Smooth, anti-staining, scratch-resistant and easy-cleaning nano-coating for glass, preparation method and construction method thereof

A nano-coating and construction method technology, which is applied in the fields of easy-to-clean nano-coating, smooth glass, anti-scratch, and anti-fouling. It can solve problems such as poor friction resistance, difficult industrialization, and poor adhesion, and achieve low friction, The effect of simple method and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

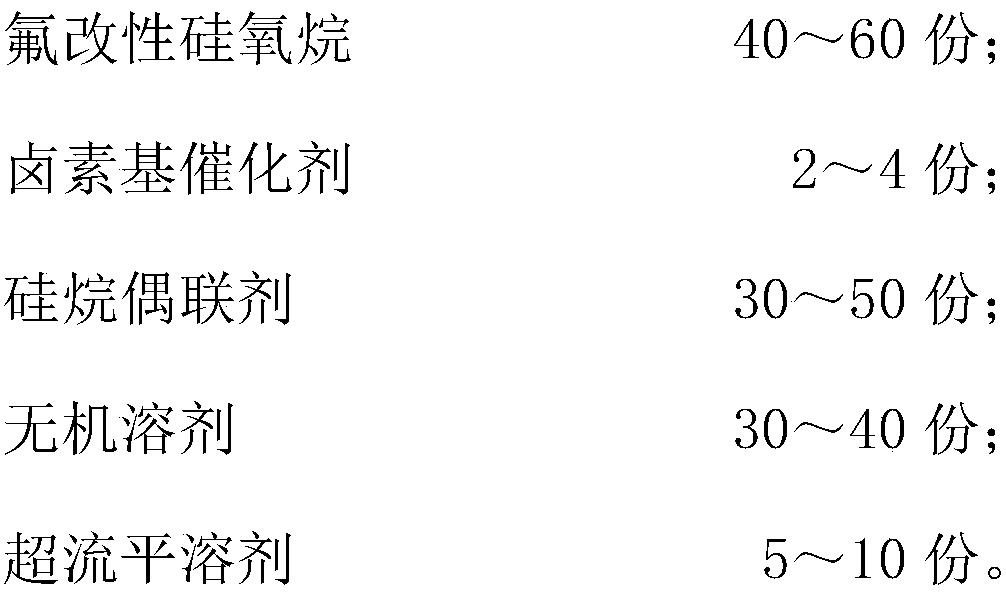

[0027] Glass smooth, anti-fouling, anti-scratch, easy-to-clean nano-coating consists of the following components by weight:

[0028]

[0029] Further, the silane coupling agent is isobutyltriethoxysilane.

[0030] Further, the super leveling solvent is one of acrylic leveling agent or alkyl modified leveling agent.

[0031] The preparation method of the smooth, stain-resistant, scratch-resistant and easy-to-clean nano-coating for glass comprises the following steps:

[0032] A. Put the proportional amount of fluorine-modified siloxane, halogen-based catalyst, silane coupling agent, super-leveling solvent and inorganic solvent into the nano homogenizer in sequence, control the pressure to 400MPa, and the speed to 3300rpm. After the dispersion is uniform, Make it fully miscible to obtain a mixed solution;

[0033] B, drop the mixed solution prepared in step A into a nanoscale grinder, so that the particles in the mixed solution are ground, and finally obtain a grinding susp...

