Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

87results about How to "Reduce smoke production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

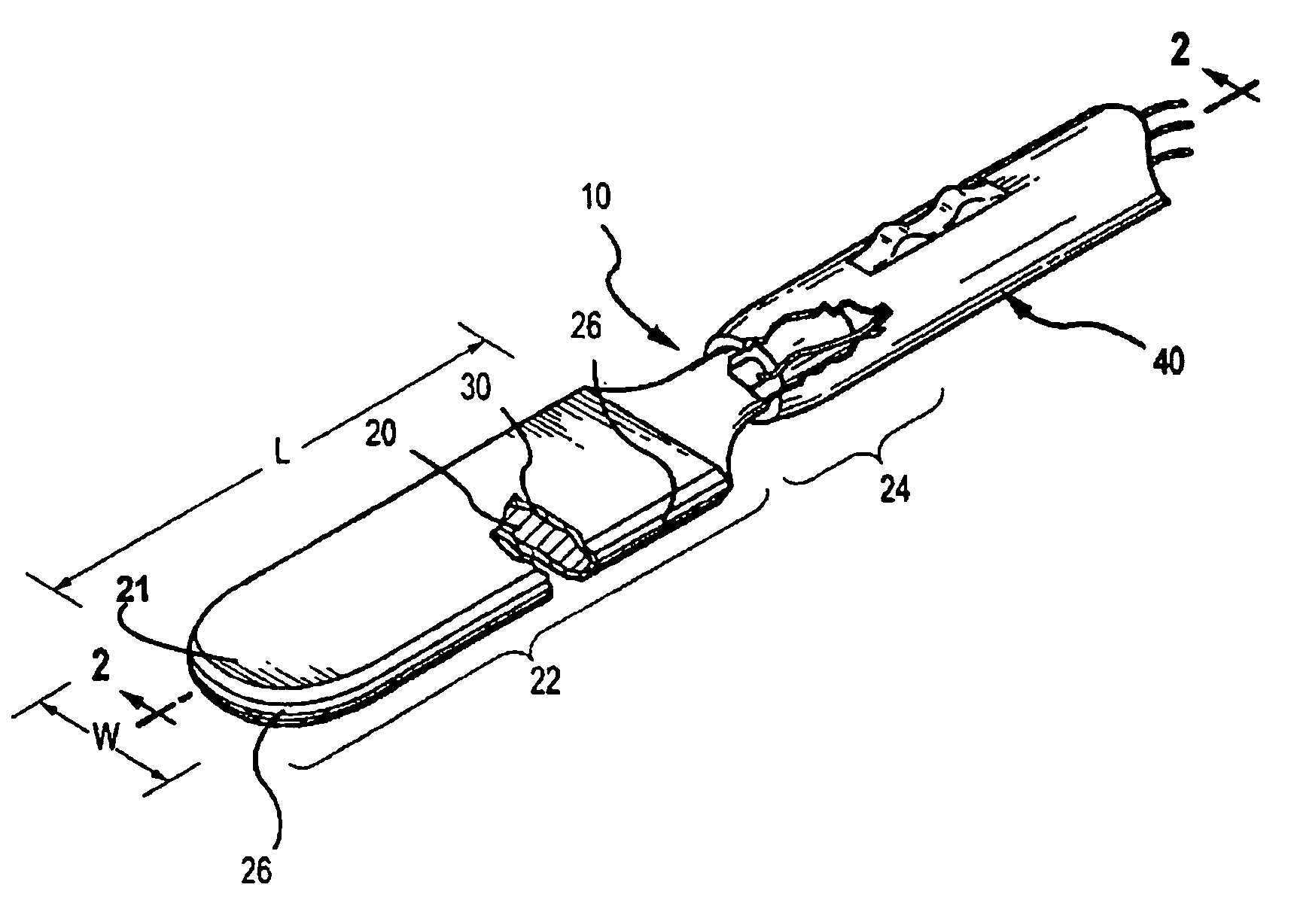

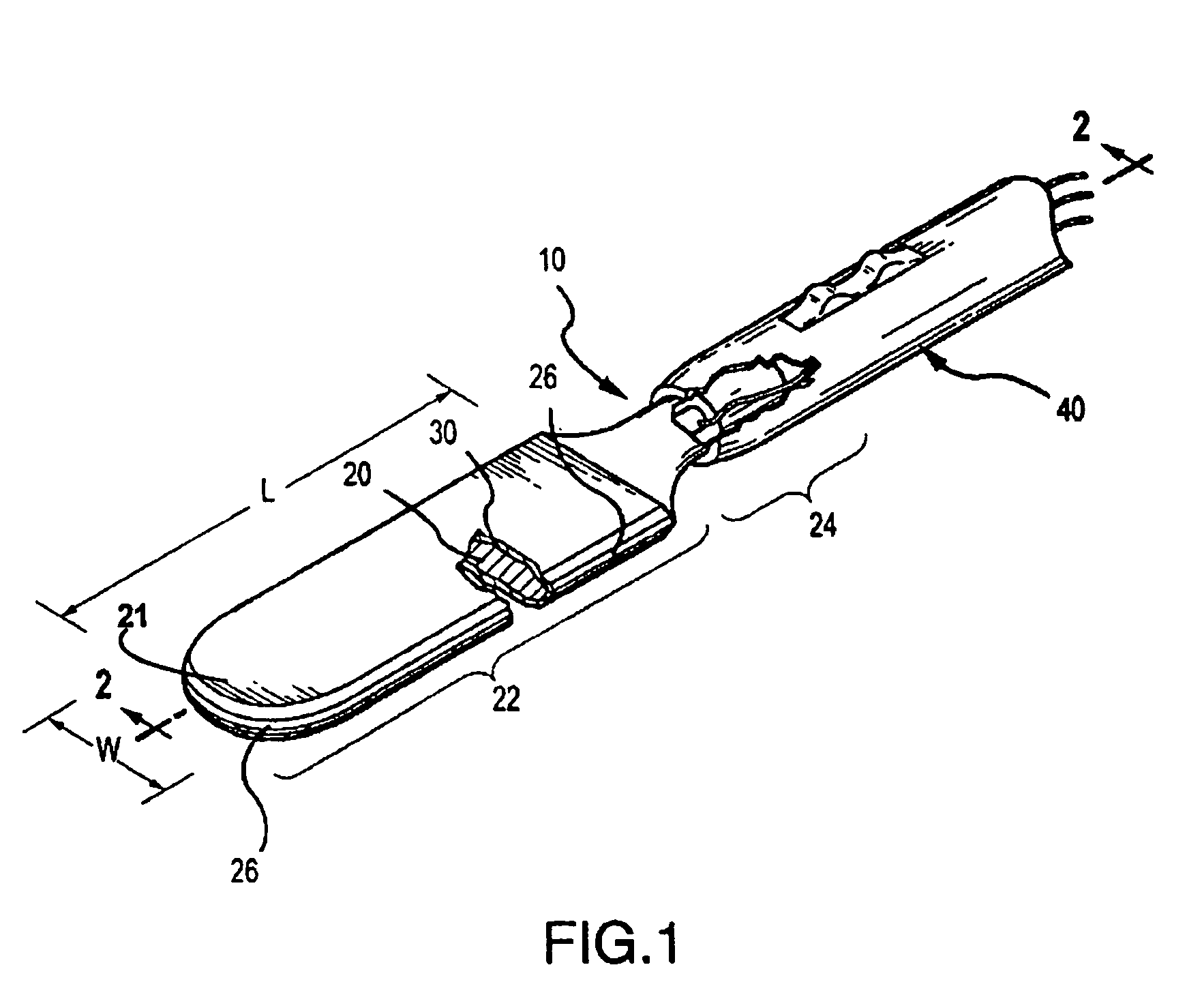

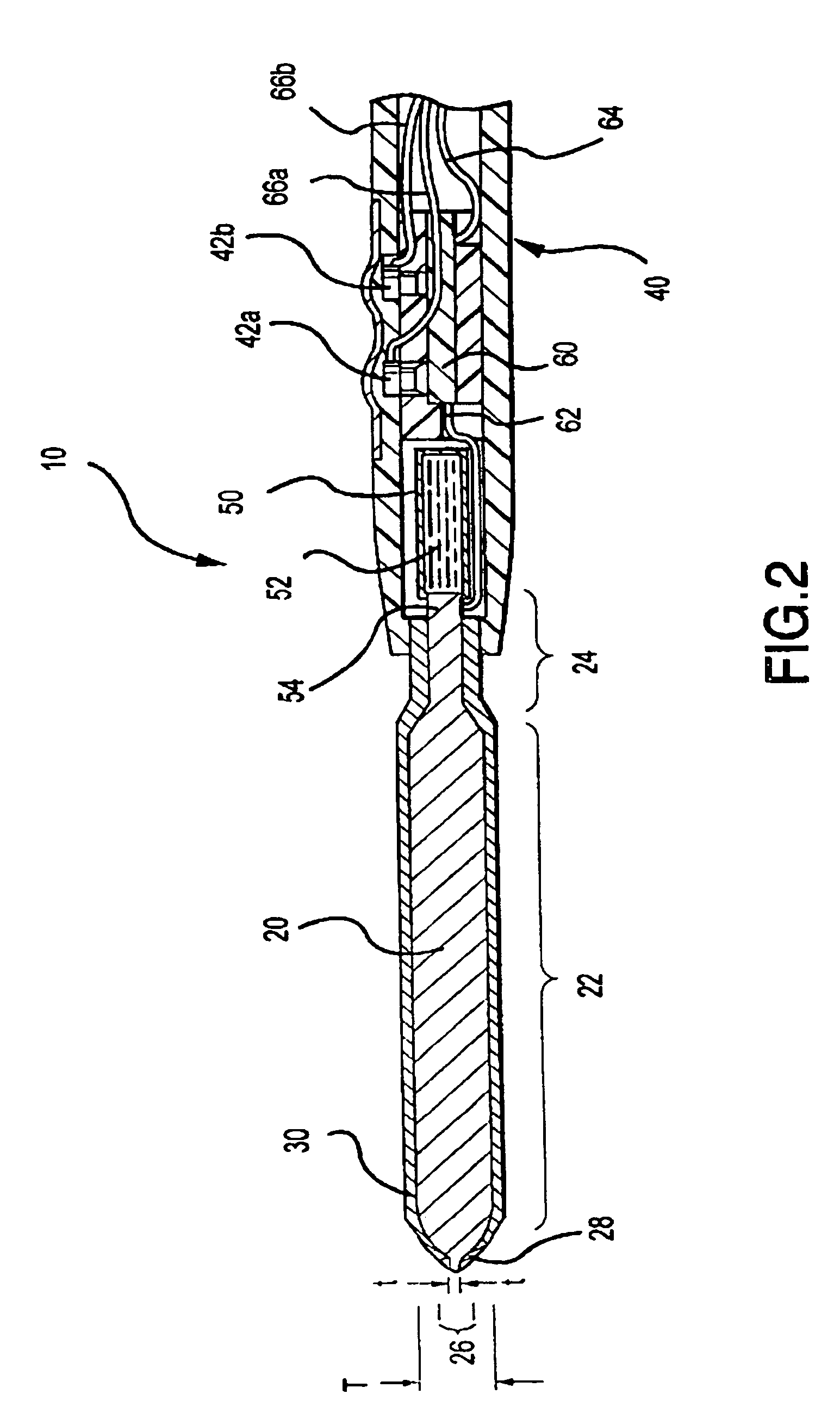

Electrosurgical instrument

ActiveUS7377919B2Reduce smoke productionAvoid excessive accumulationSurgical instruments for heatingDisinfectionSurgical siteHeat sink

An improved insulating layer for electrosurgical instruments and its use for electrosurgical instruments for reducing smoke generation at a surgical site is disclosed. The insulating layer may include a ceramic material that is substantially sealed with a coating comprising substantially of a material based on polydiorganosiloxanes or derivatives thereof that have been cured. Such an insulating layer may advantageously include one or more insulating materials with pores that have been sealed so as to prevent biological materials from entering the pores with such sealing material preferably containing one or more of silicate materials or materials that form silicates. Heat sinks may be included in various embodiments to establish a thermal gradient away from functional portions of the instrument.

Owner:MICROLINE SURGICAL INC

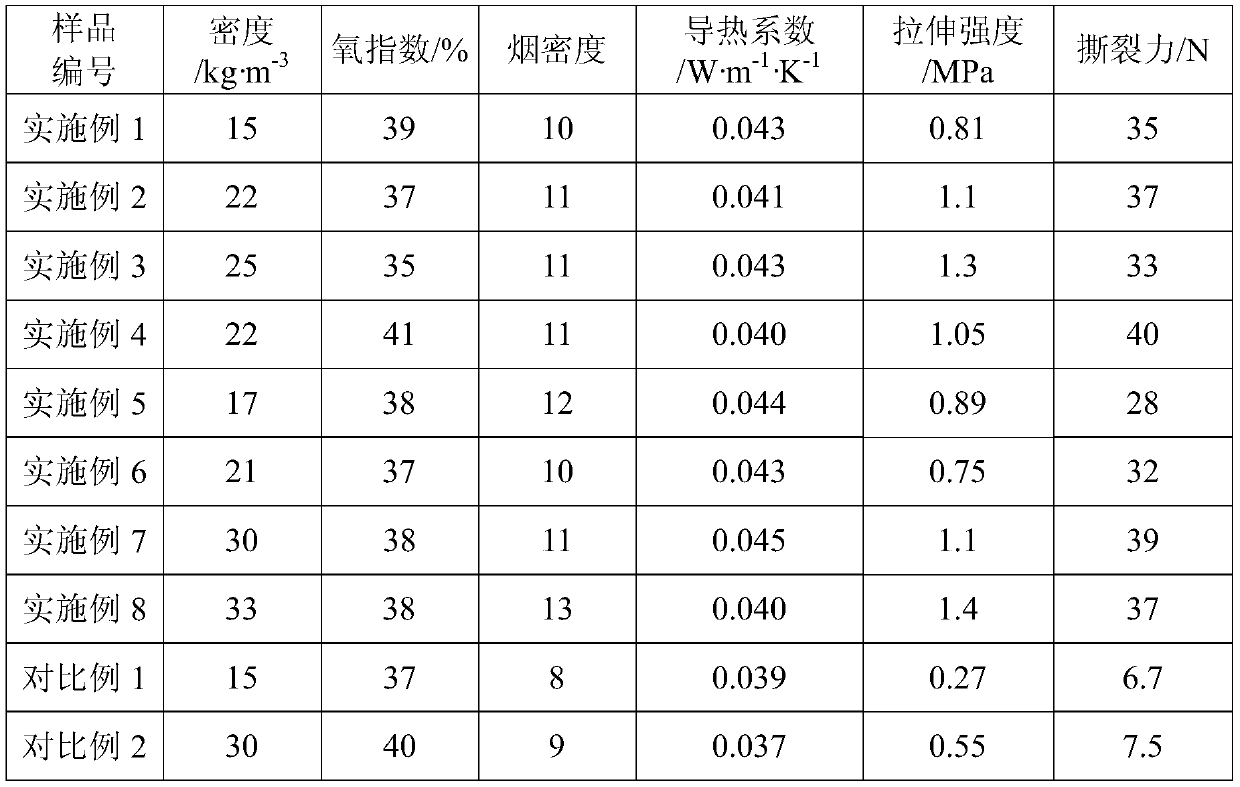

High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

ActiveCN101905475AReduce the temperatureDelay in pyrolysis combustion reactionWood working apparatusDomestic articlesFiberSocial benefits

The invention discloses a high-strength environment-friendly flame-retarding fiberboard which comprises the following raw materials of plant fibers, flame retardants, adhesives and waterproofing agents, wherein the weight ratio of the plant fibers to the flame retardants to the adhesives to the waterproofing agents is 100:(3-30):(3-30):(0.1-4). The invention also discloses a manufacturing method of the high-strength environment-friendly flame-retarding fiberboard. Not only are the mechanical properties of the flame-retarding fiberboard obviously improved, but also the combustion property can conform to the regulations of GB8624 Class B or Class C, and the formaldehyde emission, the smoke volume produced and the smoke toxicity are also reduced. Thus, the high-strength environment-friendly flame-retarding fiberboard has good quality and low price, can be widely applied to the fields of building furnishings, flame-retarding furniture production, flame-retarding floor production, wooden fireproof door production, ship and vehicle furnishings and the like, and has good economical and social benefits.

