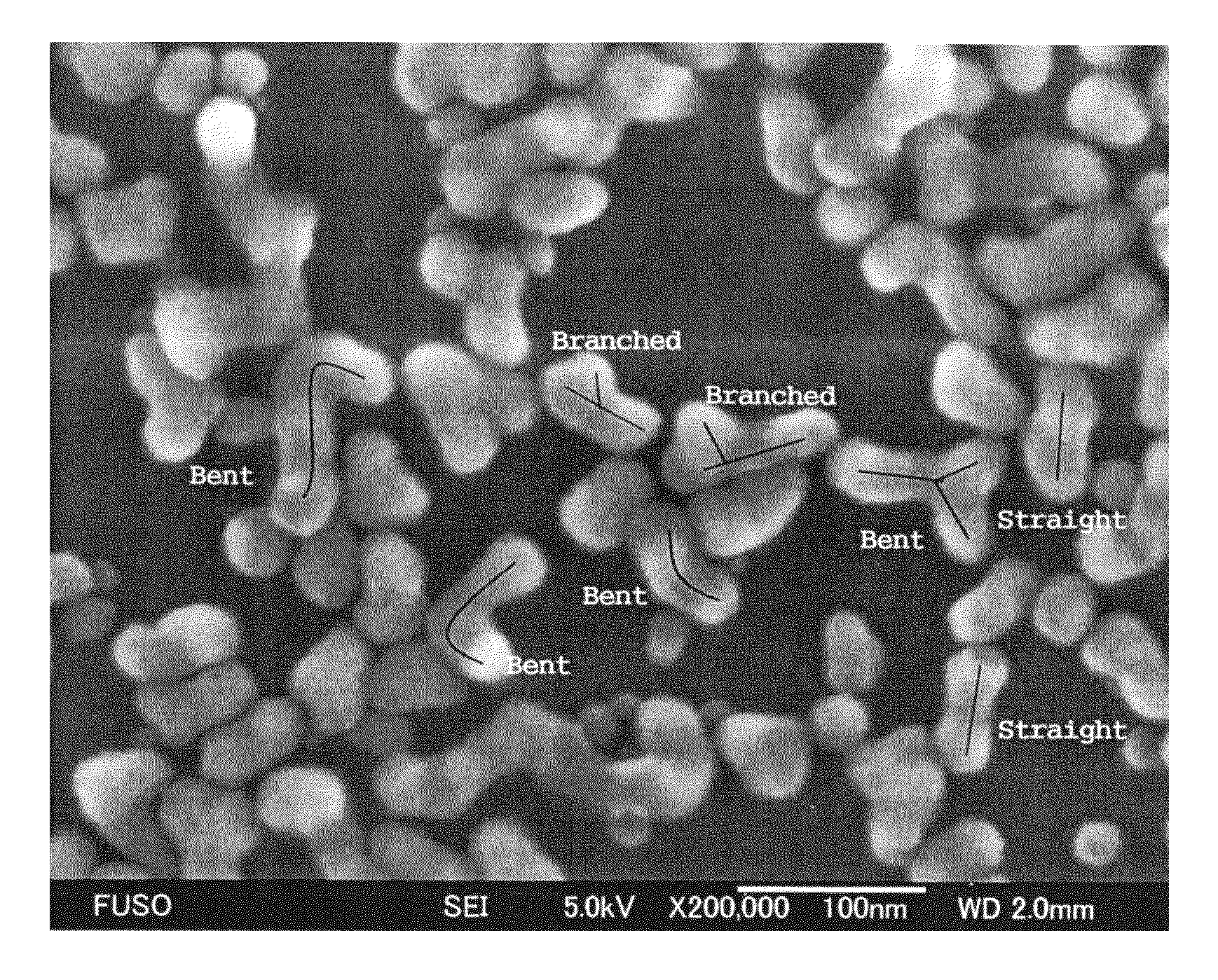

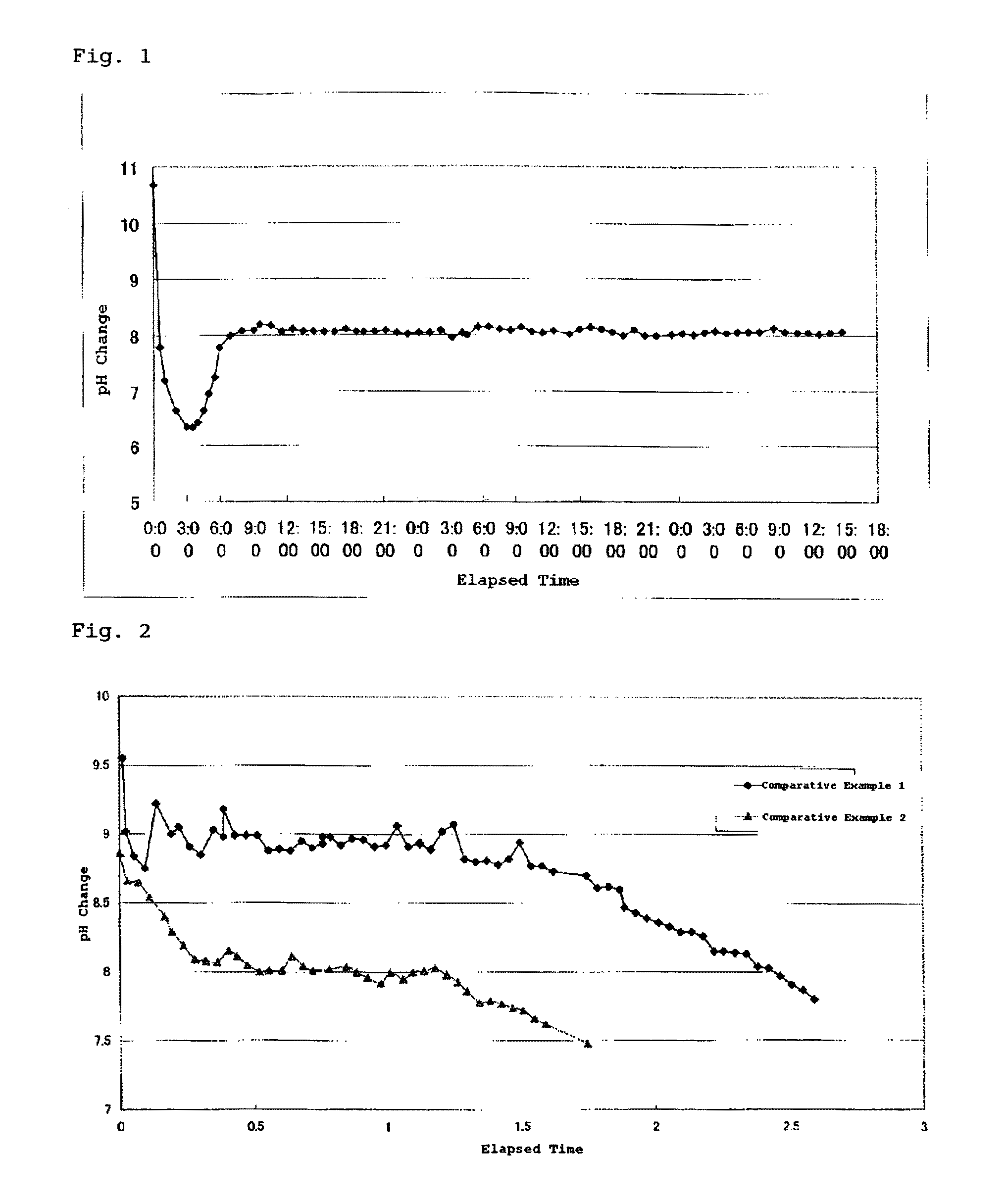

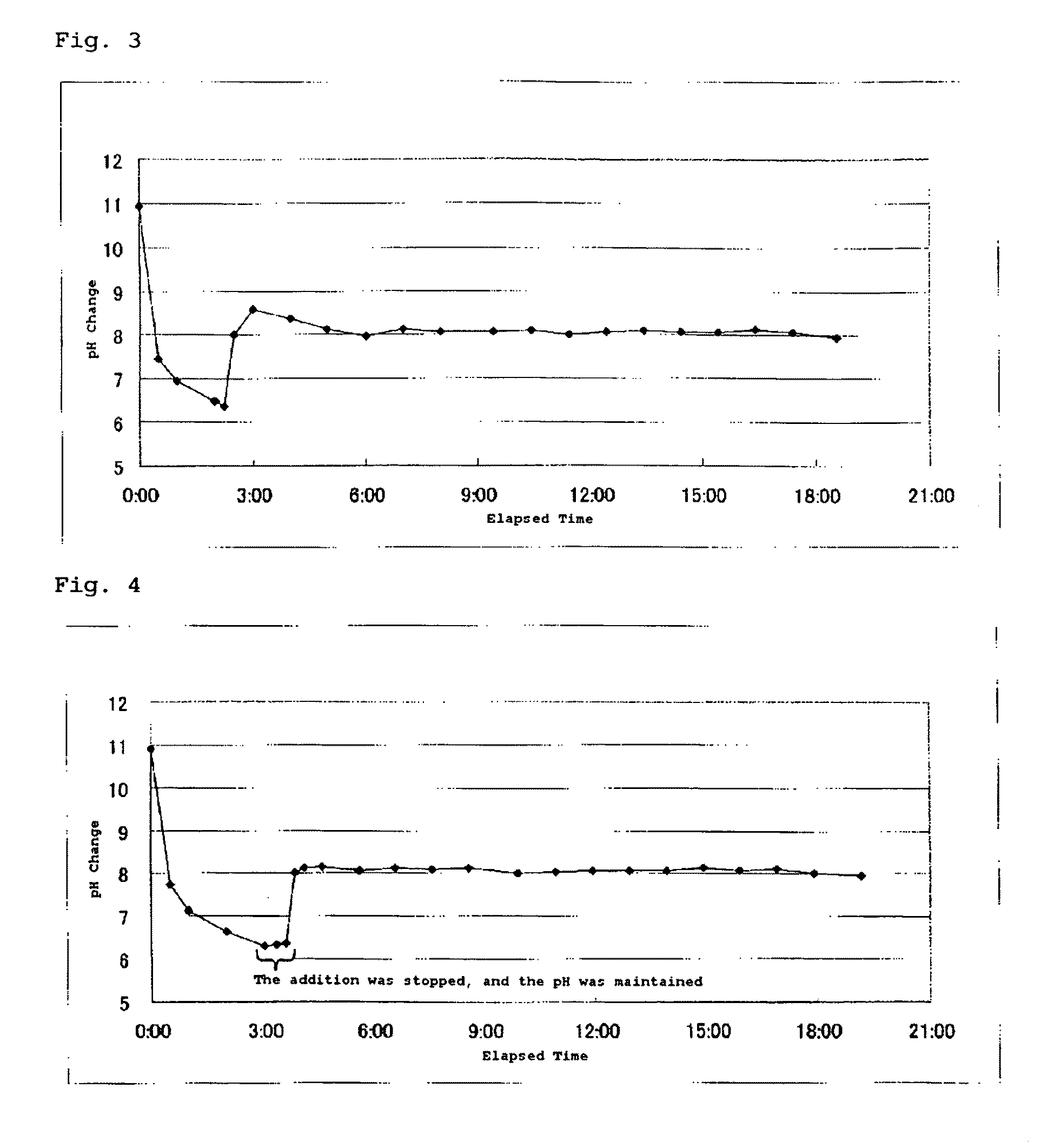

Colloidal silica containing silica secondary particles having bent structure and/or branched structure, and method for producing same

ActiveUS8529787B2Improve polishing rateLarge aspect ratioSilicaOther chemical processesColloidal silicaColloid

This invention provides a dense, high-purity colloidal silica containing silica secondary particles having a branched and / or bent structure, and a production method thereof. Specifically, this invention provides a method for producing a colloidal silica, comprising the steps of 1) preparing a mother liquid containing an alkali catalyst and water, and having a pH of 9 to 12; and 2) adding a hydrolysis liquid obtained by hydrolysis of an alkyl silicate to the mother liquid, wherein the step of adding the hydrolysis liquid to the mother liquid sequentially comprises A) step 1 of adding the hydrolysis liquid until the pH of the resulting liquid mixture becomes less than 7; B) step 2 of adding an aqueous alkali solution until the pH of the liquid mixture becomes 7 or more; and C) step 3 of adding the hydrolysis liquid while maintaining the pH of the liquid mixture at 7 or more, and a colloidal silica containing silica secondary particles having a branched and / or bent structure, obtained by this method.

Owner:FUSO CHEM

Polycarbonate diol and producing method thereof, and polyurethane and active energy ray-curable polymer composition both formed using same

ActiveUS20130109804A1Improves stain resistanceHigh hardnessOrganic chemistryPolyureas/polyurethane adhesivesMethacrylateElastomer

A novel polycarbonate diol is useful as a raw material for producing a polycarbonate diol-based polyurethane with a high degree of hardness, superior abrasion resistance, and superior hydrophilicity. The polyurethane is useful in paints, coating agents, synthetic leathers, artificial leathers, and highly-functional elastomers, or the like. The polycarbonate diol is also useful for producing an active-energy radiation curable polymer composition giving a cured film having superior contamination resistance and high degree of hardness. The curable polymer composition contains a urethane(meth)acrylate oligomer obtained from the polycarbonate diol. The polycarbonate diol is obtained, for example, by reacting two specific types of diols with diester carbonate in the presence of a transesterification catalyst. The catalyst has a metal of Group 1 or 2 on the periodic table. A metal content of the transesterification catalyst is 100 weight ppm or less.

Owner:MITSUBISHI CHEM CORP

Preparation method of boron nitride ceramic shell for titanium and titanium alloy precision casting

InactiveCN1876272AReduce the degree of reactionReduce thicknessFoundry mouldsFoundry coresWaxTitanium

The invention relates to a method for preparing boron nitride ceramic molding shell, which is used for titanium and titanium alloy accurate casting. It belongs to field of shaping thermo-stable ceramic molding shell material. The invention comprises following steps: preparing coating slurry with refined boron nitride powder and binding agent zirconium acetate or silica sol according to proportion by weight of 3:1; immersing wax tank into said coating slurry to make slurry be coated on wax mold evenly; spreading sand, spreading boron nitride powder on wax mold; repeating said dip-coating and sand-spreading steps for 1 to 2 times after drying and hardening; preparing slurry with binding agent and mullet powder, back coating with prepared slurry for 3-5 times; drying, demolding, and sintering wax mold with several coating layers under condition of 900-1100 Deg. C and nitrogen; getting boron nitride ceramic molding shell material.

