A kind of modified calcium oxide type expanded clinker, its preparation method and its application

A technology of expanded clinker and calcium oxide, which is applied in the field of building material concrete admixtures, can solve the problems of calcium oxide type expanded clinker, such as weathering resistance, poor moisture resistance, weak shrinkage compensation ability, and fast hydration speed, and achieves social and economic benefits. Significant benefits, easy access, long shelf life results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

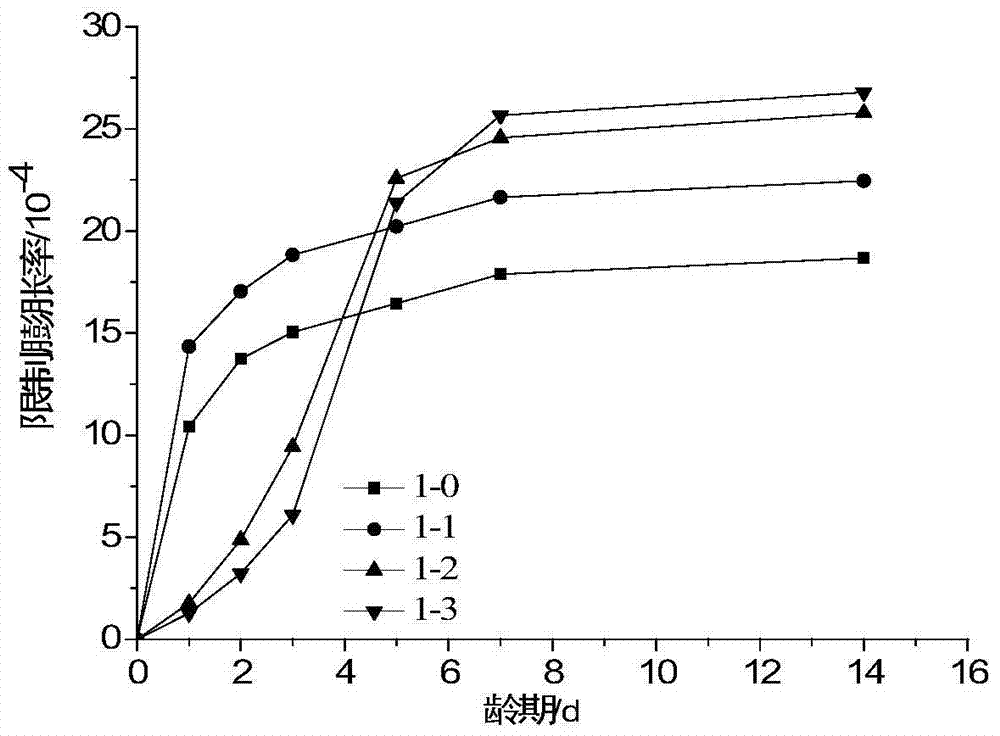

Embodiment 1

[0039] (1) Preparation of phosphorylated-coated modified calcium oxide expanded clinker (using commercially available calcium oxide expanded clinker as raw material)

[0040]Grinding and crushing the commercially available CaO-based expansion clinker into a specific surface area of 330m 2 / kg of powder. Weigh 500.0g of CaO expansion clinker and put it into a 1000ml three-necked round-bottomed flask filled with absolute ethanol. A polytetrafluoroethylene stirrer was installed in the middle of the three-neck round bottom flask. Slowly add phosphoric acid liquid with a concentration of 85% into one side port of the three-neck flask. The stirrer stirs the CaO clinker at 100r / min. Through physical adsorption and chemical reaction, a large amount of dense calcium phosphate is formed on the surface of CaO-based expanded clinker powder. Then filter and dry the modified calcium oxide expanded clinker at 55-60° C. to separate the phosphorylated coated modified calcium oxide expand...

Embodiment 2

[0055] (1) Preparation of phosphate-coated modified calcium oxide expansion agent (using 9 commercially available calcium oxide concrete expansion agents as raw materials)

[0056] Phosphorylated surface treatment was carried out on 9 commercially available calcium oxide concrete expansion agents. Weigh 200.0g of calcium oxide expansion agent and put it into a 1000ml three-necked round-bottomed flask filled with absolute ethanol. A polytetrafluoroethylene stirrer was installed in the middle of the three-neck round bottom flask. Slowly add phosphoric acid liquid with a concentration of 85% into one side port of the three-neck flask. Except for the above, the phosphoric acid treatment process is carried out in the same manner as in Example 1. By controlling the amount of phosphoric acid liquid added, the calcium phosphate wrapping amount of the expansion agent is controlled to be 4.0%. The reaction temperature is controlled at 20-50°C.

