Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

290 results about "Membrane thickness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Membranes are typically 7.5–10 nm in thickness with two regular layers of lipid molecules (a bilayer) containing various types of protein molecules.".

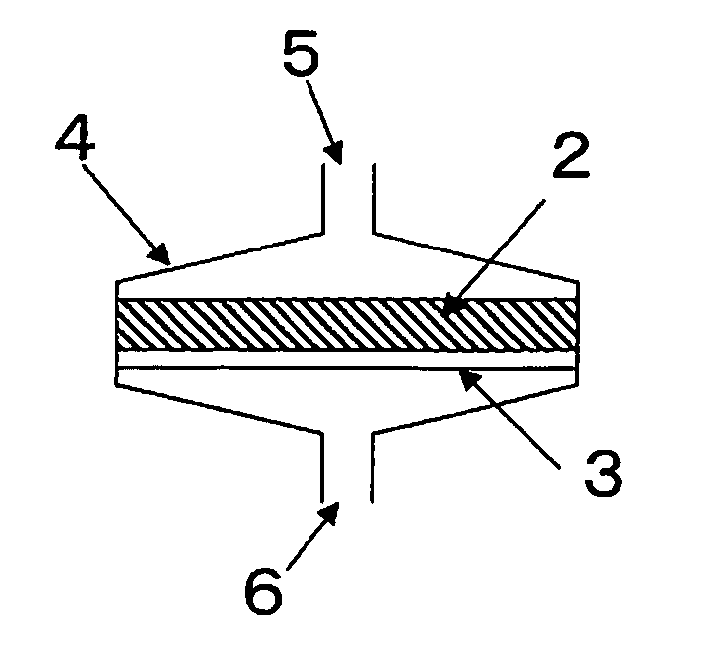

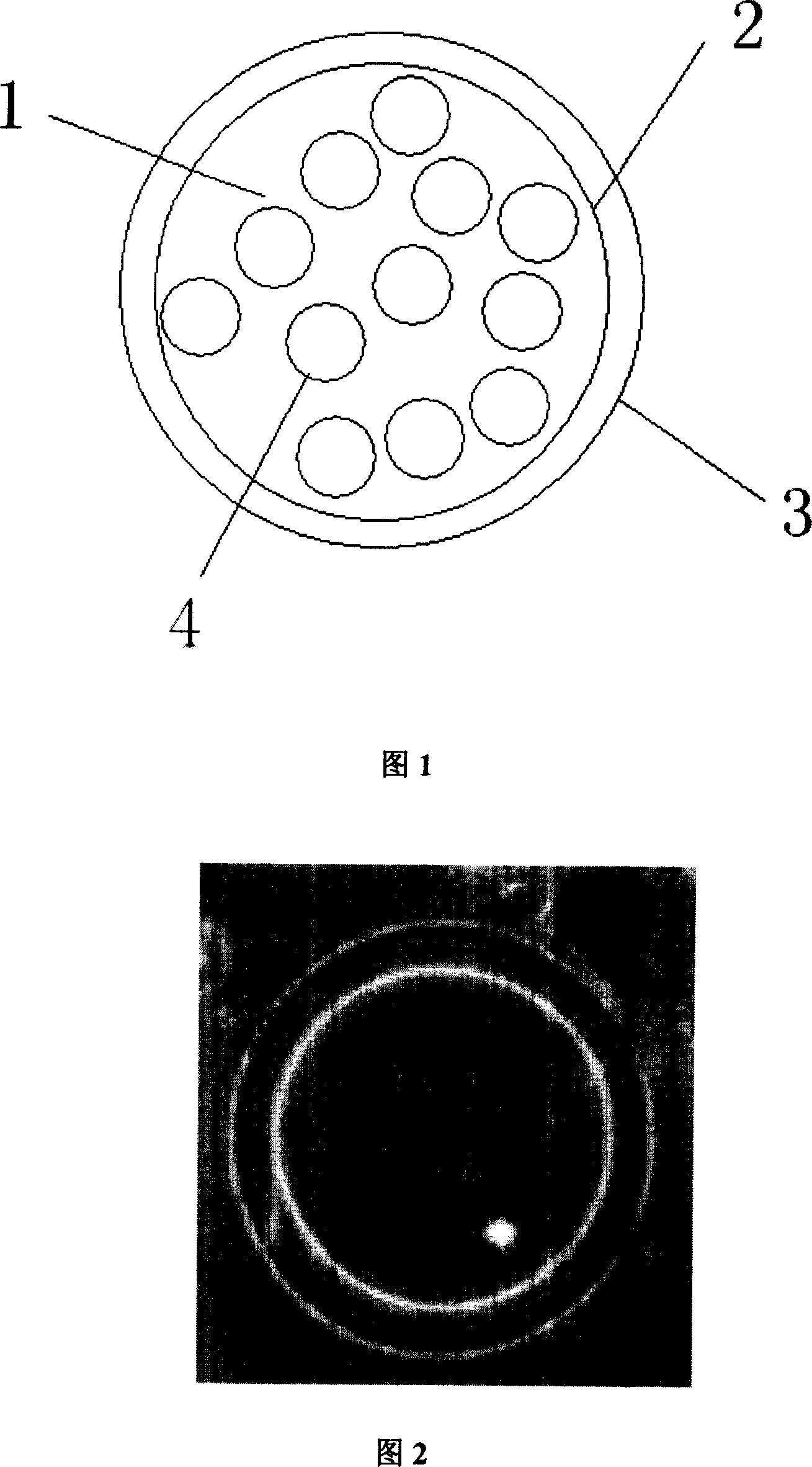

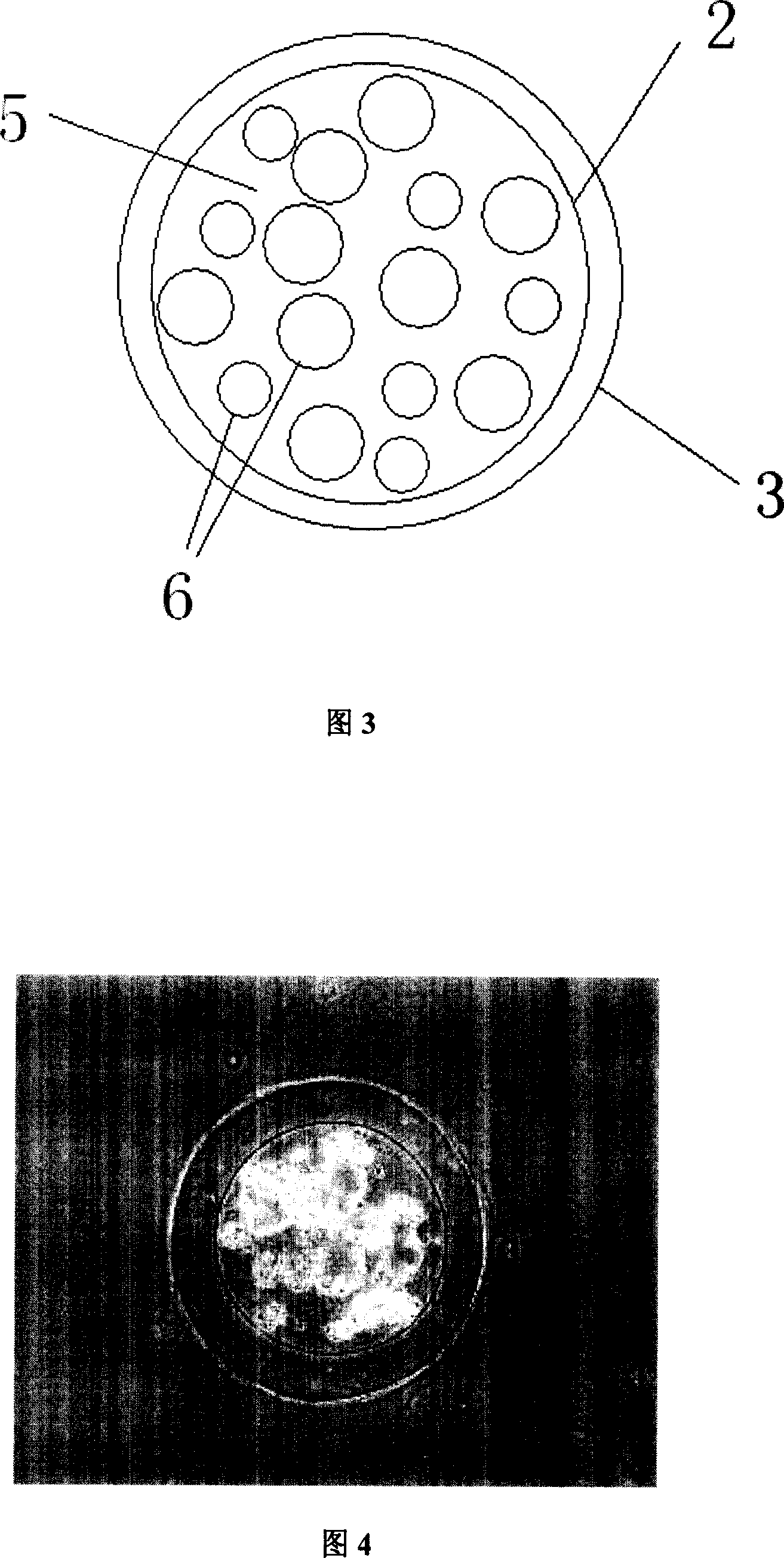

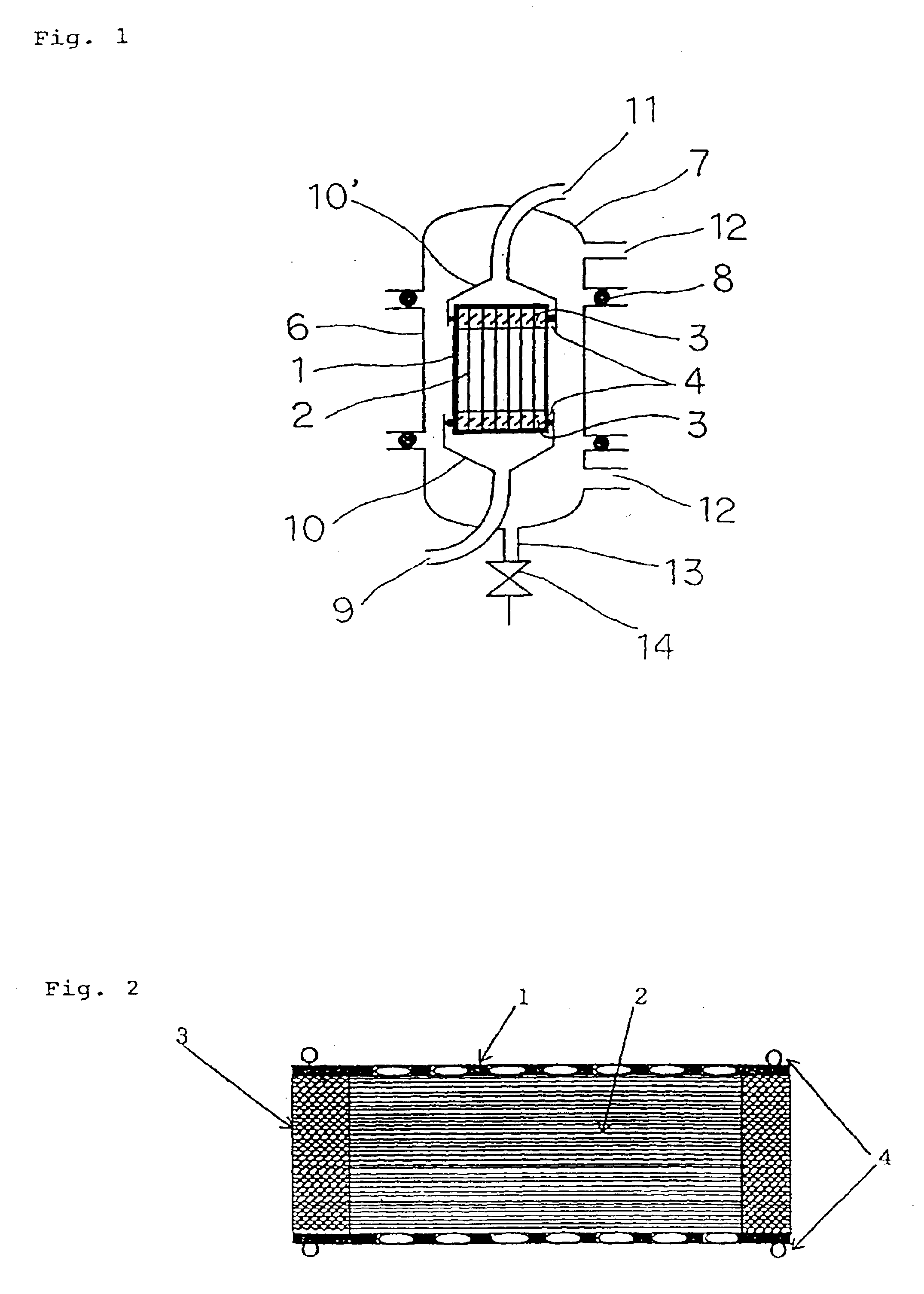

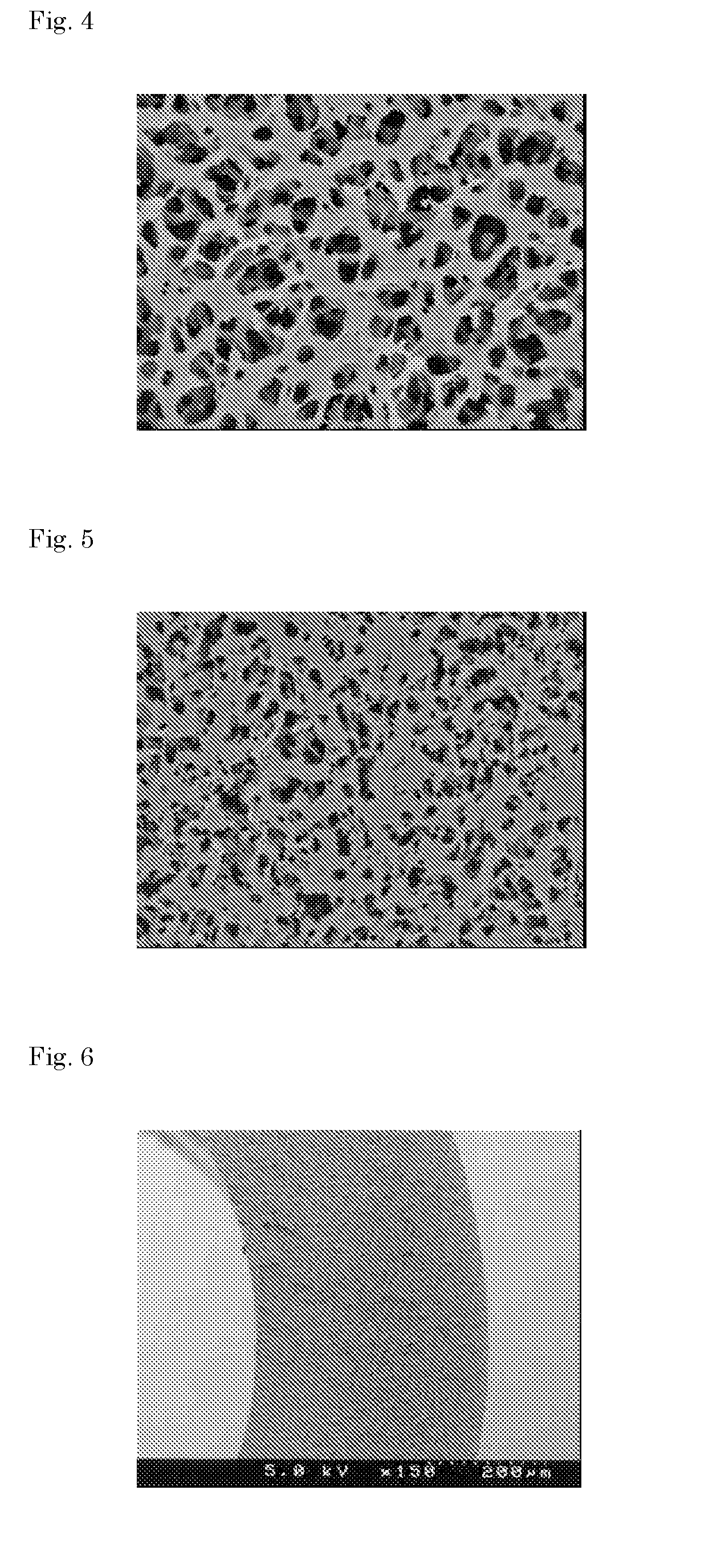

Composite porous membrane and process for producing the same

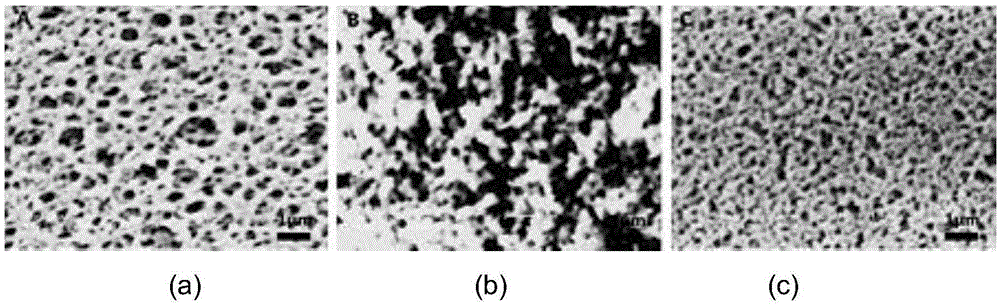

InactiveUS20070029256A1Good size uniformityLow filtration resistanceBioreactor/fermenter combinationsBiological substance pretreatmentsWhite blood cellMicron size

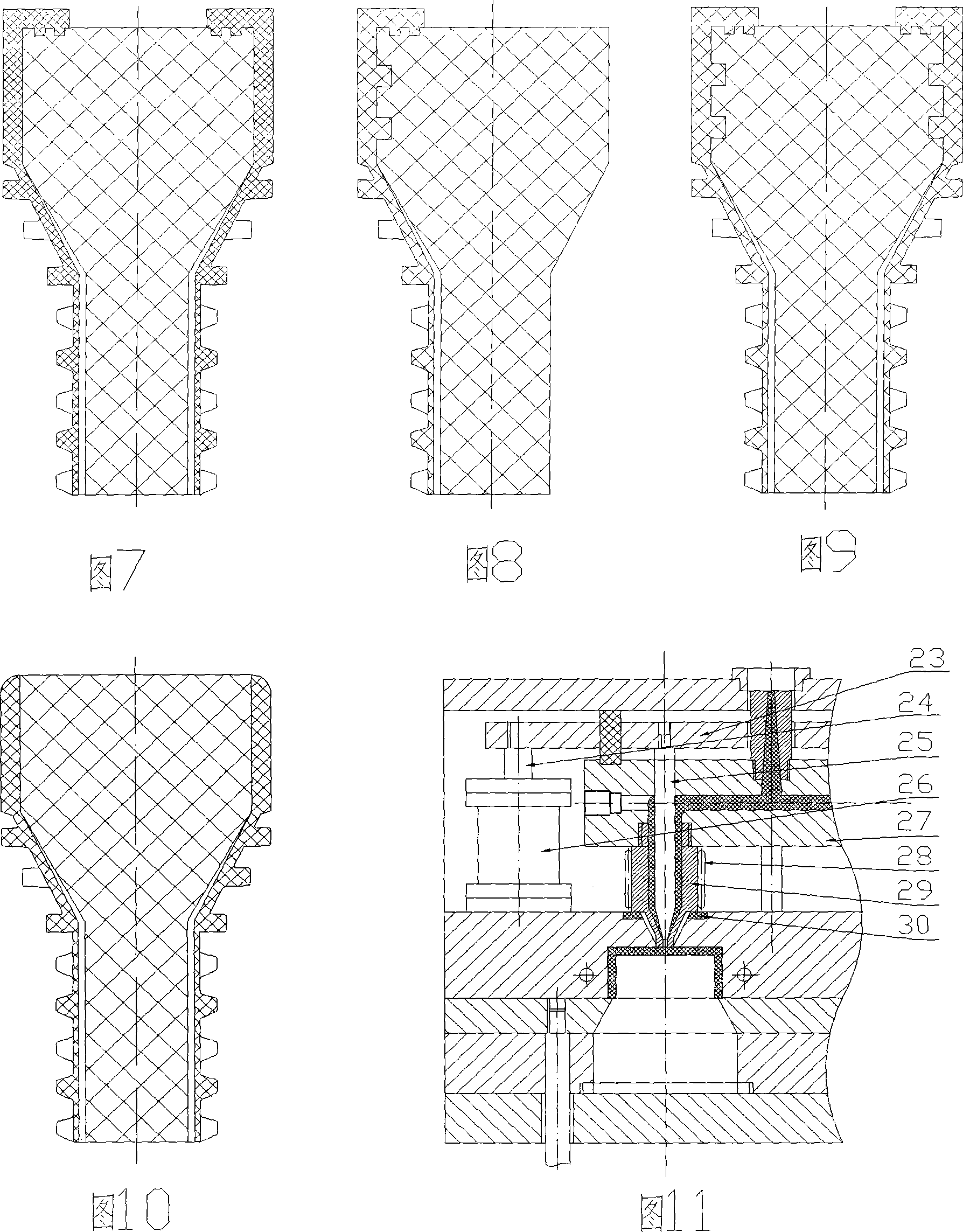

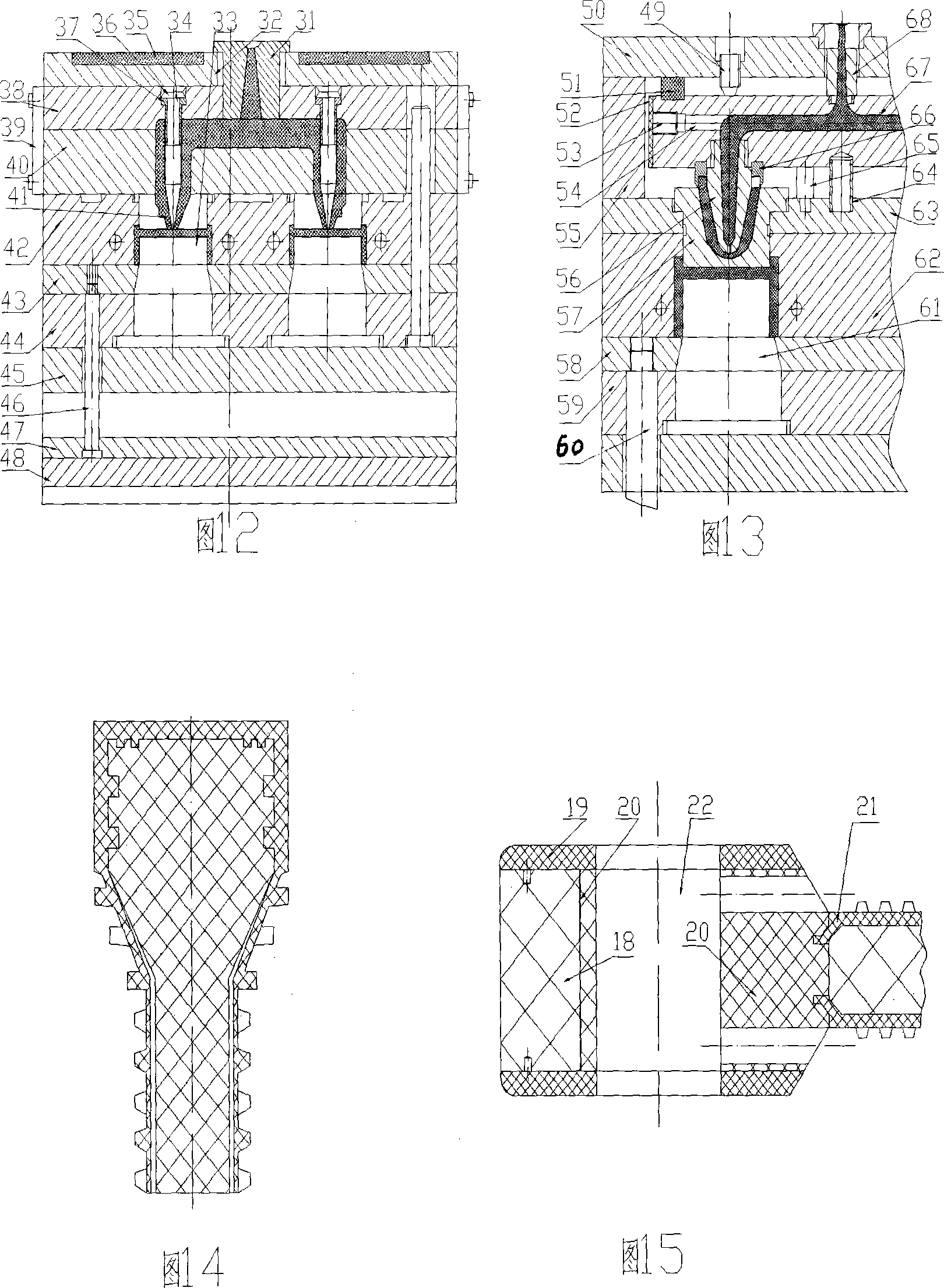

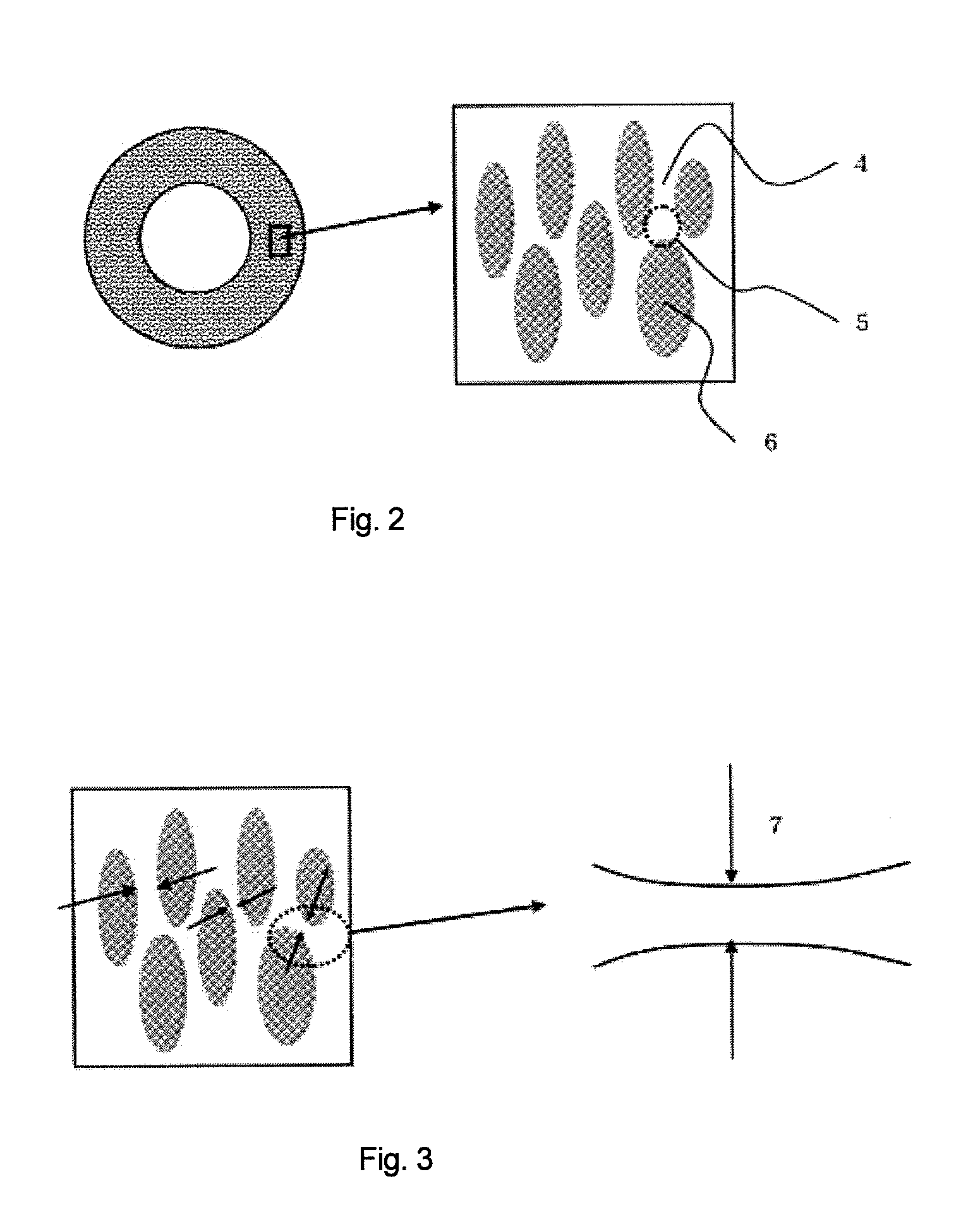

[Problems]To provide a membrane material that realizes effective and efficient separation of a target substance of micron size, being easy to handle and that can be worked into various forms; a blood filtration membrane and a leukocyte removing filter unit that realizes a substantial reduction of filter material volume while retaining high capability of removing leukocytes, thereby reducing the loss of hemocyte suspension; and a cell culturing diaphragm suitable for co-culturing and a relevant method of cell culturing. [Means for Solving Problems]There is provided a composite porous membrane comprising a porous membrane comprised of an organic polymeric compound, and a supporting porous membrane adjacent to the porous membrane, characterized in that the organic polymeric compound constituting the porous membrane penetrates in at least part of a surface adjacent to porous membrane of the supporting porous membrane, the porous membrane having specified opening ratio, average pore diameter, standard deviation of pore diameter, ratio of through pore, average membrane thickness, standard deviation of membrane thickness and internal structure, and that the supporting porous membrane has communicating pores of 0.5D μm or greater average pore diameter. Further, there are provided a blood filtration membrane comprising the composite porous membrane; a leukocyte removing filter unit comprising the composite porous membrane as a second filter; and, utilizing the composite porous membrane, a cell culturing diaphragm and method of cell culturing.