Embodiment 2

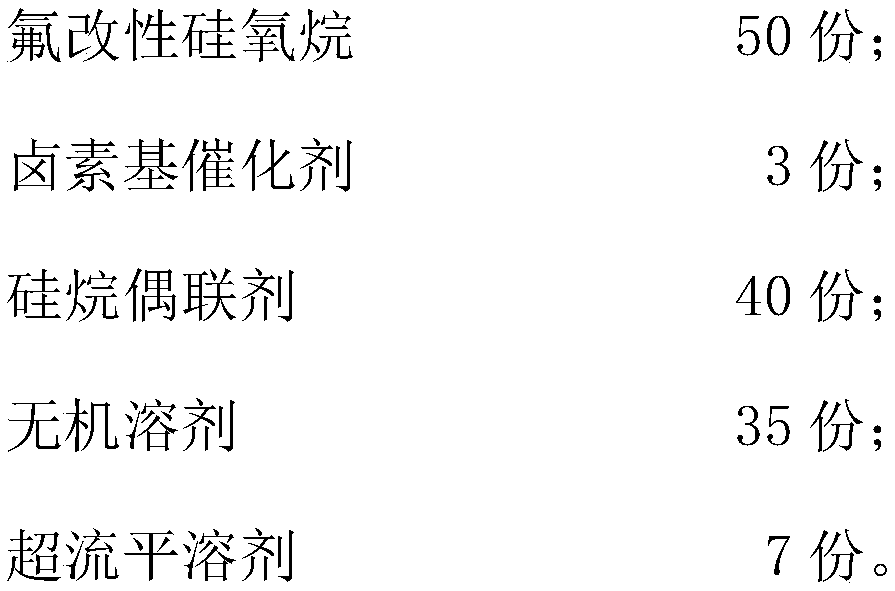

[0042] Glass smooth, anti-fouling, anti-scratch, easy-to-clean nano-coating consists of the following components by weight:

[0043]

[0044] Further, the silane coupling agent is isobutyltriethoxysilane.

[0045] Further, the super leveling solvent is one of acrylic leveling agent or alkyl modified leveling agent.

[0046] The preparation method of the smooth, stain-resistant, scratch-resistant and easy-to-clean nano-coating for glass comprises the following steps:

[0047] A. Put the proportional amount of fluorine-modified siloxane, halogen-based catalyst, silane coupling agent, super-leveling solvent and inorganic solvent into the nano homogenizer in sequence, control the pressure to 300MPa, and the speed to 3900rpm. After the dispersion is uniform, Make it fully miscible to obtain a mixed solution;

[0048] B, drop the mixed solution prepared in step A into a nanoscale grinder, so that the particles in the mixed solution are ground, and finally obtain a grinding susp...

Embodiment 3

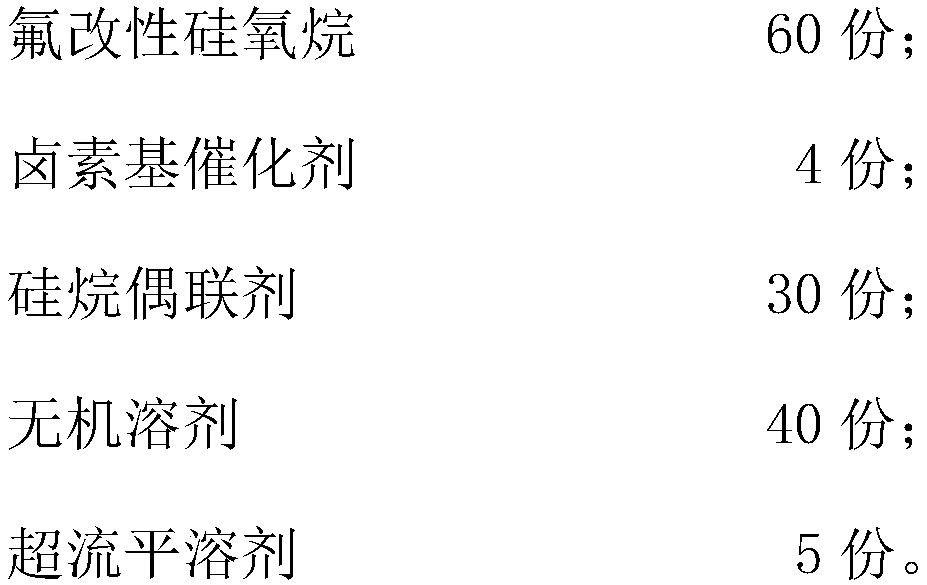

[0057] Glass smooth, anti-fouling, anti-scratch, easy-to-clean nano-coating consists of the following components by weight:

[0058]

[0059]

[0060] Further, the silane coupling agent is isobutyltriethoxysilane.

[0061] Further, the super leveling solvent is one of acrylic leveling agent or alkyl modified leveling agent.

[0062]The preparation method of the smooth, stain-resistant, scratch-resistant and easy-to-clean nano-coating for glass comprises the following steps:

[0063] A. Put the proportional amount of fluorine-modified siloxane, halogen-based catalyst, silane coupling agent, super-leveling solvent and inorganic solvent into the nano homogenizer in sequence, control the pressure to 200MPa, and the speed to 4500rpm. After the dispersion is uniform, Make it fully miscible to obtain a mixed solution;

[0064] B, drop the mixed solution prepared in step A into a nanoscale grinder, so that the particles in the mixed solution are ground, and finally obtain a gr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com