Supercritical fluid preparation method of nano-silver-coated textile fabric

A technology of textile fabrics and nano-silver, which is applied in textiles and papermaking, liquid-repellent fibers, fiber treatment, etc., can solve the problems of preparing nano-silver-plated textiles with supercritical fluids, and achieve low cost, high fastness, High binding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a method for preparing nano-silver plated textile fabrics with supercritical carbon dioxide, which is characterized in that the raw materials include silver nitrate, a reducing agent, a stabilizer and textile fabrics, wherein the mass ratio of the reducing agent to silver nitrate is 500-50, The mass ratio of stabilizer to silver nitrate is 0.1-10, and the mass of silver nitrate used per square meter of textile fabric is 5g-50g.

[0026] The textile fabric is at least one of natural fiber fabric or chemically synthesized textile fabric.

[0027] Preferably, the textile fabric is at least one of cotton, wool, linen, silk, polyester, viscose, polyester or acrylic.

[0028] The silver salt is silver nitrate, silver oxalate, silver succinimide.

[0029] The reducing agent is sodium citrate, sodium borohydride, ethylene glycol, reducing sugar, organic phosphorus.

[0030] The stabilizer is sodium citrate, polyvinylpyrrolidone, sodium lauryl sulfate, p...

Embodiment 1

[0038] The wool fabric with a size of 5cm×5cm was ultrasonically cleaned with acetone and ethanol for 15 minutes, taken out and dried; 0.1g of silver nitrate and 0.1g of polyvinylpyrrolidone were dissolved in 30ml of ethylene glycol solution, and stirred for 30min. The resulting solution was added to the reaction kettle together with the woolen cloth sample, stirred and treated with supercritical carbon dioxide at 10Mpa and 70°C for 60 minutes, then taken out, washed with water and dried.

[0039] The microstructure and macroscopic performance of gained nano-silver plating wool fabric are as follows:

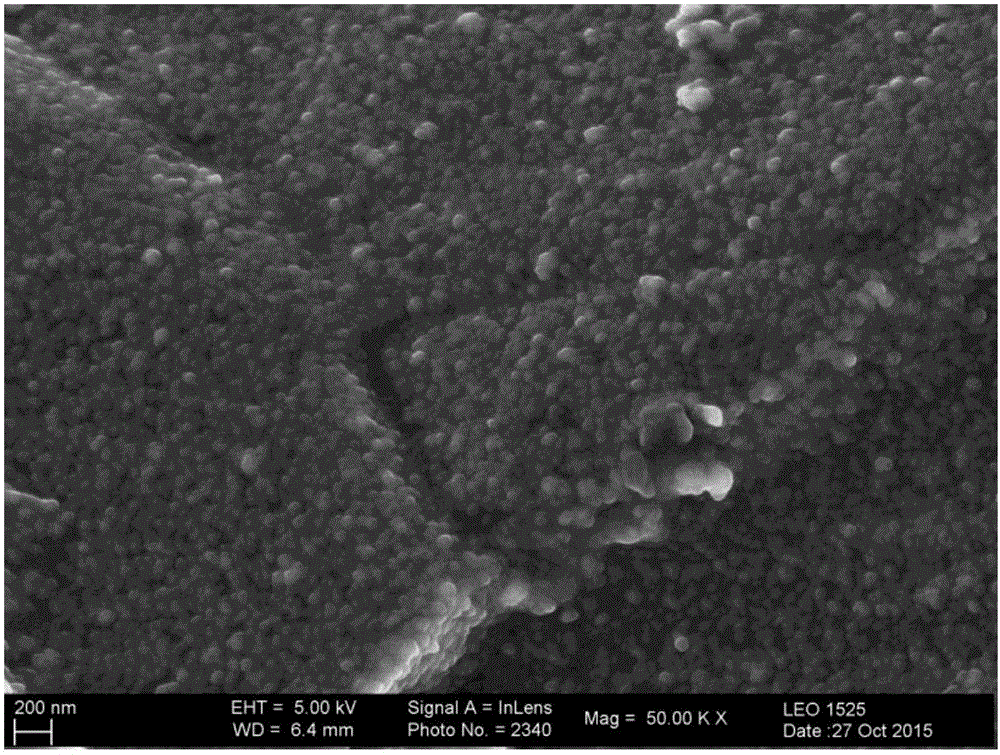

[0040] 1. Morphology of nano-silver particles:

[0041] figure 1 Scanning electron microscope (SEM) photographs of nanosilver-coated wool fabrics. Depend on figure 1 It can be seen that the nano-silver particles are deposited on the wool fiber surface very uniformly, and the nano-silver particles are in the shape of spherical particles.