Owner:北京盛大华源科技有限公司 +1

Sheet molding compound with high flame resistance, low smoke and non-toxic and preparation method thereof

InactiveCN101514254AFully dispersedImprove flame retardant performancePolymer scienceAluminium hydroxide

The invention relates to a sheet molding compound with high flame resistance, low smoke and non-toxic and a preparation method thereof. The formula of the sheet molding compound comprises the following substance in mass portion: 50-80 portions of unsaturated polyester resin, 15-60 portions of low shrink additive, 1-3 portions of evocating agent, 0.01-0.05 portions of polymerization inhibitor, 0.7-7 portions of wetting and dispersing agent, 3-8 potions of inner mold release agent, 1-2 potions of thickening agent, 20-50 potions of viscosity reduction filler, 100-200 portions of flame retardant A, 50-100 portions of flame retardant B and 50-250 portions of reinforced material; the flame retardant A is micron aluminum hydroxide and the grain diameter is 0.4-3.5 microns; the flame retardant B is nanometer aluminum hydroxide and the grain diameter is 30-80 nanometers. The sheet molding compound of the invention has the advantages of high flame resistance, low smoke and non-toxic, well mechanical performance and surface decorative effect.

Owner:BEIJING ZHONGTIE LONGDRAGON ADVANCED COMPOSITE MATERIAL

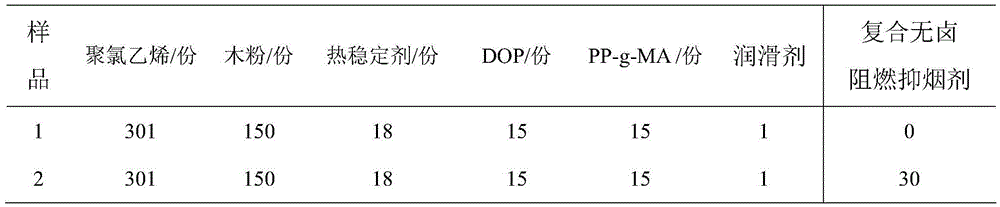

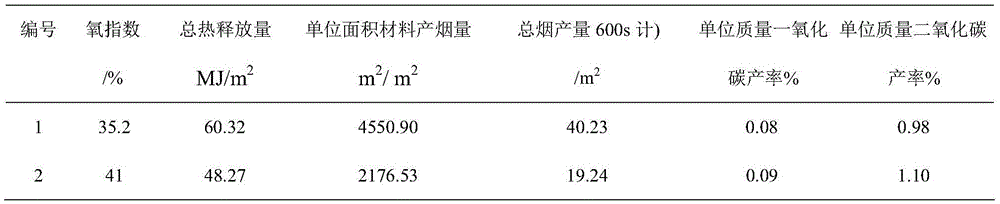

Xylem filber-polyvinyl chloride composite material and method for producing the same

A wood fiber-polyvinyl chloride composite material and a preparation method thereof, which relate to a composite material and a preparation method thereof. It solves the problem that the wood fiber-polyvinyl chloride composite material has high flammability and produces a large amount of black smoke and toxic gas when burned. The wood fiber-polyvinyl chloride composite material is mainly composed of 100-600 parts of polyvinyl chloride resin, 30-700 parts of wood fiber material, 3-145 parts of intumescent flame retardant, 1-55 parts of copper oxide, 6 ~75 parts of heat stabilizer, 4~60 parts of plasticizer and 4~65 parts of compatibilizer. Preparation method: 1. premixed material; 2. extrusion molding. According to the GB / T8924-2005 standard test of the wood fiber-polyvinyl chloride composite material of the present invention, the oxygen index of the wood fiber-polyvinyl chloride composite material of the present invention is greater than 35%, the ignition time is long, no melting drops occur, and it belongs to the flame retardant grade Material. The preparation method of the wood fiber-polyvinyl chloride composite material of the invention is simple, easy to operate, has low requirements on equipment, and is convenient for popularization and application.

Owner:NORTHEAST FORESTRY UNIVERSITY

Plasticized polyvinyl chloride composition with flame retardant

InactiveUS20120142839A1Low temperature flexibilityEase the temperatureCoatingsPolyvinyl chloridePliability

A highly flame retardant plasticized polyvinyl chloride composition includes a mixture of a dialkyl or dialkenyl tetrahalophthalate and a brominated / chlorinated paraffin. The composition exhibits an absence of brittleness, and substantial flexibility at low temperatures. The composition can be used to form sheet materials, molding compositions, roofing materials, PVC formed jackets and insulation for wire and cable products.

Owner:LENKSESS CORP

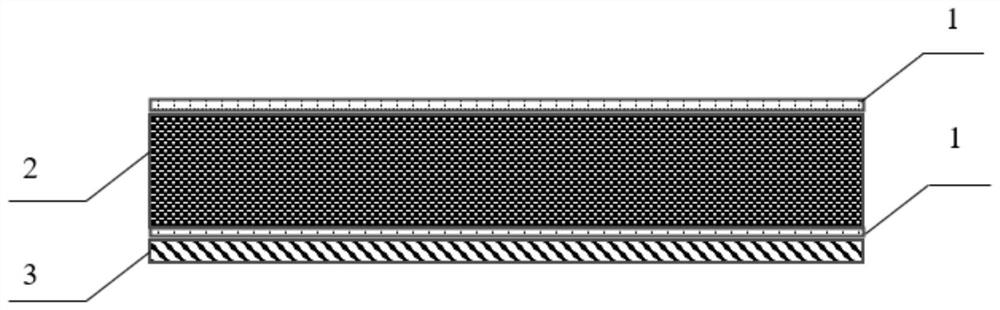

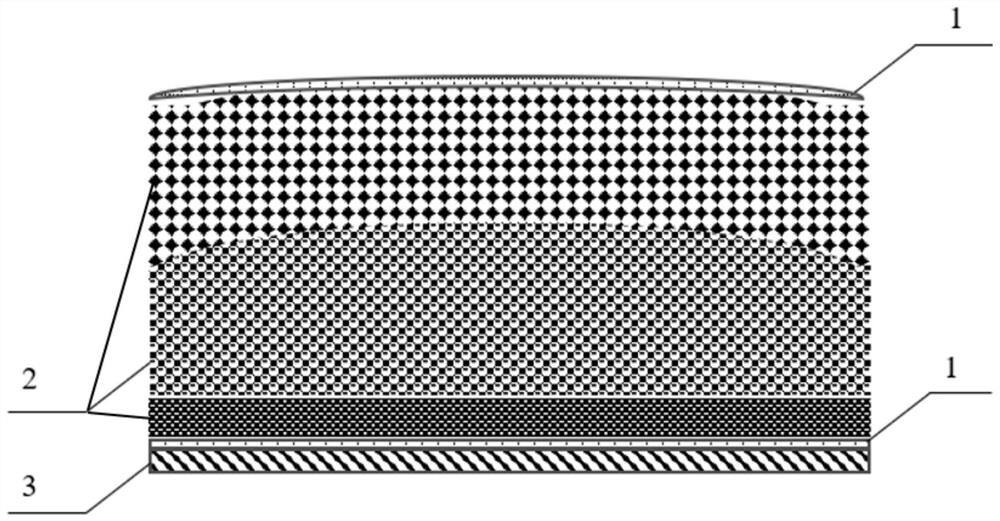

Fireproof board

A fireproof board includes a fireproof layer comprised a mixture of expandable graphite and fibers, and a decoration layer laminated on one side of the fireproof layer, and a substrate layer disposed to the other side of the fireproof layer. In case of a fire, the expandable graphite will expand rapidly and grow into vermicular intumescence, tangling with fibers to form a fire resistant layer can stop the flame spread and reduce the smoke development for achieving fireproof purpose to protect the objects covered over by the fireproof board.

Owner:INT CARBIDE TECH

Inflaming retarding system and preparation method of inflaming-retarding real silk

ActiveCN102828408AIncrease char formationReduce smoke productionFibre treatmentSilane couplingChemistry

The invention discloses an inflaming retarding system and a preparation method of an inflaming-retarding real silk. The inflaming retarding system is a phosphorus-silicon collaborative system, wherein a phosphorus component is methacryloyloxyethyl dimethyl phosphate and a silicon component is a vinyl silane coupling agent. The preparation method comprises the following steps of: preparing an inflaming-retarding working solution and adjusting the pH (Potential of Hydrogen) value of the working solution to 4-4.5; immersing a real silk textile into the inflaming-retarding working solution, and heating the real silk textile at 80-85 DEG C for 10-60 minutes; and washing the real silk textile by water and drying the real silk textile to obtain the inflaming-retarding real silk. A fire retardant provided by the invention is durable, and no formaldehyde is released in an inflaming retarding and sorting process; and the smoke amount of the real silk textile in a combustion process is as low as required.

