Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Water repellent" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Grey brick mechanically manufactured from lime sludge and construction wastes and method for manufacturing same

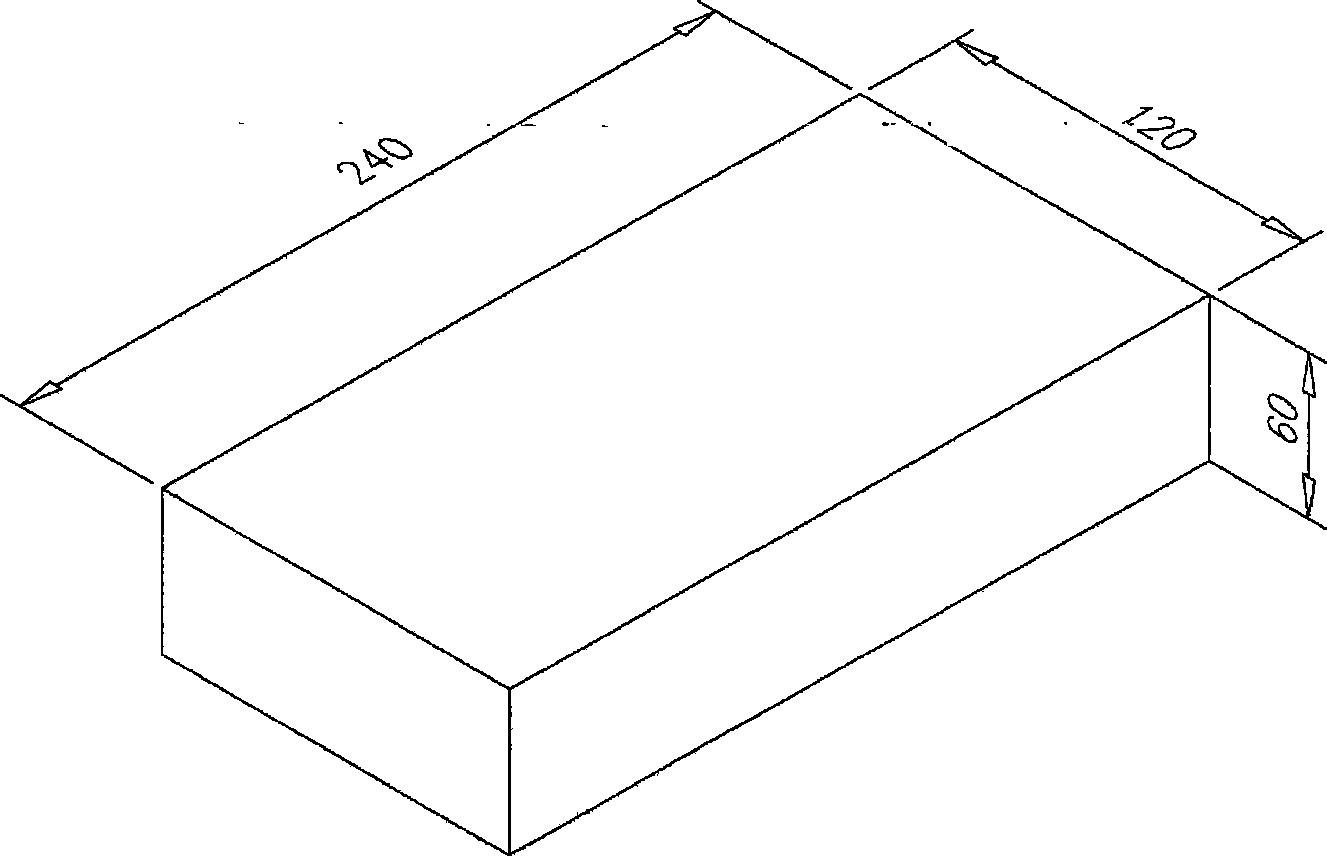

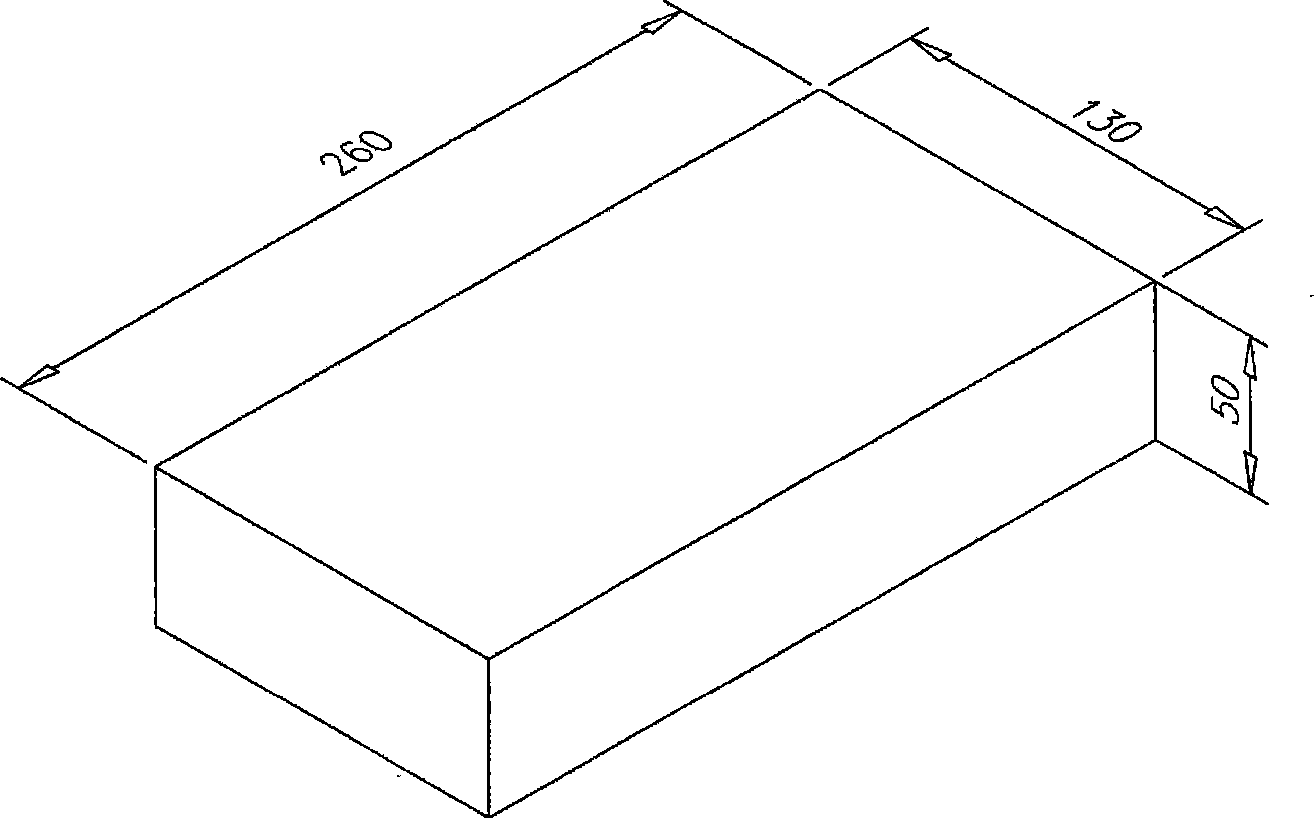

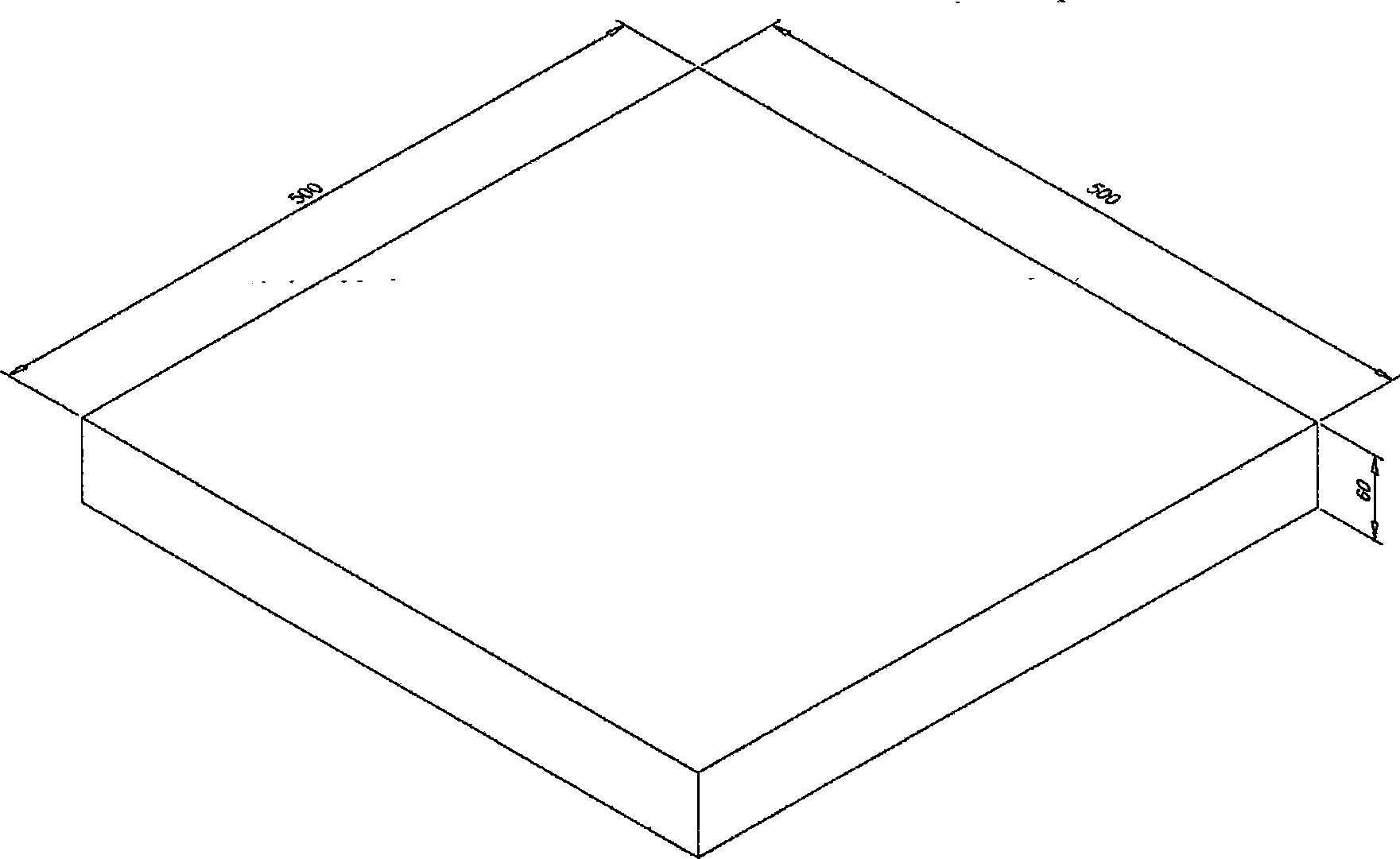

The invention discloses a gray brick mechanically manufactured from lime sludge and construction wastes and a method for manufacturing the same. The materials for mechanically manufacturing the gray brick comprise the following raw materials in portion by weight: 1,015 to 1,135 portions of construction waste crushed materials, 240 to 290 portions of cement, 810 to 1,010 portions of lime sludge, 60 to 75 portions of gray lime, and 100 to 125 portions of water, wherein the particle size of the construction waste crushed materials is less than 15 millimeters. If necessary, less than 20 portions of fly ash and proper amount of activating agent can be added to the materials. The method for mechanically manufacturing gray brick comprises the following steps: firstly, crushing the construction wastes; secondly, mixing the construction waste crushed materials with the other materials according to the proportions; and thirdly, pressing the mixture by adopting a mechanical method so as to produce the gray brick of the invention. The gray brick and the method for manufacturing the same recycle the sludge and the construction wastes in a reducing, harmless and resource-utilizing mode, and solve the problem that substituting materials and products are hard to find after clay bricks are forbidden to use and the problem of gray brick sources for civilian constructions.

