Low-temperature organic electrolyte taking gamma-butyrolactone as base solvent and application thereof

An organic electrolyte and basic solvent technology, used in electrolytic capacitors, hybrid capacitor electrolytes, circuits, etc., can solve the problems of high melting point, harsh preparation conditions, poor thermal stability, etc., to improve cycle life and improve low-temperature performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

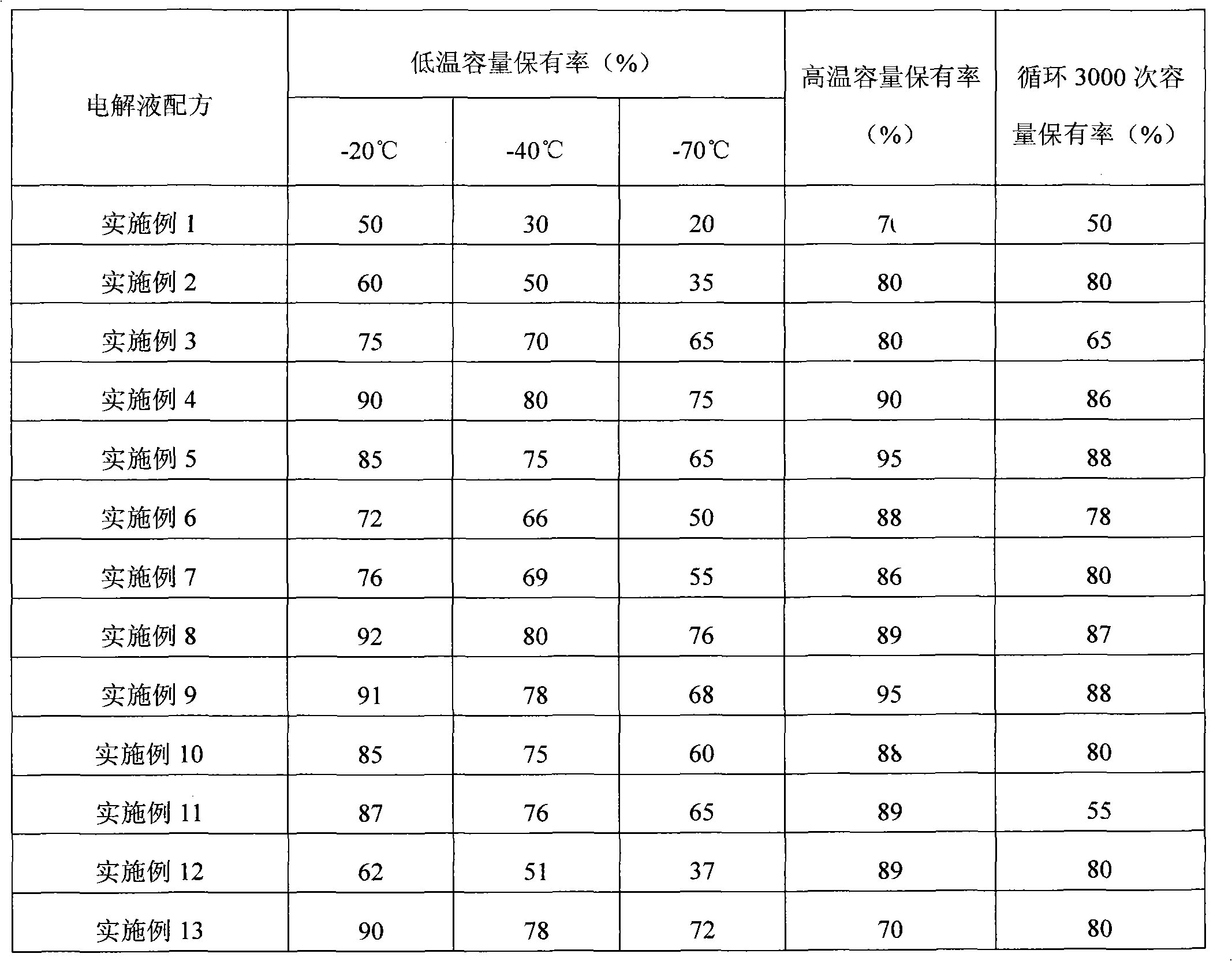

Embodiment 1

[0030] According to method 1, non-graphite negative lithium-ion batteries were prepared, and assembled into laminated flexible packaging square cells.

[0031] The formula of the electrolyte is as follows: (mass)

[0032] Solvent quality: 100 parts of γ-butyrolactone (GBL);

[0033] Additive quality (based on solvent quality): 2 parts of film-forming stabilizer vinylene carbonate (VC), 1 part of high-temperature stabilizer bisoxalate lithium borate (LiBOB), 1 part of high-voltage overcharge protection agent biphenyl (BP);

[0034] Solute concentration: lithium tetrafluoroborate (LiBF 4 ) concentration 1mol / L (electrolyte).

Embodiment 2

[0036] According to method 1, non-graphite negative lithium-ion batteries were prepared, and assembled into laminated flexible packaging square batteries.

[0037] The formula of the electrolyte is as follows: (mass)

[0038] Solvent quality: 50 parts of γ-butyrolactone (GBL), 50 parts of chain carbonate diethyl carbonate (DEC);

[0039] Additive quality (based on solvent quality): 2 parts of film-forming stabilizer vinylene carbonate (VC), 1 part of high-temperature stabilizer bisoxalate lithium borate (LiBOB), 1 part of high-voltage overcharge protection agent biphenyl (BP);

[0040] Solute concentration: lithium tetrafluoroborate (LiBF 4 ) concentration 1mol / L (electrolyte).

Embodiment 3

[0042] According to method 1, non-graphite negative lithium-ion batteries were prepared, and assembled into laminated flexible packaging square cells.

[0043] The formula of the electrolyte is as follows: (mass)

[0044] Solvent quality: 50 parts of γ-butyrolactone (GBL), 50 parts of chain carboxylate methyl propionate (PA);

[0045] Additive quality (based on solvent quality): 2 parts of film-forming stabilizer vinylene carbonate (VC), 1 part of high-temperature stabilizer bisoxalate lithium borate (LiBOB), 1 part of high-voltage overcharge protection agent biphenyl (BP);

[0046] Solute concentration: lithium tetrafluoroborate (LiBF 4 ) concentration 1mol / L (electrolyte).

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| boiling point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com