Owner:苏州盛泽科技创业园发展有限公司

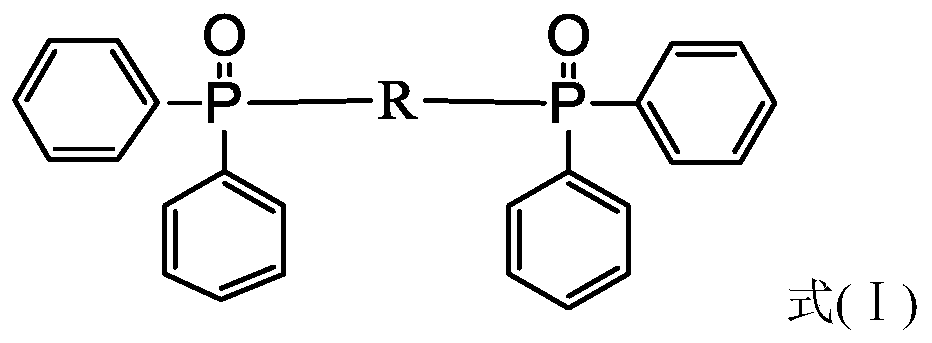

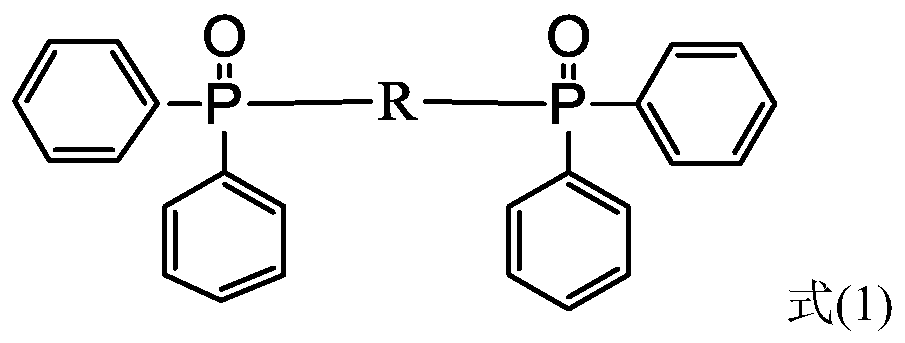

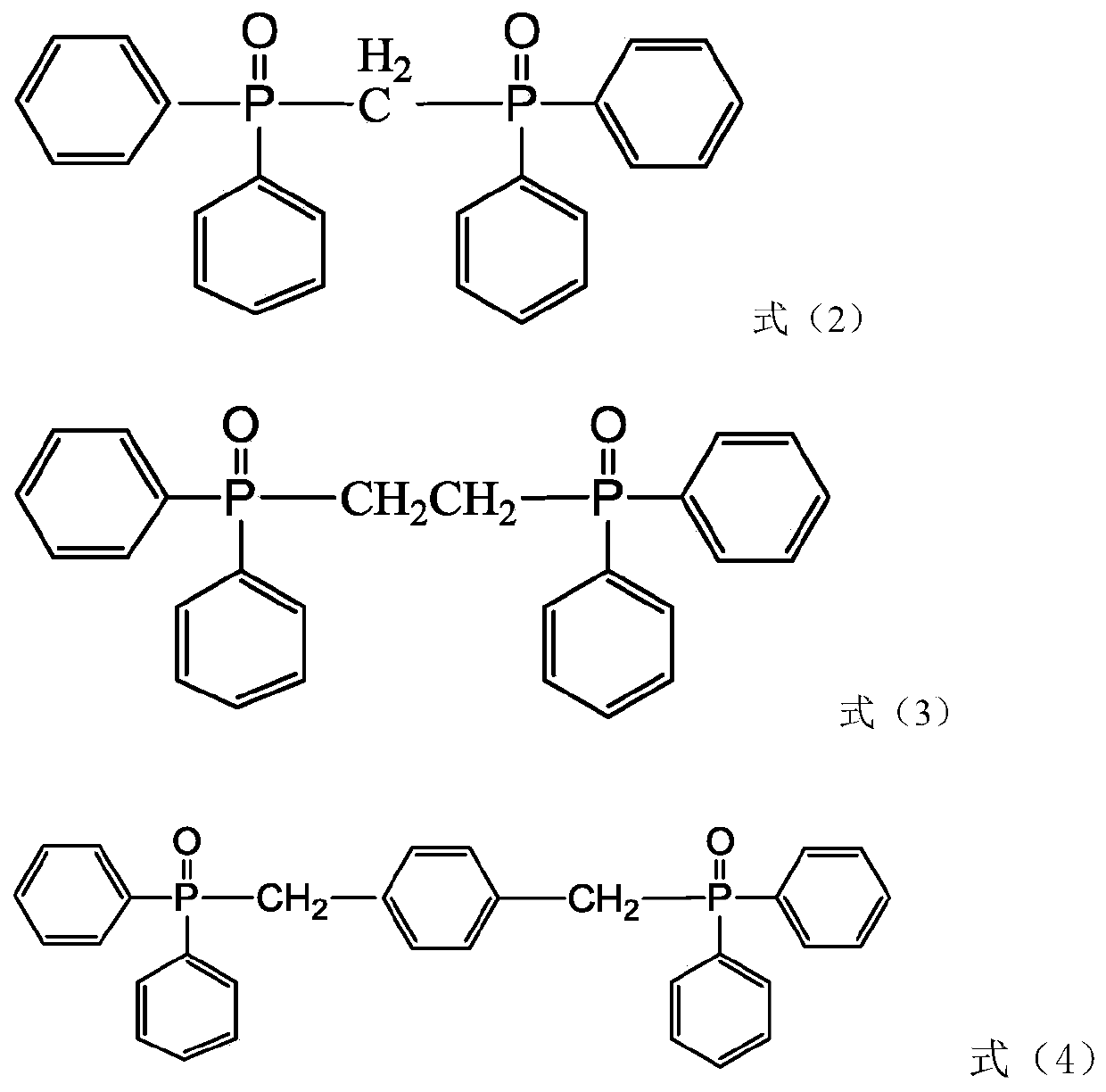

Halogen-free flame-retardant epoxy resin composition and application thereof

The invention relates to the field of high molecular materials, in particular to a halogen-free flame-retardant epoxy resin composition and application thereof. The composition comprises 100 parts ofepoxy resin, a halogen-free composite flame retardant provided with diphenylphosphine oxide flame-retardant groups, 5-15 parts of a main flame retardant, 0-10 parts of an auxiliary flame retardant, 2-30 parts of a curing agent and 0-1 part of a curing accelerating crosslinking agent. The composition further comprises a mixture of at least two of reinforced fibers, a flexibilizer, a filler, a silane coupling agent and a solvent. The composite flame retardant containing the diphenylphosphine oxide groups is high in flame-retarding efficiency and small in adding amount and has excellent compatibility and dispersity with the epoxy resin; and in the curing process, intermolecular dispersion with the epoxy resin can be realized, and the original transparent state of the epoxy resin is maintained. The finally cured flame-retardant resin composition has the advantages of low cost, high transparency, low water absorption rate, high glass conversion temperature, high thermal stability, low dielectric constant and dielectric loss, high flame retarding and the like.

Owner:SHANDONG UNIV OF SCI & TECH

Environment-friendly fireproof material for electrical equipment and preparation method thereof

ActiveCN106497339AReduce solubilityImprove thermal stabilityFireproof paintsEpoxy resin coatingsFiberCrack resistance

The invention provides an environment-friendly fireproof material for electrical equipment and a preparation method of the environment-friendly fireproof material, and belongs to the fields of fireproof materials and preparation technologies thereof. The environment-friendly fireproof material for the electrical equipment is characterized by being prepared from the following raw materials in parts by weight: 50 to 60 parts of modified epoxy resin, 30 to 40 parts of fluorocarbon resin, 60 to 90 parts of a fire retardant, 3 to 10 parts of expanded graphite, 3 to 10 parts of alumina silicate fiber and 2 to 8 parts of molecular sieves. The fireproof material provided by the invention is applied to fire protection of the electrical equipment, and is high in crack resistance, water resistance and weather resistance and good in expansion character; meanwhile, the heat release rate of a base material in a burning condition can be obviously reduced, and the quality loss is reduced; moreover, the fireproof material is small in smoke production quantity and good in environmental protection effect.

Owner:STATE GRID HENAN ELECTRIC ZHOUKOU POWER SUPPLY

Graphene grafted nitrogen, phosphorus and silicon synergistic halogen-free flame retardant and preparation method thereof

ActiveCN109180952AAchieve halogen-free synthesisGive full play to the multiple synergistic flame retardant effectIn situ polymerizationNitrogen

The invention belongs to the technical field of fire retardants and mainly relates to a graphene grafted nitrogen, phosphorus and silicon synergistic halogen-free flame retardant and a preparation method thereof. The preparation method comprises the following steps: compounding 3-aminopropyl-triethoxysilane into octa-aminopropyl caged silsesquioxane through a hydrolytic condensation polymerizationprocess; preparing graphene oxide after chemically oxidizing and peeling graphene through an improved hummers process; compounding 9,10-dihydro-9-oxa-10-phosphaphenanthrene-10-oxide and graphene oxide into a grafted product 1 with an reactivity functional group through an in situ polymerization process; grafting the octa-aminopropyl caged silsesquioxane and the grafted product 1 into the graphenegrafted nitrogen, phosphorus and silicon synergistic halogen-free flame retardant through the in situ polymerization process. The preparation method for the graphene grafted nitrogen, phosphorus andsilicon synergistic halogen-free flame retardant provided by the invention has the advantages of simple preparation process, safety, environmental friendliness, and the like; the graphene grafted nitrogen, phosphorus and silicon synergistic halogen-free flame retardant can be widely used for inflaming retarding in the fields of electronics, automobiles, cables, packaging, aviation, and the like; the graphene grafted nitrogen, phosphorus and silicon synergistic halogen-free flame retardant has a bright application prospect.

Owner:SICHUAN UNIV

Method for manufacturing stainless steel dedusting ash pressure ball

InactiveCN102212678AReduce the probability of burstingReduce pollutionPolyvinyl alcoholMixed materials

The invention relates to a method for manufacturing a stainless steel dedusting ash pressure ball, sequentially comprising the following steps of: 1, mixing the following raw materials including 10 parts of stainless steel dedusting ash and 0.8-1.2 parts of cement into a mixed material; 2, adding water and organic binder, mixing 0.2-0.3 part by weight of MgC12, 0.1-0.2 part by weight of polyvinyl alcohol and 1.3-1.8 parts by weight of water into glue, spraying the glue on the mixed material and uniformly mixing; 3, extruding and forming, conveying the mixed material in which the glue is added to a ball pressing machine, pressing into a block with the maximum outline size of 30-45 mm; 4, naturally drying and maintaining the extruded and formed block, wherein the intensity is 2100+ / -500N per one ball; and 5, drying the maintained ball in a dried ventilation region for 5+ / -1days, wherein after being dried, the water content of the ball is not more than 2.0%. When the pressure ball manufactured by using the method for manufacturing the stainless steel dedusting ash pressure ball is used for making steel in an electric furnace, the smoke level is reduced; and the environmental pollution is reduced.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

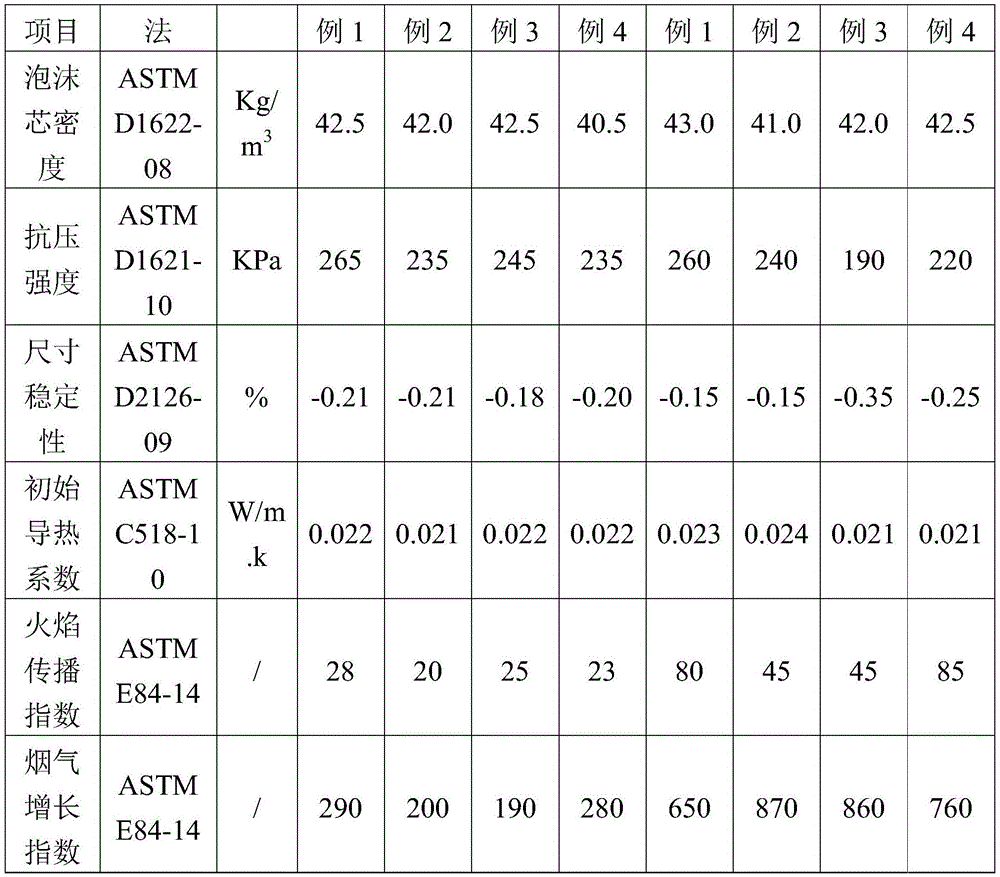

Premixed polyether polyol, polyisocyanurate foam, as well as raw material composition and preparation method of polyisocyanurate foam

The invention discloses premixed polyether polyol, polyisocyanurate foam, as well as a raw material composition and a preparation method of the polyisocyanurate foam. The premixed polyether polyol provided by the invention is prepared from the following components: polyether polyol A, polyester polyol A, a foam stabilizer, a trimer catalyzer, a foaming agent, water and a fire retardant; the foaming agent is a fluorinated hydrocarbon foaming agent; the fluorinated hydrocarbon foaming agent is 1,1,1,3,3-pentafluoropropane and / or 1,1,1,3,3-pentafluorobutane. Under the condition of not using an HCFC-141b foaming agent, the polyisocyanurate foam provided by the invention can reach the standards that the fire propagation index is less than or equal to 25 and the smoke increase index is less than or equal to 450, so that the polyisocyanurate foam provided by the invention meets the demands on inflaming retarding of thermal insulation materials used for high-rise buildings and corridors in National Fire Council Life Safety Act of America.

Owner:SHANGHAI DONGDA POLYURETHANE

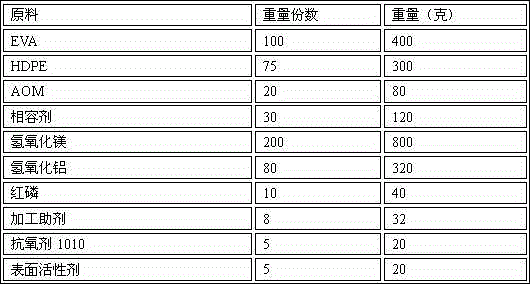

Low-smoke, halogen-free and flame-retardant cable material used for coal mine, and preparation method thereof

InactiveCN104086849AUniform thicknessImprove flame retardant performancePlastic/resin/waxes insulatorsAluminium hydroxideActive agent

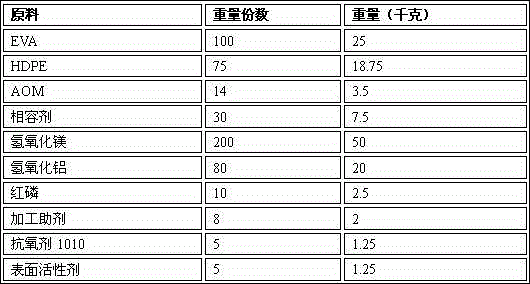

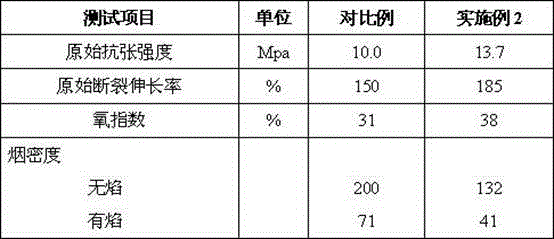

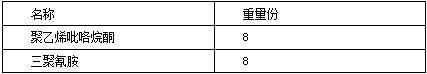

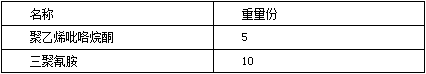

The invention discloses a low-smoke, halogen-free and flame-retardant cable material used for a coal mine. The low-smoke, halogen-free and flame-retardant cable material is prepared from the following raw materials by weight: 100 parts of a ethylene-vinyl acetate copolymer, 75 parts of high density polyethylene, 10-20 parts of a smoke-suppressing agent, 20-40 parts of a compatilizer, 250-300 parts of a flame retardant, 5-15 parts of flame-retardant aid, 7-10 parts of a processing aid, 3-6 parts of an oxidant and 3-6 parts of a surfactant. The invention also discloses a preparation method of the cable material. Ammonium octamolybdate is used as the smoke-suppressing agent, is relatively uniform in particle size and has relatively good compatibility. Magnesium hydroxide, aluminium hydroxide and red phosphorus are co-used as the flame retardant, thereby greatly increasing a flame-retardant effect of a system and reducing smoke production of the system.

Owner:HUAIBEI TIANXIANG CABLE

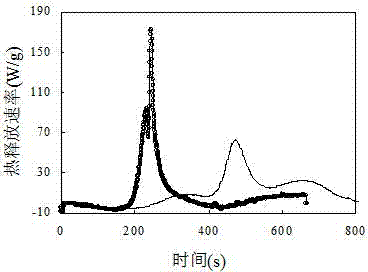

Modified expandable graphite, flame retardant as well as preparation method and application thereof in polyurethane foam

The invention relates to the technical field of flame retardants, and specifically relates to modified expandable graphite, a flame retardant, a preparation method and application thereof in polyurethane foam, and the modified expandable graphite is characterized in that one or more layer of polymer surface modifying agents with special functional groups is / are adsorbed on the surface of expandable graphite, the preparation method of the modified expandable graphite comprises: carrying out surface modification on the expandable graphite by using an organic modifier containing hydroxyl and a polar six-membered ring structure, adding a dispersing agent, uniformly mixing, and crushing and sieving to obtain the modified graphite; after adding of the modified graphite into polyurethane composite polyether according to a certain ratio and uniform mixing, the modified graphite can be uniformly dispersed and suspended in the polyether; the flame retardancy of the obtained polyurethane thermalinsulation material is greatly improved, the other performances of the polyurethane rigid foam are not influenced, the flame retardancy is good, the flame retardant effect is durable, the oxygen index is greatly improved, and the heat release rate peak value is greatly reduced.