Owner:ASAHI KASEI MEDICAL CO LTD

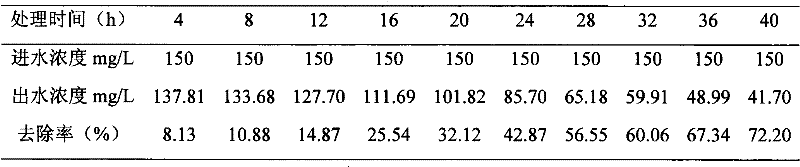

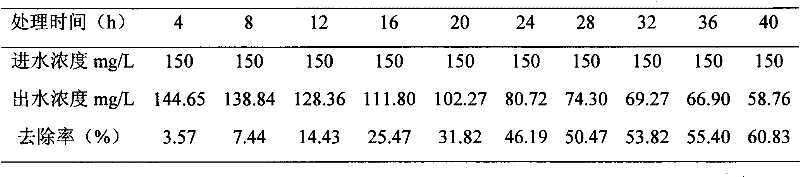

Method for preparing novel biological microcapsule for biological fluidized bed

ActiveCN102351320AImprove mass transfer effectEnhanced mass transferSustainable biological treatmentBiological water/sewage treatmentFluidized bedIon exchange

The invention discloses a method for preparing a novel biological microcapsule for a biological fluidized bed. The microcapsule is prepared through treating sodium alginate, powdery active carbon, calcium chloride and chitosan as capsule materials, and a dominant degradation bacterium as a capsule core, preparing calcium alginate gel beads through carrying out ion exchange on sodium alginate and calcium chloride, coating the surface of the gel beads with chitosan, liquefying the gel beads in sodium citrate, and coating the gel beads with sodium alginate. The diameter of the prepared microcapsule is 3.0-4.0mm, the membrane thickness of the prepared microcapsule is 10-20mum, the density of the prepared microcapsule is 1.05-1.08g / mL, and the maximum interception molecular weight of the prepared microcapsule is about PEG 4000, so a micromolecular substance with the relative molecular weight of less than PEG 1500 can freely go through the capsule membrane. Acidic conditions and most divalent cations allow the microcapsule to be stable, and monovalent cations and most anions are bad for the stability of the microcapsule.

Owner:江苏科易达环保科技股份有限公司

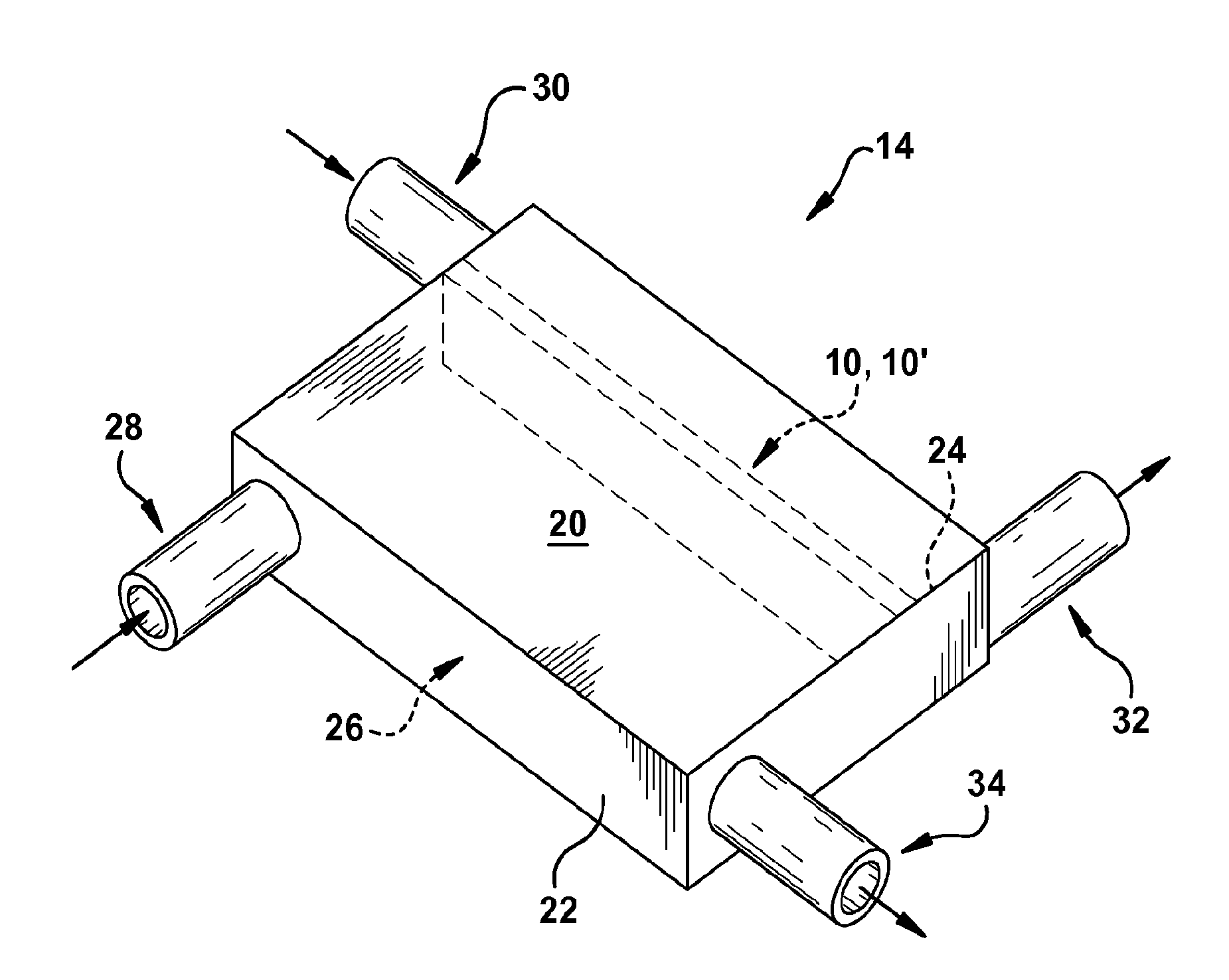

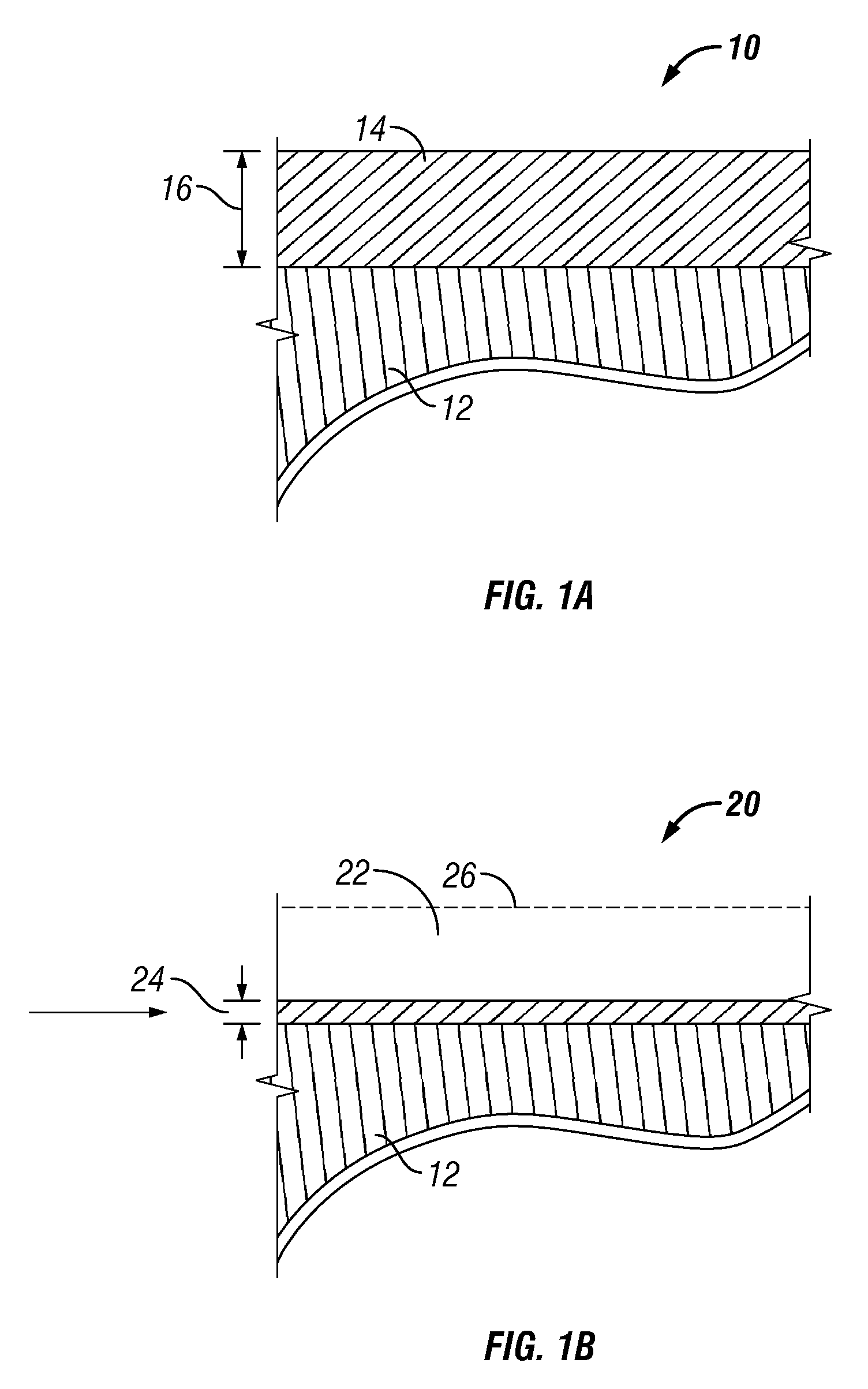

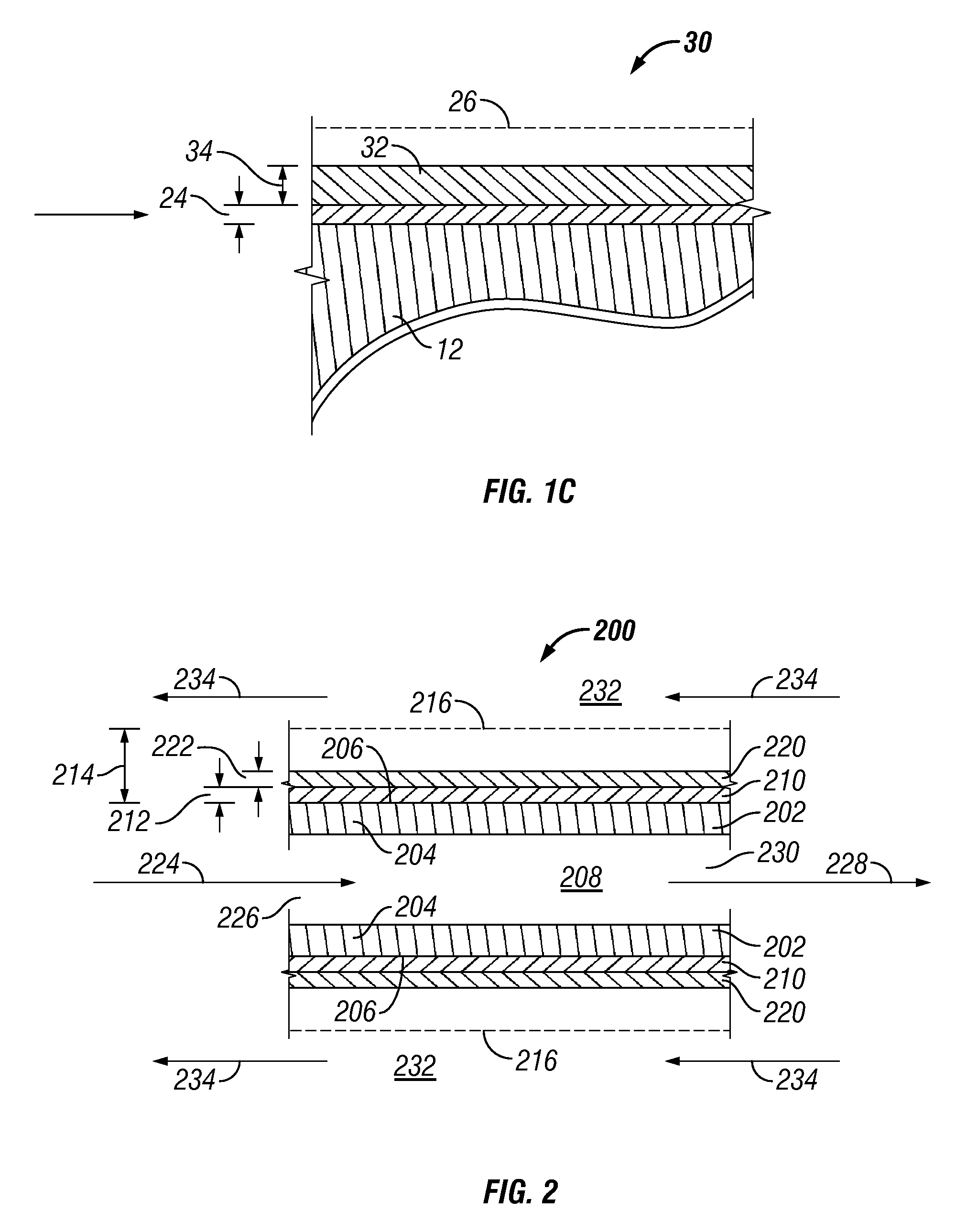

Nanoporous membranes, devices, and methods for respiratory gas exchange

One aspect of the present invention relates to a silicon nanoporous membrane for oxygenating blood. The nanoporous membrane includes a first major surface, a second major surface, and a plurality of pores extending between the first and second major surfaces. The first major surface is for contacting a gas. The second major surface is for contacting blood and is oppositely disposed from said first major surface. The first and second major surfaces define a membrane thickness. Each of the pores is defined by a length, a width, and a height. Each of the pores is separated by a uniform interpore distance.

Owner:THE CLEVELAND CLINIC FOUND +1

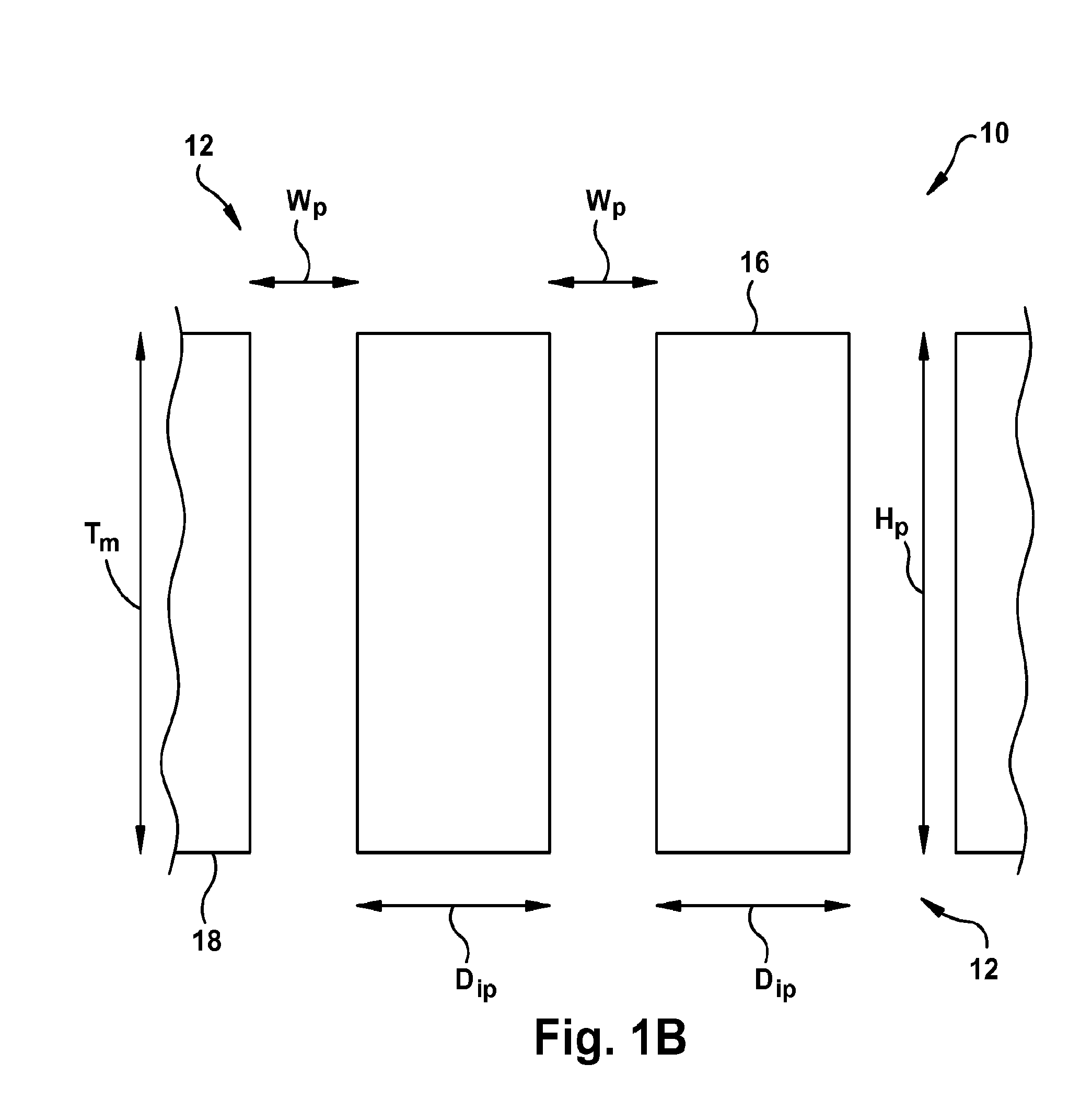

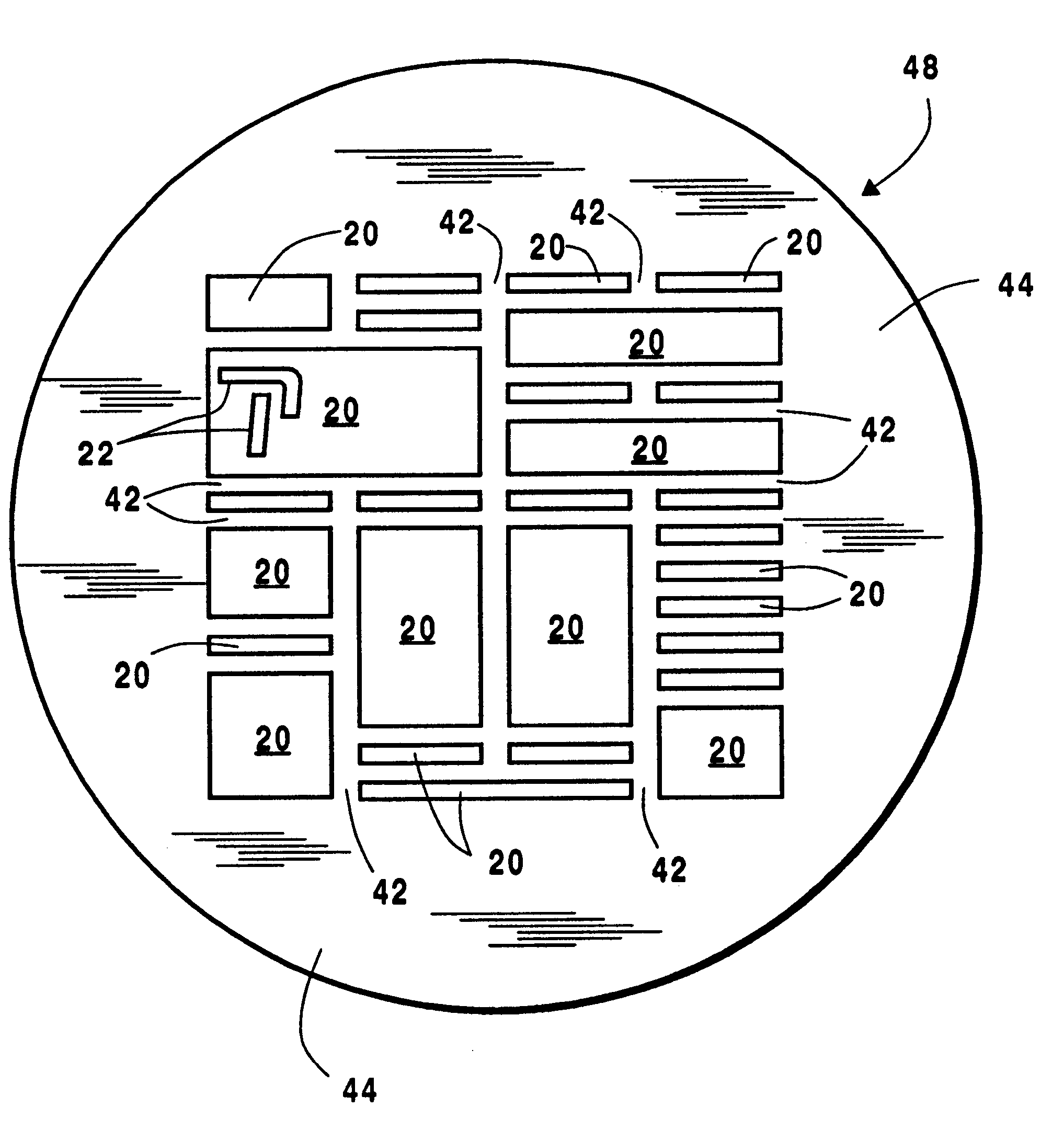

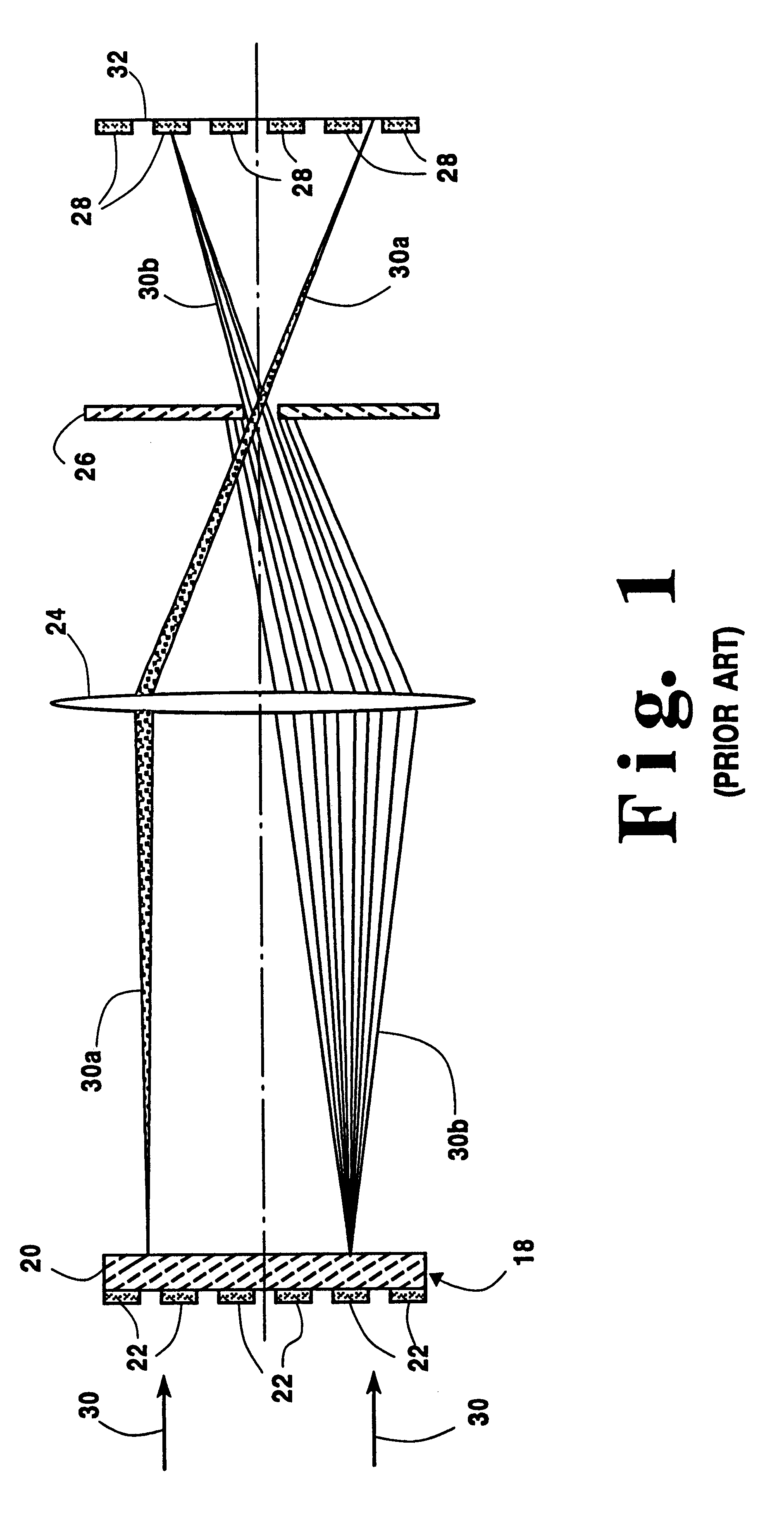

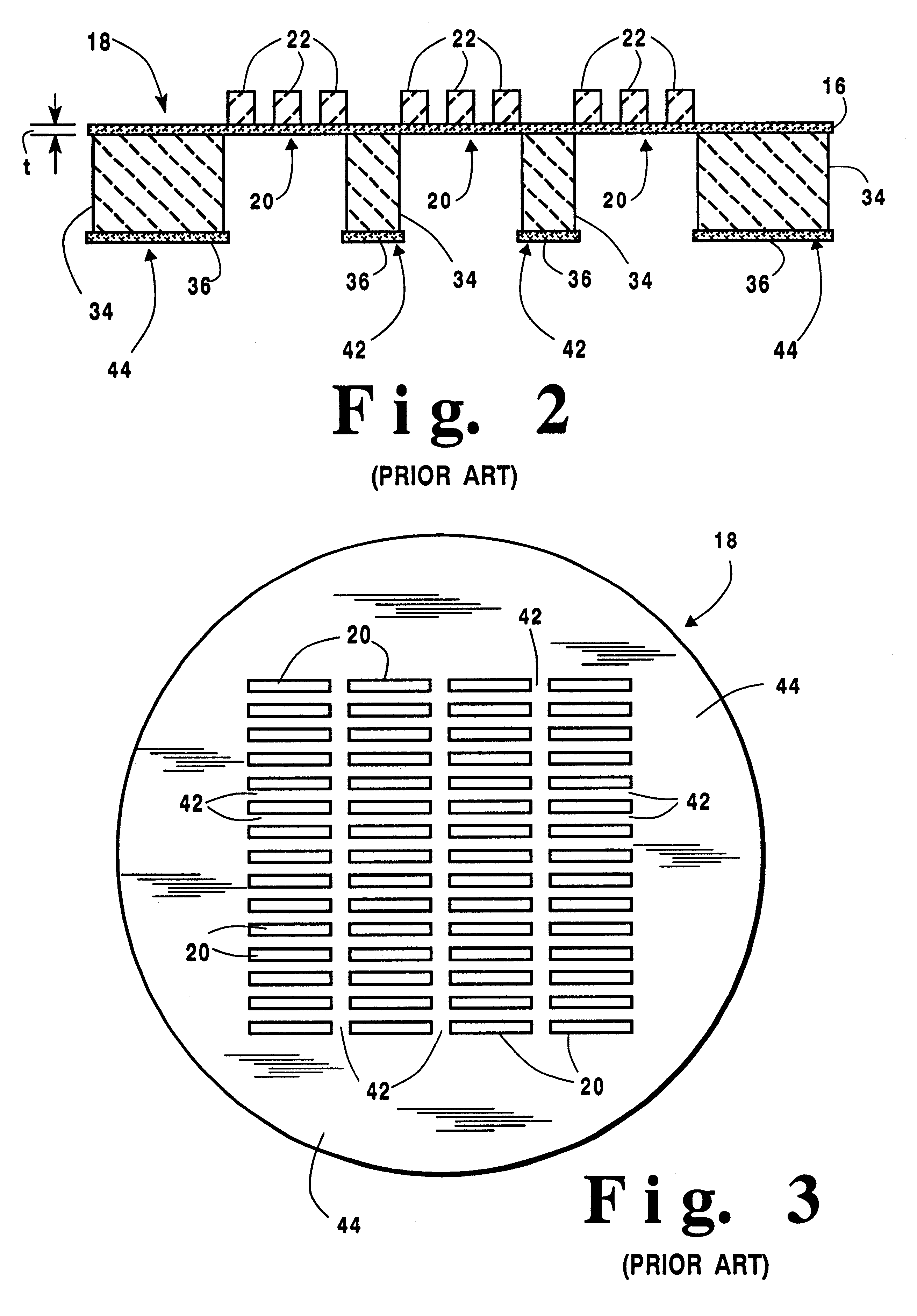

Projection electron-beam lithography masks using advanced materials and membrane size

