Waterproof zipper and processing method thereof

A processing method and technology of waterproof zipper, applied in the field of zipper, can solve the problems of being easily polluted, not easy to clean, etc., and achieve the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

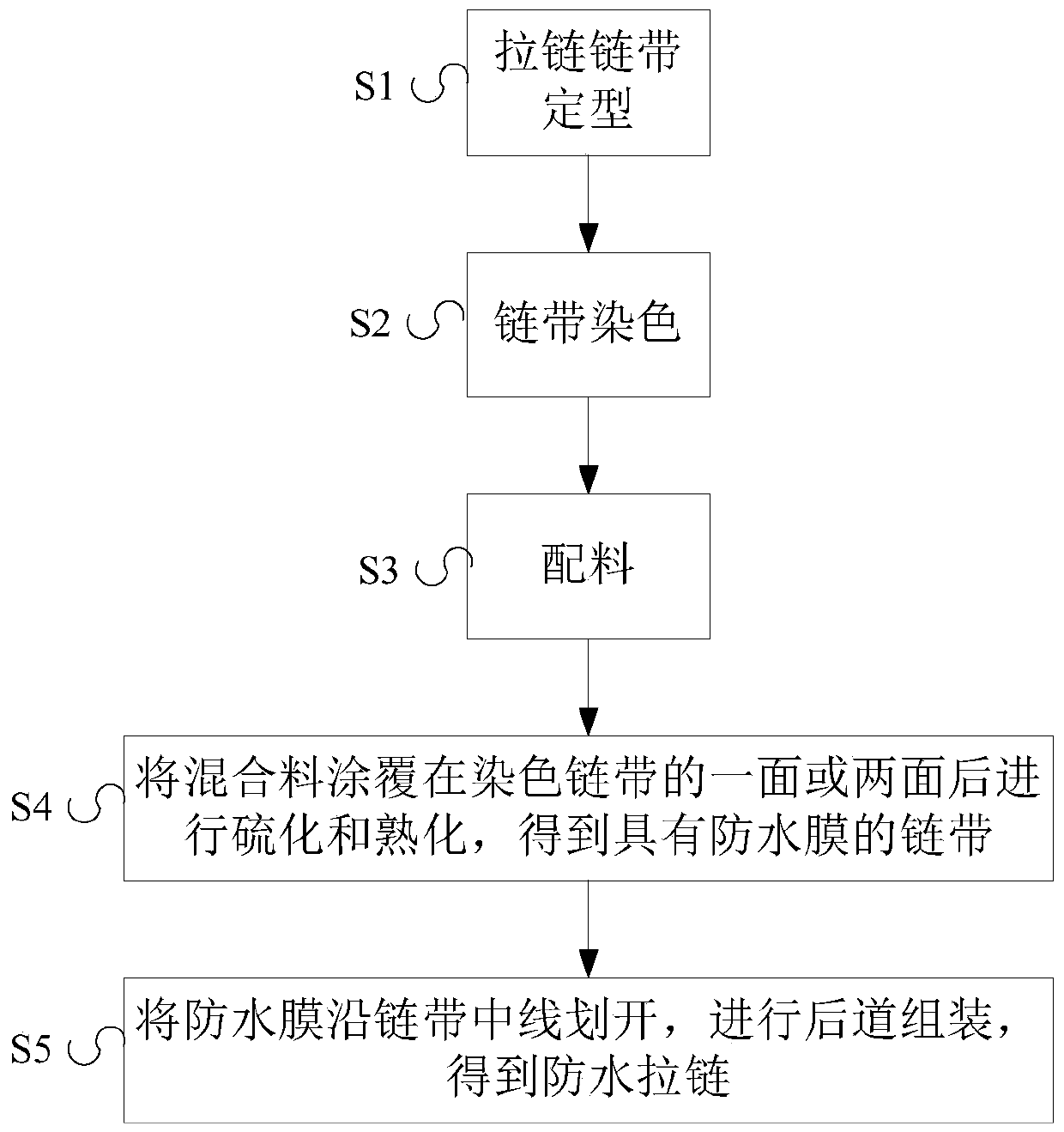

Method used

Image

Examples

Embodiment 1

[0043] Pre-setting the nylon zipper chain belt at 180°C, the setting shrinkage rate is controlled at 3%, and then dyed according to the common process of polyester zipper, and it is ready to use after dyeing;

[0044] Weigh the two-component liquid silica gel A component, B component, reinforcing agent, polymerization inhibitor, color paste, and stir them evenly. Each component weight content is as follows respectively:

[0045] BD-836A component 100 parts;

[0046] BD-836B component 90 parts;

[0047] 3 parts of color paste;

[0048] 30 parts of MQ resin reinforcing agent;

