Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

58results about How to "Reduced hydration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

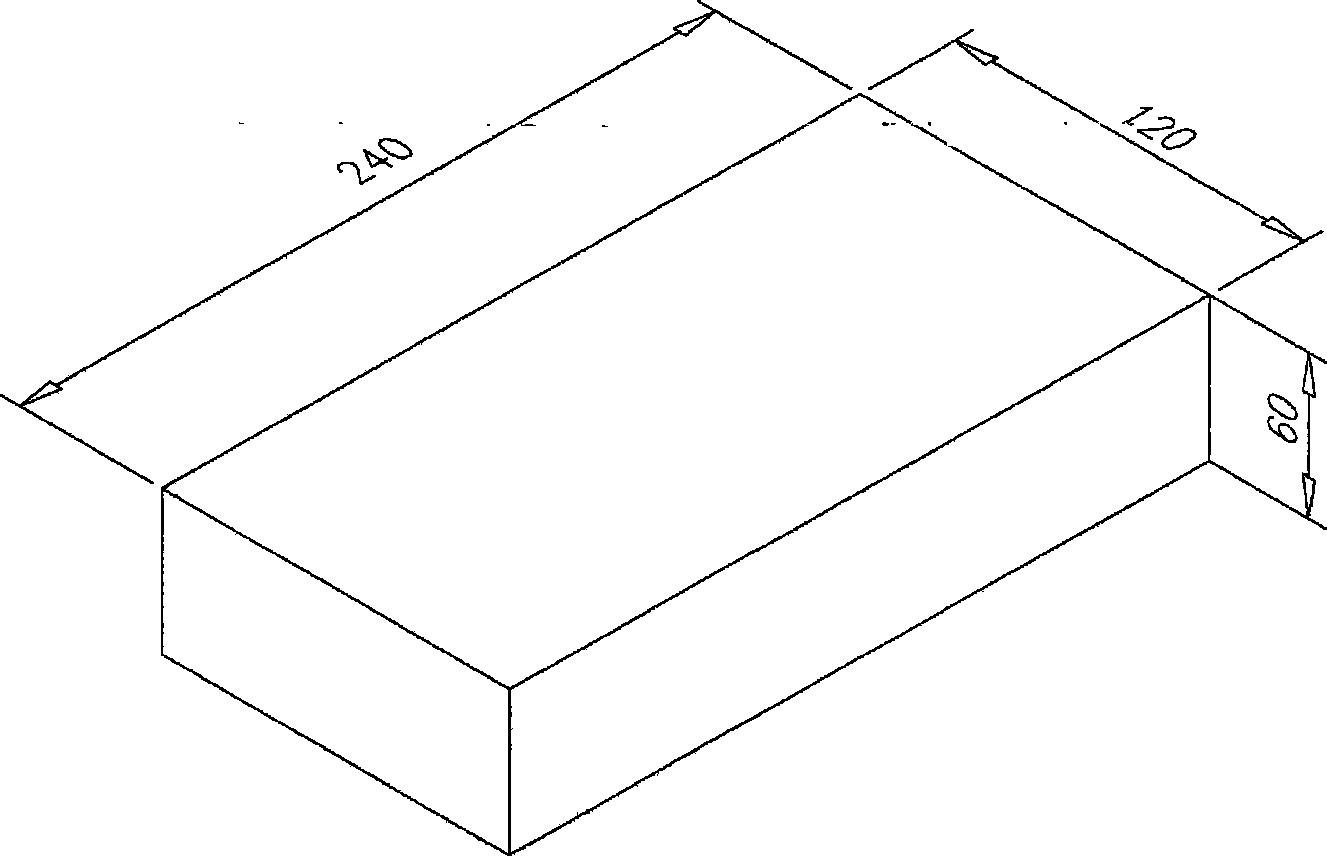

Grey brick mechanically manufactured from lime sludge and construction wastes and method for manufacturing same

The invention discloses a gray brick mechanically manufactured from lime sludge and construction wastes and a method for manufacturing the same. The materials for mechanically manufacturing the gray brick comprise the following raw materials in portion by weight: 1,015 to 1,135 portions of construction waste crushed materials, 240 to 290 portions of cement, 810 to 1,010 portions of lime sludge, 60 to 75 portions of gray lime, and 100 to 125 portions of water, wherein the particle size of the construction waste crushed materials is less than 15 millimeters. If necessary, less than 20 portions of fly ash and proper amount of activating agent can be added to the materials. The method for mechanically manufacturing gray brick comprises the following steps: firstly, crushing the construction wastes; secondly, mixing the construction waste crushed materials with the other materials according to the proportions; and thirdly, pressing the mixture by adopting a mechanical method so as to produce the gray brick of the invention. The gray brick and the method for manufacturing the same recycle the sludge and the construction wastes in a reducing, harmless and resource-utilizing mode, and solve the problem that substituting materials and products are hard to find after clay bricks are forbidden to use and the problem of gray brick sources for civilian constructions.

Owner:梁林华 +1

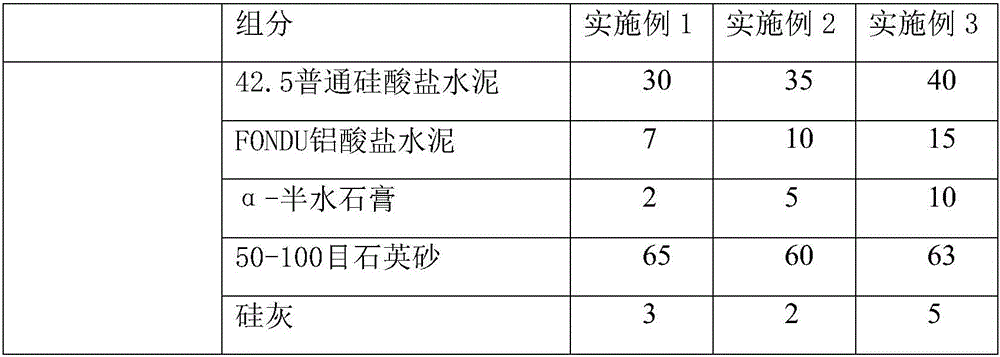

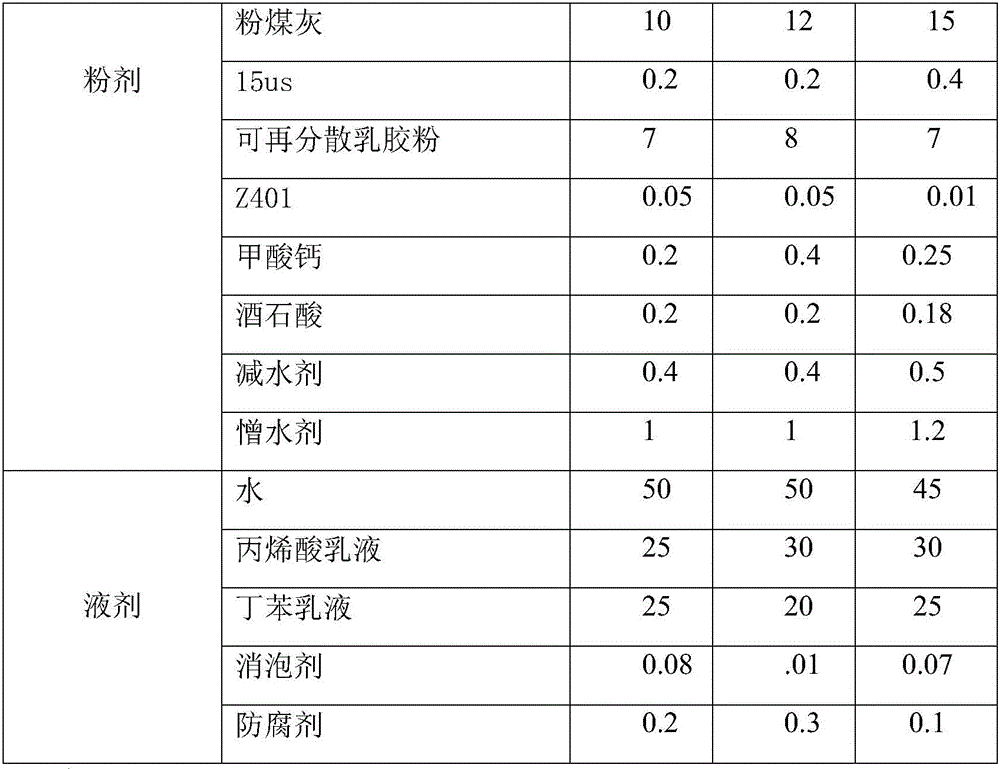

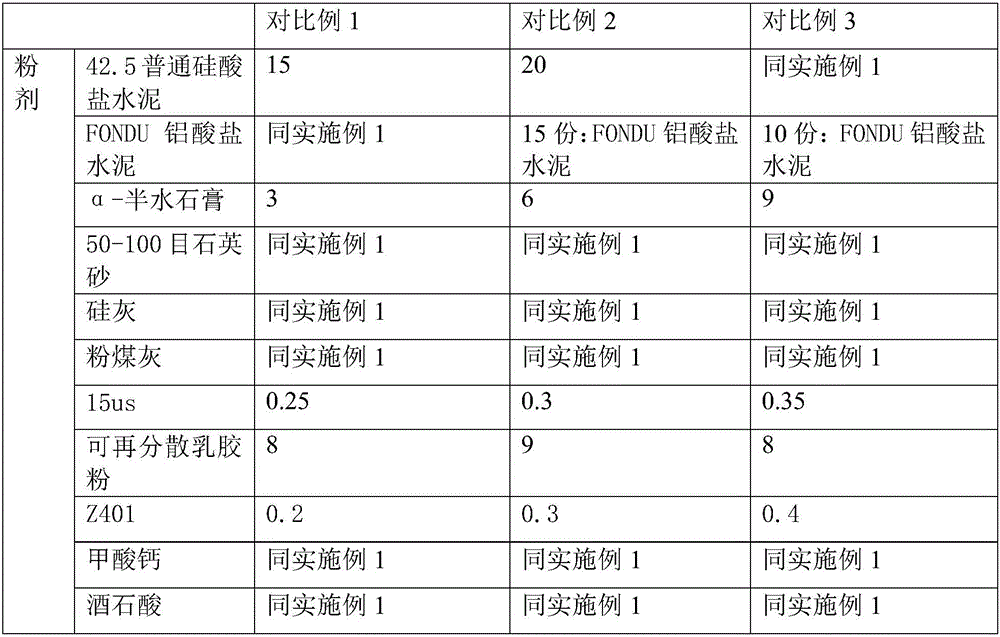

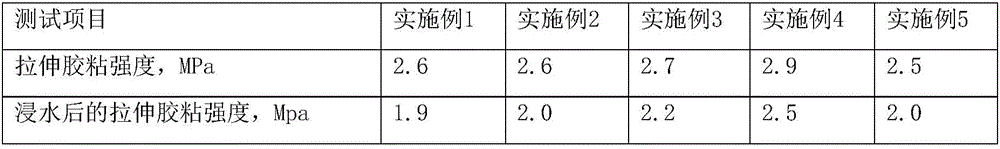

Quick-hardening waterproof ceramic tile adhesive

The invention provides a quick-hardening waterproof ceramic tile adhesive which comprises powder and liquid. The powder is prepared from, by weight, high-alumina cement, ordinary Portland cement, gypsum, silica sand, silica fume, a water repellent, a water reducer, coal ash, a water retaining agent, an anti-sagging agent, redispersible powder, a water soluble organic compound early strength agent and an alkyl carboxyl retarder; the liquid is prepared from, by weight, an acrylic emulsion, butylbenzene emulsion, water, a defoaming agent and a corrosion remover. According to the adhesive, the powder is formed by combining the ordinary Portland cement, the high-alumina cement and the gypsum and the liquid formed by combing the acrylic emulsion and the butylbenzene emulsion are matched for use, quick-hardening and waterproof effects of the ceramic tile adhesive can be achieved, and compared with an adhesive only adopting powder, the quick-hardening waterproof ceramic tile adhesive is better in adhesion effect and waterproof effect.