Owner:WEIHAI YUNSHAN TECH

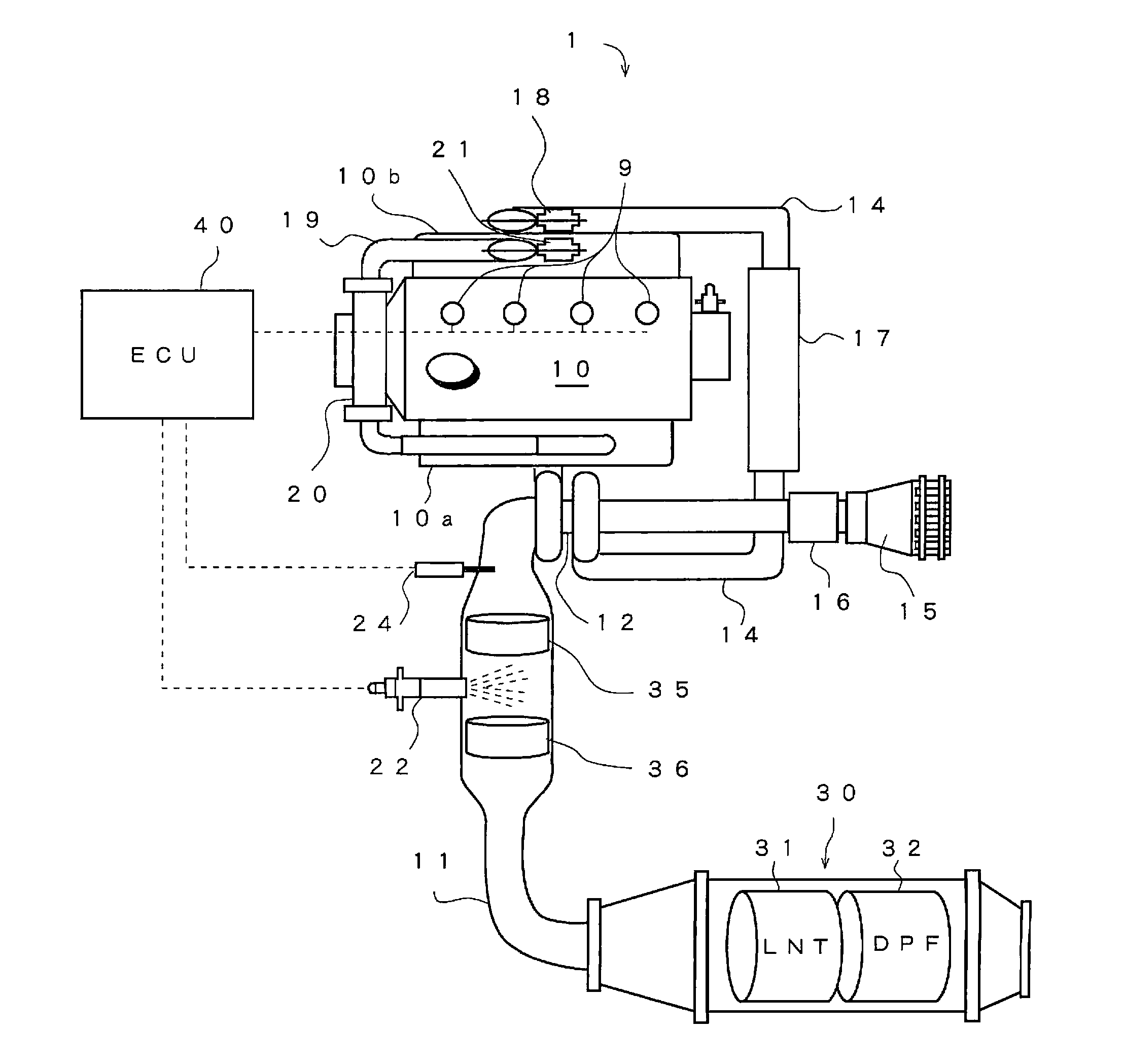

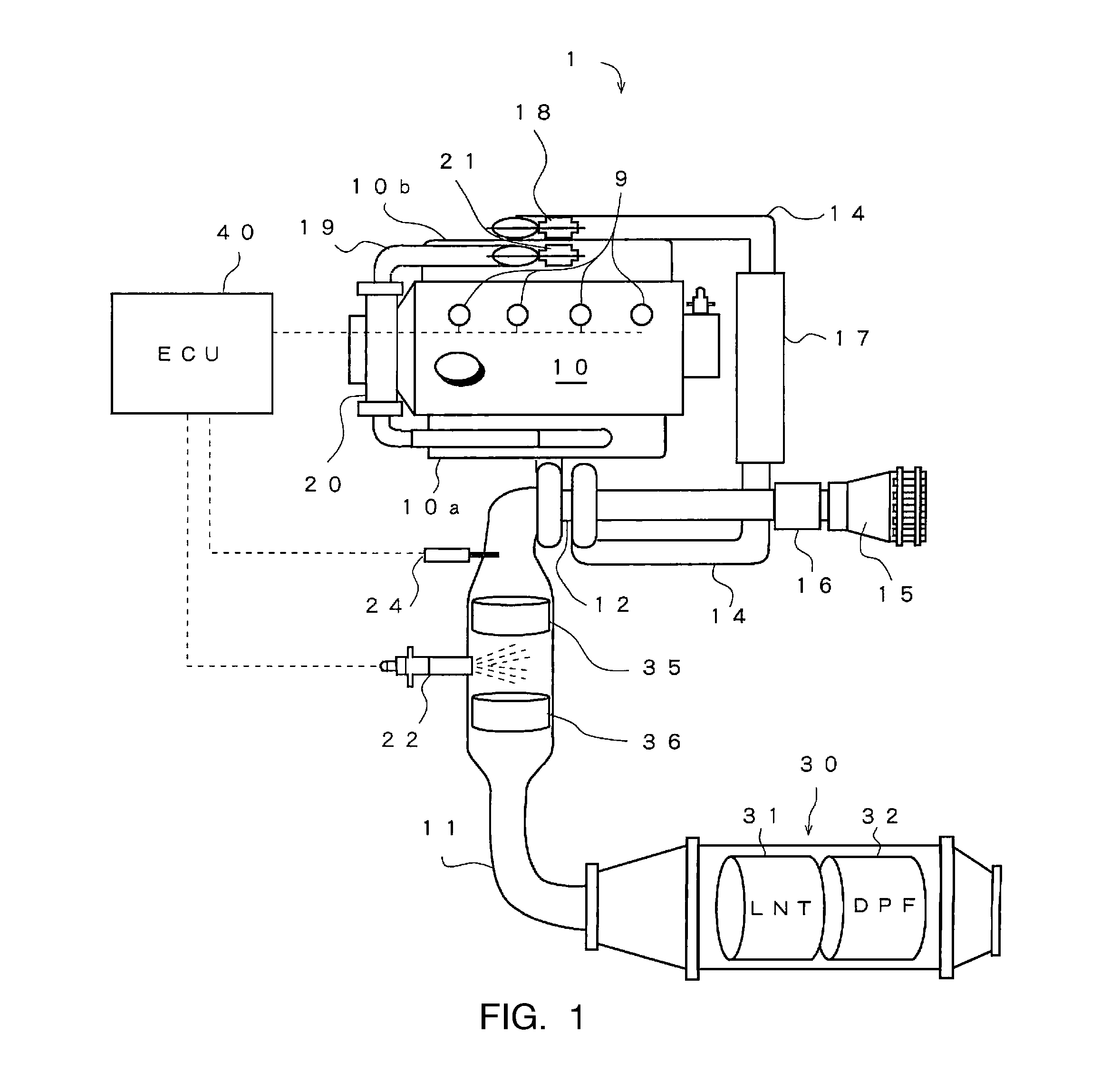

Exhaust gas purification device

ActiveUS20130025264A1Efficient reductionImprove purification rateGas treatmentElectrical controlPost injectionFuel injection

The exhaust gas purification device includes an exhaust gas post-processing device 30 provided in an exhaust passage 11 of an engine 10, an exhaust injection valve 22, a first catalyst 35, a second catalyst 36 for thermally decomposing fuel injected by the exhaust injection valve 22, an exhaust temperature estimation unit 41 for estimating an exhaust temperature, an engine injection control unit 42 for controlling fuel injection in the engine 10, and regeneration control units 43, 44 for controlling regeneration of the exhaust gas post-processing device 30. When an output value output by the exhaust gas temperature estimation unit 41 is equal to or lower than a threshold during regeneration by the regeneration control units 43, 44, the engine injection control unit 42 controls fuel injection in the engine by performing a multistage injection, which includes a post injection for supplying fuel to the first catalyst 35.

Owner:ISUZU MOTORS LTD

Low-smoke zero-halogen flame-retardant polyolefin oxygen barrier material

The invention relates to a low-smoke zero-halogen flame-retardant polyolefin oxygen barrier material with low heat release and high coking property, which comprises Levapren rubber and a ceramic master batch. The VA content of the Levapren rubber is greater than or equal to 50%, and at 100 DEG C, the mooney viscosity of the Levapren rubber is 20-30; based on the total weight of the ceramic masterbatch, the ceramic master batch comprises the following components in percentage by mass: 40-60% of ceramic powder, 40-60% of polyethylene resin, 0.1-0.3% of first antioxidant, 0.1-0.5% of polyethylene wax and 0.2-0.6% of silicone powder. The polyolefin oxygen barrier material disclosed in the invention has low heat release property, high coking property and excellent extrusion machinability.

Owner:中广核高新核材科技(苏州)有限公司

Method for reducing flame spread

InactiveUS20060249715A1Reducing flame spreadImprove suppression propertiesFire proofingFlame spreadEngineering

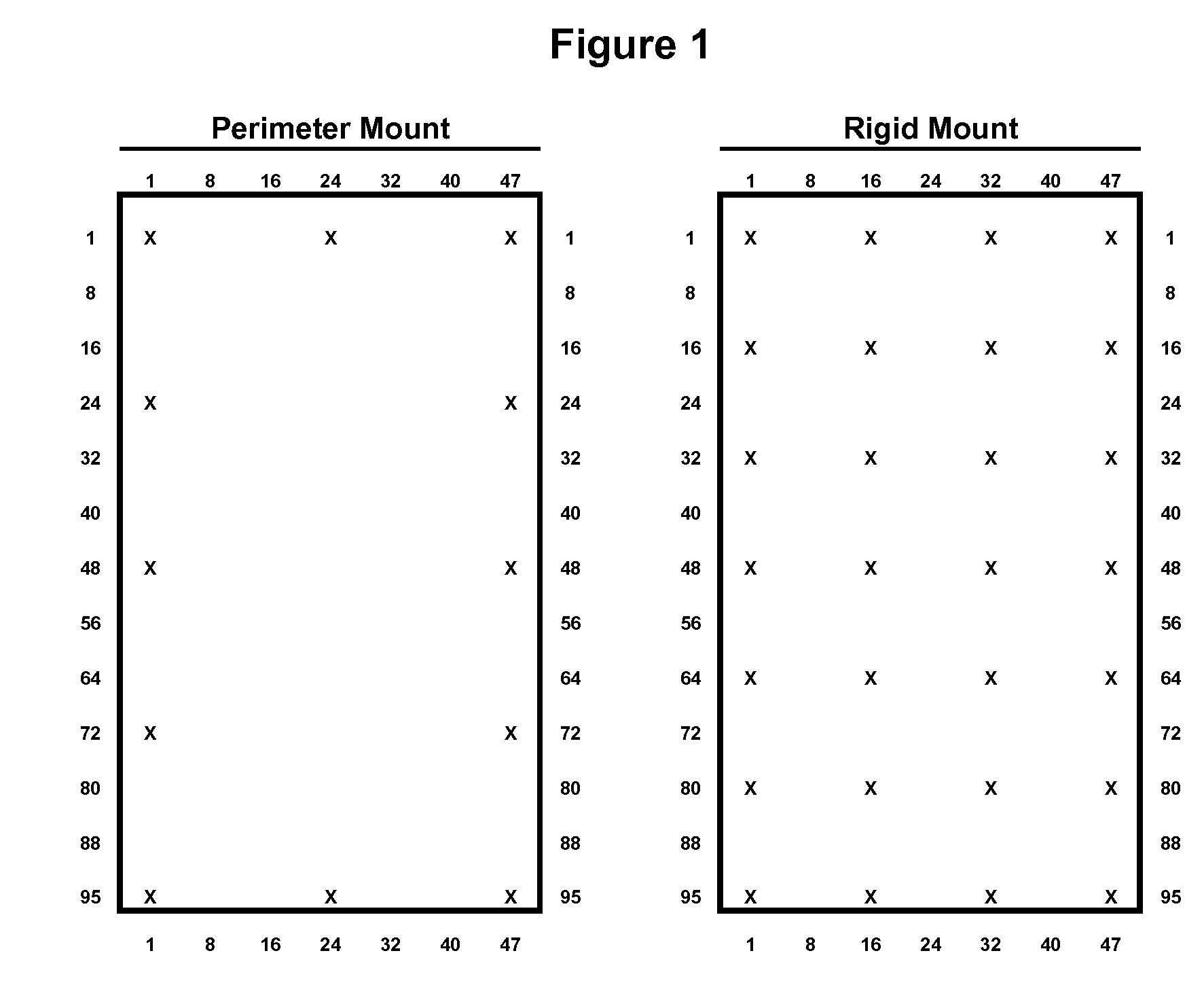

Disclosed is a method to reduce flame spread within a room by attaching an interior finish compising at least 80 weight percent of a polymer composition to a ceiling, one or more walls, or combination thereof, wherein the interior finish partially or completely detaches from the wall or ceiling upon exposure to the heat of a flame. The polymer composition has certain properties of crystallization half-time, heat release capacity, and char generation and can comprise one or more polymers. The interior finish may detach or partially detach from the ceiling or wall as a result its thermal behavior when exposed to heat or as a result of softening or melting of fasteners. The spacing of the fasteners of the interior finish is dependent on the physical properties of the polymer.