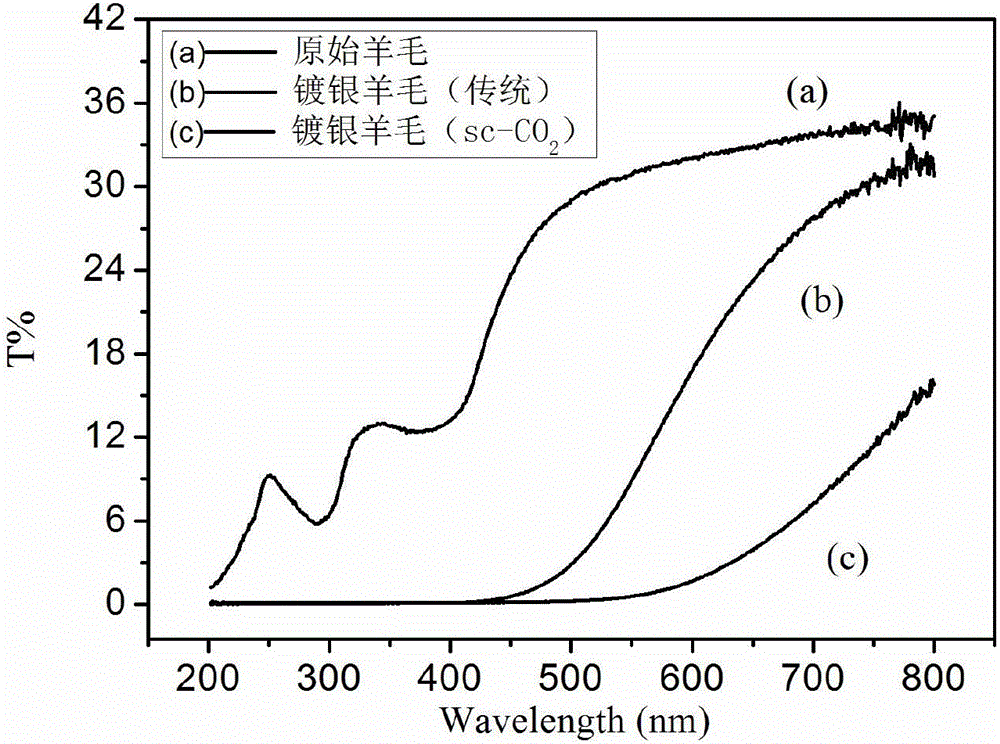

[0042] 2. UV transmittance under dif...

Embodiment 2

[0051] The wool fabric with a size of 5cm×5cm was ultrasonically cleaned with acetone and ethanol for 15 minutes, taken out and dried; 0.1g of silver nitrate and 0.1g of polyvinylpyrrolidone were dissolved in 30ml of ethylene glycol solution, and stirred for 30min. The resulting solution is added to the reaction kettle together with the woolen cloth sample, stirred and treated with supercritical carbon dioxide under the condition of 8-14Mpa and 70°C for 20-80min, then taken out, washed with water and dried.

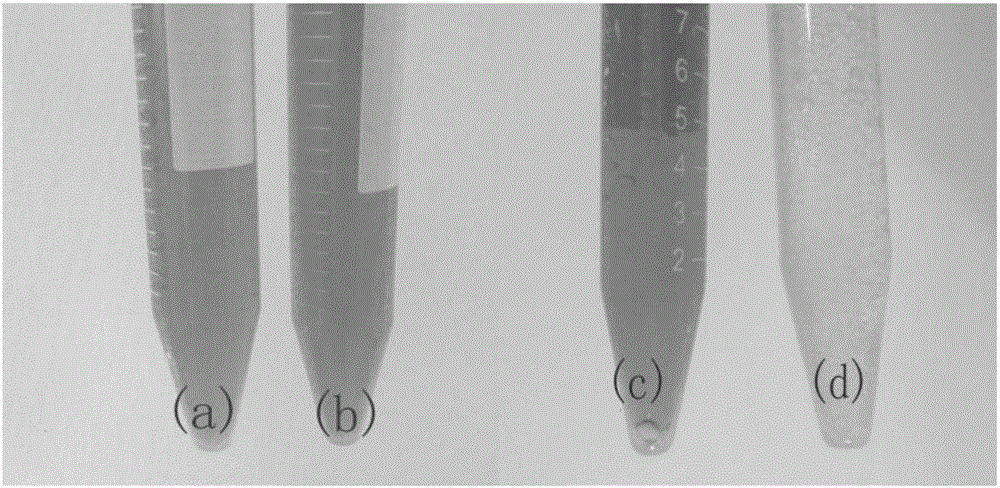

[0052] 1. The contact angle of nano-silver coated wool fabric under different carbon dioxide pressures:

[0053] Figure 4 It is the nano-silver plated fabric prepared under different carbon dioxide pressure conditions in Example 2 of the present invention, as seen from the figure, other conditions are the same, and the contact angle of the nano-silver plated wool fabric prepared under different carbon dioxide conditions increases first as pressure increases. Decrease af...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com