Owner:上海亚瓦新型建筑材料有限公司

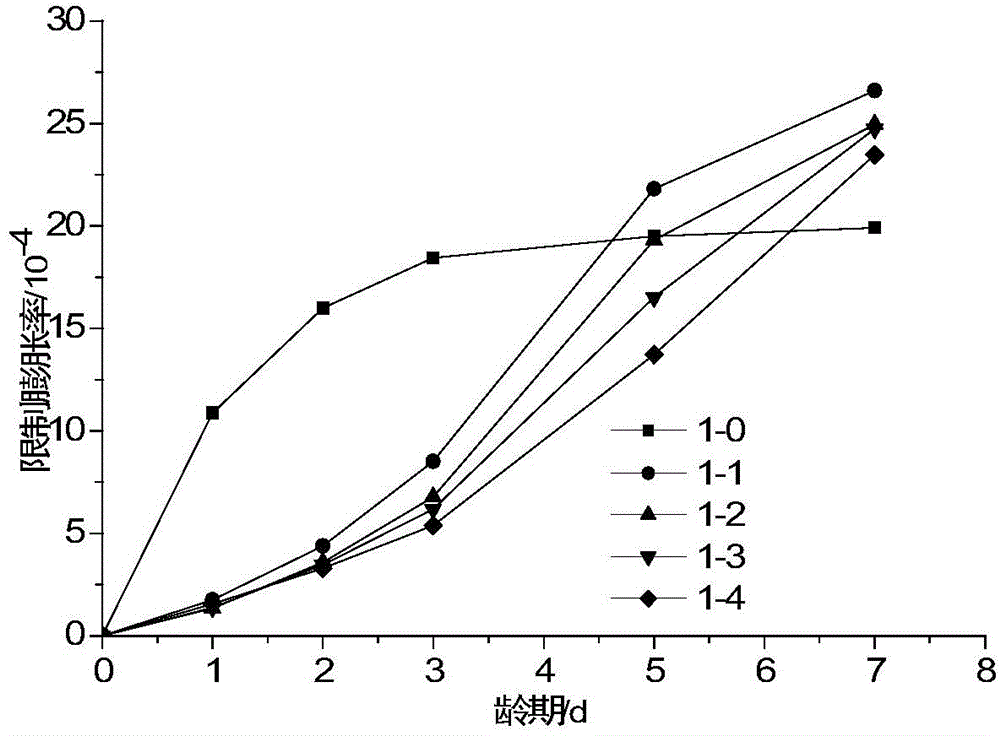

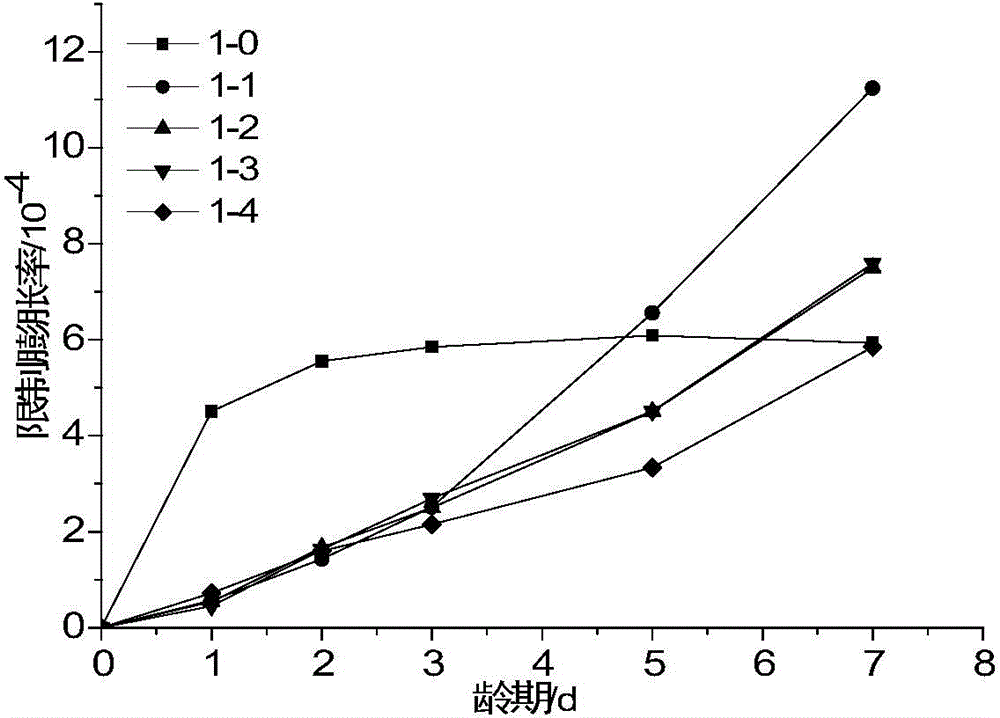

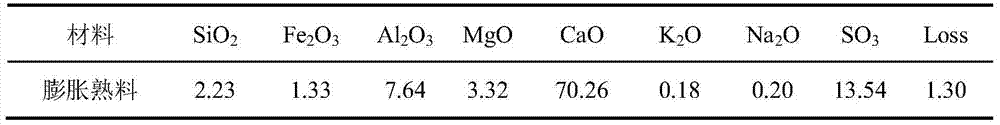

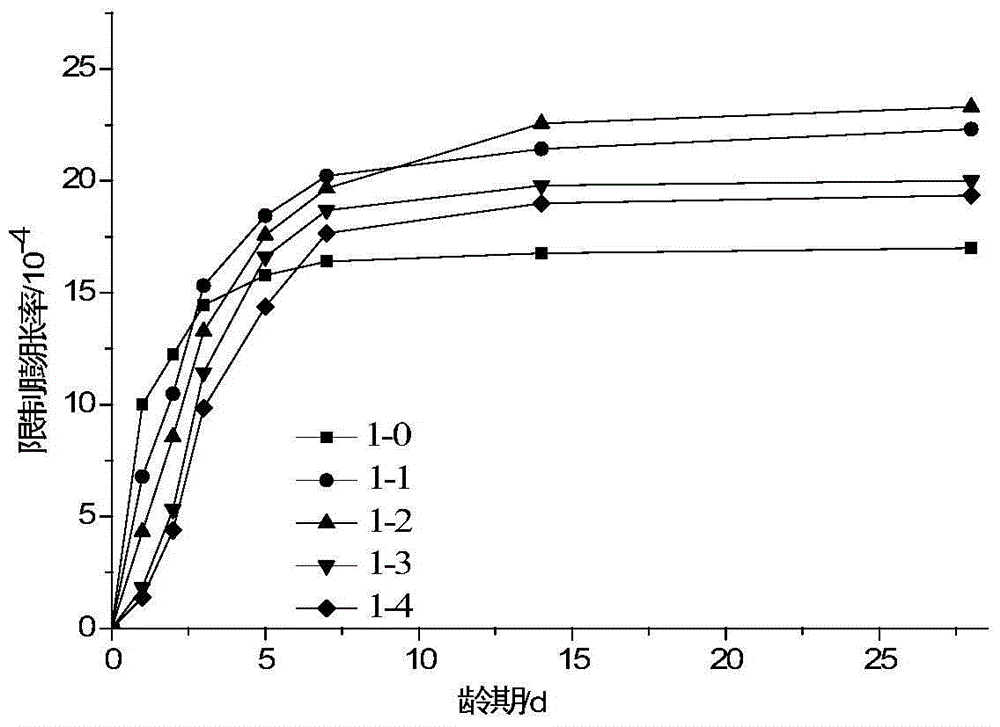

Modified calcium oxide expanding clinker as well as preparation method and application thereof

The invention relates to a modified calcium oxide expanding clinker as well as a preparation method and application thereof. The preparation method of the modified calcium oxide expanding clinker comprises the following steps: grinding a calcium oxide expanding clinker till a certain grain size, putting the calcium oxide expanding clinker powder in a carbon dioxide atmosphere with certain humidity and forming plenty of dense calcium carbonate on the surface of the expanding clinker powder, thus preparing the modified calcium oxide expanding clinker. The modified calcium oxide expanding clinker can be mixed with a dispersion supporter, thus forming a modified calcium oxide concrete expansive agent. The modified calcium oxide expanding clinker prepared by the preparation method and the expansive agent thereof have the beneficial effects that the expansion quantity and expansion stress of the expanding clinker in cement concrete are obviously increased, thus optimizing the expansion processes of the expanding clinker and the expansive agent thereof; the weather resistance and moisture resistance of the calcium oxide expanding clinker and the expansive agent thereof are improved.