Owner:EASTMAN CHEM CO

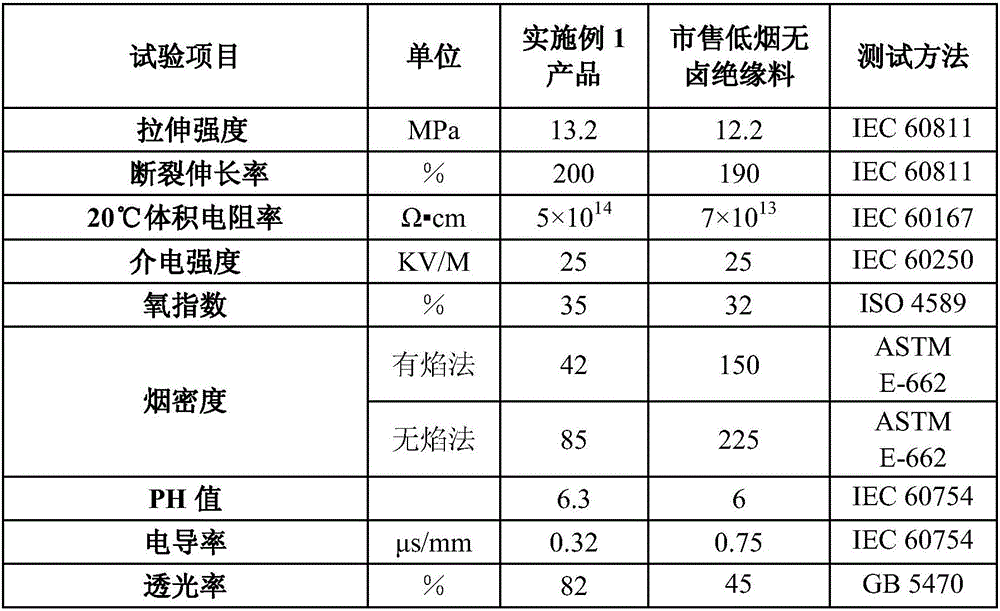

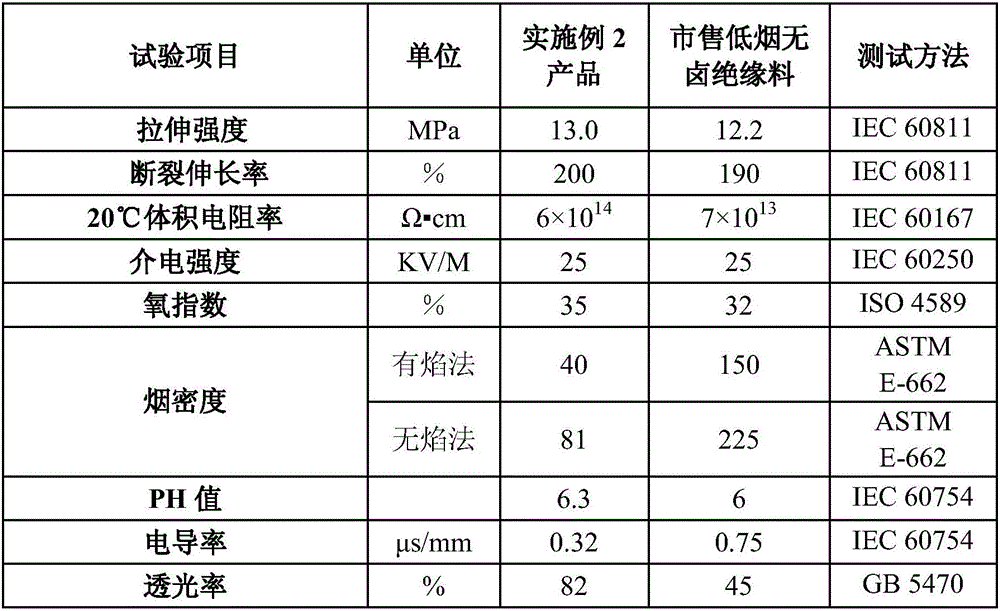

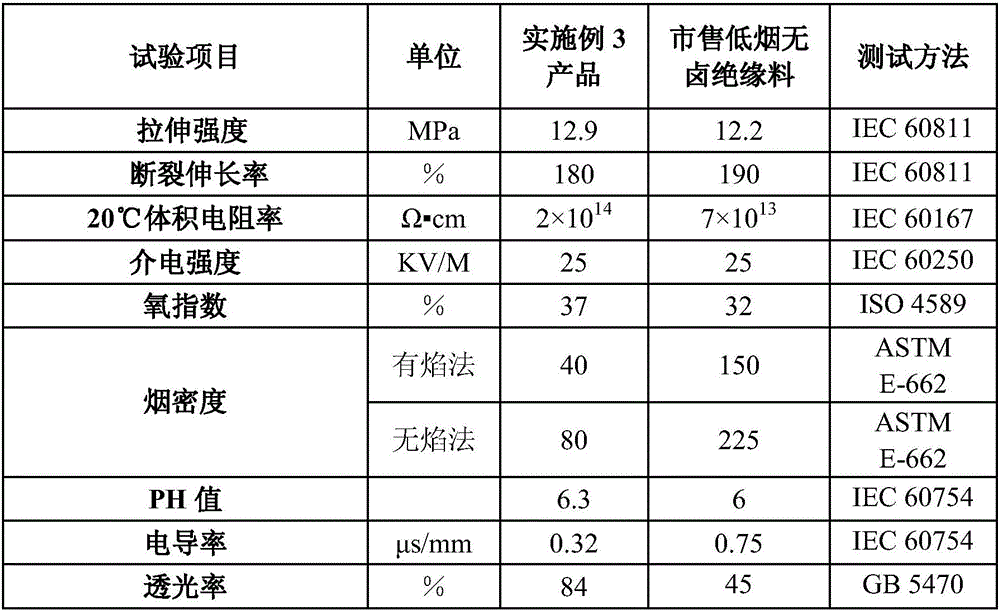

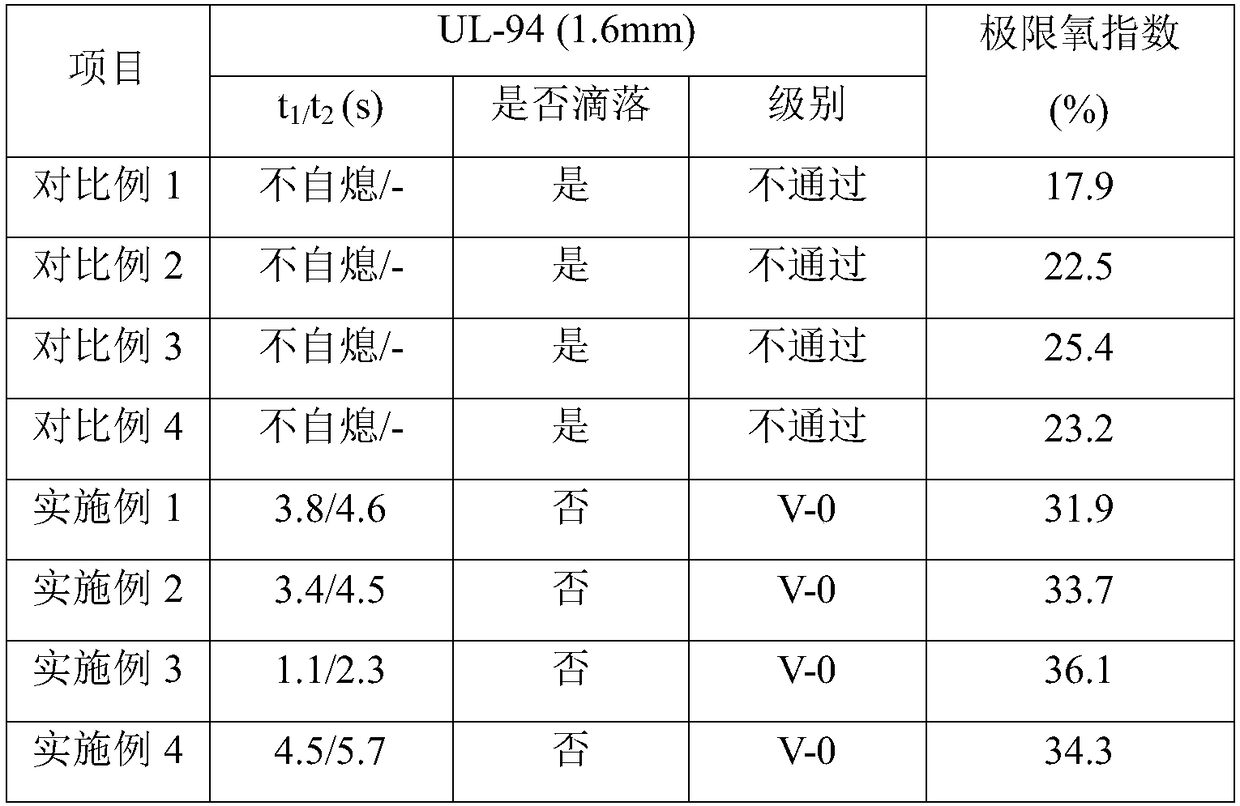

Low-smoke-amount non-halogen flame-retardant cable compound and preparation method thereof

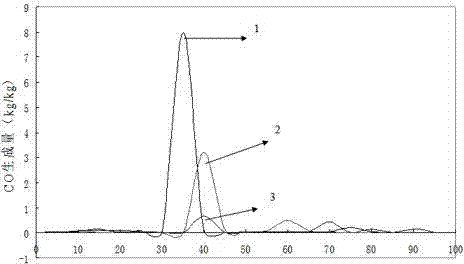

InactiveCN106349554AWiden the temperature rangeReduce smoke productionPlastic/resin/waxes insulatorsInsulated cablesHalogenCombustion

The invention discloses a low-smoke-amount non-halogen flame-retardant cable compound. The low-smoke-amount non-halogen flame-retardant cable compound comprises the following components in mass percent: 25 to 28 percent of ethylene-vinyl acetate copolymer, 3 to 5 percent of polyethylene, 2 to 4 percent of maleic anhydride grafted polyethylene, 60 to 65 percent of an inorganic flame retardant, 0.5 to 1 percent of alkylsiloxane, 3 to 5 percent of a smoke inhibitor, and 1 to 3 percent of an antioxidant assistant, and the sum of the mass percent of all the components is 100 percent. The invention further discloses a preparation method of the low-smoke-amount non-halogen flame-retardant cable compound. The low-smoke-amount non-halogen flame-retardant cable compound has excellent mechanical properties and electrical properties, greatly reduces the density of flame smoke and the density of flameless smoke during combustion, greatly improves the light transmittance of finished cables, and is particularly suitable for the preparation of cables with large sections or complex structures.

Owner:OPTA POLYMER JIANGSU

Nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant polymer composite material and preparation method thereof

The invention belongs to the technical field of macromolecular materials, and relates to a nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant polymer composite material and a preparation method thereof, wherein the composite material is prepared from the following substances in parts by weight: 60-90 parts of a polymer, and 10-40 parts of a nitrogen-phosphorus-silicon modified graphene flame retardant. All the components are weighed according to the weight percentage and are mixed uniformly, and then the mixture is added into a twin-screw extruder, melted and mixed andthen subjected to injection molding into corresponding sample strips by an injection moulding machine, or the mixture is melted and blended by an internal mixer and is subjected to compression moulding forming by a mould with a certain size on a plate vulcanizing machine, or a method of solidifying moulding by a curing agent is adopted. The nitrogen-phosphorus-silicon modified graphene halogen-free flame retardant polymer composite material provided by the invention has the advantages of high charring property, and excellent flame retardancy and thermal stability, and can be applied to flame retardancy of materials such as electric cables, automobiles and packages.

Owner:SICHUAN UNIV

Ceramic fiber board and preparation method thereof

The invention provides a ceramic fiber board. The ceramic fiber board is prepared from the following raw materials in parts by weight: 40 to 60 parts of ceramic fiber, 0 to 16 parts of alkali-free glass fiber, 5 to 15 parts of kaoline, 5 to 15 parts of attapulgite, 10 to 20 parts of expanded perlite, 2 to 6 parts of an organic binding agent and 1 to 6 parts of a smoke eliminating assistant, wherein the smoke eliminating assistant is selected from ferrocene and / or aluminum hydroxide. Compared with the prior art, the ceramic fiber board provided by the invention adopts specific using amounts ofraw materials, the components are of good mutual effect, and the prepared and obtained ceramic board has relatively low smoke yield and preferable mechanical strength, is low in production cost, and is beneficial to production and application. Experimental results indicate that the compression strength of the ceramic fiber board provided by the invention is 0.11 MPa or above, the TSP600 smoke yield does not exceed 32 m<2>, and the production cost can be controlled within 7.5 thousand yuan per ton.

