A carbon nano tube enhanced self-humidity increase compound proton exchange film and its preparation

A proton exchange membrane and carbon nanotube technology, applied in the field of proton exchange membranes, can solve the problems of not very high strength of PTFE, affecting the conductivity of the composite membrane, and the limitation of improving the strength of the composite membrane, so as to achieve increased strength, improved mechanical strength and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

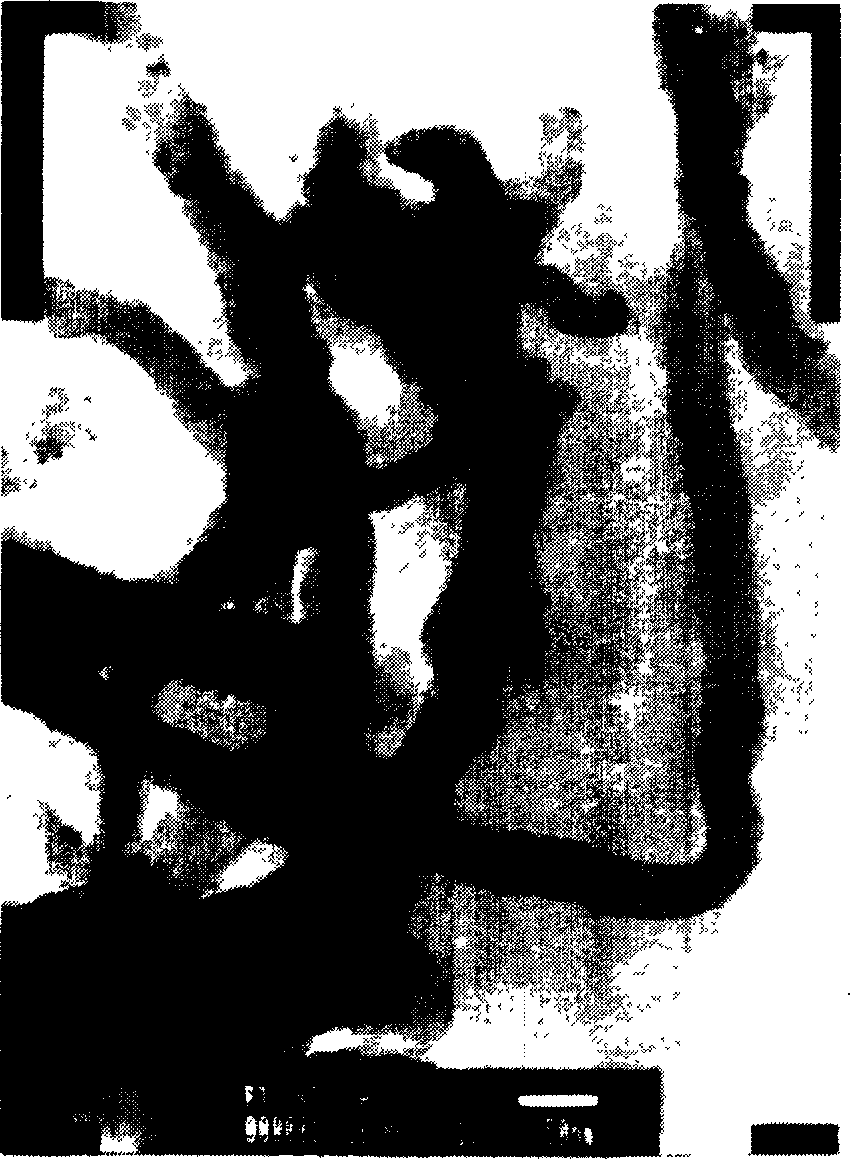

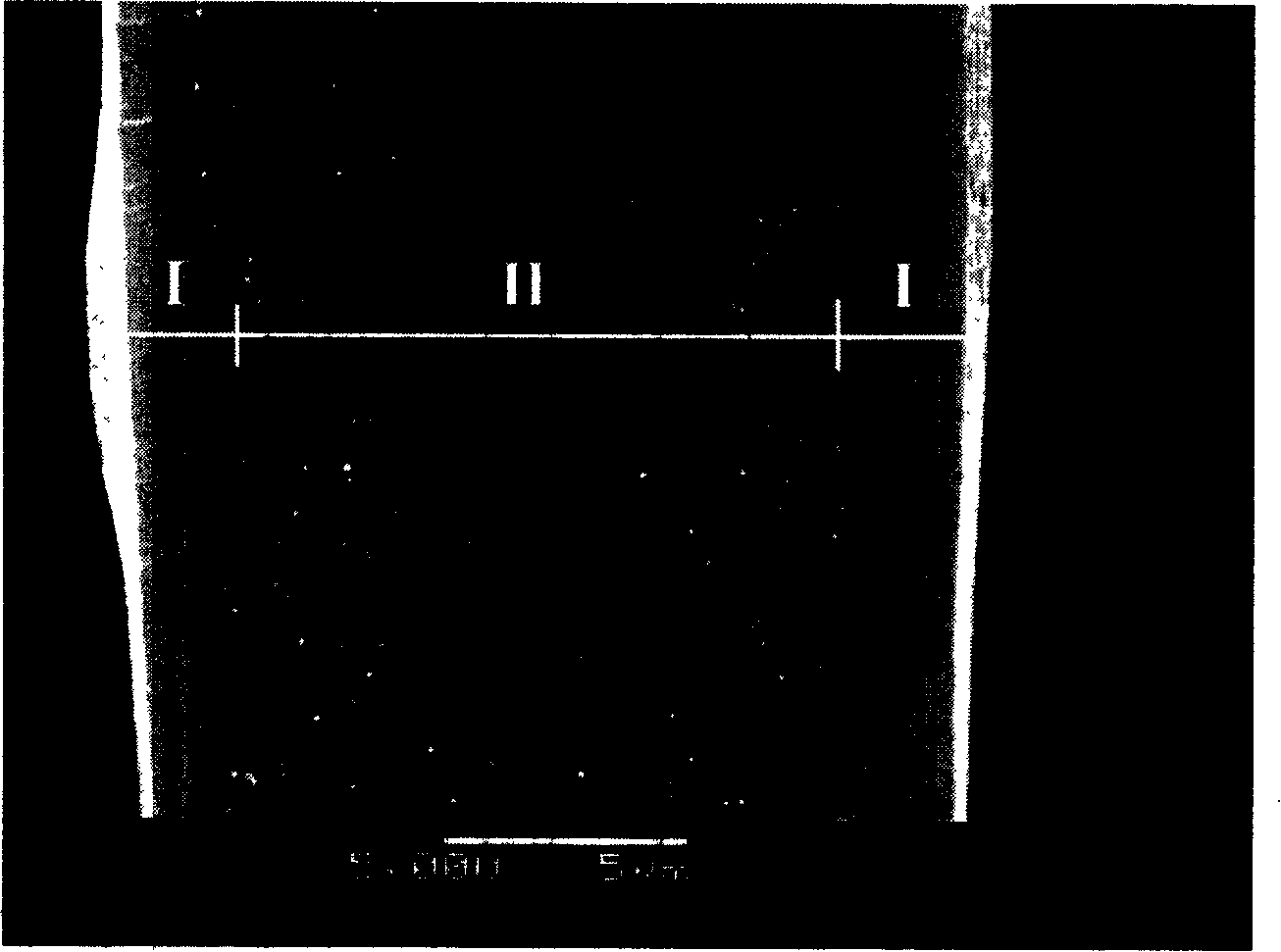

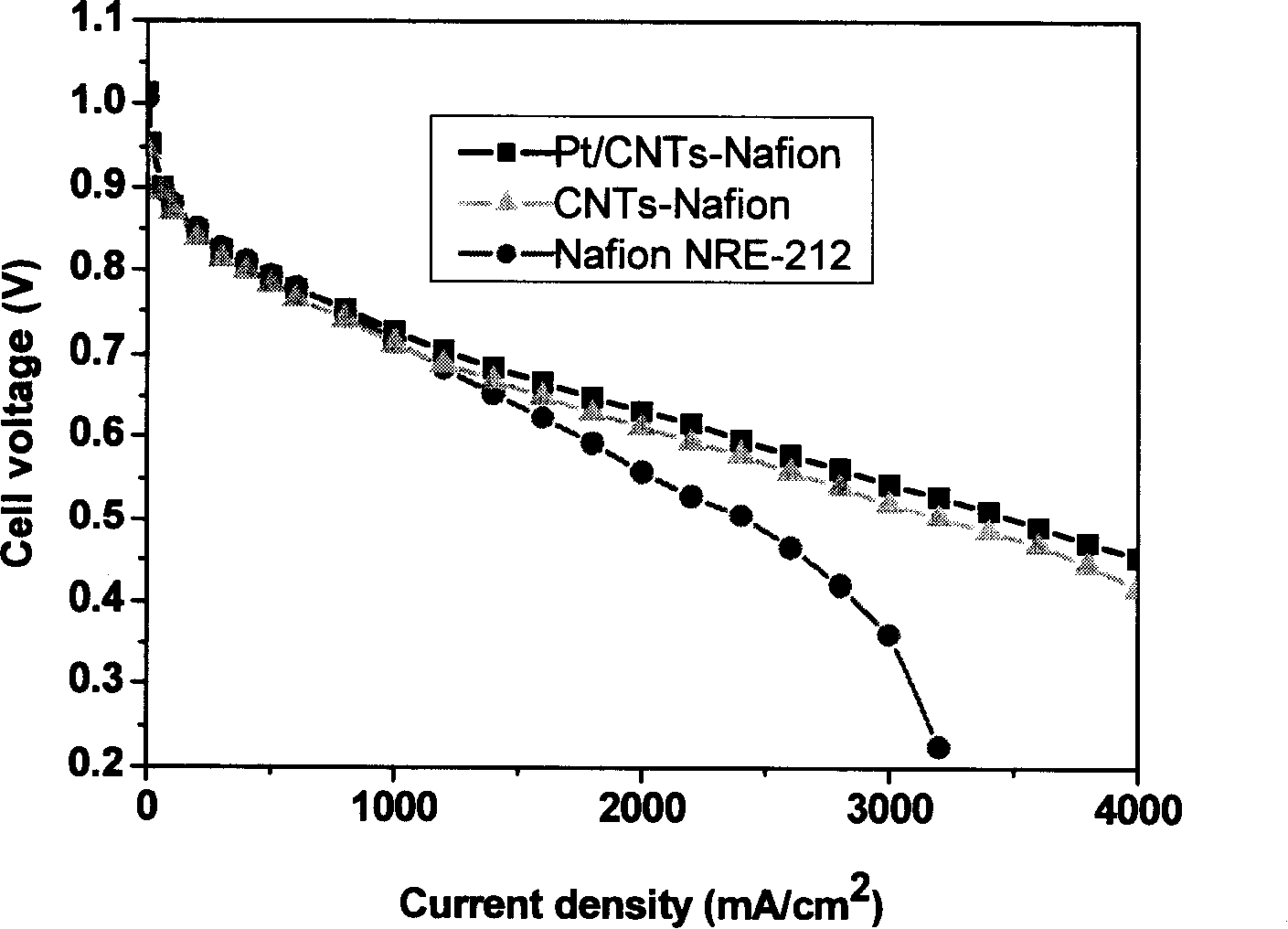

[0069] Example 1: Take 3g of 5.4% Nafion solution and pour it into a small beaker, heat it on a hot stage at 50°C to volatilize the low-boiling organic solvent, then add 3ml of analytically pure DMF solution to redissolve the Nafion resin. Pt / CNTs with a Pt mass percentage of 1% prepared by carbon nanotubes with a diameter of 30nm and a length of about 3 μm were used as self-humidifying catalysts. Add 5mg of Pt / CNTs into the Nafion solution dissolved in DMF, and ultrasonically disperse for 10min to obtain a uniform Pt / CNTs-Nafion-DMF solution. Let stand to drive away the air bubbles