InactiveUS6261726B1Without limiting strengthElectric discharge tubesSemiconductor/solid-state device manufacturingDiamond-like carbonYoung's modulus

A stencil or scatterer mask for use with charged particle beam lithography such as projection electron-beam lithography comprises a membrane layer of a material having a Young's modulus of at least about 400 GPa and support struts supporting a surface of the membrane. The struts form and surrounding a plurality of discrete membrane areas of different aspect ratios aligned to design regions of an integrated circuit. The discrete membrane areas have different aspect ratios range from about 1:1 to about 12:1, and the discrete membrane areas have different size surface areas. The membrane is preferably silicon carbide, diamond, diamond-like carbon, amorphous carbon, carbon nitride or boron nitride. When used in scatterer masks, the ratio of discrete membrane area to membrane thickness is at least about 0.18 mm2 / nm. When used in stencil masks, the ratio of discrete membrane area to membrane thickness is at least about 1.0 mm2 / nm. The stencil mask is made by depositing a diamond membrane film patterned with a hardmask layer on a substrate, depositing an etch stop layer adjacent the diamond film, and forming supporting struts surrounding a plurality of discrete areas of the membrane film. The method then includes depositing a pattern over the membrane film within the discrete membrane film areas, the pattern conforming to one or more desired circuit elements, and etching the membrane film with a reactive ion etch containing oxygen to form openings in the membrane film.

Owner:IBM CORP

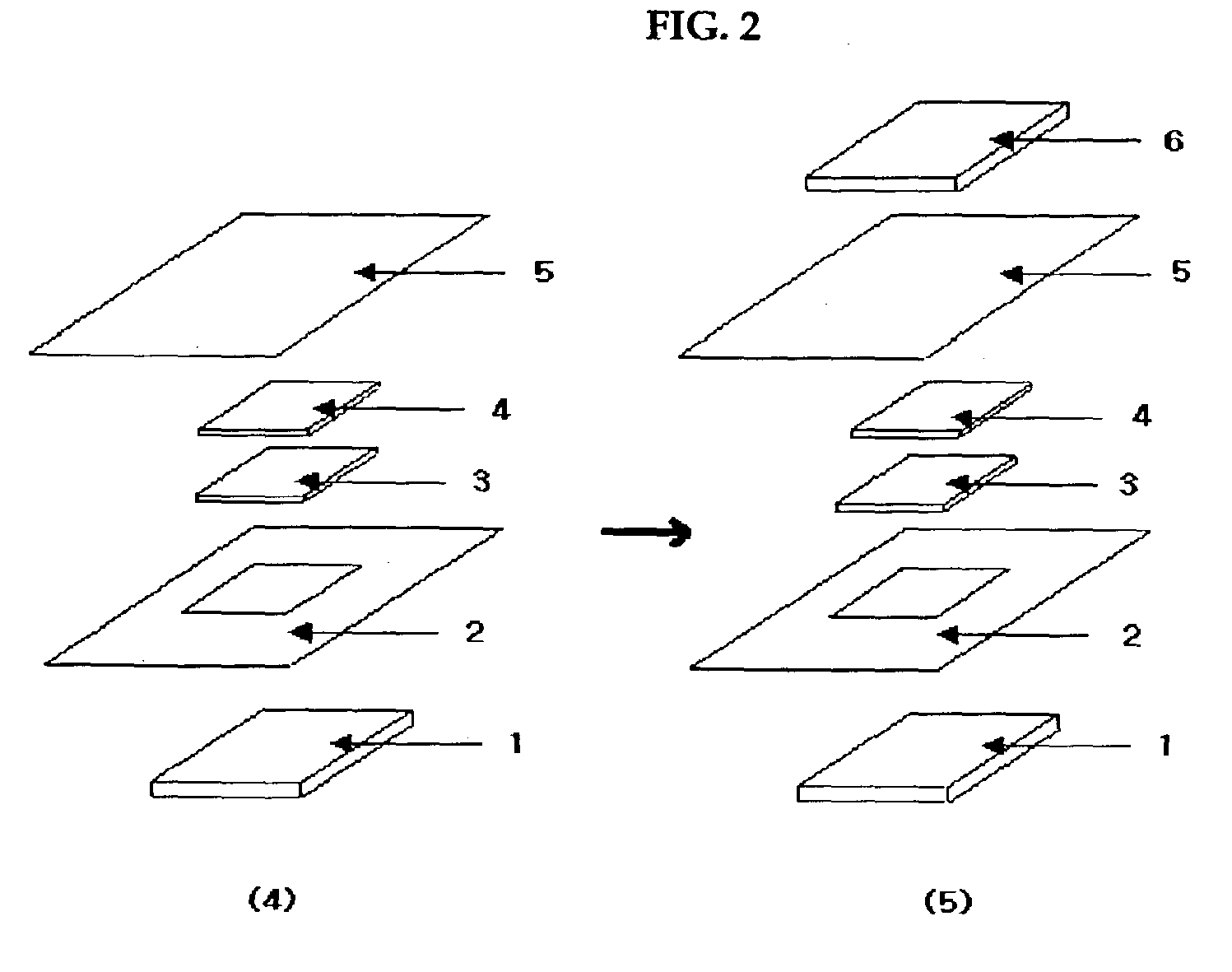

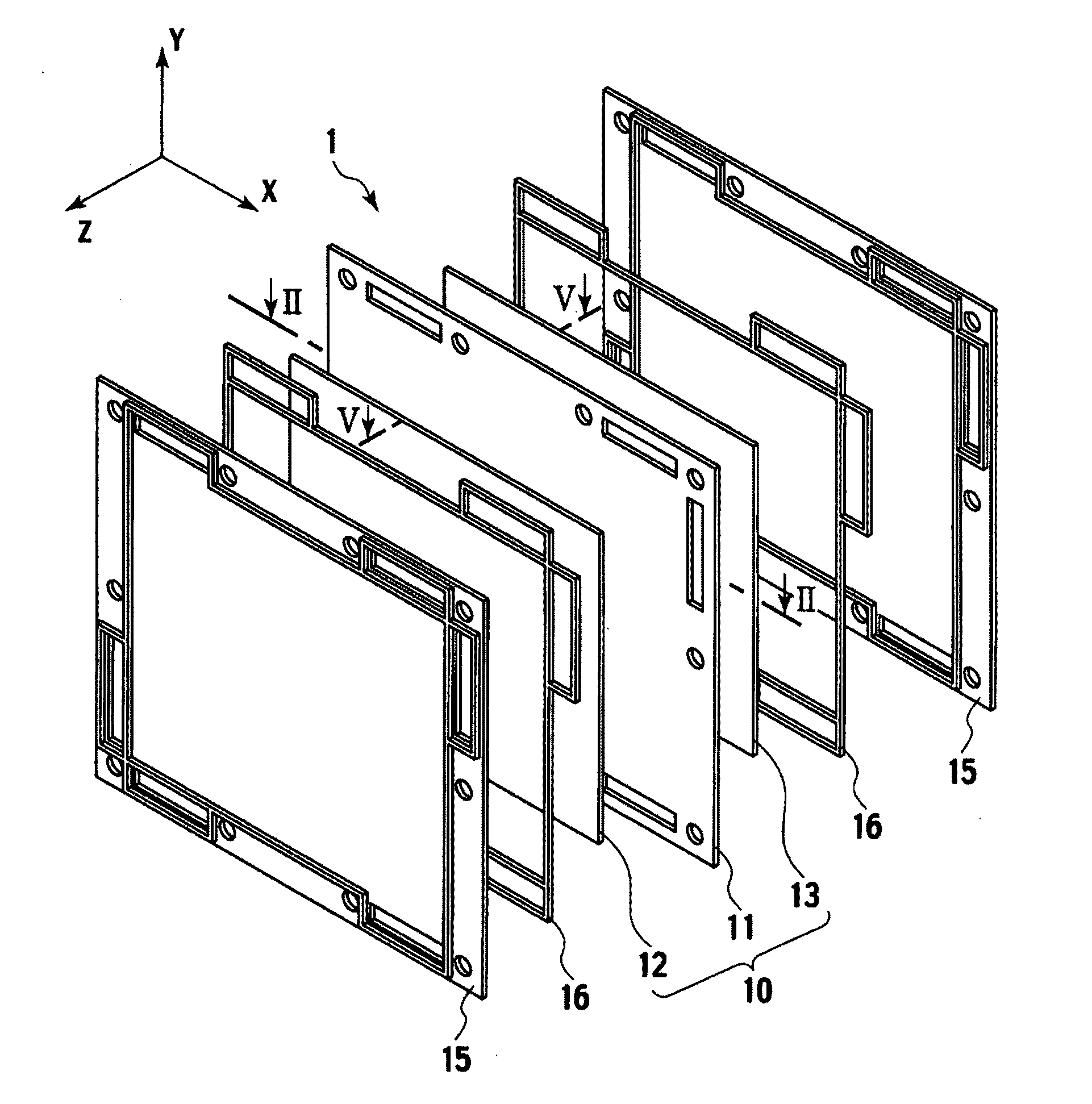

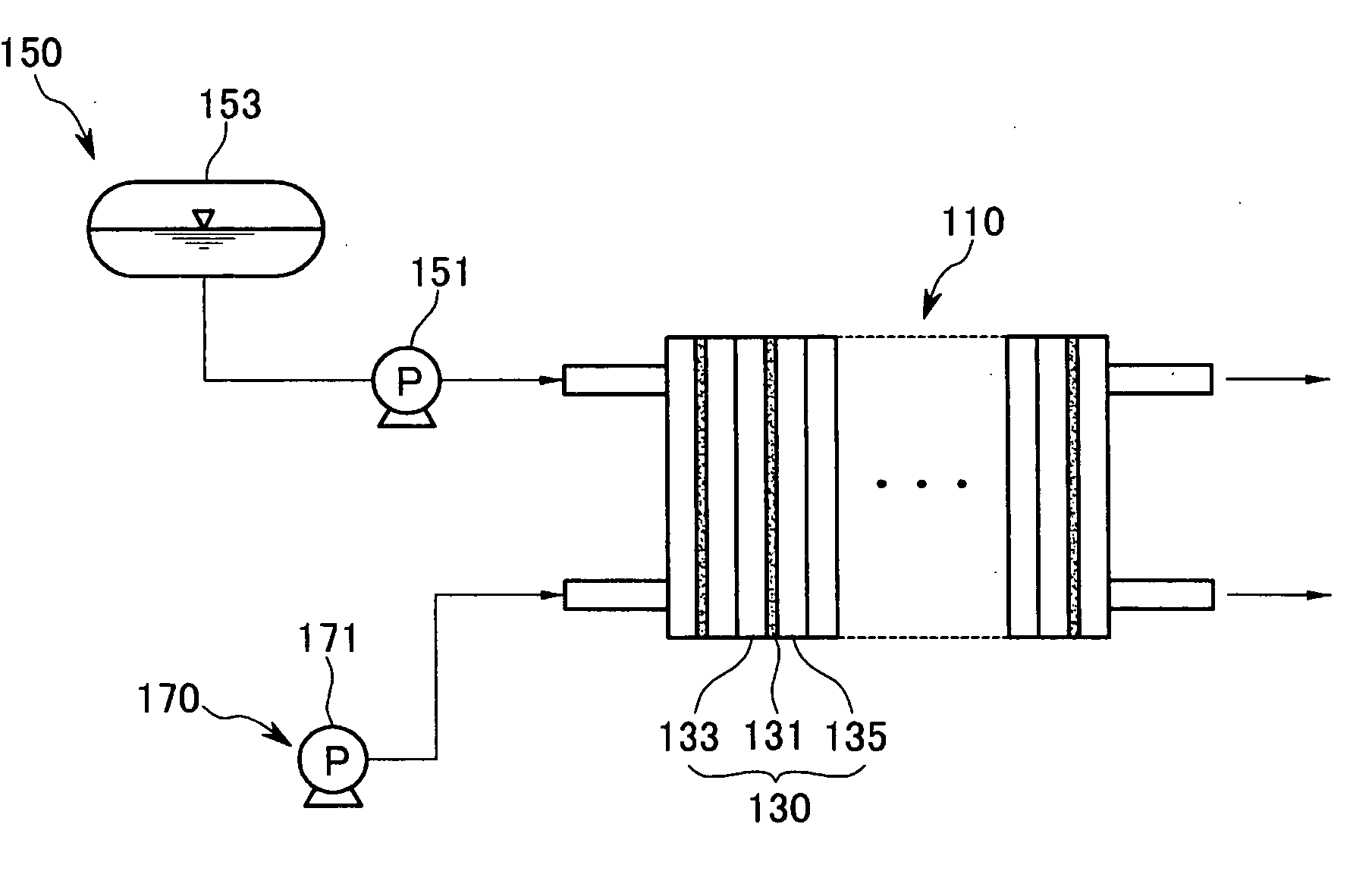

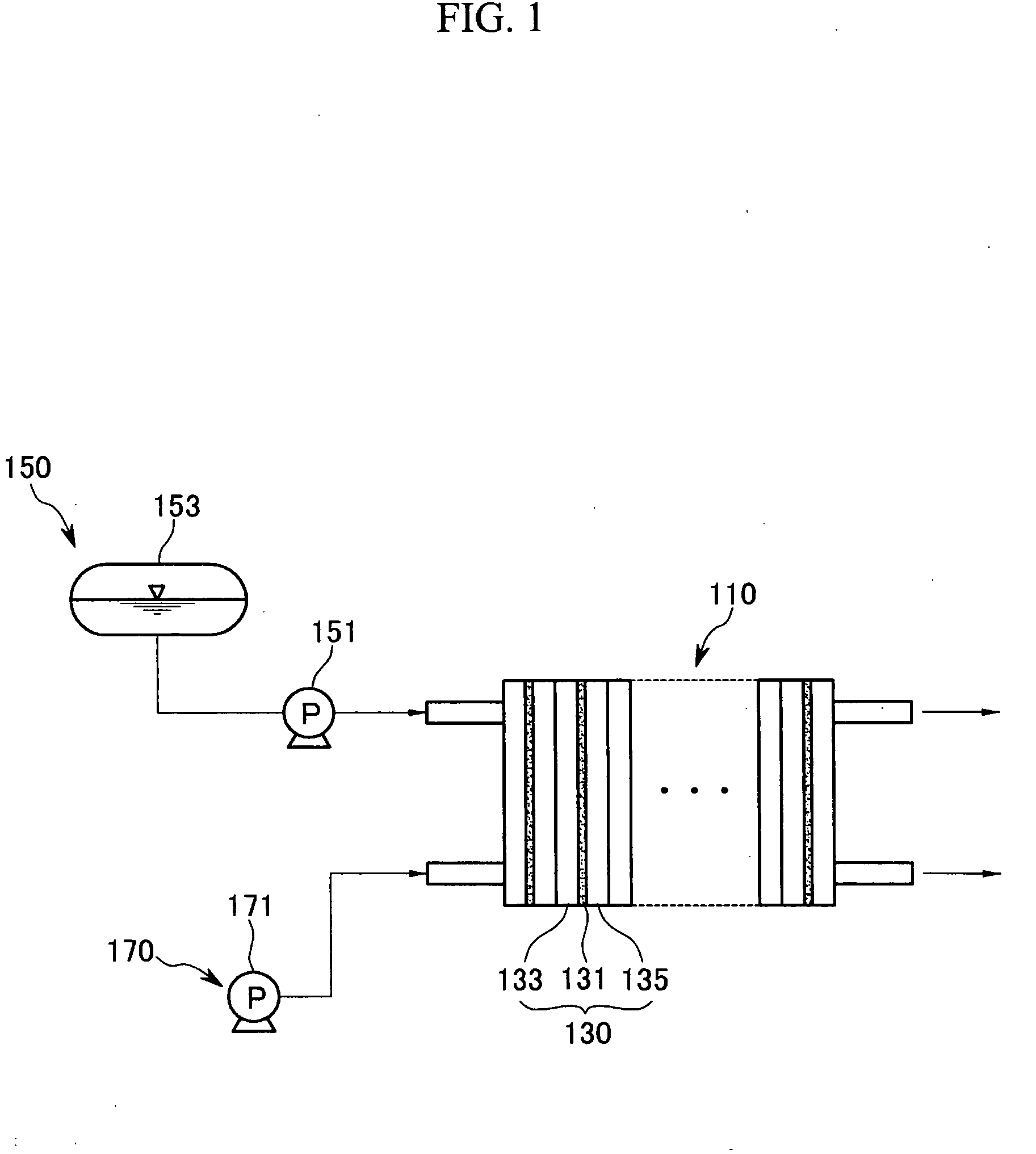

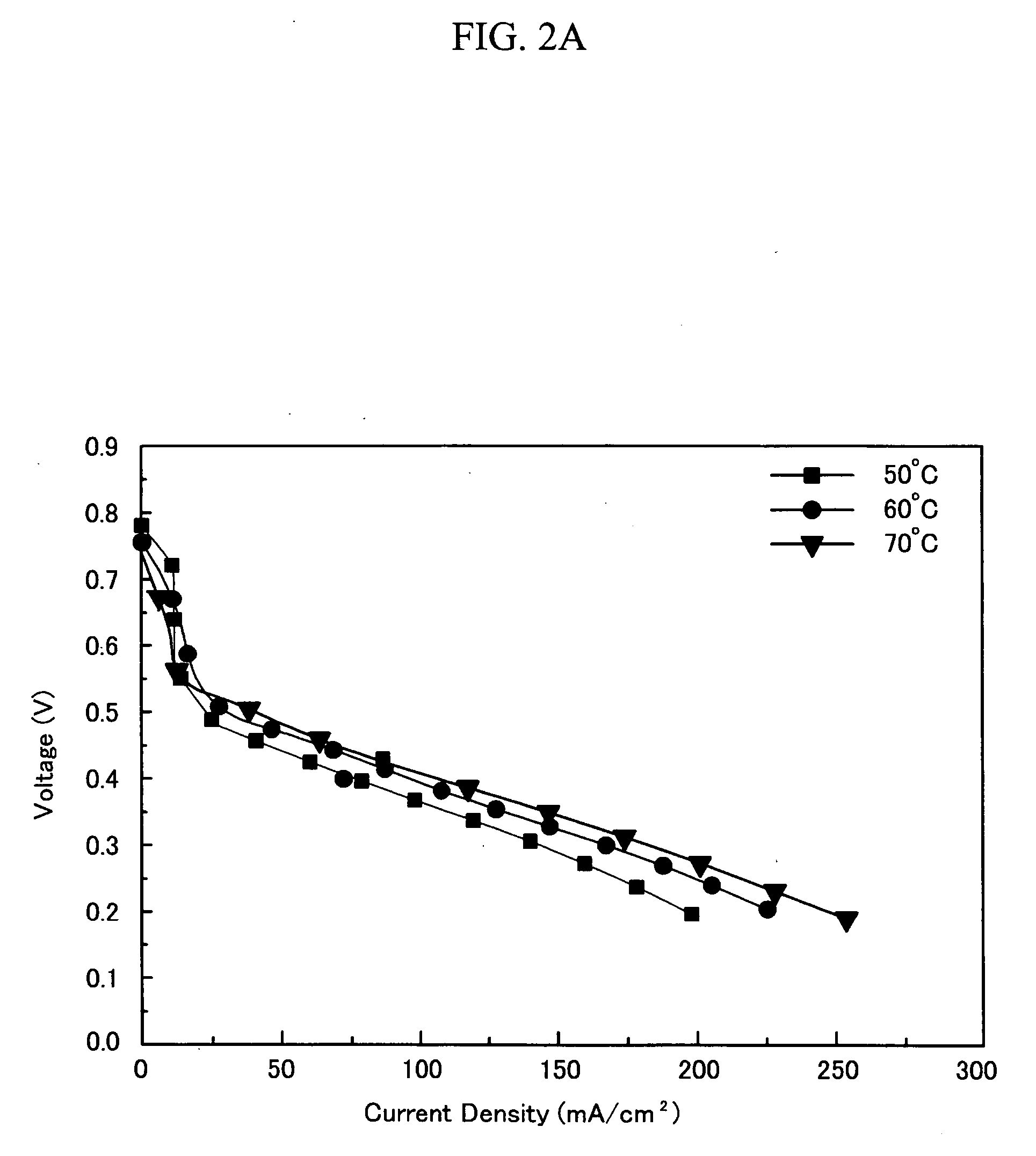

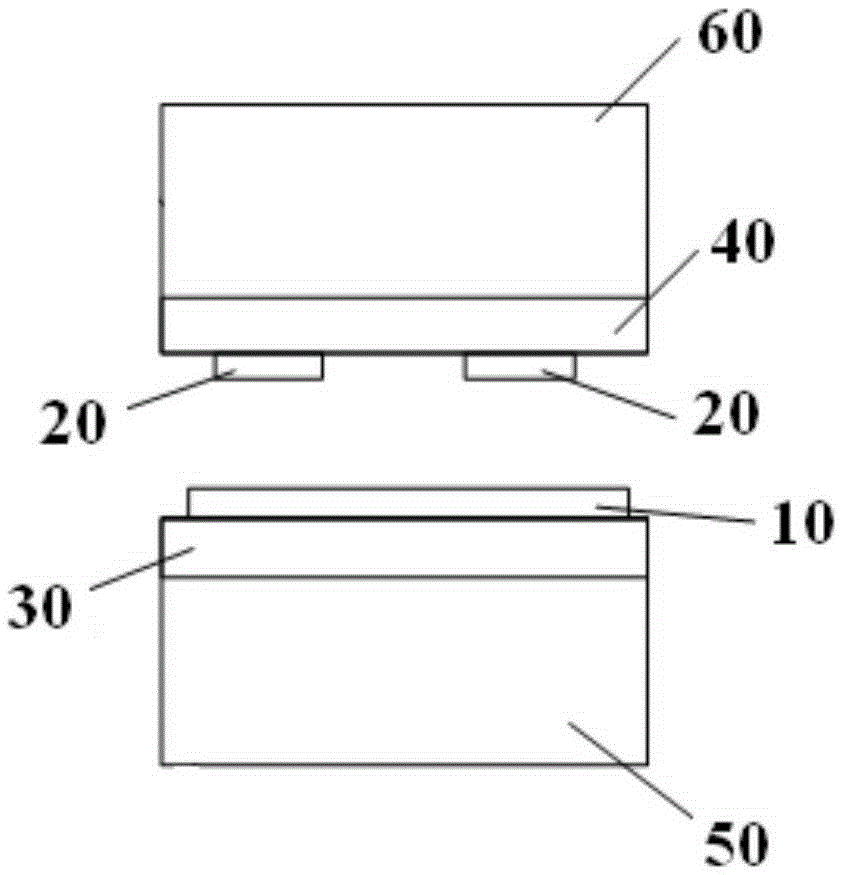

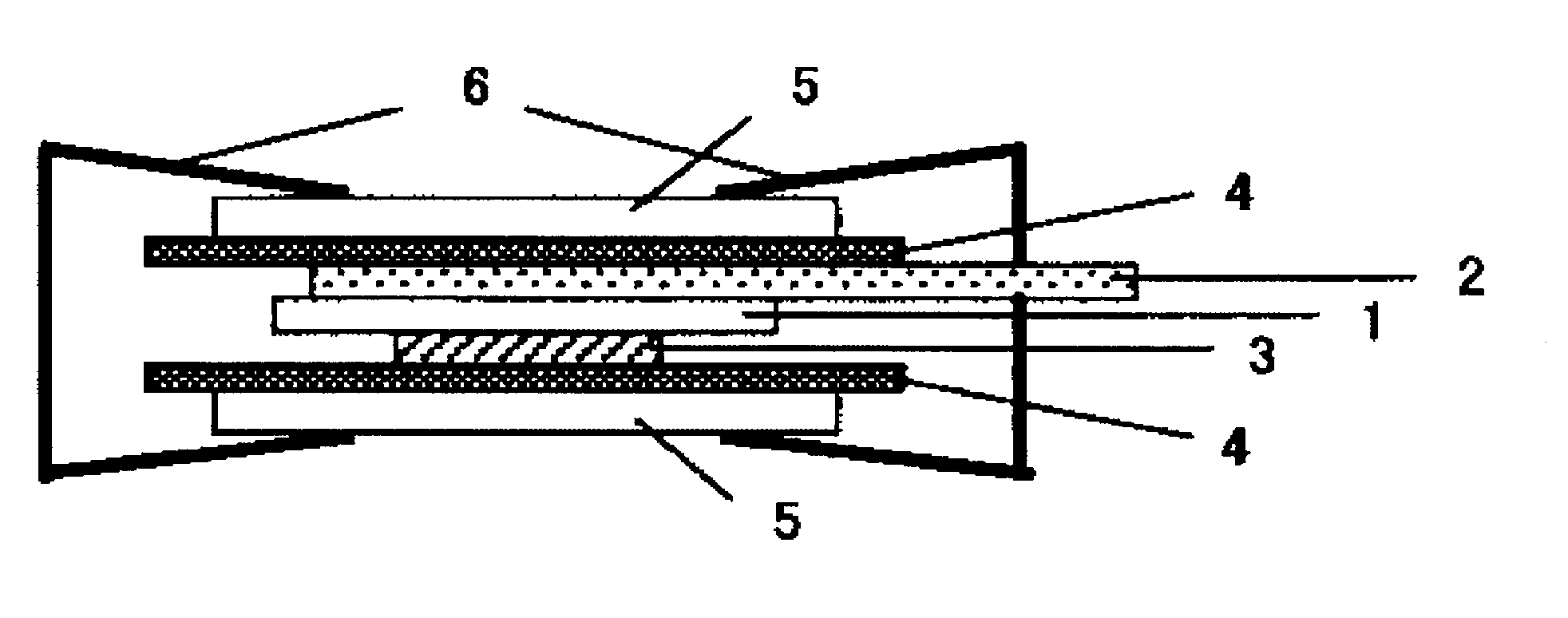

Method of preparing membrane-electrode-gasket assemblies for polymer electrolyte fuel cells

InactiveUS20030121603A1Easy to handleEasy to mass produceAdhesive processesFinal product manufacturePolymer electrolytesFuel cells

A manufacturing method of Membrane-Electrode-Gasket Assemblies (MEGAs) used for polymer electrolyte fuel cells (PEFCs) is described wherein a polymer electrolyte membrane is formed directly on a electrode. A typical PEFC is constructed by assembling membrane-electrode assembly (MEA), gaskets, and separators. According to the invented method, PEFC is fabricated by assembling separators and MEGA, into which MEA and a gasket are integrated. Compared to the conventional MEA-gasket assemblies, MEGAs are easy to handle and can be mass-produced via a manufacturing process in a series. Moreover, employing MEGAs improves PEFC performance since the membrane thickness of MEGAs is lower than that of the conventional MEA-gasket assemblies.

