Antenna for ic tag and method of manufacturing the same

A manufacturing method and antenna technology, applied to recording carriers used in machines, metal/alloy conductors, and structural forms of radiation elements, etc., can solve problems such as slow printing speed, difficulty in forming a coating, hindering IC label productivity, and cost competitiveness. , to achieve the effect of reducing manufacturing cost and reducing surface roughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

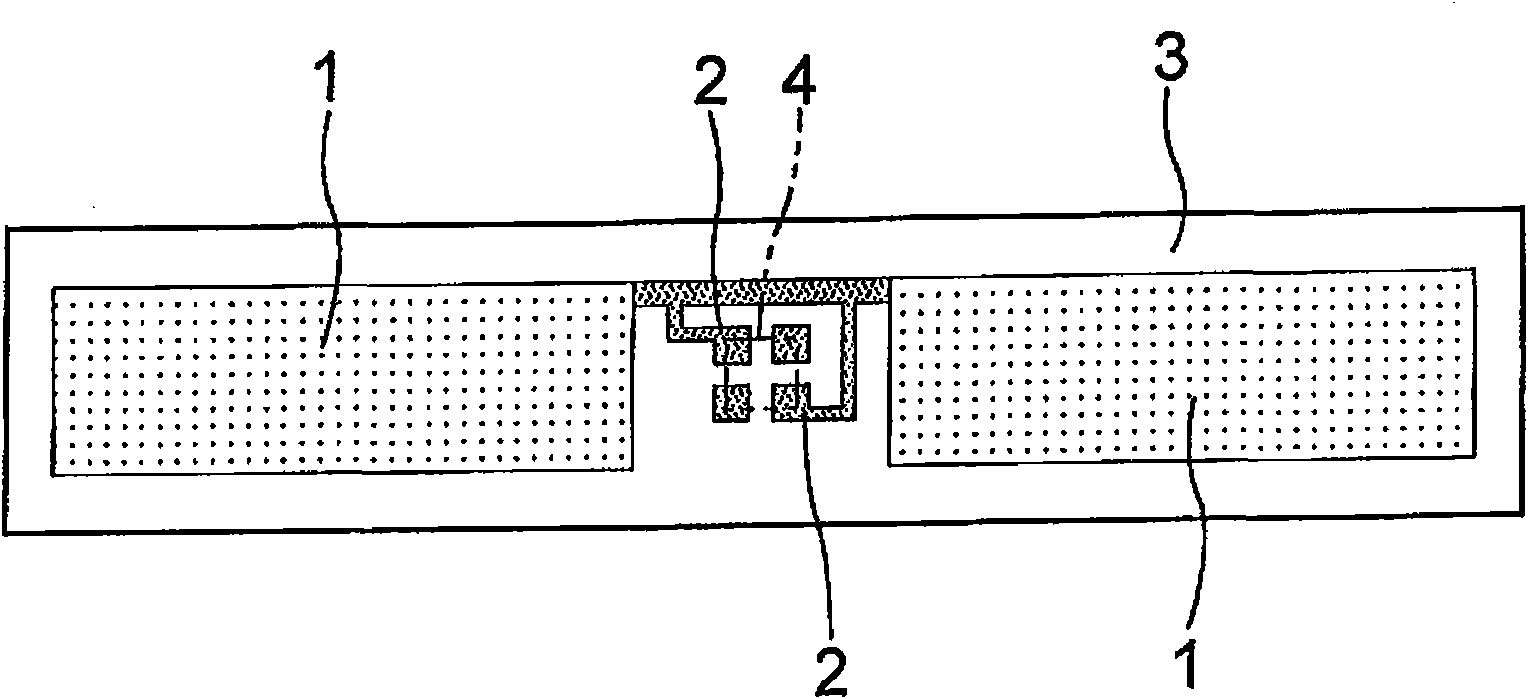

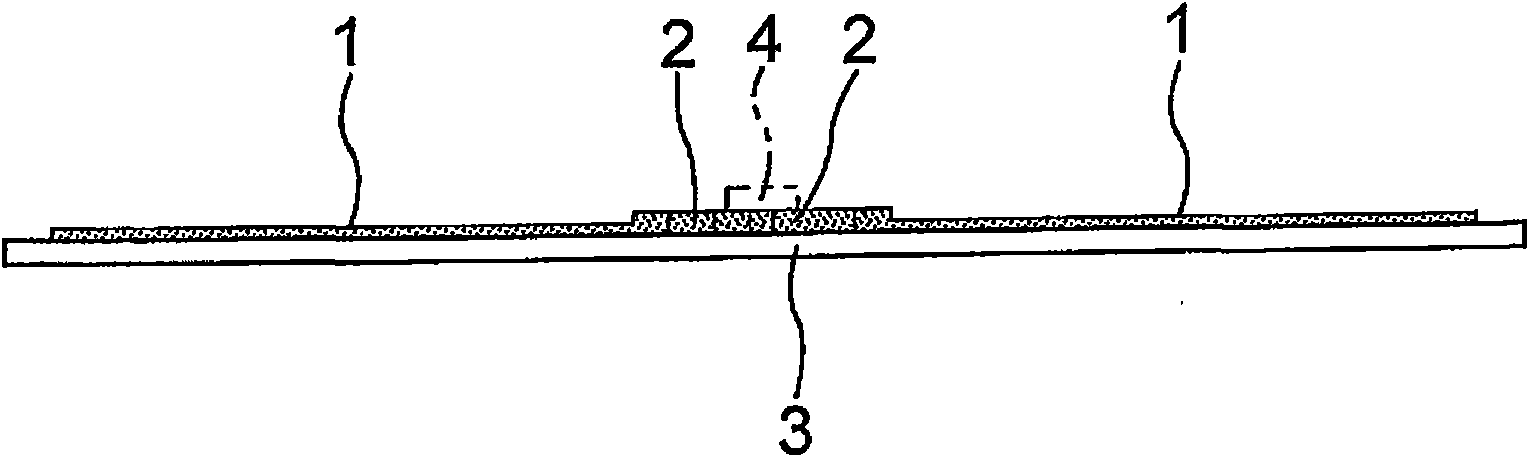

Embodiment 1

[0068] In this example, the IC tag antennas [Example 1] to [Example 3] and [Comparative Example 1] and [Comparative Example 2] prepared by flexographic printing using water-based conductive ink were used. Antennas for IC tags [Comparative Example 3] prepared by screen printing with ink, and conventional antennas for IC tags [Comparative Example 4] prepared by etching aluminum foil, compared the antenna section 1 of the antenna for IC tags above. thickness (μm), volume resistance value (resistivity: Ω·cm) of the antenna unit 1, and the like.

[0069] In Examples 1 to 3 and Comparative Examples 1 and 2, the following aqueous conductive ink (low-temperature sintered nano silver conductive ink) and substrates were used.

[0070] nano silver ink

[0071] A: TEC-PR-030 manufactured by InkTec Co., Ltd. (Korea)

[0072] Composition Silver particles - average particle size: 20-50μm Content rate: 40wt% or less

[0073] Binder (organic complex compound) content rate - 35wt% or less ...