in the solution, and pour it into an area of 20cm 2 Place the cast film frame on a horizontal heating platform. Then heat the volatile solvent on a hot stage at 50°C for 2h to form a film, take out the obtained film, then spray the mixed solution prepared by 0.185g 5.4% Nafion solution and 2g isopropanol on both sides, let it dry naturally, Pure Nafion resin layers with a thickness of 2.5 μm we...

Embodiment 2

[0076] Example 2: Pour 3g of 5.4% Nafion solution into a small beaker, heat on a hot stage at 50°C to evaporate the low-boiling point organic solvent, and then add 3ml of analytically pure DMF solution to redissolve the Nafion resin. Add 5 mg of multi-walled carbon nanotubes with a diameter of 30 nm and a length of about 3 μm to the Nafion-DMF solution, and ultrasonically disperse for 10 min to obtain a uniform CNTs-Nafion-DMF solution. Let stand to drive away the air bubbles in the solution, and pour it into an area of 20cm 2 Place the cast film frame on a horizontal heating platform. Then, heat on a hot stage at 50° C. for 2 h to evaporate the solvent to form a film, and take out the obtained CNTs-Nafion composite film. Take 1mg Pt / SiO 2 Catalyst and 0.185g 5.4% Nafion solution and 2g isopropanol are formulated into mixed solution, disperse in ultrasonic oscillator for 15 minutes and obtain homogeneous solution, wherein Pt / SiO 2 The mass percent content of Pt in the cat...

Embodiment 3

[0077] Example 3: Take 5g of 5.4% Nafion solution and pour it into a small beaker, heat it on a hot stage at 60°C to evaporate the low-boiling point organic solvent, then add 5ml of analytically pure DMF solution to redissolve the Nafion resin. Add 10 mg of multi-walled carbon nanotubes with a diameter of 10 nm and a length of about 1 μm to the Nafion-DMF solution, and ultrasonically disperse for 10 min to obtain a uniform CNTs-Nafion-DMF solution. Let it stand still to drive off the air bubbles in the solution, pour it into a flat glass cast film frame, and place the cast film frame on a horizontal heating platform. Then, heat on a hot stage at 50° C. for 2 h to evaporate the solvent to form a film, and take out the obtained CNTs-Nafion composite film. Take a certain amount of Pt / SiO 2 The catalyst, Nafion solution and isopropanol were dispersed in an ultrasonic oscillator for 15 minutes to obtain a homogeneous solution, in which Pt / SiO 2The mass percent content of Pt in th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com