Owner:HYUNDAI MOTOR CO LTD

Polyolefin microporous membrane and method of evaluating the same

The invention relates to a microporous membrane, which is provided with high safety even under a condition that the interior temperature of a battery becomes high, and which has high permeability and high mechanical strength at the same time. The polyolefin microporous membrane is characterized by a membrane thickness of 5 to 50 μm, a void content of 30 to 60%, a gas transmission rate of 40 to 300 sec / 100 cc / 20 μm, a piercing strength of not less than 2.5 N / 20 μm and a break through temperature of not lower than 110° C. The separator in accordance with the present invention is used to exhibit high safety under a high temperature condition as well as high permeability, and therefore it is particularly useful as a separator for miniaturized high capacity batteries of a non-aqueous electrolytic solution type.

Owner:ASAHI KASEI CHEM CORP

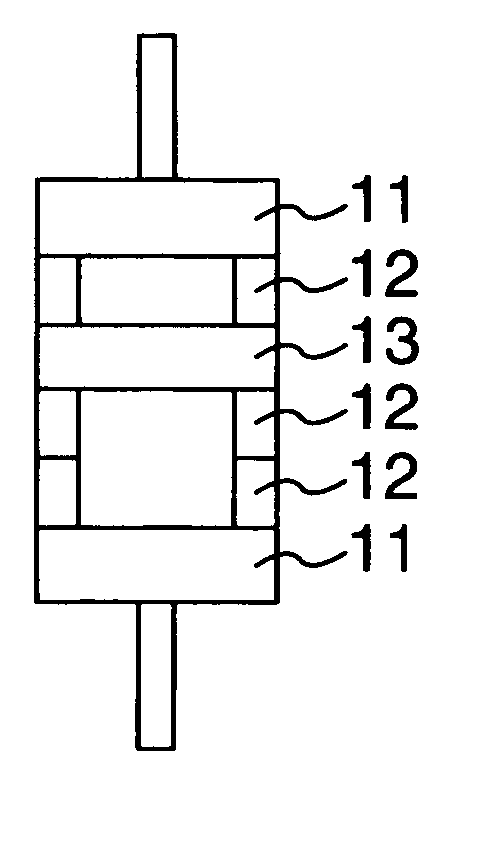

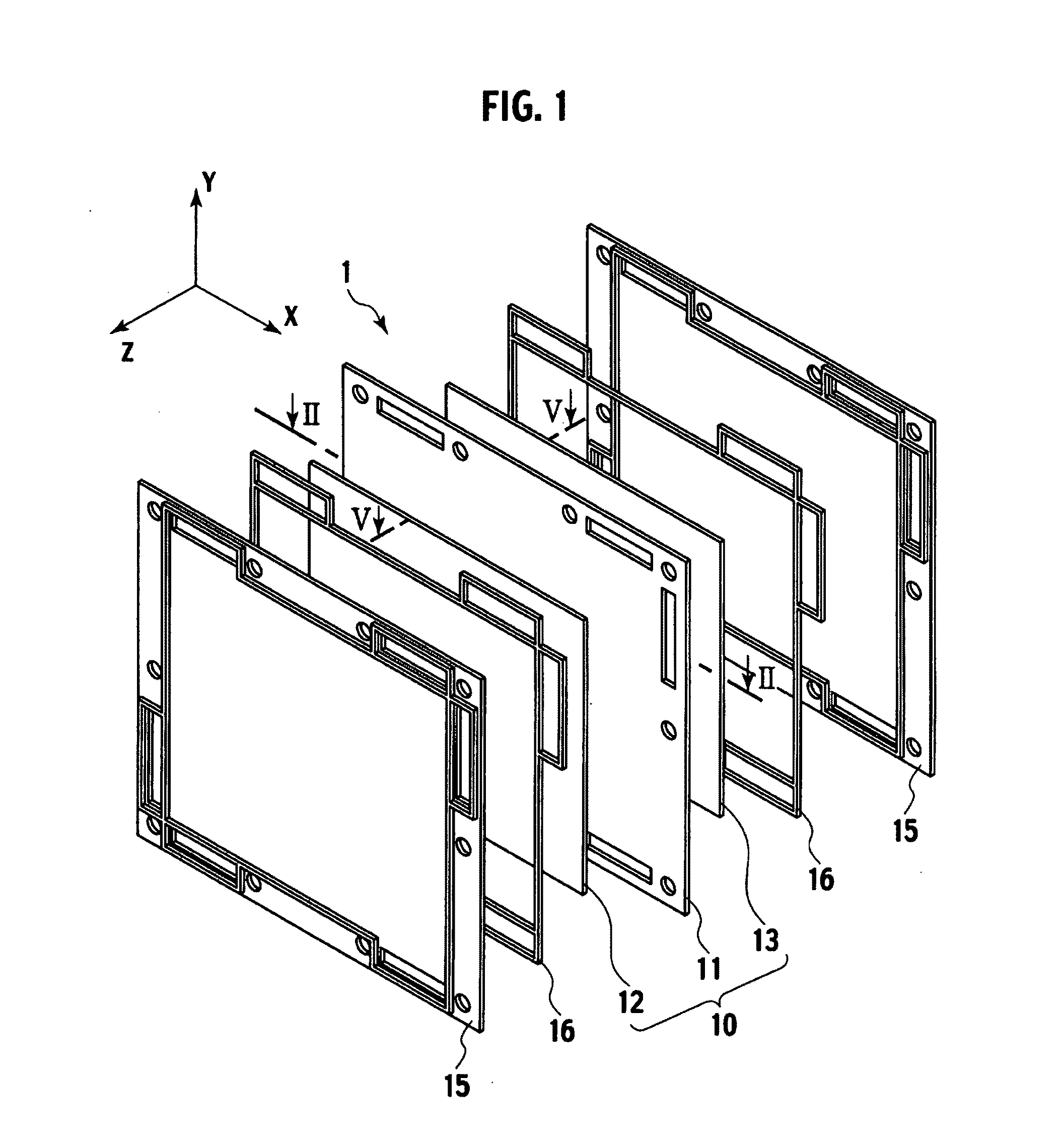

Electrolyte membrane and membrane electrode assembly using the same

InactiveUS20100143823A1Relieve pressureIncreased durabilityElectrolyte holding meansSolid electrolytesPolymer electrolytesSwelling ratio

An electrolyte membrane (11) includes: a filler (20); and a polymer electrolyte (22). A thickness of the electrolyte membrane (11) is 1 micrometer to 500 micrometer, a moisture content thereof is 10 mass % or more, and a ratio of a swelling ratio in a membrane surface direction (xy) thereof and a swelling ratio in a membrane thickness direction (z) thereof satisfies following Expression 1: where Lambda z is the swelling ratio in the membrane thickness direction (z), and Lambda xy is the swelling ratio in the membrane surface direction (xy).λxyλz<0.3[Math.1]

Owner:NISSAN MOTOR CO LTD

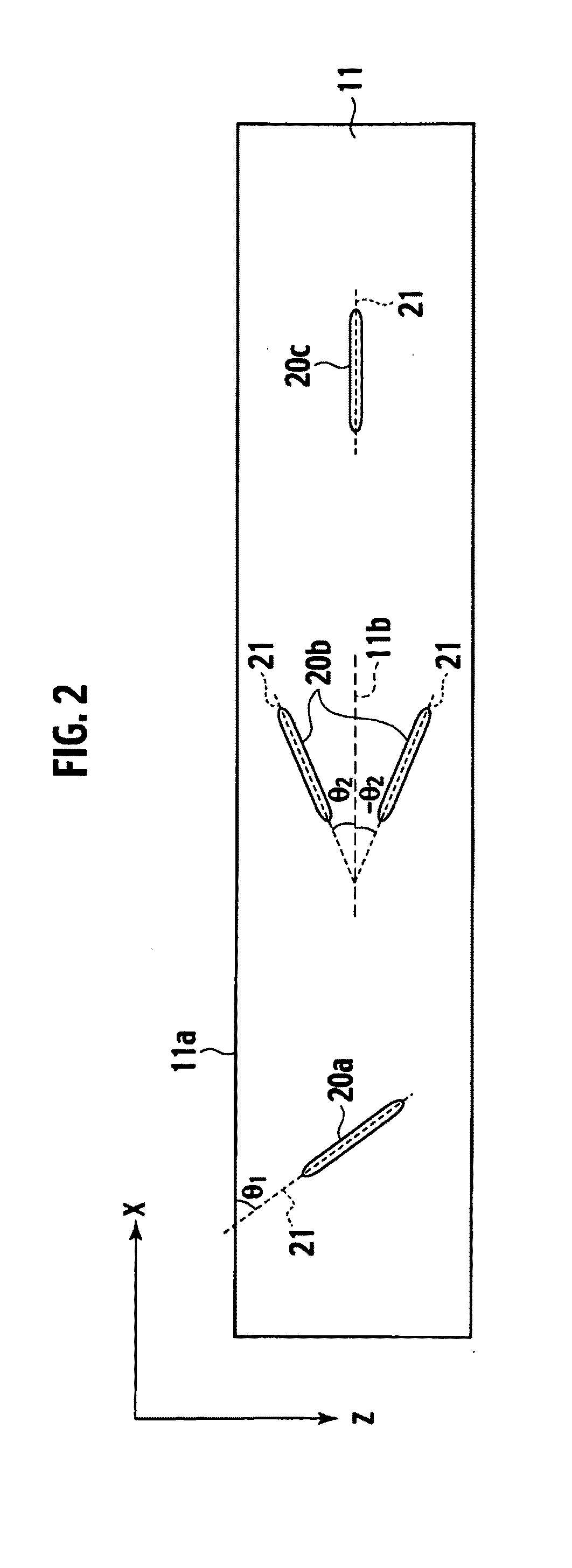

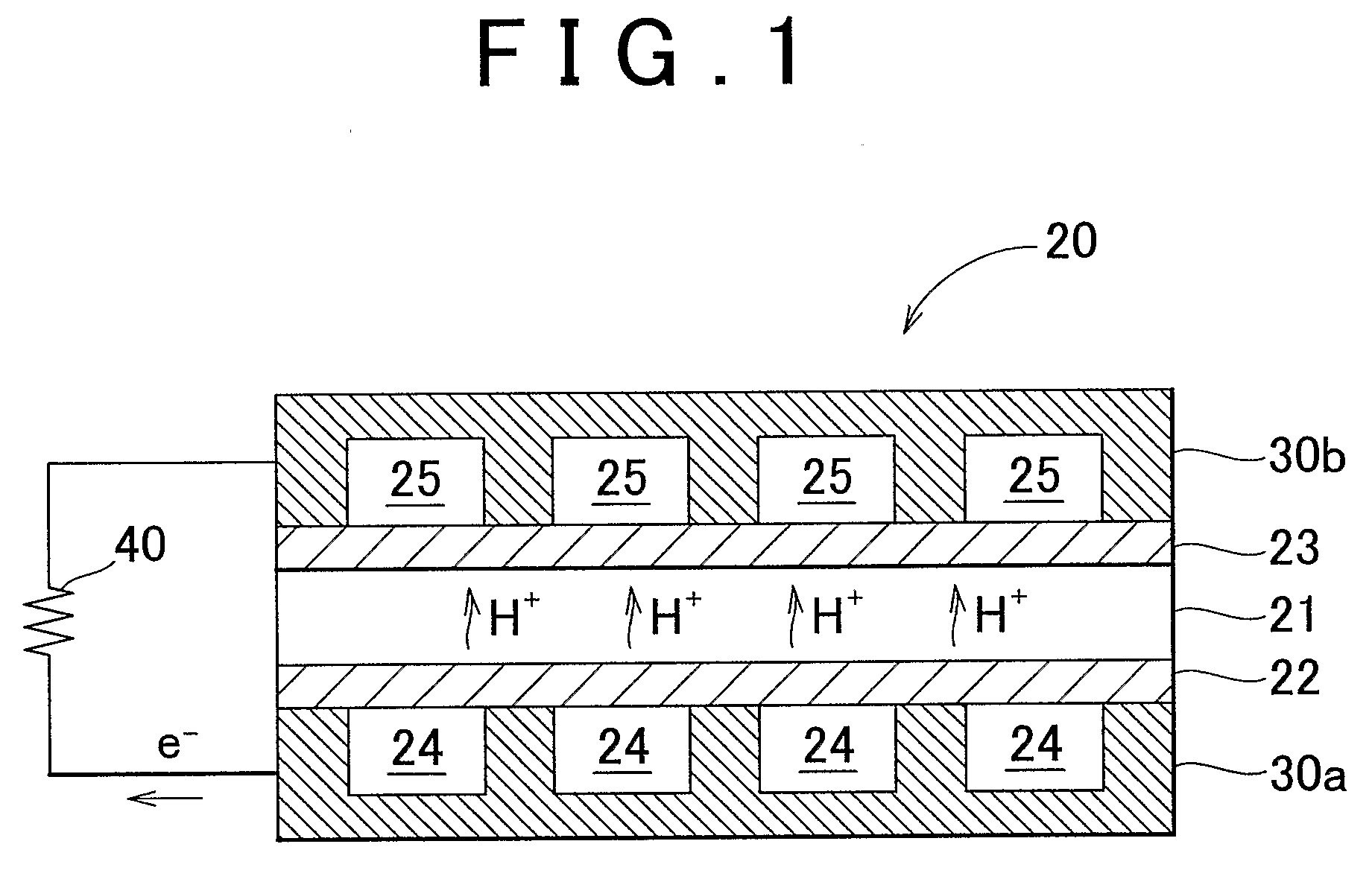

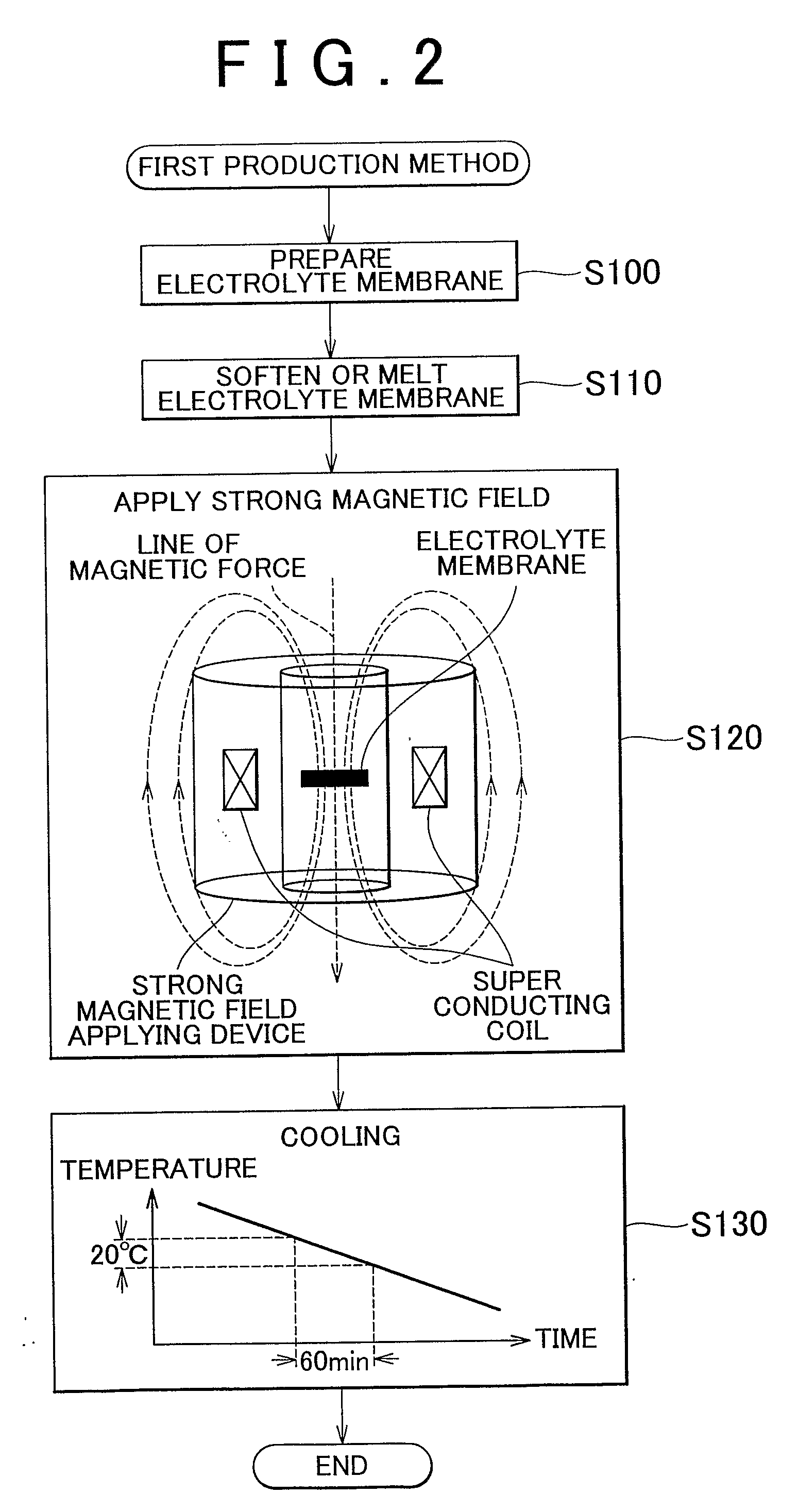

Production Method for Sold Polymer Electrolyte Membrane, Solid Polymer Electrolyte Membrane, and Fuel Cell Including Solid Polymer Electrolyte Membrane

InactiveUS20080248356A1Improve power generation efficiencyEasy to produceFinal product manufactureSolid electrolyte fuel cellsPolymer electrolytesFuel cells

The performance of an electrolyte membrane (21) is improved by imparting aeolotropy to physical properties of the electrolyte membrane (21). A first state solid polymer electrolyte membrane (21) containing a polymer having an ion-exchange group is softened, melted of dissolved, whereby a second state solid polymer electrolyte membrane (21) is formed. Then, the second state solid polymer electrolyte membrane (21) is cooled, while a strong magnetic field is applied to the second state solid polymer electrolyte membrane (21) in a predetermined direction, whereby the second state solid polymer electrolyte membrane (21) is hardened or solidified. As a result, the ion-conductivity in a membrane thickness direction can be improved in a fluorinated electrolyte membrane, and swelling in the membrane surface direction can be suppressed in an aromatic hydrocarbon electrolyte membrane.

Owner:TOYOTA JIDOSHA KK

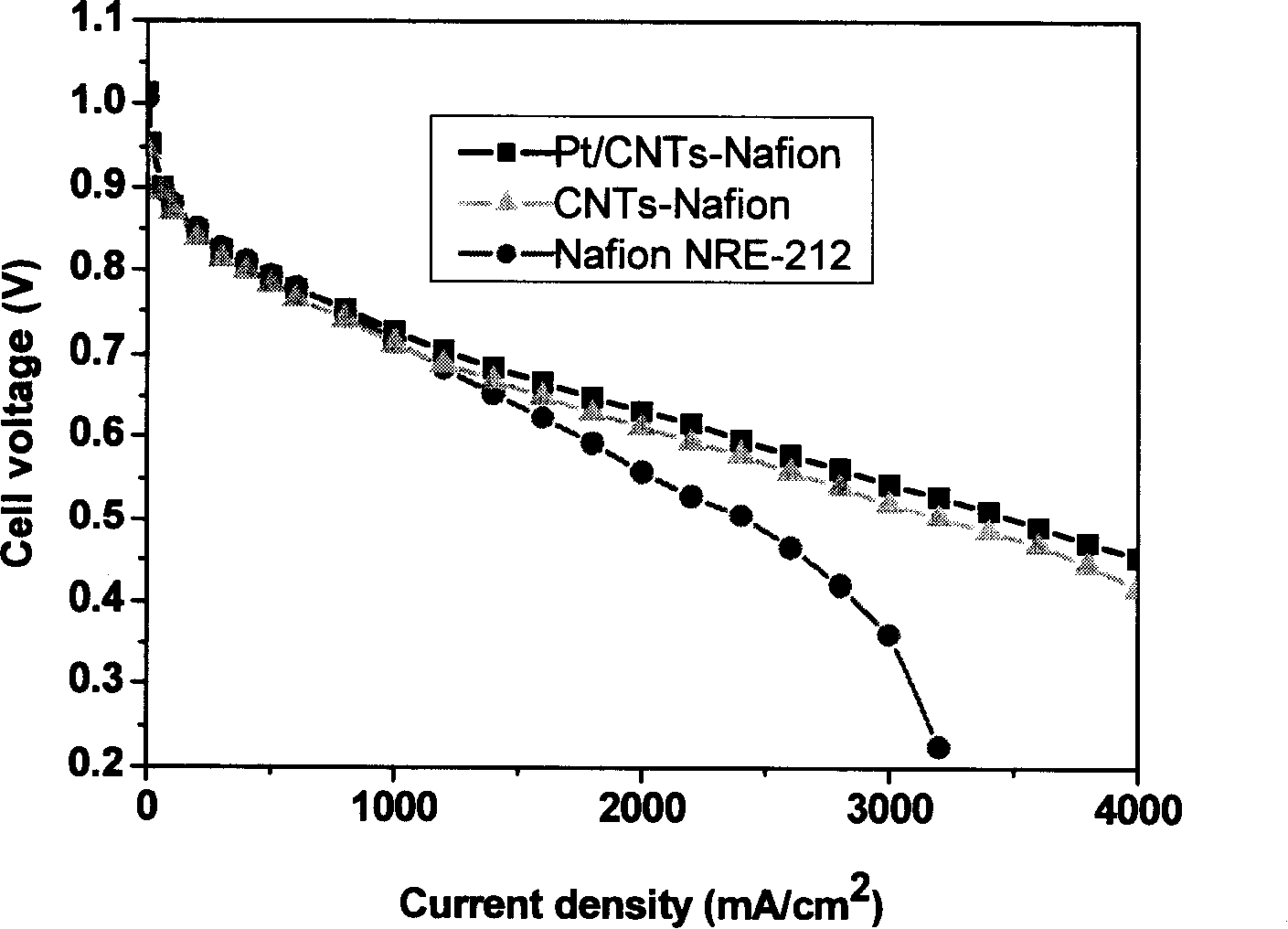

A carbon nano tube enhanced self-humidity increase compound proton exchange film and its preparation

ActiveCN101170183AEasy to operateHigh strengthFinal product manufactureSolid electrolyte fuel cellsNano sio2Carbon nanotube

The invention relates to a fuel cell, in particular to a self-humidifying combined proton exchange membrane for a strengthening fuel cell based on a carbon nanotube and a preparation method thereof, which comprises the following steps: a solution casting method is utilized to prepare and obtain a strengthened perfluorosulfonic resin membrane of the carbon nanotube, and Pt is introduced into the membrane as self-humidifying catalyst, wherein, Pt can be directly carried on the carbon nanotube or carried on nano SiO2 particle, and the prepared membrane is 10-100 [mu]m thick. The prepared combined membrane thickness and nanotube content can be easily controlled, the manufactured membrane surface is level and smooth, not ventilate, has no short-circuit with good intensity, has better cell performance on self-humidifying operation, and can be safely applied to the fuel cell.

Owner:SUNRISE POWER CO LTD

Method for producing liquid core microcapsule by electrostatic spraying

InactiveCN101152623AUniform particle sizeGood encapsulation performanceMicroballoon preparationMicrocapsule preparationCelluloseSprayer

The invention provides a method for preparation of liquid core microcapsule with static sprayer: calcium chloride solution of 2-3 percent is mixed with thickening agent and then is uniformly mixed with core material substance; a certain amount of mixed solution is taken out and then is put into solution containing sodium alginate of 0.6-1.5 percent with static sprayer while adopting a flat needle for adhesive deposite or an injection needle as a nozzle; after capsulated, liquid core sodium alginate microcapsule is filtered and then is cleaned with purified water; then liquid core sodium alginate microcapsule is put into calcium chloride solution for continuous solidification of 5-10 minutes; then microcapsule is filtered and then is cleaned with purified water; at last microcapsule is stored in storage solution with calcium ion concentration of 0.05-0.01 percent. High viscosity malt dextrin or sodium carbonxymethyl cellulose or xanthan gum is adopted as thickening agent. Microcapsule prepared with the invention has liquid core, with uniform particle size, good sacculation performance, simple process and high membrane thickness, therefore, microcapsule has high mechanical strength and can be widely used in the field of pharmaceutical chemical engineering, artificial organ implantation and food processing, etc.

Owner:UNIV OF SHANGHAI FOR SCI & TECH +1

High efficiency multifunctional membrane and filter plate with long service life, and forming method

InactiveCN101091845AAchieve ultra-thinAchieving flexibilityDomestic articlesFiltration separationEngineeringMembrane thickness

The invention relates to a structure of directly molding the membrane injection moulding on the filter pan and its molding method, it includes filter core, a filter core is put into the mould, directly injecting- moulding the fusion plastic on the one face or two faces or all faces of the filter core, and composing the membrane or membrane filter or filter pan. The merit: First, founding new structure and the new method in the filter board core directly; second, injection moulding the membrane and the filter pan, avoid drilling, two order scraps, bevel edge, deburring and so on crafts, saving the labor,and time,and has high efficiency, and the fitting grade and the seal reliability of the two reached to 100% initiated; third, realizing the ultra-thin, flexibility of the membrane thickness; fourth, using the release agent and anti-tack coat as the mold core of tympanic membrane squeezing cavity.

