Anti-corrosion anti-cracking permeability reducing agent for marine concrete and preparation method of anti-corrosion anti-cracking permeability reducing agent

A marine concrete and penetrating agent technology, applied in the field of concrete admixture, can solve the problems of corrosion of steel bars and metal embedded parts, affecting the durability of concrete, and being easily leached by erosive solutions, so as to prolong the service life, improve durability, The effect of improving the corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

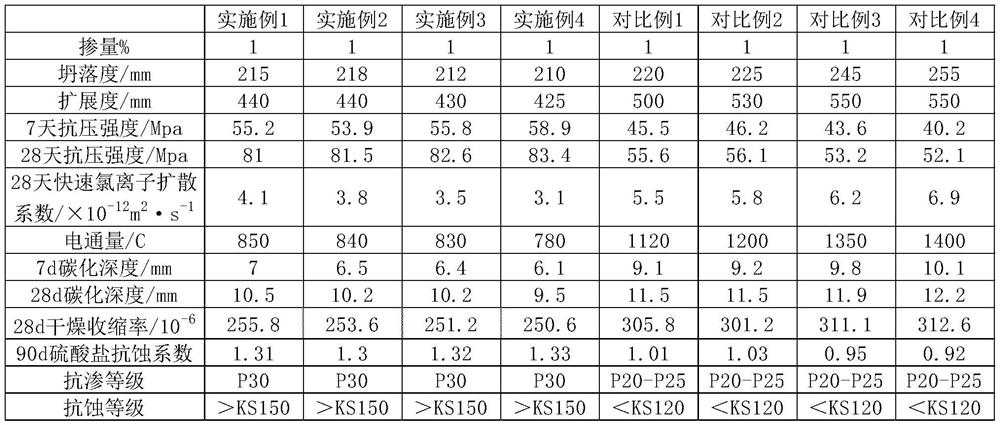

Examples

Embodiment 1

[0027] An anti-corrosion, anti-cracking, and permeability-reducing agent for marine concrete, comprising the following parts by weight of raw materials: 5 parts of water reducing agent, 4 parts of micro-nano anti-permeability components, 1.5 parts of air-entraining agent, 3 parts of anti-cracking fibers, 1 part of phytate, 1 part of polypropylene alcohol, 0.5 part of hydroxypropyl distarch phosphate, 0.5 part of chitosan, and 20 parts of water.

[0028] The water reducing agent is sodium methylnaphthalene sulfonate water reducing agent.

[0029] The preparation method of the micro-nano impermeable component is as follows: immersing the nano-silicon dioxide in a sulfuric acid solution with a mass concentration of 30% according to a solid-to-liquid ratio of 1g:10ml, and then adding coconut oil fatty acid diethanol with a mass of 1% of the mixed solution. amide, stirred and heated in a water bath for 1 hour at 60-70 °C, then added 10% of the mass of the mixed liquid redispersible...

Embodiment 2

[0037] An anti-corrosion, anti-cracking, and permeability-reducing agent for marine concrete, comprising the following parts by weight of raw materials: 7 parts of water reducing agent, 6 parts of micro-nano anti-permeability components, 2 parts of air-entraining agent, 5 parts of anti-cracking fibers, 2 parts of phytate, 2 parts of polypropylene alcohol, 0.8 part of hydroxypropyl distarch phosphate, 1 part of chitosan, and 25 parts of water.

[0038] The water reducing agent is a sulfamate water reducing agent.

[0039]The preparation method of the micro-nano impermeable component is as follows: the nano-silicon dioxide is soaked in a sulfuric acid solution with a mass concentration of 35% according to a solid-to-liquid ratio of 1g:15ml, and then the coconut oil fatty acid diethanol of 2% by mass of the mixed solution is added. amide, stirred and heated in a water bath for 1.5 hours at 60-70 °C, and then added 15% of the mass of the mixed liquid redispersible latex powder and...

Embodiment 3

[0047] An anti-corrosion, anti-cracking and permeability-reducing agent for marine concrete is prepared from the following raw materials in parts by weight: 8 parts of water reducing agent, 8 parts of micro-nano anti-permeability components, 3 parts of air-entraining agent, 7 parts of anti-cracking fibers, 2 parts of phytate, 4 parts of polypropylene alcohol, 0.7 parts of hydroxypropyl distarch phosphate, 1.2 parts of chitosan, and 25 parts of water.

[0048] The water reducing agent is an aliphatic water reducing agent.

[0049] The preparation method of the micro-nano impermeable component is as follows: the nano-silicon dioxide is soaked in a sulfuric acid solution with a mass concentration of 40% according to a solid-to-liquid ratio of 1g:20ml, and then the coconut oil fatty acid diethanol with a mass concentration of 3% of the mixed solution is added. amide, stir and heat in a water bath for 2 hours at 60-70°C, then add 20% of redispersible latex powder and 1% of fatty al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com