Owner:SHANGHAI UNIV

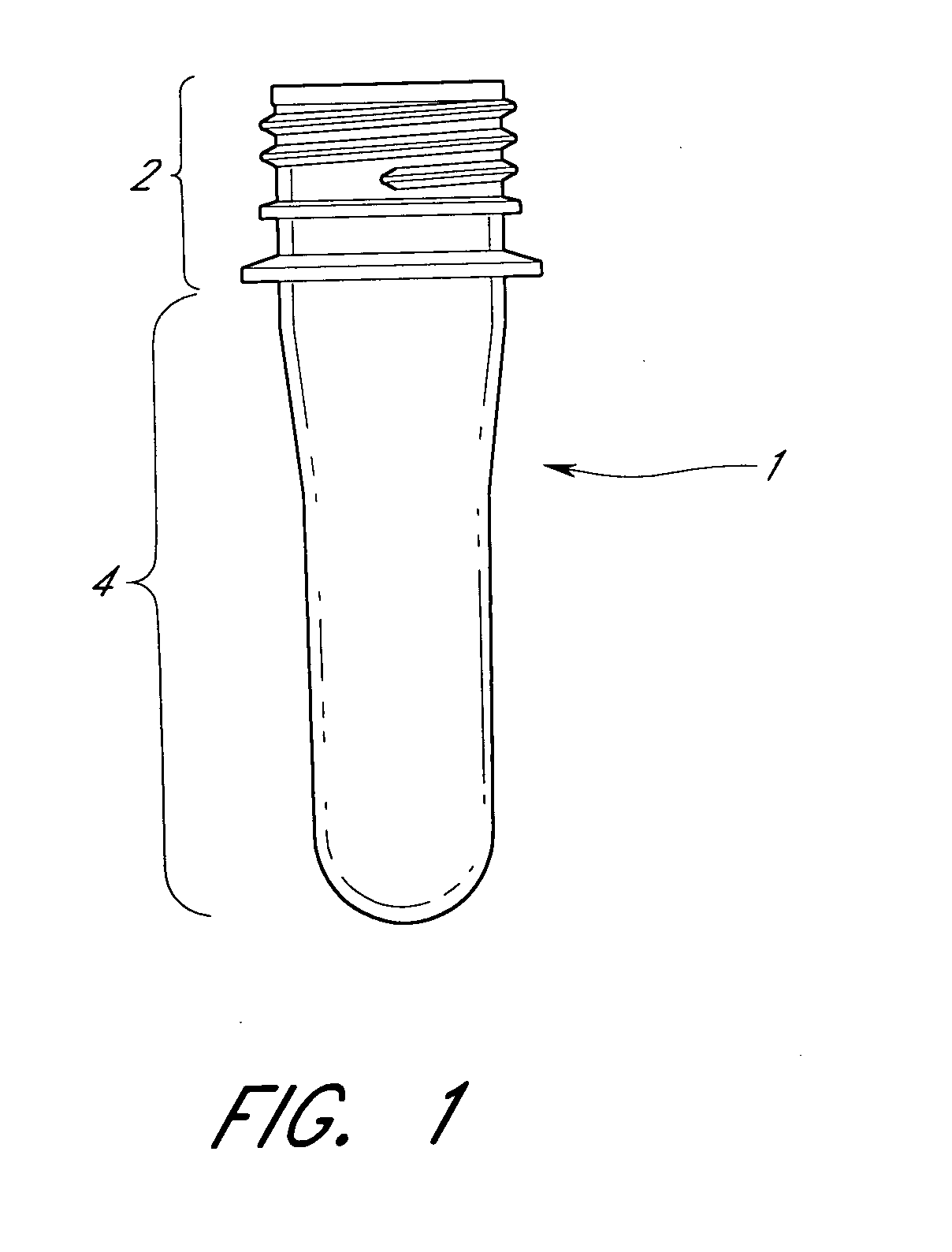

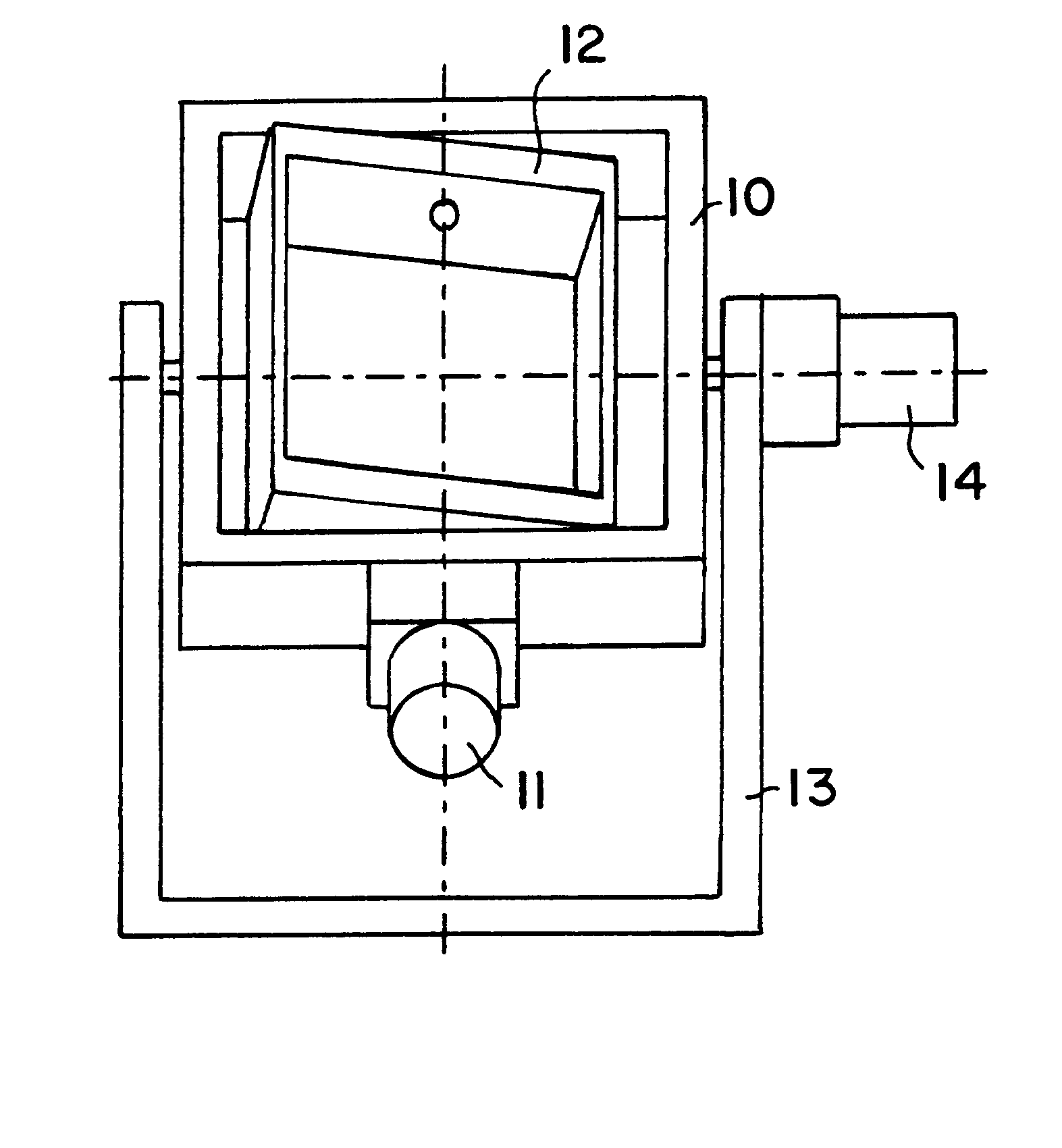

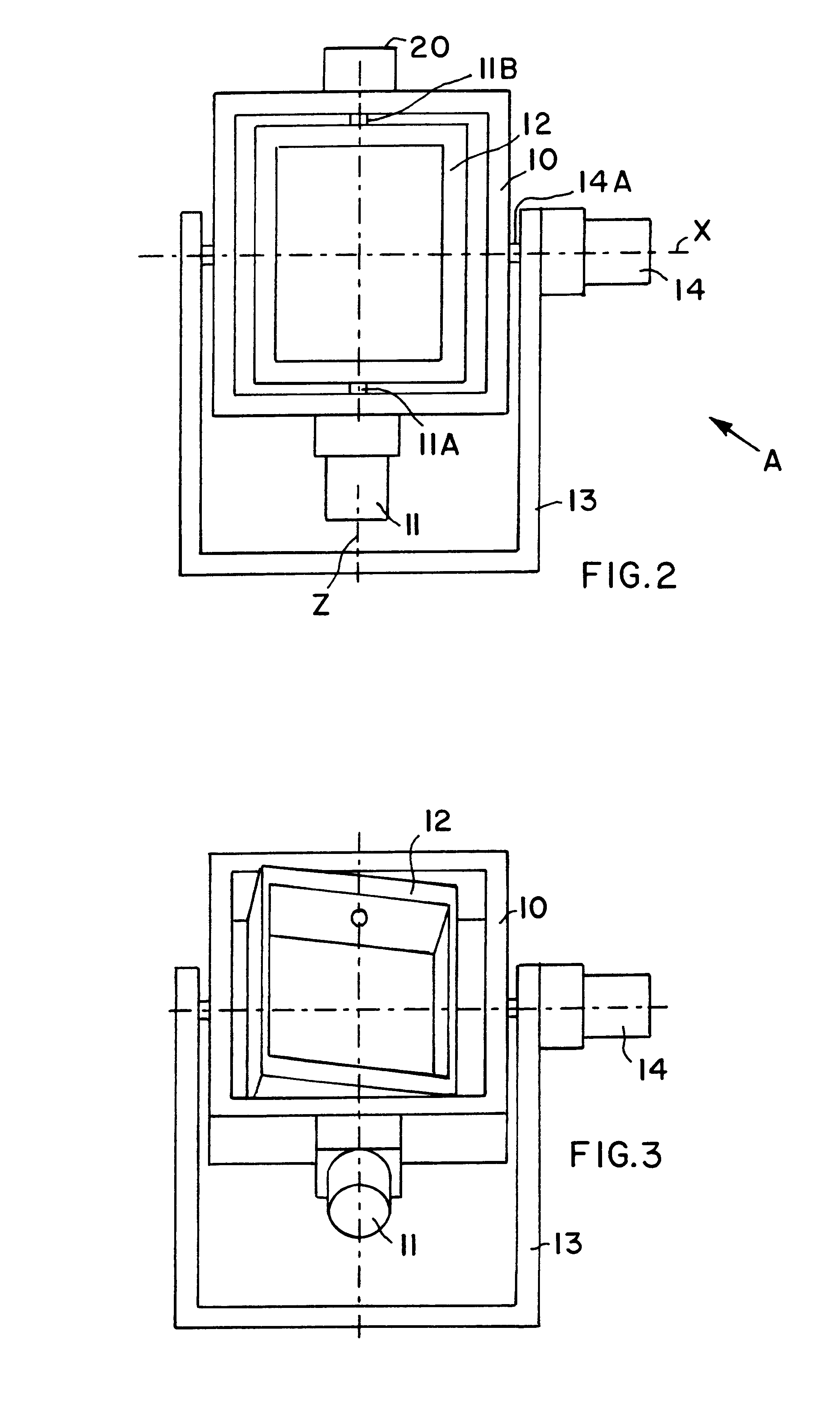

Method of surface coating medical implants

InactiveUS6214407B1Evenly distributedIncrease success rateGlovesPharmaceutical containersLiquid mediumProsthesis

To coat a surface of a medical implant such as an organ part or a synthetic prosthesis with a coating of living cells, the implant is inserted and fixed into a receiving container which is at least partially filled with a nutritive liquid medium containing the coating cells in suspension. Then the receiving container is rotated respectively about two distinct rotation axes, whereby preferably the two rotation motions are independently controllable and the two axes are substantially perpendicular to each other. Each of the two rotation motions can be a continuous rotation through 360°, or a stepwise intermittent rotation through successive rotational angle steps. The parameters of the two rotations about the two axes can be combined as needed for a particular application, for example a continuous rotation about one axis combined with a stepwise rotation about the other axis. The time period and rotational speed of each rotation can also be independently controlled. A uniform and complete coating of cells on all surfaces of the implant is achieved.

