Acid-resistant brick for incinerator and preparation method thereof

A technology of acid-resistant bricks and incinerators, applied in the field of materials, can solve the problems of adhesion, corundum brick erosion and peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

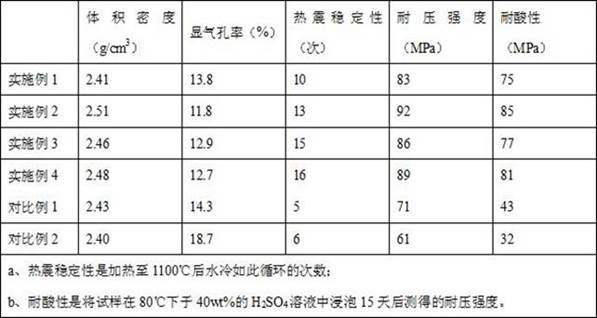

Examples

preparation example Construction

[0027] The embodiment of the present invention also provides a preparation method of the above-mentioned acid-resistant brick for an incinerator, which includes:

[0028] S1. Mix aluminum silicate material, coke gemstone, chrome corundum, china clay, feldspar powder, micropowder additive and adhesive to obtain a mixture;

[0029] S2. Cover the mixed material with a damp cloth, and trap the material at room temperature;

[0030] S3. Press-molding the trapped mixture to obtain adobe;

[0031] S4. Fire the adobe at 1500~1700°C to obtain an acid-resistant brick for an incinerator.

[0032] Further, in order to mix the raw materials more fully, the following methods are used to mix the raw materials, including

[0033] S1-1. Blend chrome corundum, china clay, feldspar powder and micropowder additives for 30-60 minutes to obtain mixed powder;

[0034] S1-2. Mix the aluminum silicate material, burnt gem and part of the adhesive for 5-10 minutes to obtain the mixed aggregate;

[0...

Embodiment 1

[0040] This embodiment provides an acid-resistant brick for an incinerator, and its raw materials include:

[0041] 50 parts of aluminum silicate material (1~5 mm), 20 parts of coke gemstone (0.1~1 mm), 15 parts of chrome corundum (320 mesh), 5 parts of china clay, 5 parts of feldspar powder, 2 parts of micropowder additive, and diphosphate 3 parts of aluminum hydrogen solution.

[0042] Its preparation method includes:

[0043] S1. Blend chrome corundum, china clay, feldspar powder and micropowder additives in a pre-mixer for 30 min to obtain a mixed powder;

[0044] Dry-mix the aluminum silicate material and burnt gemstones in a wet mill for 3 minutes, add 2 / 3 of the adhesive and mix for 10 minutes to obtain a mixed aggregate;

[0045] Mix the mixed powder and mixed aggregate for 3 minutes, add the remaining part of adhesive, and continue mixing for 25 minutes to obtain a mixture.

[0046] S2. Cover the mixture with a damp cloth, and store it at room temperature for 24 ho...

Embodiment 2

[0051] This embodiment provides an acid-resistant brick for an incinerator, and its raw materials include:

[0052] 10 parts of the first aluminum silicate material (3~5 mm), 40 parts of the second aluminum silicate material (1~3 mm), 10 parts of the first burnt gemstone (0.1~1 mm), and 10 parts of the second burnt gemstone (320 mesh ) 20 parts, chrome corundum (320 mesh) 15 parts, china clay 15 parts, feldspar powder 10 parts, micropowder additive 5 parts, and aluminum sol 3.5 parts.

[0053] Its preparation method includes:

[0054] S1. Mix the second burnt gemstone, chrome corundum, china clay, feldspar powder, and micropowder additives in a premixer for 60 minutes to obtain a mixed powder;

[0055] Dry-mix the first aluminum silicate material, the second aluminum silicate material, and the first burnt gem in a wet mill for 2 minutes, add 3 / 4 of the adhesive and mix for 5 minutes to obtain a mixed aggregate;

[0056] Mix the mixed powder and mixed aggregate for 5 minutes, a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com