Owner:朱兴源

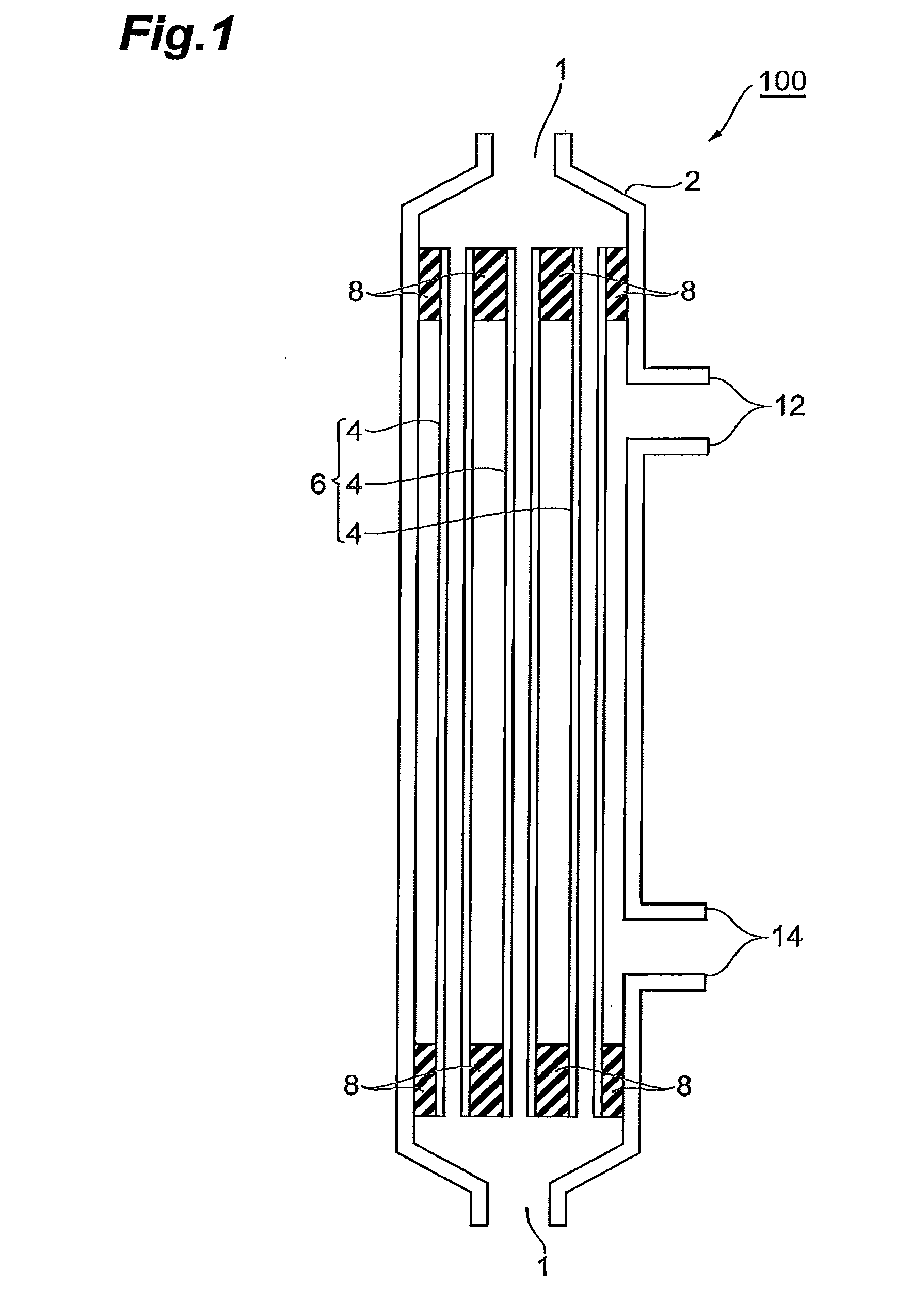

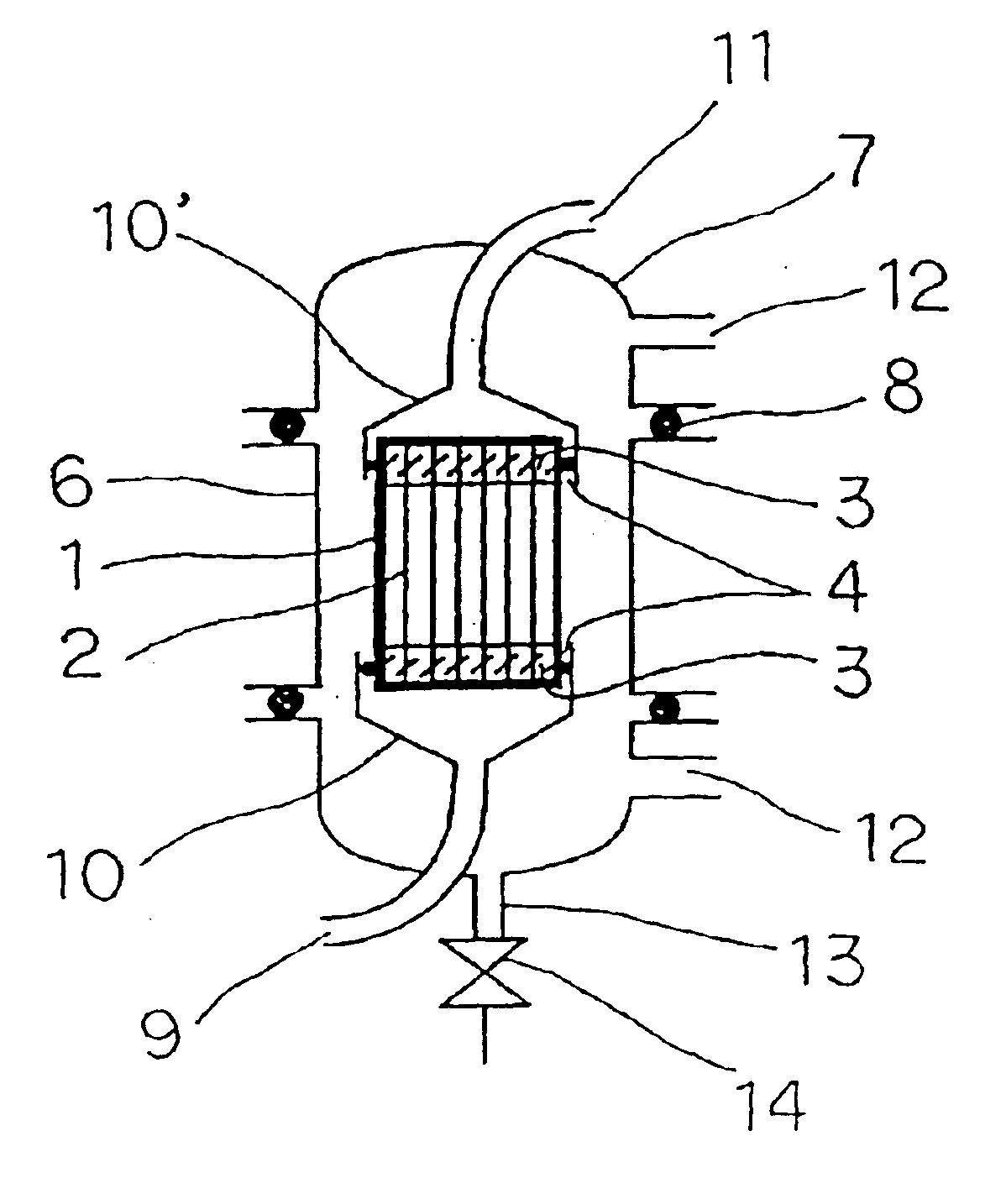

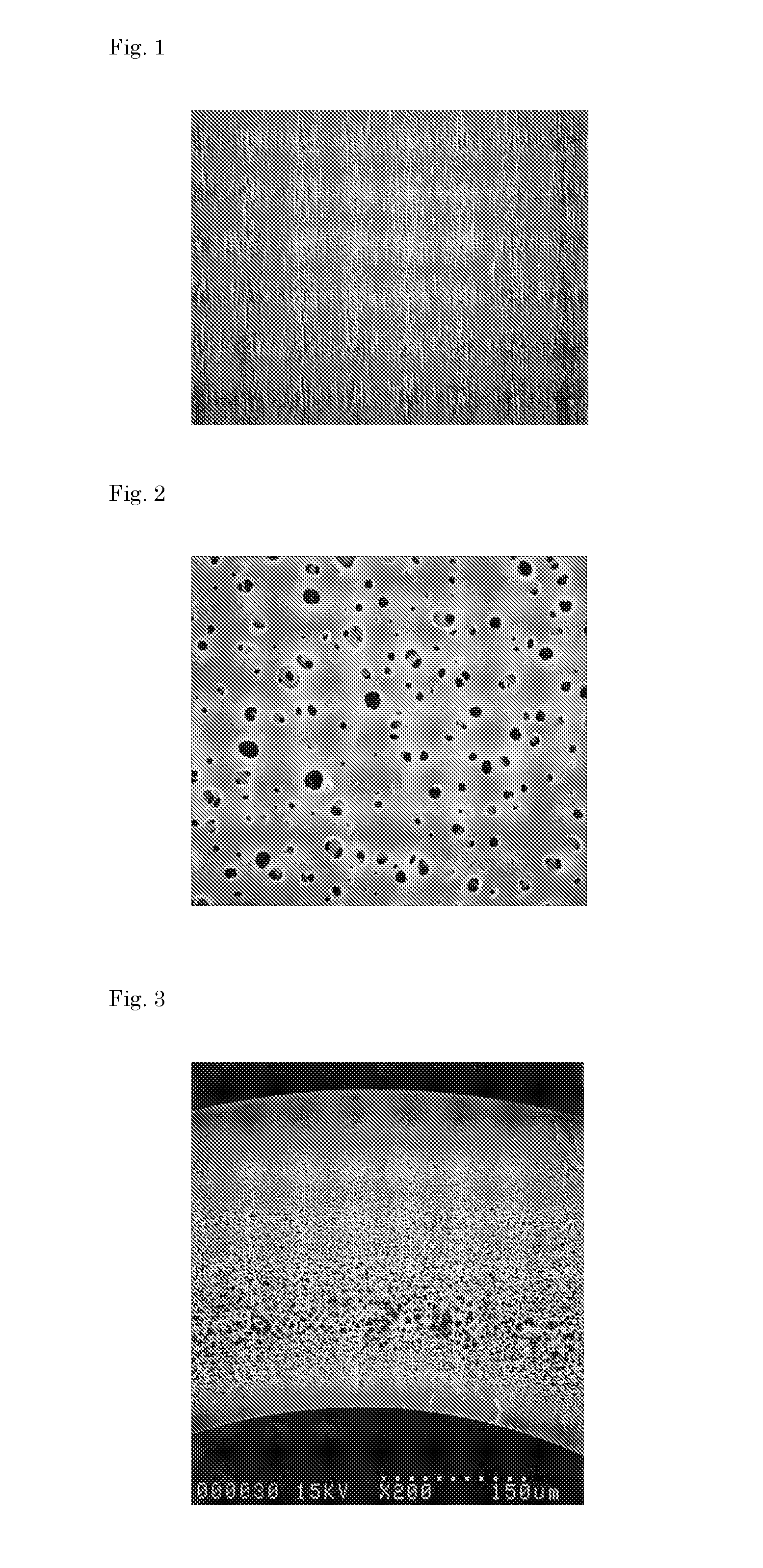

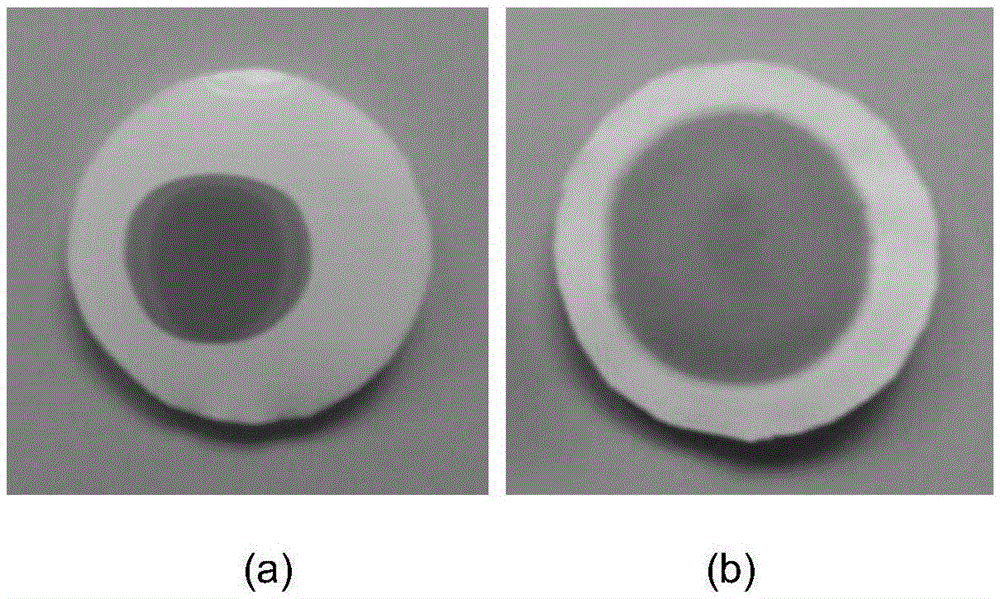

Porous hollow fiber membrane for treating blood

ActiveUS20100258496A1Improve mechanical propertiesNot easy to mechanical damageMembranesDialysisFiberHollow fibre membrane

It is intended to provide a porous hollow fiber membrane for treating blood which suffers from little mechanical damage in the course of production, transfer or handling and shows excellent fractionation properties though it is a thinned polysulfone-based hollow fiber membrane. A porous hollow fiber membrane for treating blood which comprises a polysulfone-based polymer and polyvinylpyrrolidone and has a gradient porous structure with an increase in pore size from the inside to the outside along the membrane thickness direction, characterized in that the porous structure has a membrane thickness of 25 μm or more but less than 40 μm, and fibrils having an average diameter of from 100 to 200 μm are provided in such a manner that the ratio (To / Ti) of the average outside diameter (To) along the membrane thickness direction to the average inside diameter (Ti) is adjusted to not more than 2.

Owner:ASAHI KASEI MEDICAL CO LTD

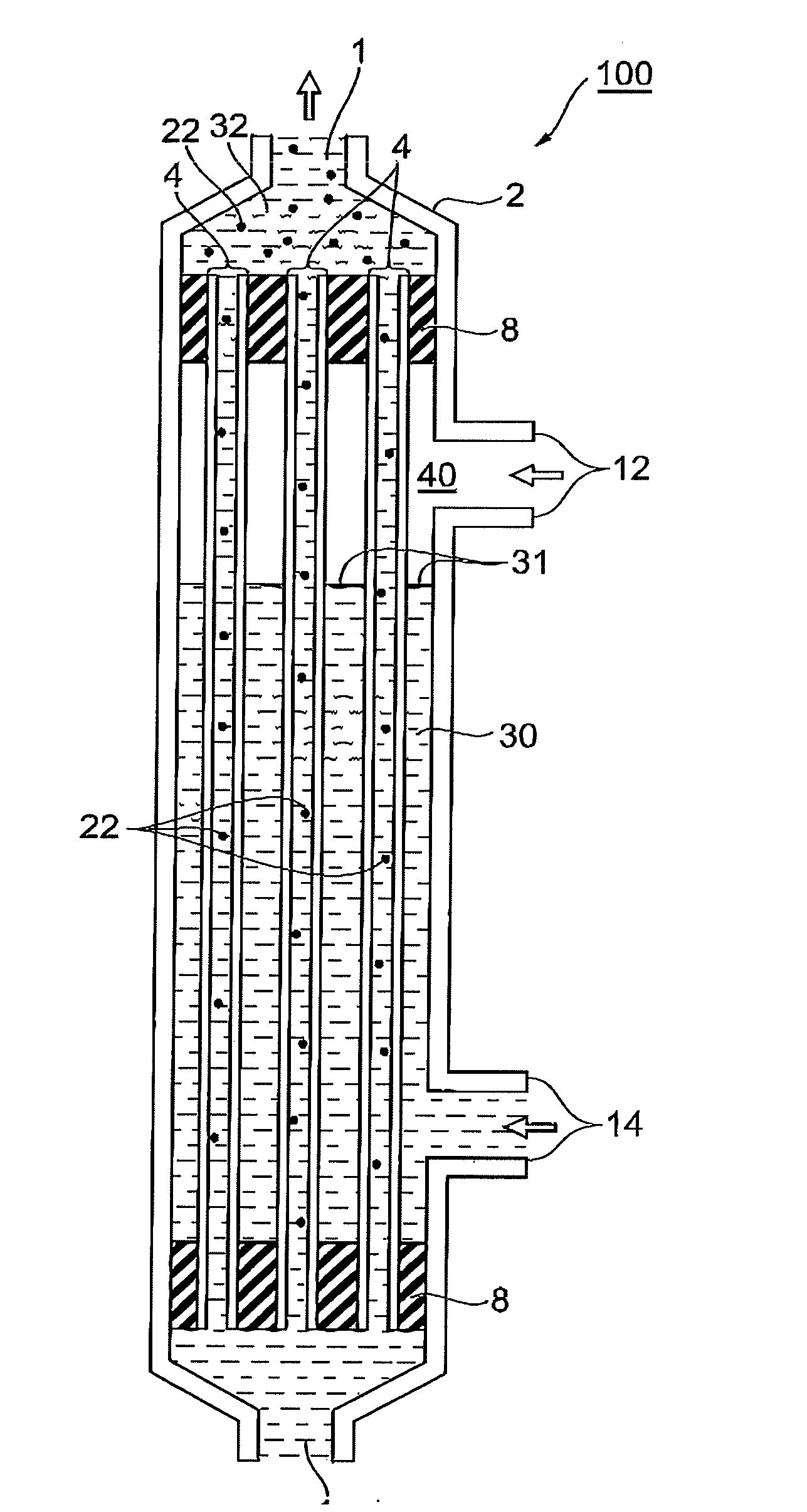

Use of porous hollow-fiber membrane for producing clarified biomedical culture medium

ActiveUS20110210067A1Efficient productionSufficient clarificationMembranesSemi-permeable membranesFiberHollow fibre membrane

Use of a porous hollow fiber membrane for producing a clarified biomedical culture medium by a method including a filtration step of distributing a biomedical culture medium over the porous hollow fiber membrane, a tube wall of the hollow fiber membrane being constituted of a blend of a hydrophobic polymer and polyvinylpyrrolidone. A content of the polyvinylpyrrolidone is not lower than 0.2% by mass and not higher than 3% by mass relative to a total mass of the porous hollow fiber membrane, and, when the tube wall is divided in a membrane-thickness direction equally into three regions, a content of the polyvinylpyrrolidone in an outer circumferential region including an outer face is higher than a content of the polyvinylpyrrolidone in an inner circumferential region including an inner face, and an average pore size in the inner face is larger than an average pore size in the outer face.

Owner:ASAHI KASEI CHEM CORP +1

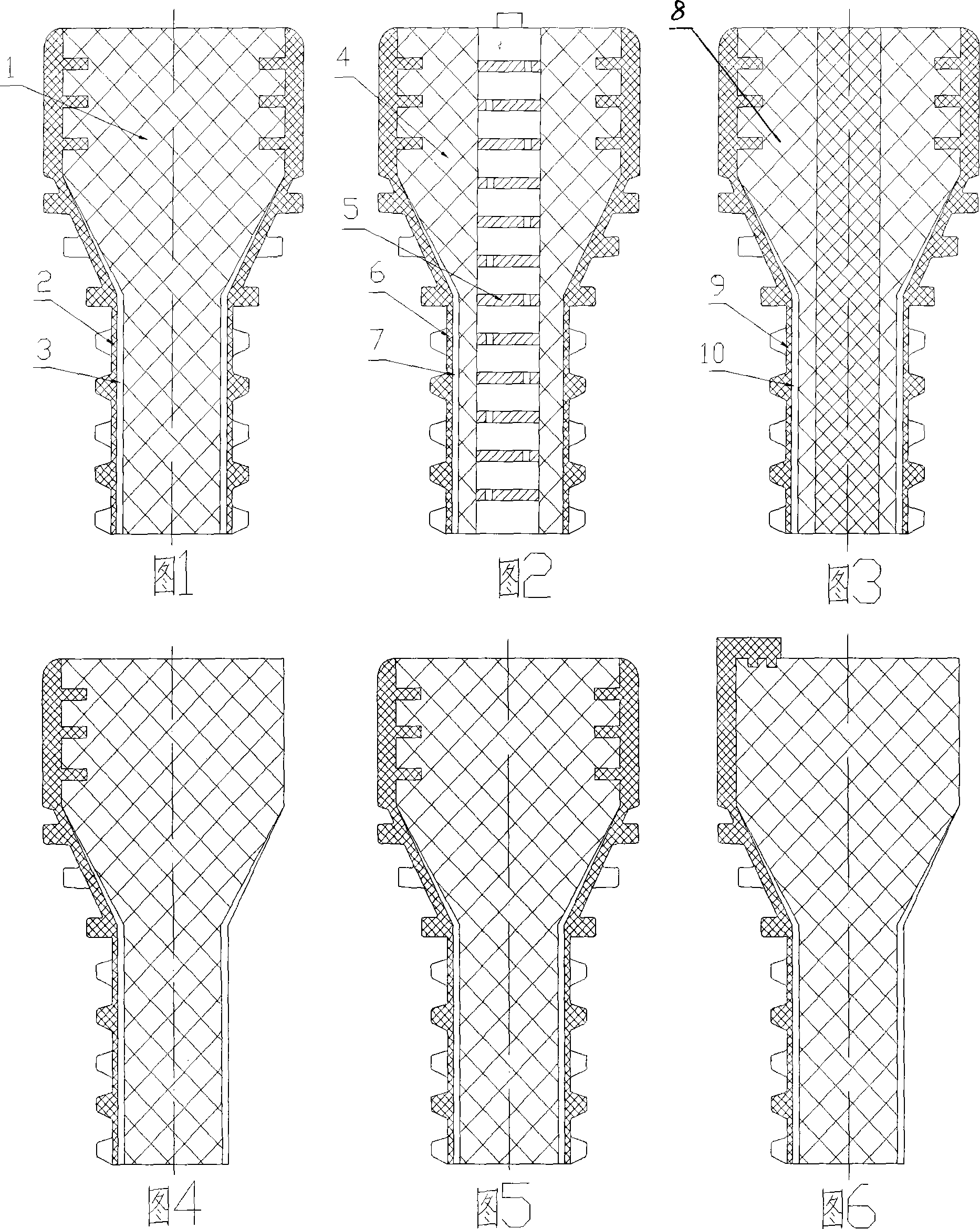

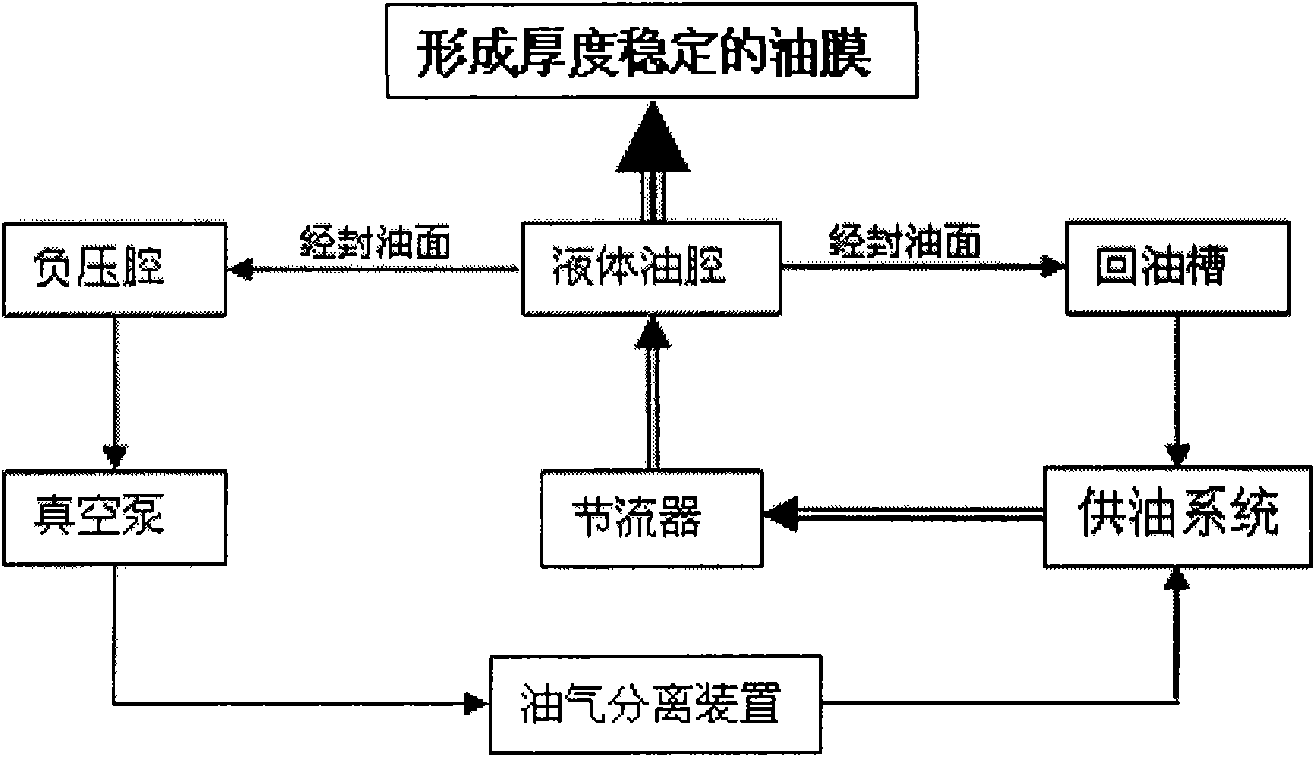

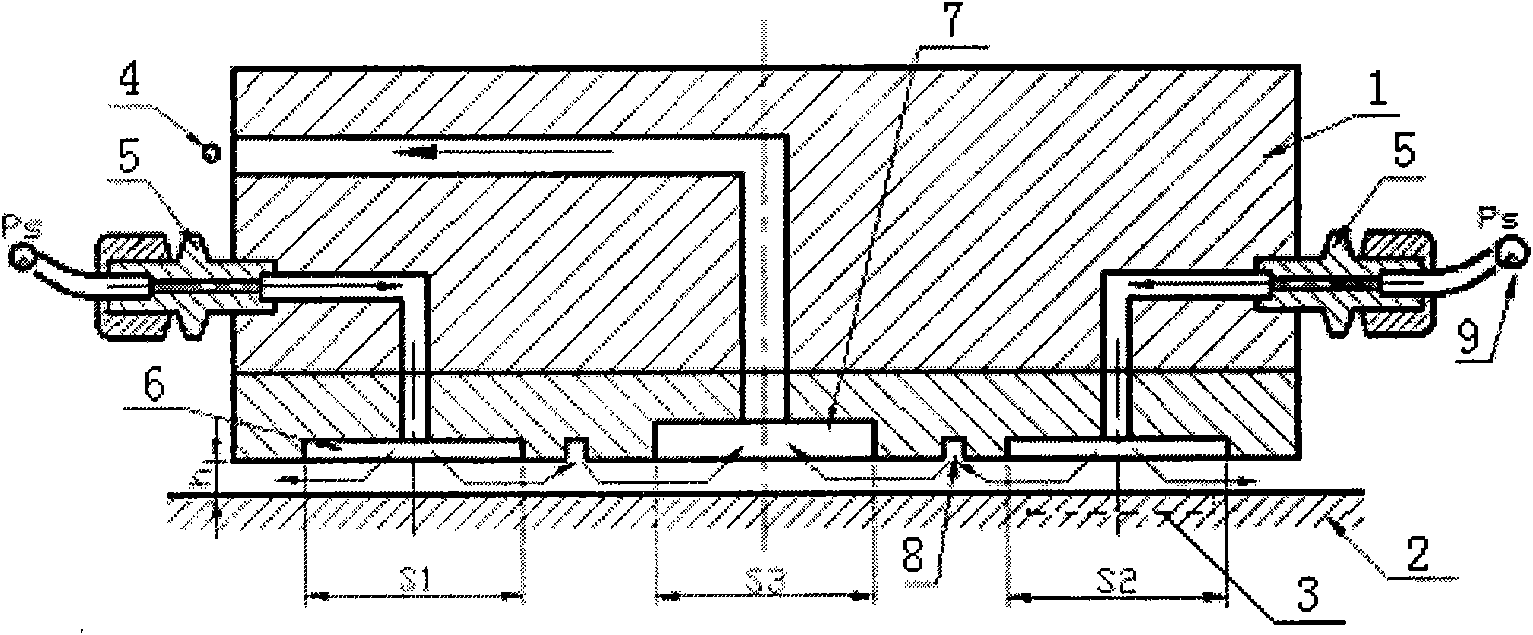

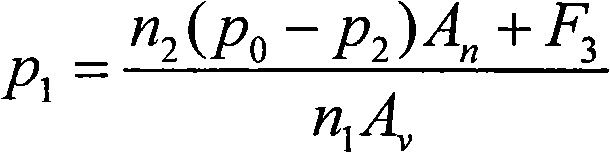

No-drifting high accurate open type static pressure guide rail

The invention relates to a no-drifting high accurate open type static pressure guide rail, which comprises a floating guide rail (1) and a supporting guide rail (2); the floating guide rail (1) is placed on the supporting guide rail (2); a static pressure oil chamber (6) and a negative pressure chamber (7) are formed on the contacting surface of the floating guide rail (1) and the supporting guide rail (2); an oil supply system (9) is connected to the static pressure oil chamber (6) by a restrictor (5); the negative pressure chamber (7) is connected with the vacuum pump (4); the vacuum pump is connected with the fuel supply system (9) by a oil gas separator; and a oil-returning groove connected with the oil supply system (9) is formed between the floating guide rail (1) and the supporting guide rail (2). The invention is simple and practicable, increases oil membrane rigidity, can regulate the oil membrane thickness by the vacuum pump, can be widely applied in open type static pressure guide rails with various structures, especially small and middle low load precision or super-precision machine tools such as precision roll grinding machine and sophisticated planer which are limited by the problem of drifting.