Owner:梁林华 +1

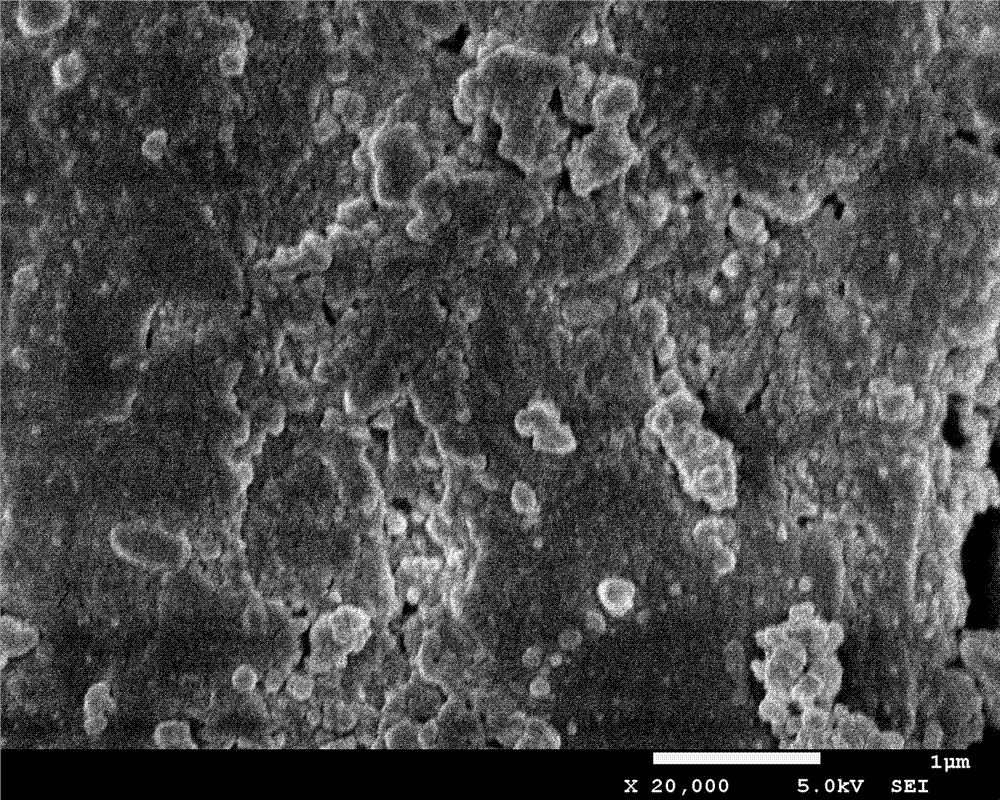

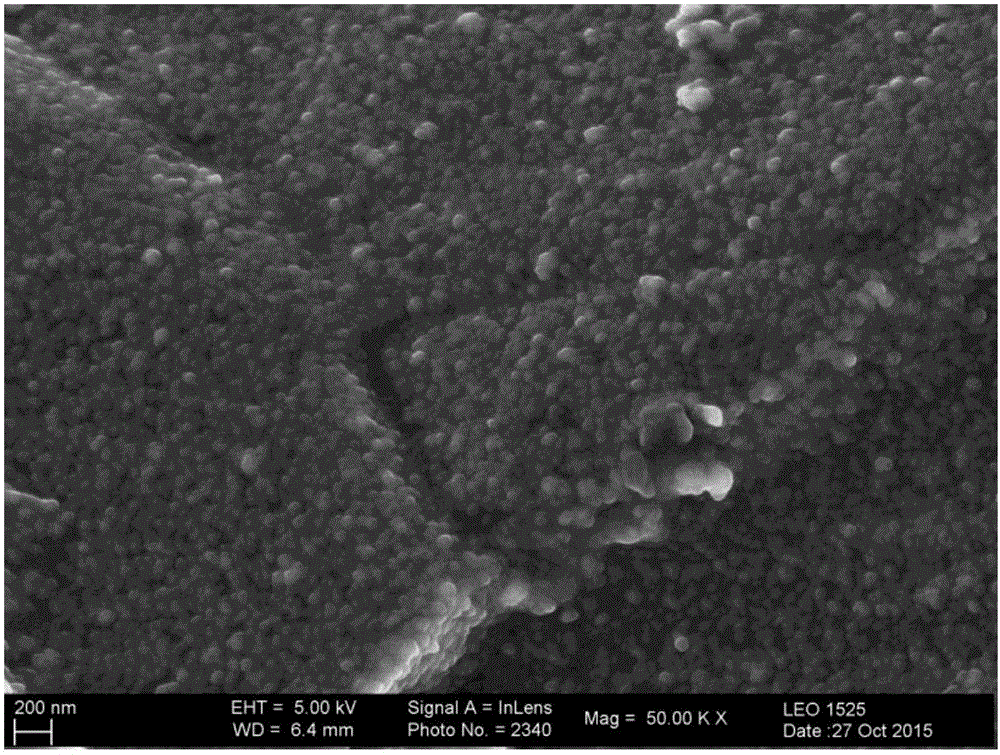

Preparation method of dopamine modified nano-silver textile fabric

InactiveCN105442306AIncrease productivityHigh binding force of nano silverLiquid repellent fibresVegetal fibresAnti bacterialWoven fabric

The invention belongs to the field of multifunctional textile fabrics and particularly relates to preparation of a multifunctional nano-silver textile fabric with antibacterial and water-repellent properties. The nano-silver textile fabric provided by the invention is prepared from raw materials including silver nitrate, a modifying agent and a textile fabric, wherein the mass ratio of the modifying agent to the silver nitrate is 1-50 and the mass of the silver nitrate used in each square meter of the textile fabric is 1g-50g. According to the multifunctional nano-silver textile fabric, dopamine is used as the modifying agent and used for carrying out pre-treatment on the textile fabric; a microwave method is used for preparing and reducing nano silver on the surface of a textile in situ; the multifunctional nano-silver textile fabric has the characteristics of environmental friendliness, high production efficiency, strong nano silver binding force, good repeatability and the like; and the obtained multifunctional nano-silver textile fabric has functional properties of bacterium resistance, water repellency, ultraviolet resistance and the like.

Owner:SICHUAN UNIV

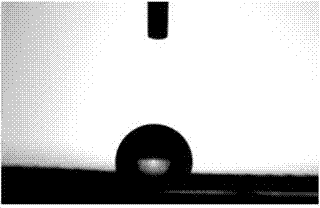

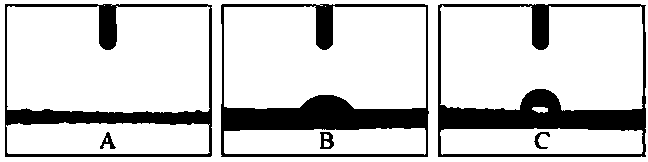

Cushioning Material for a Polishing Pad

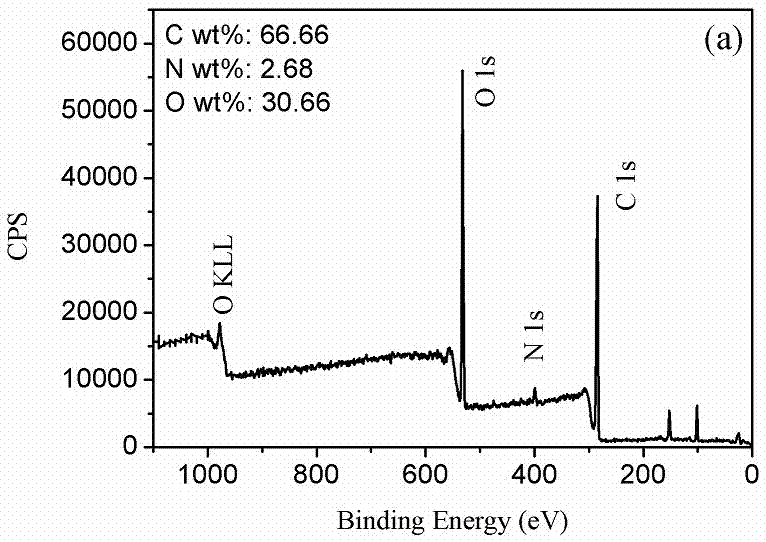

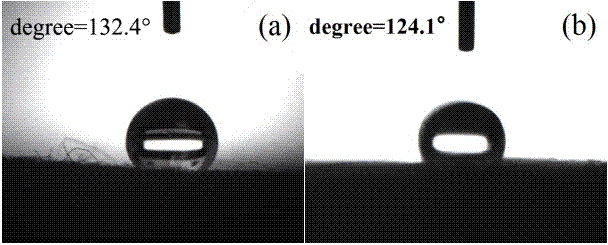

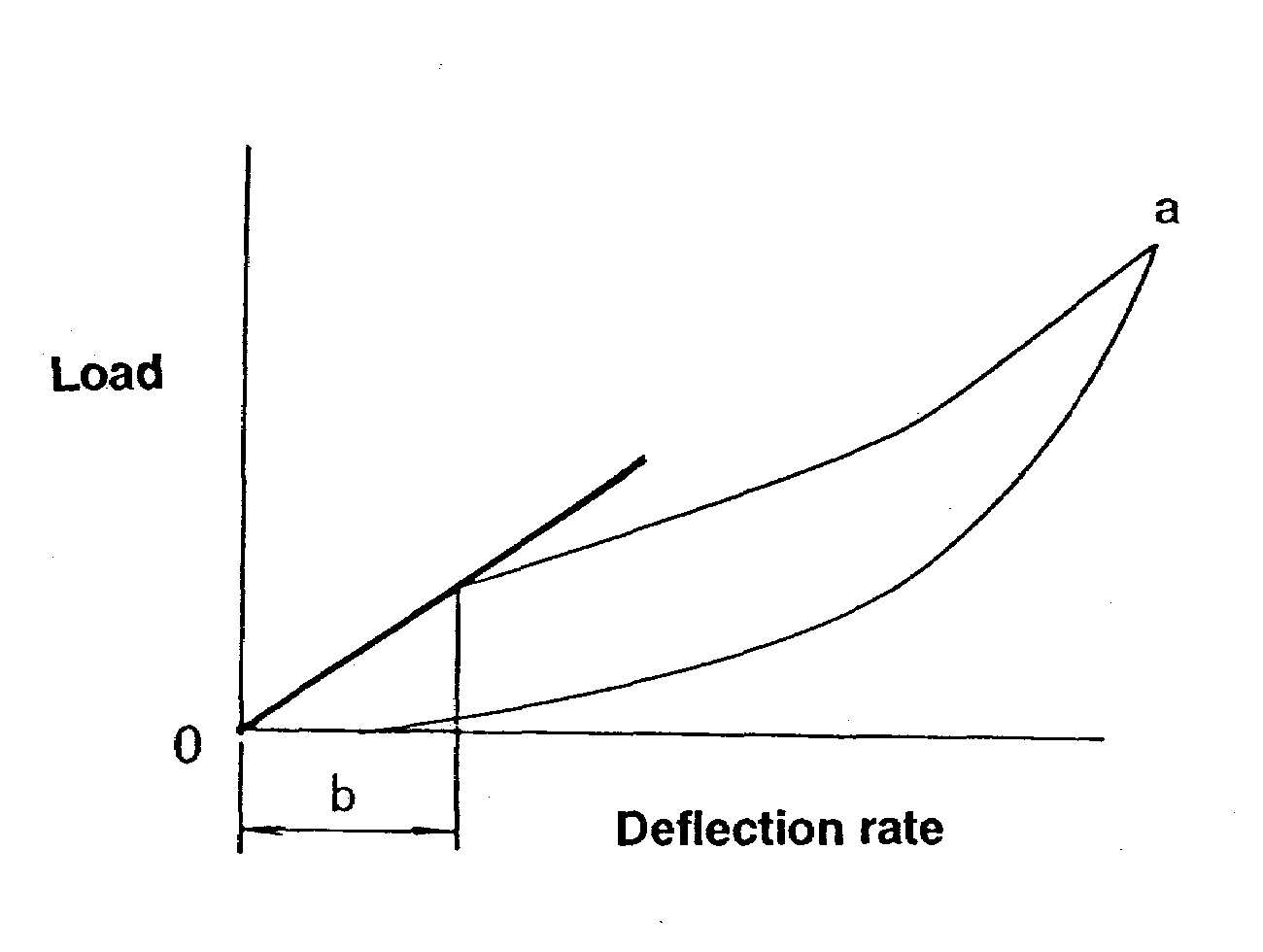

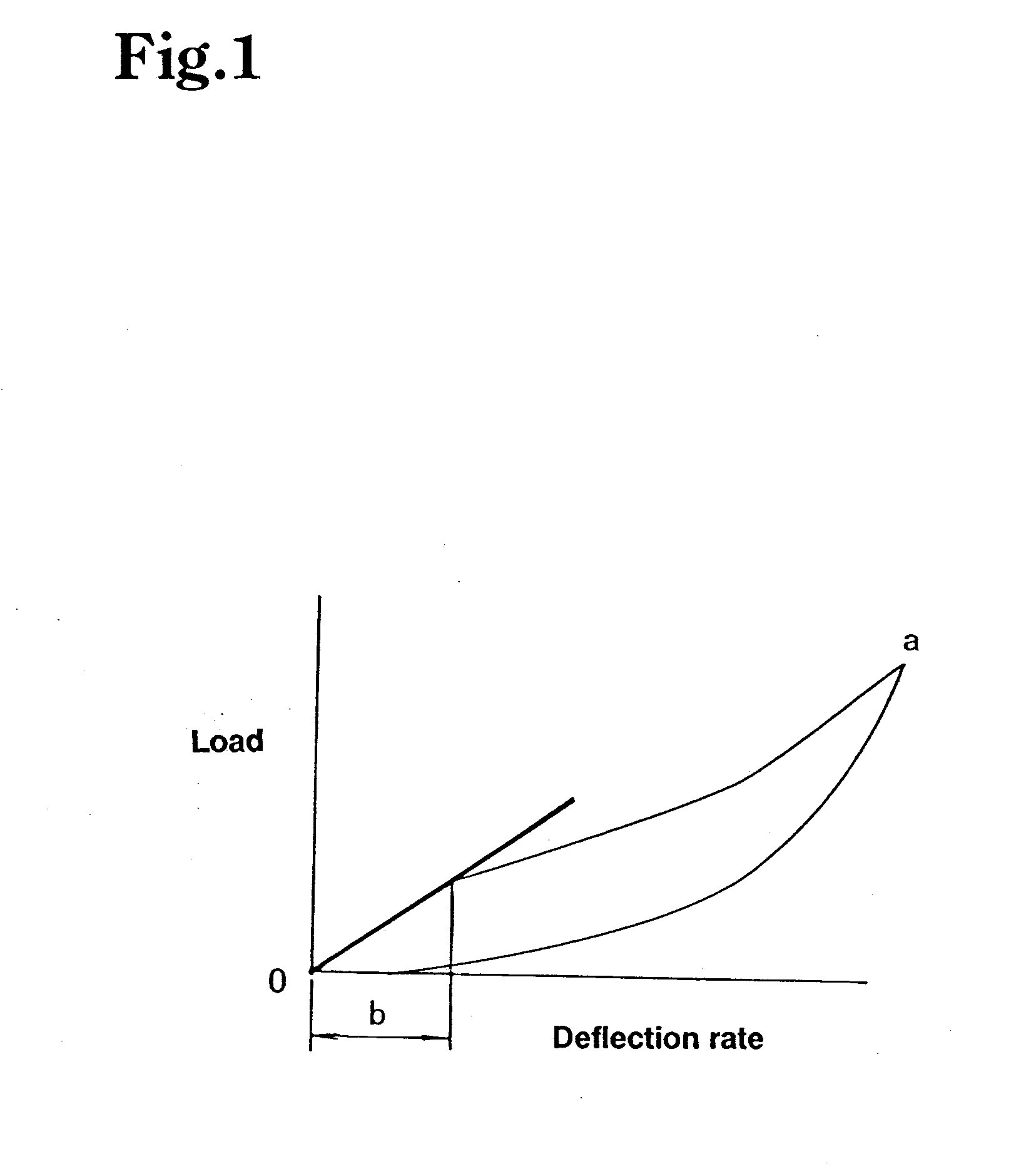

ActiveUS20090011221A1Low water absorptionHigh suppression characteristicsSynthetic resin layered productsSemiconductor/solid-state device manufacturingCushioningPolyol