Owner:CO DON AG

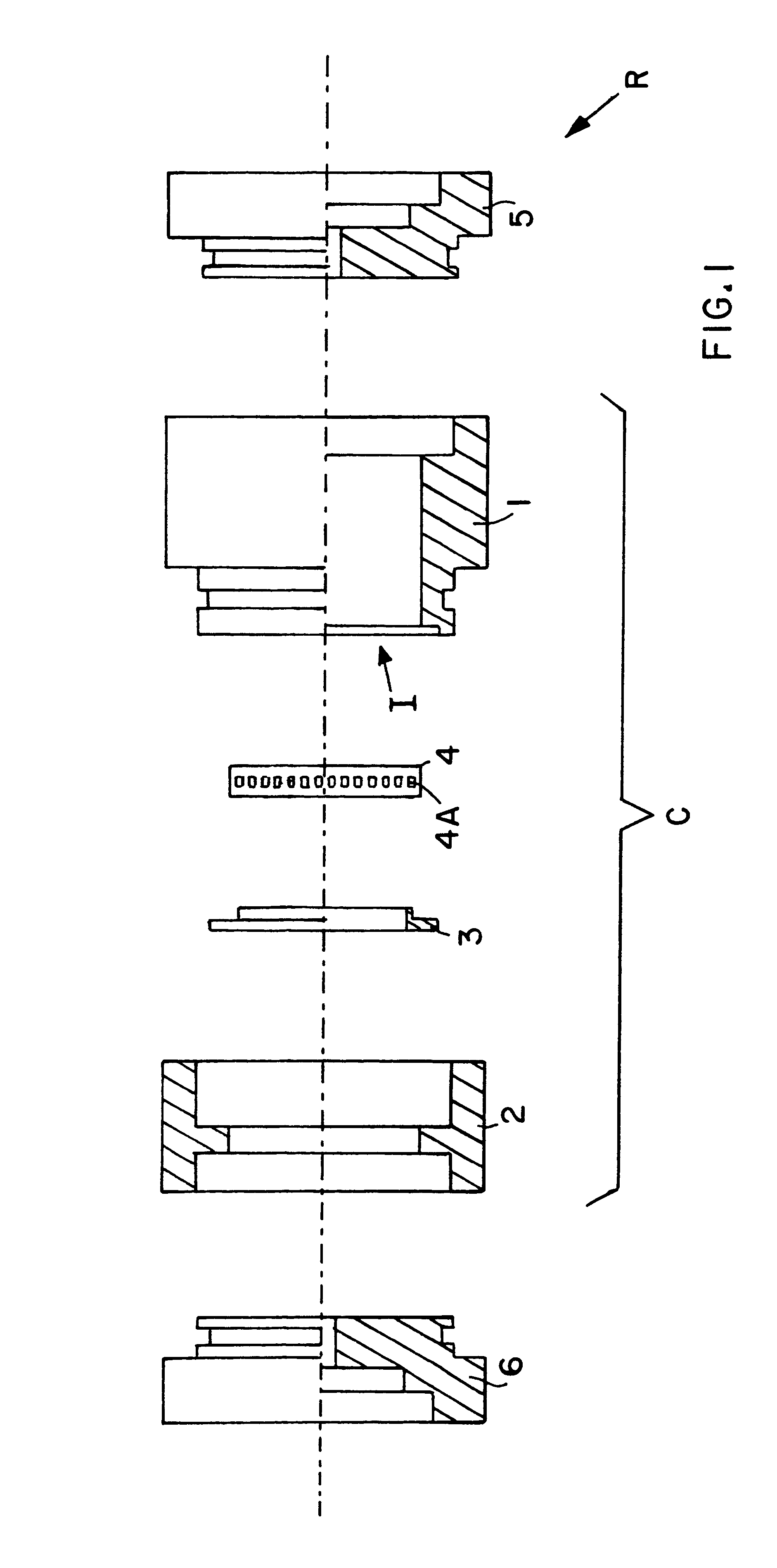

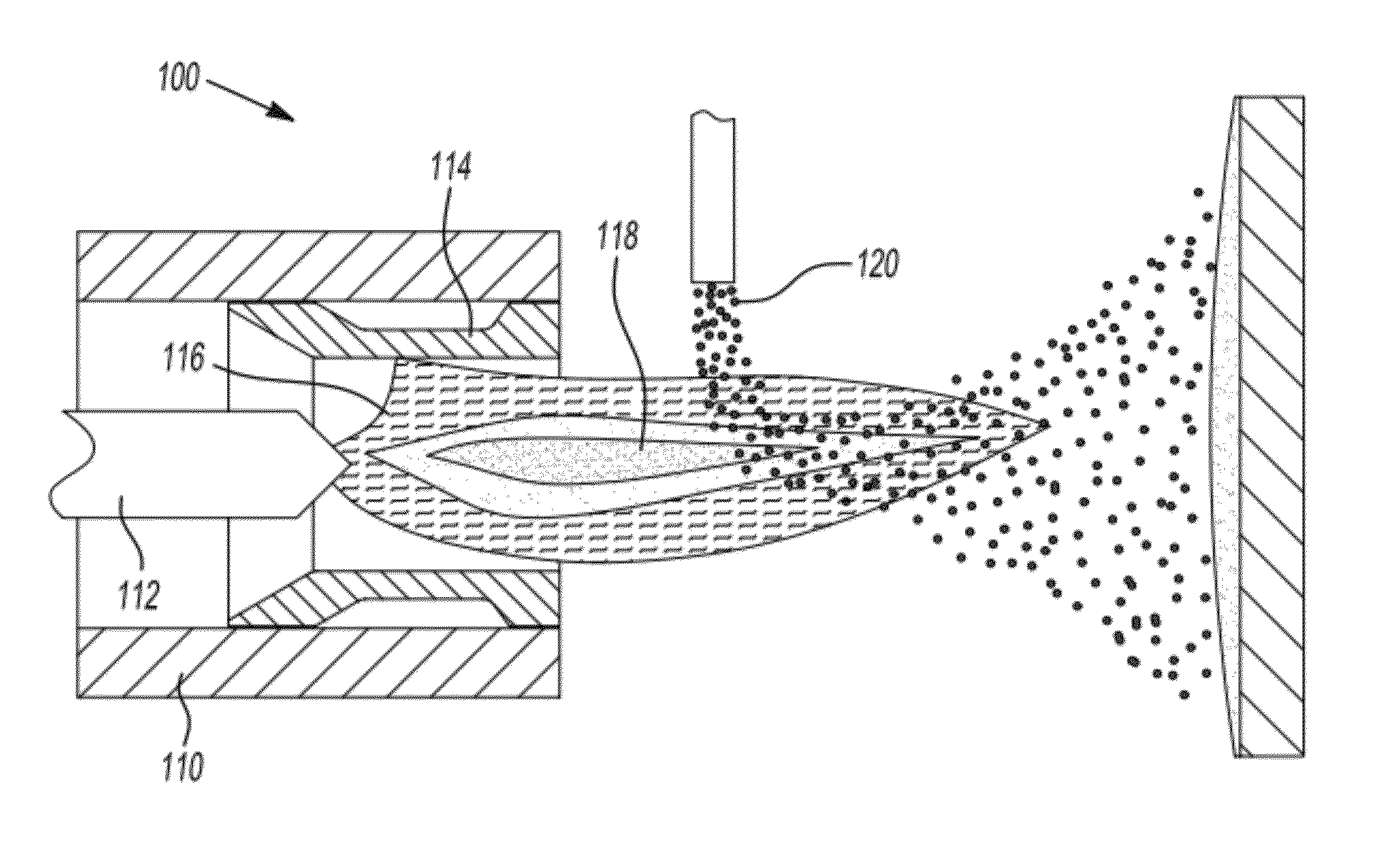

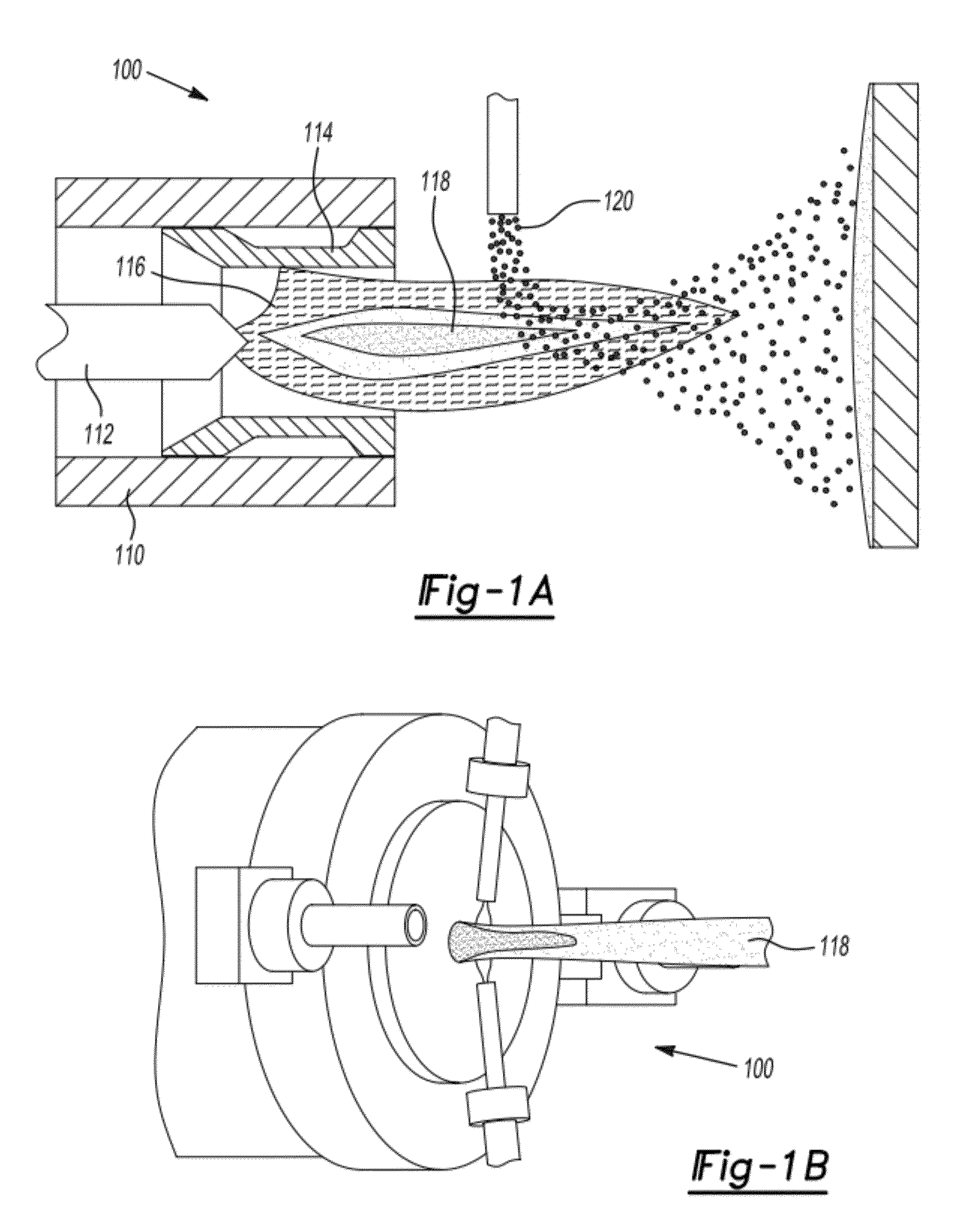

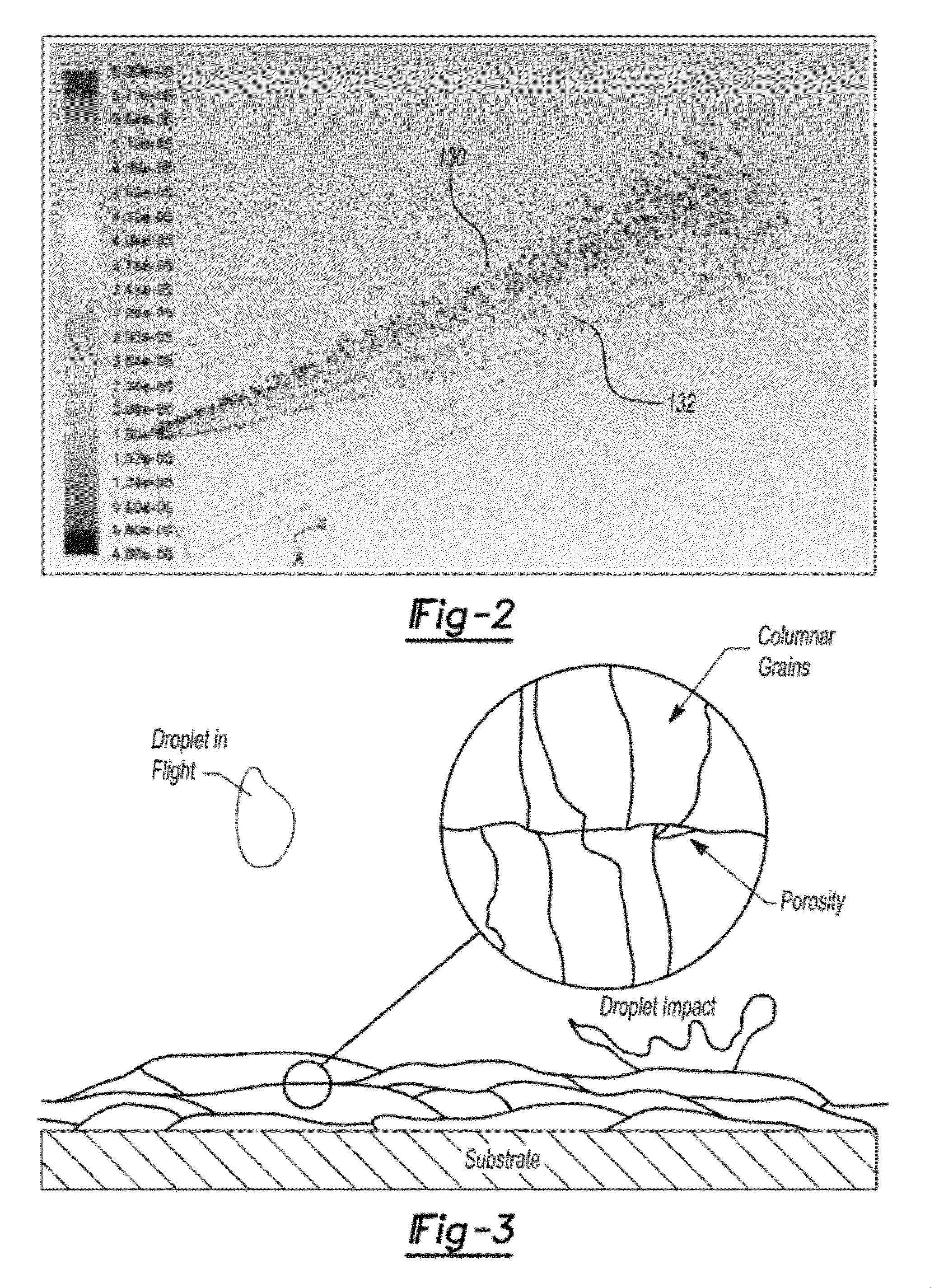

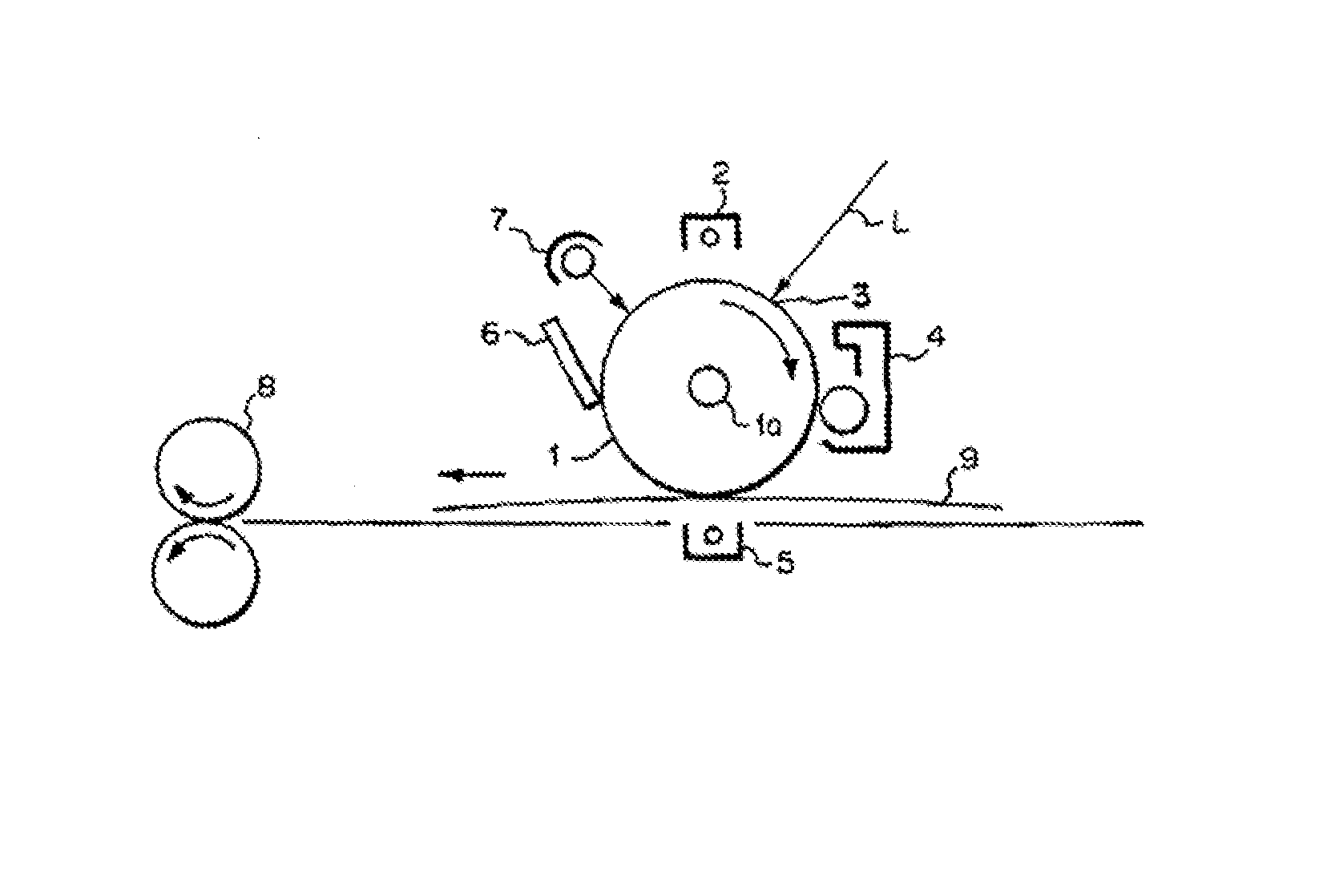

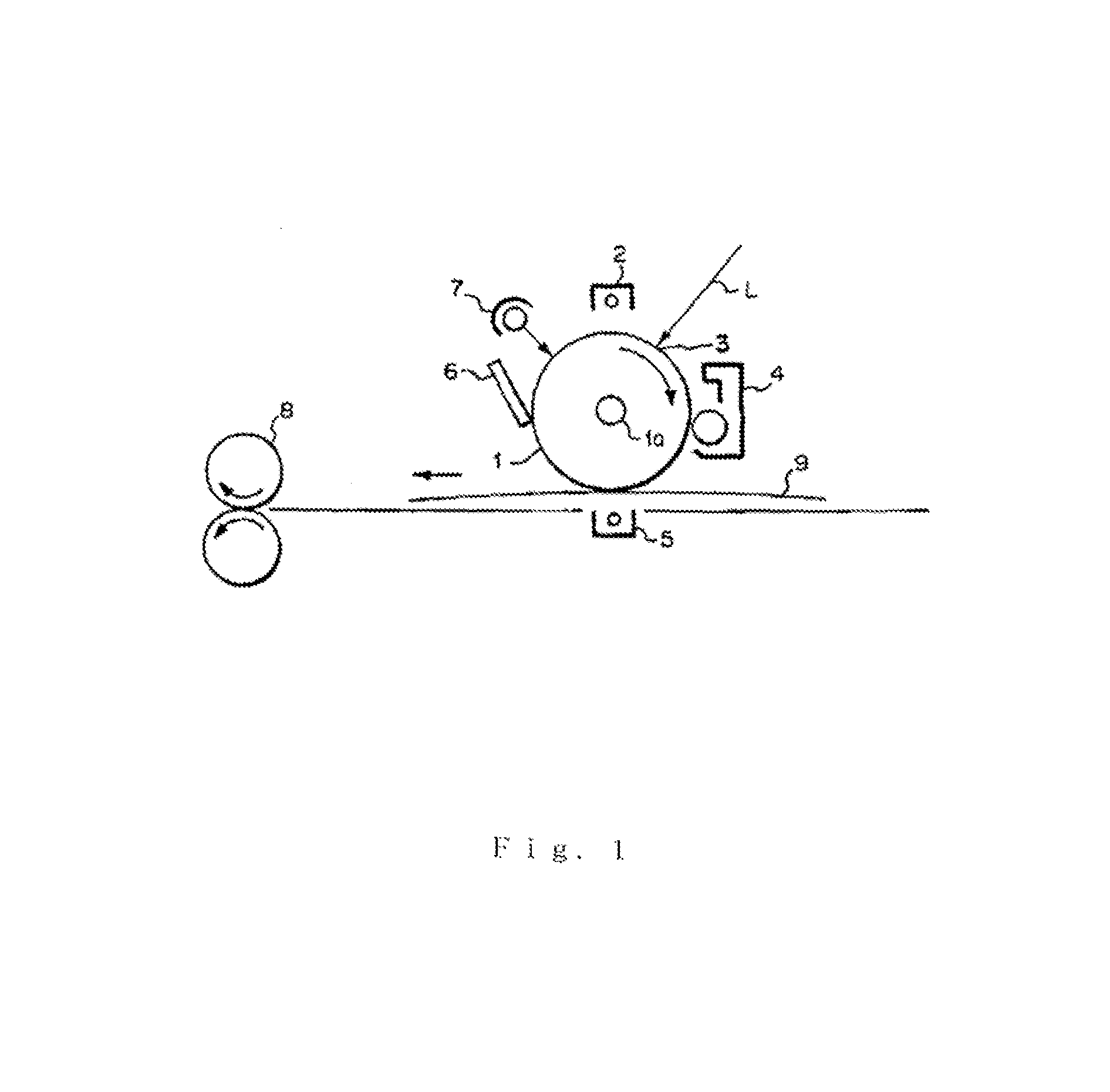

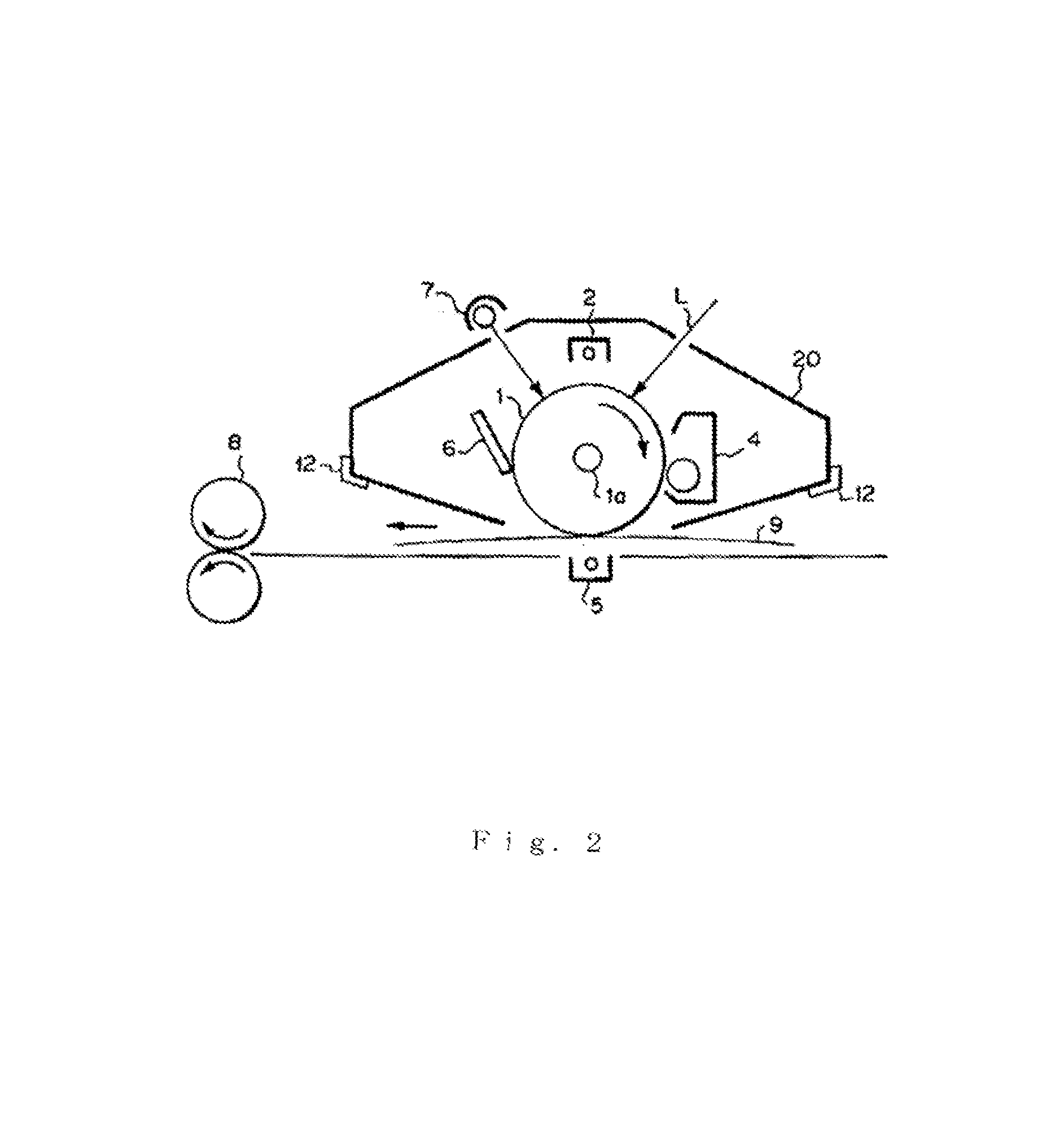

In-situ plasma/laser hybrid scheme

ActiveUS8294060B2Good coating performanceIncrease deposition rateArc welding apparatusX-ray apparatusPlasma jetLaser source

A method and apparatus for forming layers on a target. The apparatus and method employ a direct current plasma apparatus to form at least one layer using a plasma jet containing precursors. In some embodiments, the direct current plasma apparatus utilizes axial injection of the precursors through the cathode (in an upstream and / or downstream configuration) and / or downstream of the anode. In some embodiments, the direct current plasma apparatus can comprise a laser source for remelting the layer using a laser beam to achieve in-situ densification thereof.