Owner:DONGHUA UNIV

Polymer membrane for fuel cell, method of preparing same, and membrane-electrode assembly for fuel cell comprising same

InactiveUS20070117000A1Improve stabilityElectrolyte holding meansIon-exchanger regenerationFuel cellsProton

The polymer electrolyte membrane of the present invention includes polymers having a fluoroalkyl group and a proton conductive group. The present invention also provides a membrane-electrode assembly, a fuel cell system including the polymer electrolyte membrane, and a method of making the polymer electrolyte membrane by a chemical grafting method. The amount of the proton conductive groups in the polymer electrolyte membrane can be controlled, the membrane thickness can be easily controlled, adherence between a polymer electrolyte membrane and an electrode is improved due to the fluoroalkyl of the polymer, and long-term stability of a membrane-electrode assembly is improved.

Owner:SAMSUNG SDI CO LTD

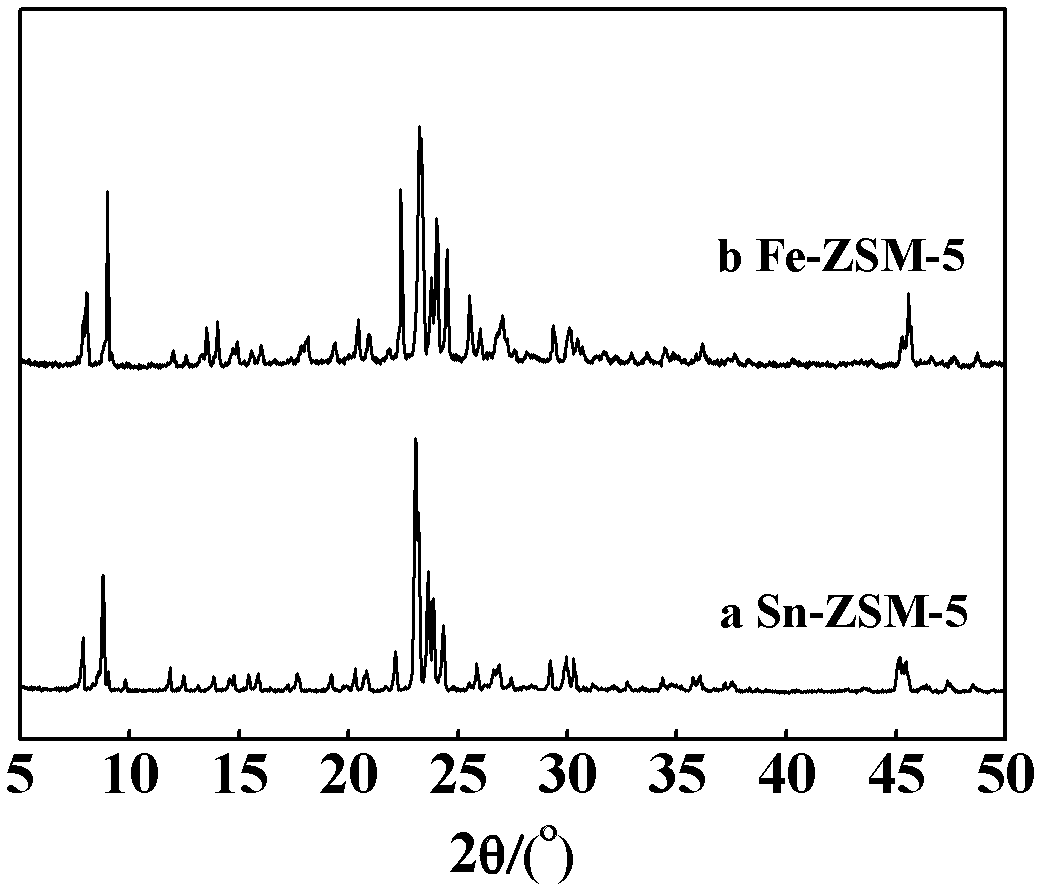

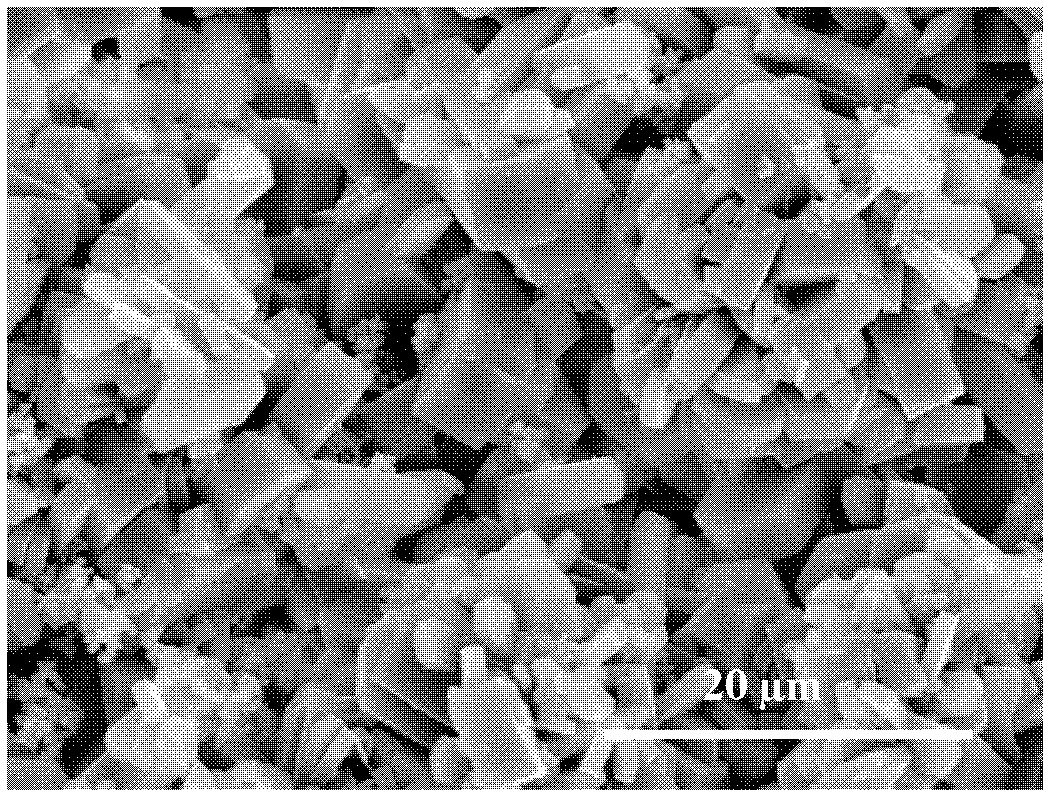

Metal element modified ZSM-5 molecular sieve composite membrane as well as preparation method and application thereof

ActiveCN102350229AHigh selectivityAdjustable thicknessSemi-permeable membranesMolecular sieveMembrane thickness

The invention provides a ZSM-5 molecular sieve composite membrane, comprising a separation layer and a support layer, wherein the separation layer is a metal element modified ZSM-5 molecular sieve; and metal elements are selected from Fe, Al, Sn, Ca, Ni, Cu, Mg, Ge, Zn or Zr and is respectively from metal compounds containing the metal elements. The metal element modified ZSM-5 molecular sieve composite membrane selectively causes organic matters to penetrate, has the advantages of simple preparation method, high membrane forming speed, easily-controlled membrane thickness and good membrane continuity, is easy to prepare on a large area and is practically applied industrially.