[0057] Table 4 shows the chemical com...

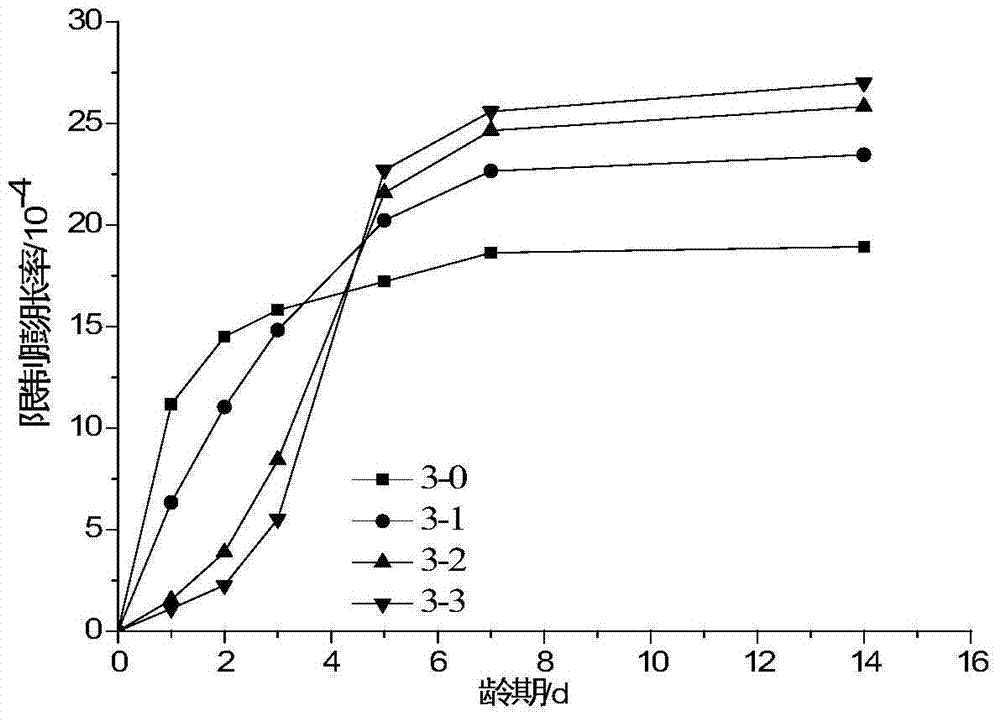

Embodiment 3

[0067] (1) Preparation of phosphorylated-coated modified calcium oxide expanded clinker (using commercially available calcium oxide expanded clinker as raw material)

[0068] Weigh 2.00kg of commercially available unground CaO expansion clinker, mix it with a phosphoric acid solution with a concentration of 85%, and grind it together in a ball mill to a fineness of about 350m 2 / kg of powder. During the grinding process, phosphoric acid reacts with calcium oxide expanded clinker powder to form a large amount of dense calcium phosphate on the surface of the expanded material.

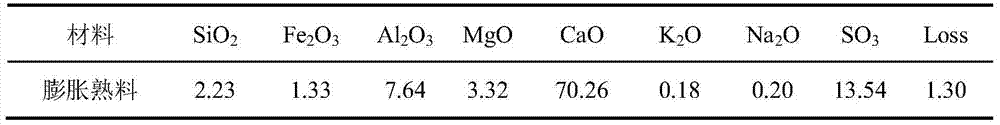

[0069] Table 6 shows the chemical composition (wt.%) of the commercially available calcium oxide expanded clinker.

[0070]

[0071] Table 7 is phosphoric acid (H 3 PO 4 ) Grinding process parameters of surface treated CaO expanded clinker.

[0072]

[0073] Note: The amount of calcium phosphate coating is the generated Ca 3 (PO 4 ) 2 Accounting for the mass ratio of modified calcium oxide e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com