Owner:RGT UNIV OF MICHIGAN

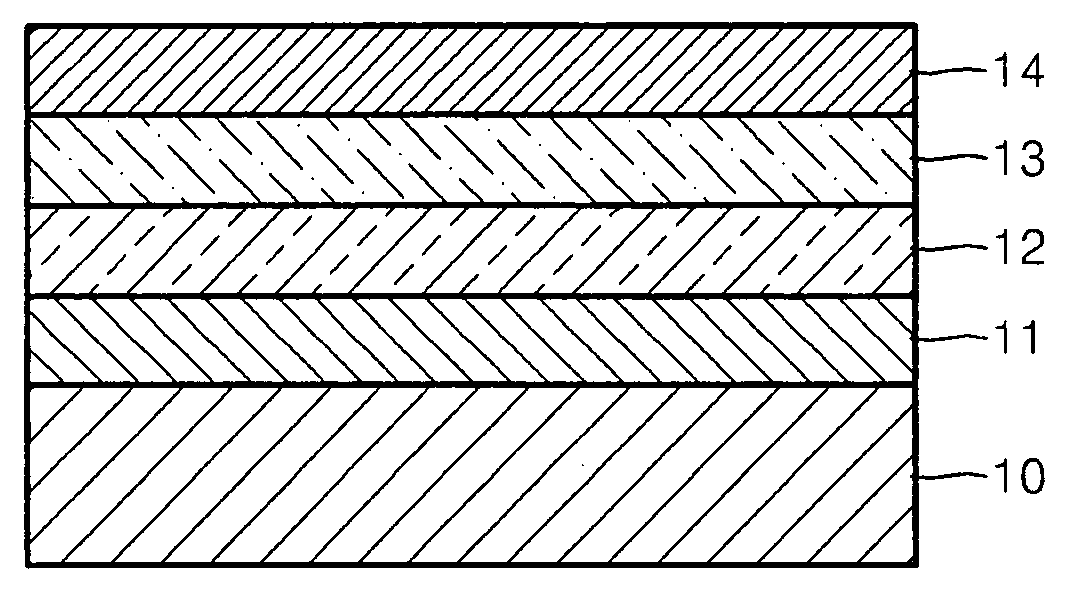

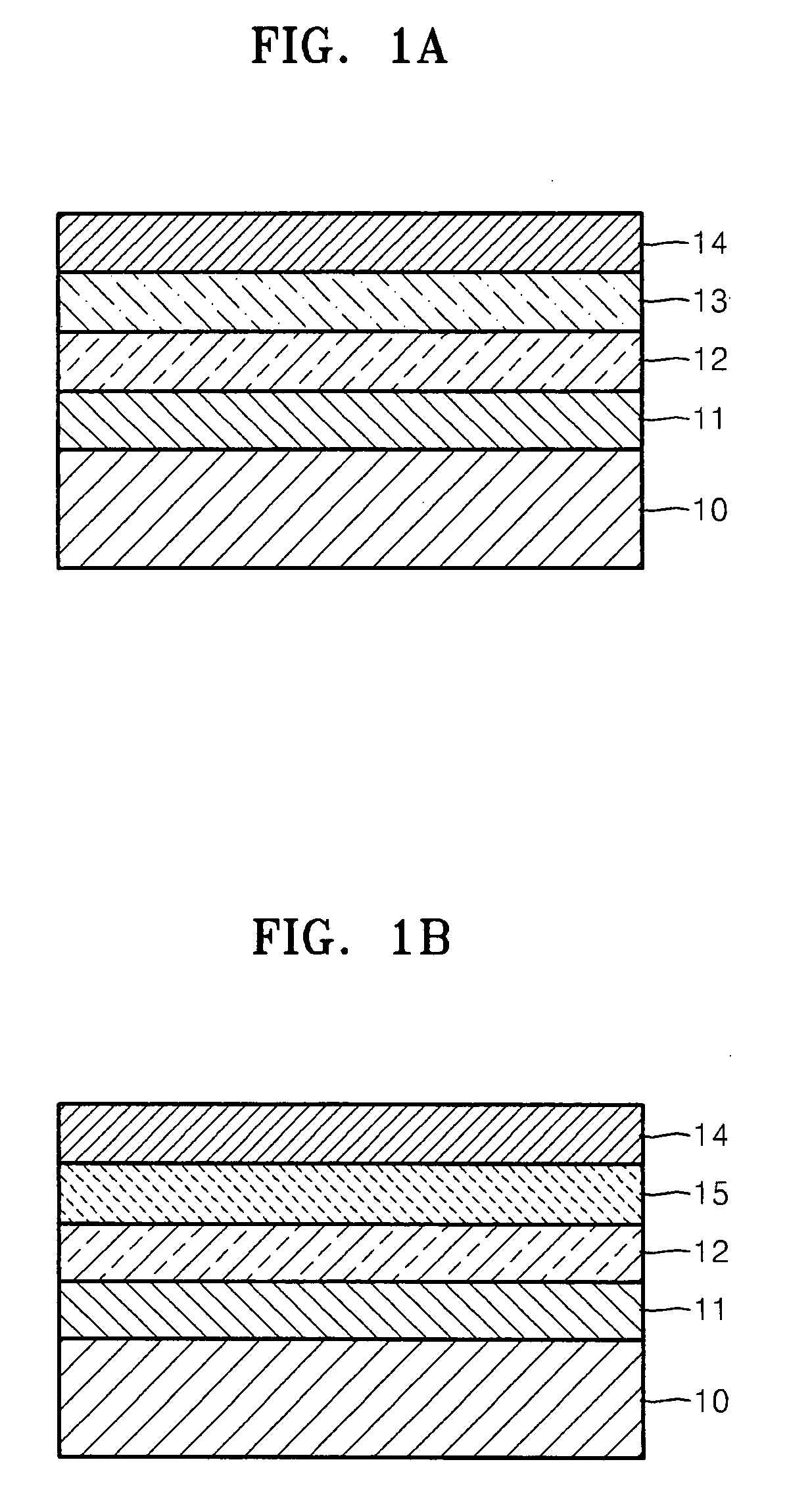

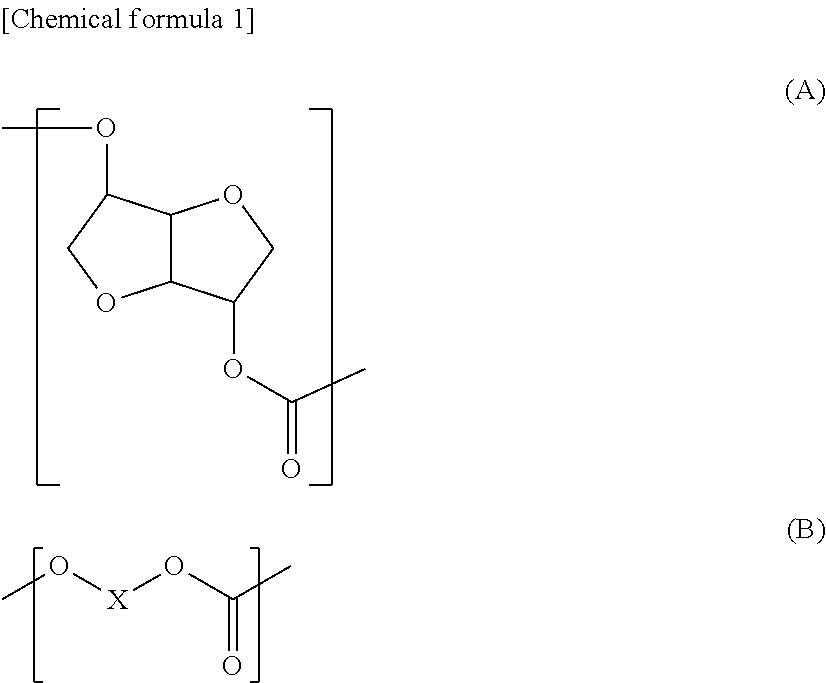

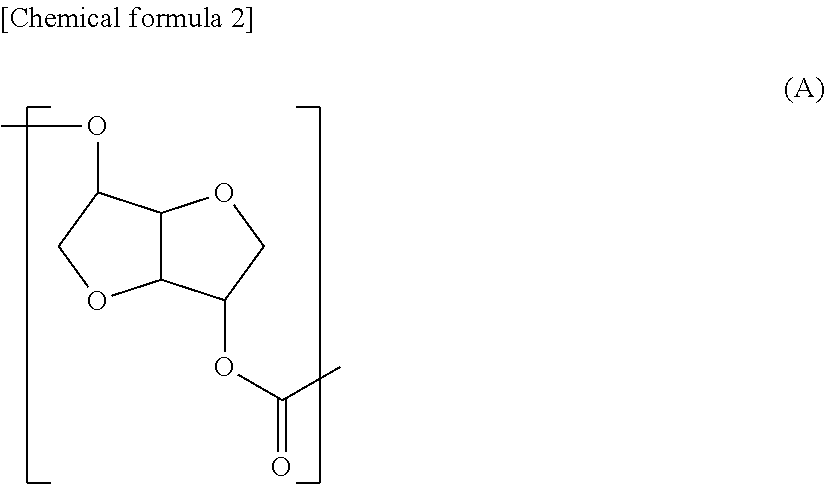

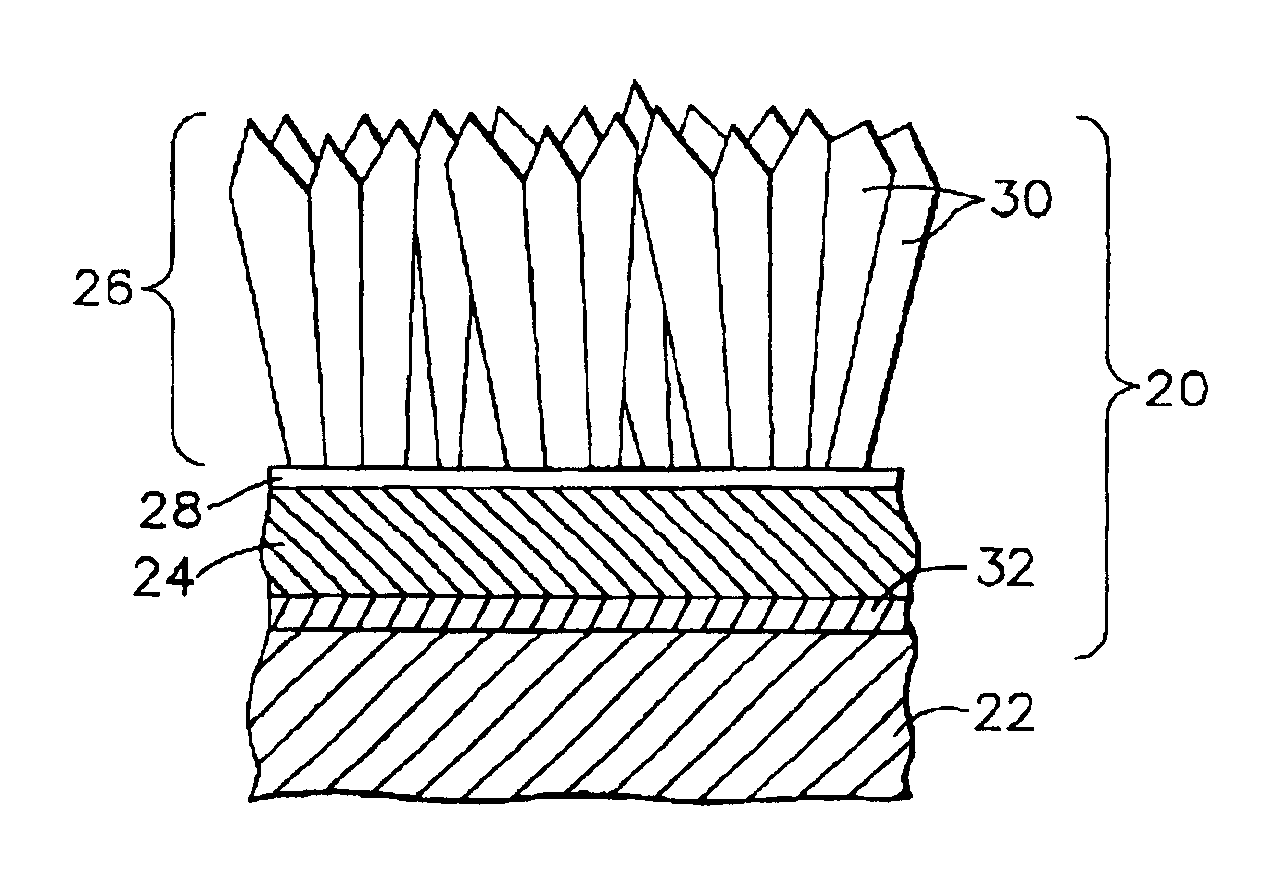

Polyvinyl acetal resin, electrophotographic photosensitive member, process cartridge, and electrophotographic apparatus

ActiveUS8088541B2Good coating performanceMaintain good propertiesElectrographic process apparatusCorona dischargeEngineeringStructural unit

The present invention relates to a polyvinyl acetal resin having a specific repeating structural unit, an electrophotographic photosensitive member using the polyvinyl acetal resin, and a process cartridge and an electrophotographic apparatus each having the electrophotographic photosensitive member.

