Synthesis process of architectural waterproof material methyl sodium silicate

A technology for sodium methyl silicate and building waterproofing, applied in the direction of silicon organic compounds, can solve the problems of social resource waste, increased cost, water resource pollution, etc., and achieve the effect of extending service life, preventing surface cracking, and protecting water resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

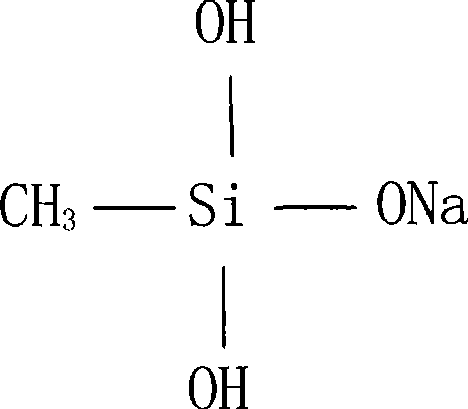

Image

Examples

Embodiment Construction

[0010] During implementation, the organic silicon functional chemical material in the present invention—sodium methyl silicate is synthesized by mixing cotton yarn bleaching waste liquid A and methyl silicate B in a weight ratio of A:B=4:1. The specific operation procedure is that after the cotton yarn bleaching waste liquid is settled in the sedimentation tank, it is poured into the reaction kettle according to the above formula as component A, and the methyl silicic acid of component B is added into the reaction kettle, stirred and mixed evenly, and heated to 90-95°C After 1-2h of heat preservation, precipitate and filter to obtain sodium methyl silicate.

[0011] Further introduce the implementation of the present invention below by embodiment:

[0012] 1. Take 800kg of cotton yarn bleaching waste liquid and put it into the reaction kettle, and gradually raise the temperature to 90°C.

[0013] 2. Take 200kg of methyl silicic acid and put it into the reaction kettle, stir e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com