Owner:LUYANG ENERGY SAVING MATERIALS CO LTD

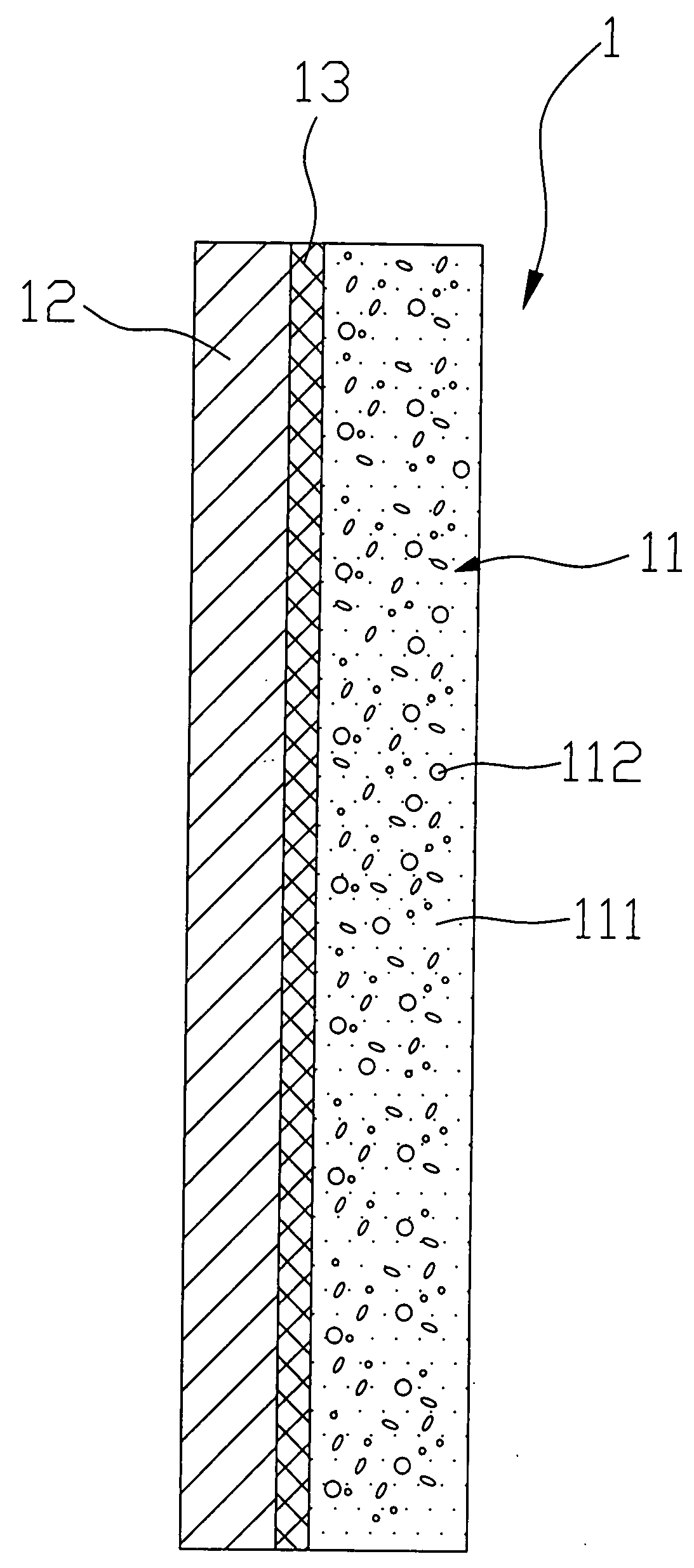

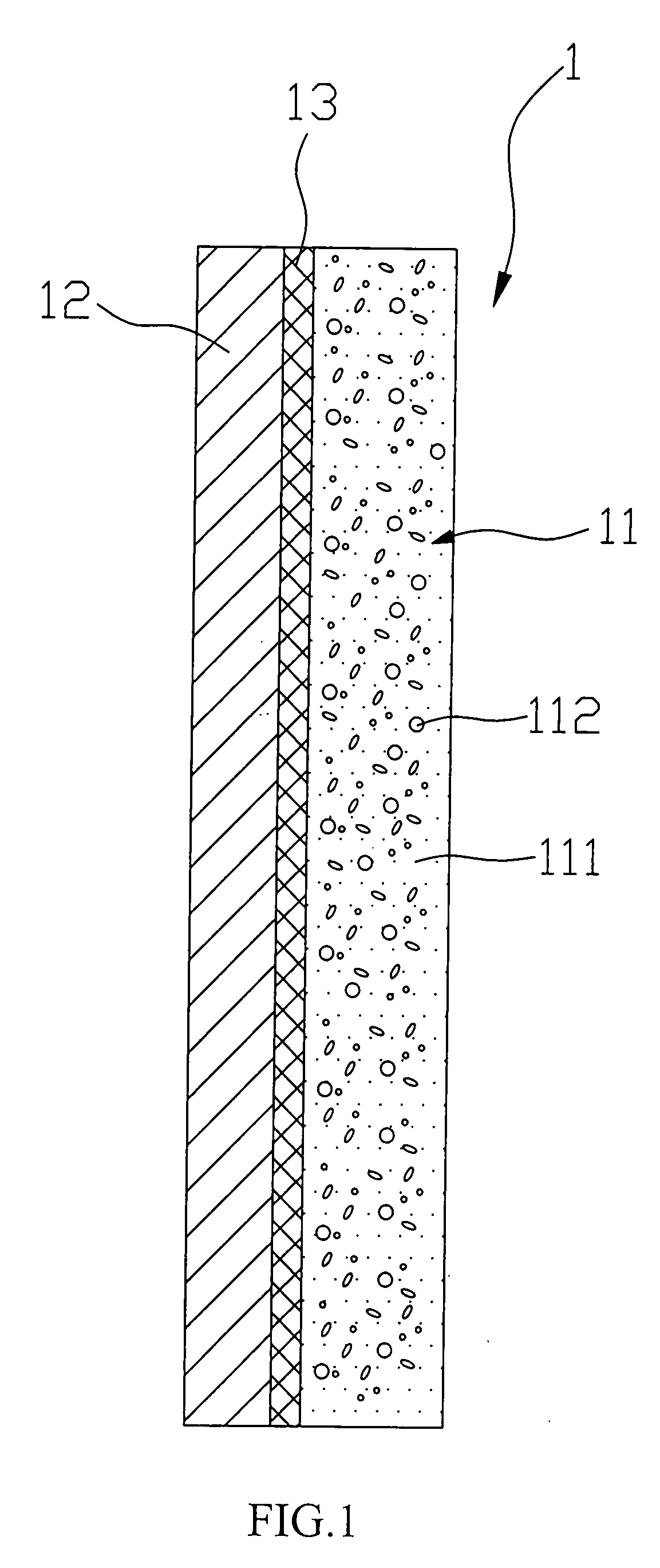

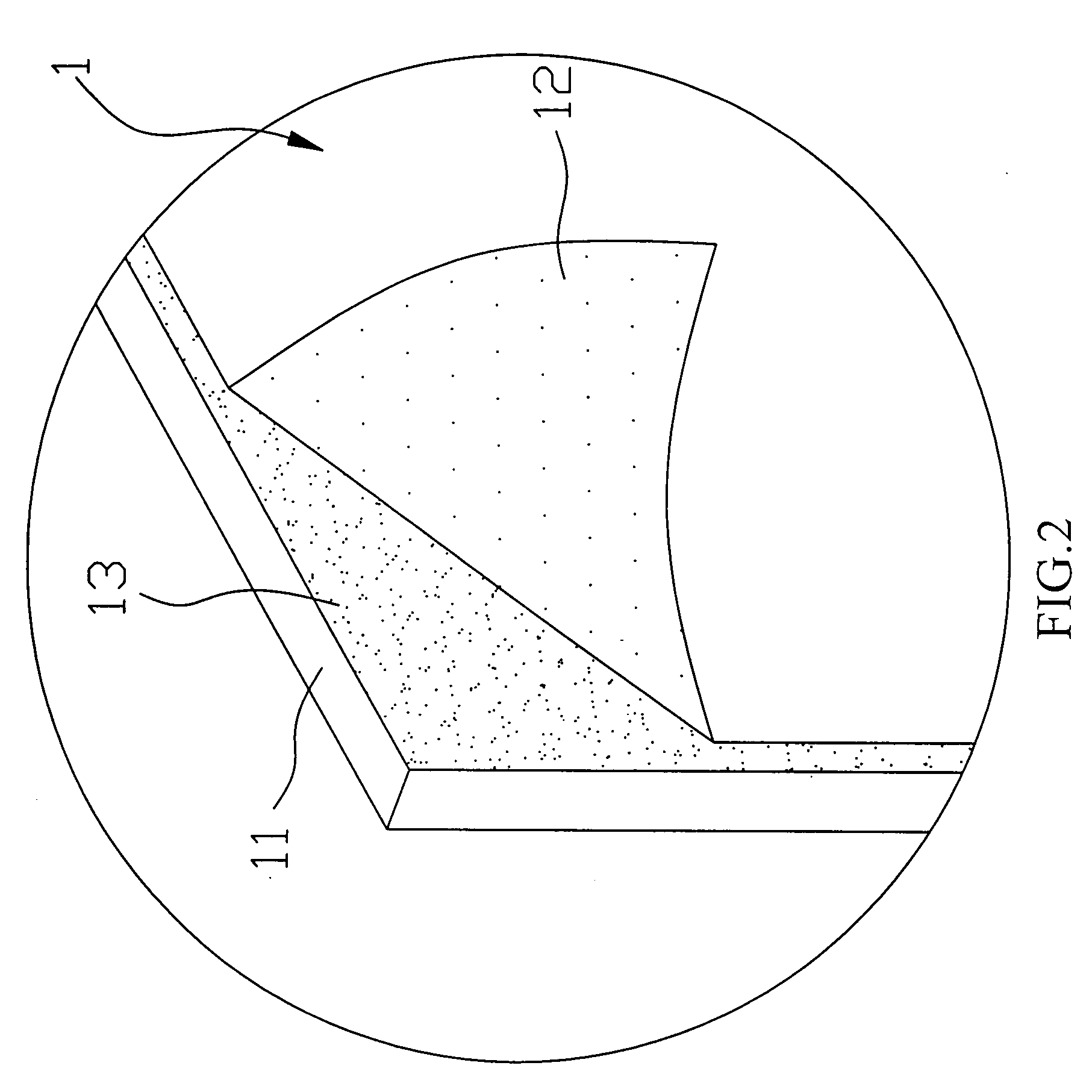

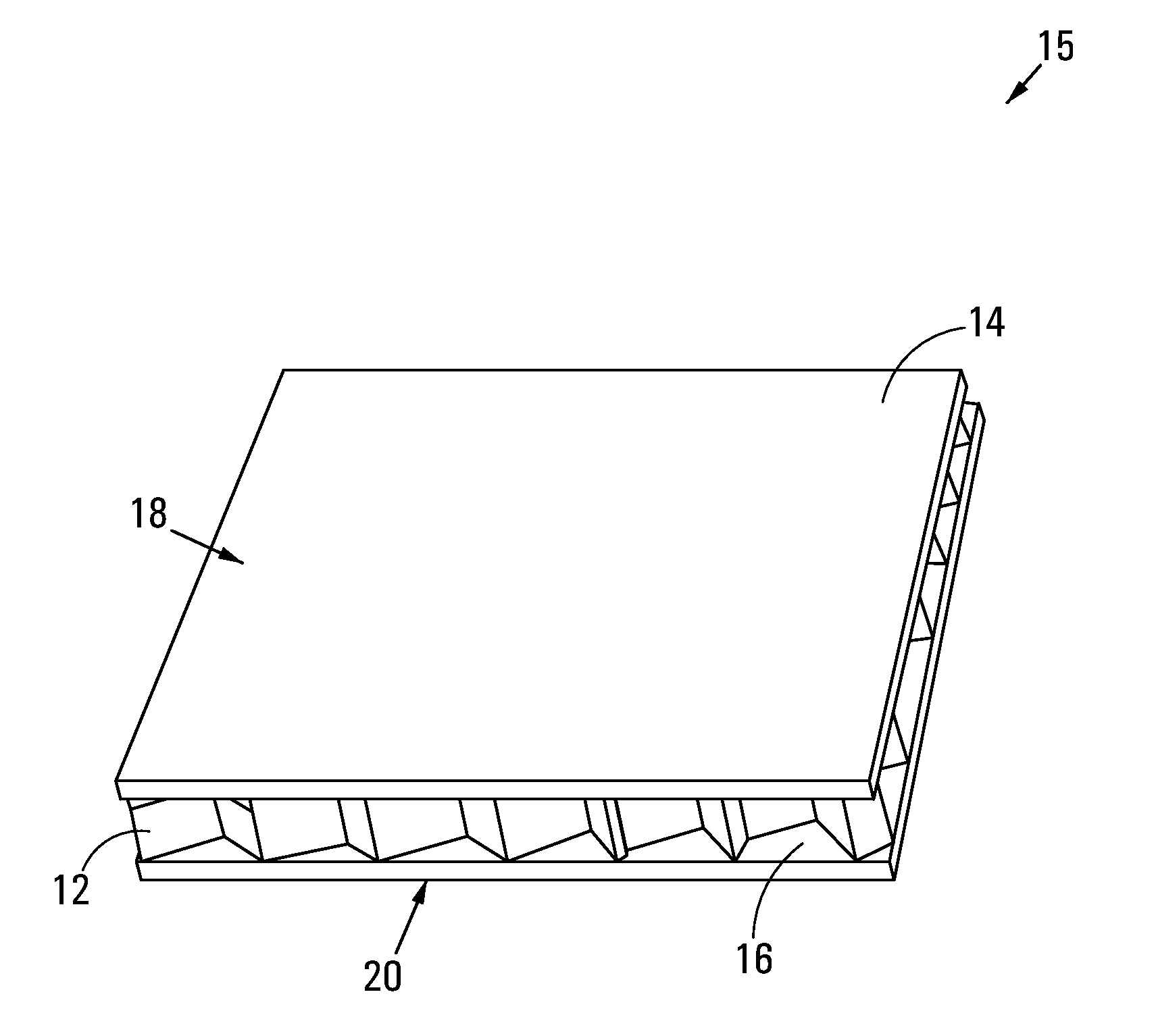

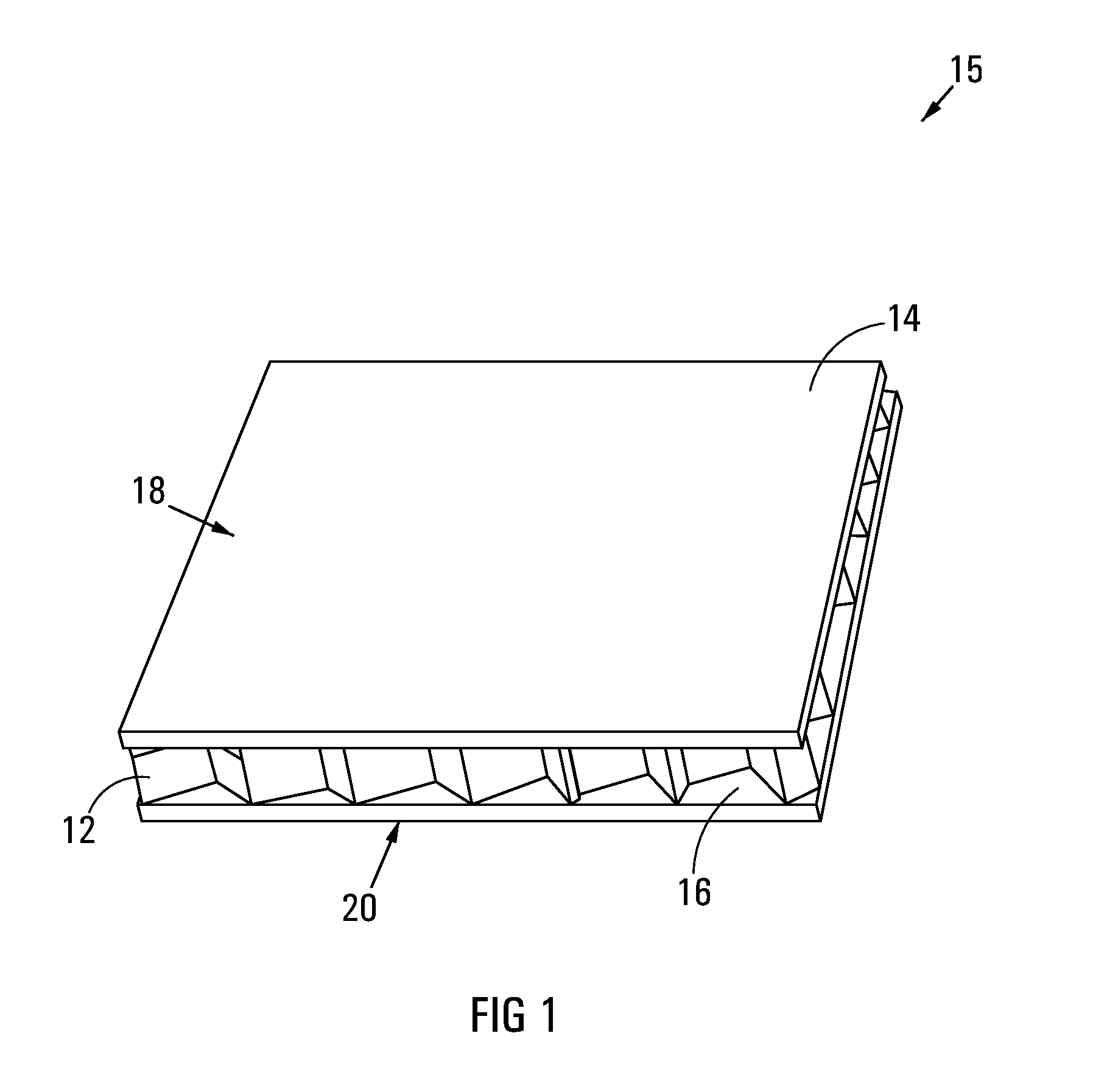

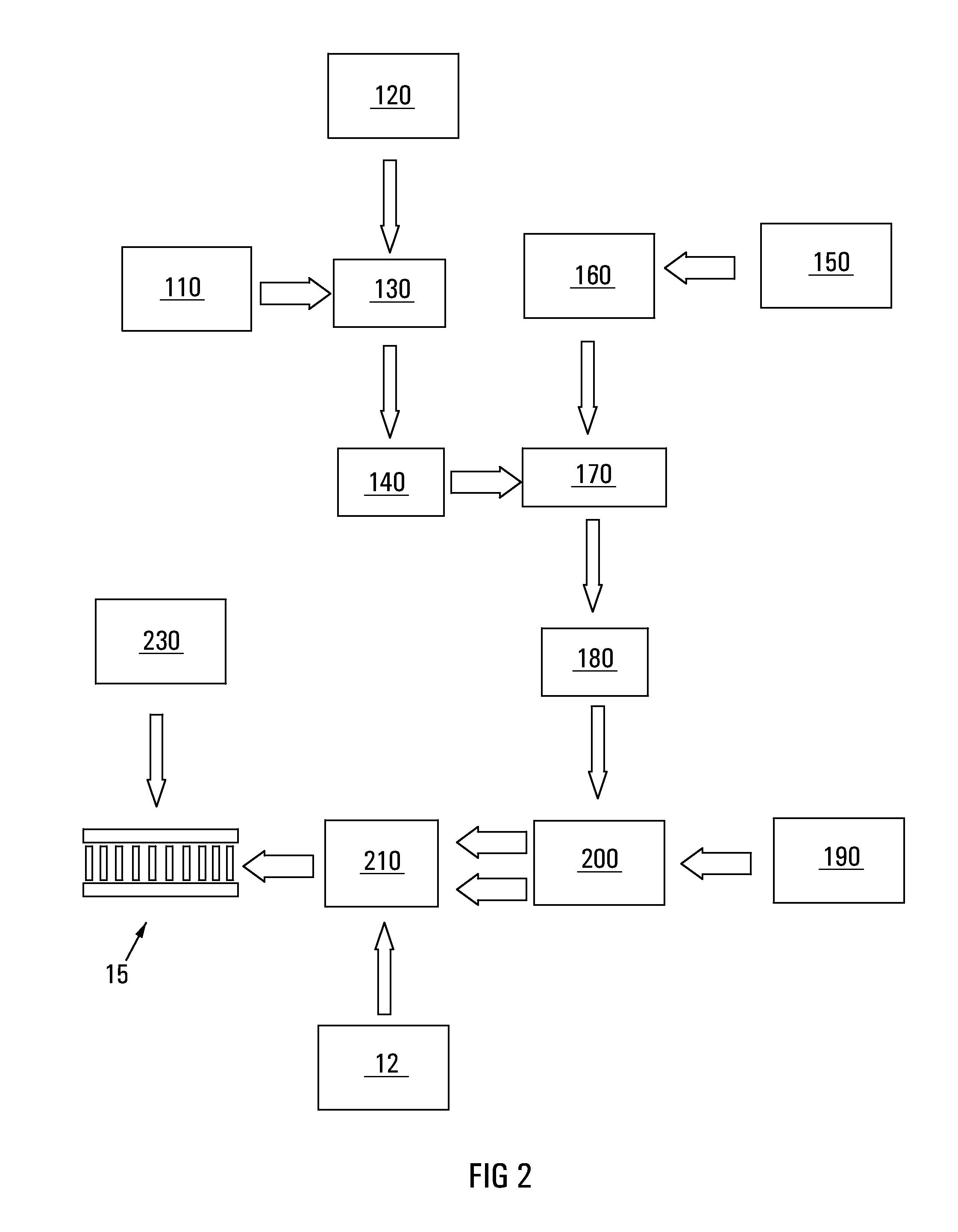

Flame-Proofed Artefact and a Method of Manufacture Thereof

ActiveUS20140302736A1Reduce heat release valueReduce smoke productionSynthetic resin layered productsLaminationNatural fiberPolymer chemistry

A method of fabricating an artefact (15) includes treating natural fibres (1 10) with a non-halogenated flame retardant agent (120), the fibres (1 10) also being treated with a smoke suppressant (120). At least one pre-preg is formed (170, 180) from the treated natural fibres and from a resin composition (160) including a smoke suppressant (150) admixed therein (160). An uncured artefact is formed from a core or substrate (12) and the pre-preg, which provides a skin, and is cured (210). A non-fibrous silicate fire resistant material (190, 230) is introduced by: (i) admixing the fire resistant material with the resin composition, and / or (ii) applying the fire resistant material to an outer surface of the pre-preg or an outer surface of the skin of the uncured artefact, and / or (iii) applying the fire resistant material to an outer surface of the skin of the cured artefact. The invention extends to a flame-proofed artefact (15).

Owner:CSIR

Polyimide foam composite material, and preparation method and application thereof

ActiveCN110014714AImprove flame retardant performanceImprove thermoplasticityLayered product treatmentSynthetic resin layered productsCooking & bakingPolyester