Owner:BEIJING CLP JIAMEI ENVIRONMENTAL PROTECTION TECH

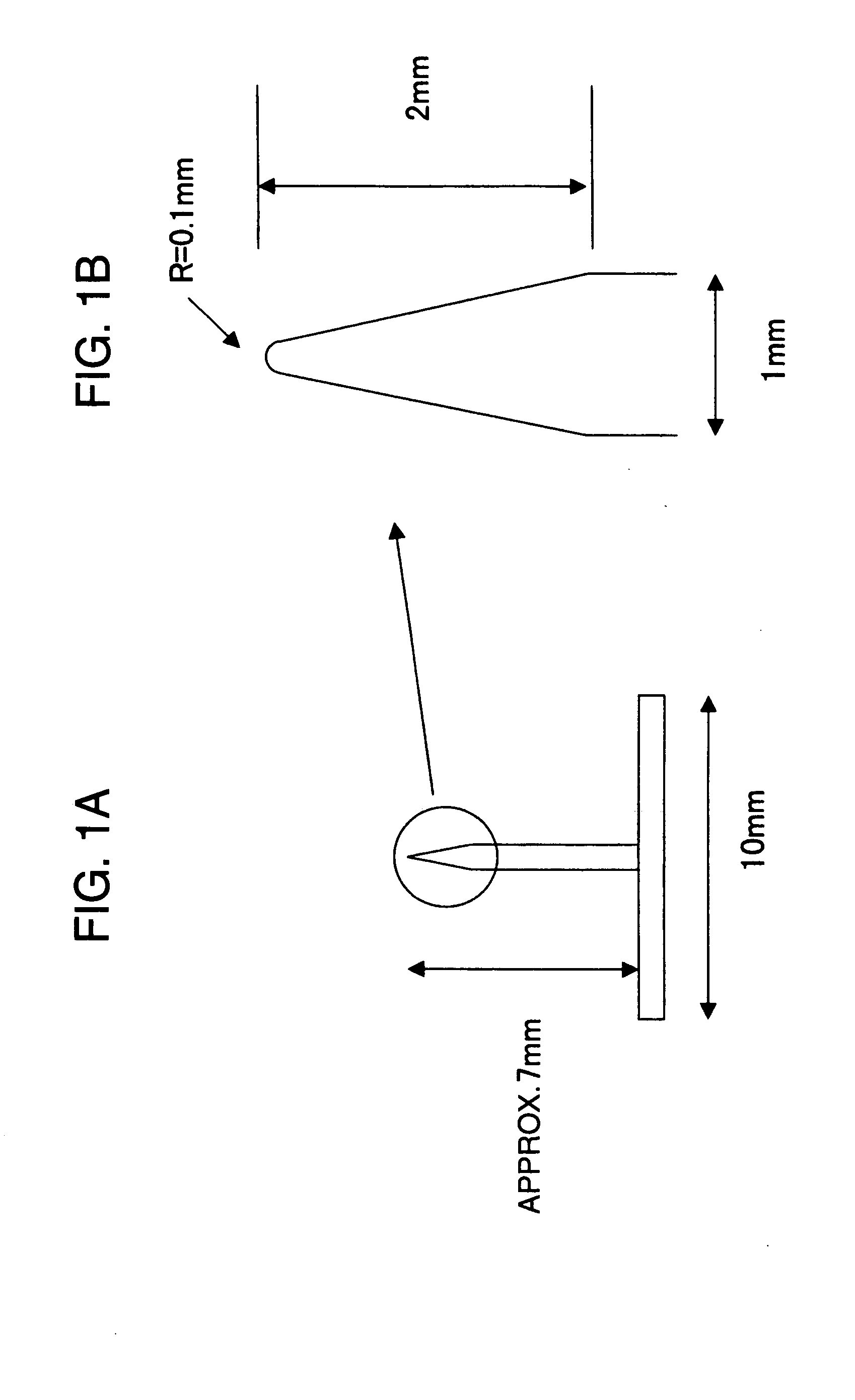

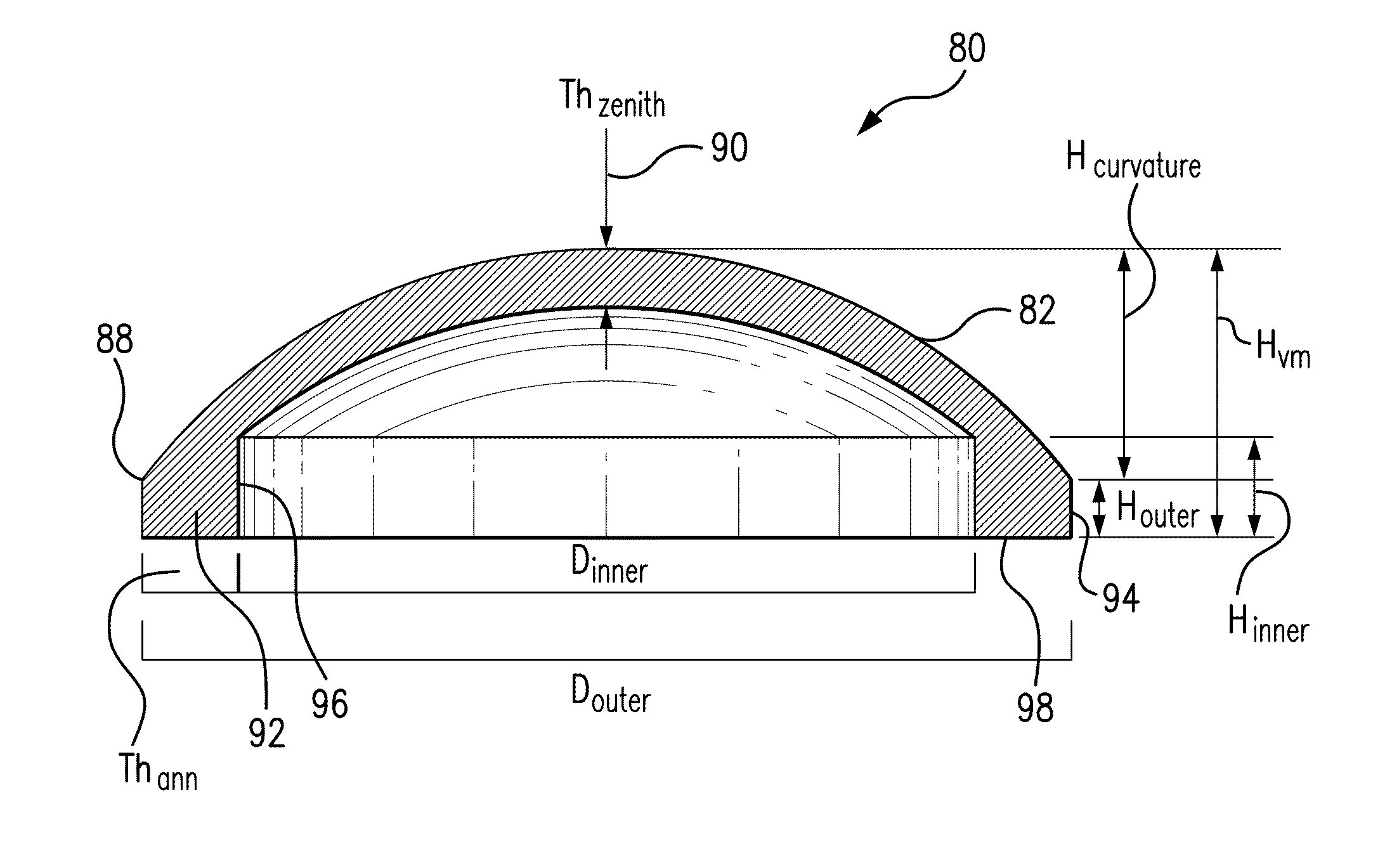

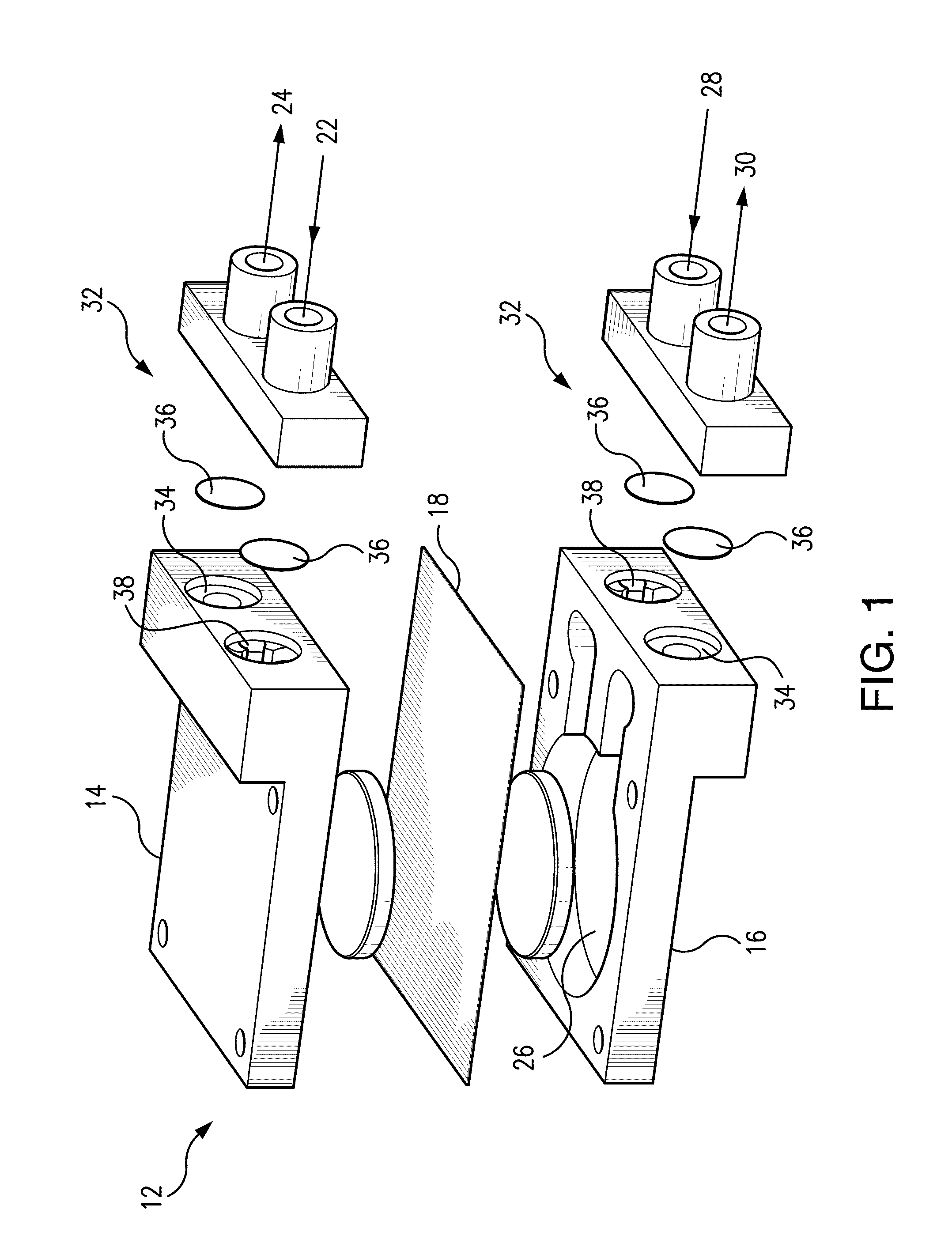

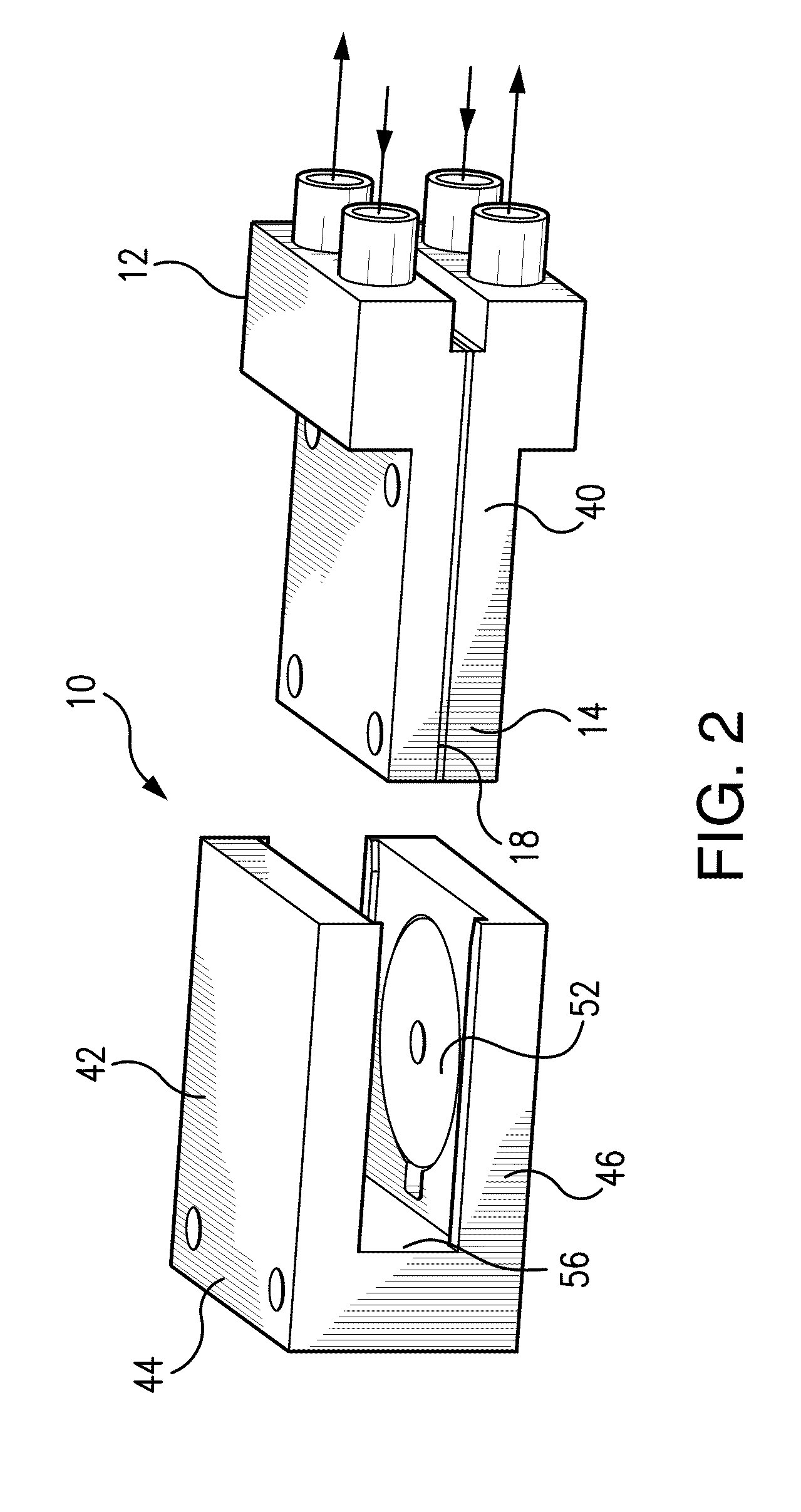

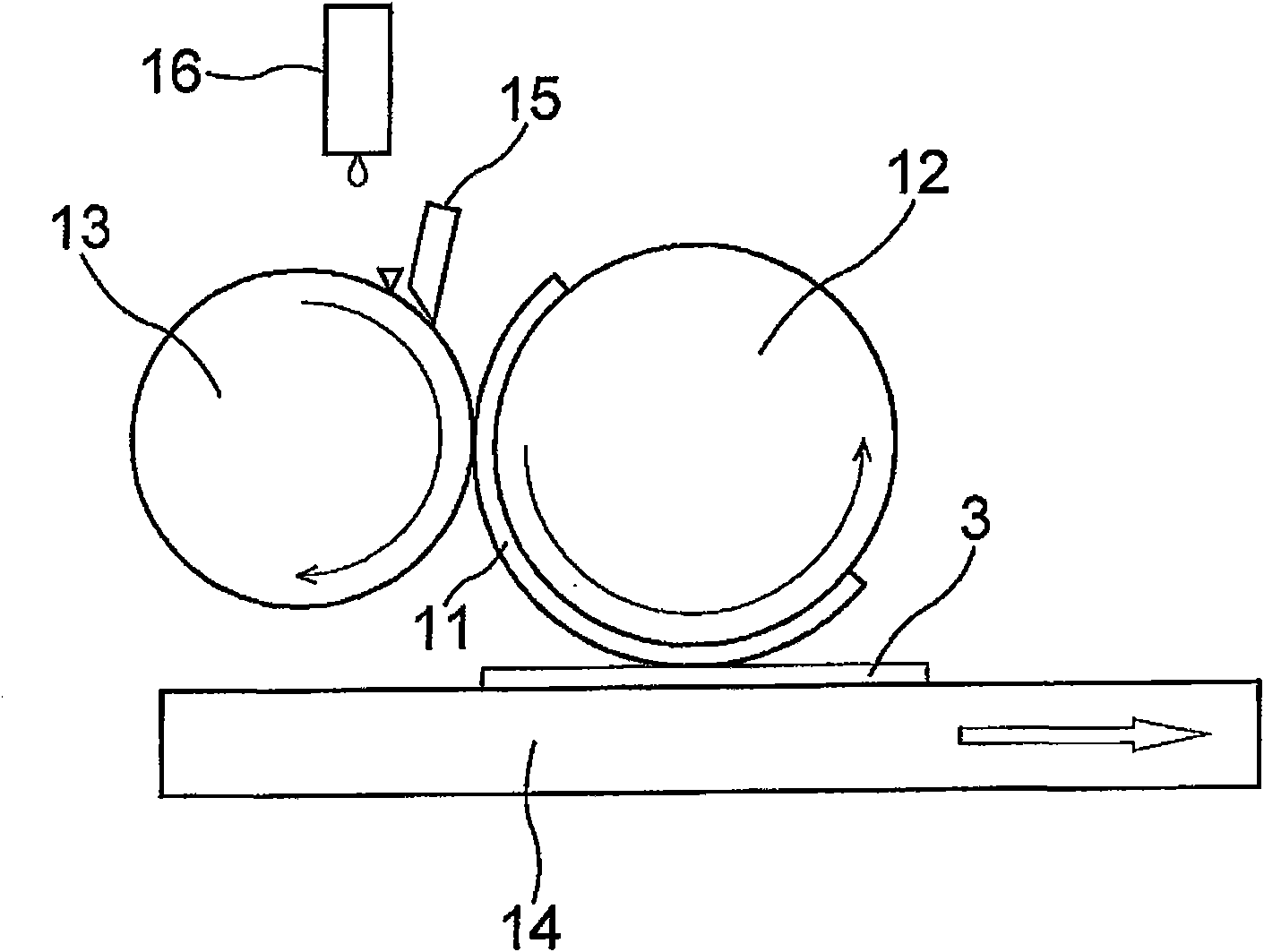

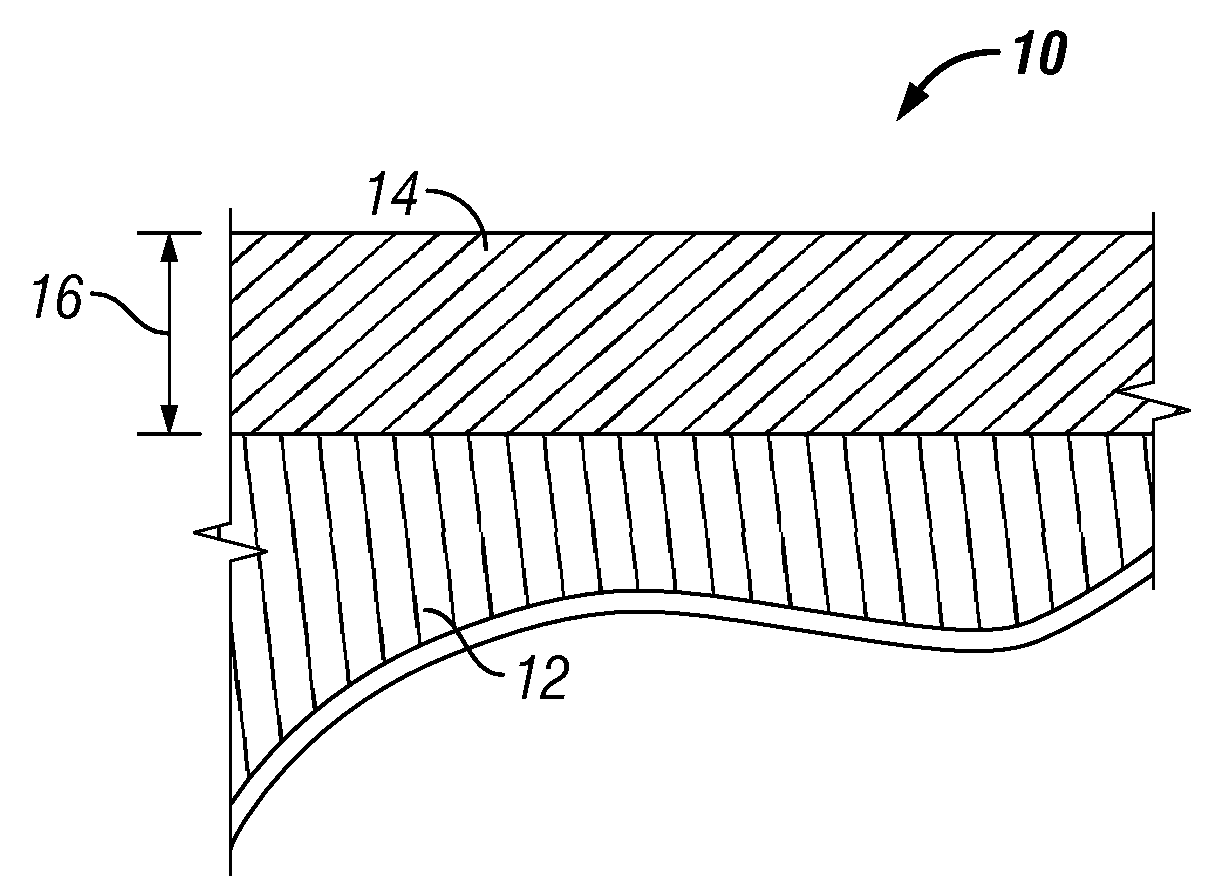

Method of Making a Membrane for Use with a Flow Control System for a Micropump

InactiveUS20110309552A1Prevent backflowEfficient power-consumption profileFlexible member pumpsMedical devicesControl systemMedicine

A method of making a membrane for use with a flow control system is disclosed. A female mold body portion and a male mold body portion are provided. A body portion support member configured to receive at least a portion of the female body portion and at least a portion of the male body portion is provided. The female and male body portions are separated from one another. Membrane manufacturing material is provided to a concave portion of the female mold body portion. The sleeve is moved downward. The lower mold portion is lowered until it is just short of its final intended position. Excess membrane manufacturing material, if any, is removed from around the seam of the mold. The upper mold portion is lowered the remaining distance so that the two mold portions are separated by the exact distance desired for the final membrane thickness.

Owner:PICOLIFE TECH

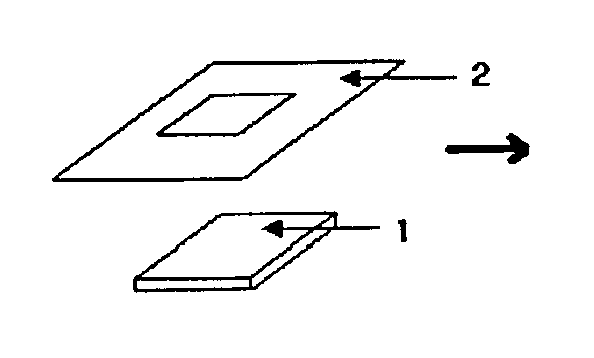

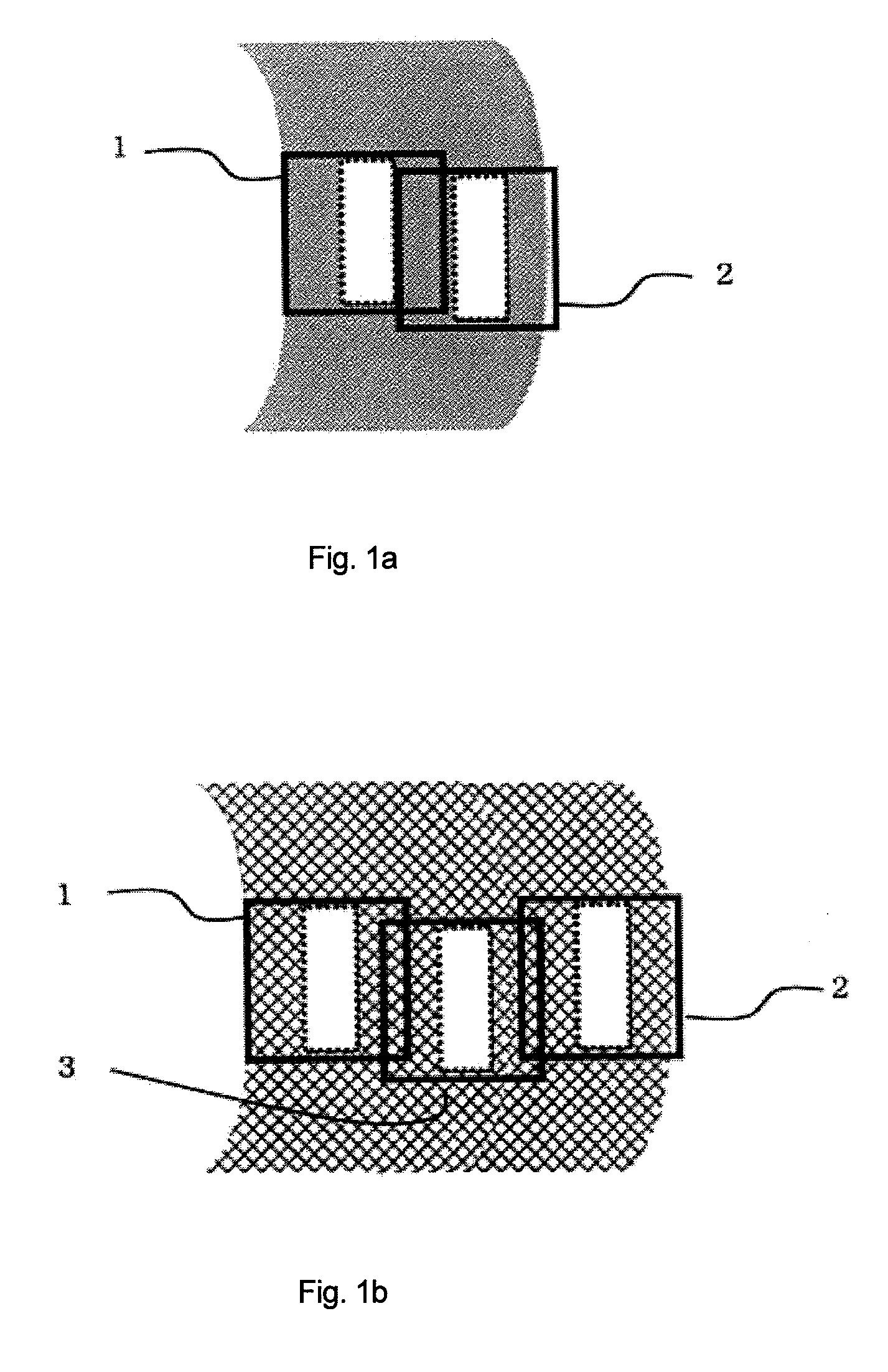

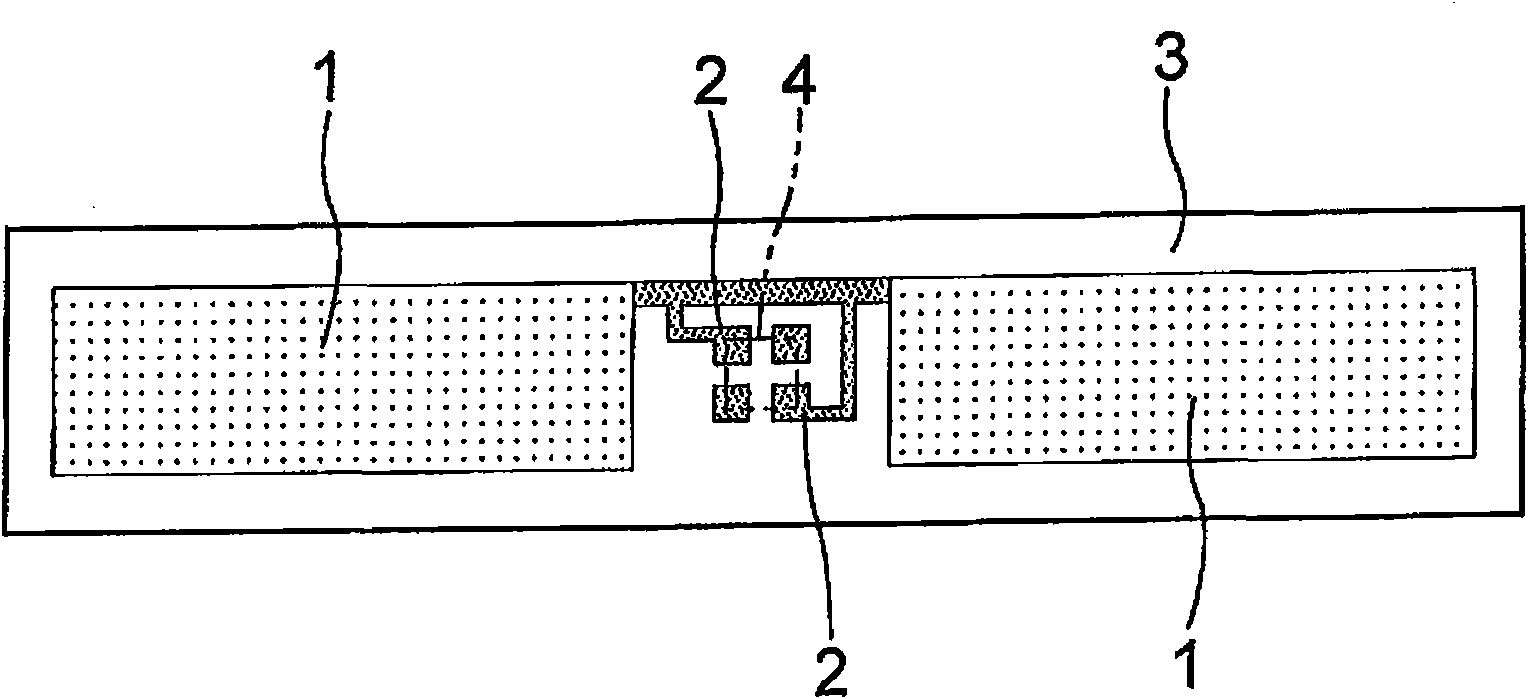

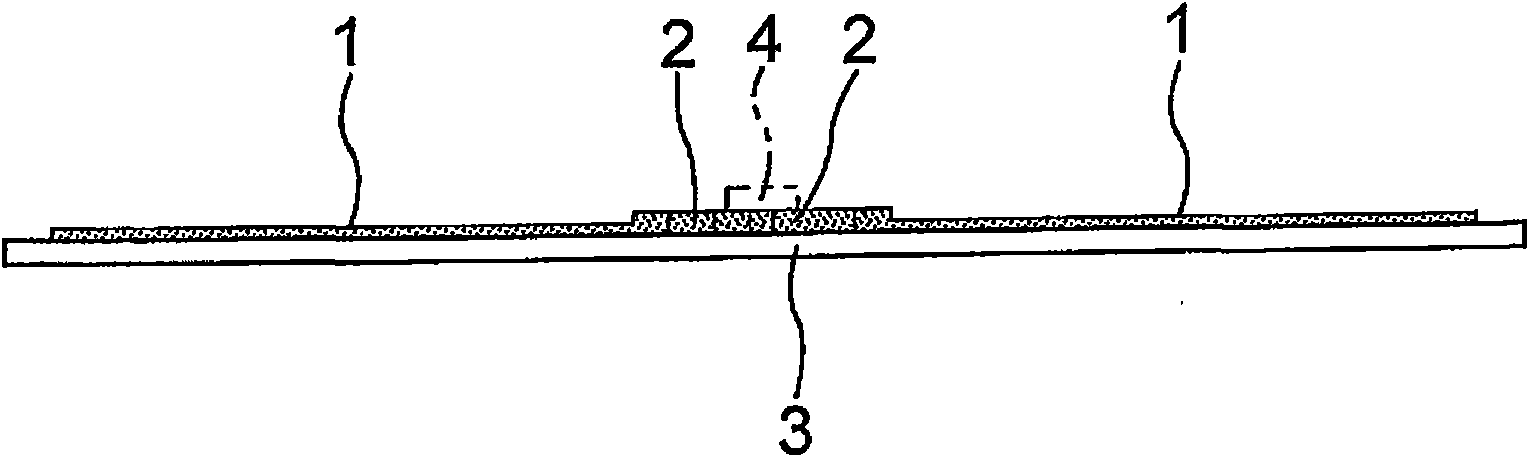

Antenna for ic tag and method of manufacturing the same

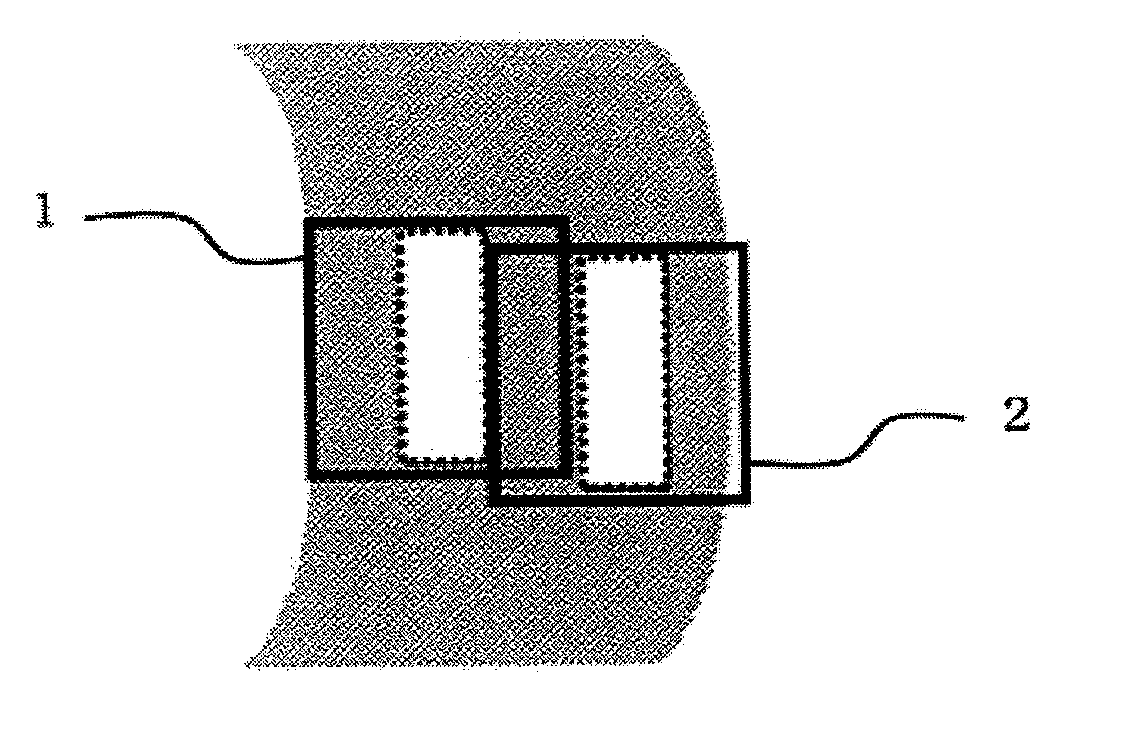

InactiveCN101888014AReduce manufacturing costLess quantityRadiating elements structural formsMetal/alloy conductorsAdhesiveEngineering

The invention provides an antenna for IC tag that has small membrane thickness than the prior products and can reach the necessary low resistance of the non-contact type storage medium, and method of manufacturing the antenna for IC tag at low cost efficiently. A film shape conductive film antenna with specified circuit pattern is formed on the surface of the substrate (3) by using the aqueous conductive ink containing silver particles, adhesive and water, the conductive film antenna includes an antenna part (1) for transmitting and receiving the electromagnetic wave, and an interconnecting piece (2) connected to the IC chip (4).

Owner:PROVIDENT

Gas separation membrane system and a method of preparing or reconditioning and the use thereof

A gas separation membrane system and a method of preparing such gas separation membrane system by providing a porous support upon which is supported a membrane layer comprising a first gas-selective material and having a membrane thickness and removing therefrom a substantial portion of the first gas-selective material from the membrane layer by the use of an ultra-fine abrasive to thereby provide the membrane layer having a reduced membrane thickness. A second gas-selective material is deposited upon the membrane layer having the reduced membrane thickness to provide an overlayer of the second gas-selective material having an overlayer thickness so as to thereby provide the gas separation membrane system having the membrane layer of the reduced membrane thickness and the overlayer of the overlayer thickness.

Owner:SHELL OIL CO

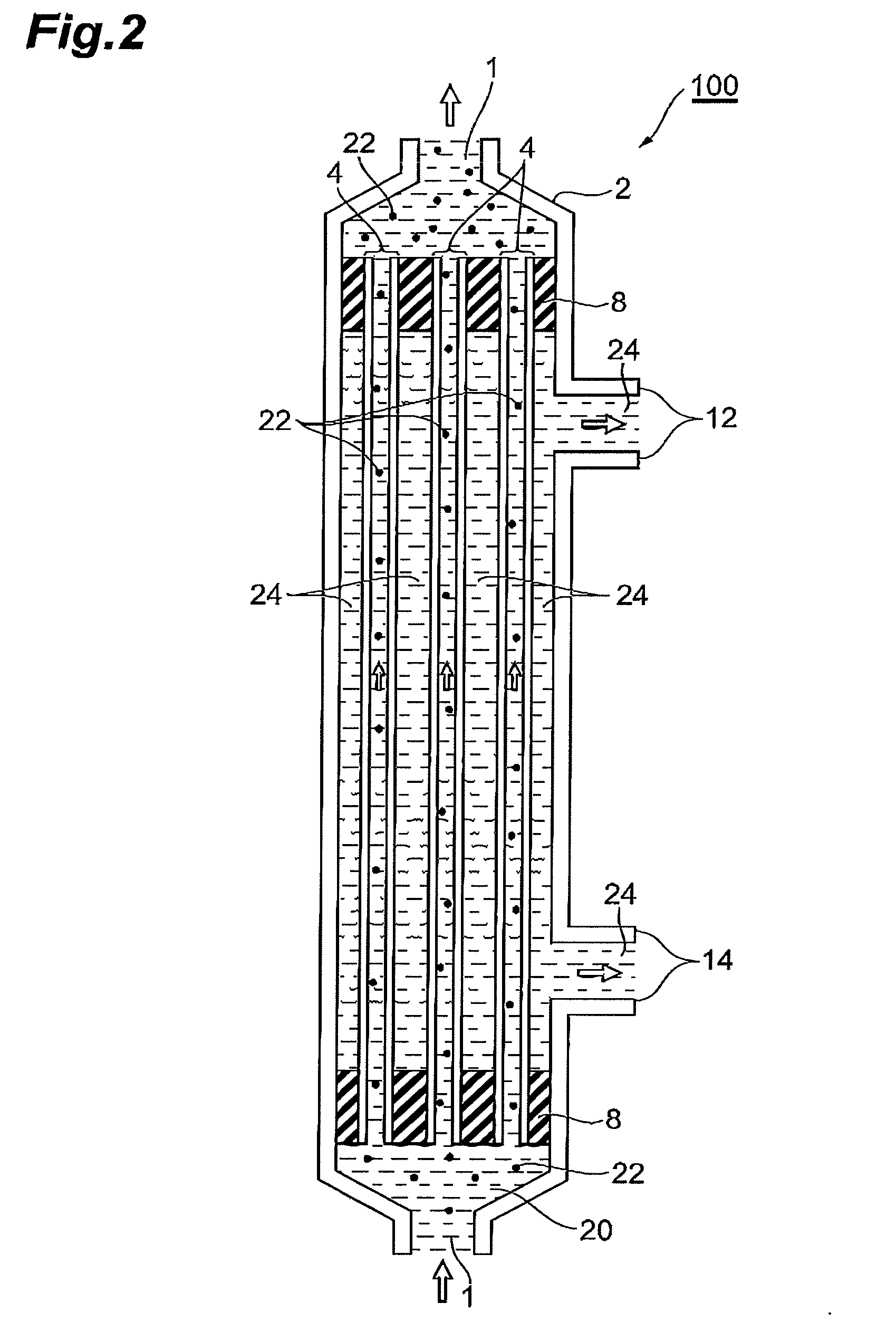

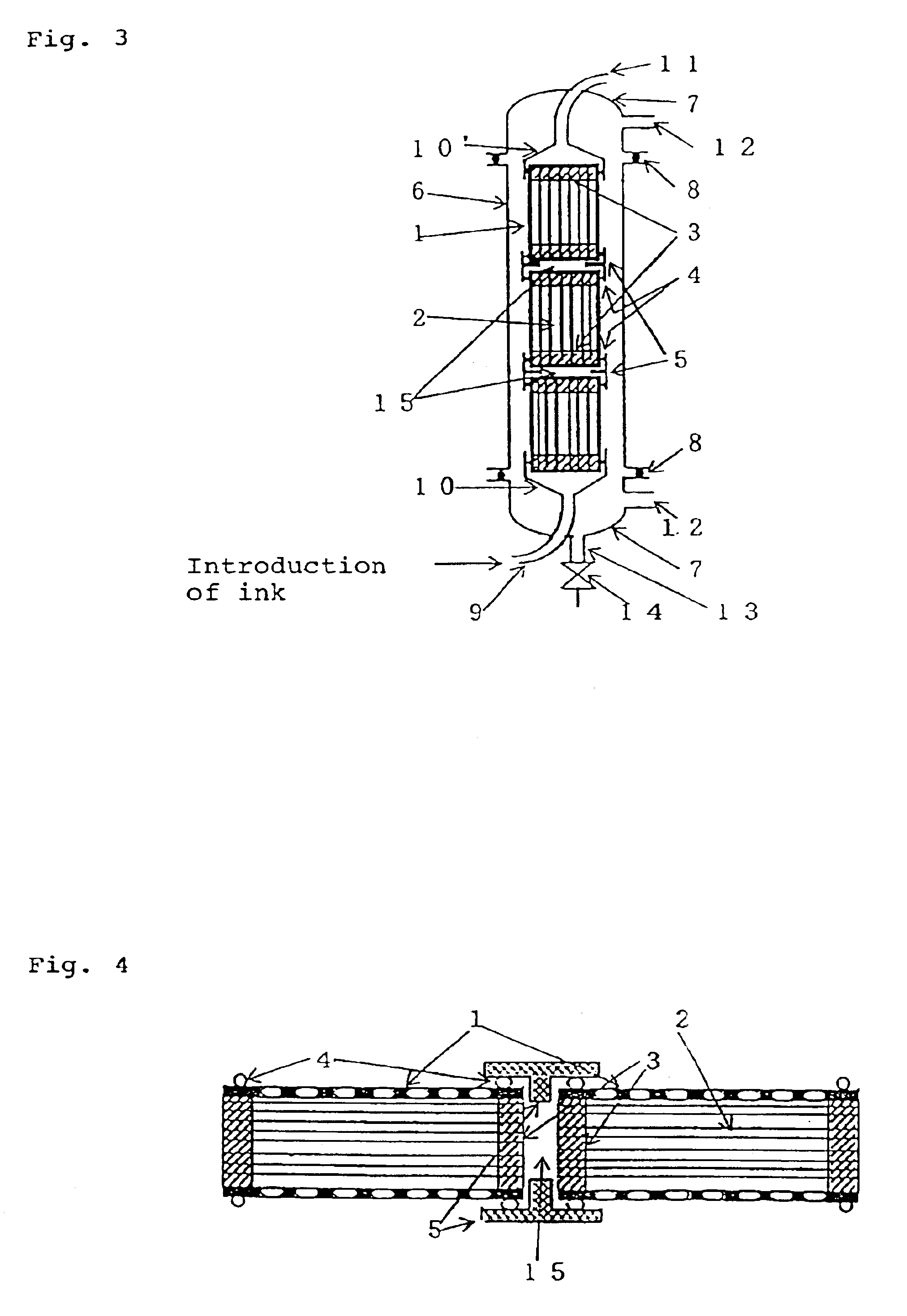

Hollow fiber membrane for the degassing of inks, ink degassing method, ink degassing apparatus, method for the fabrication of an ink cartridge, and ink

InactiveUS6860922B2Effective degassingSmall pressure lossMembranesSemi-permeable membranesHollow fibre membraneFiber

Owner:MITSUBISHI CHEM CORP

Hollow fiber membrane for treating liquids

ActiveUS20100219122A1Inhibition formationImprove filtration stabilitySemi-permeable membranesMembranesHollow fibre membraneFiber

The present invention provides a hollow fiber membrane for treating liquids. When used for a hollow fiber membrane module for refining a fermented liquid such as beer or wine, the hollow fiber membrane exhibits a high filtration performance per unit area thereof, with reduced clogging of the membrane. The membrane performance is sufficiently recovered by washing.The present invention is a hollow fiber membrane for treating liquids, wherein a ratio of Flux 120 to Flux 30 is 0.45 or higher when filtration is performed by supplying a solution having a turbidity of 20 NTU into a hollow fiber membrane having an internal diameter of 500 to 1500 μm and a membrane thickness of 100 to 500 μm with a transmembrane pressure of 1.5 bar, the Flux 30 being flux 30 minutes after the start of the filtration, the Flux 120 being flux 120 minutes after the start of the filtration.

