Ultrafine molecular sieve structured catalytic material based on porous silicon carbide carrier and preparation thereof

A technology of porous silicon carbide and catalytic materials, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

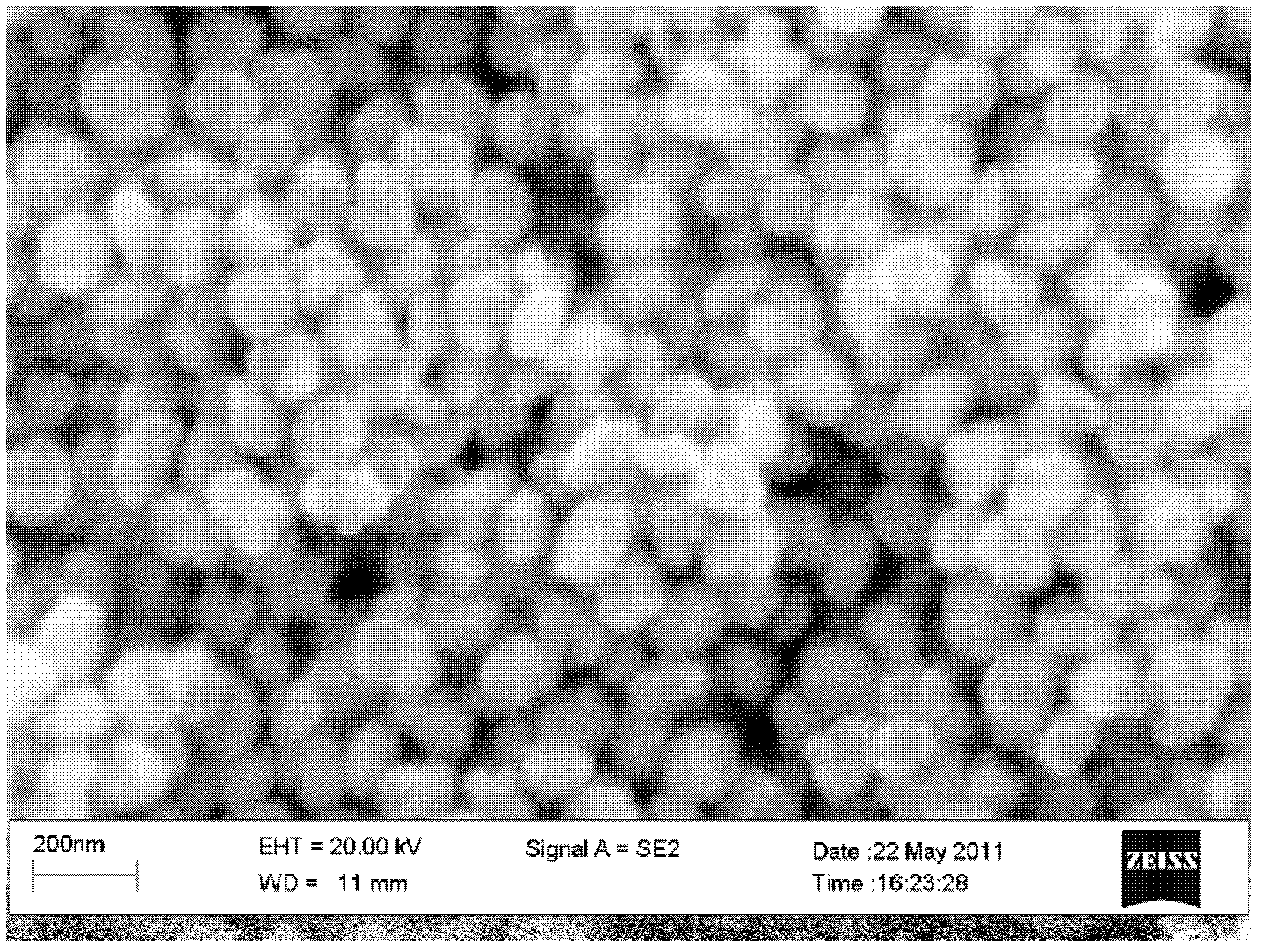

[0042] In this embodiment, the preparation method of the superfine ZSM-5 molecular sieve coating on the surface of the foamed silicon carbide carrier:

[0043] First, the surface of the porous silicon carbide carrier is modified by using a colloidal zeolite seed crystal directing agent. For the method of the colloidal zeolite seed crystal directing agent, refer to the silicon carbide ceramic surface mentioned in the Chinese invention patent application (application number: CN200910013245.7). Porous zeolite molecular sieve coating material and its preparation method: mix ethyl orthosilicate, tetrapropylammonium hydroxide, and deionized water in a molar ratio of 1:0.32:29, and after the ethyl orthosilicate is completely hydrolyzed, the above The solution was placed in a reaction kettle for hydrothermal synthesis, and hydrothermal synthesis was carried out at 120° C. for 4 hours to obtain the zeolite precursor sol. The foamed silicon carbide carrier is impregnated in the zeolite ...