The invention provides a polyimide foam composite material, and a preparation method and application thereof. The preparation method comprises the following steps: adding aromatic dianhydride into a tetrahydrofuran / methanol mixed solvent, carrying out heating to dissolve the aromatic dianhydride and carry out an esterification reaction, adding aromatic diamine and a foam stabilizer after the solution is transparent, and uniformly carrying out mixing to obtain a foam precursor solution; drying the foam precursor solution, then crushing the dried solid product to obtain polyester ammonium salt powder, and carrying out foaming and a preliminary imidization reaction to prepare partially imidized polyimide foam; and cutting the partially imidized polyimide foam, then carrying out thermal compounding on the cut product and a reinforcing material, and then carrying out a complete imidization reaction on the product obtained after the thermal compounding to obtain the polyimide foam compositematerial. The polyimide foam composite material provided by the invention has good flame retardancy, heat insulation performance, scratch resistance, and tear and tensile properties, and is low in smoke production amount during high-temperature baking and decomposition;

Owner:BEIJING RADIATION APPL RES CENT

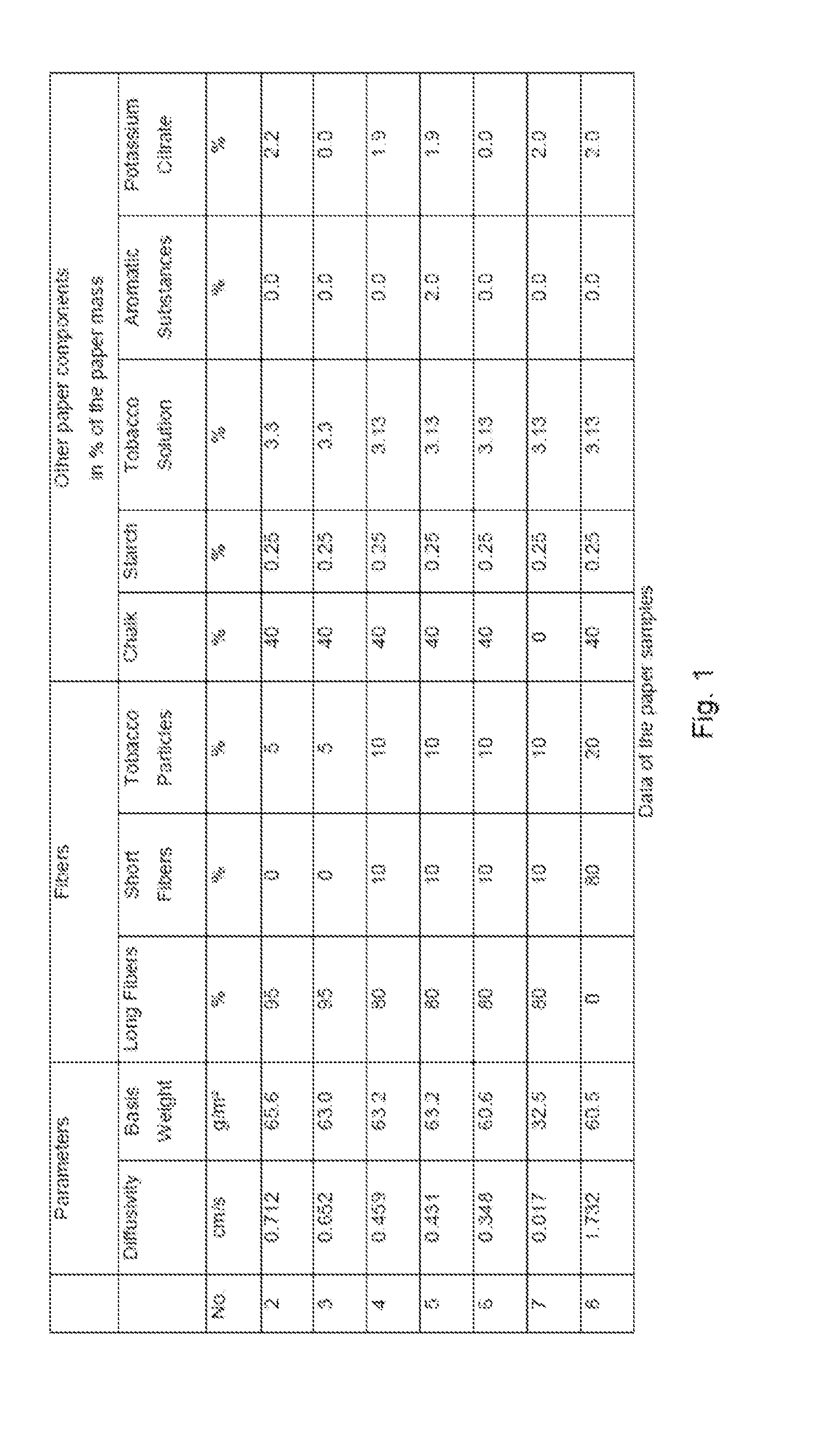

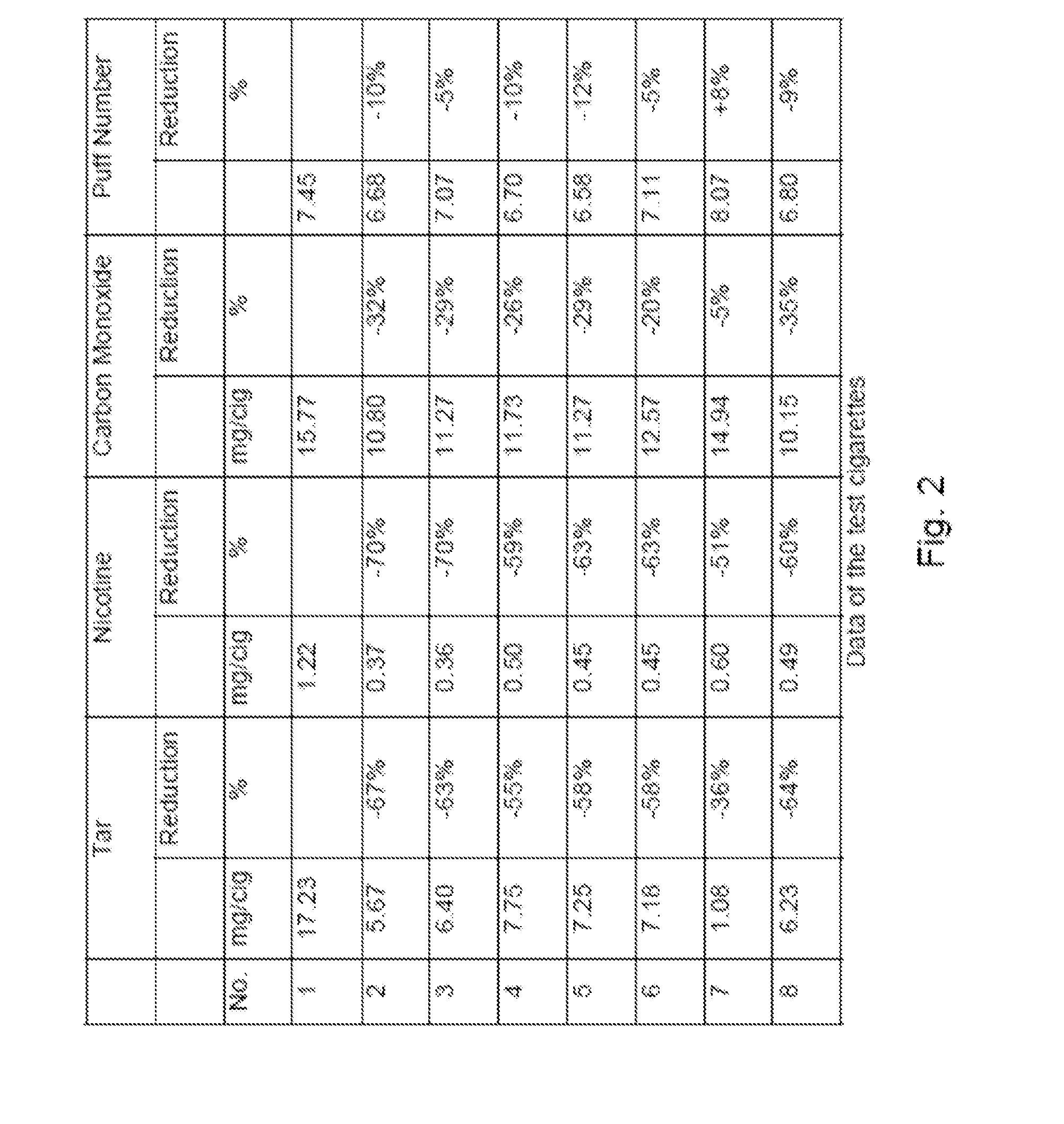

Paper Filled with Tobacco Particles

ActiveUS20140326262A1Reduction of smoke yieldTasteTobacco preparationTobacco treatmentFiberPulp and paper industry