Embodiment 2

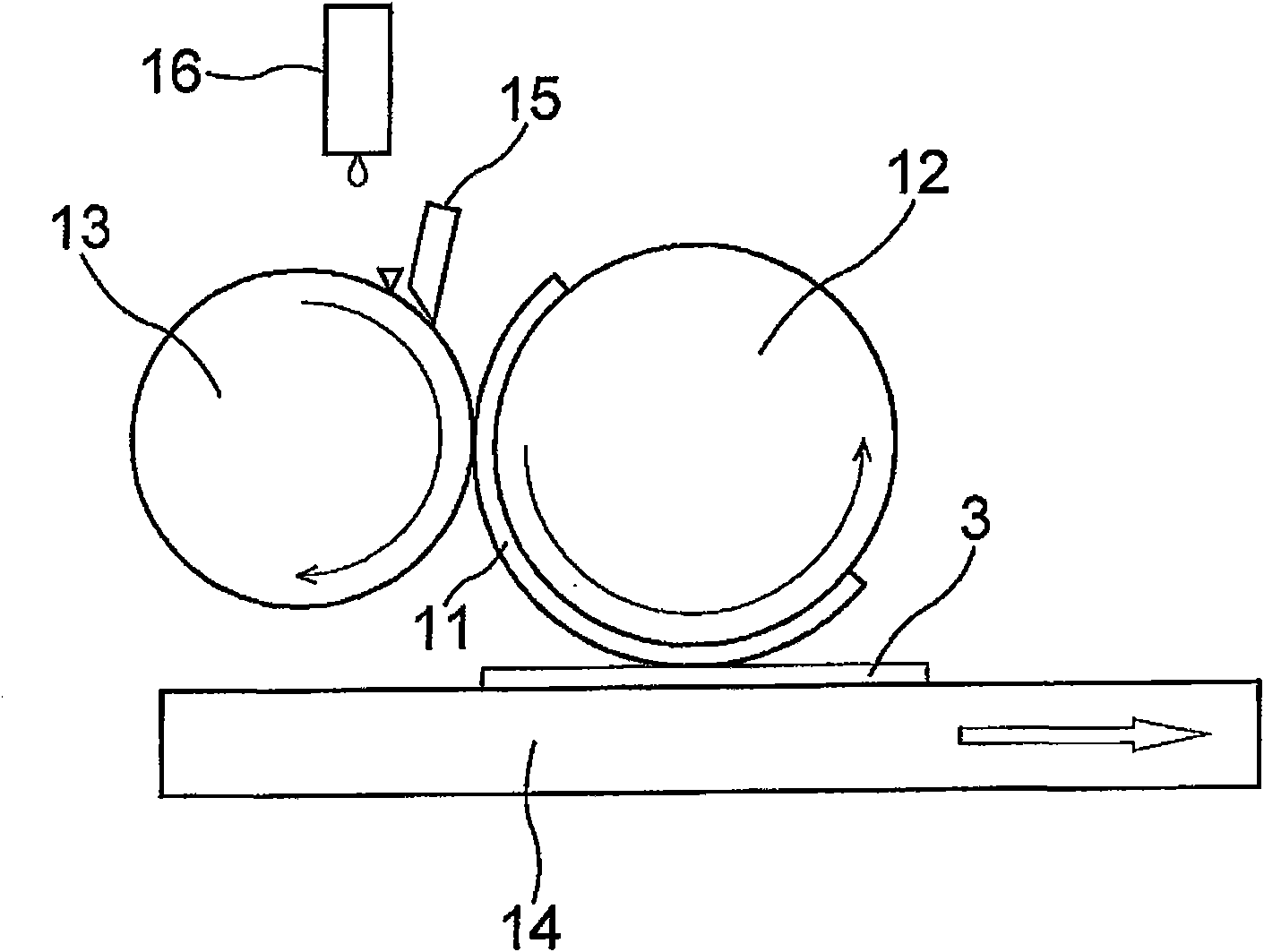

[0107] Use ink retention of 0.3ml / m 2 The printing plate of the above-mentioned flexographic printing machine was used to print and transfer the ink A to the PET substrate, and after drying at 120° C. for 2 minutes, the IC tag antenna of Example 2 was obtained.

Embodiment 3

[0109] The ink holding capacity of the antenna part is 1.5ml / m 2 , The ink holding capacity of the chip connection part is 3.0ml / m 2 The printing plate of the above-mentioned flexographic printing machine was used to print and transfer the ink A to the PET substrate, and after drying at 120° C. for 2 minutes, the IC tag antenna of Example 3 was obtained.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com