Heavy oil or residual oil hydrogenation catalyst and preparation method thereof

A residue hydrogenation and catalyst technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalyst, catalyst carrier, etc., can solve the problems of unsuitable hydrogenation catalyst, small pore size, etc. The effect of increasing acid content and good peptization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

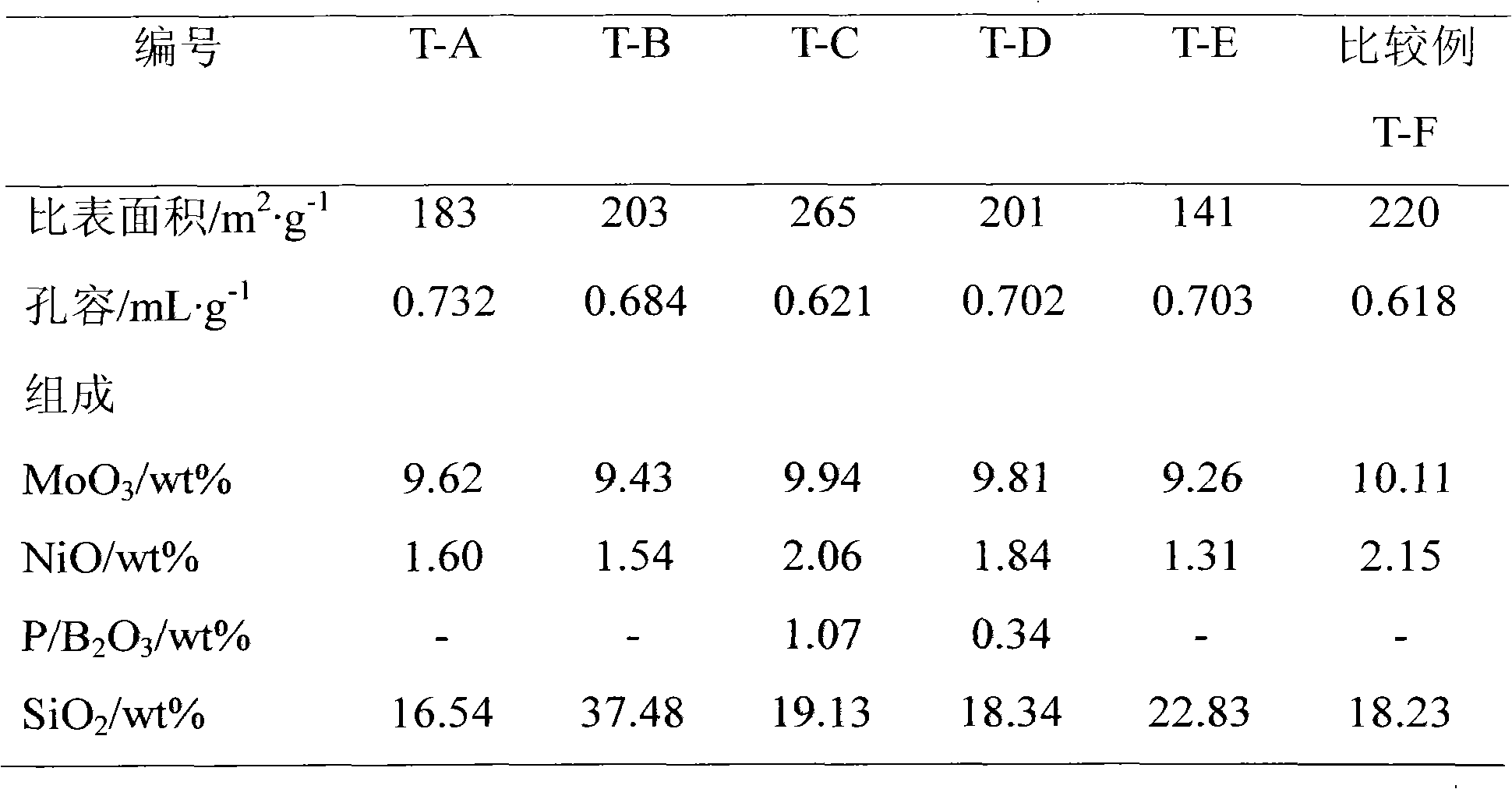

Embodiment 1

[0028] (1) Preparation of silicon-containing aluminum hydroxide

[0029] Preparation of sodium metaaluminate solution concentration is 45gAl 2 o 3 / L, the caustic ratio is 1.45, a total of 1.6L, and the concentration of aluminum sulfate solution is 15gAl 2 o 3 / L total 0.8L, ready for use.

[0030] Roast kaolin raw soil in a high-temperature furnace at a temperature of 600°C and hold a constant temperature for 4 hours. After cooling, weigh 30 g and put it into a container. Add 150 mL of 2 mol / L nitric acid and 150 mL of 2 mol / L citric acid, and heat for reaction. The reaction temperature is 60°C, the reaction time is 8h.

[0031]Add 700 mL of distilled water to the modified kaolin slurry, the slurry has a solid content of 3 wt%, and heat to 70°C. Add the prepared sodium metaaluminate solution to the modified kaolin slurry, adjust the pH to 10.9, then add aluminum sulfate solution to adjust the pH to 8.5, keep the pH at 8.5, and add sodium metaaluminate and aluminum sulfat...

Embodiment 2

[0036] The other conditions of the silicon-containing aluminum hydroxide are the same as in Example 1, except that the amount of kaolin after calcination is increased to 60 g, and the solid content in the slurry is 6 wt % to prepare silicon-containing aluminum oxide.

[0037] The preparation method of the catalyst is the same as in Example 1, and the catalyst T-B is prepared.

Embodiment 3

[0039] The preparation method of silicon-containing aluminum hydroxide is the same as in Example 1.

[0040] Take by weighing 100g of silicon-containing aluminum hydroxide (containing 75wt% aluminum oxide) prepared, add 1.5g carbon black and 3.0 grams of scallop powder, mix well, take by weighing 3.0 grams of ammonium bicarbonate and 6 grams of polyethylene glycol, respectively Add 55 grams of distilled water to dissolve it completely, then add it to the mixed raw materials in sequence, knead and extrude it into a rod, then dry at 110°C for 4 hours, and bake at 650°C for 3 hours to obtain carrier C.

[0041] Weigh 21.37g of phosphoric acid, add 450ml of distilled water, then sequentially add 72.76g of molybdenum oxide and 19.81g of basic nickel carbonate, heat and stir until completely dissolved, then adjust the solution to 500ml with distilled water to obtain solution L-3. Saturated carrier C was impregnated with L-3 solution, dried at 120°C for 2 hours, and calcined at 430°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com