Method for preparing perfluorinated sulfonic acid ionic membrane by melting-extruding-flattening film

A technology of perfluorosulfonic acid ion and perfluorosulfonic acid, which is applied in the fields of semi-permeable membrane separation, chemical instruments and methods, and membrane technology, and can solve the problems of easy discoloration of products, long process, low efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

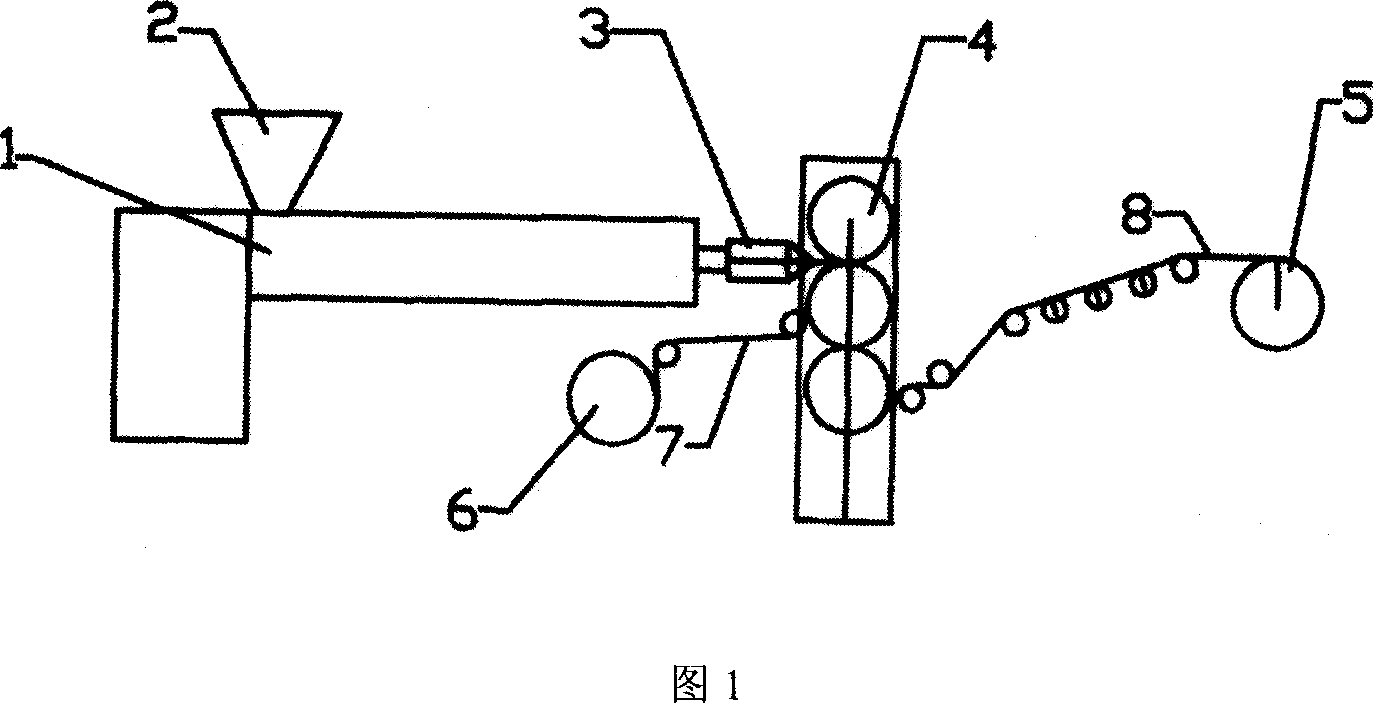

Method used

Image

Examples

Embodiment 1

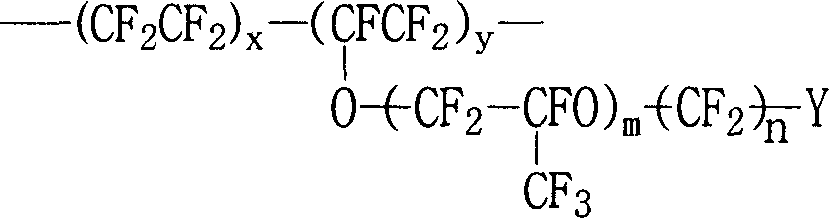

[0015] Example 1: Raw materials used: the group form is Rf-SO 2 F perfluorosulfonic acid fluororesin, density 1.98g / cm 3 , granular raw materials, the extruder is a single-screw extruder Φ30, L / D=25; the slit thickness of the sheet mold is adjustable at 1.0mm, and the slit width is 150mm; after extruding the film, it enters the three-roll calender for calendering and cooling Rewinding; Among them, the steel materials used for the extruder screw, barrel and slit die are all special stainless steel. The temperature of each section of the extruder is 140-190°C, of which the die temperature is 175°C; the roll temperature of the three-roll calender is ≤30°C. After the equipment is heated to the set temperature, the resin is added through the feeding port of the extruder, and the extruded film is melted and plasticized, and then calendered and cooled by a three-roll calender to obtain an apparent free-standing film with a thickness of 120±5μm and a width of 140mm. Defective perf...

Embodiment 2

[0017] Embodiment 2: using raw materials: the group form is Rf-SO 2 F perfluorosulfonic acid fluororesin, density 1.98g / cm 3 , granular raw materials, the extruder is a single-screw extruder Φ65, L / D=25; the slit of the sheet mold is adjustable at 1.0mm, and the slit width is 300mm; after extruding the film, it enters the three-roll calender for calendering and cooling Winding; Among them, the steel materials used for the extruder screw, barrel and die are all special stainless steel. The temperature of each section of the extruder is 140-205°C, of which the die temperature is 185°C; the roll temperature of the three-roll calender is about 30°C. The resulting film thickness is 155 μm and the width is 260 mm, which is an apparently defect-free perfluorosulfonic acid fluorine ion membrane.

[0018] The membrane was saponified by NaOH methanol solution for 16 hours, and then reacted with HCl solution to obtain sodium perfluorosulfonate and hydrogen perfluorosulfonate ion exch...

Embodiment 3

[0019] Embodiment three: using raw materials: the group form is Rf-SO 2 F perfluorosulfonic acid fluororesin, density 1.98g / cm 3 , granular raw material, the extruder is a twin-screw extruder Φ20, L / D=40; the slit of the sheet die is 1.0mm, and the width is 150mm; after extruding the film, it enters the three-roller calender for calendering and cooling before winding; Among them, the steel materials used for extruder screw, barrel and slit die are all special stainless steel. The temperature of each section of the extruder is 140-185°C, of which the die temperature is 185°C; the roll temperature of the three-roll calender is about 30°C. After the equipment is heated to the set temperature, the resin is metered and fed into the twin-screw extruder through the screw feeder, extruded to form a film, and an apparently defect-free perfluorosulfonic acid fluorine type with a thickness of 140 μm and a width of 140 mm is obtained. ionic membrane.

[0020] The membrane was saponif...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com