Owner:JIANGSU SOBUTE NEW MATERIALS

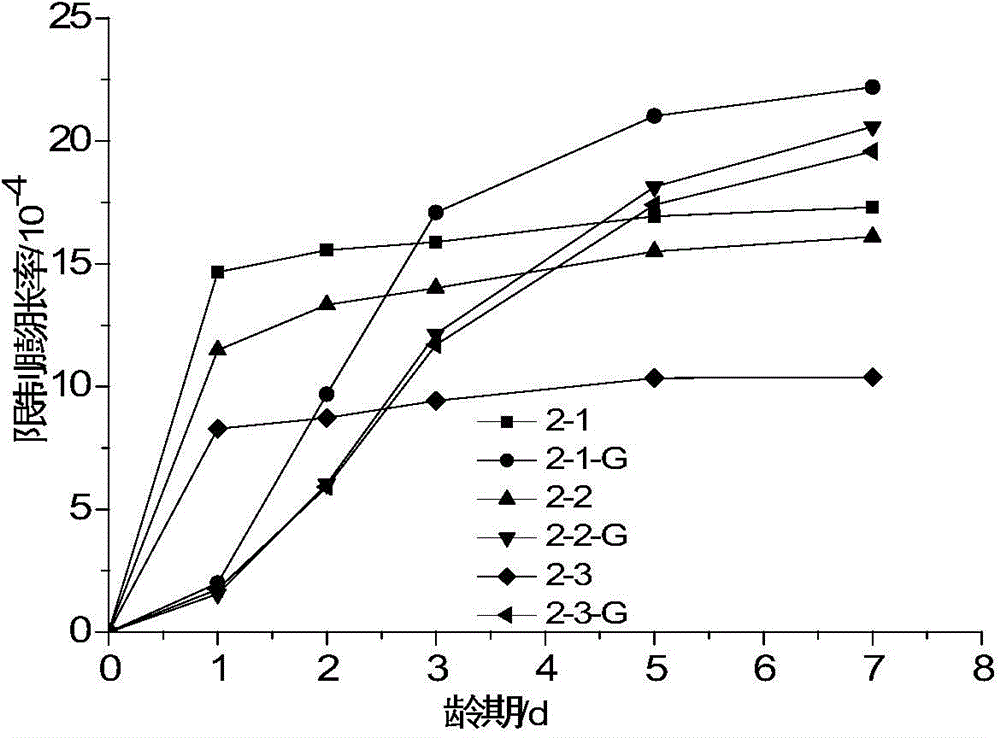

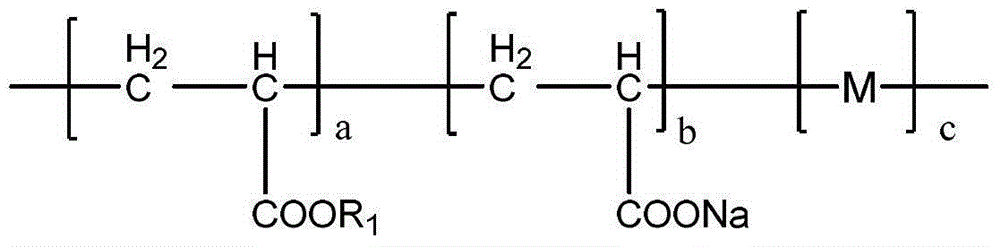

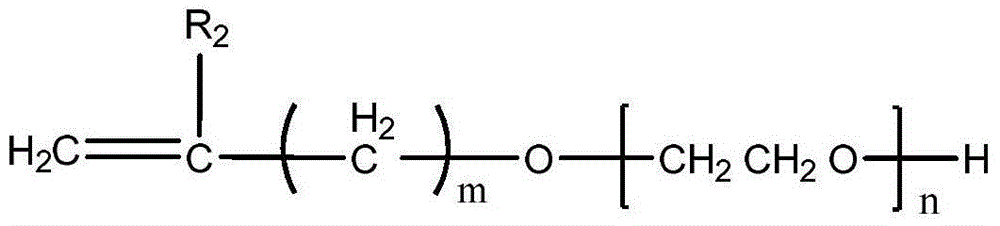

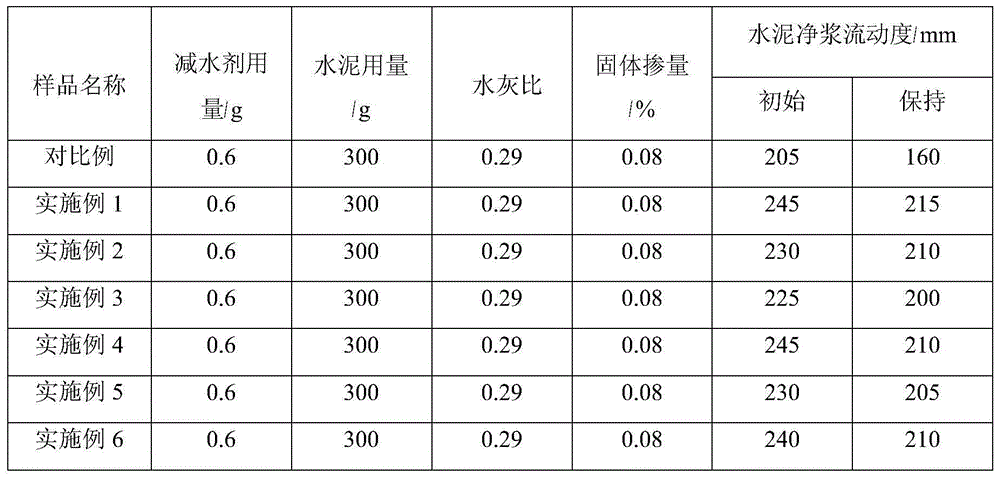

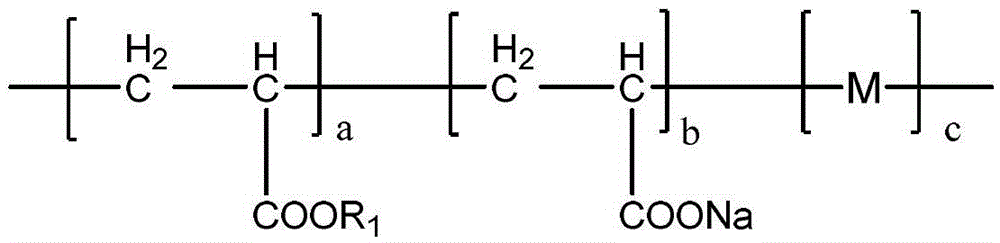

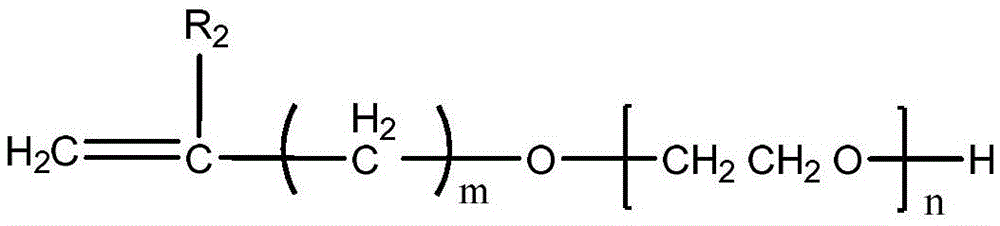

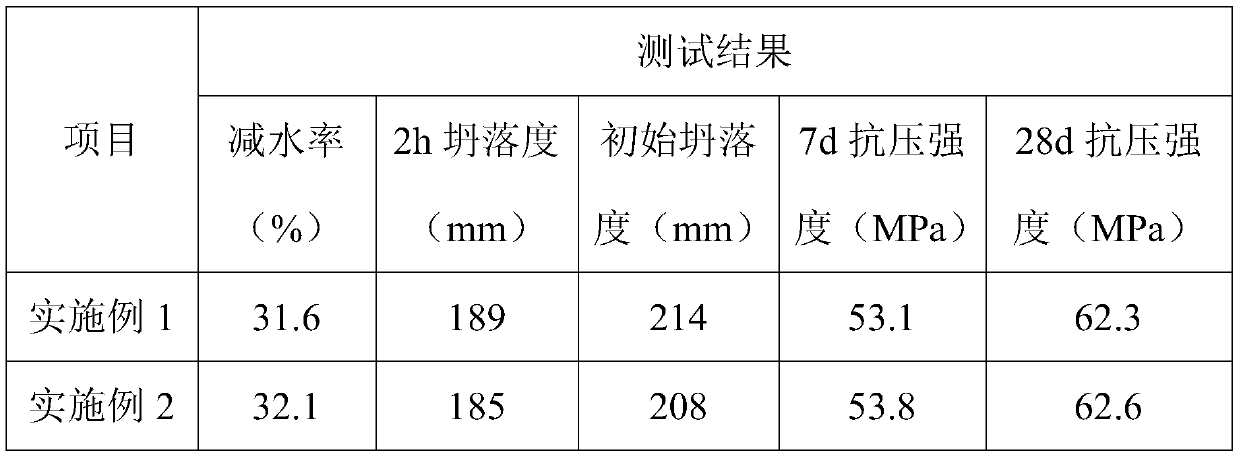

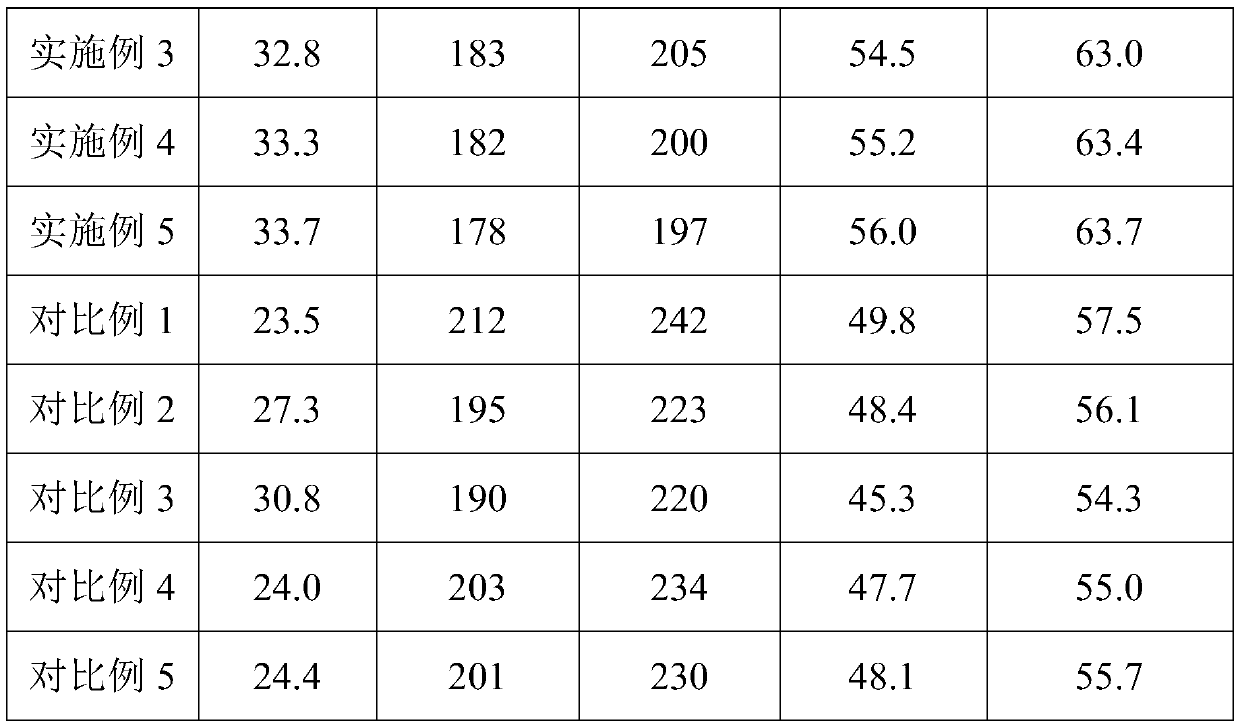

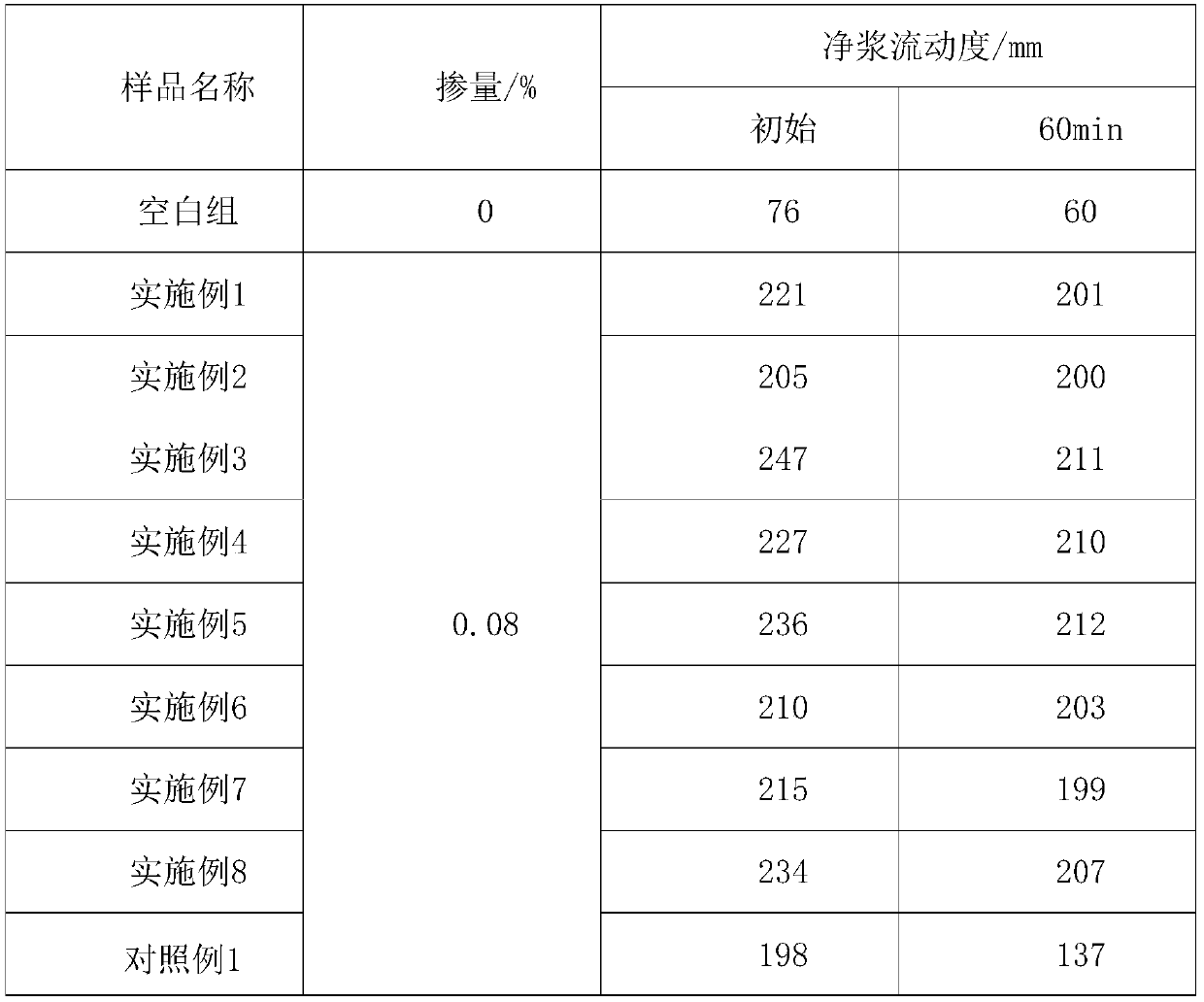

Polycarboxylate water reducer containing modified water-soluble acrylate and preparation method thereof

The invention provides a polycarboxylate water reducer containing modified water-soluble acrylate and a preparation method thereof. The preparation method comprises the following steps: firstly, directly carrying out esterification reaction on polyhydroxy-alcohol carbohydrates and crylic acid so as to prepare modified water-soluble acrylate micromonomers; then putting polyether macromonomers into deionized water, and fully dissolving so as to prepare a reaction base solution; dissolving the acrylate micromonomers, crylic acid, an initiator vitamin C and a chain transfer agent mercaptoacetic acid into deionized water, so as to prepare drop concentrate; putting an initiator hydrogen peroxide into the reaction base solution, dropwise adding the drop concentrate into the reaction base solution at a constant speed, reacting while stirring, then regulating the pH value of the solution to be 7-8, so as to prepare the polycarboxylate water reducer. According to the preparation method, the regulating function of the polyhydroxy-alcohol carbohydrates is directly used in the water reducer, so that the property of the water reducer is optimized; the polycarboxylate water reducer prepared by the method has high water reducing rate, and the concrete is obviously improved in fluidity retainability and has less slump loss, so that the water reducer can meet higher construction requirements.

Owner:SHANXI UNIV +1

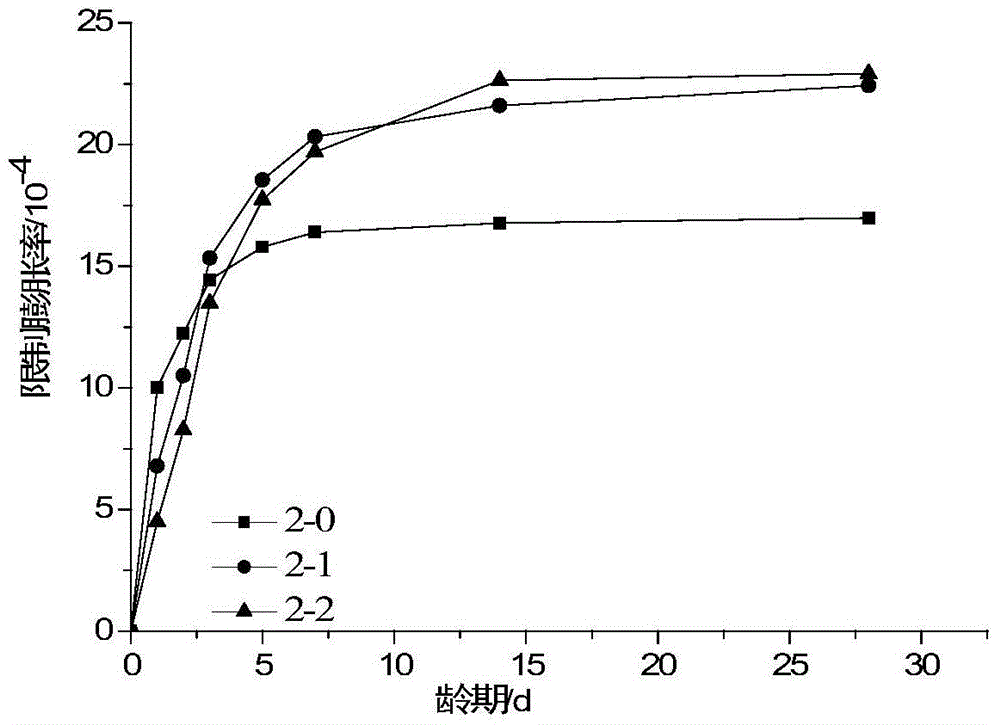

Modified calcium oxide expanding clinker as well as preparation method and application thereof

The invention relates to a modified calcium oxide expanding clinker as well as a preparation method and application thereof. The preparation method of the modified calcium oxide expanding clinker comprises the following steps: forming a dense calcium sulfate layer on the surface of an expanding clinker through reaction between sulfur dioxide gases or sulfuric acid and the calcium oxide expanding clinker, thus preparing the modified calcium oxide expanding clinker. The modified calcium oxide expanding clinker can be mixed with a dispersion supporter, thus forming a modified calcium oxide concrete expansive agent. The sulfated packing modified calcium oxide expanding clinker prepared by the preparation method and the expansive agent thereof have the beneficial effects that the expansion quantity and expansion stress of the expanding material in cement concrete are obviously increased, thus optimizing the expansion processes of the expanding clinker and the expansive agent thereof; the weather resistance and moisture resistance of the calcium oxide expanding clinker and the expansive agent thereof are improved.

Owner:JIANGSU SOBUTE NEW MATERIALS

Method for preparing shell primary layer coating for titanium alloy precision investment casting

InactiveCN104923721AReduced hydrationHigh shell strengthFoundry mouldsFoundry coresOrganic acidOrganic solvent

The invention discloses a method for preparing a shell primary layer coating for titanium alloy precision investment casting. The method includes the steps that electric melting yttrium oxide powder with a certain coarse and fine powder ratio is obtained through preprocessing of primary layer fireproof materials, a compound binding agent is prepared from organic acid, an inert organic solvent and acetic acid zirconium, and finally the primary layer coating is prepared. According to the method for preparing the shell primary layer coating for titanium alloy precision investment casting, the specific surface area of the yttrium oxide powder is reduced, organic acid and yttrium oxide can generate hydroxide of yttrium salt, the hydration of yttrium oxide is weakened, and the function of the high-temperature binding agent is achieved; viscosity is adjusted regularly, volatilization is reduced regularly, and stability of the coating is kept. The performance of the primary layer coating prepared through the method is stable and can be prolonged for 20 days, the temperature of the coating is 20+ / -5 DEG C, and therefore preparing and preserving can be conducted in a common constant-temperature and constant-humidity environment, and the coating preparing and preserving technology control is simplified.

Owner:HEBEI GANGYAN DEKAI TECH CO LTD

Painting and repairing material in use for wall of casting ladle

A coating material for repairing the wall of pouring ladle is composed of high-Al particles, fine corundum powder, fine powder of magnesium oxide, micro powder of magnesium oxide, micro Si powder, organic fibers and water-reducing agent (sodium or calcium lignosulfonate or carboxymethyl cellulose) proportionally.