Disclosed is a cushioning material for a polishing pad, which hardly suffers swelling deformation caused by water because it is extremely low in water-absorbing characteristics and water-swelling characteristics. The cushioning material for a polishing pad includes a polyurethane foam capable of polishing even a semiconductor wafer having an undulated surface or a wafer having a local step that is formed during circuit forming process so that the undulation or step becomes smaller by uniformly polishing an entire surface of the wafer along the undulation or step. The cushioning material for a polishing pad is characterized by including a polyurethane foam obtained by reacting polyol and polyisocyanate with each other, the polyurethane foam having a contact angle with water of 90° or more. The polyurethane foam is preferably made by using hydrophobic polyol, and preferably has a self-skin layer formed thereon.

Owner:NHK SPRING CO LTD

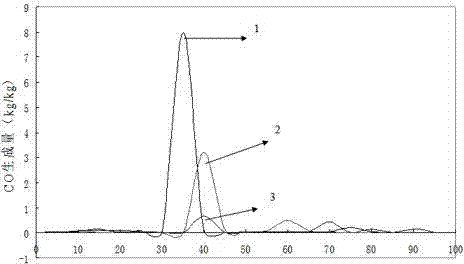

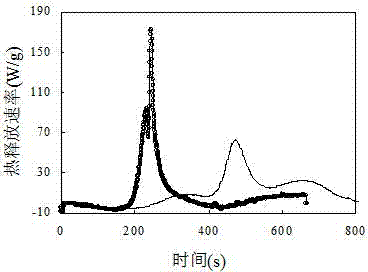

Inflaming retarding system and preparation method of inflaming-retarding real silk

ActiveCN102828408AIncrease char formationReduce smoke productionFibre treatmentSilane couplingChemistry

The invention discloses an inflaming retarding system and a preparation method of an inflaming-retarding real silk. The inflaming retarding system is a phosphorus-silicon collaborative system, wherein a phosphorus component is methacryloyloxyethyl dimethyl phosphate and a silicon component is a vinyl silane coupling agent. The preparation method comprises the following steps of: preparing an inflaming-retarding working solution and adjusting the pH (Potential of Hydrogen) value of the working solution to 4-4.5; immersing a real silk textile into the inflaming-retarding working solution, and heating the real silk textile at 80-85 DEG C for 10-60 minutes; and washing the real silk textile by water and drying the real silk textile to obtain the inflaming-retarding real silk. A fire retardant provided by the invention is durable, and no formaldehyde is released in an inflaming retarding and sorting process; and the smoke amount of the real silk textile in a combustion process is as low as required.

Owner:苏州盛泽科技创业园发展有限公司

Method for preparing nano multiple films on surface of glass

The present invention relates to a method for preparing nano multilayer film on glass surface. Said invention utilizes the combination of sol-gel method and spray pyrolysis method to prepare first layer silicon dioxide film, second layer antimony-fluorine combination doped tin dioxide film and third layer composite film using silicon dioxide and titanium dioxide as main component. Said invention also provides the concrete function of the above-mentioned energy layer film, and said glass has the hydrophobic and bacteriostatic characteristics.

Owner:西安陆通科技发展有限公司 +1

Waterproofing agent of acrylic ester coat, and preparation method

ActiveCN101092532AWeather resistantWashableAntifouling/underwater paintsPaints with biocidesCold resistanceMaterials science

This invention discloses a method for preparing a waterproof acrylate coating agent. The object coated with the waterproof acrylate coating agent has such advantages as soft touching sense, high water resistance, high waterproof effect, and high film -forming performance, and high wind, rain, gigging and cold resistance. The generated waste gases can be incinerated in a catalytic incinerator, thus the waterproof acrylate coating agent is environmentally friendly.

Owner:ZHEJIANG SATELLITE PETRO CHEM CO LTD

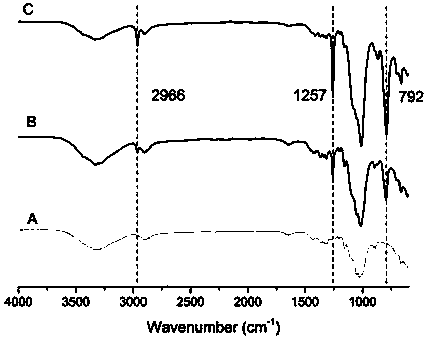

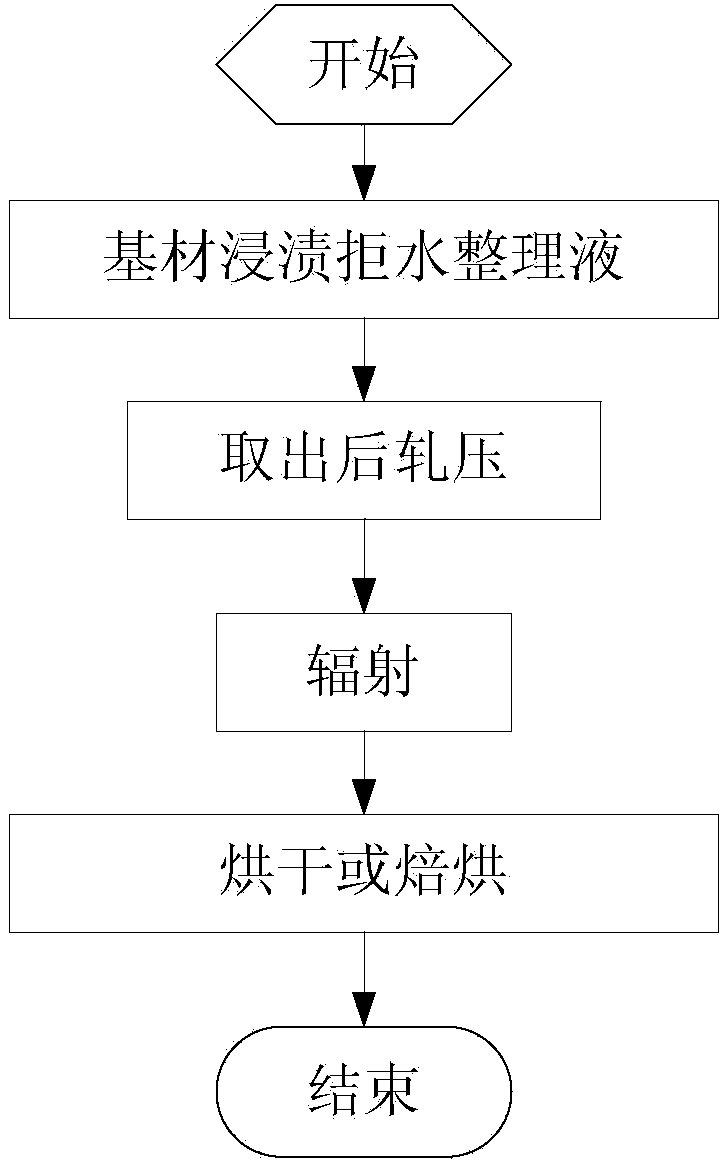

Method for preparing water-repellent textile

InactiveCN104278512AShort processing timeReduce energy consumptionPhysical treatmentAfter treatmentPolymer science

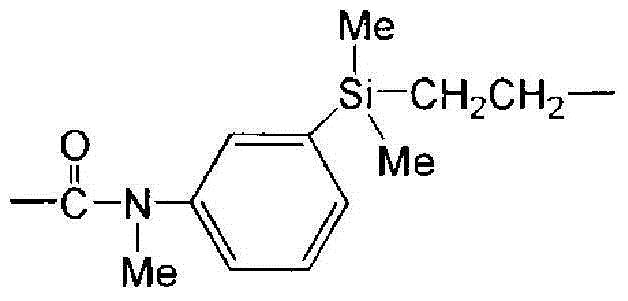

The invention provides a method for preparing a water-repellent textile. An electron radiation technology is adopted, a reactive organic silicon compound is taken as a water repellent, and the textile is subjected to water-repellent treatment. According to the main technical scheme, the method comprises the following steps: padding the textile in a water-repellent or a coating water repellent, radiating, drying or baking, performing after-treatment, thereby obtaining the water-repellent textile. The water-repellent textile prepared by the method disclosed by the invention is excellent in water-repellent performance and can be reacted at normal temperature, the grafting ratio is greatly improved, and the method has the advantages of simple processing technology, simplicity in control and low energy consumption and is worthy of popularization and application.

Owner:HUBEI ERAY NUCLEAR TECH

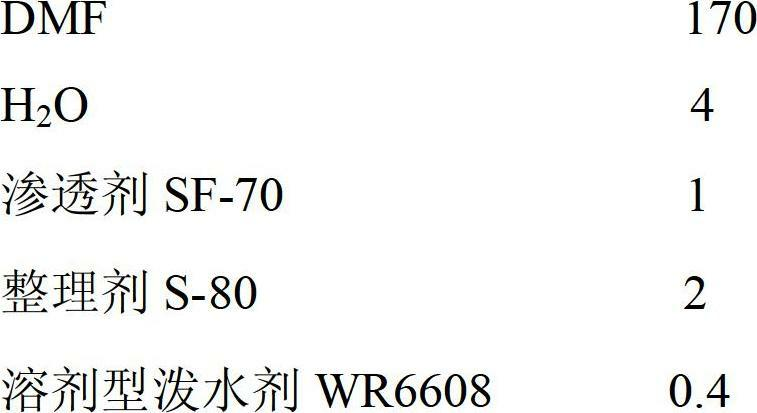

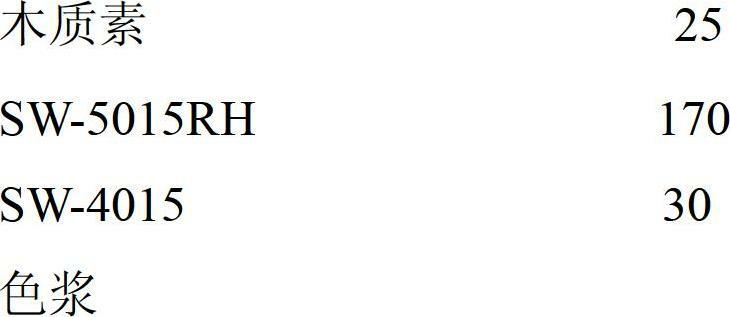

Preparation method for polyurethane synthetic leather with water repellent performance

ActiveCN102650103AWater repellentGood dispersionPretreated surfacesCoatingsWater basedAdditional values

The invention discloses a preparation method for polyurethane synthetic leather with a water repellent performance. A solvent type water repellent agent is added into a wet-process material for the synthetic leather, and a semi-finished product of the synthetic leather is subjected to water repellent treatment by a water-based water repellent agent in a processing process, so that high water repellent property of the synthetic leather is achieved. According to the preparation method, the 'siphon effect' of the synthetic leather can be effectively improved so as to increase the additional value of the synthetic leather.