Owner:CANON KK

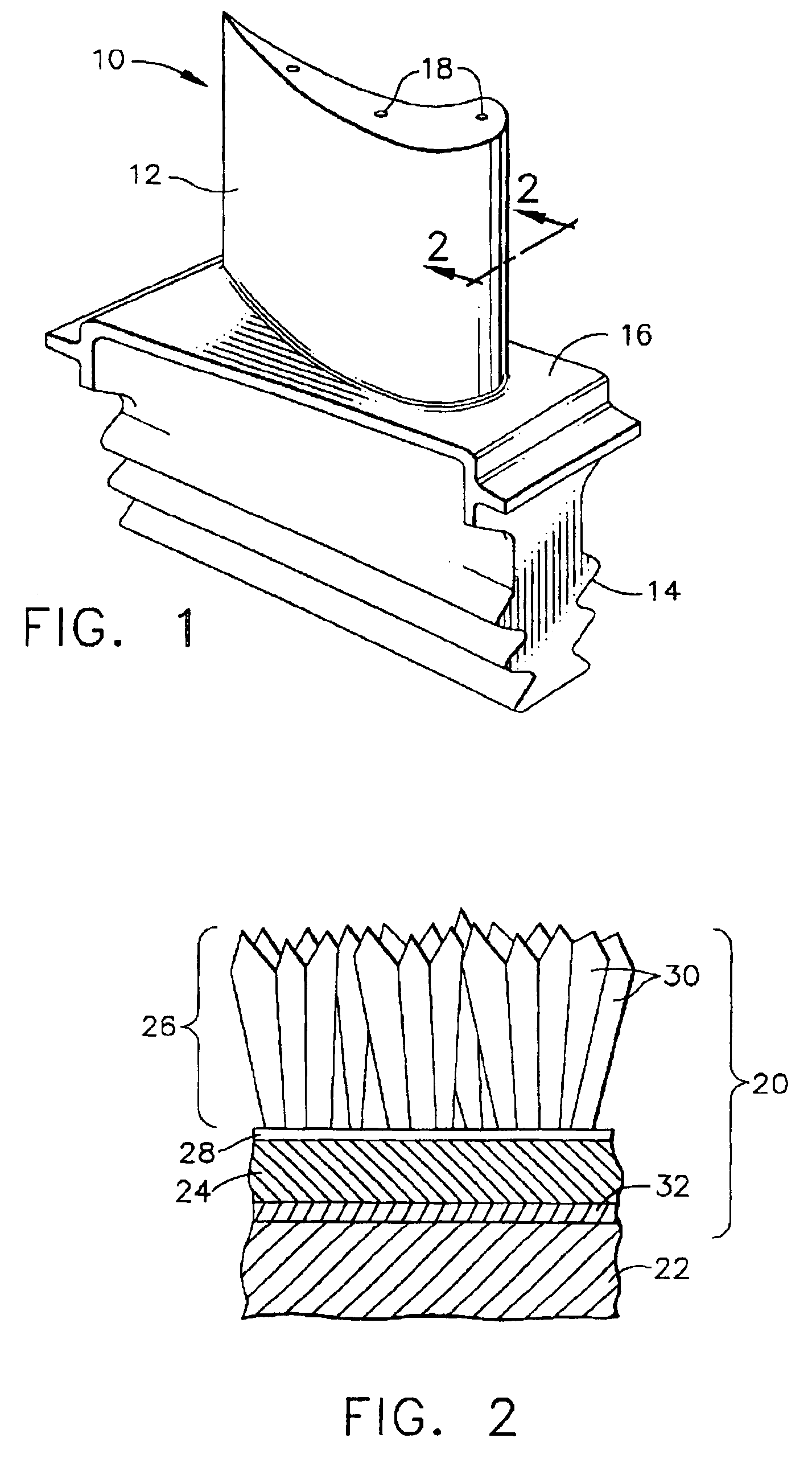

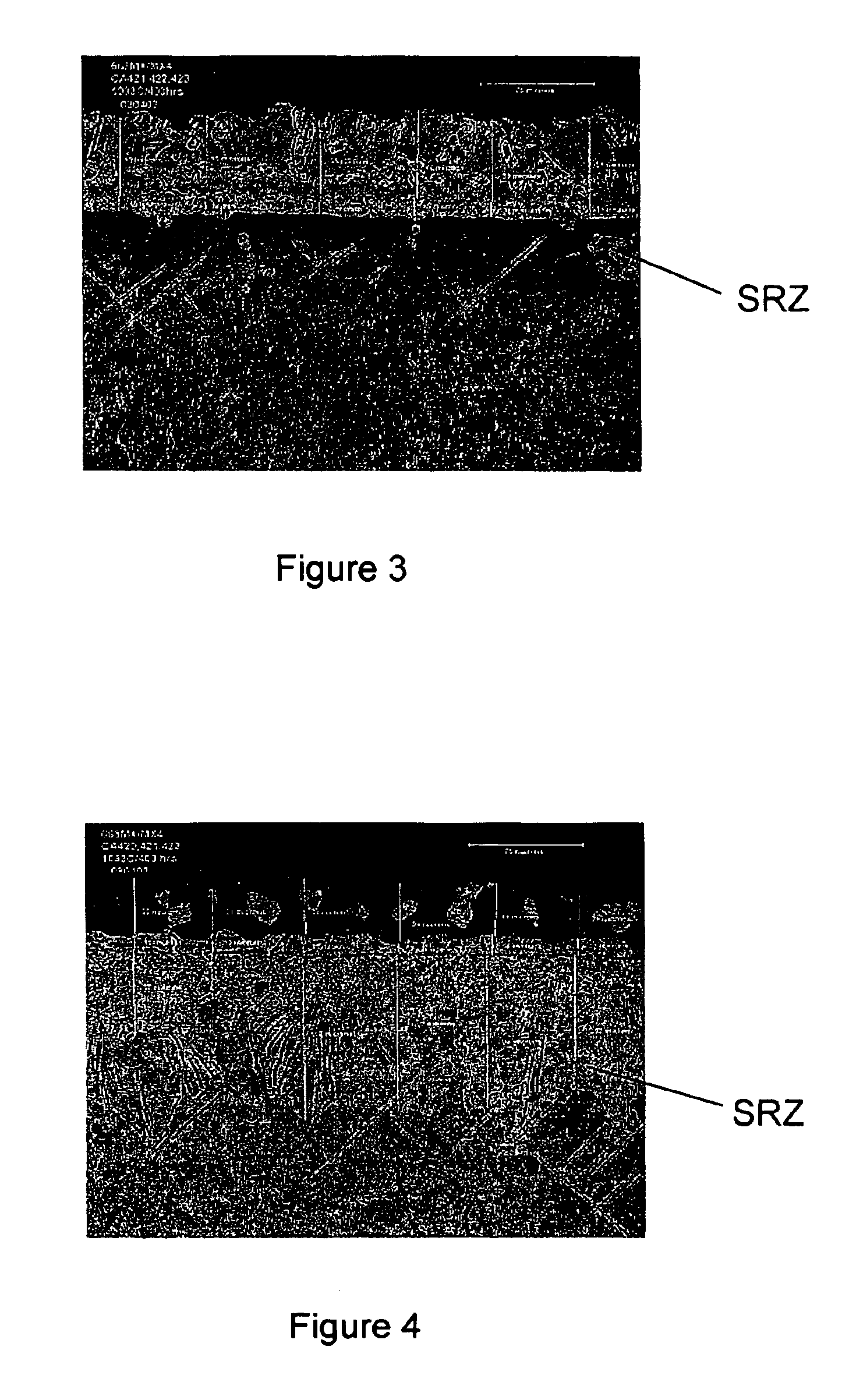

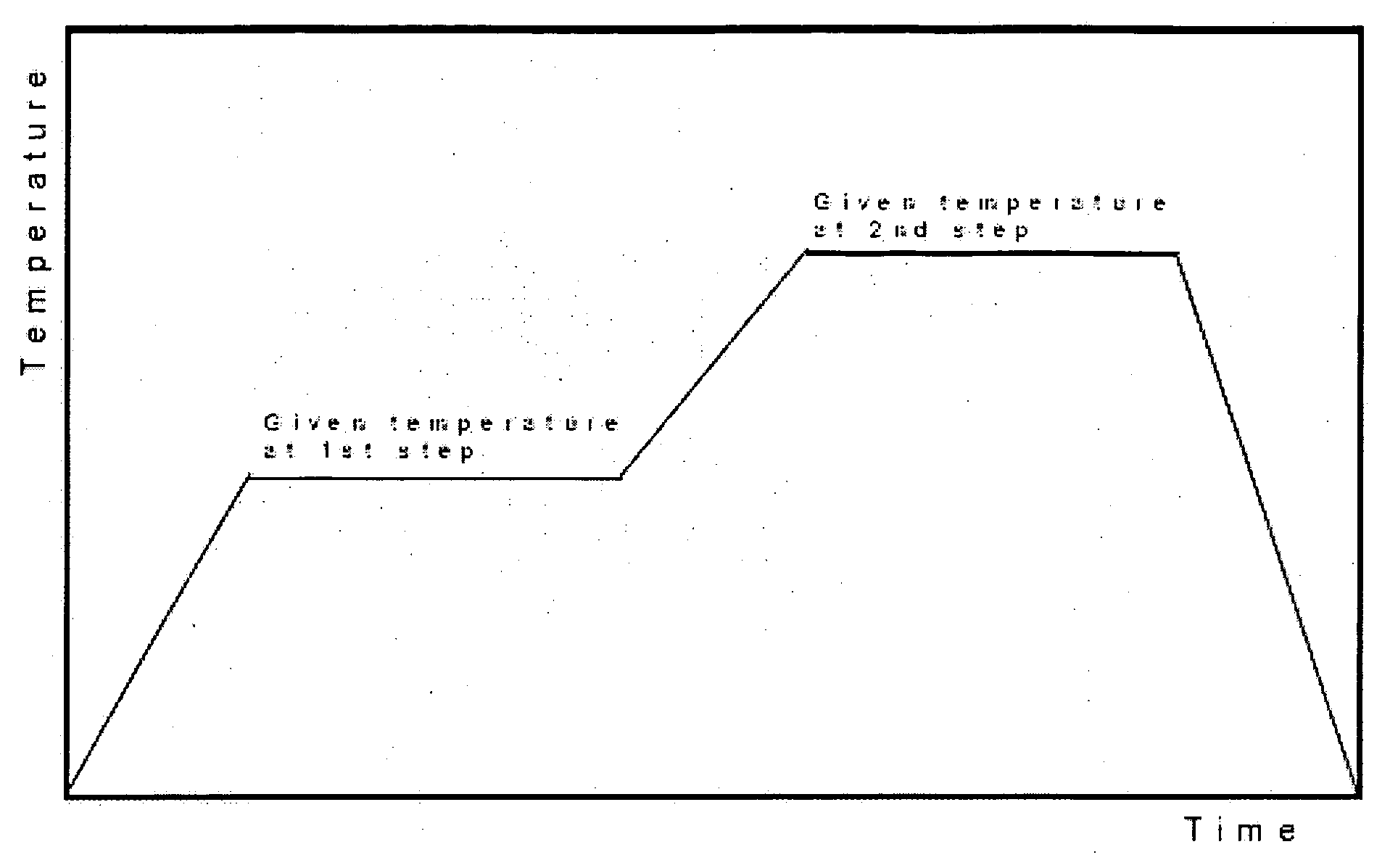

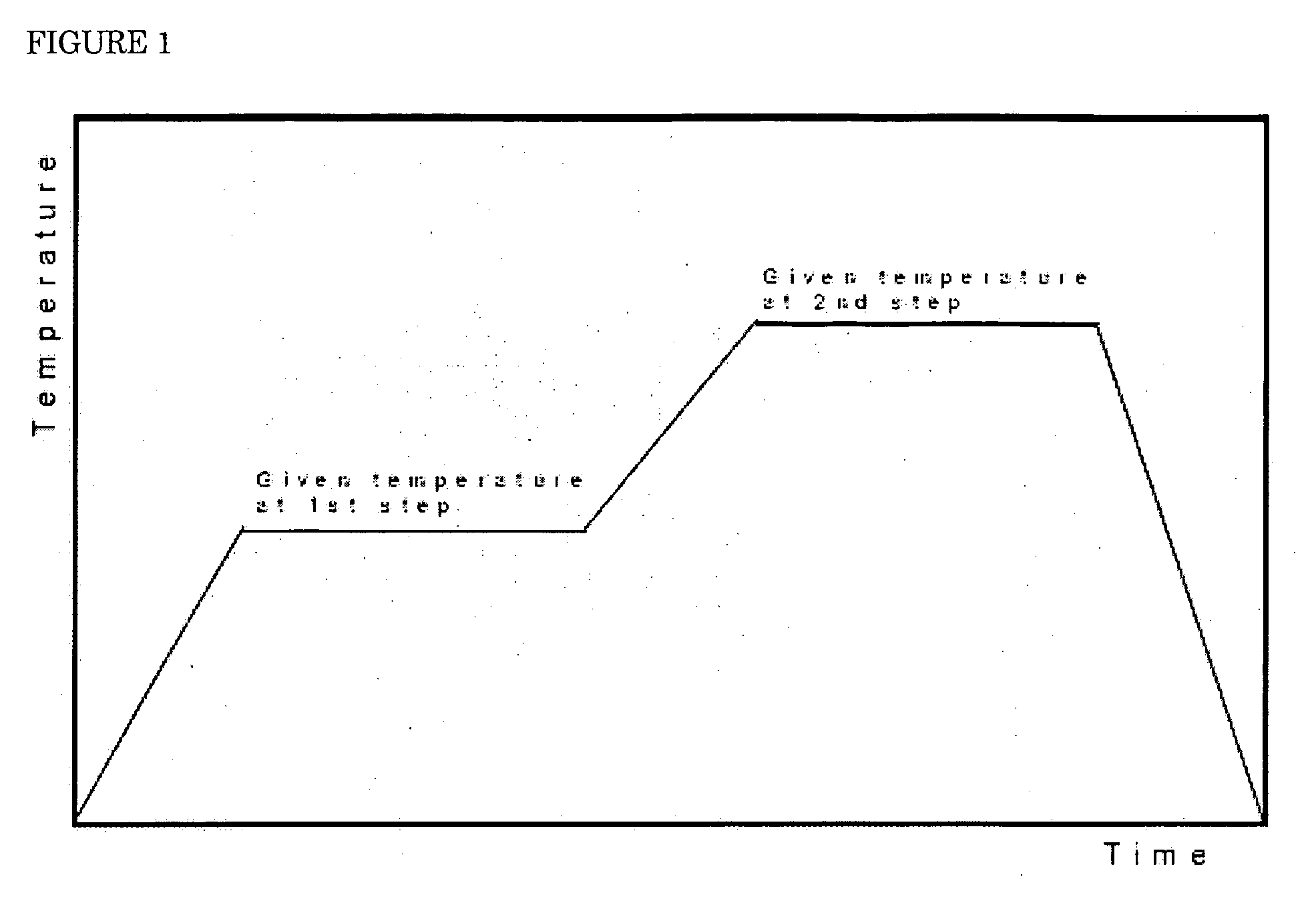

Ni-Base superalloy having a coating system containing a diffusion barrier layer

InactiveUS6921586B2Inhibited DiffusionReduces SRZ formation and growthBlade accessoriesSolid state diffusion coatingCoating systemAluminium

A coating system for an article comprising a substrate formed of a metal alloy that is prone to the formation of a deleterious secondary reaction zone (SRZ) as a result of containing more than three weight percent rhenium and at least one additional refractory metal. The coating system comprises an aluminum-containing overlay coating and a diffusion barrier coating between the overlay coating and the substrate. The diffusion barrier coating consists of, in atomic percent, about 20% to about 90% ruthenium, about 2% to about 60% chromium, optionally up to about 50% aluminum, optionally up to about 20% of a platinum-group metal, and the balance at least one of nickel, cobalt, and iron and incidental impurities. The diffusion barrier coating sufficiently inhibits diffusion of aluminum from the overlay coating into the substrate, such that the substrate remains essentially free of SRZ.

Owner:GENERAL ELECTRIC CO

Lithium-manganese composite oxides for lithium ion battery and process for preparing same

ActiveUS20090289218A1Improve cycle performanceIncrease battery capacityElectrode manufacturing processesConductive materialLithium-ion batteryComposite oxide

A lithium-manganese composite oxide for a lithium ion battery having a good cycle property at high-temperature and battery property of high capacity is provided.A spinel type lithium-manganese composite oxide for a lithium ion battery represented by a general formula: Li1+xMn2−yMyO4 (wherein M is one or more elements selected from Al, Mg, Si, Ca, Ti, Cu, Ba, W and Pb, and, −0.1≦x≦0.2, and 0.06≦y≦0.3), and when D10, D50 and D90 are defined as a particle size at which point the cumulative frequency of volume reaches 10%, 50% and 90% respectively, d10 is not less than 2 μm and not more than 5 μm, d50 is not less than 6 μm and not more than 9 μm, and d90 is not less than 12 μm and not more than 15 μm, and BET specific surface area thereof is greater than 1.0 m2 / g and not more than 2.0 m2 / g, and the tap density thereof is not less than 0.5 g / cm3 and less than 1.0 g / cm3.

Owner:JX NIPPON MINING& METALS CORP

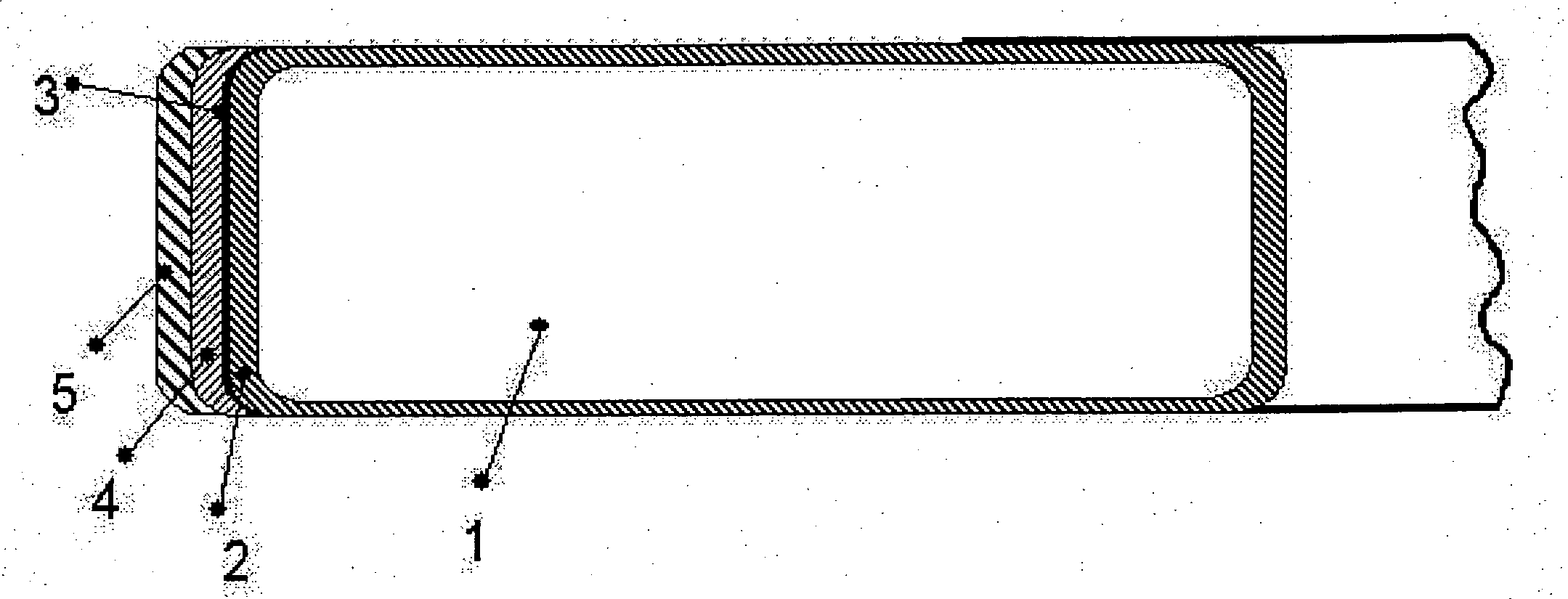

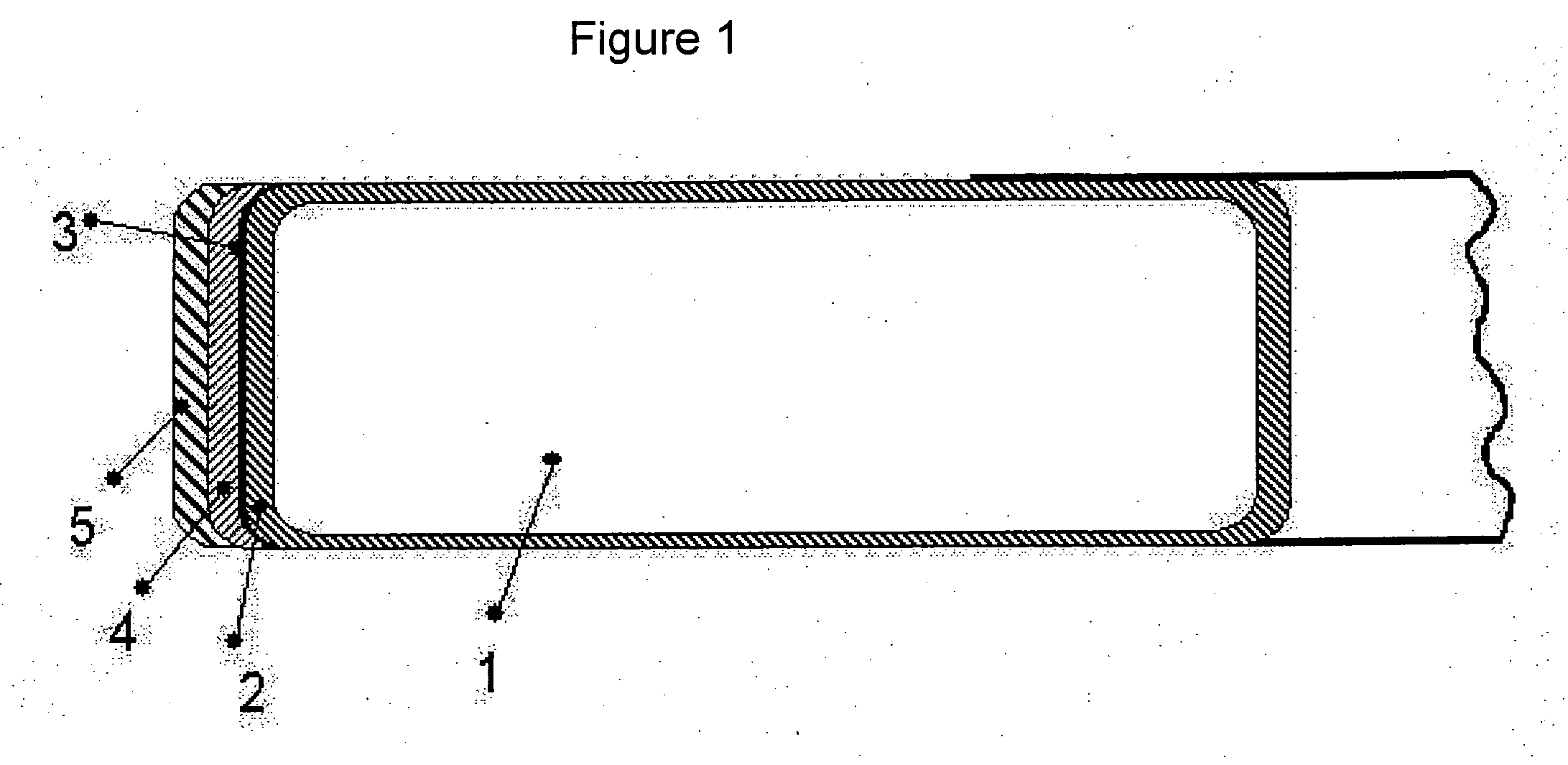

Piston ring for internal combustion engines

InactiveUS20060269790A1Promote absorptionReduce toughnessPiston ringsVacuum evaporation coatingCrazingEngineering

A piston ring for internal combustion engines with a coating of Chromium nitride (CrN) deposited by a physical vapor deposition process on a sliding surface with a typical crystal structure of CrN phase, has a high wear resistance and superior resistance to the generation of micro-cracks and consequent localized loss of pieces of the coating. The coating is a columnar crystalline coating of CrN having a dispersed pore content lower than 10% in volume and ratio of intensities, measured through x-ray diffraction, between the crystal planes (111) and planes (200), parallel to the surface, in the range of 0.40 to 0.70. This crystalline distribution is obtained through an oxygen content impregnated in the CrN coating between 1.0% in weight to 7.0% in weight. The Vickers hardness of the film ranges from 1,500 to 2,200 HV.

Owner:MAHLE METAL LEVE +1

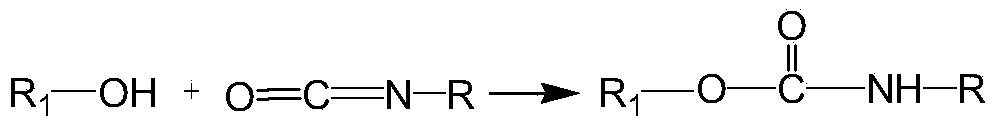

Aqueous two-component wood varnish and application thereof

The invention discloses an aqueous two-component wood varnish and application thereof. The aqueous two-component wood varnish mainly comprises a main agent and a curing agent. The main agent comprises the following components in percentage by mass: 60-80% of emulsion containing hydroxyl polymer, large than 0 and less than or equal to 6% of polycarbodiimide cross-linking agent. The curing agent mainly comprises the following component in percentage by mass: 80-85% of water dispersible polyisocyanate. By adopting double cross-linking, a varnish film with sensory effect and final performance better than that of a one-component aqueous self-crosslinking paint and an ordinary two-component aqueous paint is obtained; the varnish has the advantages of quick varnish film drying speed, quick performance improving speed, excellent varnish film performance and small dosage of aqueous isocyanate. The aqueous two-component aqueous varnish can be used as surface paint in match with the one-component priming paint which is excellent in initial water resisting property and quick in hardness improvement, thereby achieving the coating effect and performance of the conventional two-component aqueous paint at lower cost.