Owner:BAOSHAN IRON & STEEL CO LTD

Porous vegetation concrete capable of improving vegetation performance

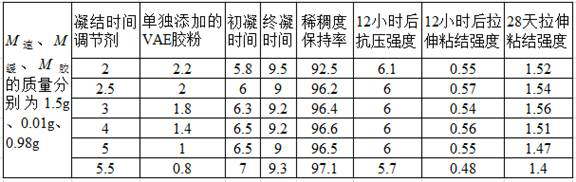

The invention discloses porous vegetation concrete capable of improving vegetation performance. The porous vegetation concrete is prepared from the following raw materials in parts by mass: 180-200 parts of cement, 1200-1400 parts of recycled coarse aggregate, 8-15 parts of emulsion and 40-70 parts of water, the emulsion is composed of a styrene-acrylic emulsion, a VAE emulsion and a styrene-butadiene emulsion. The mixed emulsion composed of the styrene-acrylic emulsion, the VAE emulsion and the styrene-butadiene emulsion is added, so that the hydration reaction of C2S can be delayed, and further the hydration of sulphoaluminate water cement is delayed; meanwhile, in the hydration process, Al (OH) 3 formed by the modified cement paste doped with the emulsion is reduced along with the increase of the mixing amount of the emulsion, so that the pH value of the cement is reduced. The recycled aggregate plant-growing concrete modified by the emulsion can greatly reduce the pH value of a pore solution, improves the plant-growing performance of the concrete, can adapt to the growth of green plants, can achieve the effects of greening the environment and restoring ecology for a long time, and also can improve the compressive strength of the plant-growing concrete.

Owner:广西壮族自治区水利科学研究院

Self-retarding concrete

The invention relates to the technical field of concrete, in particular to self-retarding concrete. The self-retarding concrete is prepared from the following raw materials in parts by weight: 20-40 parts by weight of fly ash, 15-35 parts by weight of cement, 5-30 parts by weight of fine sand, 10-20 parts by weight of clay ceramsite, 5-15 parts by weight of bentonite, 6-18 parts by weight of kaolin, 4-12 parts by weight of gypsum, 2-4 parts by weight of diethylenetriamine pentamethylphosphonic acid, 3-15 parts by weight of aluminum silicate fiber, 3-12 parts by weight of unsaturated glyceryl alcohol, 1-5 parts by weight of fatty alcohol-polyoxyethylene ether, 1-5 parts by weight of polyhydric alcohol, 2-3 parts by weight of polyamine, 2-6 parts by weight of acid anhydride, and 0-5 parts byweight of an auxiliary agent. The self-retarding concrete has a setting time of 60 to 85 hours, has broad application prospects, and is low in cost and high in economic benefit.

Owner:芜湖恒固混凝土材料有限公司

Flowing-type ground adhesive

InactiveCN106316282ARealize rapid hardening and waterproofingImprove liquidityHydration reactionUltimate tensile strength

The invention discloses a flowing-type ground adhesive. The flowing-type ground adhesive is prepared from, by weight, 20-55 parts of cement, 60-70 parts of quartz sand, 0.1-0.7 part of a water reducing agent, 0.2-0.8 part of a water retaining agent, 0.01-0.5 part of an anti-sagging agent and 7-10 parts of redispersible latex powder. According to the flowing-type ground adhesive, by means of organic combination of a mineral gel material and the polymeric redispersible latex powder, the adhesive strength and the rapid hardening performance are improved, and then the material achieves the superior adhesive strength on different base surfaces; under the action of an anti-gliding material, the construction performance is improved, and therefore operation of the adhesive is more convenient; a retarder delays a hydration reaction, and therefore the construction performance of the ceramic tile adhesive material is greatly improved and promoted; the water reducing agent can decrease the blending water dosage and effectively improves the waterproof performance of the ceramic tile adhesive by combining the functions of a water repellent.

Owner:上海亚瓦新型建筑材料有限公司

Mass concrete and preparation method thereof

The invention relates to the field of concrete, and particularly discloses mass concrete as well as a preparation method and application thereof. The mass concrete is prepared from the following raw materials in parts by weight: 340-355 parts of cement; 40 to 45 parts of fly ash; 100 to 110 parts of mineral powder; 680 to 720 parts of fine aggregate; 1080 to 1100 parts of coarse aggregate; 7-9 parts of a water reducing agent; and 135 to 145 parts of water. The preparation method comprises the following steps: weighing the cement, the fly ash, the mineral powder, the fine aggregate and the coarse aggregate in proportion, and uniformly mixing and stirring to obtain a first mixture; and weighing the water reducing agent and the water according to the proportion, adding the weighed water reducing agent into the water, uniformly mixing, adding the water doped with the water reducing agent into the first mixture, and uniformly stirring to obtain the mass concrete. The mass concrete has the advantages that the crack generation probability is reduced, and the crack generation amount is reduced.

Owner:襄阳嘉众和建材实业有限公司

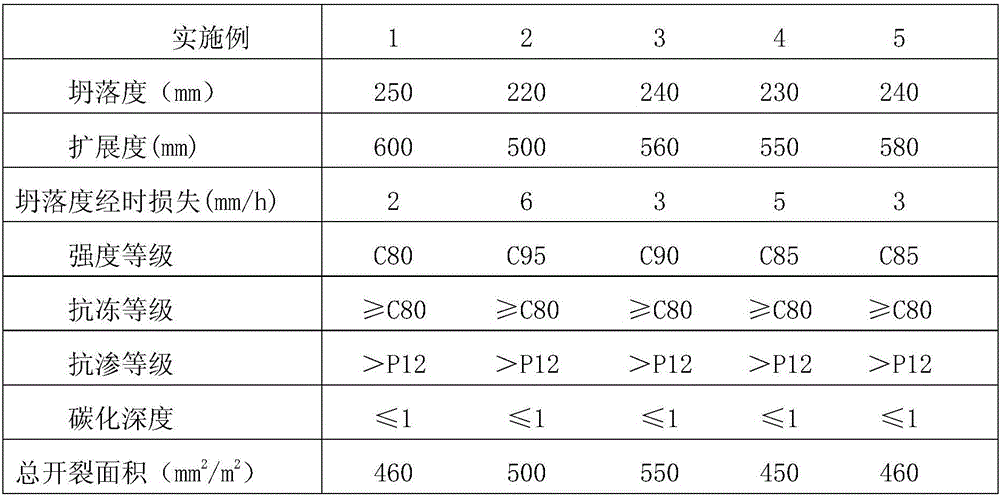

Preparation method of high-adaptability concrete

ActiveCN106587817AImprove efficiencyReduce energy consumptionSolid waste managementHigh strength concreteScrew press

The invention relates to a preparation method of high-adaptability concrete, wherein the preparation method comprises the steps: mixing 224-300 kg of cement with 100-135 kg of water, wet-grinding, adding 143-298 kg of a composite superfine admixture and 600-700 kg of a fine aggregate, and mixing to obtain cement mortar; allowing the cement mortar to enter from a slurry inlet of a screw press dehydrator, gradually dehydrating and concentrating the slurry due to the radial and axial mechanical squeezing effects, putting 1000-1100 kg of a coarse aggregate, stirring, then putting 10-20 kg of a pumping agent, 5-10 kg of a self-curing micro expansion agent and 3-6 kg of a high compatible plasticity-maintaining agent, and stirring into the high-adaptability concrete. The obtained concrete has the advantages of high plasticity maintaining, low shrinkage, low hydration heat, low cost, self compacting and self-curing performance; all the performance indicators are in line with needs of the ''technical specification for application of high strength concrete'' JGJ / T 281-2012, and the concrete is mainly used in super high-rise buildings, large marine engineering, long-span bridges, tunnels and railway, and nuclear power engineering.

Owner:HUBEI UNIV OF TECH

Polycarboxylate water reducer containing modified water-soluble acrylate and preparation method thereof

Owner:SHANXI UNIV +1

Safe static breaking agent for coal mines

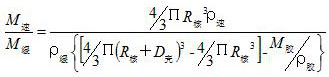

InactiveCN110357559ASlow down the hydration reactionReduced hydrationDisloding machinesBlasting cartridgesCoalSufficient time

The invention provides a safe static breaking agent for coal mines. The preparation method comprises: adding the heavy calcium powder and an additive to water, mixing uniformly, and firing to form anagent cake, wherein the content of the heavy calcium powder is 85-95%, and the additive is SiO2, Fe2O3 and Al2O3; and grinding the agent cake into powder, loading the powder into a cylinder, and packaging to form an agent column so as to obtain the safe static breaking agent for coal mines. According to the present invention, the safe static breaking agent, ie., the agent column, is pounded into the drilling hole after soaking for a sufficient time, the agent column can be subjected to condensing hardening swelling in the hole, and can generate pressure to the hole wall to achieve the tensilestrength of the object breaking so as to break the object; and the safe static breaking agent can be produced in advance at the factory, and then be directly used under the mine without a stirrer.

Owner:HARBIN ENG UNIV

Concrete pumping agent capable of preventing pipe blockage and water seepage

The invention discloses a concrete pumping agent capable of preventing pipe blockage and water seepage. The concrete pumping agent is characterized in being prepared from the following components in parts by weight: 4 to 7 parts of di (2-chloroethyl) hydrophosphate / piperazine-N, N-bis (2-hydroxyethane sulfonic acid) disodium salt polycondensate, 0.2 to 0.5 part of hyperbranched polyamino acid, 10to 15 parts of maleimide-tri (ethylene glycol)-propionic acid / triethanolamine oleate soap / vinyl phosphonic acid copolymer, 2 to 4 parts of kleemanite, 0.1 to 0.3 part of carboxymethyl chitosan and 30to 40 parts of water. The invention further provides a preparation method of the concrete pumping agent capable of preventing pipe blockage and water seepage. The concrete pumping agent disclosed by the invention is good in adaptability to cement, good in pumping effect, excellent in comprehensive performance, small in mixing amount, small in negative influence on the comprehensive performance ofconcrete, stable in quality and safe and environment-friendly to use, and the concrete added with the pumping agent is good in workability, excellent in pumpability and free of a water seepage phenomenon.

Owner:石旭艳

Setting time regulator, preparation method thereof and ceramic tile glue

The invention relates to the technical field of building materials, in particular to a setting time regulator, a preparation method thereof and a ceramic tile glue. The setting time regulator is a core-shell type material and comprises an inner core and a shell layer coating the inner core, wherein the shell layer is made of a composite material of a water-soluble organic gel material and a retarder; and the inner core is made of a setting accelerator, wherein the melting point of the setting accelerator is Taccelerator, the melting point of the retarder is Tslow, and the melting point of thewater-soluble organic gel material is Tgel, the Taccelerator being greater than the Tslow, and the Taccelerator being greater than the Tgel. The setting time regulator solves the problem that the material property is not matched with the robot construction process in the construction process of paving ceramic tiles by the building robot at present, and is suitable for the robot construction rhythm.

