Polyimide as well as preparation method and application thereof

A technology of polyimide and polycondensation reaction, applied in the field of polyimide and its preparation, can solve the problems of low optical transmittance of flexible materials, poor solubility, and increase the difficulty of production of flexible materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0067] The invention provides a kind of preparation method of polyimide, comprises the following steps:

[0068] The dianhydride compound and the diamine compound are subjected to a polycondensation reaction in the presence of a catalyst to obtain a polyimide;

[0069] The dianhydride compound is 2,3,2',3'-dicyclohexyl tetracarboxylic dianhydride, 3,4,3',4'-dicyclohexyl ether tetracarboxylic dianhydride, 2,3,3', 4'-Dicyclohexyl ether tetracarboxylic dianhydride, 2,3,2',3'-Dicyclohexyl ether tetracarboxylic dianhydride, 1,4-bis(3,4-dicarboxycyclohexyl)cyclohexyl Dianhydride, 2,5,7,10-decalin tetracarboxylic dianhydride, 4,4'-didecalinyl-1,1',8,8'-tetracarboxylic dianhydride, bis(3,4 - dicarboxycyclohexyl)methane dianhydride or 2,2-bis(3,4-dicarboxycyclohexyl)hexafluoropropane dianhydride;

[0070] Described polyimide comprises the repeating unit with formula (I) structure:

[0071]

[0072] In formula (I), R 1 One of the following structures:

[0073]

[0074] R 2 I...

Embodiment 1

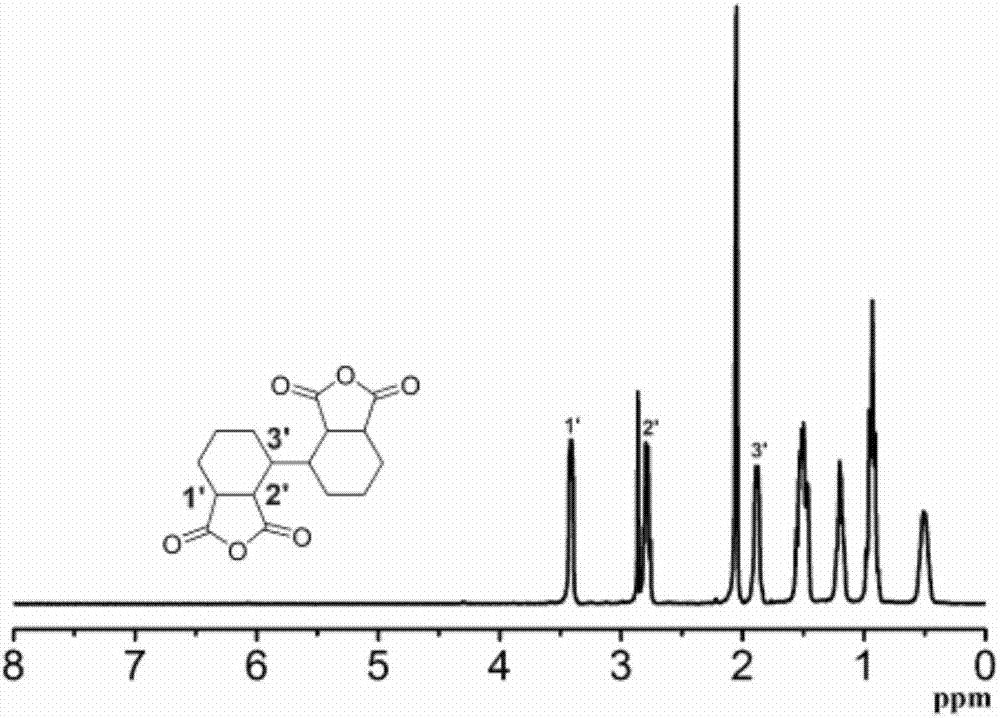

[0142] Preparation of 2,3,2',3'-dicyclohexyltetracarboxylic dianhydride:

[0143](1) Add 69g of zinc powder, 7.67g of nickel bromide, and 32.21g of triphenylphosphine into 132ml of N,N-dimethylacetamide, stir until dark brown at 60°C, add 132ml of N,N-di 200g of 3-chlorophthalamide solution in methylacetamide was maintained at 60-80°C for 6h, the catalyst was filtered off, washed several times with dilute hydrochloric acid, and recrystallized with ethanol to obtain 143g of tetraester.

[0144] (2) Add 5g of tetraester and 0.5g of rhodium / activated carbon catalyst (Acros, Rhodium on activated carbon, 5%Rh) into a 250ml autoclave, then add 40ml of THF, at a temperature of 120°C and a hydrogen pressure of 2 to 5Mpa under magnetic stirring After reacting for 5 to 8 hours, the catalyst was filtered off, and then THF was evaporated to obtain the hydrogenated tetraester.

[0145] (3) Dissolve 5 g of the obtained hydrogenated tetraester in 25 ml of methanol, add 40 g of 20 wt % sodiu...

Embodiment 2

[0149] 1) Preparation of polyimide:

[0150] Under nitrogen protection, 0.7276g 2,3,2',3'-dicyclohexyl tetracarboxylic dianhydride, 0.4756g 4,4'-diaminodiphenyl ether and 0.2898g benzoic acid were added to the polymerization bottle, and then 4.81 g m-cresol, heated to 90°C and stirred until completely dissolved. After dissolution, the temperature was raised to 180°C for 20 hours. After the reaction, m-cresol was added to dilute and the temperature was lowered to 100°C, and the solution was poured into ethanol to obtain a white filamentous solid. Soxhlet extraction was performed with ethanol. After extraction, dry at 100° C. under vacuum to obtain polyimide.

[0151] The polyimide that present embodiment makes has following structure:

[0152]

[0153] Infrared spectrum analysis is carried out to the above-mentioned polyimide that makes, the result is as follows: figure 2 as shown, figure 2 It is the polymer infrared spectrogram provided by Example 2 of the present i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com