Inorganic solid silicon-based sulfonic acid and/or phosphoric acid catalyst, and preparation method and application thereof

A technology of solid acid catalysts and phosphoric acid catalysts, applied in physical/chemical process catalysts, inorganic chemistry, chemical instruments and methods, etc., can solve the problems of high cost, unstable sulfonic acid group, easy to fall off, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

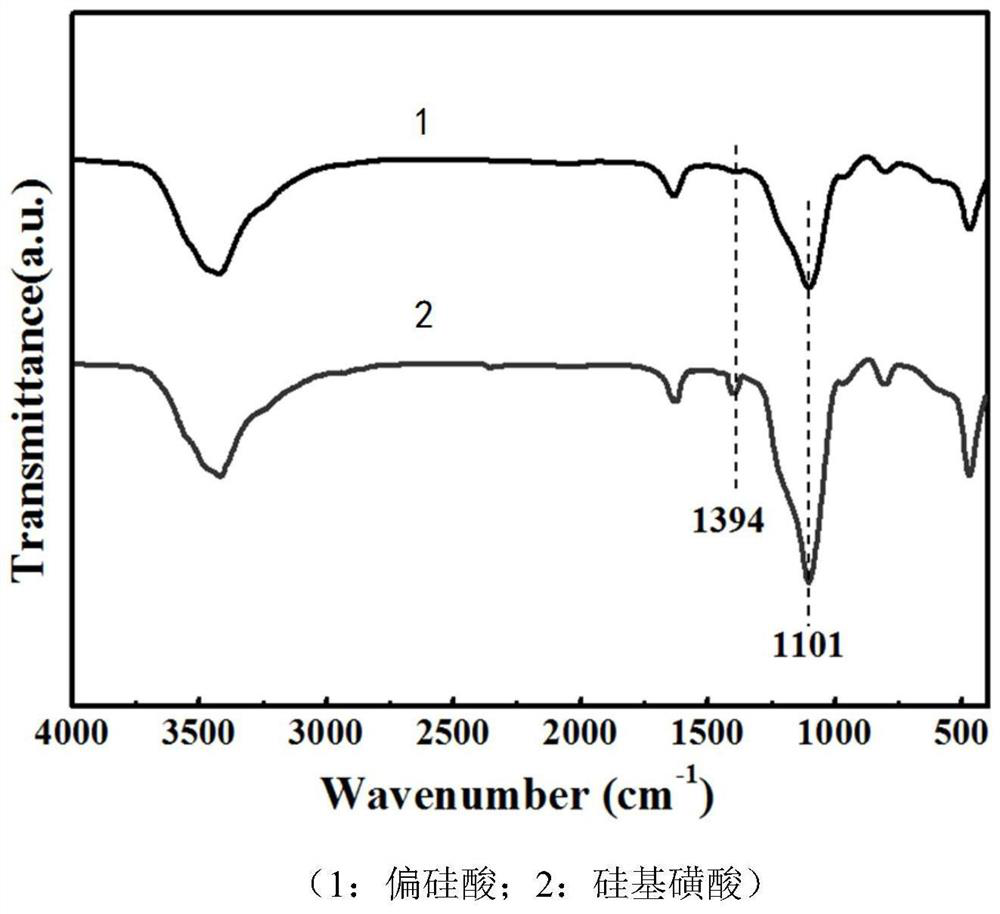

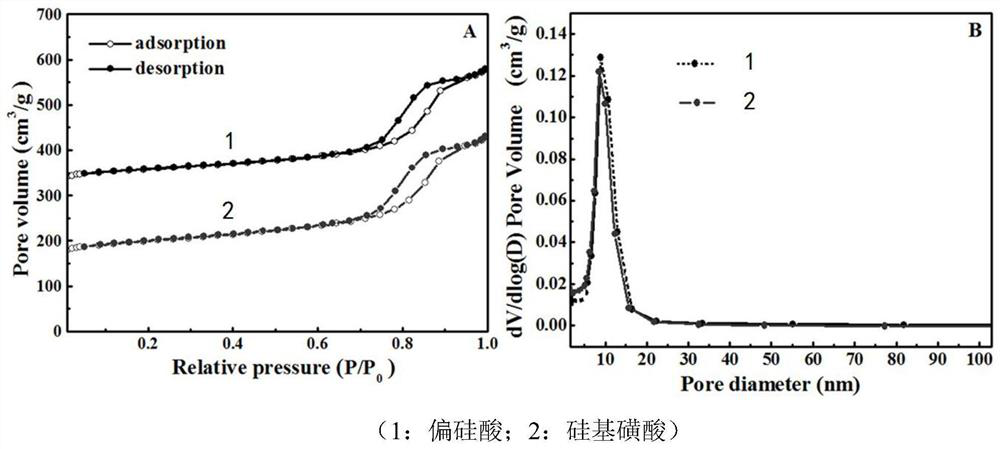

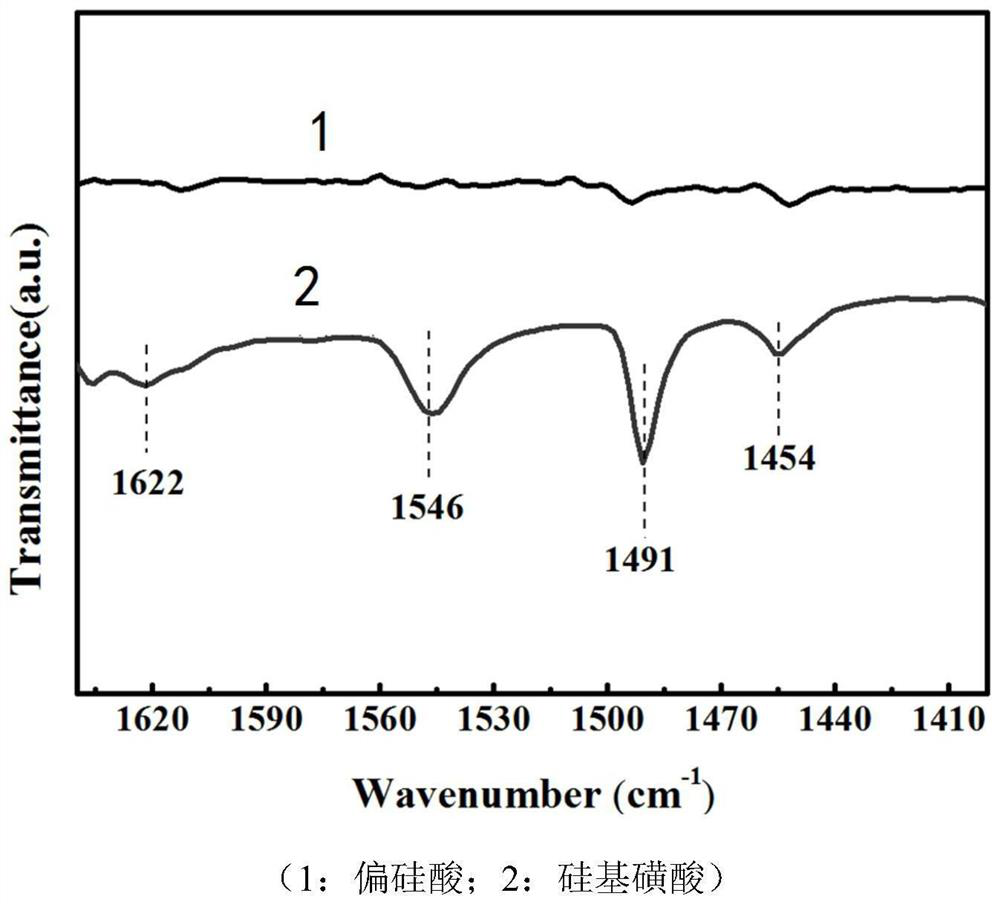

Embodiment 1

[0156]Fully dissolve 50 g of sodium silicate nonahydrate in 400 mL of deionized water to obtain a sodium silicate solution. Then add 1.8mol / L hydrochloric acid solution 200mL (the molar ratio of sodium silicate to hydrochloric acid is 0.5) in sodium silicate solution, carry out ion exchange reaction at room temperature, control pH value to be 5~6, obtain ortho silicic acid (H 4 SiO 4 )gel. Then the gel was left to stand at 60°C for 12 hours to crystallize, then filtered and washed until the filtrate was neutral. Finally, the obtained gel solid was vacuum-dried at 110° C. for 12 hours to obtain solid powder metasilicate (H 2 SiO 3 ), measuring its specific surface area to be 293m 2 / g. Add 5 g of metasilicate powder with an average particle size of 90 μm into 100 mL of concentrated sulfuric acid (concentration 98 wt%), stir, sulfonate at 130 ° C for 6 h, then cool to room temperature, filter, and wash the filter cake with deionized water until The filtrate became neutral,...

Embodiment 2