Owner:GUANGDONG BOZHILIN ROBOT CO LTD

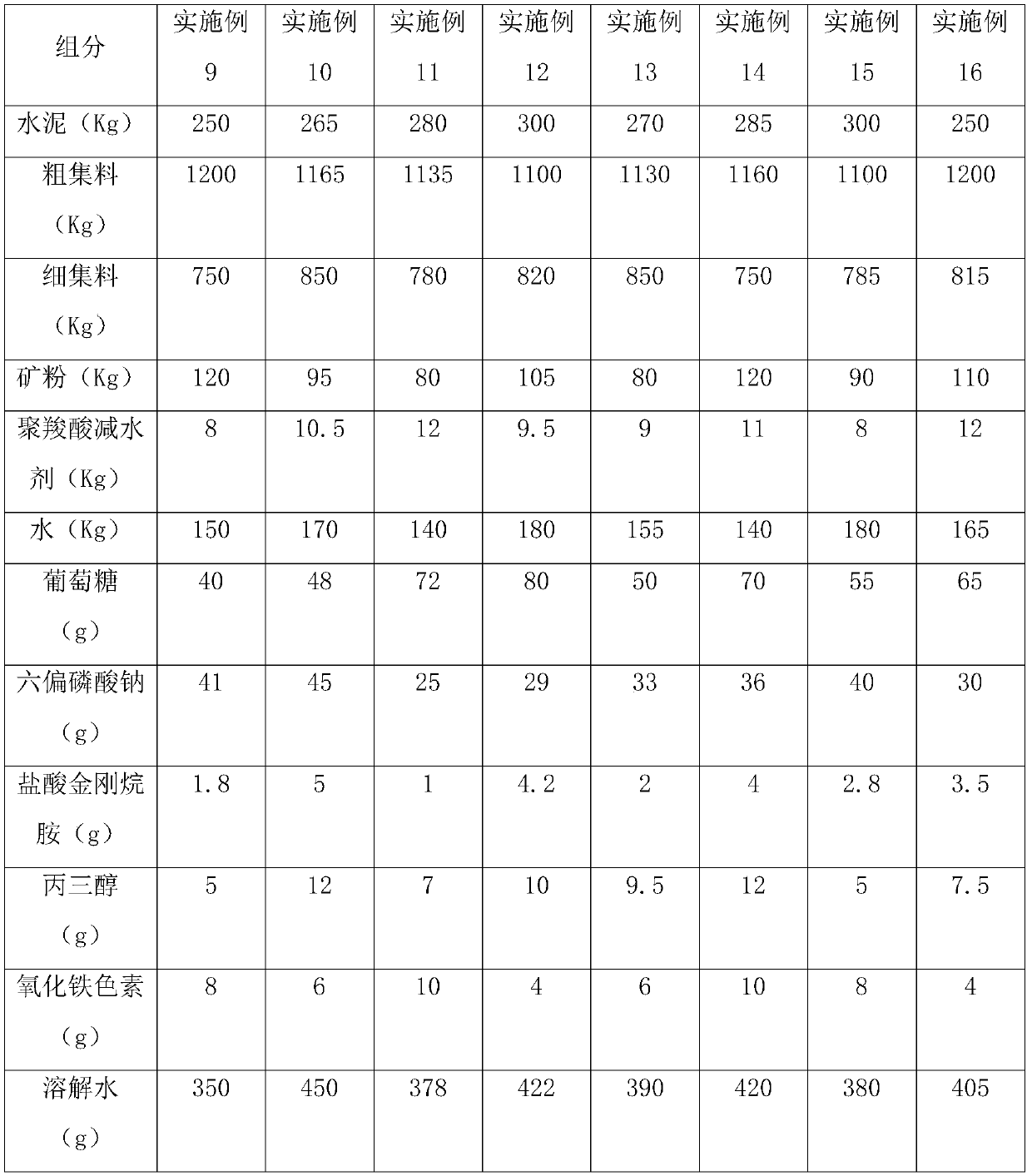

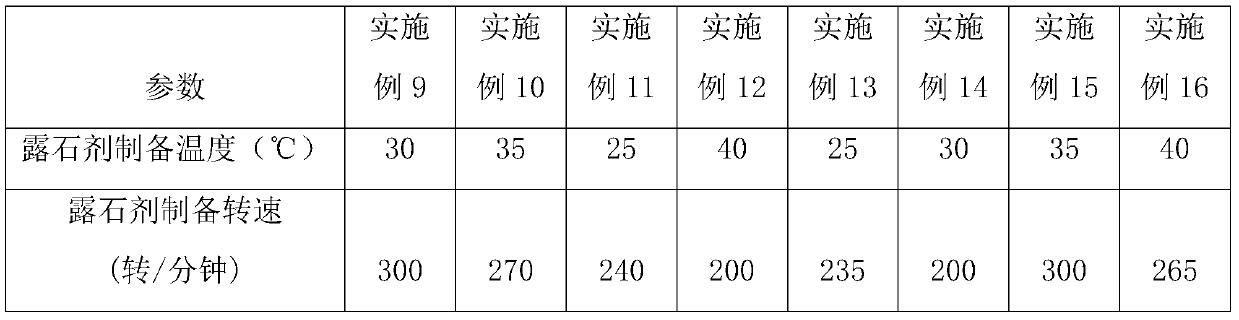

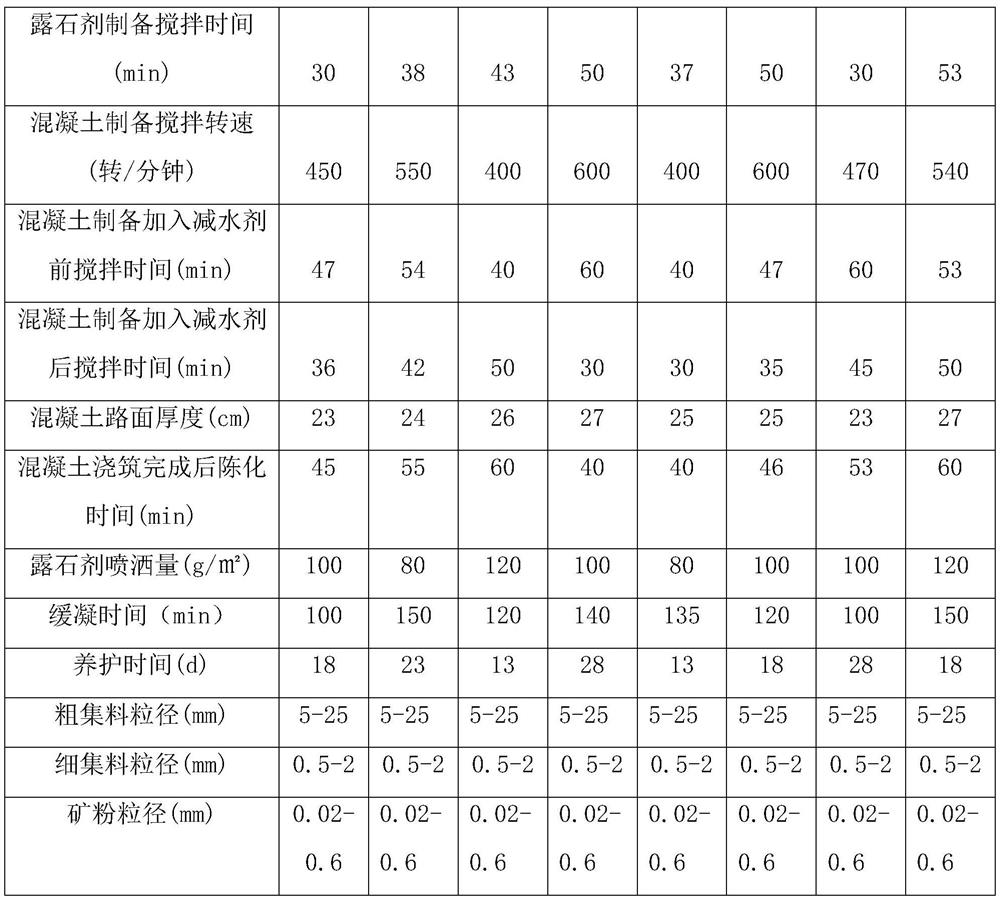

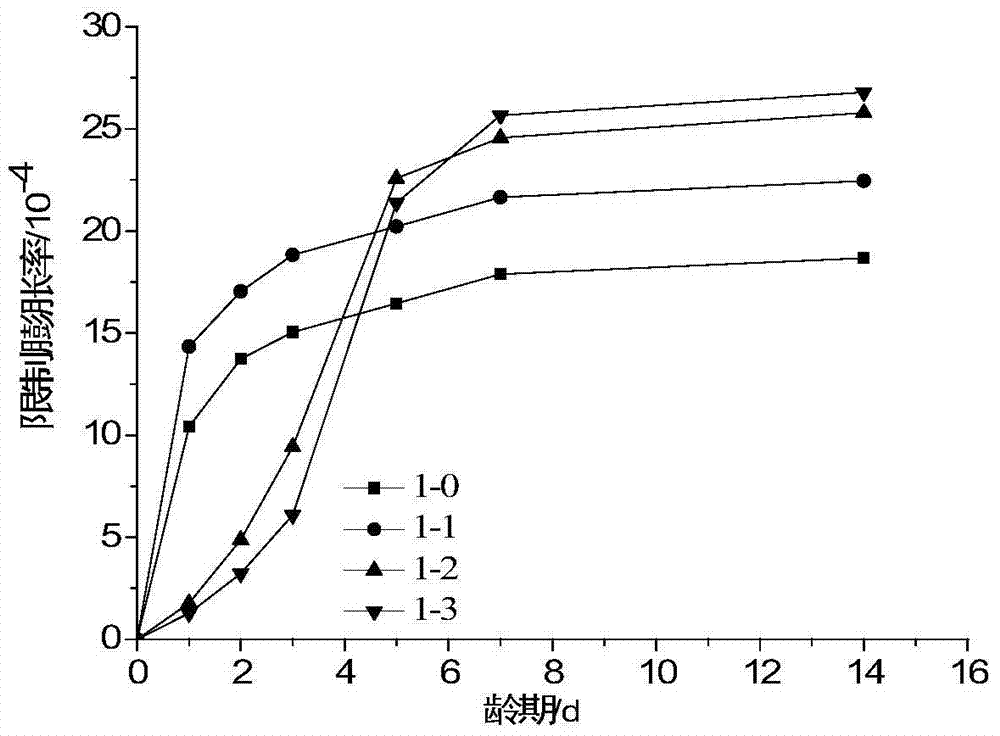

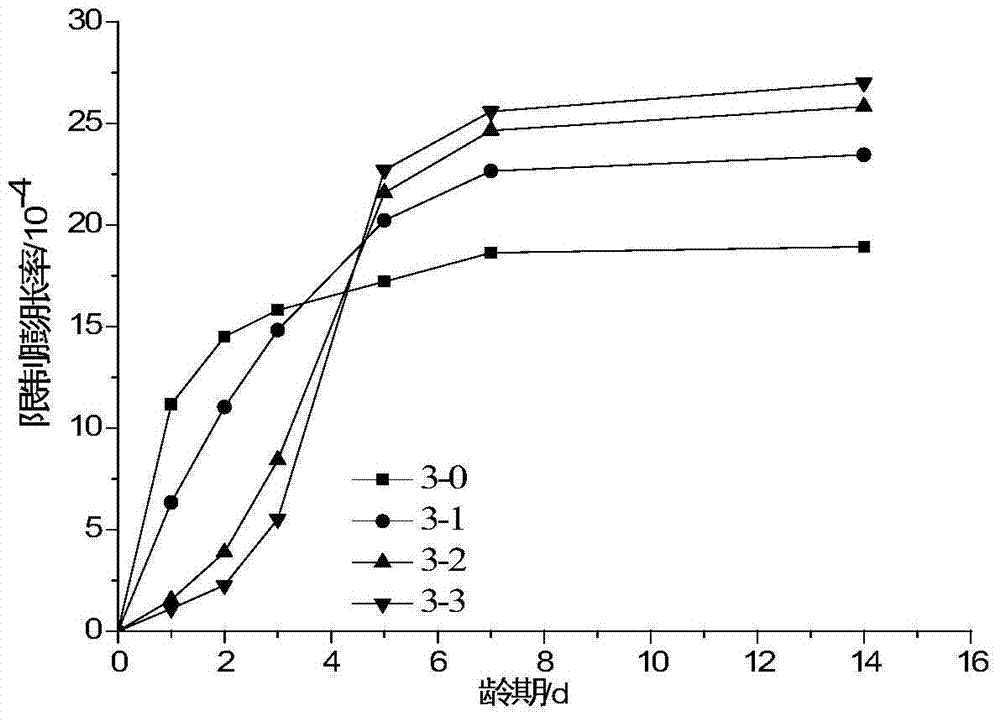

Exposed-aggregate concrete and construction method thereof

ActiveCN111187044AImprove retarding efficiencyReduce dosageIn situ pavingsRoads maintainencePavement maintenanceSodium phosphates

The invention discloses exposed-aggregate concrete and a construction method thereof, and relates to the technical field of concrete construction. The exposed-aggregate concrete is prepared from the following exposed-aggregate concrete raw materials in parts by weight: 250-300 parts of cement, 1100-1200 parts of coarse aggregate, 750-850 parts of fine aggregate, 80-120 parts of mineral powder, 8-12 parts of a water reducing agent and 140-180 parts of water. Raw materials of the exposed-aggregate concrete further comprise an exposed-aggregate agent, and the exposed-aggregate agent is prepared from the following raw materials in parts by weight: 0.04 to 0.08 part of glucose, 0.025 to 0.045 part of sodium hexametaphosphate, 0.001 to 0.005 part of amantadine hydrochloride and 0.35 to 0.45 partof dissolving water. The exposed-aggregate concrete has the advantages of good retarding effect and good environmental protection performance. The construction method of the exposed-aggregate concrete comprises the following steps of exposed-aggregate agent preparation, concrete preparation, pavement pouring, pavement maintenance and the like. The construction method of the exposed-aggregate concrete has the advantage that the retarding effect of the product is conveniently improved.