Owner:ANHUI ANLI MATERIAL TECH

Fluorine-containing, silicon-containing polymer and surface treatment agent

ActiveCN105121517AOil-repellentAntifoulingPolyether coatingsOptical elementsPolymer scienceFluorine containing

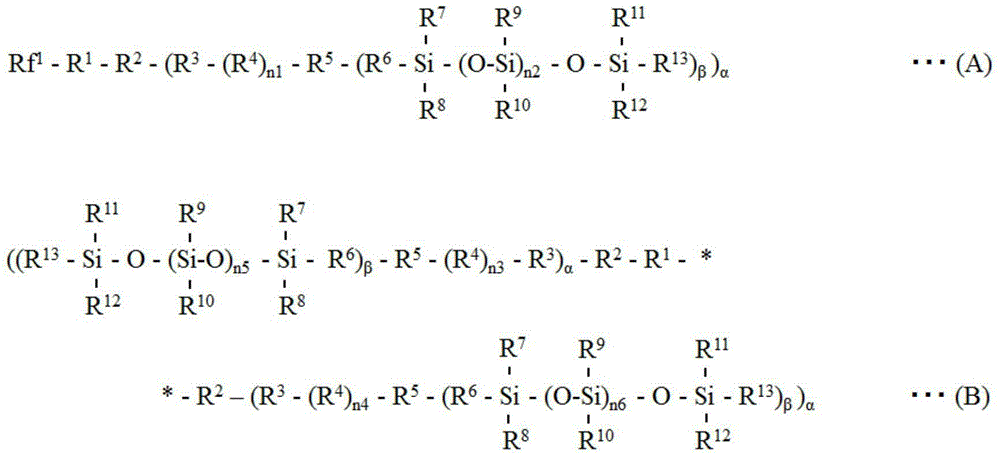

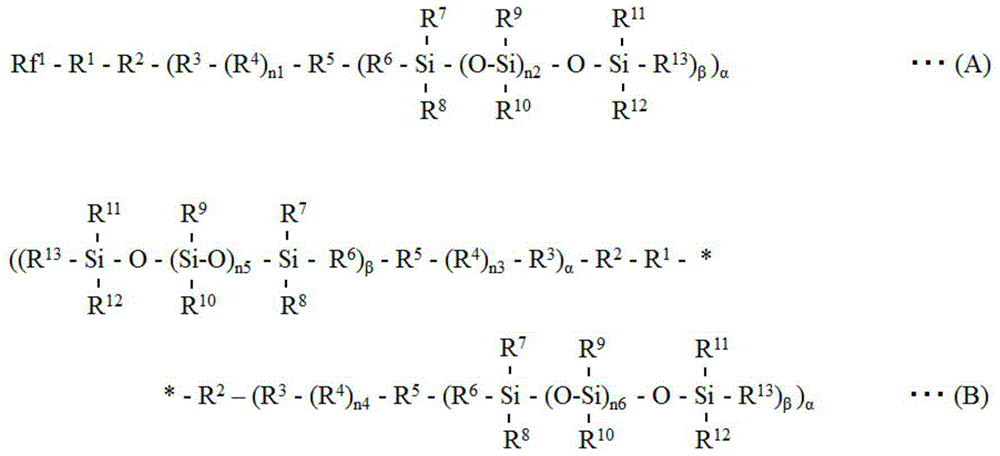

Provided is a fluorine-containing, silicon-containing polymer which is useful in forming a surface treatment layer that has water repellency, oil repellency, and antifouling properties, and has excellent surface lubricity. At least one type of fluorine-containing, silicon-containing polymer shown in general formulas (A) and (B) (wherein, each symbol is as defined in the description).

Owner:DAIKIN IND LTD

Hot-melt pressure-sensitive adhesive special for foot patch bottom support and preparation method thereof

InactiveCN111718676AIncrease viscosityWater repellentMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesElastomerPolymer science

The invention provides a hot-melt pressure-sensitive adhesive special for a foot patch bottom support, which at least comprises the following preparation raw materials in parts by weight: 20-50 partsof a thermoplastic elastomer, 40-60 parts of tackifying resin, 10-30 parts of a plasticizer, 1-5 parts of an antioxidant and 0-3 parts of an auxiliary antioxidant.

Owner:RUGAO JIAHAO HOT MELT ADHESIVE

Silk broadcloth surface biological branch-meeting water-repellent finishing method

InactiveCN101130930AGood hygroscopicity and air permeabilityGood hygroscopicityBiochemical fibre treatmentAnimal fibresSorptionChemistry

The present invention relates to a real silk surface biological grafting hydrophobic finishing method. It is characterized by that said invention utilizes that under the action of lipase the carboxyl of silk protein on the real silk surface and high-grade fatty alcohol can produce esterification reaction to make hydrophobic hydrocarbon chain be grafted on the real silk so as to obtain permanent hydrophobic finished effect. The surface of said real silk fabric has hydrophobic property, and its interior still has good moisture sorption characteristics and air permeability.

Owner:SOUTHWEST UNIVERSITY

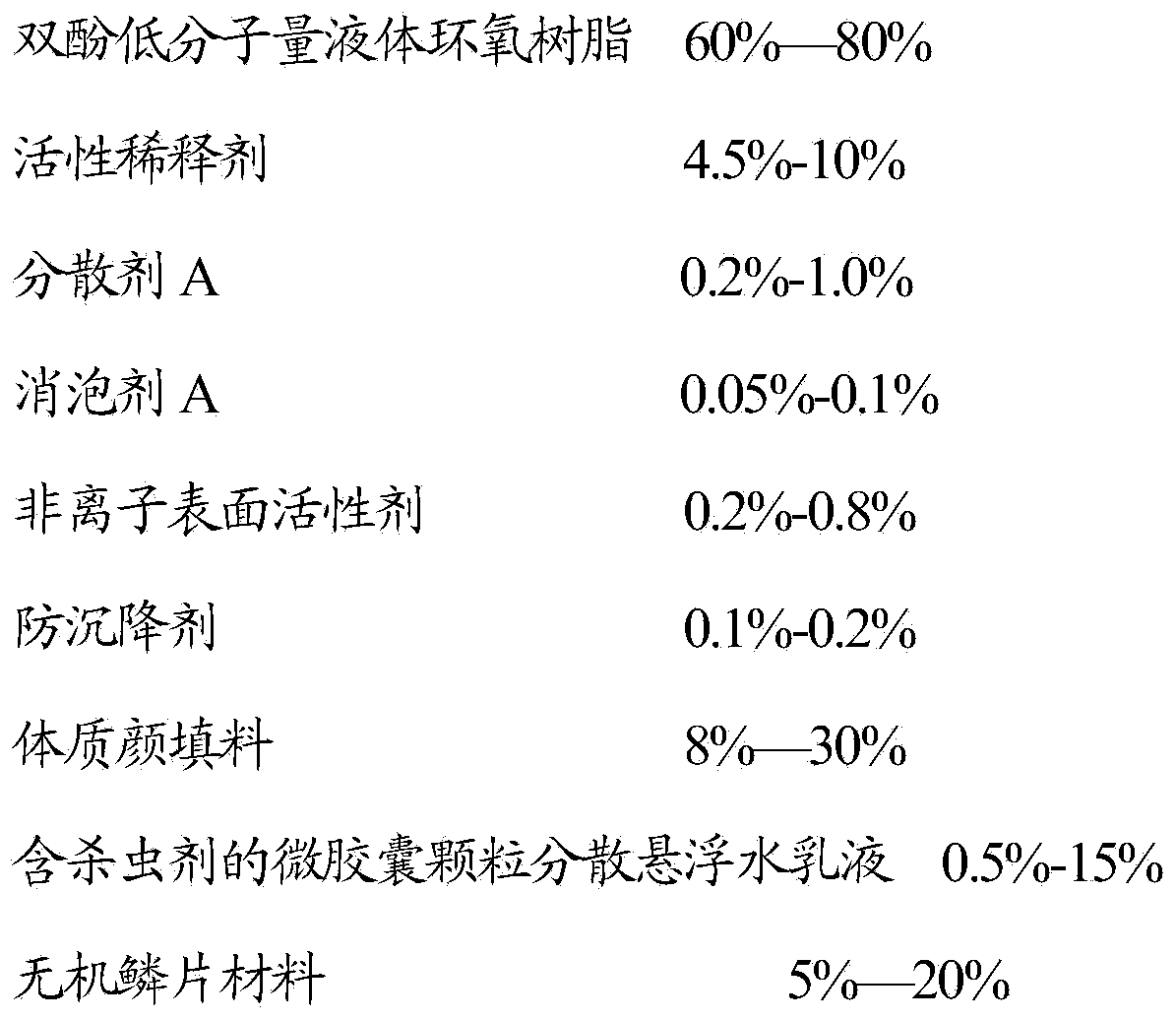

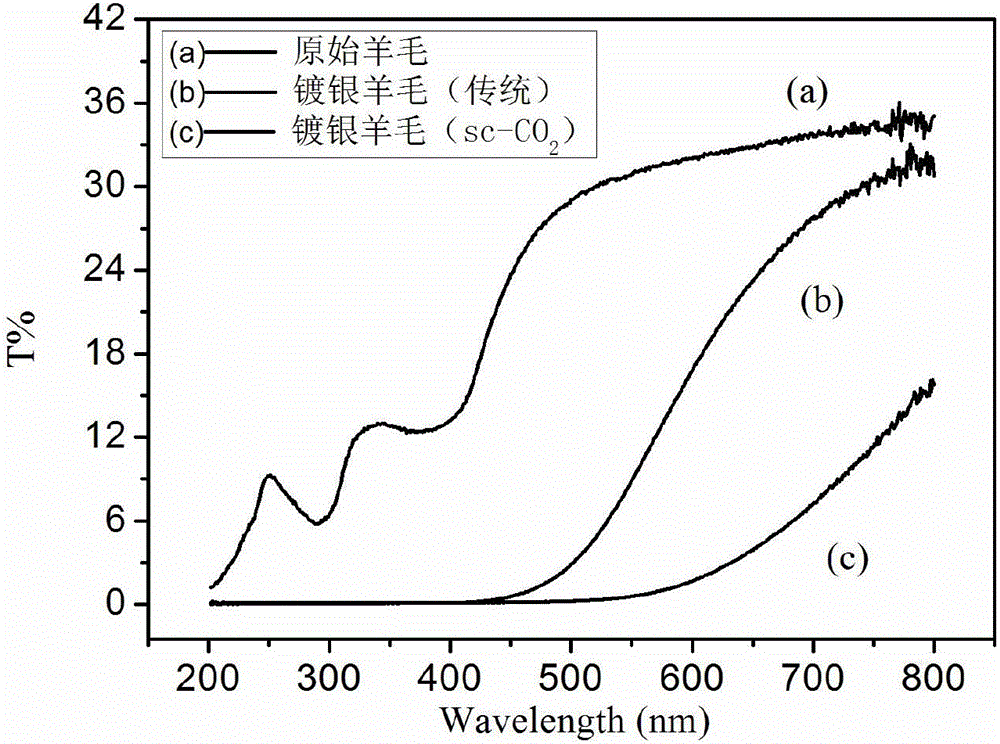

Anti-termite inorganic flake waterborne epoxy resin coating

ActiveCN104231867AHighly corrosiveInsulationAntifouling/underwater paintsPaints with biocidesEmulsionResin coating

The invention discloses an anti-termite inorganic flake waterborne epoxy resin coating. The waterborne epoxy resin coating comprises a component A and a component B, wherein the component A comprises the following components in percentage by weight: 60%-80% of bisphenol low-molecular-weight liquid epoxy resin, 4.5%-10% of active diluent, 0.2%-1.0% of dispersing agent, 0.05%-0.1% of defoaming agent, 0.2%-0.8% of non-ionic surfactant, 0.1%-0.2% of anti-settling agent, 8%-30% of extender pigment / filler, 0.5-15% of microcapsule particle dispersion suspension aqueous emulsion containing an insecticide and 5%-20% of inorganic flake material; and the component B comprises the following components in percentage by weight: 39%-65% of modified waterborne amine curing agent, 34%-60% of water, 0.2%-0.4% of dispersing agent, 0.2%-0.5% of defoaming agent and 0.2%-0.8% of flatting agent. The waterborne epoxy resin coating disclosed by the invention has the advantages of very good waterproof and moisture-proof property and anti-termite property.

Owner:HAINAN SEQUOIA CREATION

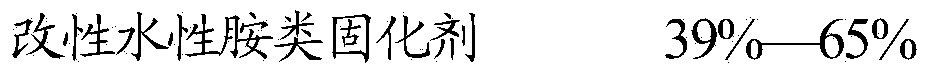

Supercritical fluid preparation method of nano-silver-coated textile fabric

InactiveCN105970611AIncrease productivityImprove bindingLight resistant fibresLiquid repellent fibresChemistryBinding force

The invention belongs to the field of multifunctional textile fabrics, and particularly relates to a nano-silver-coated textile fabric which has the multiple functions such as the catalytic degradation property, the ultraviolet resistance and the water repellency. The invention further provides a preparation method of the nano-silver-coated textile fabric. The nano-silver-coated textile fabric is prepared from silver nitrate, a reducing agent, a stabilizing agent and a textile fabric, wherein the mass ratio of the reducing agent to silver nitrate is 500-50, the mass ratio of the stabilizing agent to silver nitrate is 0.1-10, and 5 g-50 g of silver nitrate is used in every square meter of the textile fabric. According to the preparation method, the nano-silver-coated textile fabric is prepared by adopting a supercritical fluid technique, the textile fabric is treated for 10-100 min under the condition that the pressure is 7 Mpa-30 Mpa and the temperature is 20 DEG C-100 DEG C and then taken out, washed and dried. The textile surface is obtained by depositing nano-silver in supercritical carbon dioxide, the advantages of being environmentally friendly, high in production efficiency and nano-silver binding force, good in repeatability and the like are achieved, and the obtained nano-silver-coated textile fabric as the functions such as the catalytic degradation property, the ultraviolet resistance and the water repellency.

