Method for firing ceramsite from coal mixed slag and sludge

A cinder and sludge technology, applied in the production of clay products, ceramic products, ceramic materials, etc., can solve the problems of sludge dehydration or long time, difficult granulation, high water content of sludge, etc., to increase the resistance to sulfuric acid Salt erosion performance and impermeability, the effect of reducing the density of ceramsite and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

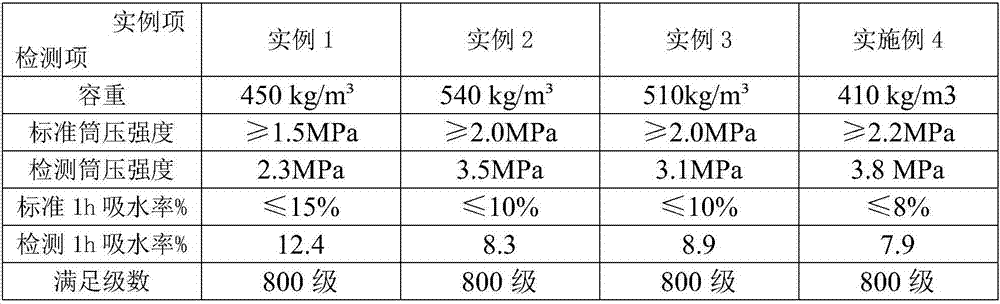

Examples

Embodiment 1

[0025] 1. Grind and dry clay and cinder into powder, and dehydrate the sludge by flocculant; 2. Weigh 2 parts of clay, 5 parts of sludge and 3 parts of cinder by volume; 3. Mix the three raw materials evenly without adding water 4. Bake in a constant temperature oven at 105±5°C for 2 hours and 50 minutes; 5. Bake in a constant temperature electric oven at 450°C for 20 minutes; 6. Bake in a constant temperature electric oven at 1150°C for 10 minutes to obtain the product of the present invention.

Embodiment 2

[0027] 1. Grind and dry the clay and cinder into powder; the sludge is dehydrated by flocculant, 2. Weigh 2 parts of clay, 3 parts of sludge and 5 parts of cinder by volume; 3. Mix the three raw materials evenly without adding water 4. Bake in a constant temperature oven at 105±5°C for 2 hours and 30 minutes; 5. Bake in a constant temperature electric oven at 400°C for 25 minutes; 6. Bake in a constant temperature electric oven at 1100°C for 13 minutes to obtain the product of the present invention.

Embodiment 3

[0029] 1. Grind and dry the clay and cinder into powder; the sludge is dehydrated by flocculant, 2. Weigh 2.5 parts of clay, 4 parts of sludge and 3.5 parts of cinder by volume; 3. Mix the three raw materials evenly without adding water 4. Bake in a constant temperature oven at 105±5°C for 2 hours; 5. Bake in a constant temperature electric oven at 380°C for 20 minutes; 6. Bake in a constant temperature electric oven at 1060°C for 15 minutes to obtain the product of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com