Owner:陕西隆生建材有限公司

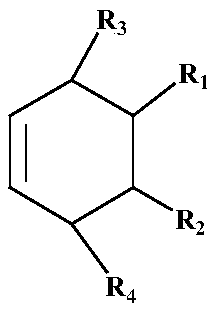

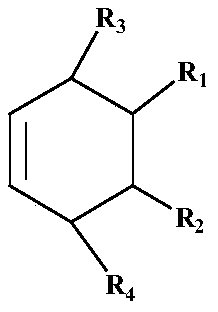

Micromolecular concrete retarder and preparation method thereof

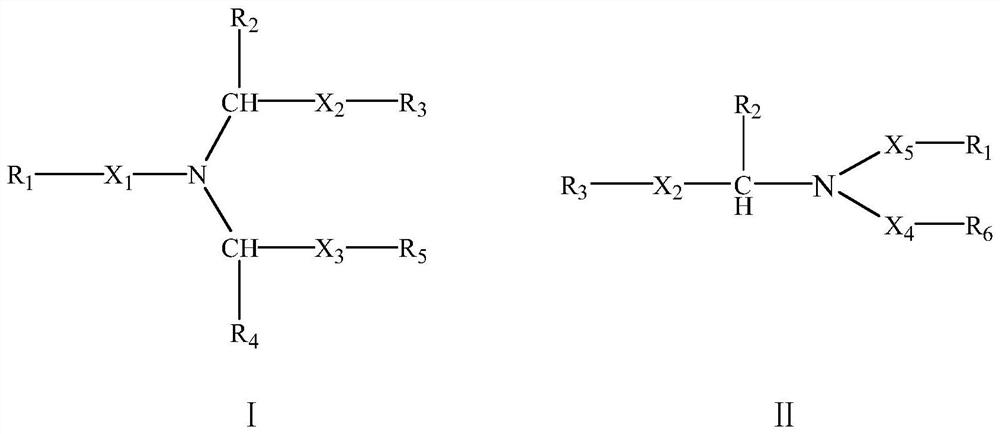

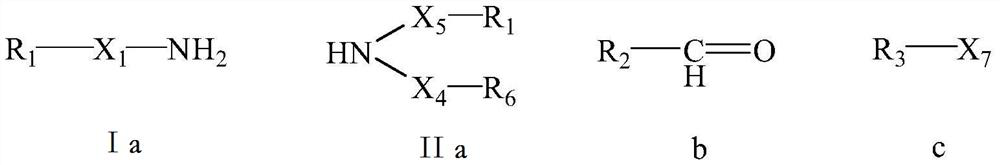

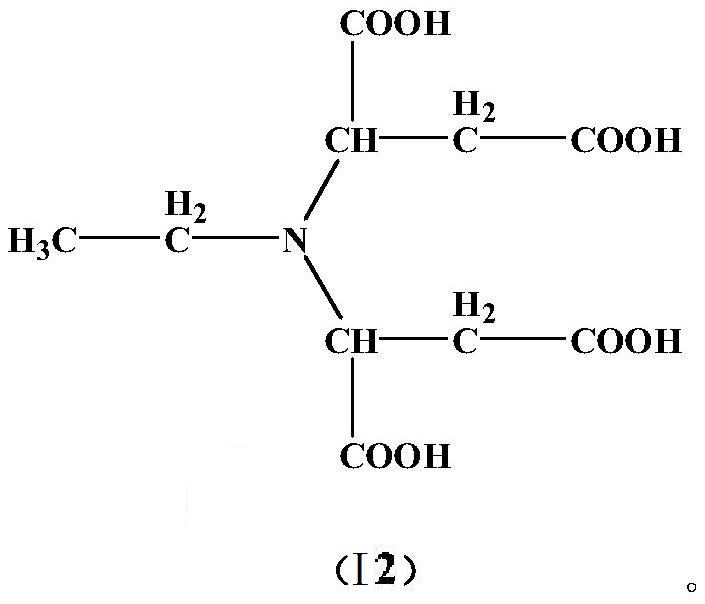

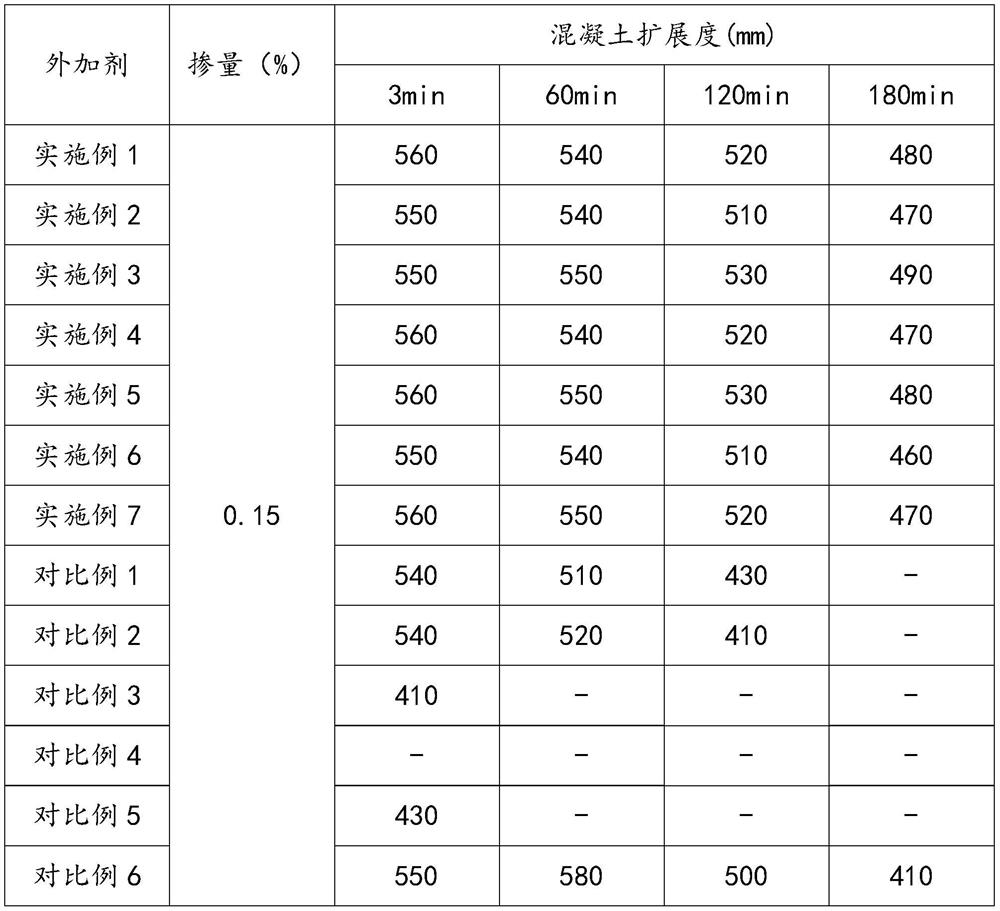

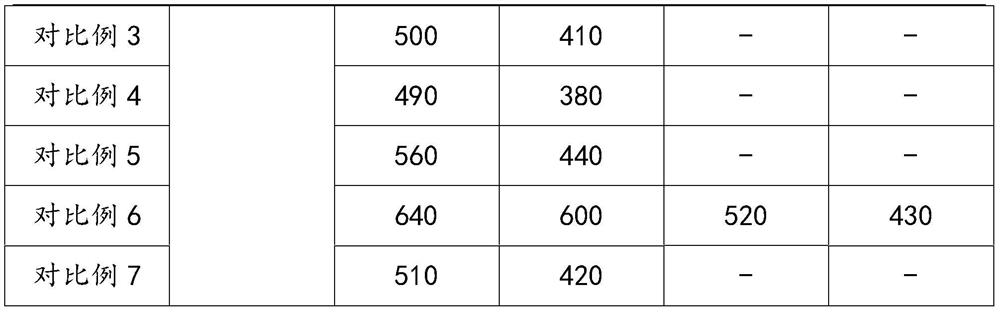

ActiveCN112521041AGood slump performanceStrong metal complexing abilityHydration reactionCement paste

The invention provides a micromolecular concrete retarder. The chemical structure of the micromolecular concrete retarder is shown as a formula (I) or a formula (II). The micromolecular concrete retarder has strong metal complexing ability, can delay hydration reaction of mineral substances in cement, and can be used for prolonging initial setting time and final setting time of cement paste, mortar and concrete. The micromolecular concrete retarder disclosed by the invention has the advantages of difficult decay, long shelf life, obvious retarding effect and good weather resistance when beingapplied to concrete in a small mixing amount; the micromolecular concrete retarder provided by the invention has excellent compatibility with a water reducing agent product, and can also improve the slump loss resistance of concrete during working.

Owner:GUANGDONG REDWALL NEW MATERIALS

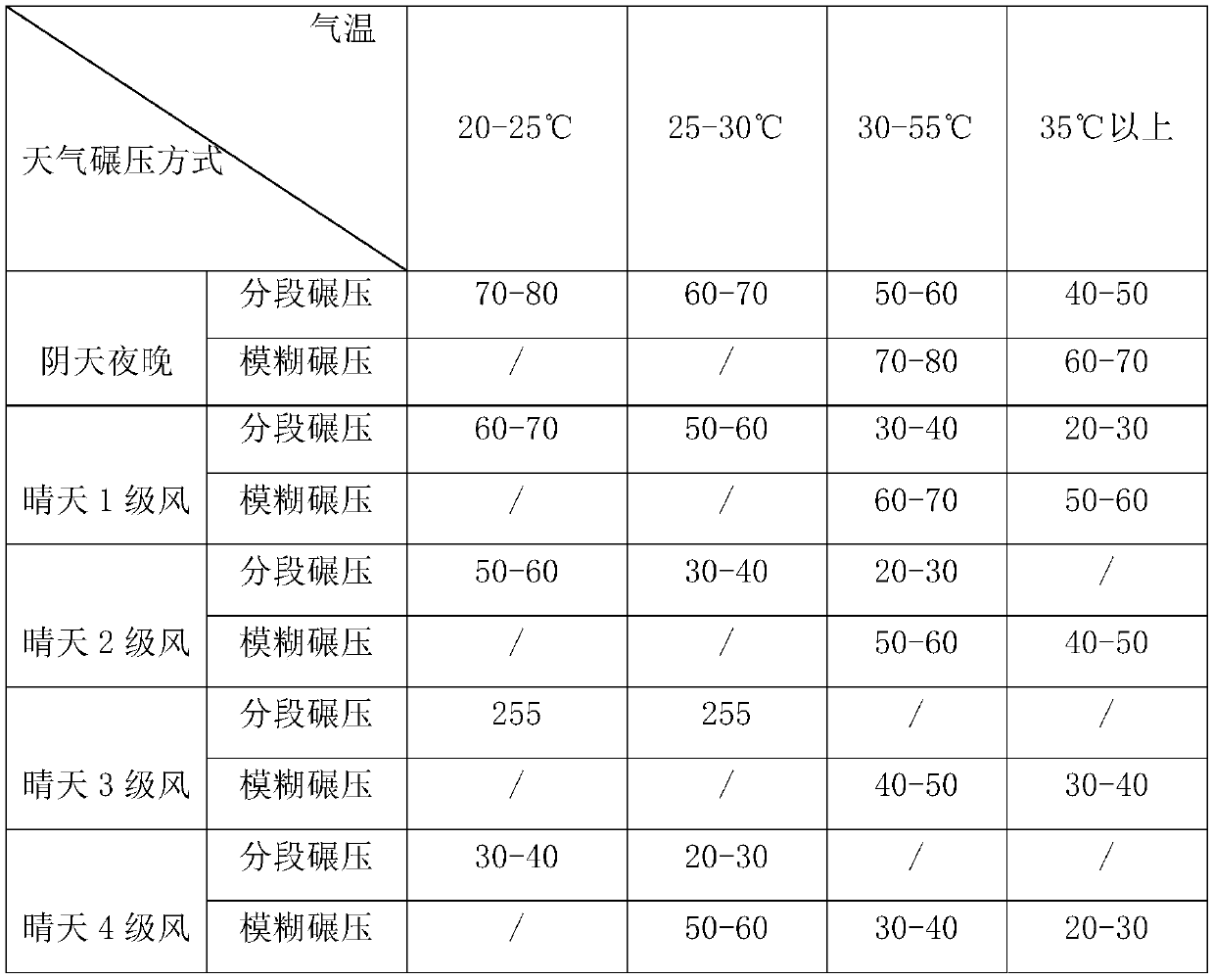

Cement stabilized macadam mixture and road base layer construction method used in high-temperature seasons

ActiveCN110714382AReduced hydrationRealize retarding effectRoadwaysCement mixing apparatusHydration reactionPolymer chemistry

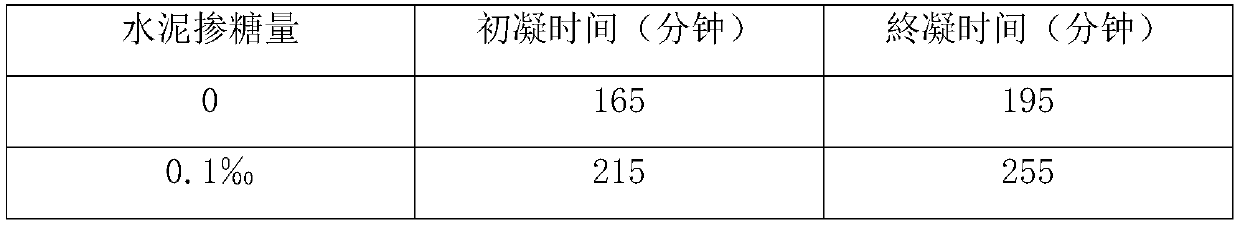

The invention discloses a cement stabilized macadam mixture and a road base layer construction method used in high-temperature seasons. The mixture comprises cement, a saccharose solution, stabilizedmacadam rough aggregates and fine aggregates. Saccharose is fused in cement stabilized macadam mixed water, the cement hydration reaction can be delayed, the non-delayed-coagulation cement delayed coagulation effect is achieved, and the cement stabilized macadam mixture has sufficient construction delay time. The construction delay time can be flexibly adjusted according to the mixing amount, thesufficient construction time can be achieved for the cement stabilized macadam mixture under the situation that ordinary cement is used in the scorching summer, and accordingly the engineering qualityis ensured.

Owner:北京城建华晟交通建设有限公司

Low-temperature-difference mass concrete suitable for articulated chute construction and preparation process of low-temperature-difference mass concrete

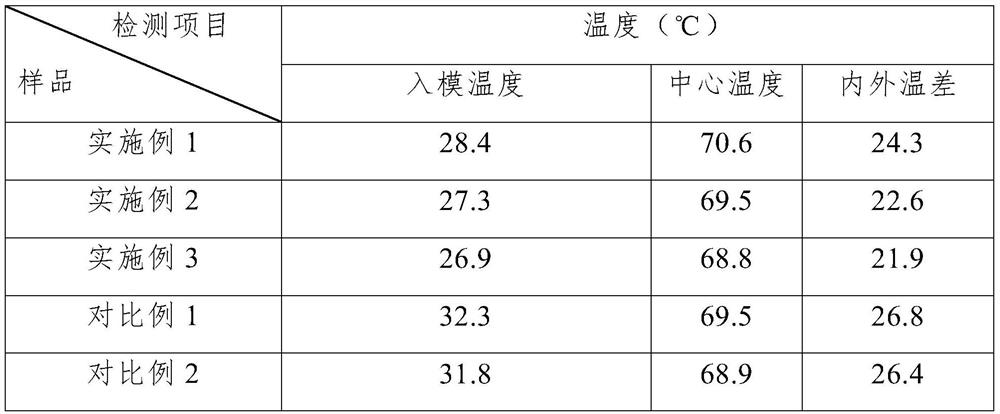

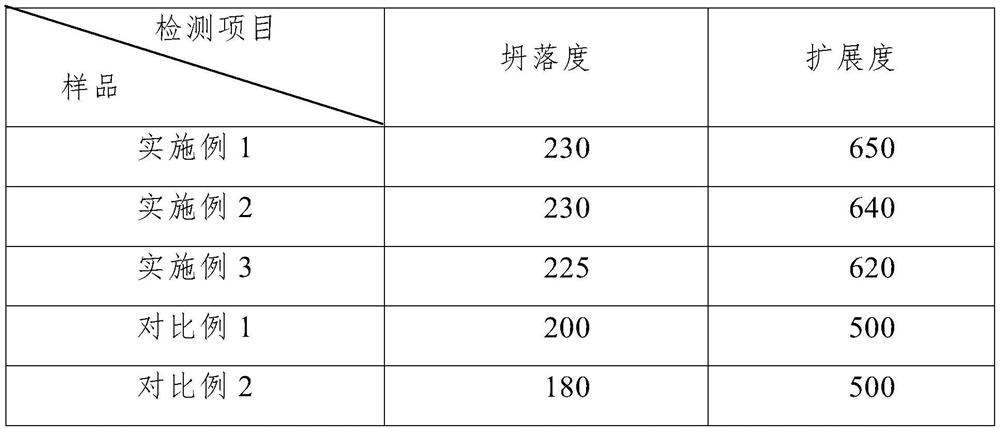

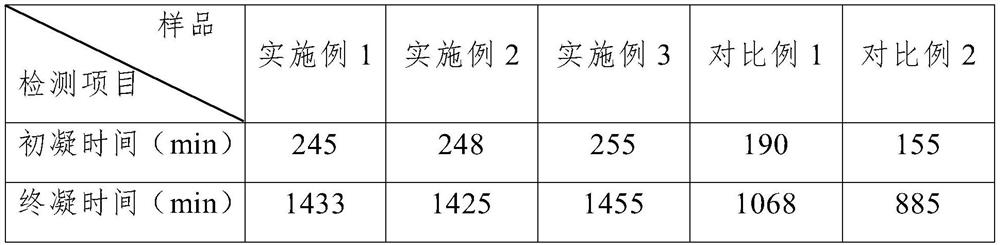

The invention discloses low-temperature-difference mass concrete suitable for articulated chute construction. The low-temperature-difference mass concrete is prepared from the following components inparts by mass: 150-200 parts of cement, 260-320 parts of mineral powder, 80-120 parts of fly ash, 100-150 parts of water, 900-1200 parts of gravels, 700-800 parts of sand and 8-20 parts of a pumping agent. The invention further discloses a process for preparing the low-temperature-difference mass concrete suitable for articulated chute construction. The sand, gravels and water are evenly mixed, then the cement, the fly ash, the mineral powder and the pumping agent are added, and the mixture is evenly stirred. The fly ash and the mineral powder are adopted, the hydration heat of the cement is reduced, the temperature difference between the inside and the outside of the mass concrete is reduced, the segregation resistance of the mass concrete is improved, and the strength and the working performance of the mass concrete are ensured, so that shrinkage deformation and slurry-bone separation of the mass concrete are reduced, and the mass concrete is suitable for articulated chute construction; the preparation process is simple and easy to implement.