Owner:SICHUAN UNIV

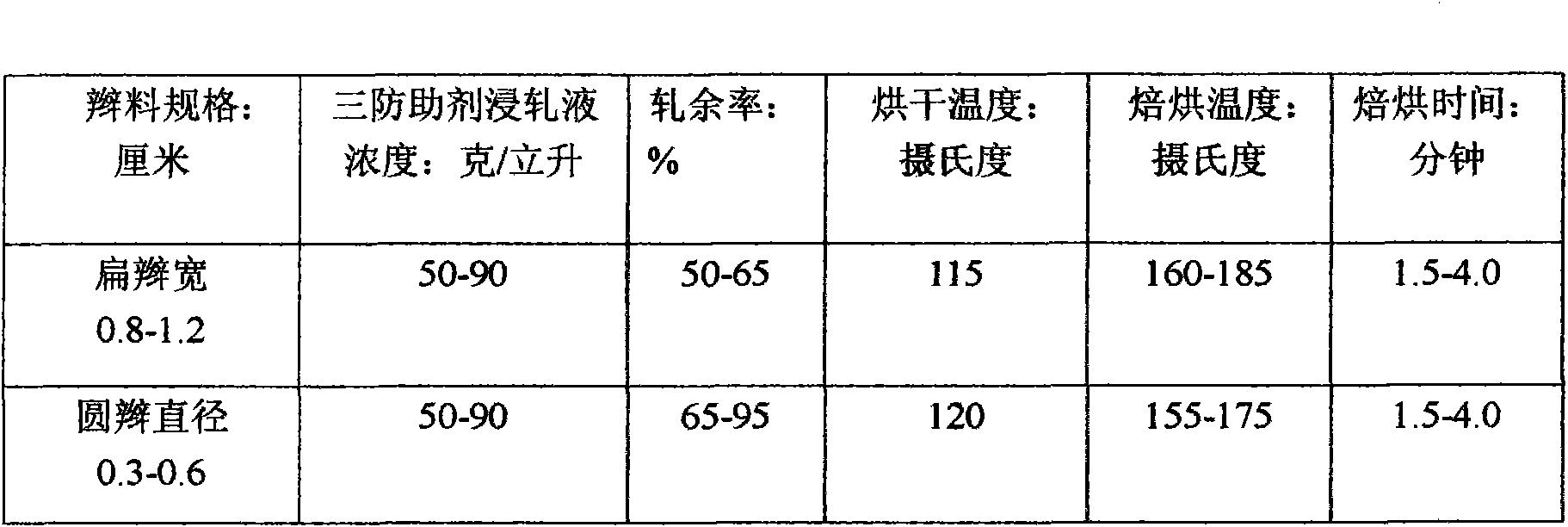

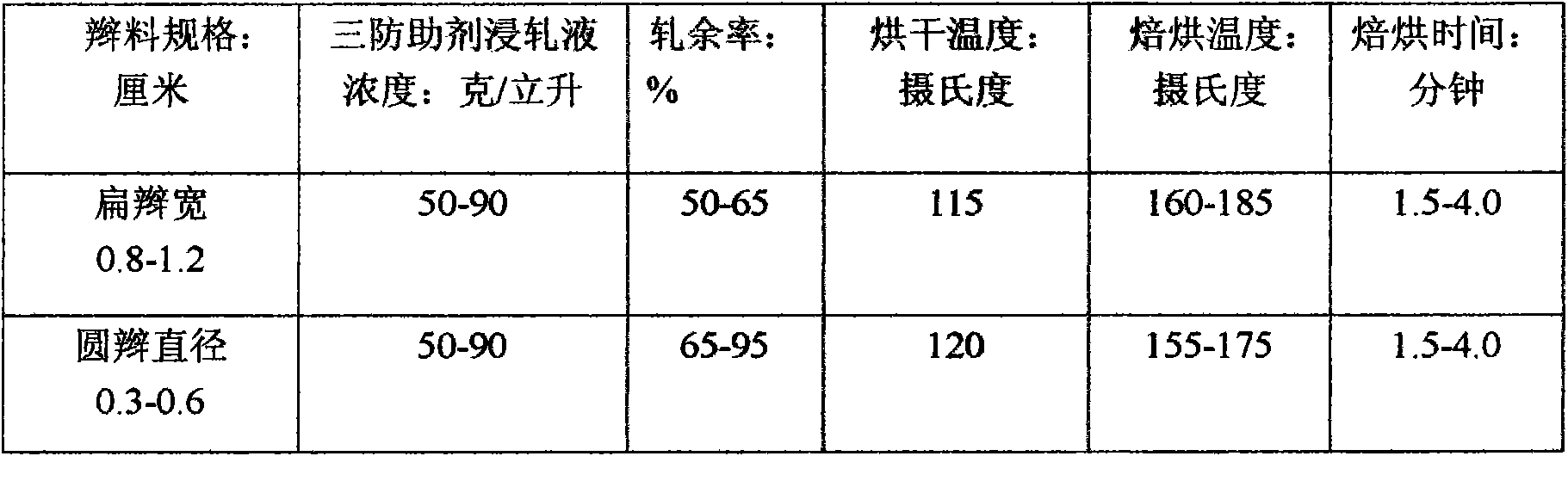

Process for manufacturing three-protection automobile seat cushion

The invention provides a process for manufacturing a three-protection automobile seat cushion, relating to the field of automobile seat cushions. The process comprises the following steps: plaiting raw material threads, forming axis, and padding in a three-protection auxiliary; drying, baking, and cutting and rolling the material; manually weaving, and sewing; and inspecting and packaging into a finished product. By utilizing the unique performance of a three-protection auxiliary nanometer technology, through a special process means, the three-protection arrangement material can be applied to the surface of plaited material fibers, the cushion has rich hand feel, and the cushion is ensured to be far away from various harmful bacteria and pollution, and has the advantages of water resistance, oil resistance, and no damage to the original style of the fibers.

Owner:张振和

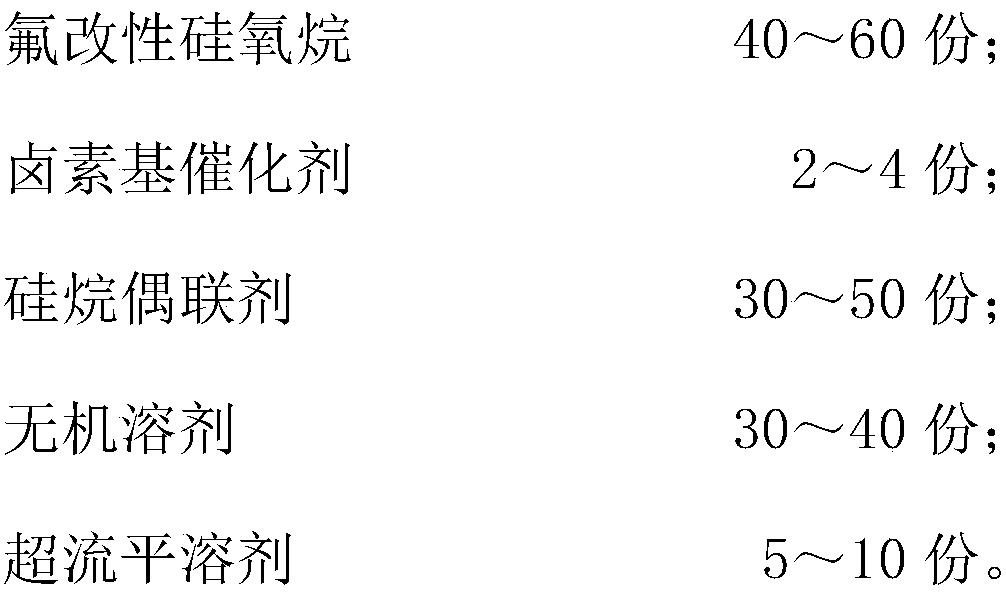

Smooth, anti-staining, scratch-resistant and easy-cleaning nano-coating for glass, preparation method and construction method thereof

InactiveCN109294441AImprove hydrophobicityImprove bindingAntifouling/underwater paintsPaints with biocidesStainingUltraviolet

The invention relates to a smooth, anti-staining, scratch-resistant and easy-cleaning nano-coating for glass. The nano coating is composed of the following components in parts by weight: 40 to 60 parts of fluorine-modified silicone; 2 to 4 parts of a halogen-based catalyst; 30 to 50 parts of a silane coupling agent; 30 to 40 parts of an inorganic solvent; and 5 to 10 parts of a super-leveling solvent, and the invention also disclose a preparation method and a construction method thereof. The nano coating has the advantages that by binding a plurality of active fluorine bonds to a Si bond in the glass, the fluorine has many excellent characteristics such as water repellency, oil repellency, low friction, abrasion resistance, corrosion resistance and ultraviolet resistance, the ultra-thin nano-coating with anti-fouling, self-cleaning and scratch resistance is finally formed on the surface of the glass, which is simple in method and low in cost. The coating not only has excellent hydrophobicity, but also excellent adhesion between the coating and the glass, and ensures that the coating maintains the superior hydrophobicity for a long time.

Owner:深圳市派旗纳米技术有限公司

Post-treatment method for silver-plated textile fabrics

InactiveCN105696354AEnvironmentally friendlyImprove corrosion resistanceFibre typesEnvironmental resistanceSilver plate

The invention discloses a post-treatment method for silver-plated textile fabrics.Raw materials for implementing the post-treatment method include a post-treatment agent, organic solvents and the silver-plated textile fabrics.The concentration of the post-treatment agent is 0.01-1 mol / L, and a bath ratio of the post-treatment agent is 1-100:1.The post-treatment method has the advantages that the post-treatment agent can be n-octadecyl mercaptan after processes are adopted, and the silver-plated textile fabrics obtained by the aid of the post-treatment method are environmentally friendly, are good in corrosion resistance and have functional characteristics such as water repellency; the processes are simple and are low in cost, and uniform water-repellency protective films with high fastness can be formed on the surfaces of the textile fabrics.

