Concrete water reducing agent and preparation method thereof

A technology of concrete water reducing agent and photoinitiator, applied in the field of building admixtures, can solve problems such as poor slump retention of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

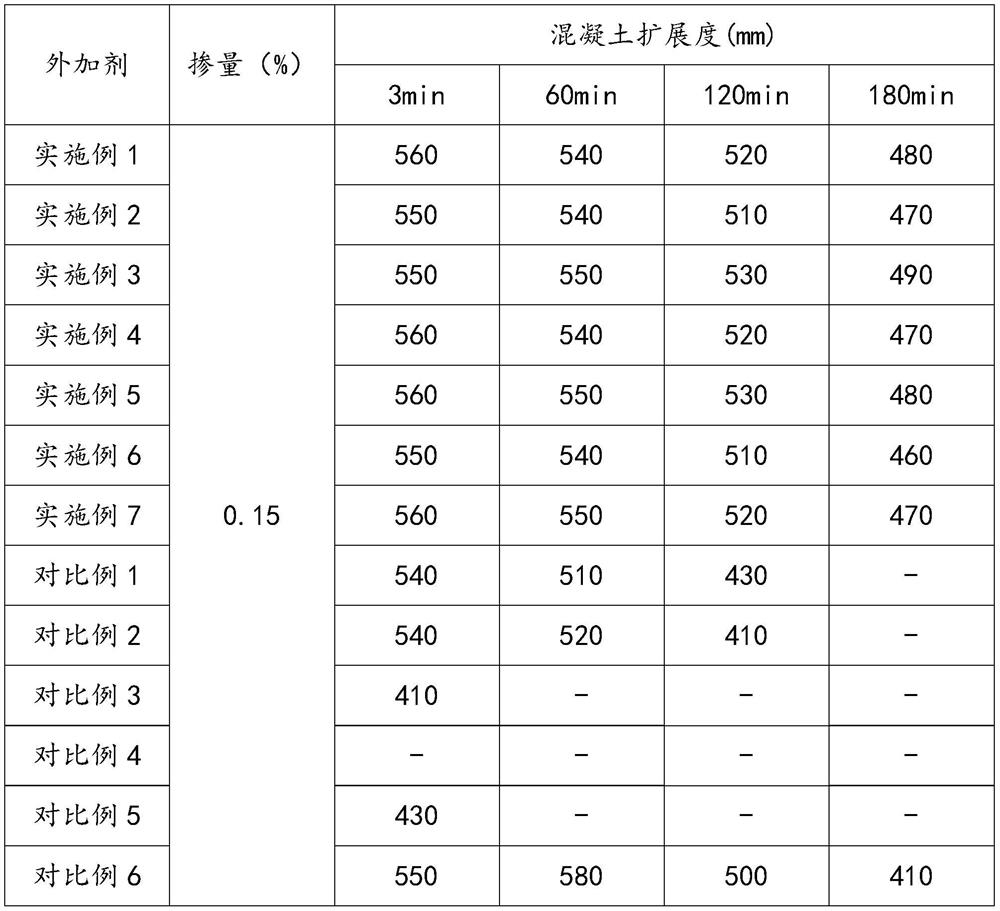

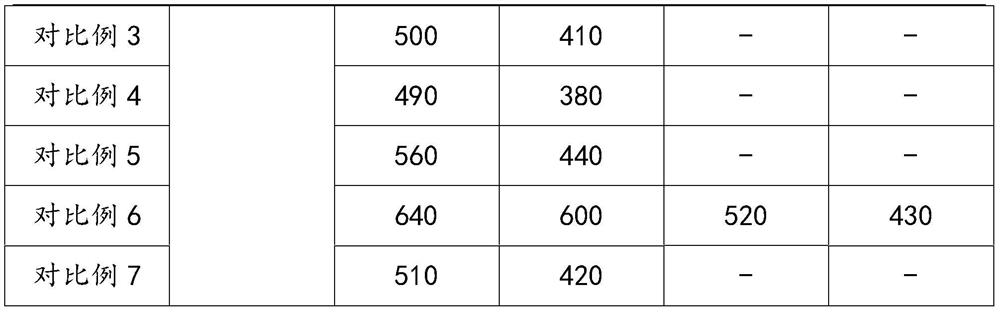

Examples

Embodiment 1

[0037] A concrete water reducer, made of the following raw material components by weight: 260 parts by weight of methoxypolyethylene glycol, 0.35 parts by weight of hydroquinone, 42 parts by weight of methacrylic acid, 350 parts by weight of water, 3.7 parts by weight Parts by weight of thioglycolic acid, 26 parts by weight of acrylic acid, 9.8 parts by weight of benzylethanol ketone and 5.5 parts by weight of sodium propylene sulfonate.

[0038] Concrete preparation method comprises the following steps:

[0039] (1) In a reaction vessel including a thermometer, a stirrer, a nitrogen inlet pipe and a reflux cooling pipe (condenser), add 260 parts by weight of methoxypolyethylene glycol, 42 parts by weight of methacrylic acid and 0.35 parts by weight of Hydroquinone, the temperature was raised to 105°C, and nitrogen replacement was carried out with nitrogen at a flow rate of 400ml / min for 4 hours, the temperature was lowered to 60°C, and nitrogen was stopped to obtain mixed sol...

Embodiment 2

[0043] A concrete water reducer, made of the following raw material components by weight: 270 parts by weight of methoxypolyethylene glycol, 0.39 parts by weight of hydroquinone, 45 parts by weight of methacrylic acid, 380 parts by weight of water, 3.1 parts by weight Parts by weight of mercaptoethanol, 28 parts by weight of itaconic acid, 10.3 parts by weight of benzophenone and 6.4 parts by weight of sodium propylene sulfonate.

[0044]Concrete preparation method comprises the following steps:

[0045] (1) In a reaction vessel including a thermometer, a stirrer, a nitrogen inlet pipe and a reflux cooling pipe (condenser), add 270 parts by weight of methoxypolyethylene glycol, 45 parts by weight of methacrylic acid and 0.39 parts by weight of Hydroquinone, the temperature was raised to 110°C, and nitrogen replacement was carried out with nitrogen at a flow rate of 400ml / min for 4 hours, the temperature was lowered to 60°C, and nitrogen was stopped to obtain mixed solution A; ...

Embodiment 3

[0049] A concrete water reducer, made of the following raw material components by weight: 265 parts by weight of methoxypolyethylene glycol, 0.36 parts by weight of hydroquinone, 49 parts by weight of methacrylic acid, 385 parts by weight of water, 6 parts by weight Parts by weight of mercaptopropionic acid, 25 parts by weight of crotonic acid, 10.5 parts by weight of benzophenone and 7 parts by weight of sodium propylene sulfonate.

[0050] Concrete preparation method comprises the following steps:

[0051] (1) In a reaction vessel including a thermometer, a stirrer, a nitrogen inlet pipe and a reflux cooling pipe (condenser), add 265 parts by weight of methoxypolyethylene glycol, 49 parts by weight of methacrylic acid and 0.36 parts by weight of Hydroquinone, the temperature was raised to 112°C, and nitrogen replacement was carried out with nitrogen at a flow rate of 400ml / min for 4 hours, the temperature was lowered to 60°C, and nitrogen was stopped to obtain mixed solution...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com