A copper alloy slider

A technology of copper alloy and slider, which is applied in the field of copper alloy slider and its preparation, can solve the problems that there is no way to solve the corrosion effect of landfill leachate, cannot bear the impact force, and the structural strength is small, so as to reduce the pores on the surface of the workpiece and prevent the Abrasion, the effect of reducing stamping tear seams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

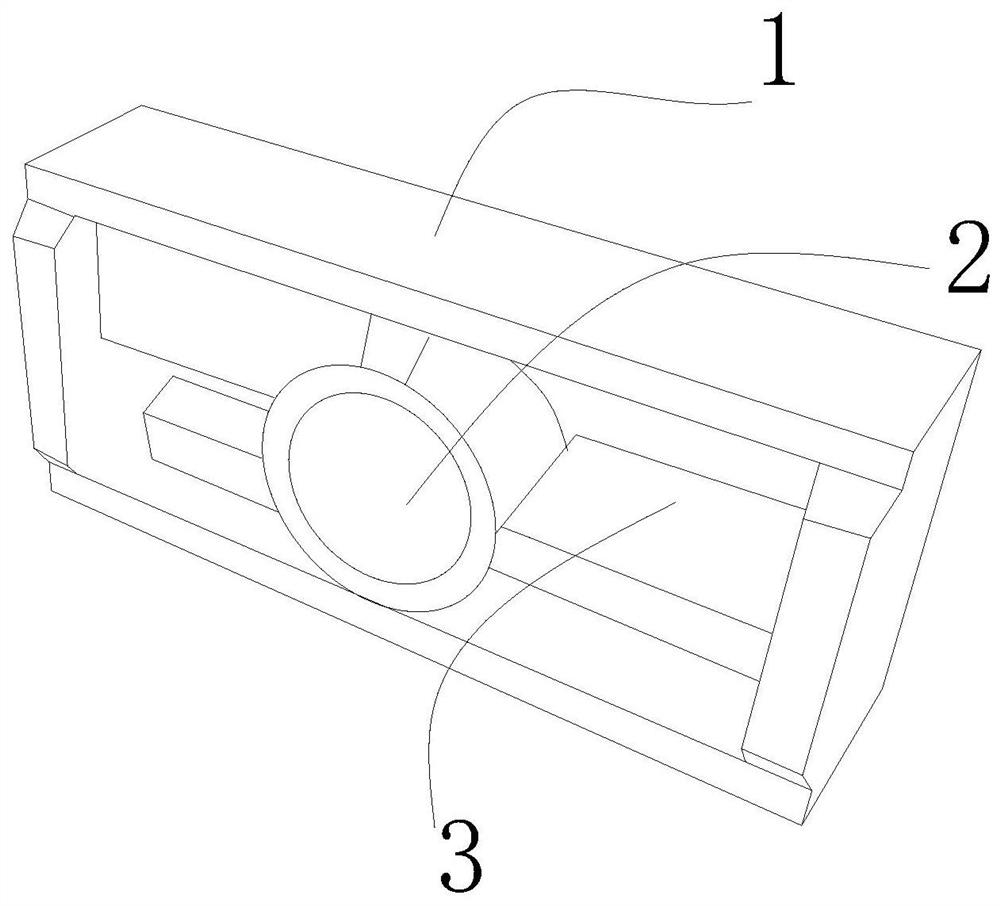

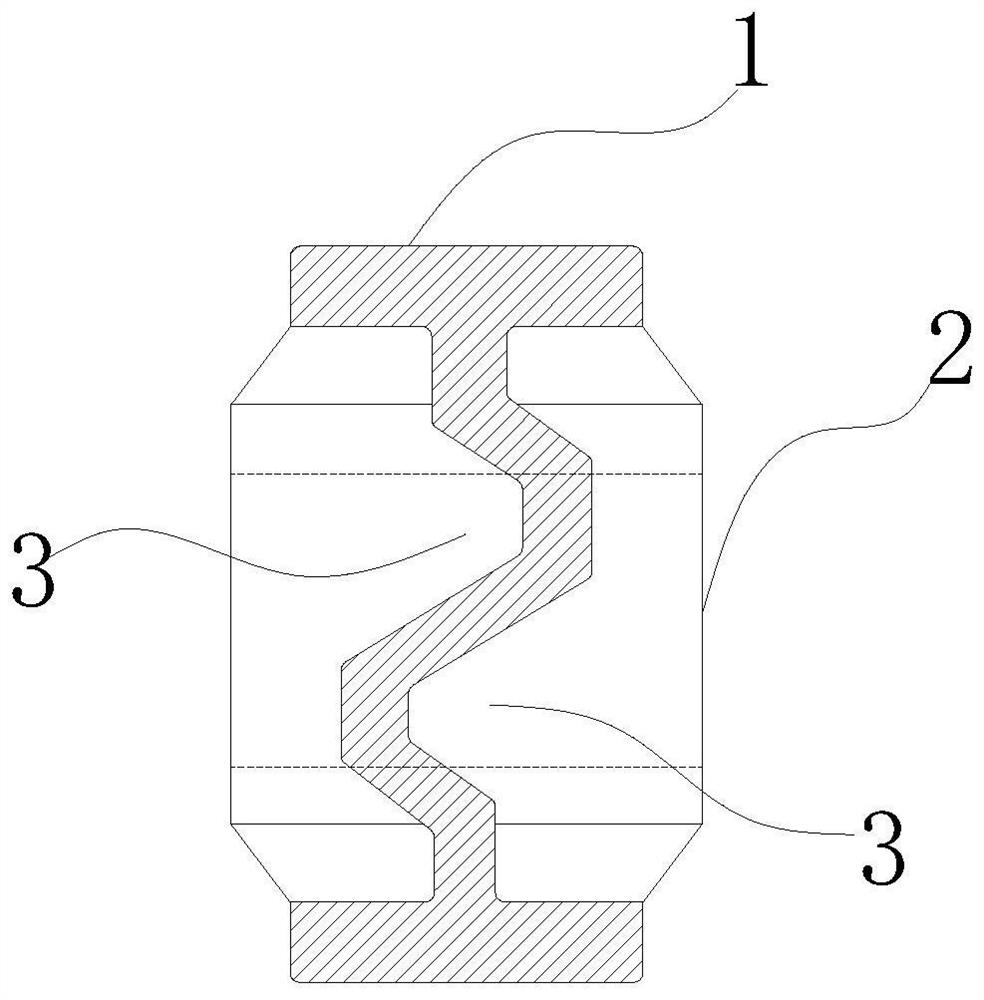

[0022] Example. A copper alloy slider such as figure 1 As shown: It includes a slider body 1 with a basic outline of a cuboid and a shaft hole 2 located in the center of the slider body 1. The slider body 1 is provided with a hollow part 3, and the hollow part 3 is located on the two surfaces through which the shaft hole 2 penetrates. The slider body 1 is a copper alloy, and the components of the copper alloy include 79% to 80% by mass of copper, 9% to 10% by mass of aluminum, 4% to 5% by mass of iron and 4% to 5% by mass 5% nickel by mass.

[0023] The preparation method of above-mentioned copper alloy slider, comprises the following steps:

[0024] ① Metal raw materials are mixed and melted in proportion to obtain raw material A;

[0025] ② Extrude raw material A into round bar B;

[0026] ③ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brinell hardness | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com