Owner:NINGBO GRAND HOME FURNISHING

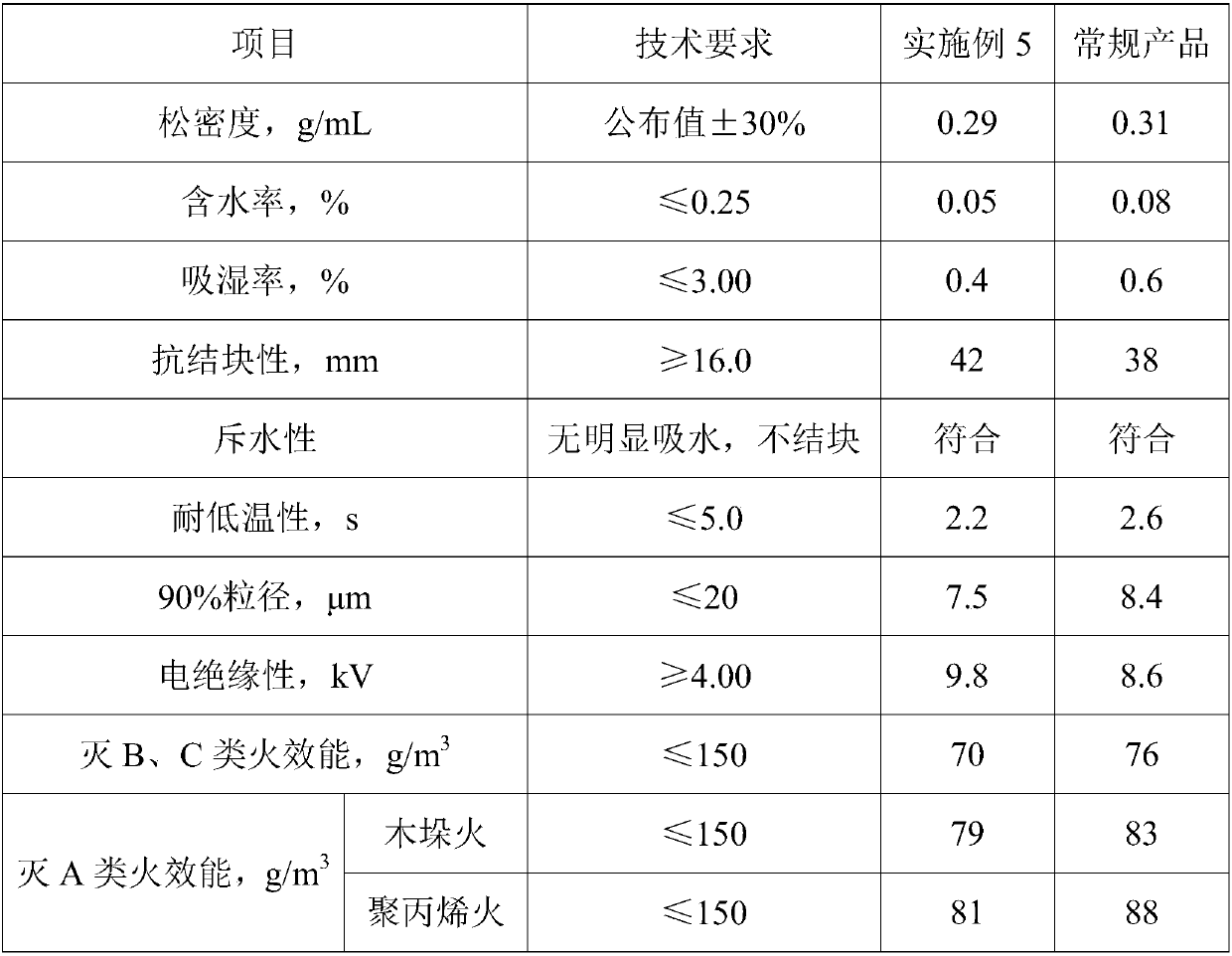

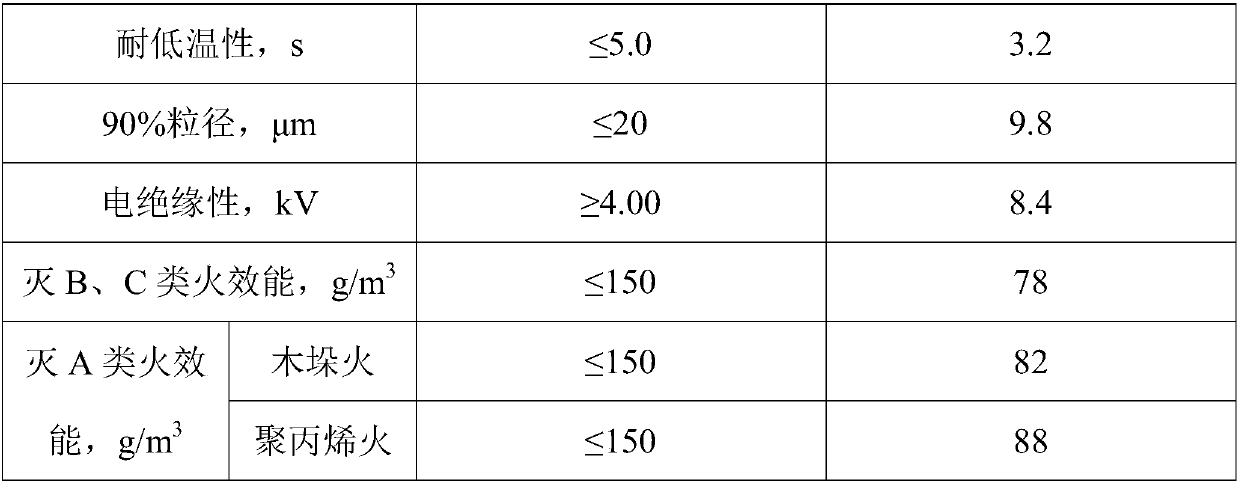

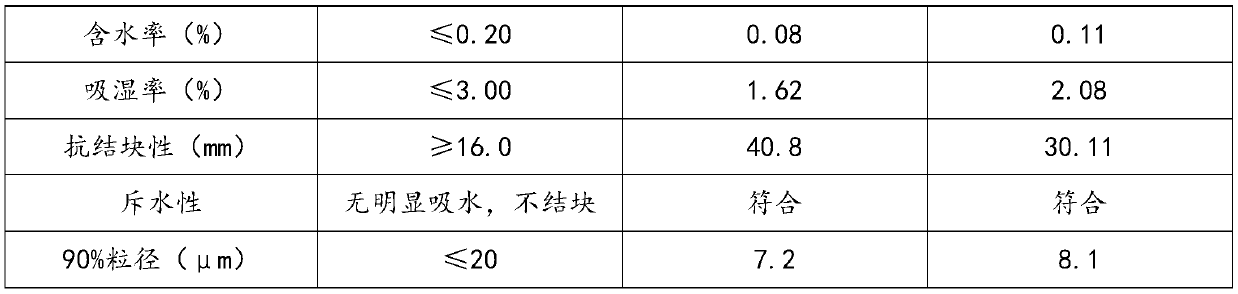

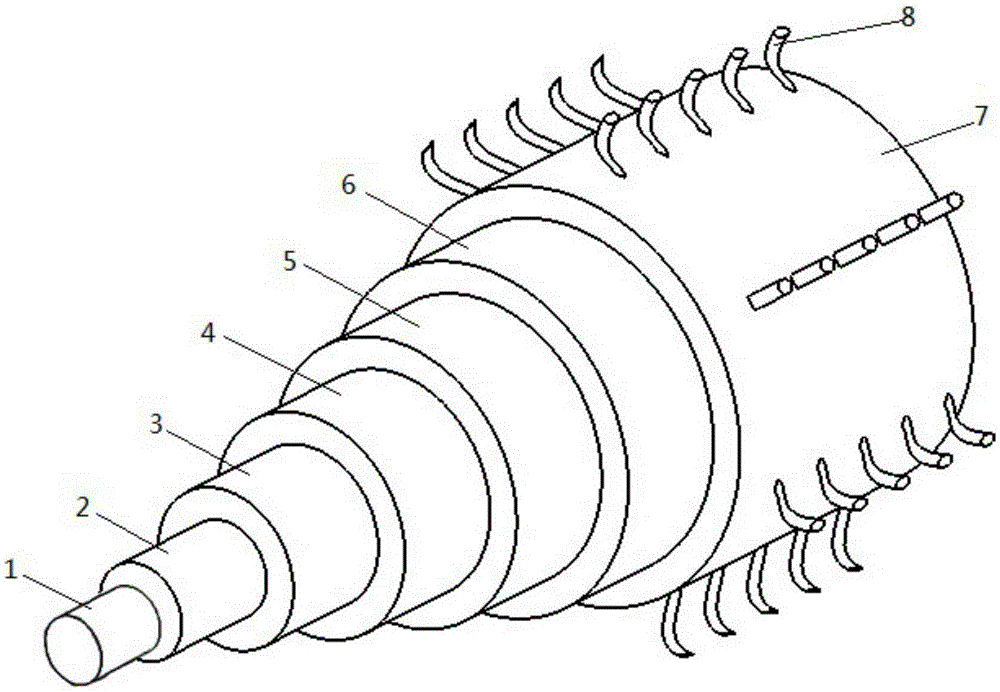

Preparation method of ultrafine dry powder extinguishing agent with good water repellency

InactiveCN107823832AImprove fire extinguishing performanceImprove efficiencyFire extinguisherPhosphomolybdic acidSodium bicarbonate

The invention discloses a preparation method of an ultrafine dry powder extinguishing agent with good water repellency. The preparation method comprises the following steps: gypsum, carbon nanotubes,phosphomolybdic acid and magnesium carbonate powder are uniformly mixed for drying and grinding to obtain precast materials; the precast materials are preheated; sodium bicarbonate, monoammonium phosphate, alum compounds, magnesium carbonate powder and ammonium sulfate are added in sequence in a stirring state for continuous stirring; silicone oil is sprayed inside in the stirring state for continuous stirring; pentaerythritol is added for continuous stirring; and the ultrafine dry powder extinguishing agent with good water repellency is obtained through drying, crushing and screening. The alum compounds are prepared by adopting the following process: alums are added in ethanol solution for uniform mixing; liquid paraffin is added for heat stirring, filtering and spray stirring; magnesiumstearate, pentaerythritol and white oil are added in sequence in the stirring state for uniform stirring; and the alum compounds are obtained through cooling. The preparation method is simple and lowin production cost; and the prepared dry powder extinguishing agent is excellent in fire extinguishing performance, and achieves excellent water repellency, fluidity and caking resistance.

Owner:BENGBU LONGTAI FIRE FIGHTING

Finish coat paint for facing mortar

The present invention discloses a finish coat paint for facing mortar. The finish coat paint comprises the following components, by weight, 15-25% of an antifouling polymer, 10-20% of an emulsion, 5-10% of an additive, and 40-60% of water. With the technical scheme of the present invention, the antifouling polymer is adopted as the main component by the finish coat paint of the present invention, wherein the main component of the antifouling polymer is an organic fluorine resin, and the antifouling polymer has special surface performances of stain resistance, water repellency, oil repellency, and the like so as to provide a good antifouling effect; with additions of the emulsion, the additive and the like, the disadvantages of the antifouling polymer are improved so as to achieve high quality complementation and completely provide respective effects.

Owner:JIANGSU NIGAO SCI & TECH +2

Water-repellent finishing method of clothes

InactiveCN104294589AWater repellentIncreased durabilityFibre treatmentAcrylic resinPolyethylene glycol

The invention discloses a water-repellent finishing method of clothes. The water-repellent finishing method comprises the following steps: (1) mixing 23 parts of water, 1-2 parts of polyethylene glycol distearate, 2-3 parts of acrylic resin, 3-4 parts of polyvinylpyrrolidone and 4-5 parts of triethanolamine, simultaneously slowly adding 7-8 parts of anionic polyacrylamide, 1-2 parts of polyoxyethylene ether, 6-7 parts of an HPC-1 finishing agent, 8-9 parts of dimethylol ethylene urea and 1-2 parts of glycerin monostearate within 40 minutes, and continuously mixing for 2 hours to obtain a steeping liquid; and (2) steeping the clothes into the steeping liquid, and carrying out constant temperature treatment on the clothes at 145 DEG C for 2.5 hours after the clothes are dried, wherein the steeping pressure is 2.5MPa, and the pick-up rate is 73%. The clothes finished by virtue of the water-repellent finishing method have water repellency and good durability.

Owner:苏州庄爵服饰有限公司

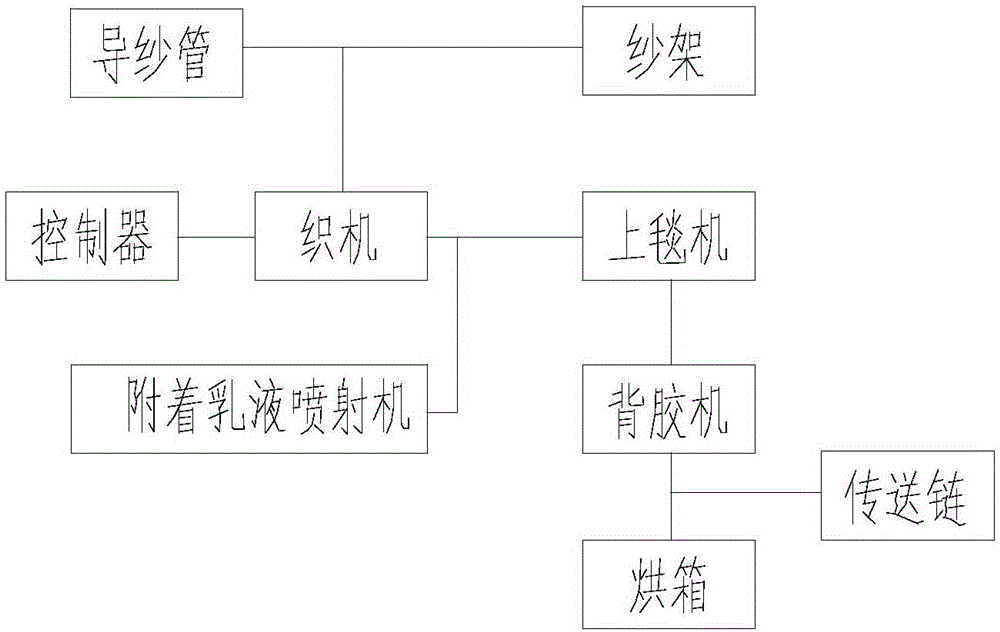

Preparation technology and device for waterproof and antifreezing artificial turf provided with pattern

InactiveCN106320142AExcellent waterproof and antifreeze performanceImprove performanceAntifouling/underwater paintsPaints with biocidesEmulsionStatic performance

The invention provides a preparation technology for waterproof and antifreezing artificial turf provided with a pattern. The preparation technology comprises the following steps: (1) a controller transmits a designed pattern to a loom through a weaving instruction; (2) the loom starts tufting after receiving the weaving instruction, a tufting finished product passes through a carpet feeder and enters a gluing machine to be glued; an adhering emulsion injection machine is arranged at a tufting finished product outlet of the loom, an injection port of the adhering emulsion injection machine aligns at the tufting finished product at an outlet of the loom, and the tufting finished product is fed through the carpet feeder into the gluing machine to be glued after an adhering emulsion is injected to the tufting finished product by the adhering emulsion injection machine; (3) glued artificial turf enters a drying oven to be dried through a conveying chain. The service life can be prolonged two-three times, the artificial turf has anti-static performance, heat absorption and insulation, surface water repellency, mould proofness, sterilization and soil resistance, the water repellency of the artificial turf is 3-5 times that of common artificial turf, and grass does not get hard when the artificial turf is placed in an environment at the temperature of subzero 1-15 DEG C and does not get frozen after the rain.

Owner:江蘇聯創人造草坪股ふん有限公司

Water-repelling finishing method for clothes

The invention discloses a water-repelling finishing method for clothes. The water-repelling finishing method comprises the following steps: (1) mixing 30 parts of water, 1-2 parts of alkylolamide polyoxy-ethane ether, 2-3 parts of acrylic resin, 3-4 parts of polyvinylpyrrolidone and 4-5 parts of isopropanolamine, then slowly adding 7-8 parts of anionic polyacrylamide, 1-2 parts of ethylene glycol monostearate, 6-7 parts of an HPC-1 finishing agent, 8-9 parts of dihydroxymethyl ethylene urea and 1-2 parts of glycerin monostearate, adding all the materials within 35 minutes and continually mixing for 2.5 hours to obtain impregnation liquid; and (2) carrying out padding treatment on clothes in the impregnation liquid under the conditions that the pressure is 2.3MP and the liquid carrying rate is 71%, and keeping the constant temperature of the clothes at 143 DEG C for 3 hours after the clothes are dried. The clothes subjected to finishing by the water-repelling finishing method have good water-repelling performance and good durability.

Owner:HUZHOU ZHILI CHILDRENS CLOTHING DEV

ABC ultra-fine dry powder extinguishing agent

InactiveCN107837485AGood fire extinguishing performanceImprove efficiencyFire extinguisherPotassiumUltra fine

The invention discloses an ABC ultra-fine dry powder extinguishing agent. The ABC ultra-fine dry powder extinguishing agent comprises the raw materials of, by weight, 15-25 parts of ammonium dihydrogen phosphate, 5-9 parts of potassium sulphate, 5-10 parts of alum, 2-5 parts of magnesium carbonate, 4-8 parts of ammonium sulfate, 2-4 parts of raw gypsum, 10-12 parts of hydrophobic white carbon black, 0.5-1 part of raw gypsum, 2-4 parts of bentonite, 1-2 parts of methylsilicone oil and 2-5 parts of pentaerythritol. The ABC ultra-fine dry powder extinguishing agent provided by the invention is superior in extinguishing performance and high in efficiency, has the water repellency, is good in fluidity and superior in anticaking capacity, can be stored for long time and has a good market prospect, and by means of the ABC ultra-fine dry powder extinguishing agent, the material cost is greatly lowered, and the diminishing phosphate rock resources are further saved.

