Sludge incineration ash based geopolymer and preparation method thereof

A sludge incineration and polymer technology, applied in cement production and other directions, can solve the problems of limited life, damaged structure, low corrosion resistance, etc., and achieve the effect of extending service life and strong acid corrosion resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

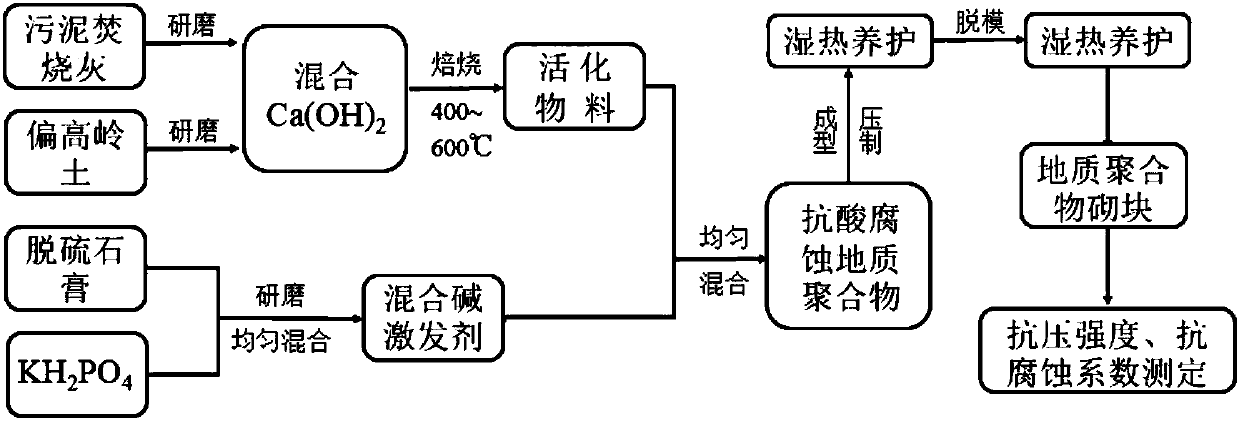

Method used

Image

Examples

Embodiment 1

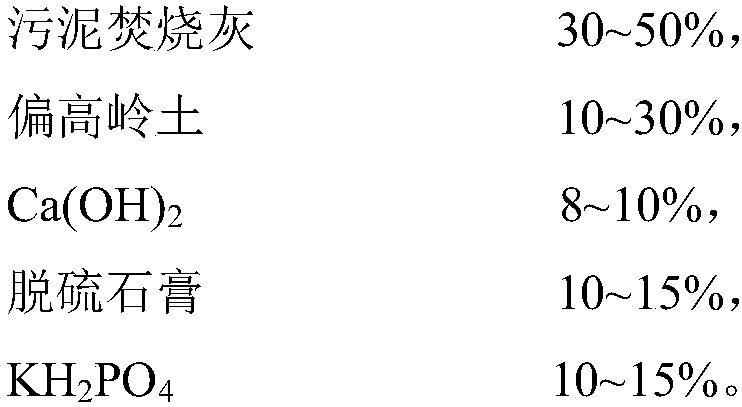

[0030] A sludge incineration ash-based geopolymer, the basic composition of which includes the following components by mass percentage:

[0031]

[0032] The preparation method is as follows: weigh the sludge incineration ash and metakaolin according to the formula amount, grind the two separately and pass through an 80 μm square hole sieve, and then mix with the formula amount of Ca(OH) 2 The three are mixed, roasted and activated at a temperature of 600°C for 1.5h, and the activated material is mixed with desulfurized gypsum (CaSO 4 2H 2 O) and KH 2 PO 4 The alkali activator obtained by mixing is activated, and the water-cement ratio of the total mixed material is controlled at 0.28. The mixed material is filled in a 40×40×160mm mold, pressed for 50s under a pressure of 15MP, and placed in a standard curing box (temperature After curing for 24 hours at about 25°C and humidity of about 90%, demoulding was carried out, followed by 7 days of humid heat curing at 80°C to o...

Embodiment 2

[0034] A sludge incineration ash-based geopolymer, the basic composition of which includes the following components by mass percentage:

[0035]

[0036]

[0037] The preparation method is as follows: weigh the sludge incineration ash and metakaolin according to the formula amount, grind the two separately and pass through an 80 μm square hole sieve, and then mix with the formula amount of Ca(OH) 2 The three are mixed, roasted and activated at a temperature of 600°C for 1.5h, and the activated material is mixed with desulfurized gypsum (CaSO 4 2H 2 O) and KH 2 PO 4 The alkali activator obtained by mixing is activated, and the water-cement ratio of the total mixed material is controlled at 0.28. The mixed material is filled in a 40×40×160mm mold, pressed for 50s under a pressure of 15MP, and placed in a standard curing box (temperature After curing for 24 hours at about 25°C and humidity of about 90%, demoulding was carried out, followed by 7 days of humid heat curing ...

Embodiment 3

[0039] A sludge incineration ash-based geopolymer, the basic composition of which includes the following components by mass percentage:

[0040]

[0041] The preparation method is as follows: weigh the sludge incineration ash and metakaolin according to the formula amount, grind the two separately and pass through an 80 μm square hole sieve, and then mix with the formula amount of Ca(OH) 2 The three are mixed, roasted and activated at 600°C for 2 hours, and the activated material is mixed with desulfurized gypsum (CaSO 4 2H 2 O) and KH 2 PO 4 The alkali activator obtained by mixing is activated, and the water-cement ratio of the total mixed material is controlled at 0.28. The mixed material is filled in a 40×40×160mm mold, pressed for 50s under a pressure of 15MP, and placed in a standard curing box (temperature After curing for 24 hours at about 25°C and humidity of about 90%, demoulding was carried out, followed by 7 days of humid heat curing at 80°C to obtain a certai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com