Owner:陕西秦汉恒盛新型建材科技股份有限公司

Preparation method of self-slow-setting concrete

The invention relates to the technical field of concrete and preparation, and specifically relates to a preparation method of self-slow-setting concrete. The preparation method of the self-slow-setting concrete comprises the following steps: (1) modifying gypsum through roasted bentonite and kaolin and etidronic acid to obtain mineral powder; (2) uniformly mixing unsaturated glyceryl alcohol, fatty alcohol-polyoxyethylene ether, polyhydric alcohol, anhydride and polyamine; and reacting for 2-4h under the temperature of 80-120 DEG C to obtain a slow setting intermediate; and (3) uniformly dispersing the slow setting intermediate, coal ash, cement, fine sand, clay ceramsite, alumina silicate fibers, modified mineral powder and additives in water; and continuously stirring for 60-150s to obtain the self-slow-setting concrete. The self-slow-setting concrete prepared by the method is set for 60-85h, and has a good application prospect, and is low in cost and high in economic benefit.

Owner:芜湖恒固混凝土材料有限公司

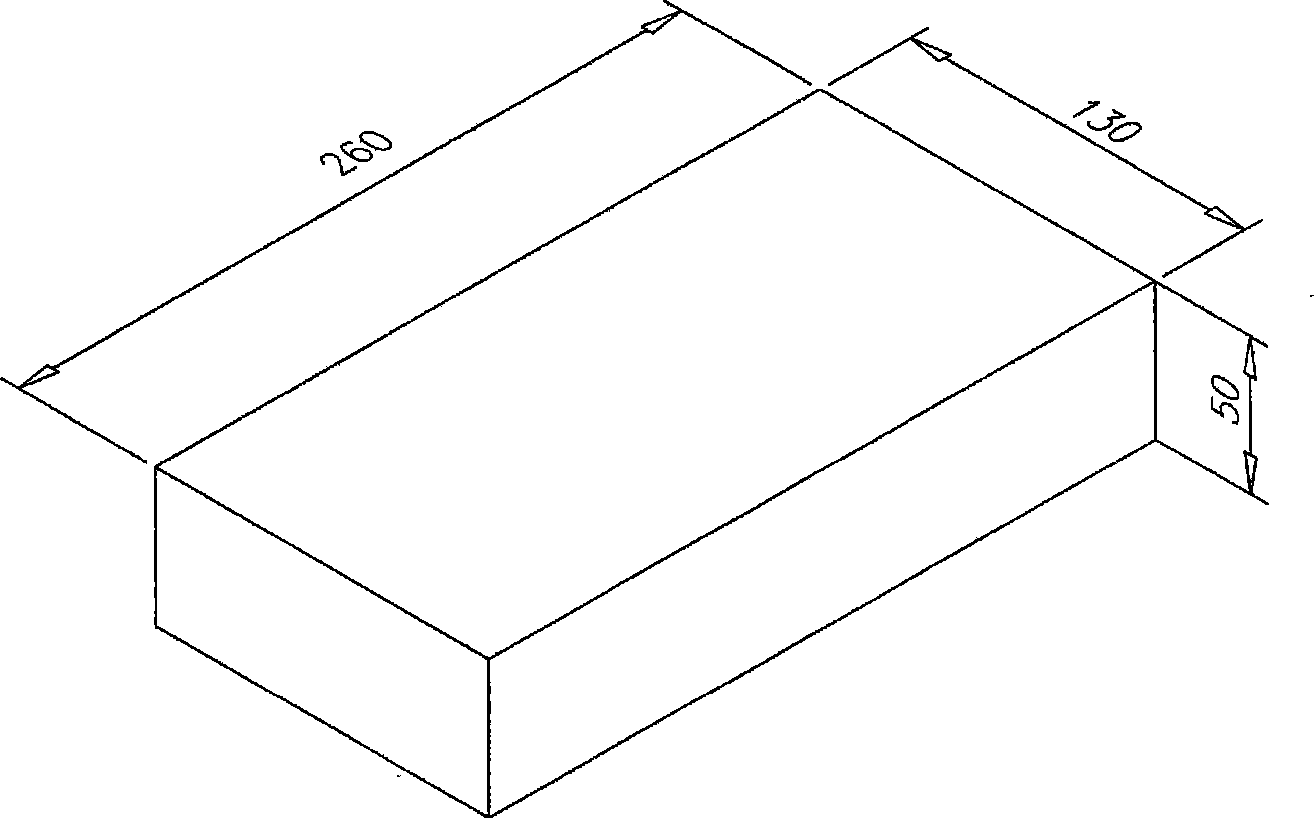

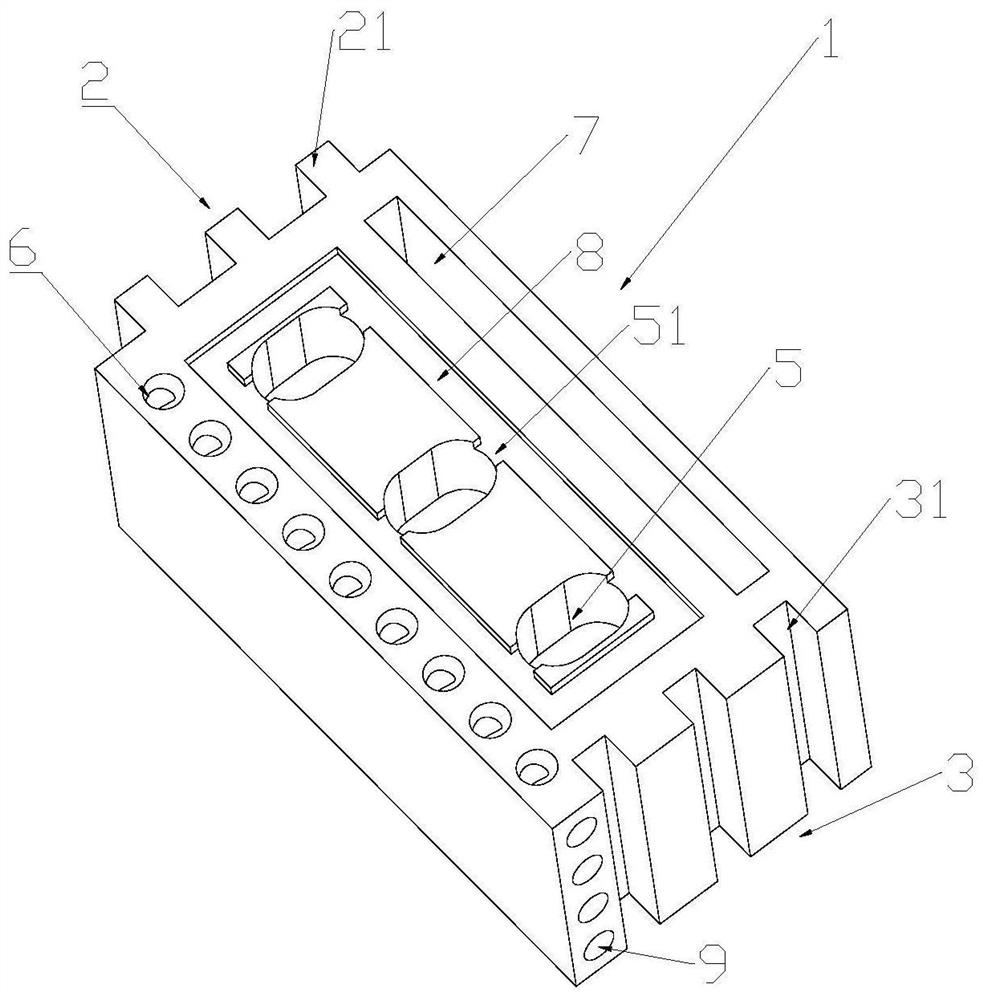

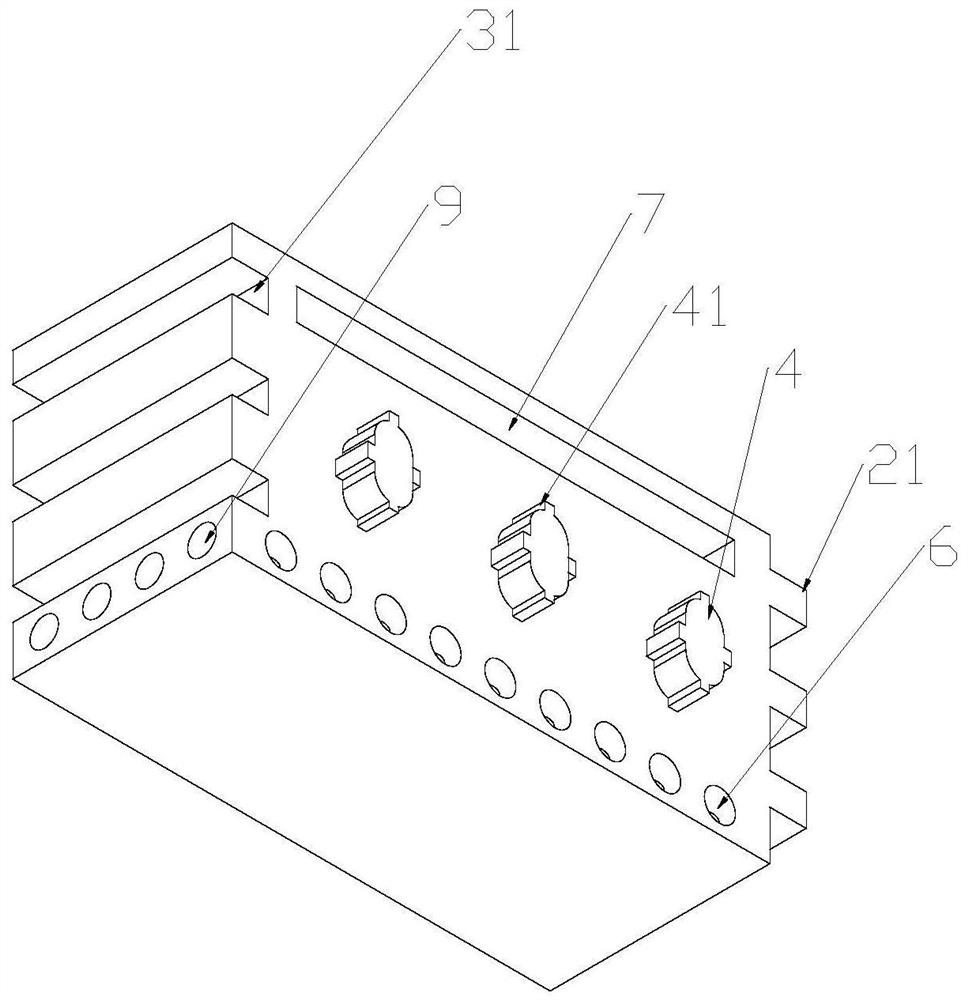

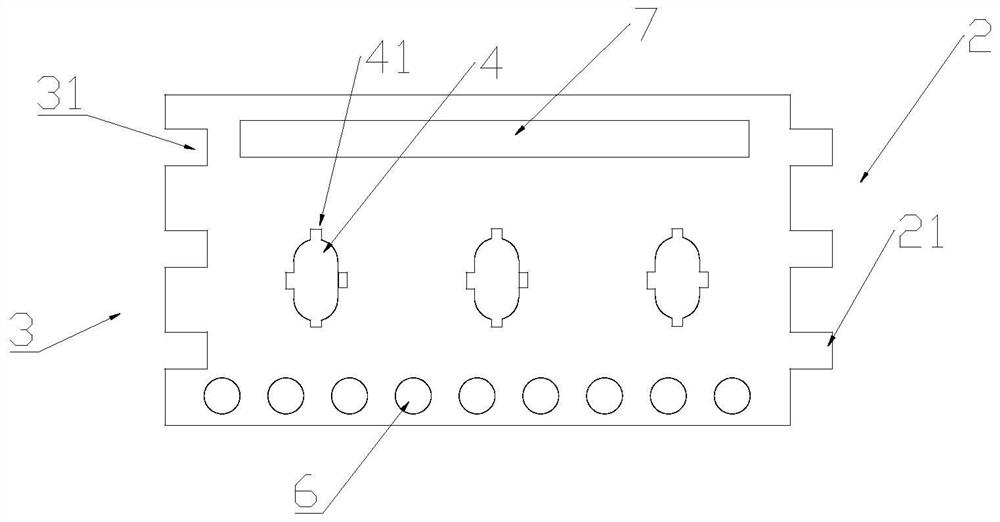

Fabricated concrete brick based on machine-made sand material and preparation method of fabricated concrete brick

ActiveCN113152777AImprove pressure resistanceImprove impact resistanceConstruction materialWallsCompressive resistanceBrick

The invention relates to the field of building materials, in particular to a fabricated concrete brick based on a machine-made sand material and a preparation method of the fabricated concrete brick. Mortise and tenon joint structures used for splicing are arranged at the two ends of the concrete brick; a plurality of inserting blocks and inserting grooves are formed in the middles of the lower surface and the upper surface of the concrete brick at intervals; a plurality of vertical through holes are formed in one side of each inserting block at intervals in a penetrating mode; an additional material insertion cavity is formed in the other side of each inserting block; flash grooves are formed around the inserting grooves; a plurality of transverse through holes are formed in the sides, close to the vertical through holes, of the two end faces of a brick body in a penetrating mode from top to bottom at intervals; and the transverse through holes communicate with the vertical through holes. On one hand, rapid connection and splicing of concrete bricks are achieved, and the concrete brick is high in positioning precision, stable and compact in connection and suitable for later expansion construction; and on the other hand, the provided preparation method guarantees the strength of the brick body, and the concrete brick is light in weight, high in compressive strength, good in bearing capacity and easy to install and operate, and has the practical effect in a practical sense.