Owner:BENGBU LONGTAI FIRE FIGHTING

Preparation method of hydrophilic and soil-release bedding fabric

InactiveCN108505341AWater-repellentGood film formingStain/soil resistant fibresCooking & bakingPolyethylene terephthalate glycol

The invention discloses a preparation method of hydrophilic and soil-release bedding fabric, and belongs to the field of textile. The method comprises the following steps: a, fabric pretreatment: a cold pad-batch pretreatment technique is adopted for pretreatment; b, padding of the fabric: a solution for padding is prepared from a finishing agent with concentration being 70-75g / L, a fatty alcoholpolyoxyethylene ether penetrant with concentration being 8-12g / L, a softener with concentration being 6-8g / L and acid ammonium with concentration being 2.5-4g / L, pH of a working solution is 5-6, and the finishing agent is prepared from fluoro-hydrocarbon acrylate resin with concentration being 7-8g / L, 5-5.5g of a polyethylene glycol and polyethylene terephthalate block copolymer and citric acid with concentration being 15-27g / L; c, centrifugal dewatering; d, infrared or hot air drying of the fabric; e, fabric baking; f, fabric printing.

Owner:浙江肯特科技股份有限公司

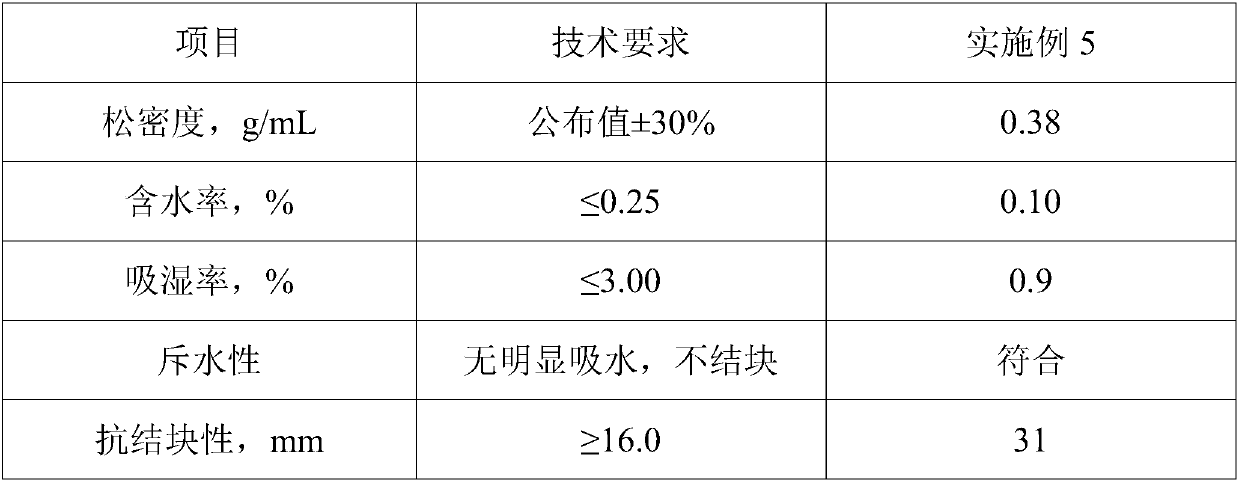

Ultrafine dry powder extinguishing agent and preparation method thereof

InactiveCN111135520AReduce moisture contentLow moisture absorptionFire extinguisherPhosphatePhosphoric acid

The invention discloses an ultrafine dry powder extinguishing agent and a preparation method thereof, and relates to the technical field of extinguishing agents. A purpose of the invention is to solvethe problems that the existing dry powder extinguishing agent is large in particle size, high in moisture absorption rate and easy to cake. The ultrafine dry powder extinguishing agent comprises thefollowing main raw materials in parts by mass: 82-95 parts of monoammonium phosphate, 4-8 parts of white carbon black, 0.2-1 part of silicone oil, 2-5 parts of mica powder and 2-5 parts of talcum powder, and has the advantages of low particle moisture content, low moisture absorption rate, water repellency, strong anti-caking ability and long storage life.

Owner:ZHENGZHOU HAITIAN FIREFIGHTING MATERIAL CO LTD

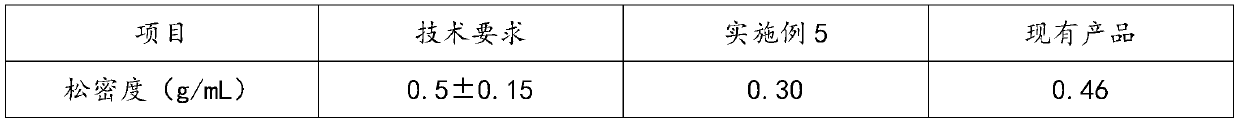

Light precursor cable

ActiveCN105336423AReduce weightHigh tensile strengthInsulated cablesInsulated conductorsShallow seaOptoelectronics

The invention relates to a light precursor cable, comprising a core, a shielding layer, a waterproof layer, a tensile layer, a waterproof wear-resisting layer, a damping layer and a buoyancy layer, wherein the shielding layer coats the core, the waterproof layer coats the shielding layer, the tensile layer coats the waterproof layer, the waterproof wear-resisting layer coats the tensile layer, the damping layer coats the waterproof wear-resisting layer, and the buoyancy layer coats the damping layer. The light precursor cable has the characteristics of light weight, strong tension, wear resistance, small creep deformation, cutting resistance and water repellency; the length of the cable which is sunk into water is reduced under the condition that a float marker is not used, so that power loss of a tractor tug is greatly reduced to significantly reduce the operation difficulty of shallow sea operation.

Owner:曹波

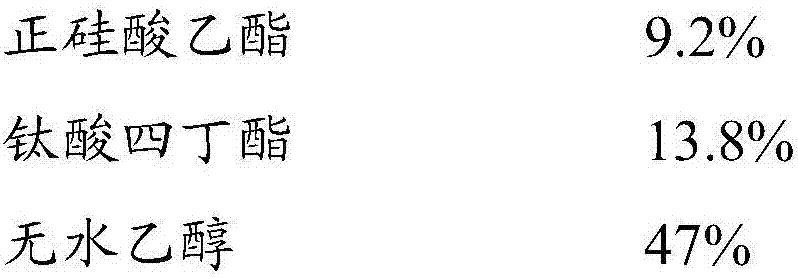

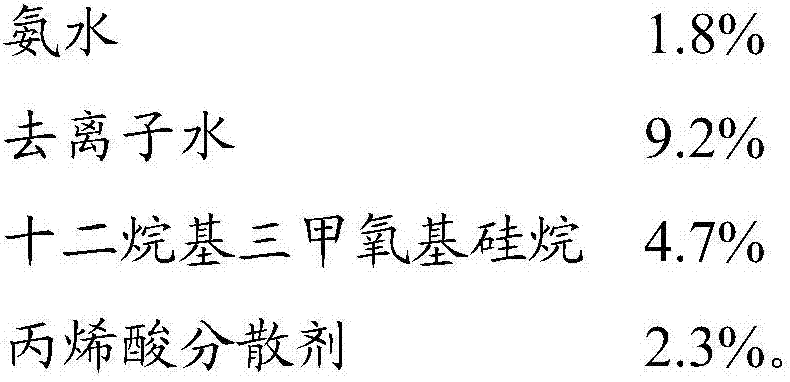

Nanometer anti-pollution self-cleaning shoe upper material and arrangement method thereof

The invention provides a nanometer anti-pollution self-cleaning shoe upper material and an arrangement method thereof. The shoe upper material comprises a shoe upper material body and a nanometer anti-pollution agent, wherein the nanometer anti-pollution agent contains the following components in percentage by weight: 9.2% of tetraethoxysilane, 13.8% of tetrabutyl titanate, 47% of absolute ethyl alcohol, 1.8% of ammonia water, 9.2% of deionized water, 4.7% of dodecyltrimethoxysilane and 2.3% of an acrylic acid dispersing agent. The nanometer anti-pollution self-cleaning shoe upper material has environment-protection, anti-pollution and waterproof functions.

