Polytetrafluoroethylene interlayer protective ion exchange membrane, its preparation method and flow battery

An ion exchange membrane, polytetrafluoroethylene technology, applied in fuel cells, battery electrodes, regenerative fuel cells, etc., can solve problems such as poor stability, and achieve the effects of stable battery performance, uniform pore size distribution, and simple preparation steps.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] (1) The ion exchange capacity of 1.5g is 1.80mmol g -1 , sulfonated polyetheretherketone (SPEEK) with a sulfonation time of 3 hours and a sulfonation degree of 0.61 was added to 10 mL of N,N-dimethylformamide solvent (DMF), fully ultrasonically dispersed at 25°C, and magnetically Stir for 24 hours to make a homogeneous solution of SPEEK.

[0036] (2) Remove bubbles and impurities from the homogeneous solution of SPEEK prepared in step (1), form a film on a horizontal clean glass plate by casting method, dry at 60°C for 12 hours, and vacuum dry at 100°C for 12 hours, and then in Membrane removal in deionized water can prepare sulfonated polyether ether ketone ion exchange membrane base membrane. In this example, the basement membrane thickness of the obtained ion exchange membrane is 70 μm.

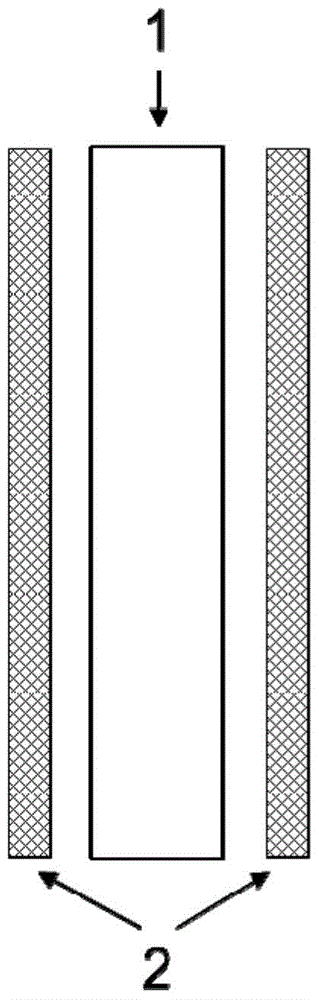

[0037] (3) Cut the required polytetrafluoroethylene (PTFE) microporous membrane with a thickness of 30 μm and a pore size of 0.45 μm to the required size, and place a PTFE micropo...

Embodiment 2

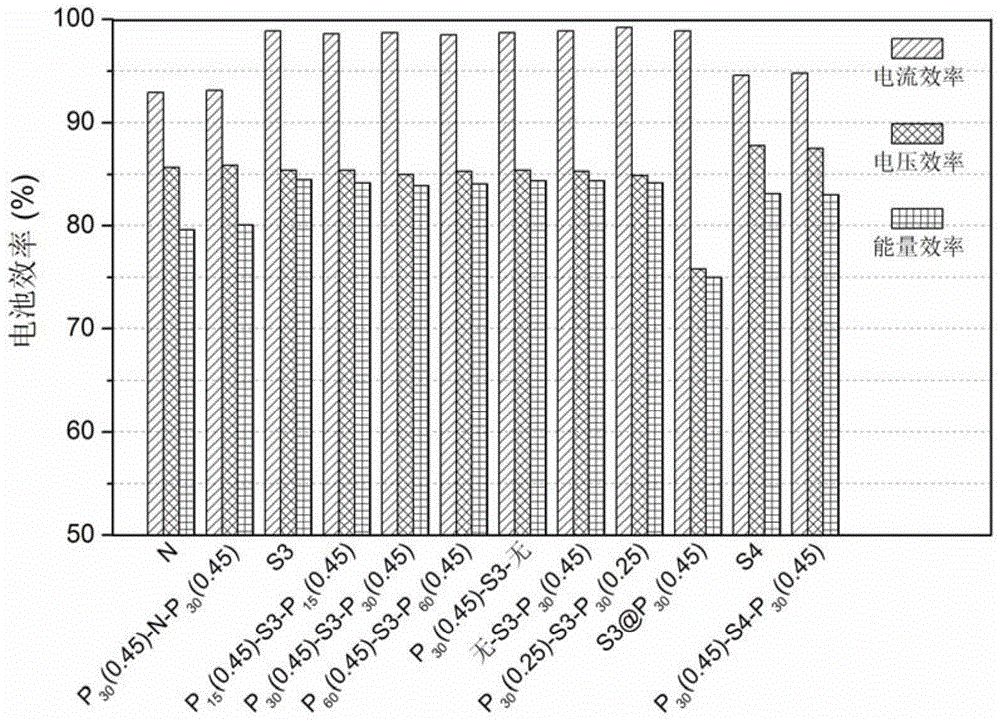

[0041] The preparation method of the sulfonated polyether ether ketone-polytetrafluoroethylene interlayer membrane in Example 2 is the same as in Example 1, the thickness of the polytetrafluoroethylene (PTFE) film used is 60 μm, and the pore size is 0.45 μm, and P 60 (0.45)-S3-P 60 (0.45) interlayer film. This interlayer film was used to assemble a single cell of an all-vanadium redox flow battery, and other assembly conditions and test conditions were the same as in Example 1. The current efficiency of a single cell is 98.5%, the voltage efficiency is 85.3%, and the energy efficiency is 84.1% (such as figure 2 shown). In the cycle charge and discharge life experiment, the battery charge and discharge current density is 80mA cm -2 , the current efficiency is very stable and the battery charging capacity decays slowly. After 605 cycles, the charging capacity retention rate is 60% (such as image 3 shown).

Embodiment 3

[0043] The preparation method of the sulfonated polyether ether ketone-polytetrafluoroethylene interlayer membrane in Example 3 is the same as in Example 1, the thickness of the polytetrafluoroethylene (PTFE) film used is 15 μm, and the pore size is 0.45 μm, and P 15 (0.45)-S3-P 15 (0.45) interlayer film. This interlayer film was used to assemble a single cell of an all-vanadium redox flow battery, and other assembly conditions and test conditions were the same as in Example 1. The current efficiency of a single cell is 98.6%, the voltage efficiency is 85.4%, and the energy efficiency is 84.2% (such as figure 2 shown). In the cycle charge and discharge life experiment, the battery charge and discharge current density is 80mA cm -2 , the current efficiency is very stable and the battery charging capacity decays slowly. After 478 cycles, the charging capacity retention rate is 60% (such as image 3 shown).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size distribution | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com