Owner:BAUHINIA PAINTS SHANGHAI CO LTD

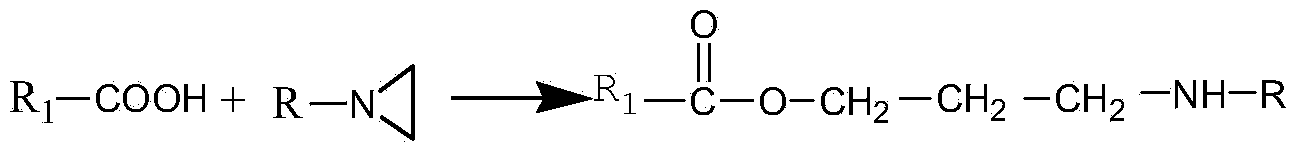

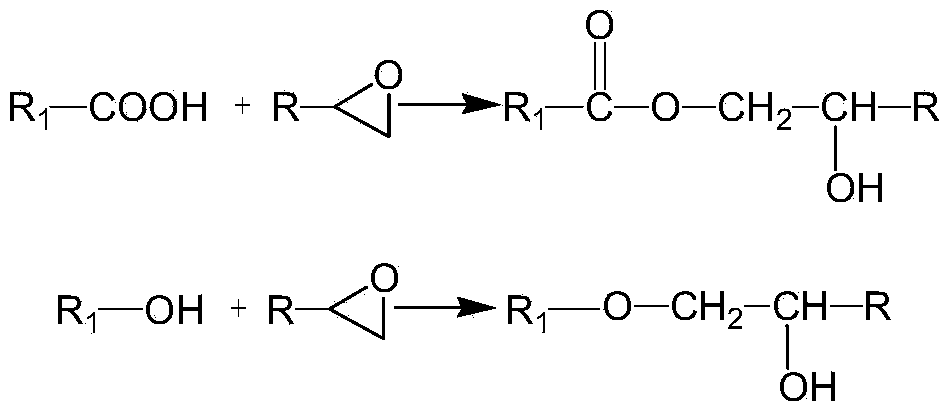

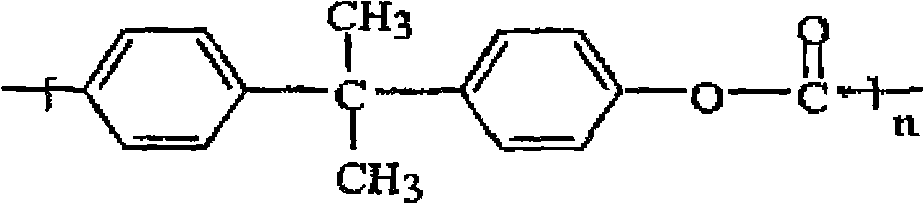

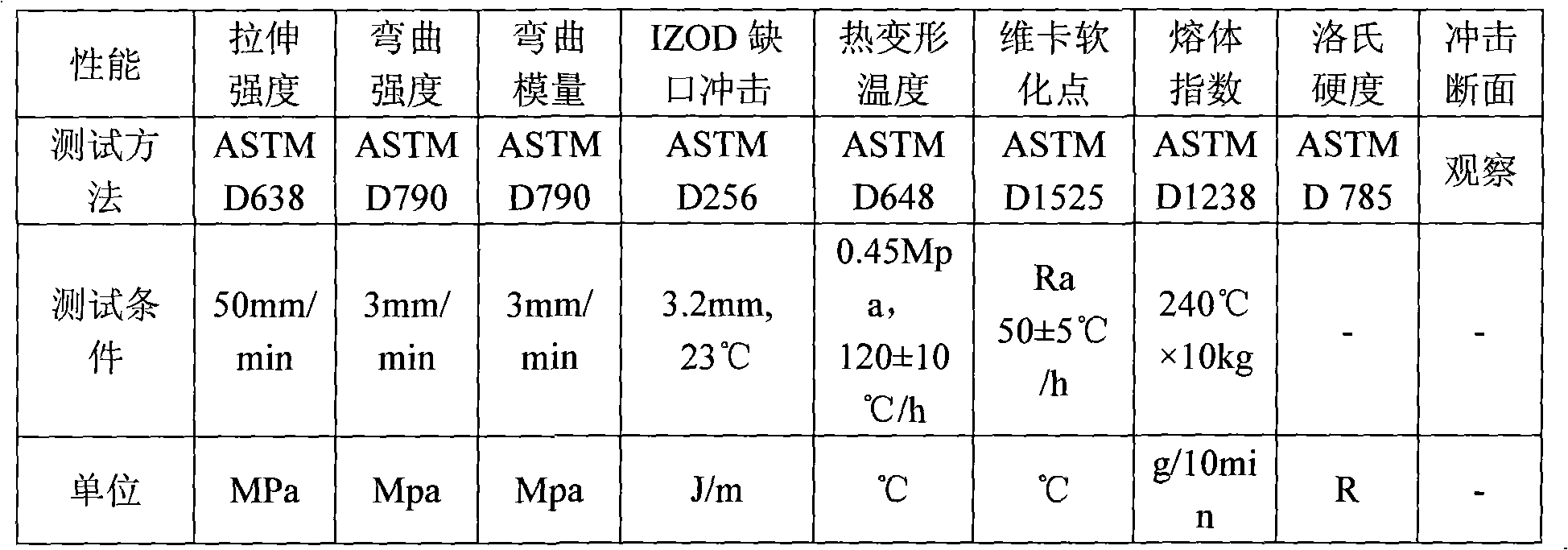

Polycarbonate/polyamide alloy and preparation method thereof

The invention relates to a polycarbonate / polyamide alloy and a preparation method thereof. The alloy contains the following components by weight percentage: 30-80 of polycarbonate, 20-70 of polyamide, 5-30 of toughening agent, 1.5-15 of compatibilizer and 0.2-3 of assistant; wherein the contents of the toughening agent, the compatibilizer and the assistant are based on the total weight of the polycarbonate and the polyamide. Compared with the prior art, due to the blending of the polycarbonate and the polyamide with the excellent compatibilizer in the preparation method, the preparation process is reasonable, the prepared polymer has good paint adhesion, solvent resistance and impact resistance and simultaneously combines the low moisture absorption, heat resistance, wear resistance and self-lubricity of the polycarbonate, and the polycarbonate / polyamide alloy can be widely applied in automobiles (front and rear baffles, column covers, wheel covers and instrument covers), electronic appliances (electric tool housings, wiring devices and relays) and other fields.

Owner:SHANGHAI KUMHO SUNNY PLASTICS +1

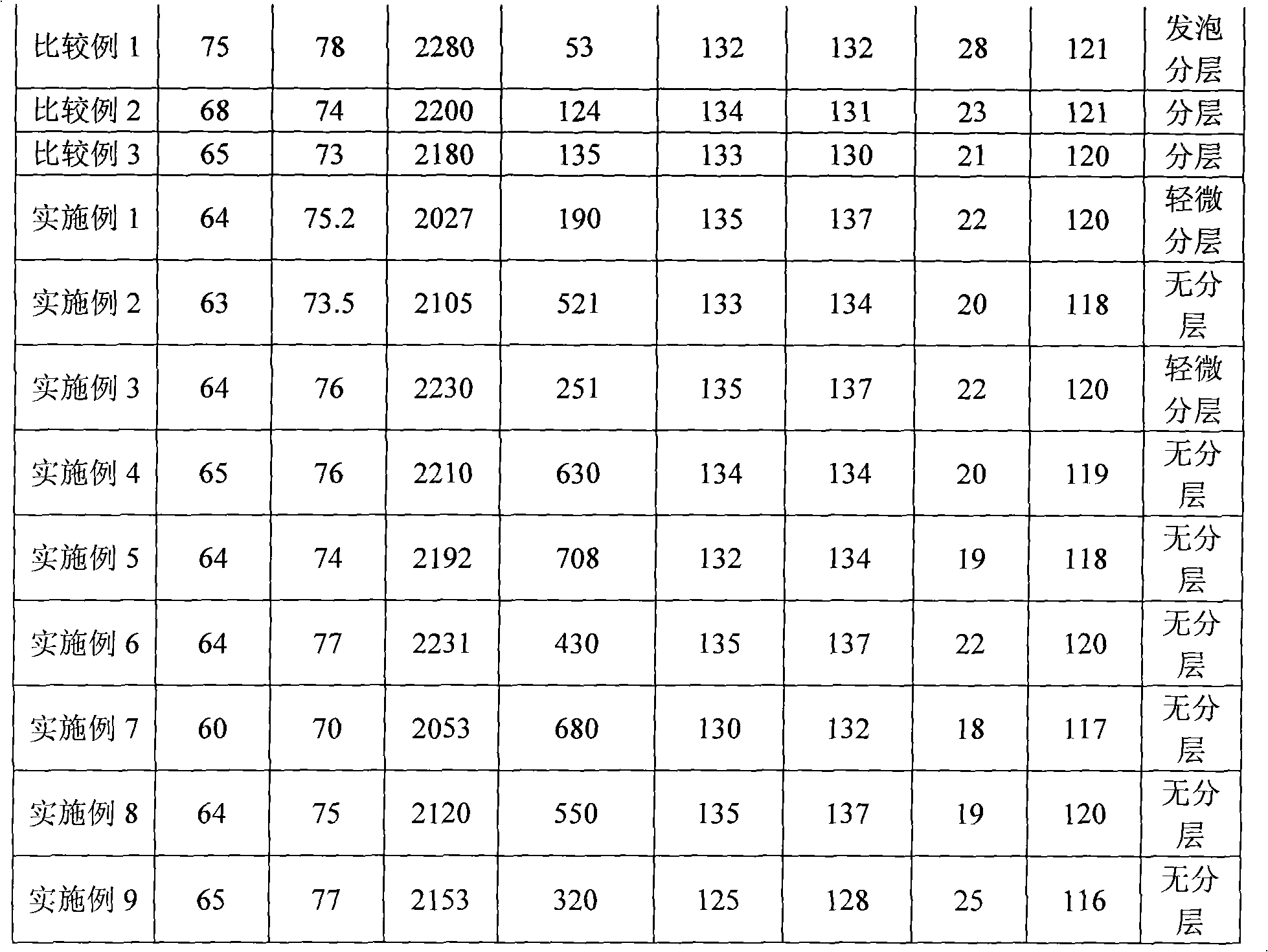

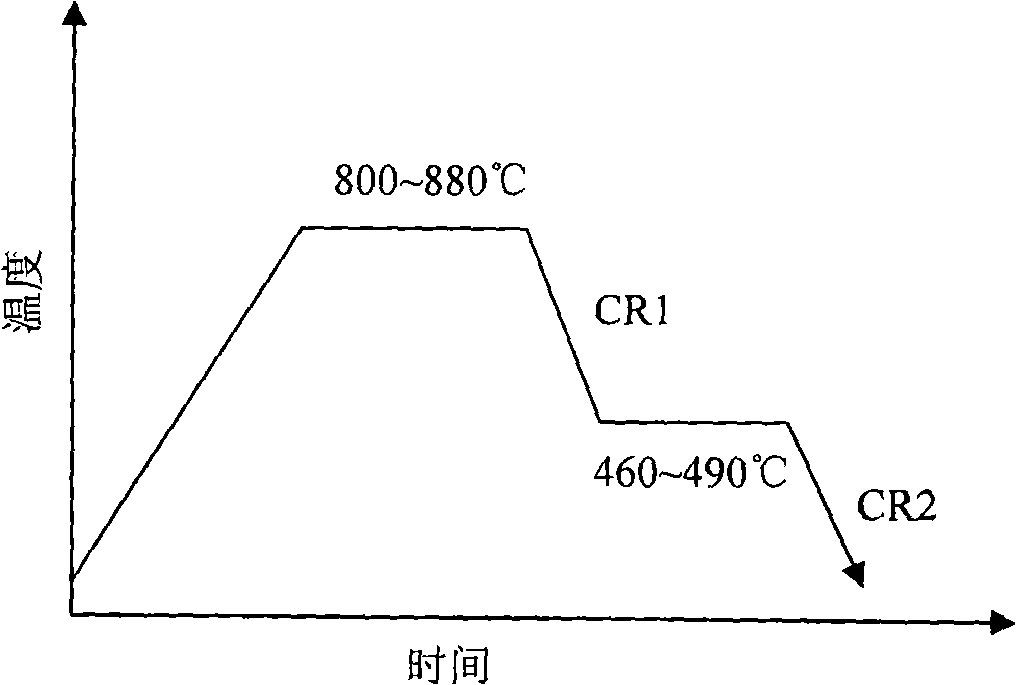

TRIP steel plate for high strength cold rolling hot dip galvanizing and preparation thereof

InactiveCN101353761AImprove PlatabilityGood coating performanceHot-dipping/immersion processesSheet steelTRIP steel

The invention pertains to the metal material processing field and particularly provides a TRIP steel sheet used for high-strength cold rolling and hot galvanizing and a manufacturing method thereof. The TRIP steel sheet comprises the following components: 0.1wt percent to 0.4wt percent of C, not more than 0.06wt percent of Si, 0.5wt percent to 2.5wt percent of Mn, 0.5wt percent to 2.0wt percent of Al, not more than 0.03wt percent of P, not more than 0.02wt percent of S, 0.01wt percent to 0.10wt percent of Nb, 0.01wt percent to 0.10wt percent of Ti, 0.1wt percent to 1.0wt percent of Cu, 0.1wt percent to 0.6wt percent of Ni and the rest is iron. Through the measures of controlling the content of the elements such as C, Mn, Nb and Ti in the steel, and the temperature and time of hot rolling, reeling, cold rolling, annealing and the like, the comprehensive performance of the TRIP steel sheet is improved. Compared with the traditional TRIP steel, the TRIP steel sheet has the following advantages of: 1) good platability: due to the low silicon adopted, the requirements of the plating layer of hot plated pure zinc and alloy plated zinc can be met to obtain the plating layer with good performance; and 2) good grain refining effect: due to Nb micro-alloying, grain can be effectively refined.

Owner:UNIV OF SCI & TECH BEIJING +1

High temperature and wear resistant graphene coating and preparation method thereof

The invention relates to a high temperature and wear resistant graphene coating, and the graphene coating is characterized by comprising the following components by weight percent: 35.0-60.0wt% of silicate, 0.01-20.0wt% of graphene, 0.1-25.0wt% of additive, and the balance of water as a solvent. The invention further provides a method for preparing the coating. The high temperature and wear resistant graphene coating disclosed by the invention can be used for well protecting matrixes by coating on pipelines, chemical equipment, storage, kiln furnace, medicine, aerospace and sewage, the service life of the matrix is prolonged, and the performance of the coating is much greater than that of a common material.

Owner:ZHUHAI LETONG NEW MATERIAL TECH CO LTD

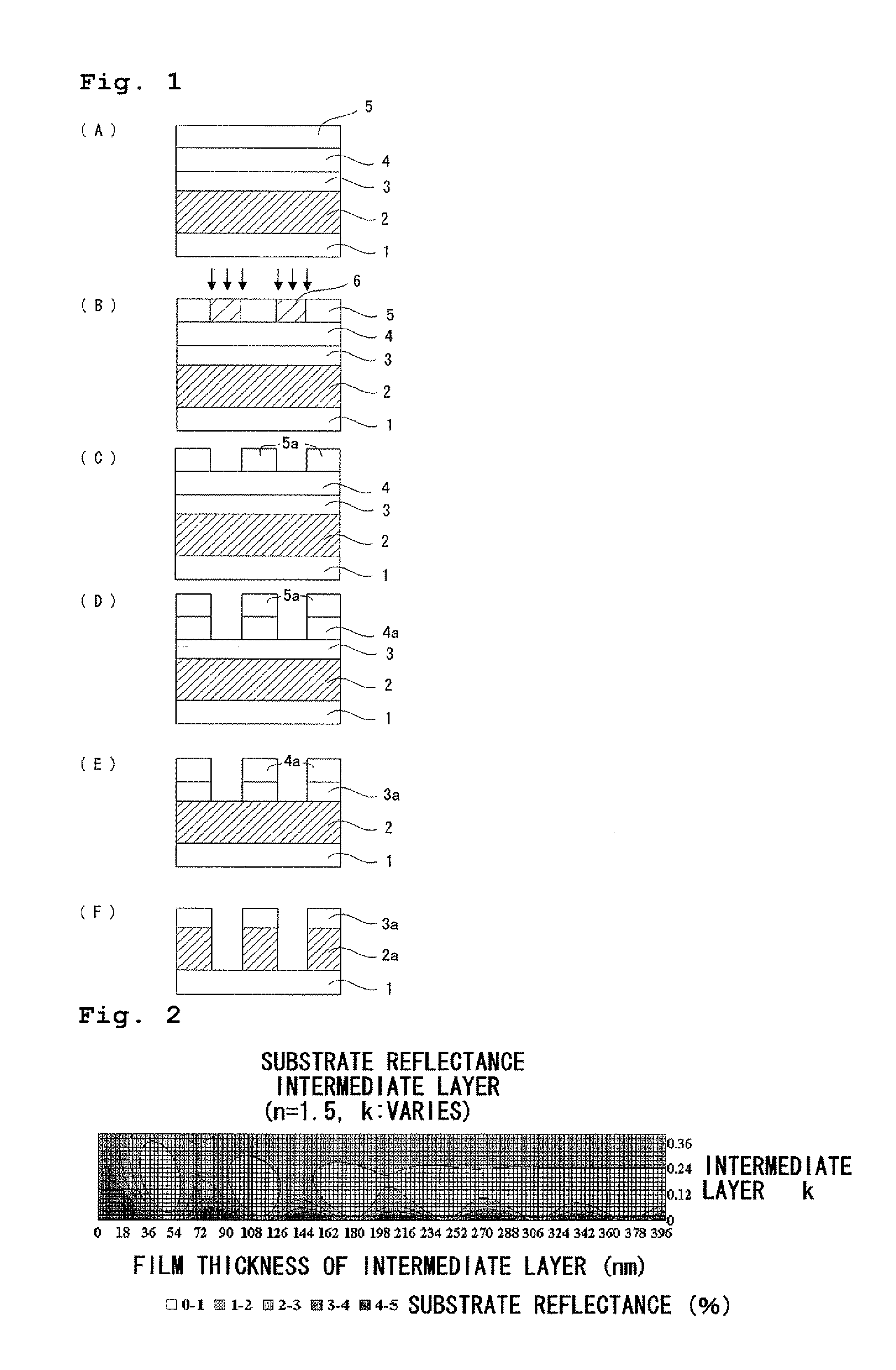

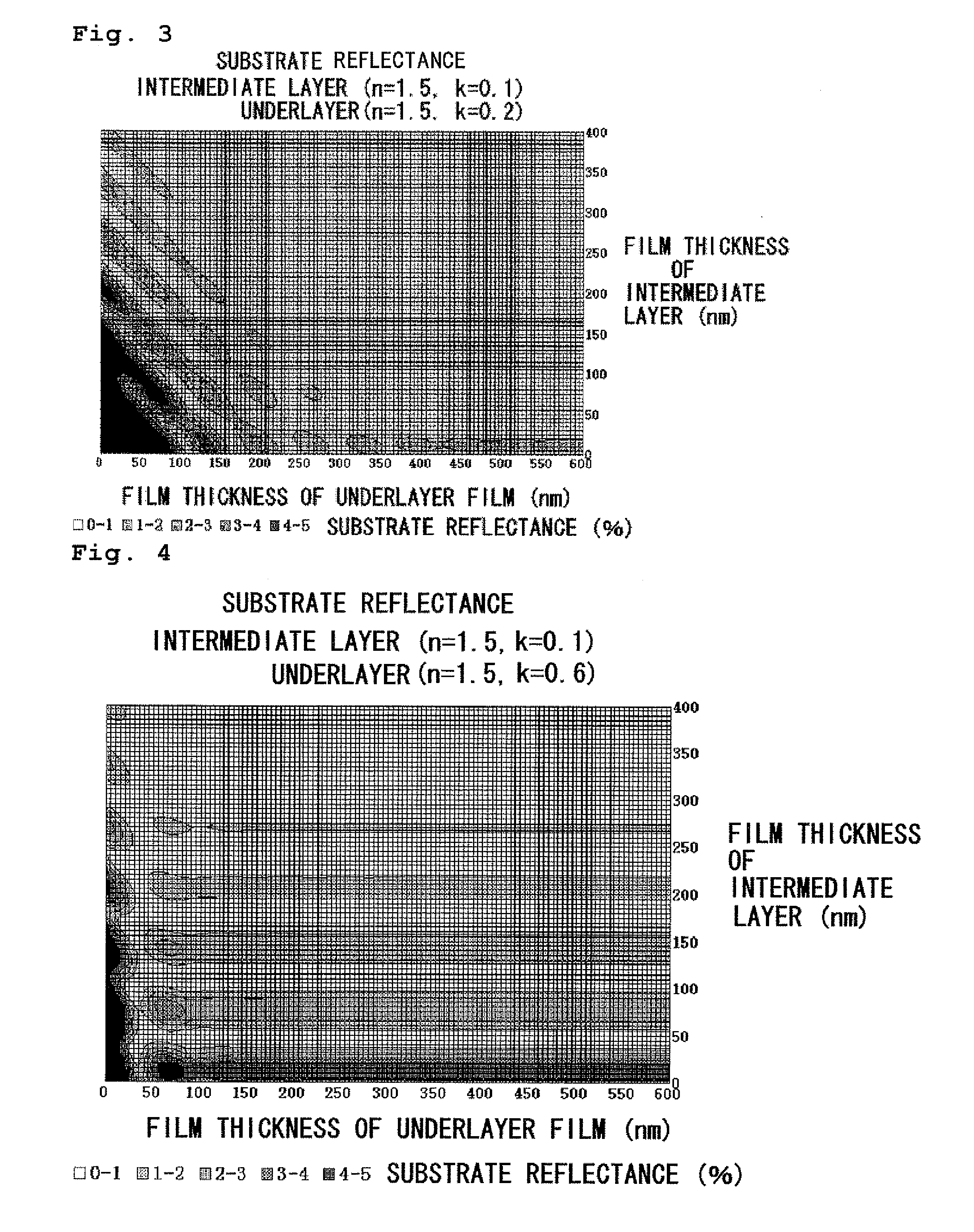

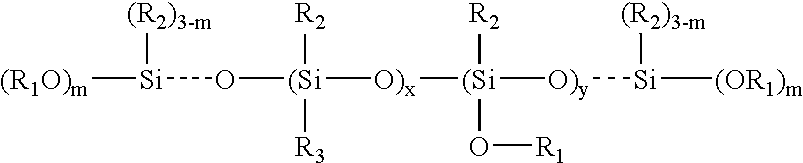

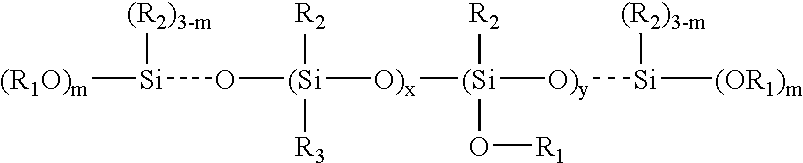

Resist underlayer film composition and patterning process using the same

ActiveUS20120184103A1High precisionExcellent propertyPhotomechanical apparatusSemiconductor/solid-state device manufacturingResistReflectivity

There is disclosed a resist underlayer film composition, wherein the composition contains a polymer obtained by condensation of, at least, one or more compounds represented by the following general formulae (1-1) and / or (1-2), and one or more kinds of compounds, represented by the following general formulae (2-1) and / or (2-2), and / or equivalent bodies thereof. There can be provided an underlayer film composition, especially for a trilayer resist process, that can form an underlayer film having reduced reflectance, (namely, an underlayer film having optimum n-value and k-value as an antireflective film), excellent filling-up properties, high pattern-antibending properties, and not causing line fall or wiggling after etching especially in a high aspect line that is thinner than 60 nm, and a patterning process using the same.