Owner:TOYO TOYOBO CO LTD

Ultraviolet crosslinking polyaryletherketone porous membrane, preparation method and application of ultraviolet crosslinking polyaryletherketone porous membrane

InactiveCN105585732AUniform pore structureHigh porosityCell component detailsUltravioletLithium-ion battery

The invention provides an ultraviolet crosslinking polyaryletherketone porous membrane, a preparation method and an application of the ultraviolet crosslinking polyaryletherketone porous membrane in a lithium ion battery separator material and belongs to the technical field of polymer membrane materials. The membrane has the characteristics of high porosity, good infiltration performance, excellent heat resistance and the like. According to the technical scheme, the preparation method comprises steps as follows: firstly, a patented soluble ultraviolet crosslinking polyaryletherketone polymer (the patent No. 201510991547.7) with excellent comprehensive performance is adopted, and an ultraviolet crosslinking polyaryletherketone microporous membrane with high porosity is prepared with a phase separation method and an auxiliary phase reversal method; then, the electrolyte resistance, the stability of thermal dimension, the chemical stability and the mechanical performance of the microporous membrane are further improved with an ultraviolet crosslinking curing technique on the basis that the pore structure and the membrane thickness are maintained. The material has a great significance in improvement of the high safety of a lithium ion battery and has wide application prospect.

Owner:吉林省聚科高新材料有限公司

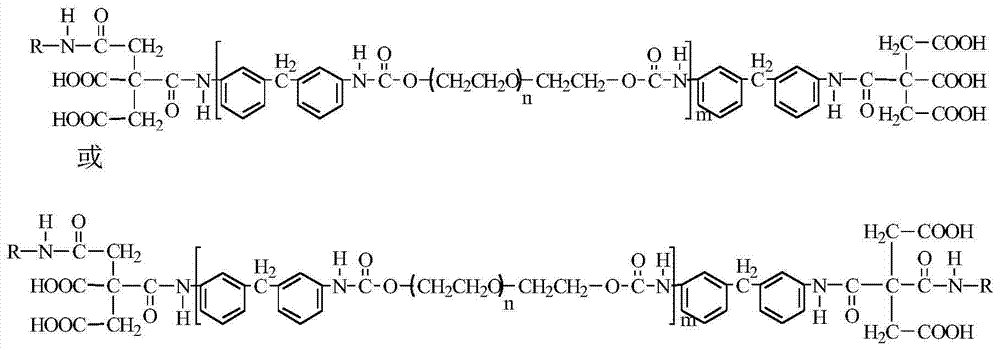

Citric acid-chitosan-modified anticoagulation polyurethane blood dialysis membrane and preparation method thereof

InactiveCN104841285AGood blood compatibilityImprove antibacterial propertiesSemi-permeable membranesPeritoneal dialysisESCHERICHIA COLI ANTIGENDialysis membranes

The invention discloses a citric acid-chitosan-modified anticoagulation polyurethane blood dialysis membrane and a preparation method thereof. The membrane is of a hollow fibrous structure, and the inner surface and outer surface are dense cortical layers, and the middle is a porous supporting layer, so that the blood dialysis membrane is high in permeability and separating property and antibacterial property; the inner diameter is 160 to 250mu m; the membrane thickness is 30 to 50 mu m, and the ultrafiltration coefficient is 7.0 to 60 ml / m<2>.h.mmHg; citric acid-chitosan-modified anticoagulation polyurethane is taken as membrane materials, and in membrane solution, the percentage mass content of the modified anticoagulation polyurethane is 15 to 30%, and the percentage mass content of a solvent is 70 to 85%, and the blood dialysis membrane is prepared by using a nonsolvent induced phase separation method. The preparation process of the dialysis membrane is simple and easy to control, and the prepared membrane has good anticoagulant activity, biocompatibility and antibacterial property, and the clearance rates of urea, beta2-microglobulin and albumin are respectively 55 to 80%, 48 to 60%, and 2.5 to 9%, and the rate of resisting pathogenic escherichia coli is 99%.

Owner:CENT SOUTH UNIV

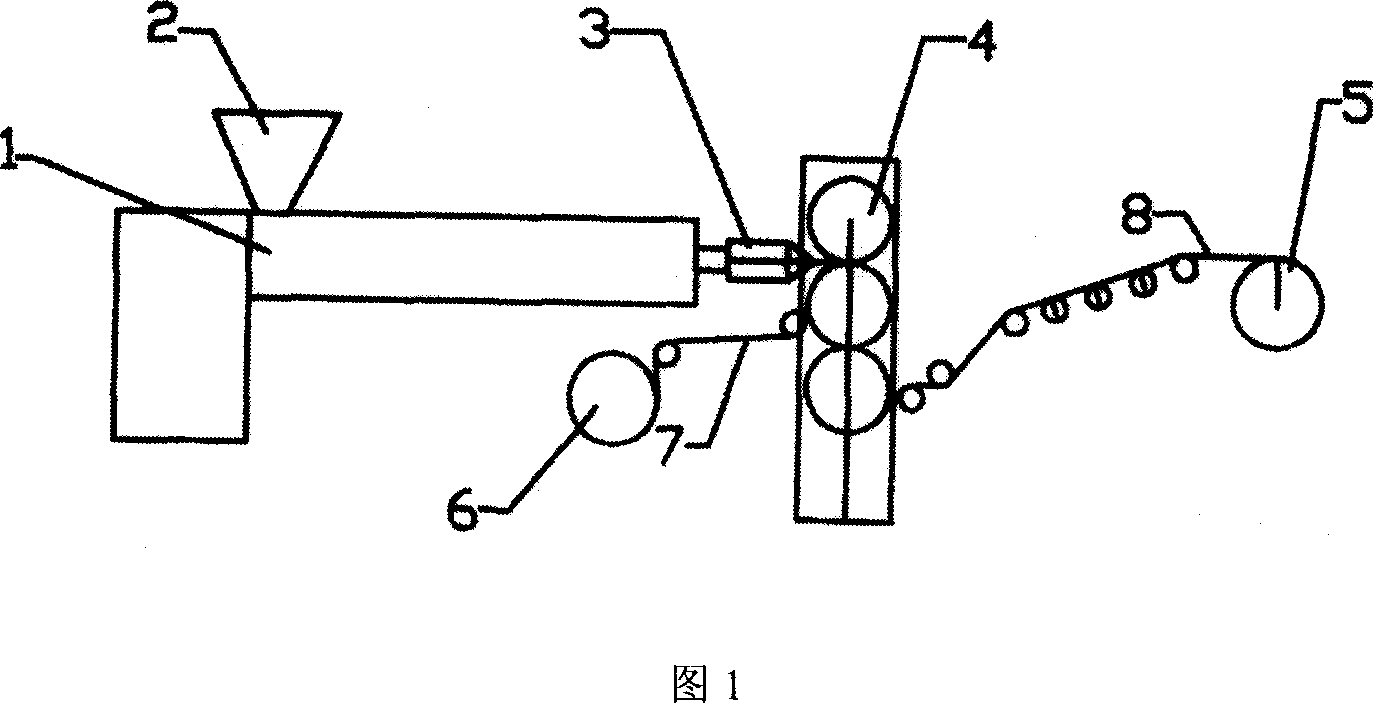

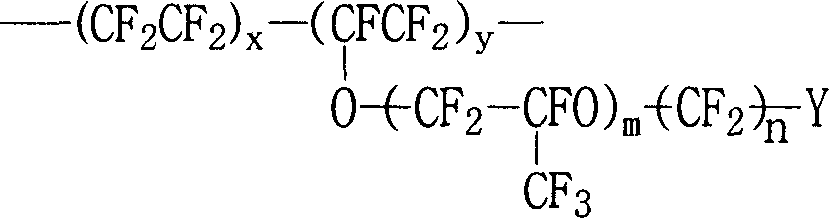

Method for preparing perfluorinated sulfonic acid ionic membrane by melting-extruding-flattening film

The invention discloses a method for preparing perfluorosulfonic acid ion-exchange membrane. The melting extrusion calendaring method is to improve the performance of membrane and increase its production rate. The method comprises following steps: putting perfluorosulfonic acid resin to extrusion machine for melting and extrusion, getting sheet membrane through lamel die head forming, calendaring with three- roll calendar, or compositing with polytetrafluoroethylene net cloth on three- roll calendar directly to produce perfluorosulfonic acid ion-exchange membrane or composite membrane, then forming ionic or acid kind through chemical treatment. The thickness uniformity of membrane is adjusted by thickness moderation screw on slit die, and membrane thickness is controlled by extrusion speed of extrusion machine and drawing velocity of three- roll calendar. The membrane produced with perfluorosulfonic acid resin can be converted into perfluorosulfonic acid ion membrane, and the exchange capacity of membrane IEC is 0.67- 1.5 mmol / g.

Owner:BEIJING UNIV OF CHEM TECH +1

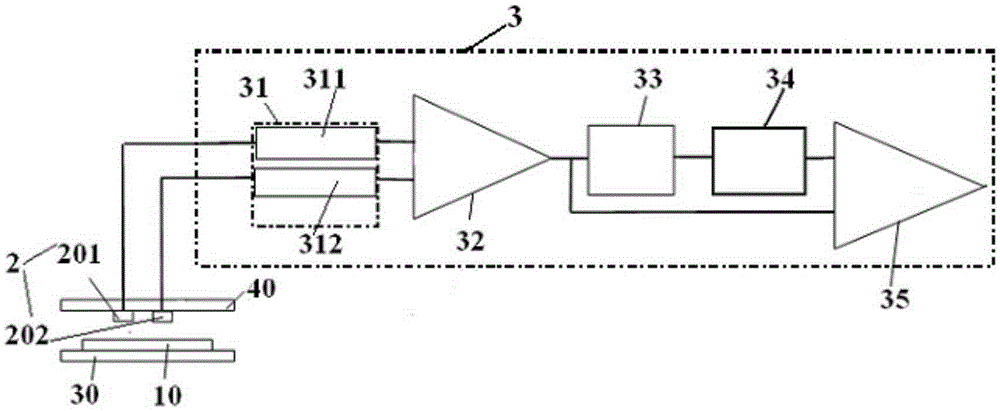

Membrane thickness detection device

ActiveCN105318819AThe test result is accurateNoise signal removalElectrical/magnetic thickness measurementsElectricitySignal on

The application provides a membrane thickness detection device, comprising a common electrode, at least one detection electrode and a detection circuit, wherein each detection electrode and the common electrode are arranged oppositely and at intervals in a first direction; the first common surface of the common electrode and the first detection surface of each detection electrode are opposite, and form a detection channel therebetween for a membrane to be measured; the detection circuit is in electric connection with each detection electrode, and comprises an error elimination unit used for eliminating noise signals, wherein the noise signals are electric signals on the detection electrode when a voltage is not applied to the common electrode. The membrane thickness detection device utilizes the error elimination unit to eliminate noise signals on the detection electrode, furthermore eliminates detection errors caused by the noise signals, and makes detection results more accurate.

Owner:WEIHAI HUALING OPTO ELECTRONICS CO LTD

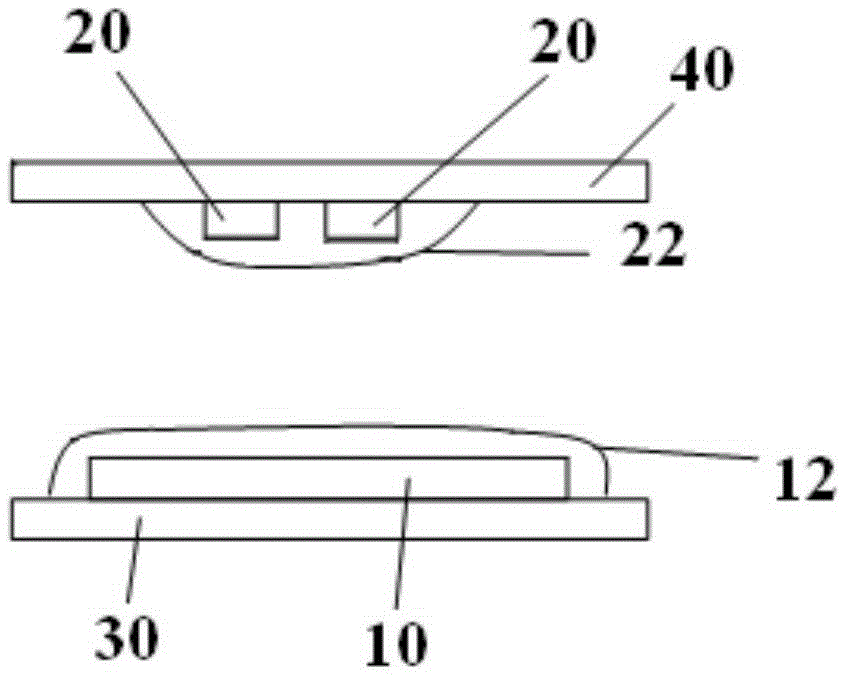

Battery separator with Z-direction stability

InactiveUS20060088769A1Cell seperators/membranes/diaphragms/spacersFinal product manufactureParticulatesMembrane thickness

A battery separator is a microporous membrane. The membrane has a major volume of a thermoplastic polymer and a minor volume of an inert particulate filler. The filler is dispersed throughout the polymer. The membrane exhibits a maximum Z-direction compression of 95% of the original membrane thickness. Alternatively, the battery separator is a microporous membrane having a TMA compression curve with a first substantially horizontal slope between ambient temperature and 125° C., a second substantially horizontal slope at greater than 225° C. The curve of the first slope has a lower % compression than the curve of the second slope. The curve of the second slope is not less than 5% compression. The TMA compression curve is graphed so that the Y-axis represents % compression from original thickness and the X-axis represents temperature.

Owner:CELGARD LLC

Ion-exchange fluororesin membrane

InactiveUS20040097603A1Ion-exchange process apparatusElectrolyte holding meansPhysical chemistryIon exchange

An ion exchange fluorocarbon membrane having a membrane thickness of 1 to 500 mum, an equivalent puncture strength of at least 300 g and a thermal shrinkage in air at 160° C. of 45% or less.

Owner:ASAHI KASEI KK

Polyolefin microporous membrane and separator for nonaqueous electrolyte battery

ActiveUS20160181584A1Fine poresImprove permeabilitySemi-permeable membranesSecondary cellsPolymer sciencePolyolefin

The present invention provides a polyolefin microporous membrane made of a polyolefin resin and an inorganic particle, and the puncture strength of the microporous membrane is 3 N / 20 μm or more and the membrane thickness retention ratio in penetration creep is 16% or more, thereby being excellent in safety and long-term reliability, and a separator for a nonaqueous electrolyte battery, and the like can be provided.

Owner:ASAHI KASEI CHEM CORP

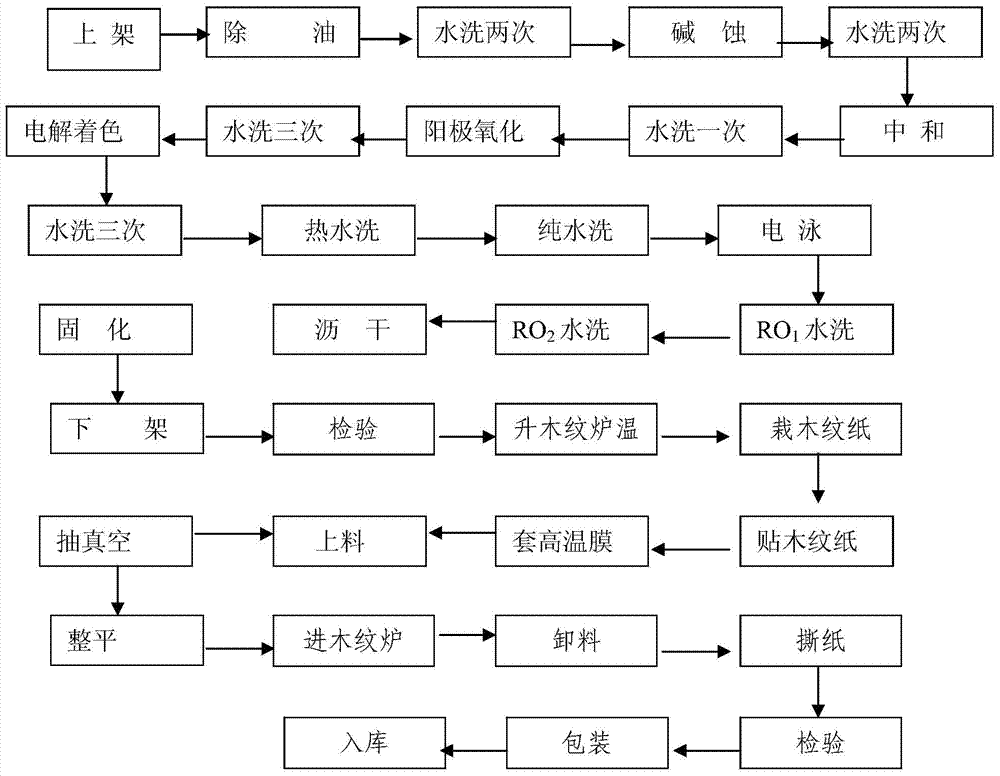

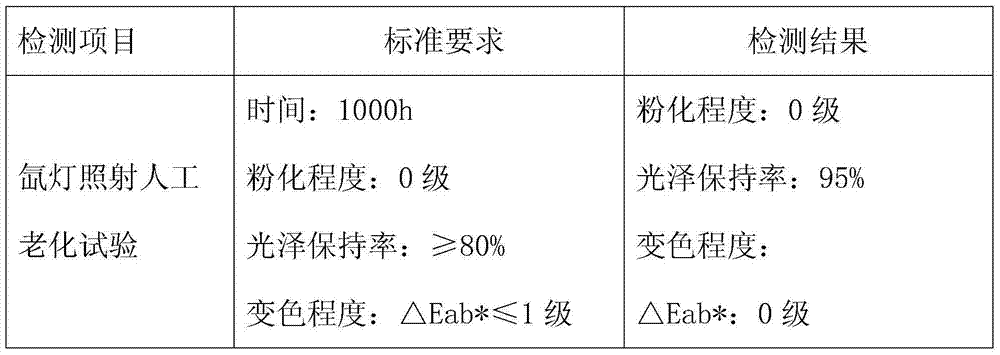

Technology for producing wood-like aluminium alloy section bar with environmental protection and super weatherability

InactiveCN104499027AImprove corrosion resistanceGood weather resistanceAnodisationElectrophoretic coatingsElectrophoresis5005 aluminium alloy

The invention relates to a technology for producing wood-like aluminium alloy section bar with environmental protection and super weatherability, which comprises the following steps: grounding, removing oil by employing sulfuric acid; performing alkali corrosion by employing NaOH; neutralizing in a neutralization groove, wherein a liquid in the neutralization groove is a mixture of sulfuric acid and nitric acid; performing anodization, wherein an aluminium alloy section bar is introduced in an oxidation, and liquid in the oxidation groove is energized for oxidation; performing electrolytic coloring, wherein the aluminium alloy section bar is introduced in a coloring groove, the coloring groove is energized for coloring; performing electrophoresis; detecting, and pasting the wood grain. The average oxide-film thickness is greater than or equal to 6mum, the average electrophoresis paint film thickness is greater than or equal to 20mum, and average conposite membrane thickness is greater than or equal to 26mum. The product has the advantages of good weatherability and corrosion resistance with 9.8 grade, luster maintenance rate can reach more than 95%, color losing is not generated on surface after weatherability tests on surface, and the wood-like aluminium alloy section bar is suitable for all building door and windows, curtain walls and indoor decoration.

Owner:GUANGDONG YONGLIJIAN ALUMINUM

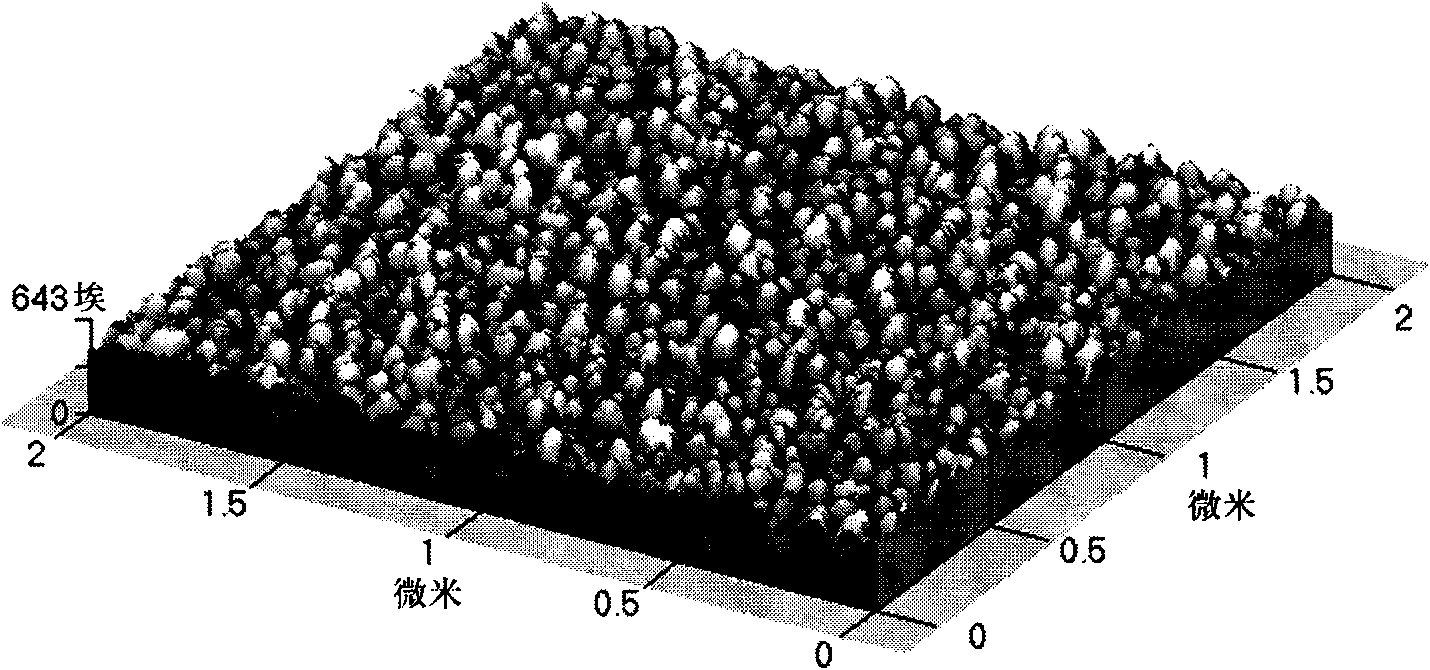

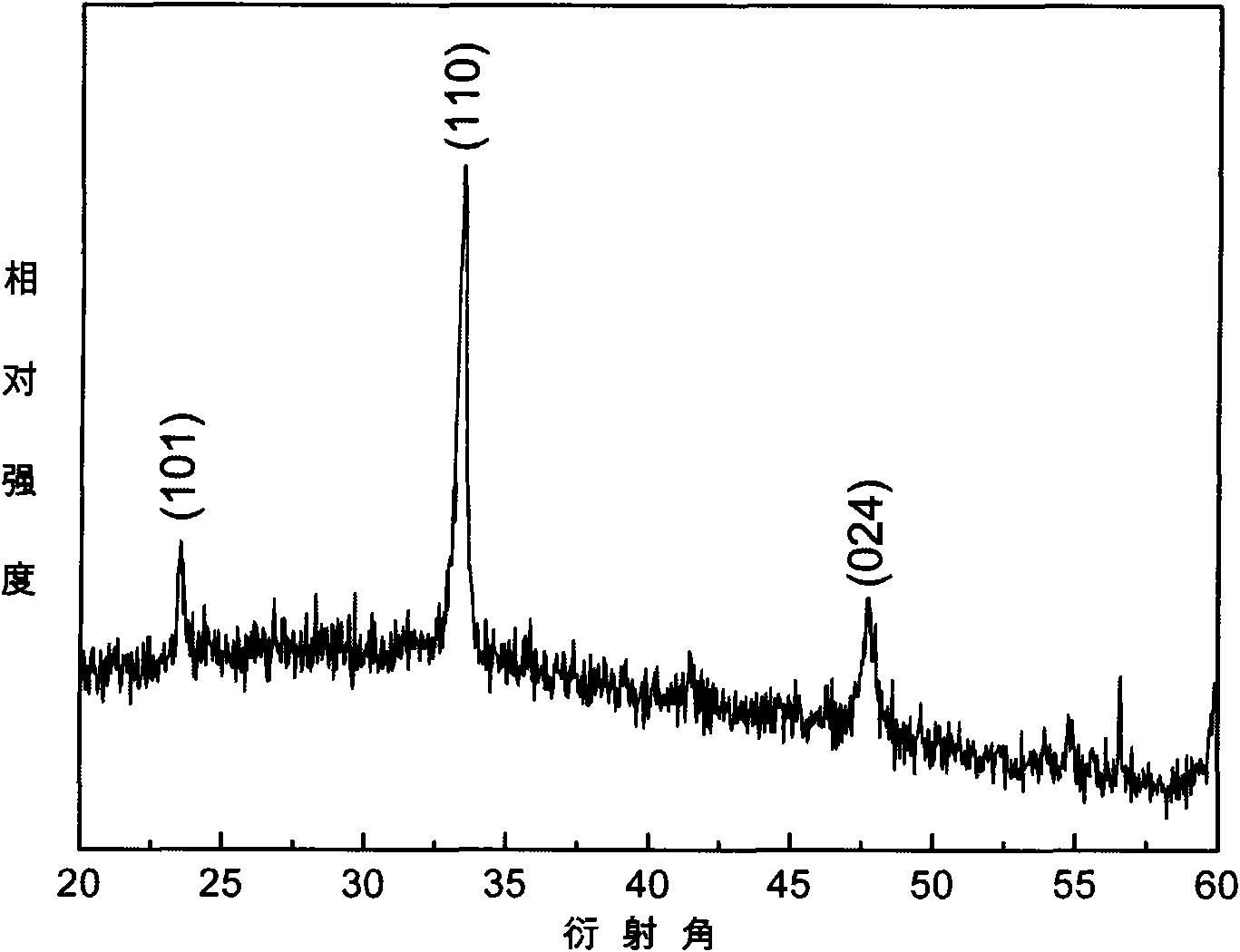

Method for preparing lanthanum nickel oxide thin-film material

InactiveCN101863679ADense shapeSmooth appearanceAfter-treatment detailsNickel compoundsAcetic acidPropanoic acid

The invention discloses a method for preparing lanthanum nickel oxide thin-film materials. The method comprises the following steps: weighing nickel acetate and lanthanum acetate according to 1:1 of molar ratio of nickel to lanthanum; respectively adding the nickel acetate and lanthanum acetate into propanoic acid which is taken as a solvent; respectively stirring for 10-30min at the temperature of 40-70 DEG C to obtain nickel acetate solution; adding lanthanum acetate to the nickel acetate solution; stirring the solution at the temperature of 40-70 DEG C; stirring to transparent state at room temperature to obtain the mixed solution; filtering the mixed solution to obtain a precursor colloid of the lanthanum nickel oxide; placing the precursor colloid of the lanthanum nickel oxide on a substrate to rotatably spray into a gel membrane, then pyrolyzing the gel membrane for 15-30min at the temperature of 300-450 DEG C; repeating the above steps until the pyrolysis membrane with needed thickness is acquired; finally, placing the pyrolysis membrane at the temperature of 600-750 DEG C for annealing for 60-240min to prepare into the lanthanum nickel oxide thin-film material with the membrane thickness of 10nm-1mu m, wherein the material has wide application prospects in the fields, such as membrane materials, information materials, superconducting materials and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com