[0158] Drop 280mL of 1.8mol / L hydrochloric acid solution into 21g of tetraethylorthosilicate (0.1mol) in ethanol solution (the molar ratio of silicate to hydrochloric acid is 0.2), carry out the hydrolysis reaction at 20°C, and control the pH value to 5 ~6, to get orthosilicic acid (H 4 SiO 4 )gel. Then the gel was left to stand at 60°C for 12 hours to crystallize, then filtered and washed until the filtrate was neutral. Finally, the obtained gel solid was vacuum-dried at 110° C. for 12 hours to obtain solid powder metasilicate (H 2 SiO 3 ), measuring its specific surface area to be 305m 2 / g. Add 5 g of metasilicate powder with an average particle size of 88 μm into 100 mL of concentrated sulfuric acid, stir, sulfonate at 130 ° C for 6 h, then cool to room temperature, filter, and wash the filter cake with deionized water until the filtrate becomes neutral. The obtained white solid powder was vacuum-dried at 110°C for 5 hours, and finally, the dried sulfonated solid pow...

Embodiment 3

[0161] Embodiment 3 (application embodiment-catalyst stability)

[0162] Study on the Stability of Inorganic Solid Silicon-based Sulfonic Acid Catalytic Materials. The inorganic solid silicon-based sulfonic acid catalytic material in Example 1 of the present invention was selected to be used in the cyclohexanone oxime liquid-phase Beckmann rearrangement reaction system, and its service life was investigated. After running for 136 hours, the conversion rate of cyclohexanone oxime and the selectivity of caprolactam did not decrease significantly. The conversion rate of cyclohexanone oxime was maintained at 98%, and the selectivity of caprolactam was maintained at 99%, and the acid content was almost not decreased after the reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com