Owner:DELFORTGROUP

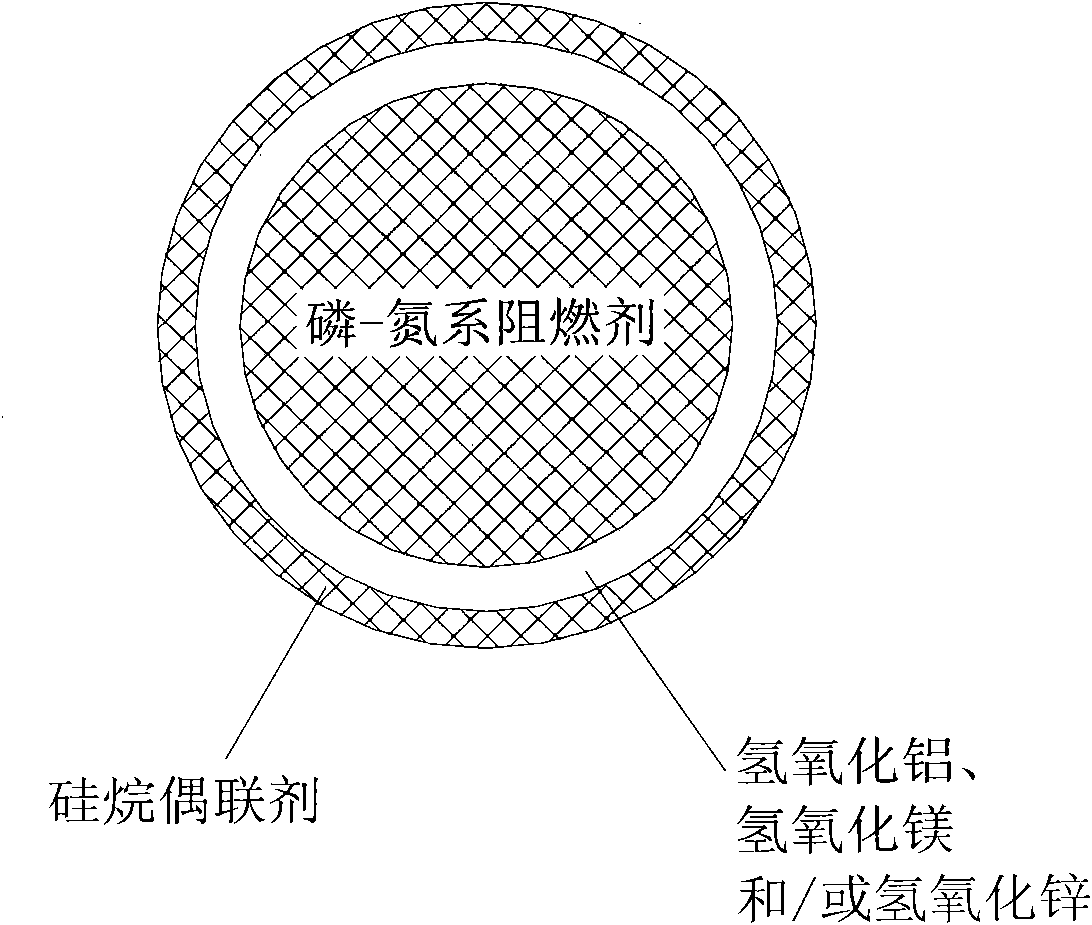

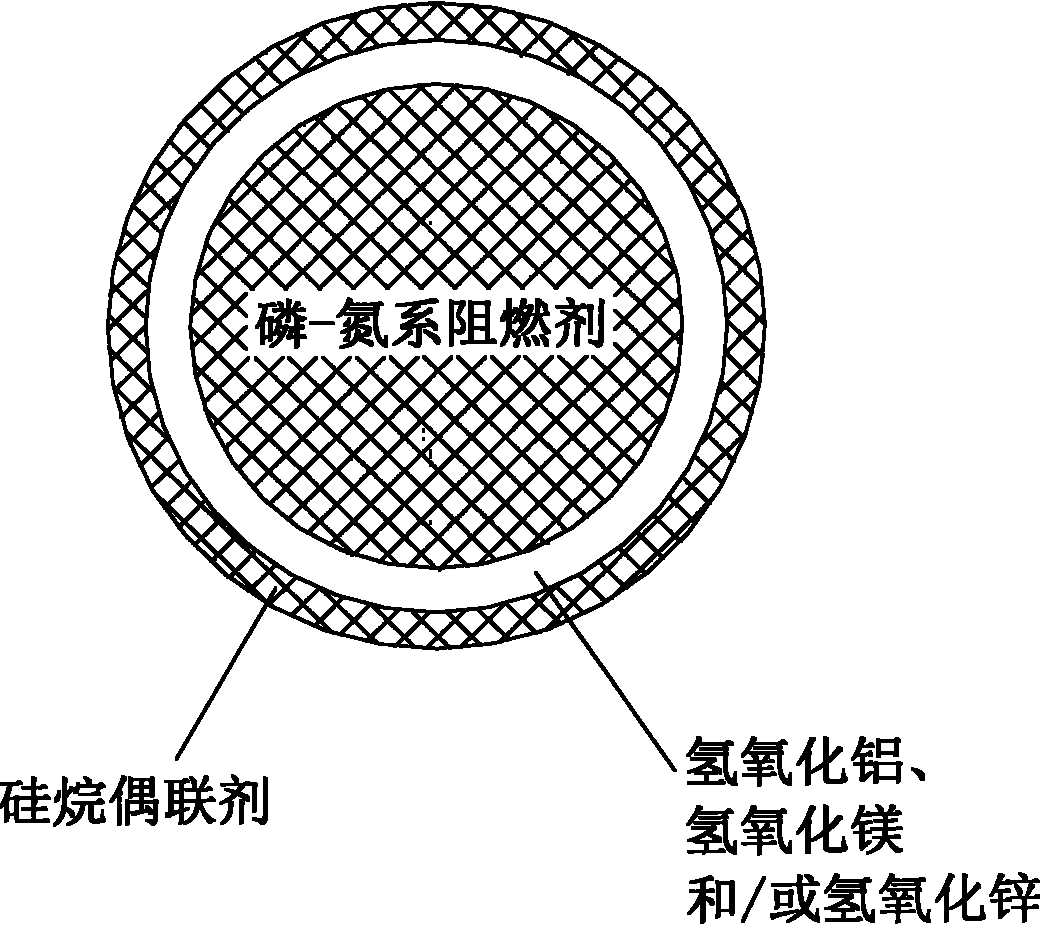

Low-smoke halogen-free flame-retardant waterproof board, drain board and preparation method thereof

ActiveCN107793630AImprove mechanical propertiesIncreased self-extinguishing performanceElastomerLinear low-density polyethylene

The invention provides a low-smoke halogen-free flame-retardant waterproof board or drain board, which comprises the following raw materials in parts by weight: 30-90 parts of ethylene-vinyl acetate copolymer, 20-50 parts of linear low-density polyethylene, 1-50 parts of high-density polyethylene, 0.5-5 parts of a silane coupling agent, 5-45 parts of an elastomer POE15, 10-60 parts of nano magnesium hydroxide, 5-40 parts of a phosphorus-nitrogen flame retardant, 0.01-3 parts of an ultraviolet absorber and 0.5-1.5 parts of an antioxidant. The waterproof board provided by the invention is an equal-thickness flat plate with smooth two surfaces; and the drain board is a flat plate with one side being smooth and the other side provided with solid bosses arranged regularly. The invention also provides a preparation method of the waterproof board or the drain board. The waterproof board or the drain board provided by the invention has good flame-retardant property and mechanical property.

Owner:METALS & CHEM RES INST CHINA ACAD OF RAILWAY SCI +1

High-performance intumescent sandwich-structure ultrathin fireproof anticorrosive composite coating for steel structures and preparation method thereof

ActiveCN112940611AEffective combinationPlay effectivelyFireproof paintsAnti-corrosive paintsWeather resistanceCeramic coating

The invention discloses a high-performance intumescent sandwich-structure ultrathin fireproof anticorrosive composite coating for steel structures and a preparation method thereof. The composite coating is characterized in that organic silicon ceramic coatings are used as a bottom layer and a surface layer, intumescent fireproof coatings are used as middle layers, and the organic silicon ceramic coatings and the intumescent fireproof coatings are alternately arranged; the total number of the organic silicon ceramic coatings and the expansion fireproof coatings is at least three; and the multilayer structure is subjected to a polymer cross-linking reaction to form the composite coating with a sandwich structure. The composite coating provided by the invention has the advantages of ultra-thin and long fire-resistant effects, good hardness, wear resistance, weather resistance and decorativeness, relatively simple construction, and great application prospect and market potential.

Owner:ZHEJIANG UNIV HANGZHOU GLOBAL SCI & TECH INNOVATION CENT

Smoke-free moxibustion moxa stick with effects of activating blood circulation and promoting menstruation and preparation method thereof

InactiveCN106822316ARelieve painQuick resultsDevices for heating/cooling reflex pointsAntipyreticJoint arthralgiaMugwort

The invention relates to a smoke-free moxibustion moxa stick with effects of activating blood circulation and promoting menstruation and a preparation method thereof. The smoke-free moxibustion moxa stick is prepared from the following raw materials in parts by weight: 1000 to 1100 parts of mugwort leaf, 40 to 60 parts of Chinese angelica, 30 to 50 parts of fructus evodiae and 1 to 10 parts of rhizoma chuanxiong. The smoke-free moxibustion moxa stick and the preparation method have the advantages that by adding the Chinese angelica, the fructus evodiae and the rhizoma chuanxiong, the amenorrhea and dysmenorrheal, deficiency-cold stomachache and rheumatic arthralgia can be effectively treated, and the moxibustion is convenient; the effects of activating blood circulation and promoting menstruation can be realized without using other medicines, and the pain of the patient caused by medicine taking is reduced; the convenience in use is realized, the cost is reduced, and the smoke-free moxibustion moxa stick is suitable for all ages of patients.

Owner:河南忠澜艾瓷文化开发有限公司

A kind of high flame retardant and low smoke toxicity sheet molding compound and its preparation method

InactiveCN101514254BFully dispersedImprove flame retardant performancePlastic materialsFire retardant

Owner:BEIJING ZHONGTIE LONGDRAGON ADVANCED COMPOSITE MATERIAL

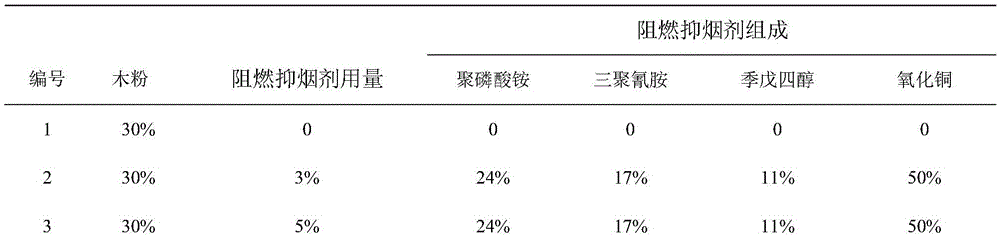

Composite halogen-free flame-retardant smoke suppression agent of PVC wood-plastic composite material and preparation method and application of agent

InactiveCN105566811AAdvantages of flame retardant and smoke suppression effectAdd lessPentaerythritolCombustion

The invention relates to a composite halogen-free flame-retardant smoke suppression agent of a PVC wood-plastic composite material and a preparation method and application of the agent, which relate to the composite halogen-free flame-retardant smoke suppression agent and the preparation method and application of the agent, and aim at solving the problems that the PVC wood-plastic composite material is combustible, a great amount of smoke is produced when the composite material is combusted, the addition amount of the existing PVC wood-plastic composite material flame-retardant smoke suppression agent is large, the flame-retardant effect and the smoke suppression effect are poor, and the existing PVC wood-plastic composite material flame-retardant smoke suppression agent is harmful to the health of people. The composite halogen-free flame-retardant smoke suppression agent consists of ammonium polyphosphate, melamine, pentaerythritol and copper oxide. The preparation method comprises the following steps: I, preparing an expansion-type flame-retardant agent; II, preparing the composite halogen-free flame-retardant smoke suppression agent. The application method comprises the following steps: I, weighing raw materials; II, preparing high-temperature materials; III, preparing a premix; IV, extruding and forming. The flame-retardant smoke suppression agent solves the problems that the wood-plastic composite material is combustible, a great amount of smoke is produced when the composite material is combusted, the addition amount of the existing flame-retardant smoke suppression agent is large, the effect is poor, and the existing flame-retardant smoke suppression agent is harmful to the health of people. The composite halogen-free flame-retardant smoke suppression agent is used for resisting the combustion and suppressing the smoke of the PVC wood-plastic composite material.

Owner:白晓艳

Fast-gelling plasticizer preparations

InactiveUS20090197998A1Reduce flammabilityReduce smoke productionOther chemical processesArylPolymer science

The invention relates to fast-gelling plasticizer preparations comprising at least one aryl alkylsulfonate of the formula R1—SO2—O—R2 and at least one diol dibenzoate of the general formula R3C(O)O—Y—O(O)CR4 and / or at least one dibenzyl dicarboxylate of the general formula R3CH2O(O)C-Z-C(O)OCH2R4, and also to its use as plasticizer in plastics, and to plastics which comprise these plasticizer preparations.

Owner:LANXESS DEUTDCHLAND GMBH

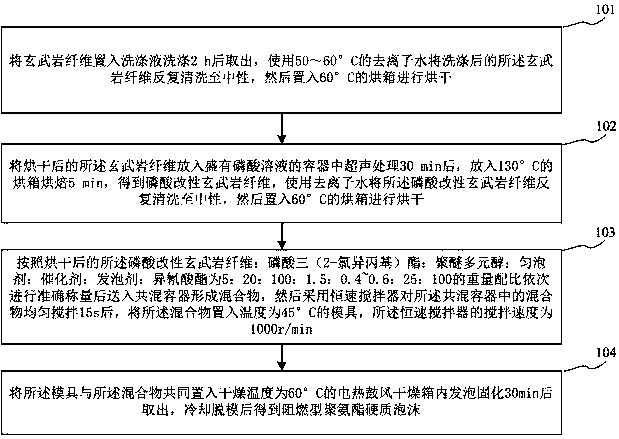

Flame-retardant type polyurethane rigid foam and preparation method thereof

InactiveCN109054355AImprove mechanical propertiesImprove flame retardant and smoke suppression performancePhosphoric acidBasalt fiber

The invention discloses a flame-retardant type polyurethane rigid foam and a preparation method thereof, and relates to the technical field of processing of materials. The flame-retardant type polyurethane rigid foam and the preparation method have the advantages that the surface of basalt fiber is modified by phosphoric acid to obtain the phosphoric acid-modified basalt fiber, so that the surfaceactivity of the basalt fiber is improved; the phosphoric acid-modified basalt fiber is mixed with phosphotriester-(2-isopropyl chloride) to form a flame-retardant agent for preparing the flame-retardant type polyurethane rigid foam, so as to solve the problems of poor compatibility and low mechanical property due to direct compounding of the basalt fiber and the polyurethane rigid foam matrix, and reach the technical effects of accelerating the formation of a crosslinking network of a polyurethane foam system and improving the mechanical property of the flame-retardant type polyurethane rigidfoam; the phosphoric acid-modified basalt fiber and the phosphotriester-(2-isopropyl chloride) as the flame-retardant agent can be uniformly dispersed into the flame-retardant type polyurethane rigidfoam matrix, so as to reduce the heat release rate and smoke production amount of the polyurethane foam, and reach better flame-retardant and smoke-inhibiting properties of the polyurethane foam.

Owner:JIAXING UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com