Owner:MINJIANG UNIV

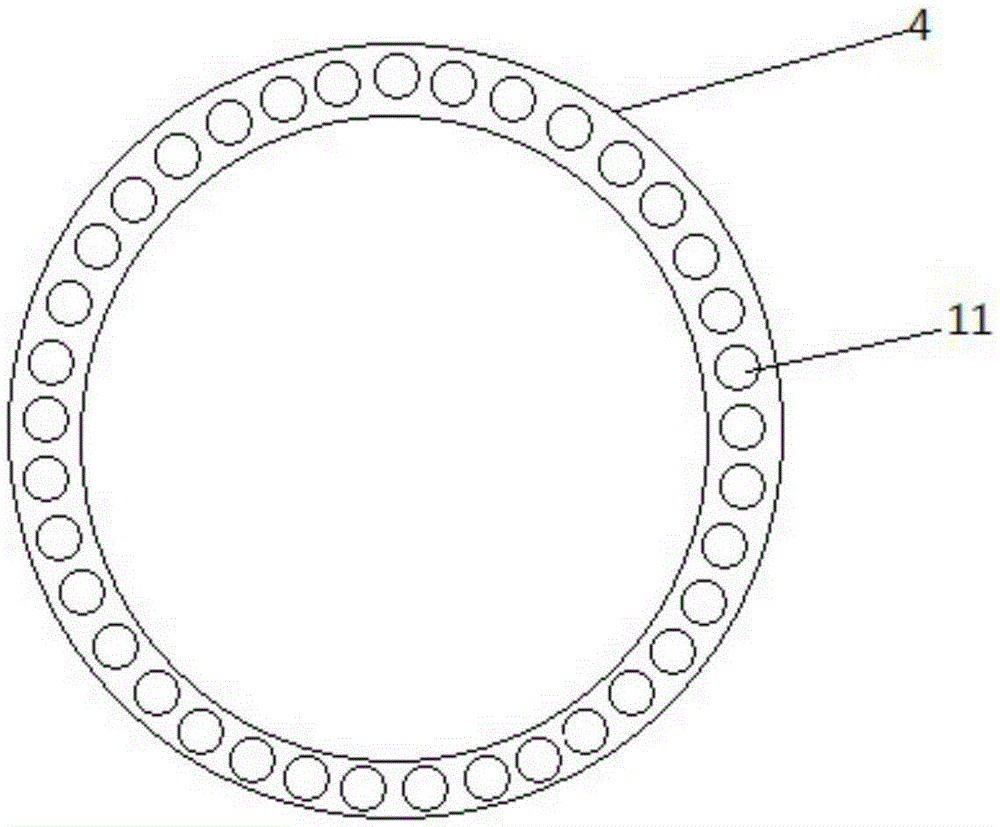

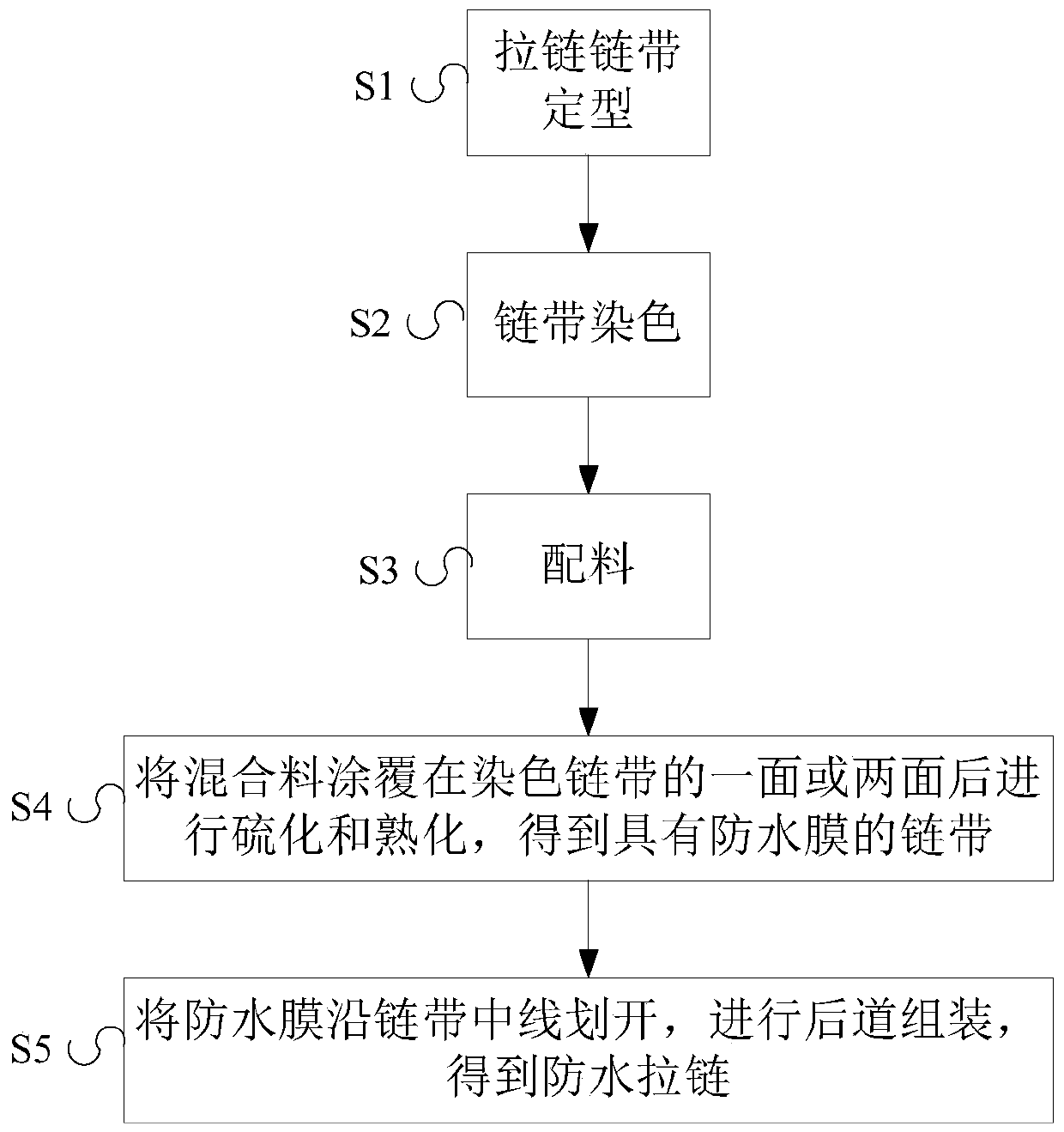

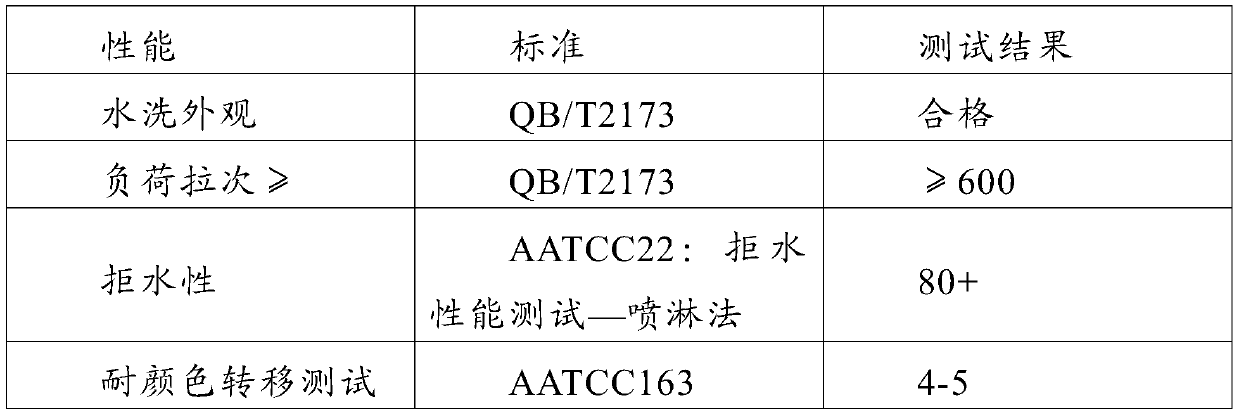

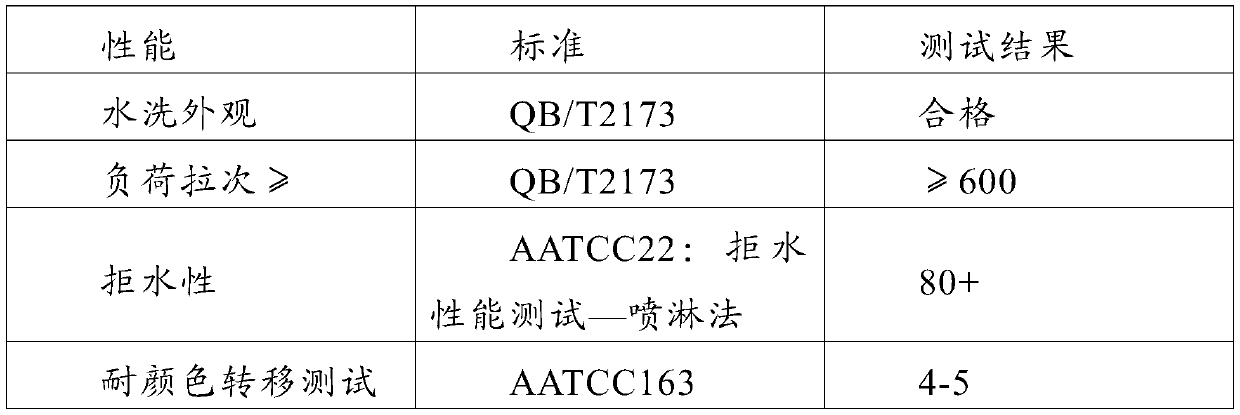

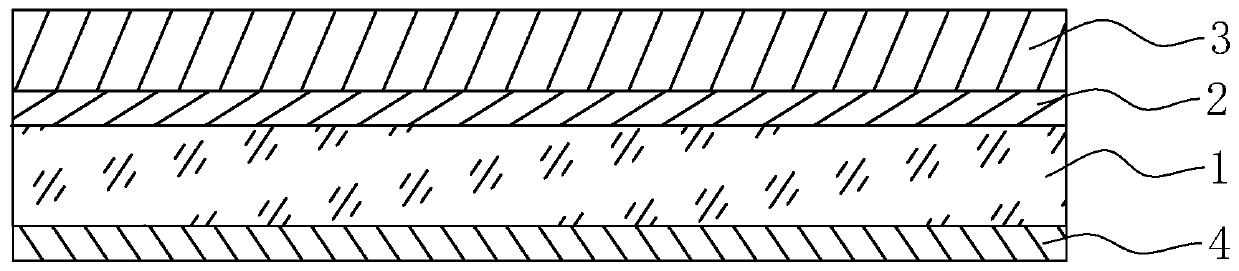

Waterproof zipper and processing method thereof

The invention discloses a processing method of a waterproof zipper. The processing method comprises the following steps: shaping a zipper chain belt to obtain a flat chain belt; dyeing: dyeing the flat chain belt to obtain a dyed chain belt; preparing materials: weighing 90-100 parts of two-component liquid silica gel A component, 90-100 parts of two-component liquid silica gel B component, 0-6 parts of color paste, 10-70 parts of reinforcing agent and a polymerization inhibitor by 0.1% of the weight sum of the two-component liquid silica gel A component and the two-component liquid silica gel B component, and uniformly stirring to obtain a mixed material; coating the mixed material on one side or two sides of the dyed chain belt, and then vulcanizing and curing to obtain the chain belt with a waterproof film; gashing the waterproof film along a middle line of the chain belt, and then assembling a puller, an upper / lower stopper or a square pin, so as to obtain the waterproof zipper. The waterproof zipper processed by the method disclosed by the invention has the anti-fouling and anti-splashing performance and greater high-temperature resistance. In addition, the process is simpler.

Owner:ZHEJIANG WEIXING IND DEV

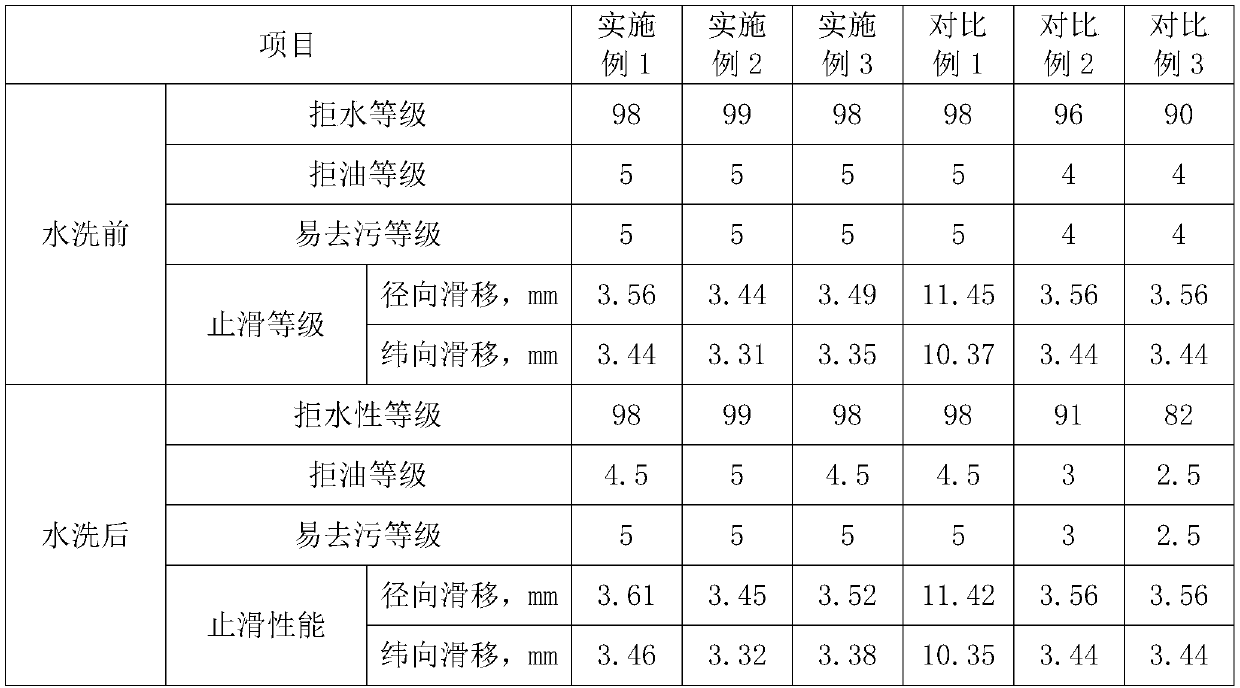

Water-proof, oil-proof, contamination-proof anti-slip fabric and processing method thereof

InactiveCN110396821AImprove slip resistanceImprove stiffnessStain/soil resistant fibresLiquid repellent fibresEngineeringContamination

The invention discloses a water-proof, oil-proof, contamination-proof anti-slip fabric and a processing method thereof, and relates to the technical field of fabric finishing. The water-proof, oil-proof, contamination-proof anti-slip fabric is characterized by including base cloth. The upper surface of the base cloth is successively provided with a bottom coating and a surface coating, and the lower surface of the base cloth is an anti-slip layer. The processing method of the water-proof, oil-proof, contamination-proof anti-slip fabric includes the following steps of water repellent finishing,calendering finishing, bottom coating, surface coating and anti-slip finishing. After the base cloth of the fabric is subjected to water repellent finishing by using a water repellent finishing agent, the surface of the fabric can maintain the water-proof, oil-proof and contamination-proof characteristics for a long time, and after bottom coating, surface coating and anti-slip finishing, and thefabric can be resistant to water, oil, contamination and slip and is suitable for use as a tablecloth.

Owner:三赢家居用品(河源)有限公司

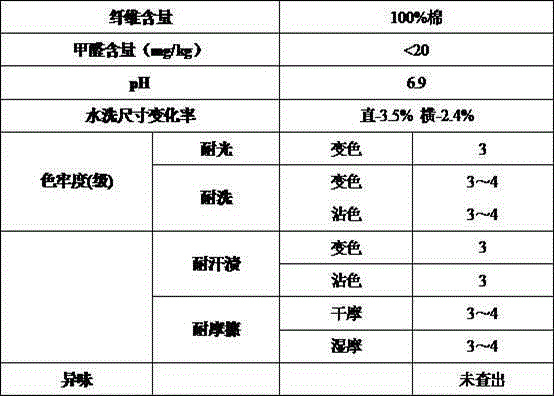

Preparation technology of primary-color ecological cotton fabric

InactiveCN105077785ASoft touchSoft and elegant colorBiochemical fibre treatmentVegetal fibresSpinningEnvironmental engineering

The invention relates to a preparation technology of primary-color ecological cotton fabric. The technology comprises the following steps: selecting colored cotton raw materials; carrying out cotton assorting; spinning; weaving; arranging; scutching; forming, wherein the arrangement technology adopts the biological enzyme arrangement technology; as for the weaving technology, the primary-color ecological cotton fabric is formed through interweaving warp yarns with weft yarns; 60 S plus white ecological cotton, 60 S primary-color ecological cotton, 60 S orange ecological cotton and 60 S grass green ecological cotton are selected as the warp yarns; 60 S plus white ecological cotton, 60 S primary-color ecological cotton, 60 S brown ecological cotton and 60 S gray ecological cotton are selected as the weft yarns. The primary-color ecological cotton fabric prepared through the technology is soft, comfortable, air permeable and thermal, and gives play to the characteristics of natural colored cotton, namely, the color and luster is gentle and elegant; direct contact with chemical dyes is avoided, so that the primary-color ecological cotton fabric is quite high in safety.

Owner:梁晓莉

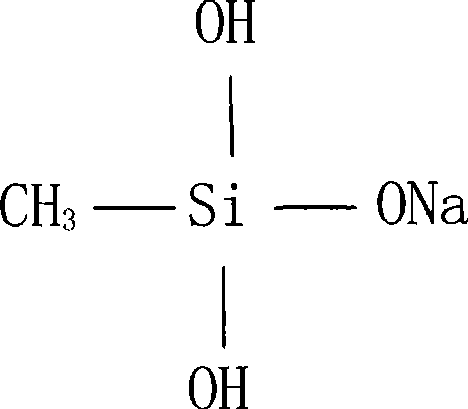

Synthesis process of architectural waterproof material methyl sodium silicate

The invention discloses a synthesis process of waterproof material methyl sodium silicate in construction industry. The synthesis process comprises the following steps: firstly, cotton bleaching efflue is infiltrated into a reaction vessel; then methyl- silicic acid is added for forming mixture; the mixture is greatly stirred and heated until the temperature reaches 90 to 95 DEG C; the temperature is kept for 2hs, and the methyl sodium silicate solution is obtained after the processes of sedimentation and filtration. The waterproof material methyl sodium silicate has a simple process and low manufacturing cost, particularly the waste cotton bleaching liquor is selected and used as main raw materials, not only the waste is converted to useful materials and a great deal of water resource is saved, but also the general goal of saving resources, protecting the environment and pursuing economic efficiency in human production is realized.

Owner:武汉春申高新技术有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com