Owner:ANHUI INST OF BUILDING RES & DESIGN +1

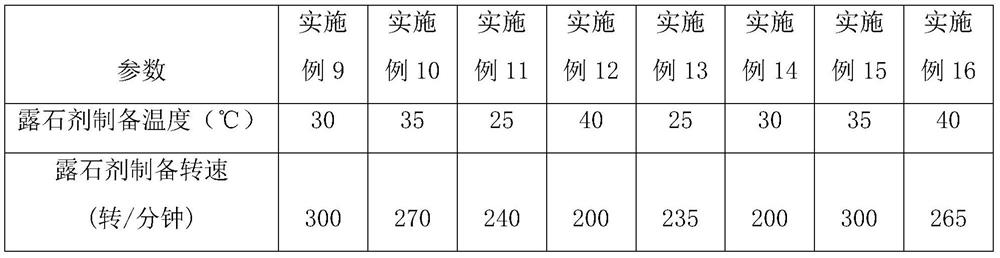

A kind of exposed stone concrete and construction method thereof

ActiveCN111187044BImprove retarding efficiencyReduce dosageIn situ pavingsRoads maintainencePavement maintenanceSodium phosphates

The invention discloses an exposed stone concrete and a construction method thereof, and relates to the technical field of concrete construction; an exposed stone concrete is made of exposed stone concrete raw materials containing the following parts by weight: 250-300 parts of cement and 1100 parts of coarse aggregate ‑1200 parts, 750‑850 parts of fine aggregate, 80‑120 parts of mineral powder, 8‑12 parts of water reducer, 140‑180 parts of water; the exposed stone concrete raw material also includes exposed stone agent; the exposed stone agent It is made of dew stone agent raw materials containing the following parts by weight: 0.04-0.08 parts of glucose, 0.025-0.045 parts of sodium hexametaphosphate, 0.001-0.005 parts of amantadine hydrochloride, and 0.35-0.45 parts of dissolved water; it has good retarding effect And the advantages of good environmental protection performance; the construction method of exposed stone concrete includes the following steps: preparation of exposed stone agent, concrete preparation, pavement pouring, road surface maintenance, etc.; the construction method of exposed stone concrete has the advantage of being convenient to improve the retarding effect of the product.

Owner:陕西隆生建材有限公司

Building thermal insulation mortar material taking vanadium-titanium magnet tailings as raw material as well as preparation method and application thereof

PendingCN112500095AAchieve recyclingTo achieve the purpose of resource reuseCovering/liningsSolid waste managementCrack resistanceAllyl thiocyanate

The invention discloses a building thermal insulation mortar material taking vanadium-titanium magnet tailings as a raw material as well as a preparation method and application of the building thermalinsulation mortar material. The thermal insulation mortar comprises the following raw materials in parts by weight: 30-40 parts of vanadium-titanium magnet tailings, 100-120 parts of cement, 10-30 parts of glass beads, 15-20 parts of gypsum, 3-5 parts of sodium carboxymethyl starch, 2-4 parts of allyl isothiocyanate, 5-8 parts of diallyl sulfide, 5-8 parts of sodium lauryl sulfate, 2-4 parts of lithium hydroxide, 6-8 parts of sodium hydroxide, 5-10 parts of kanuma soil, 1-2 parts of water glass and 8-12 parts of an air entraining agent. According to the invention, through reasonable design ofthe raw materials and the ratio thereof and synergistic effect of the raw materials, the thermal insulation mortar can be ensured to have good thermal insulation performance, waterproof performance and fireproof performance, and the workability and crack resistance of the thermal insulation mortar can be improved, so that the use effect of the thermal insulation mortar is improved; therefore, thethermal insulation mortar is more suitable for internal and external wall thermal insulation systems of buildings and has good social and economic benefits.

Owner:尤建芬

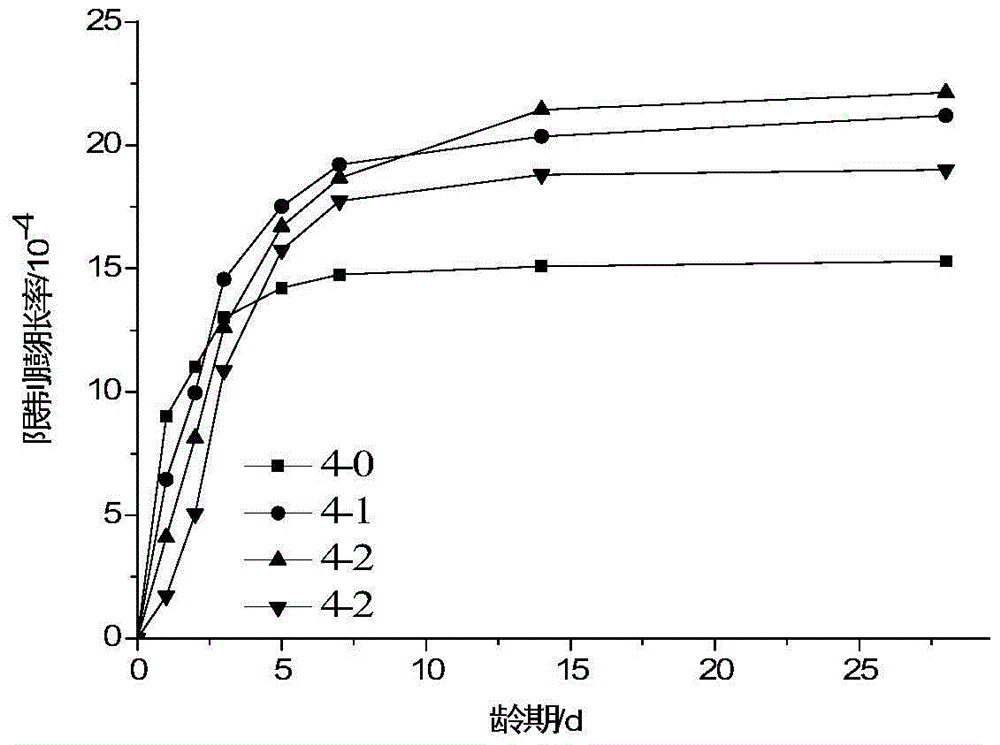

A kind of modified calcium oxide type expanded clinker, its preparation method and its application

The invention relates to a modified calcium oxide expansion clinker as well as a preparation method and application thereof. The preparation method of the modified calcium oxide expansion clinker comprises the following steps: carrying out physical adsorption and chemical reaction on calcium oxide expansion clinker powder in phosphoric acid which serves as a solvent, or mixing a calcium oxide expansion clinker with phosphoric acid and grinding the mixture into powder of a certain finesses, and forming a large number of compact calcium phosphate on the surface of the calcium oxide expansion clinker powder to obtain the modified calcium oxide expansion clinker. The modified calcium oxide expansion clinker can be mixed with a dispersible carrier to form a modified calcium oxide concrete expansion agent. By adopting the phosphorylated coated modified calcium oxide expansion clinker and the modified calcium oxide concrete expansion agent, the expansion quantity and expansion stress of an expansion material in cement concrete can be increased significantly, the expansion process of the modified calcium oxide expansion clinker and the modified calcium oxide concrete expansion agent can be optimized, and the weather resistance and moisture resistance of the modified calcium oxide expansion clinker and the modified calcium oxide concrete expansion agent can be enhanced.

Owner:JIANGSU SOBUTE NEW MATERIALS

Concrete water reducing agent and preparation method thereof

PendingCN112708050AGood slump performanceImprove conversion rateHydration reactionPolyethylene glycol

The invention relates to the technical field of building admixtures, in particular to a concrete water reducing agent and a preparation method thereof. The concrete water reducing agent comprises a photopolymerizable monomer selected from alkoxy polyethylene glycol esterification intermediates, and a photoinitiator which is benzoin. According to the concrete water reducing agent provided by the invention, the alkoxy polyethylene glycol esterification intermediate is adopted, slump retaining performance and water reducing performance can be both considered, meanwhile, the reaction can be carried out at normal temperature or low temperature, monomer prepolymerization is directly initiated through light irradiation, the polymerization rate is greatly increased, the synthesis conversion rate is increased, and the sensitivity is reduced; and in addition, the sulfonic acid group is added, so that the surfaces of cement particles can be stably adsorbed, the hydration reaction can be effectively delayed, the dispersing and slump retaining effects in concrete with medium and low strength grades are enhanced, and the market application prospect is extremely wide.

Owner:重庆建研科之杰建材有限公司 +1

Preparation method of polycarboxylic acid water reducer containing paw type short side chains

The invention discloses a preparation method of a polycarboxylic acid water reducer containing paw type short side chains. The preparation method comprises following specific steps: cis-hexadiene diacid and a small monomer containing an active double bond and polycarboxylic acid groups are subjected to Diels-Alder reaction in an alcohol solution at 40 to 50 DEG C so as to obtain a claw type unsaturated small monomer; the claw type unsaturated small monomer, and a unsaturated carboxylic acid small monomer and an unsaturated large monomer are subjected to free radical polymerization under the co-effect of an initiator, a reducing agent, and a chain transferring agent at 10 to 50 DEG C for 3 to 5h so as to obtain a copolymerization product, an alkali is added to adjust the pH value to 5 to 7,and water is added so as to obtain the polycarboxylic acid water reducer containing paw type short side chains with a mass concentration of 20 to 50%. The adsorption groups of conventional polycarboxylic acid water reducers are increased, the reaction is simple and convenient, the claw type adsorption groups are stable in performance, finished product yield is high, and the polycarboxylic acid water reducer containing paw type short side chains prepared using the preparation method is a functional polycarboxylic acid water reducer with both sludge resistance and plasticity maintenance performance.

Owner:江苏博思通新材料有限公司

High-strength concrete mixture, preparation method thereof and concrete

The invention relates to the field of concrete, and particularly discloses a high-strength concrete mixture, a preparation method thereof and concrete. The preparation method of the high-strength concrete mixture comprises the following steps: step 1) stirring and uniformly mixing water, cement and a retarder under the action of ultrasonic waves to obtain plain cement slurry; 2, adding an aggregate into the plain cement slurry and mixing to be uniform, and obtaining a concrete mixture, wherein the mass ratio of the cement to the retarder is 1: (0.014-0.016). The method has the advantage that the utilization rate of the cement is increased.

Owner:广州市建筑集团混凝土有限公司

A modified calcium oxide expanded clinker, its preparation method and application

Owner:JIANGSU SOBUTE NEW MATERIALS

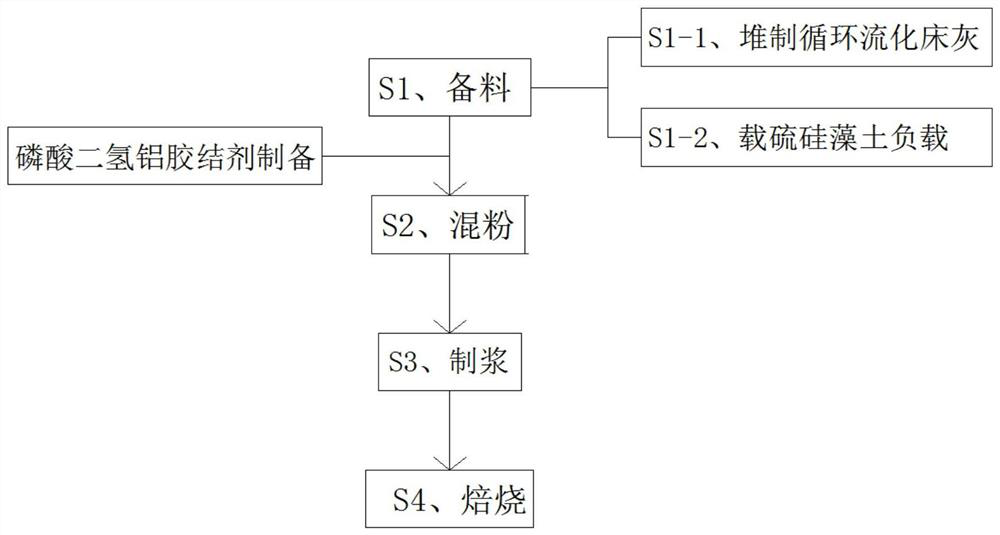

Wear-resistant repair material for CFB boiler and preparation method of wear-resistant repair material

InactiveCN113943170AGood wear resistanceExtended service lifeCirculating fluidized bed boilerRepair material

The invention discloses a wear-resistant repair material for a CFB boiler and a preparation method of the wear-resistant repair material. The wear-resistant repairing material is prepared from the following components in parts by weight: 45 to 50 parts of brown fused alumina powder, 3 to 5 parts of modified circulating fluidized bed ash, 1.5 to 2 parts of aluminum dihydrogen phosphate cementing agent, 0.8 to 1 part of explosion-proof fiber, 0.6 to 0.9 part of ceramic fiber, 0.2 to 0.5 part of dispersing agent, 2 to 3 parts of zirconium dioxide powder, 2.5 to 4 parts of yttrium oxide powder and 0.8 to 1.5 parts of titanium diboride powder. The preparation method comprises the following steps of: S1, preparing materials; S2, mixing powder; S3, carrying out pulping; and S4, carrying out roasting. The wear-resistant repair material for the CFB boiler has good wear resistance at a high temperature, is suitable for large-area repair and replacement of a dense-phase region of a hearth and the like, can also repair parts with complex structures of a water-cooling air chamber, can adopt an edited smearing repair method, and prolongs the service life of a CFB.

Owner:宜兴市兴贝耐火保温工程有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com