Owner:SHIN ETSU CHEM IND CO LTD

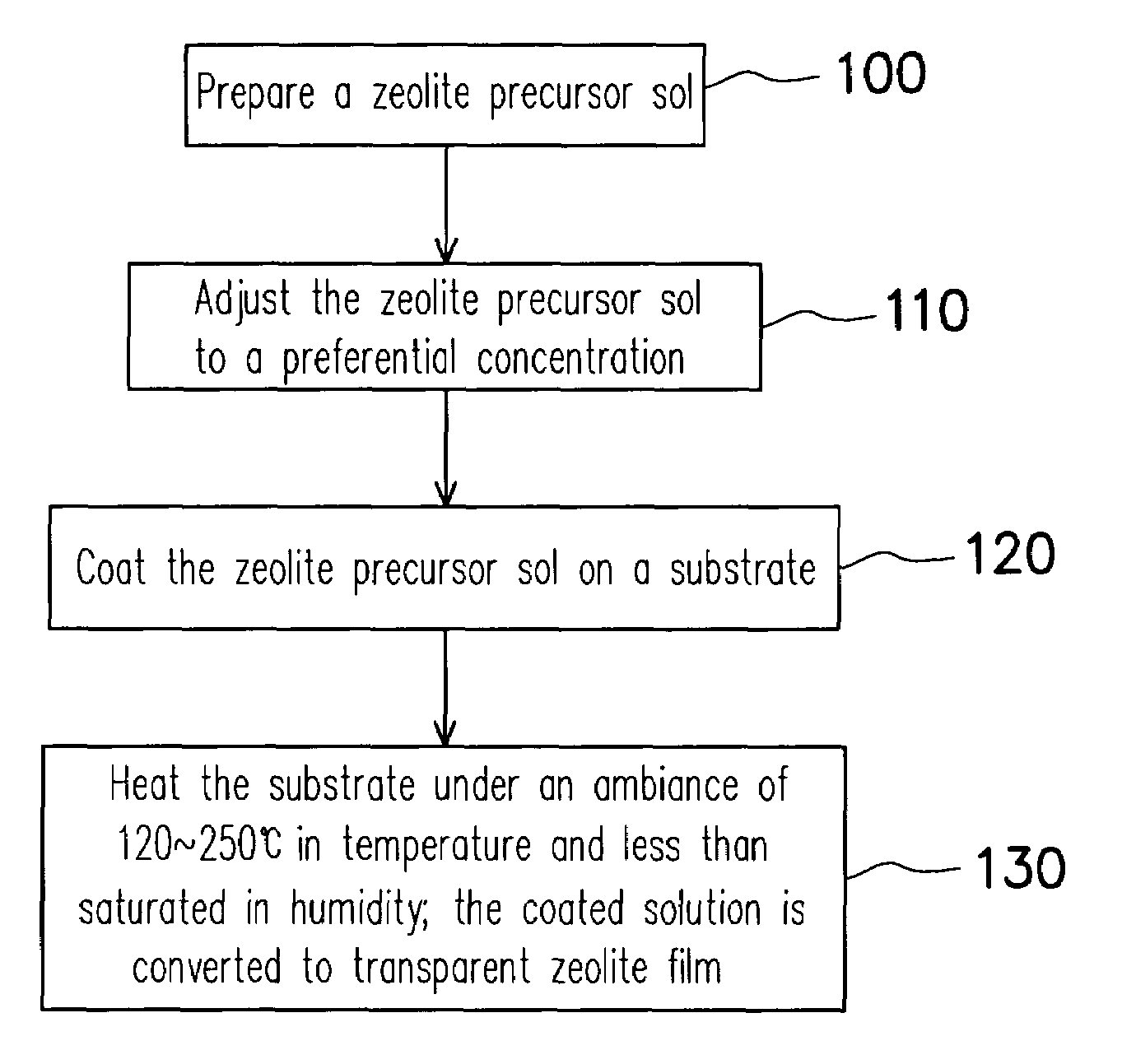

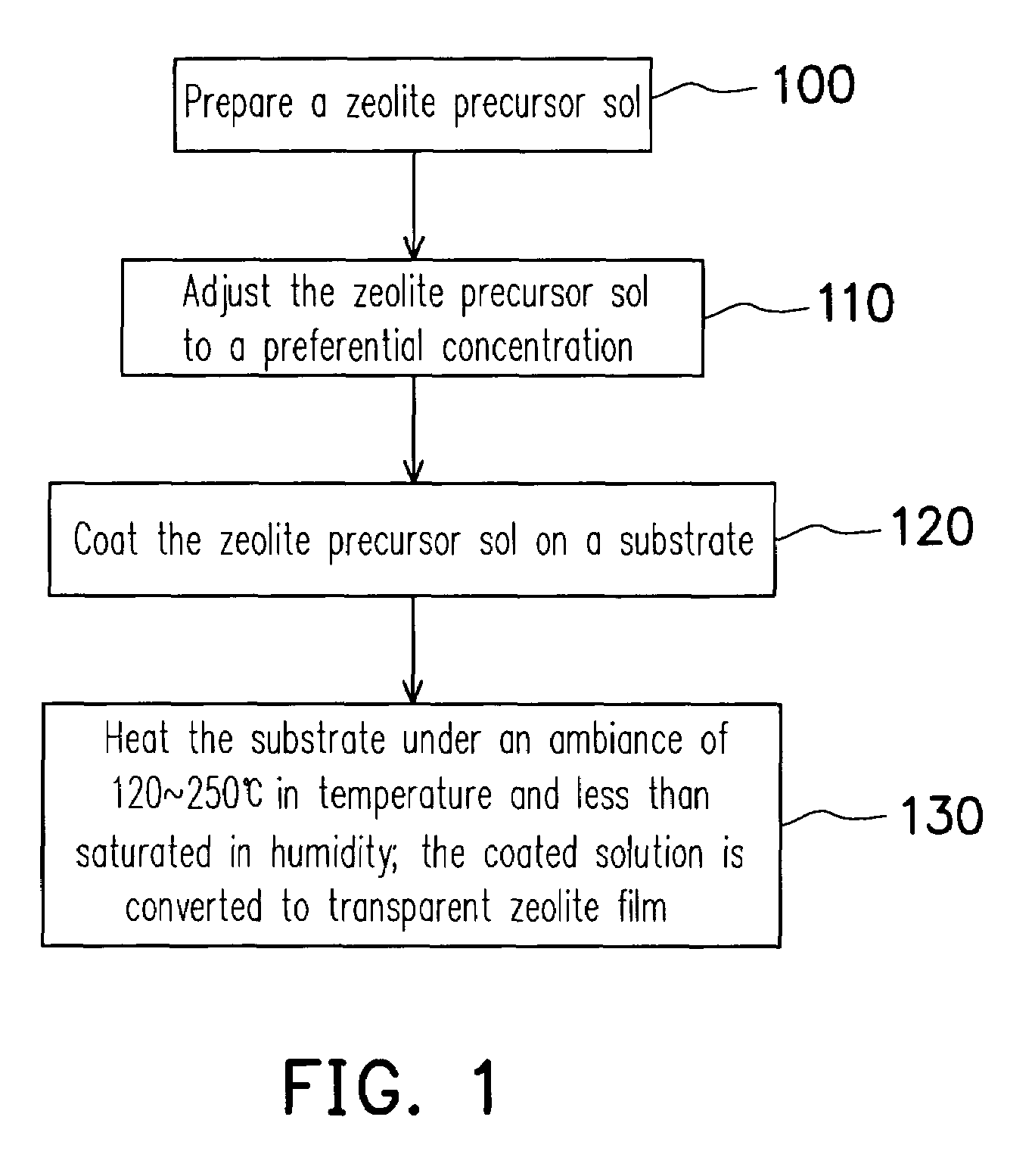

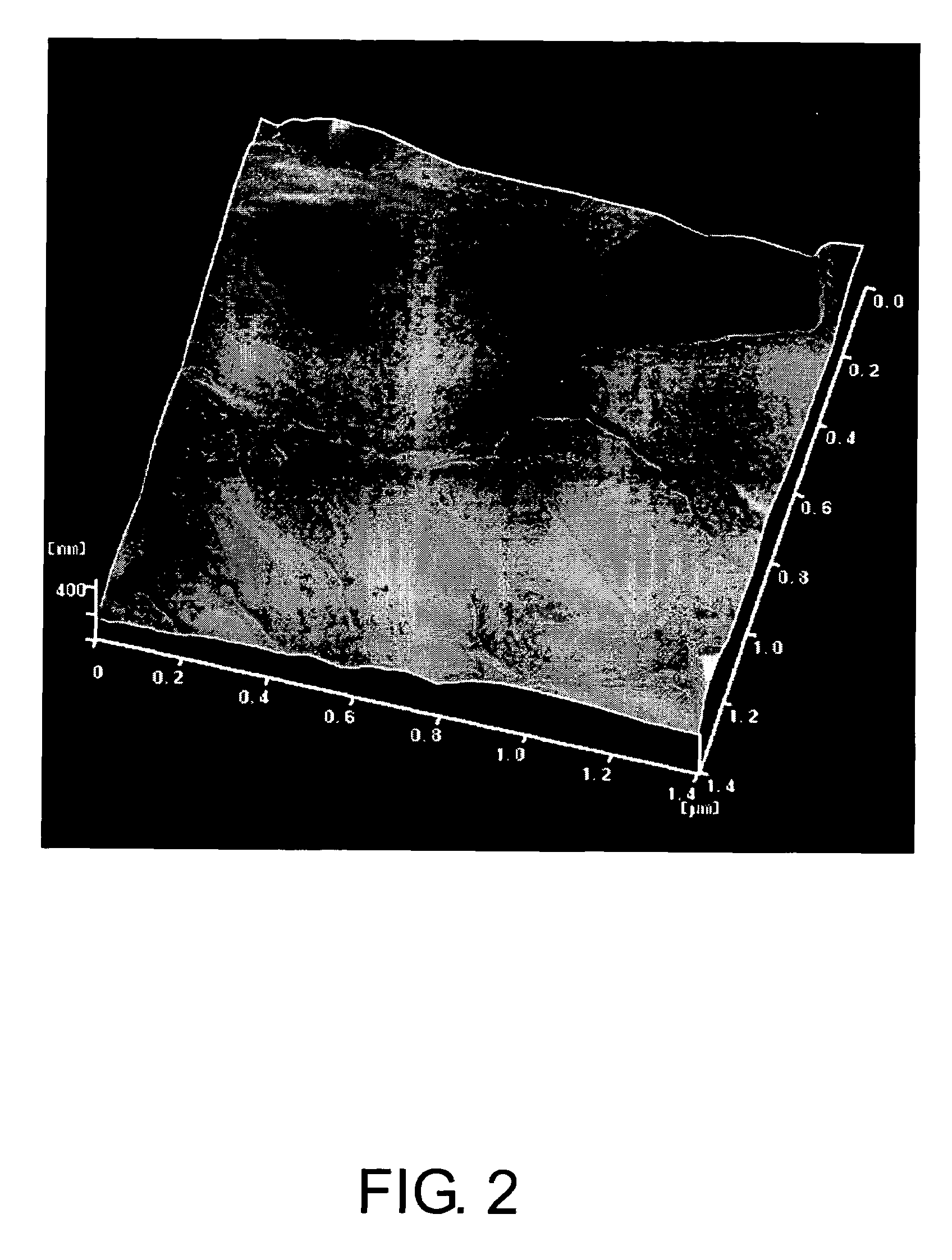

Method for making transparent continuous zeolite film and structure of the zeolite film

InactiveUS7253130B2Avoid disadvantagesGood coating performanceMembranesSemi-permeable membranesNanocrystalNanometre

A method for making transparent continuous zeolite film is provided. First a transparent precursor sol is prepared, and the precursor sol is processed to a specific concentration. The precursor solution is coated on a surface of a substrate which is heated under an ambiance of 120˜250° C. in temperature and a humidity less than saturated humidity. The packing of zeolite nanocrystals in the film converted from coated precursor sol has preferred orientation and the film shows super-hydrophobic property.

Owner:NAT CENT UNIV

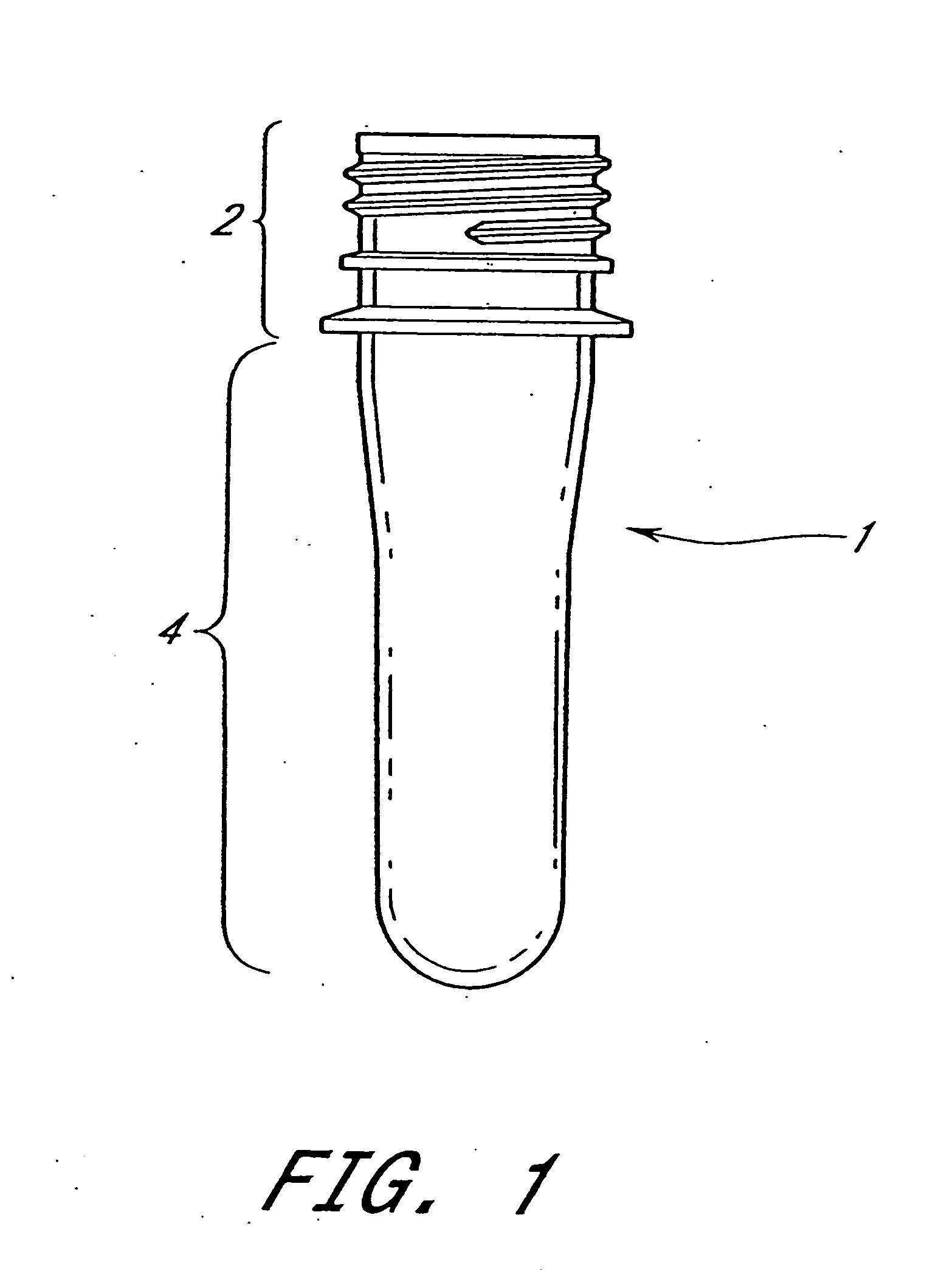

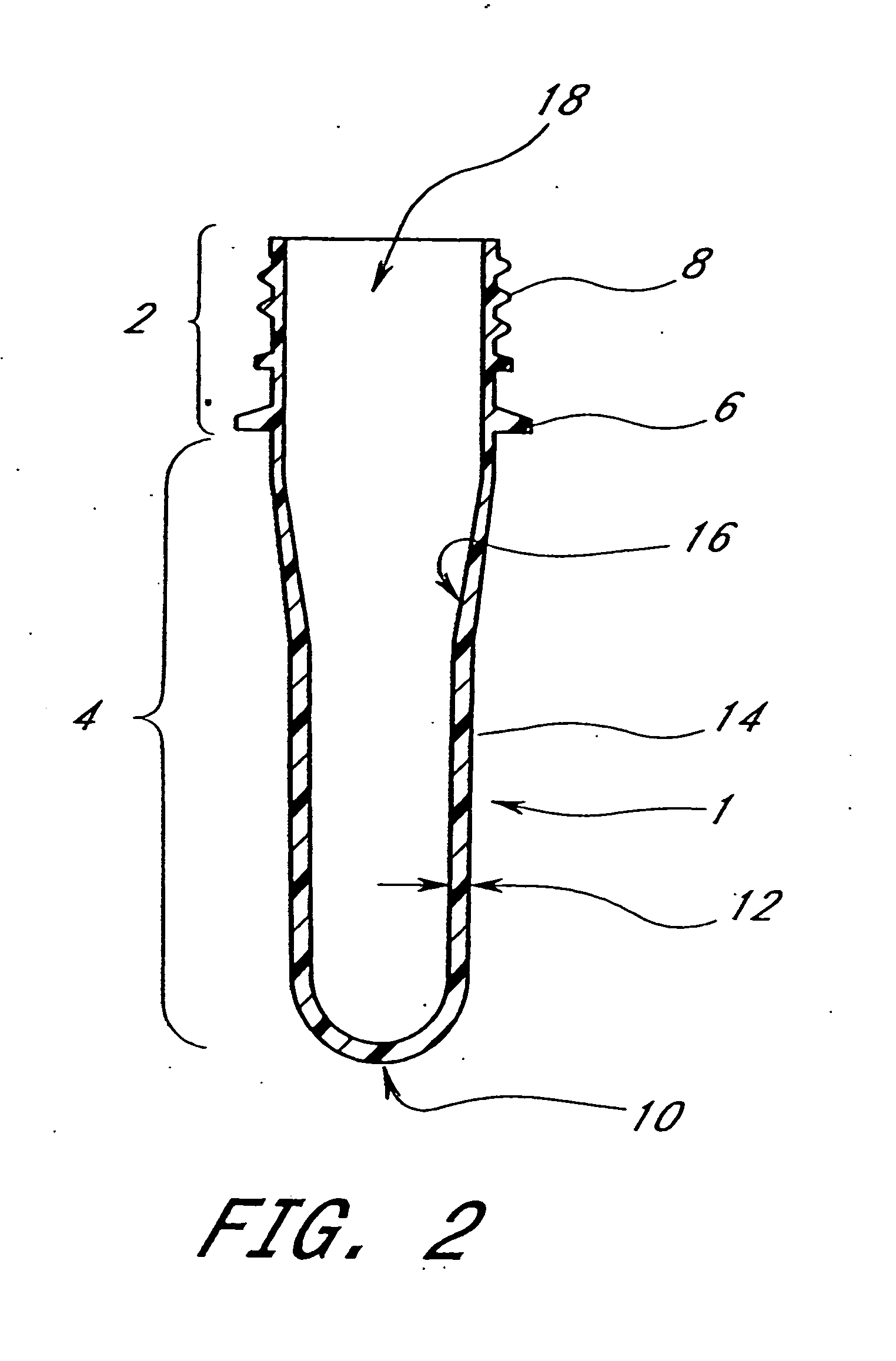

Water-resistant coated articles and methods of making same

InactiveUS20060292323A1Good coating effectReduction of surface voidLiquid surface applicatorsLayered productsEmulsionPolyethylene terephthalate

Coated articles may comprise one or more coating layers, including water resistant coatings. A method comprises applying such coating layers by dip, spray or flow coating. The methods can make coated containers, preferably comprising polyethylene terephthalate, from coated preforms. In some methods, the aqueous solutions, dispersions, or emulsions are substantially or completely free of VOCs.