[0049] Two-component liquid silica gel A component and B component weight and 0.1% dienyl maleate inhibitor;

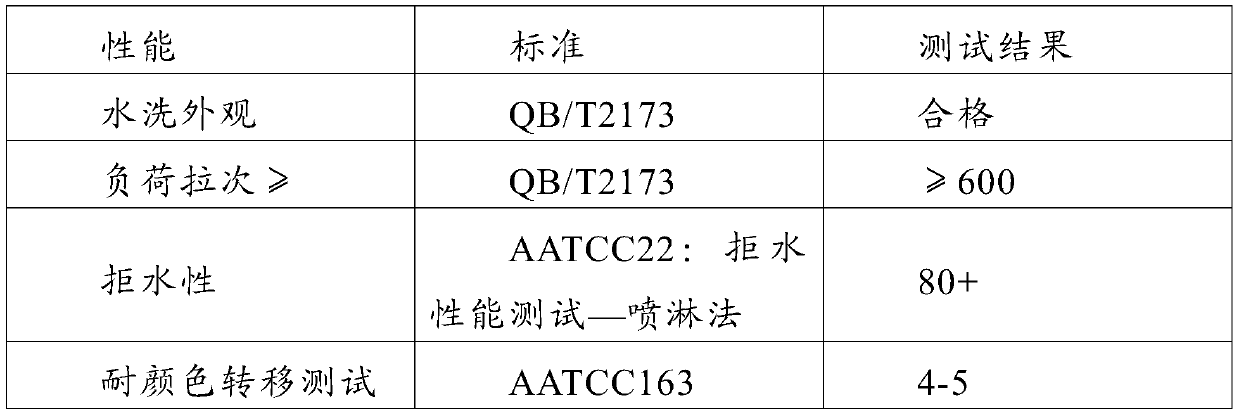

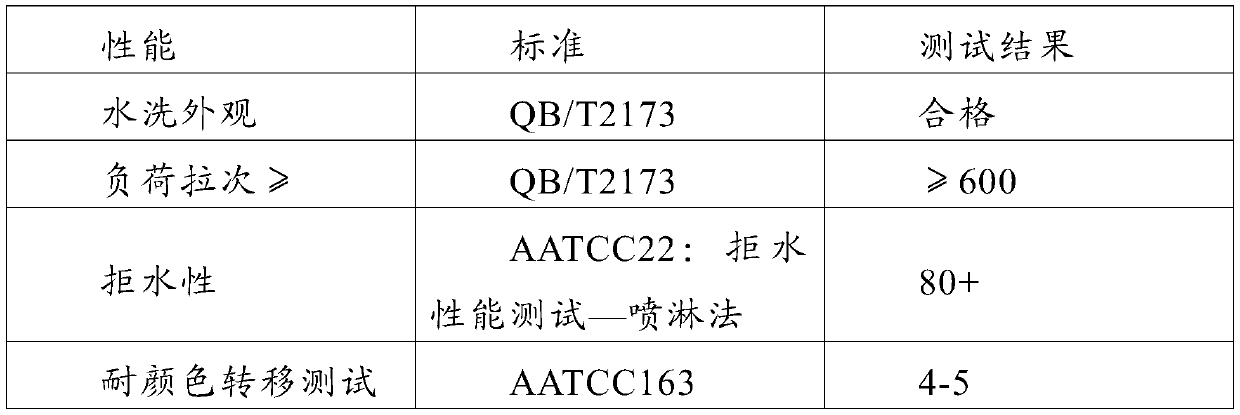

[0050] Apply the above mixture to one side of the zipper tape by roller coating or scraping, with a coating thickness of 200um, and then put it into a 120°C oven for 30 minutes of vulcanization, and then cure it at 80°C for 24 hours. Then cut the waterproof membrane along the midline for rea...

Embodiment 2

[0054] Pre-setting the nylon zipper chain tape at 170°C, the setting shrinkage rate is controlled at 3%, and then dyed according to the common process of polyester zipper, and it is ready to use after dyeing;

[0055] Weigh the two-component liquid silicone rubber A component, B component, reinforcing agent, polymerization inhibitor, color paste, and stir evenly. Each component weight content is as follows respectively:

[0056] BD-836A component 100 parts;

[0057] BD-836B component 100 parts;

[0058] 3 parts of color paste;

[0059] MQ resin reinforcing agent 50 parts

[0060] Diallyl maleate inhibitor 0.1%

[0061]Apply the above mixture to one side of the zipper tape by roller coating or scraping, with a coating thickness of 150um, and then put it into a 120°C oven for 15 minutes of vulcanization, and then cure it at 50-80°C for 12 hours. Then cut the waterproof membrane along the midline for rear assembly to obtain a waterproof zipper. Perform a performance test on...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com