Fabricated concrete brick based on machine-made sand material and preparation method of fabricated concrete brick

A technology of concrete bricks and machine-made sand, which is applied to building materials, manufacturing tools, ceramic molding machines, etc., can solve problems such as increased environmental pressure, concrete bricks are easy to separate from each other, and wall damage, so as to improve pressure resistance and durability Impact resistance, avoiding the risk of aging and falling off, reducing weight and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

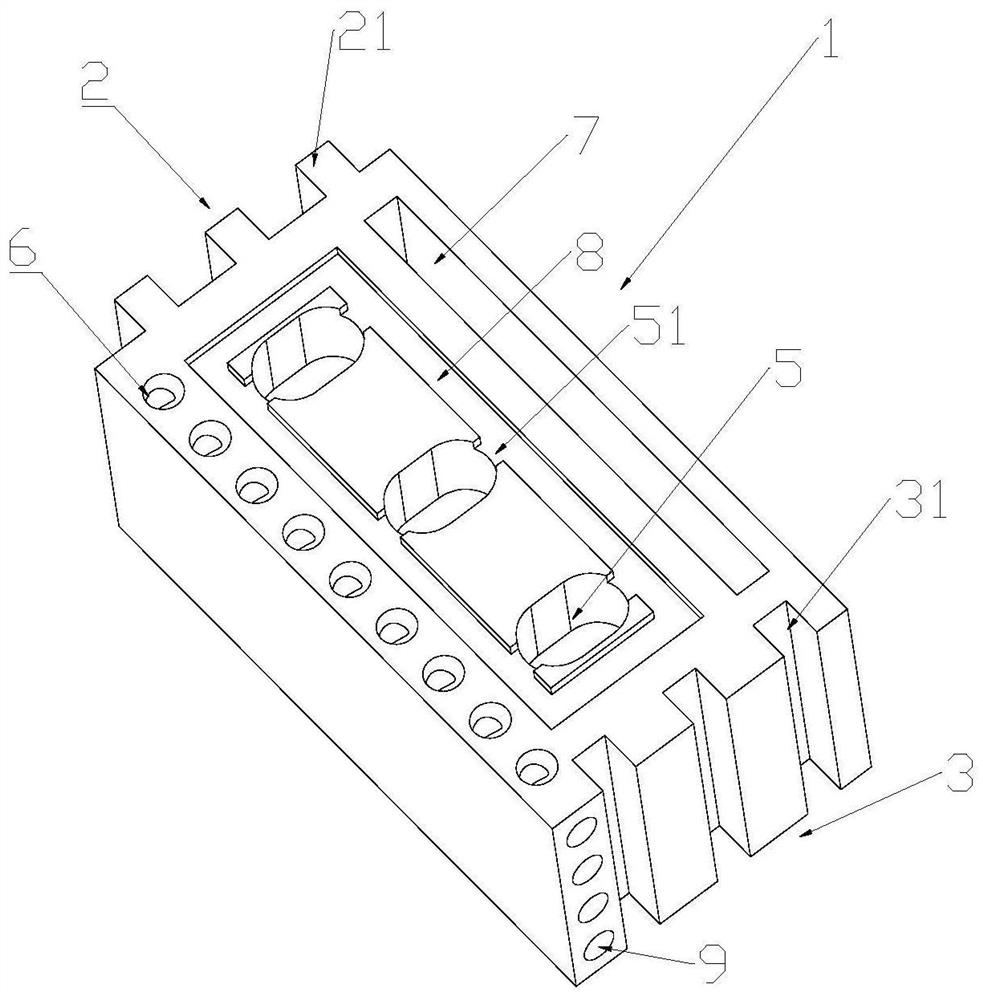

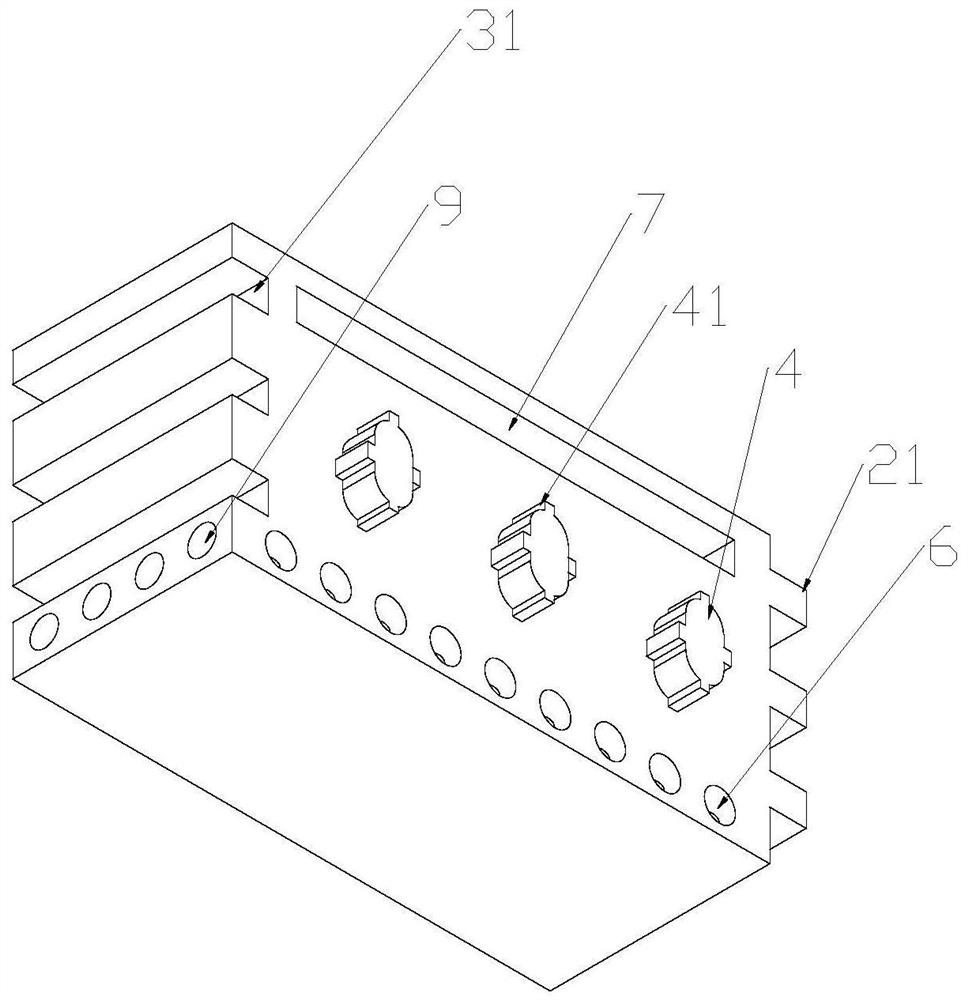

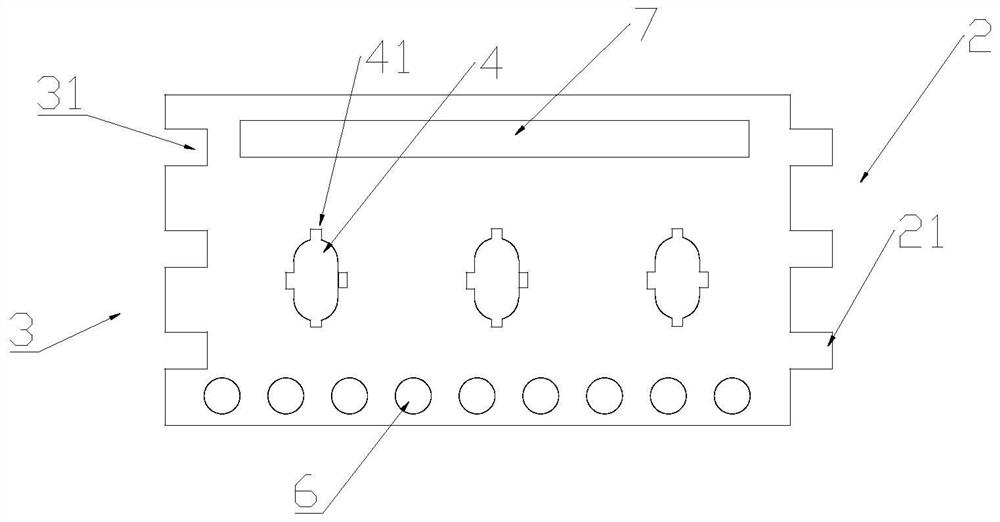

[0037] Please refer to Figure 1-4 , this embodiment provides a prefabricated concrete brick based on machine-made sand material, including:

[0038] A brick body 1, the two ends of the brick body 1 are respectively provided with a mortise and tenon structure for splicing. The tenon and tenon structure in this embodiment includes a male tenon strip 2 and a female tenon groove 3 respectively arranged at the two ends of the brick body. The male tenon bar 2 includes three slide bars 21 set through the upper and lower surfaces at one end of the brick body, and the female tenon groove 3 includes three slide grooves 31 matched with the slide bars at the other end of the brick body through the upper and lower surfaces. Bar 21 is rectangular, and of course trapezoidal or dovetail shape can also be used, and will not be repeated here;

[0039] In the present embodiment, the brick body 1 is provided with a number of inserts 4 at intervals in the middle of its lower surface, and on its ...

Embodiment 2