Owner:ADVANCED PLASTICS TECH LUXEMBOURG SA

Self-lubricating passivation solution and hot galvanizing self-lubricating coating steel sheet coated thereby

InactiveCN103289569AGood corrosion resistanceGood paintability and adhesionAnti-corrosive paintsPolyurea/polyurethane coatingsCorrosion resistantLubrication

The invention discloses a self-lubricating passivation solution and a hot galvanizing self-lubricating coating steel sheet coated thereby. The self-lubricating passivation solution is formed by modified solid lubricants, a film forming matter, a film forming additive, an accelerant, a pH modifier, an organic solvent and deionized water through compounding. The solid content after compounding is 15-25%, and the modified solid lubricants are modified nanometer MoS2 and modified nanometer teflon particles. According to the total weight of 1000g, the self-lubricating passivation solution comprises the following components: 10-20g / kg of modified nanometer MoS2, 10-20g / kg of modified nanometer teflon particles, 80-120g / kg of film forming matter, 10-30g / kg of film forming additive, 5-15g / kg of the accelerant and the balance of mixed solution of the organic solvent and the deionized water; and the pH value is adjusted to 3-6 by the pH modifier. The hot galvanizing self-lubricating coating steel sheet coated by the self-lubricating passivation solution comprises a hot galvanizing substrate and a self-lubricating coating attached to the hot galvanizing substrate. The self-lubricating passivation solution does not contain Cr<6+> and other environmentally harmful substances and has environmental protection property, corrosion resistance, wear extreme pressure resistance as well as coating and self-lubrication properties.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY +1

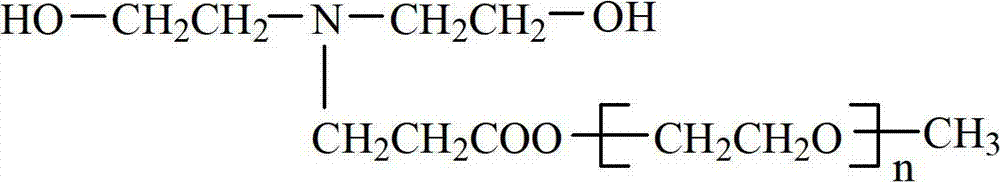

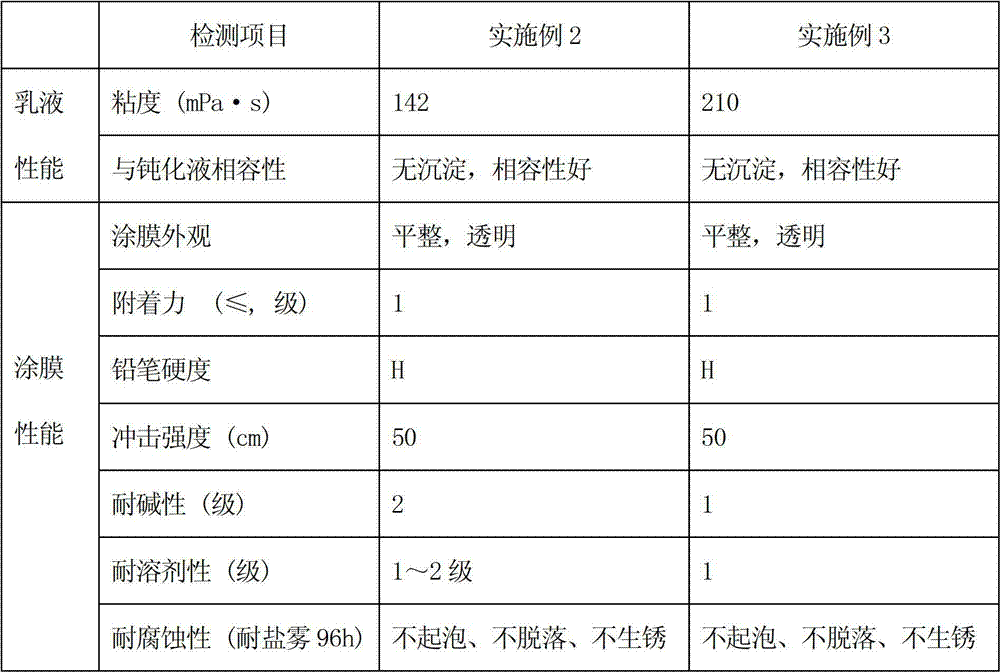

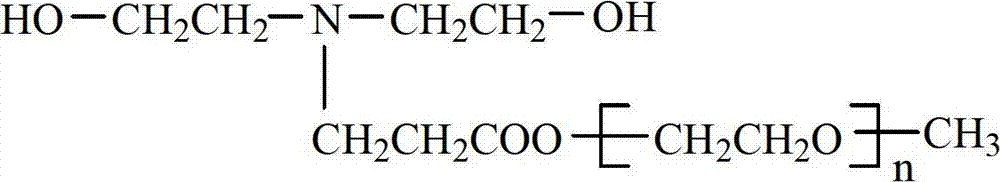

Cation-nonionic mixed aqueous polyurethane emulsion and preparation method thereof

ActiveCN102775578AGood chemical resistanceImprove corrosion resistancePolyurea/polyurethane coatingsChromium freePropanoic acid

The invention relates to a cation-nonionic mixed aqueous polyurethane emulsion and a preparation method thereof. The emulsion is aqueous polyurethane which has a cation hydrophilic group and a nonionic hydrophilic side chain. The preparation method comprises the steps of firstly introducing the nonionic hydrophilic side chain by using a specific nonionic hydrophilic chain extender; and introducing the cation hydrophilic group by using a cation hydrophilic chain extender, wherein the amounts of the nonionic hydrophilic chain extender and the cation hydrophilic chain extender respectively account for 1-10 percent and 1-8 percent according to the total weight of the raw materials, and the specific nonionic hydrophilic chain extender is 3-(N,N-dihydroxyethyl) amino-propionic acid polyethyleneglycol monomethyl ether ester which is prepared by heating and reacting methoxy polyethylene glycol single methyl acrylate and diethanol amine in a molar ratio of 1:1. By using the emulsion, the defect of the existing emulsion is overcome, and the requirement of zinc-plating steel plate chromium-free passivation pretreatment on aqueous polyurethane resins are met, so that the cost is reduced.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

Nanocomposite road marking coating material

InactiveCN104263198AWith sterilizationWear-resistantAntifouling/underwater paintsLuminescent paintsEpoxyNano structuring

The invention discloses a nanocomposite road marking coating material. The nanocomposite road marking coating material comprises the following ingredients in parts by weight: 20-30 parts of glass powder, 6-10 parts of aluminum oxide powder, 50-80 parts of filler, 30-40 parts of epoxy resin, 15-20 parts of aqueous epoxy modified acrylate, 15-20 parts of glass micro-beads, 10-20 parts of chitin, 15-20 parts of chitosan, 20-40 parts of nano titanium white, 15-20 parts of nano zinc oxide, 10-15 parts of nano-silica, 2-4 parts of 25wt% ammonia water, 30-40 parts of acrylic emulsion and 15-20 parts of nano rare-earth self-luminous material. The invention further discloses a preparation method of the nano coating material. The nanocomposite road marking coating material disclosed by the invention is high in drying speed and long in service life, is wear-resistant and anti-fouling and has a bacterium resisting effect, and nano-materials or nano-structured ingredients are introduced into an organic coating material, so that organic and inorganic matched compositing or hybridization is realized. The advantages of organic polymers and inorganic-structured ingredients are integrated, so that the properties of the coating material are obviously improved.

Owner:句容亿格纳米材料厂

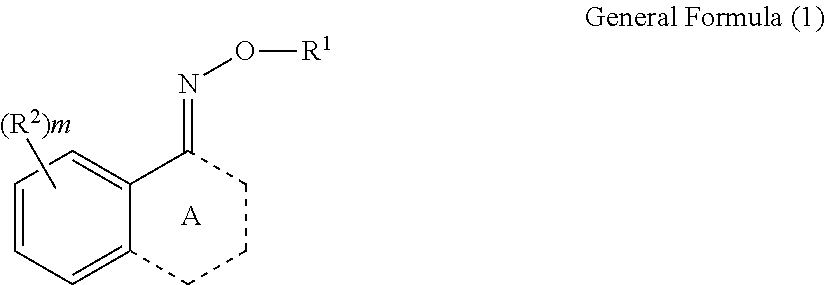

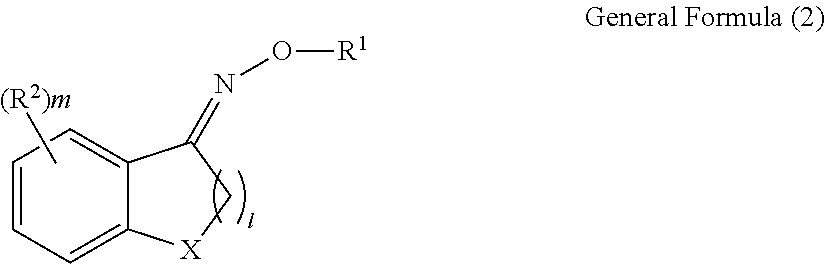

Oxime compound, photosensitive composition, color filter, production method for the color filter, and liquid crystal display element

InactiveUS20110123929A1Short timeExcellent stabilityOrganic chemistryOrganic compound preparationLiquid-crystal displayOxime

Provided are an oxime compound represented by General Formula (1), a photosensitive composition containing the oxime compound as a photopolymerization initiator, a production method for a color filter using the photosensitive composition, and a color filter obtained by the production method:in General Formula (1), R1 represents a hydrogen atom, an acyl group, an alkoxycarbonyl group or an aryloxylcarbonyl group, each of which may have a substituent; R2 represents or R2s each represent a halogen atom, an alkyl group, an aryl group, an alkyloxy group, an aryloxy group, an alkylthio group, an arylthio group or an amino group; m is an integer of 0 to 4; when m is an integer of 2 or more, R2s may be linked together to form a ring; and A represents a 4-, 5-, 6- or 7-membered ring.

Owner:FUJIFILM CORP

Curable resin composition for use in water-based coating materials

InactiveUS6103788ALowering of curabilityExcellent solventPlastic/resin/waxes insulatorsSemiconductor/solid-state device detailsWater basedSilylene

PCT No. PCT / JP96 / 03476 Sec. 371 Date Jul. 22, 1997 Sec. 102(e) Date Jul. 22, 1997 PCT Filed Nov. 28, 1996 PCT Pub. No. WO97 / 20004 PCT Pub. Date May 6, 1997The present invention relates to a curable resin composition for use in water-based coating materials which includes as essential components an emulsion polymer (A) containing tertiary amino groups obtained by carrying out emulsion polymerization of a vinyl monomer containing a tertiary amino group with another copolymerizable vinyl monomer in a water-based medium, and a compound (B) containing, at least, an epoxy group and a hydrolyzable silyl group, with this composition preferably also including a water-based compound (C) obtained by adding a neutralizing agent to a vinyl polymer (I) containing acidic groups and / or tertiary amino groups so as to neutralize at least 10% of the acidic groups and / or the tertiary amino groups, and then dispersing or dissolving in water, and / or a compound (D), which is not included in compound (B), and contains hydrolyzable silyl group and / or a silanol group. The coating material provided by the composition of the present invention is curable at ambient temperatures and demonstrates excellent coating properties. Moreover, the cured coating obtained from the composition of the present invention offers superior resistance to weathering, solvents, chemicals and water, and is not problematic with respect to conservation of the environment.

Owner:DAINIPPON INK & CHEM INC

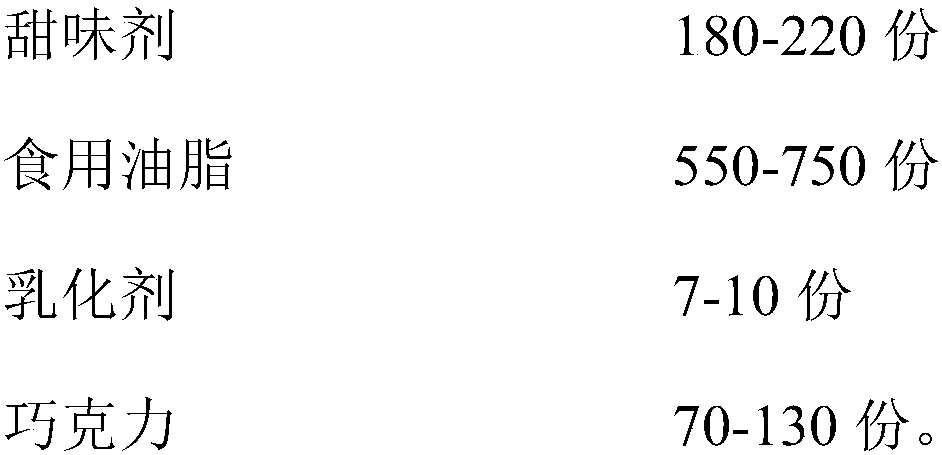

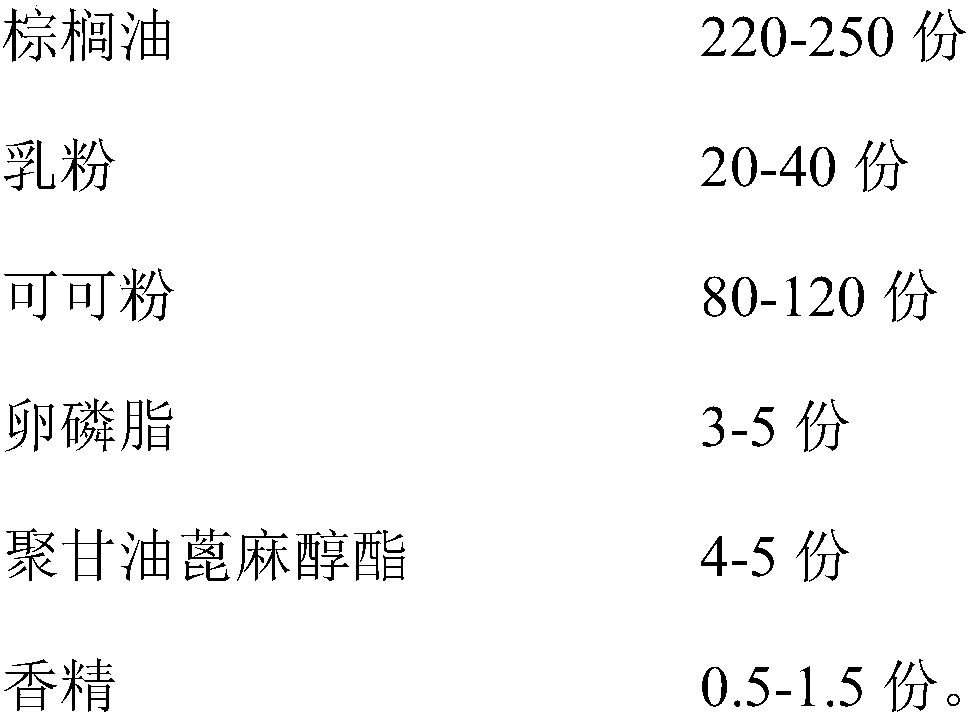

Chocolate composition, coating layer and preparation method thereof and frozen drink coated with the coating layer

The present invention discloses a chocolate composition, a coating layer and a preparation method thereof and frozen drink coated with the coating layer. The chocolate composition is prepared by a combined use of oil and an emulsifier at a specific ratio, reduces viscosity, improves fluidity of slurry, finally improves uniformity of coating of the chocolate coating layer, can flexibly adjust thickness of the chocolate coating layer, can prepare the chocolate coating layer of 2 mm or more, and can also prepare the chocolate coating layer with the thickness of 1 mm or less. At the same time, through combined cooperation and synergistic effects of a sweetener, edible oil, an emulsifier and chocolate at a specific ratio, the preparation method also avoids problems of cracking, material discharging and waxing feeling problems caused by too thin thickness of the chocolate coating layer, improves coating effects of the chocolate coating layer, and also improves taste and mouthfeel of the chocolate coating layer.

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

Multi-coordination-agent cyanide-free electrogilding liquid and electrogilding process

ActiveCN103741181AExcellent bath performanceGood coating performancePotassium hydroxidePotassium carbonate

The invention relates to multi-coordination-agent cyanide-free electrogilding liquid and an electrogilding process, which belong to the technical field of electrogilding. The electrogilding liquid is prepared from a main coordination agent, an auxiliary coordination agent, potassium hydroxide, potassium carbonate, goldpotassium chloride, combined additives and ultrapure water. The electrogilding process comprises the following steps: 1, preprocessing a substrate; 2, electroplating an intermediate nickel plating layer; 3, electrogilding, namely washing the substrate after electroplating the intermediate nickel plating layer with ultrapure water, directly feeding the substrate into a plating cell containing the multi-coordination-agent cyanide-free electrogilding liquid to be electrogilded, taking out a sample from the electrogilding liquid after the electrogilding, washing the surface of the sample by utilizing distilled water, and drying the sample through cold air. Double coordination agents are used as the coordination agents of gold ions in the electrogilding liquid, so that a cyanide-free electrogilding system which has high current efficiency, smoothness and compactness in plating layer crystallization, wide current density range, wide temperature requirement and capability of guaranteeing the golden bright appearance of the plating layer compared with those of a single coordination agent system is obtained.

Owner:HARBIN INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com