Embodiment 2

[0046] In this example, the preparation method of the ultrafine β molecular sieve coating on the surface of the foamed silicon carbide carrier:

[0047] First, the surface of the foamed silicon carbide carrier is modified by cationic polymers, and the specific process is to immerse the foamed silicon carbide carrier in a 50 wt % tetraethylammonium hydroxide solution for 2 hours. Mix ethyl orthosilicate, sodium metaaluminate, tetraethylammonium hydroxide, and deionized water in a molar ratio of 1:0.5:0.5:20. After the tetraethyl orthosilicate is completely hydrolyzed, the surface-modified foamed silicon carbide carrier and the above solution are placed in a reaction kettle, and hydrothermally synthesized at 140° C. for 48 hours to prepare a β ultrafine molecular sieve precursor. Adding 8wt% polyvinylamine and 1.5wt% polyvinyl alcohol to the precursor as pore-forming agents. Soak the foamed silicon carbide carrier in the colloid for 20 minutes, blow off excess slurry, and dry at ...

Embodiment 3

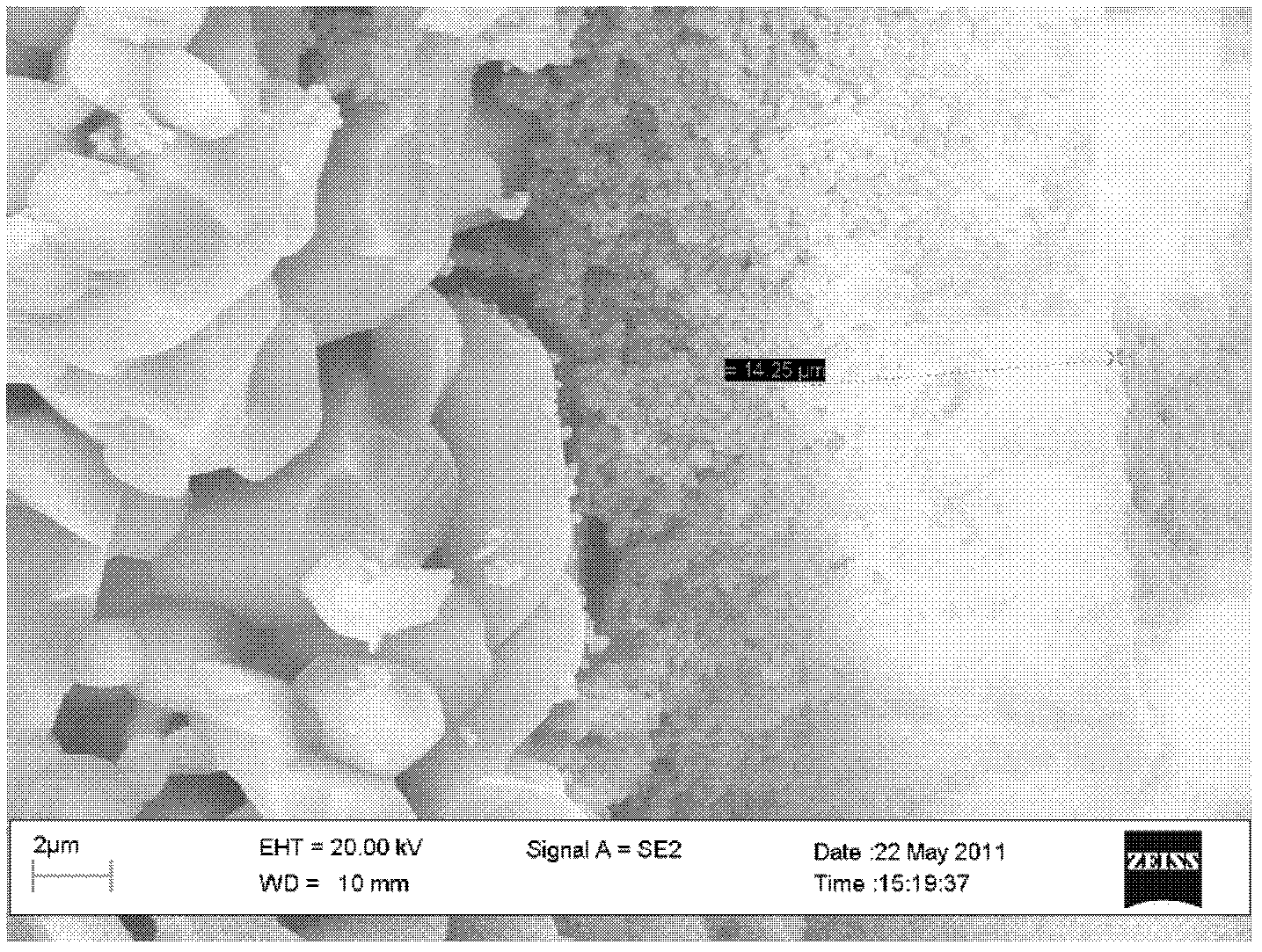

[0049] In this embodiment, the preparation method of the superfine Y-type molecular sieve coating material on the surface of the honeycomb silicon carbide carrier:

[0050] First, use concentrated nitric acid to modify the surface of the foamed silicon carbide carrier. The specific process is to treat the honeycomb silicon carbide carrier in concentrated nitric acid for 30 minutes. Mix ethyl orthosilicate, aluminum isopropoxide, sodium hydroxide, tetramethylammonium hydroxide, and deionized water in a molar ratio of 1:0.6:0.006:0.8:100). After the tetraethyl orthosilicate is completely hydrolyzed, the surface-modified foamed silicon carbide carrier and the above solution are placed in a reaction kettle, and hydrothermally synthesized at 95° C. for 24 hours to prepare an ultrafine Y molecular sieve precursor. 12 wt% polyether and 1.5 wt% sodium carboxymethyl cellulose are added therein as pore-forming agents. Soak the foamed silicon carbide carrier in the colloid for 20 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com