Method for preparing novel biological microcapsule for biological fluidized bed

A biological fluidized bed, microcapsule technology, applied in chemical instruments and methods, sustainable biological treatment, biological water/sewage treatment, etc., can solve the problems affecting the application of microcapsule carriers, poor mass transfer performance, low stability, etc. , to achieve good mass transfer performance, good biocompatibility, and improve the treatment effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] A novel biological microcapsule carrier for a biological fluidized bed, characterized in that the microcapsule is composed of an inner core and an outer membrane, and the inner core is a liquid sodium alginate gel, which contains powdered activated carbon and Immobilized dominant bacteria, the inner core is coated with chitosan, the chitosan is coated with sodium alginate film, and the embedded bacteria in the inner core material are o-dichlorobenzene efficient degradation bacteria.

[0018] The microcapsule carrier of the present embodiment is prepared by the following methods and steps:

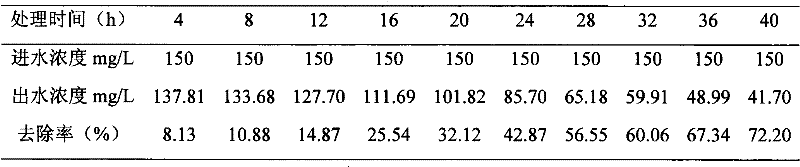

[0019] (1) Preparation of microbial mixed solution: add emulsifier Tween 80 and powdered activated carbon to sodium alginate solution and stir to obtain solution A, wherein the mass fraction of sodium alginate is 2.0%, the concentration of Tween 80 is 0.5%, powder Activated carbon 0.75%; add 10% to 20% (V / V) o-dichlorobenzene efficient degrading bacteria liquid to solution A in solut...

Embodiment 2

[0029] A novel biological microcapsule carrier for a biological fluidized bed, characterized in that the microcapsule is composed of an inner core and an outer membrane, and the inner core is a liquid sodium alginate gel, which contains powdered activated carbon and Immobilized dominant bacteria, the inner core is coated with chitosan, and the chitosan is coated with a sodium alginate film, and the embedded bacteria in the inner core material are highly efficient p-chlorophenol degrading bacteria.

[0030] The microcapsule carrier of the present embodiment is prepared by the following methods and steps:

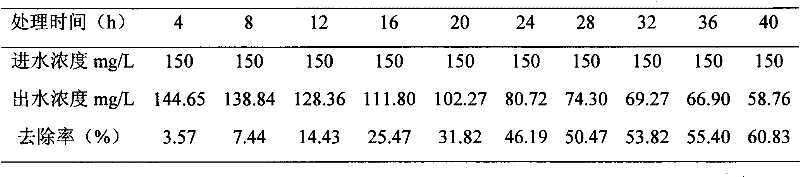

[0031] (1) Preparation of microbial mixed solution: add emulsifier Tween 80 and powdered activated carbon to sodium alginate solution and stir to obtain solution A, wherein the mass fraction of sodium alginate is 2.0%, the concentration of Tween 80 is 0.5%, powder Activated carbon 0.75%; add 10% to 20% (V / V) p-chlorophenol high-efficiency degradation bacteria wet cells in sol...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com