[0045] This embodiment provides a formula component of the concrete brick in Embodiment 1, including: 250-350 parts of cement, 30-80 parts of fly ash, 30-80 parts of gneiss machine-made sandstone powder, and 600-840 parts of machine-made sand 800-1000 parts of mechanism coarse aggregate, 230-270 parts of water, 1-2 parts of early strength agent, 6-8 parts of modifier, 3-7 parts of bentonite, 25-50 parts of steel fiber, 2 parts of polypropylene fiber -6 parts, metakaolin 30-60 parts, water reducer 5-10 parts, cellulose ether 0.2-0.5 parts.

[0046] Within the value range of this embodiment, we can arbitrarily carry out the proportioning of components, but as the most preferred mass ratio of our selected fly ash and gneiss machine-made sandstone powder is 1:1, at this time stone powder powder The proportion of coal ash can reduce the heat of hydration in the concrete curing process, thereby reducing or even eliminating the cracks in the concrete curing process. Wide and its own...

Embodiment 3

[0051] The present embodiment provides a kind of method for preparing the concrete brick as embodiment 1, comprises the following steps:

[0052] A, prepare raw material according to the composition ratio in embodiment 2;

[0053] b. Prepare hydrogen peroxide, acetic acid, and water as a pretreatment solution in a weight ratio of 10:2:120, put the machine-made sand into the pretreatment solution for immersion treatment for 15-25 minutes, and then filter the pretreated sand Spray a coupling agent solution of about 2-3% of the mass of the aggregate, stir evenly, and dry in an oven at 160°C for 2 hours to obtain modified machine-made sand, wherein the weight percentage of the silane coupling agent in the coupling agent solution is 4-6 %, and adjust the pH of the coupling agent solution to 4.5-5.5 with acid;

[0054] c. Stir cement, fly ash, and gneiss machine-made sandstone powder in a forced mixer for 2-5 minutes to obtain mixture A, and add modified machine-made sandstone, pol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com