Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

202results about How to "Dilution concentration" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-strength environment-friendly flame-retarding fiberboard and manufacturing method thereof

ActiveCN101905475AReduce the temperatureDelay in pyrolysis combustion reactionWood working apparatusDomestic articlesFiberSocial benefits

The invention discloses a high-strength environment-friendly flame-retarding fiberboard which comprises the following raw materials of plant fibers, flame retardants, adhesives and waterproofing agents, wherein the weight ratio of the plant fibers to the flame retardants to the adhesives to the waterproofing agents is 100:(3-30):(3-30):(0.1-4). The invention also discloses a manufacturing method of the high-strength environment-friendly flame-retarding fiberboard. Not only are the mechanical properties of the flame-retarding fiberboard obviously improved, but also the combustion property can conform to the regulations of GB8624 Class B or Class C, and the formaldehyde emission, the smoke volume produced and the smoke toxicity are also reduced. Thus, the high-strength environment-friendly flame-retarding fiberboard has good quality and low price, can be widely applied to the fields of building furnishings, flame-retarding furniture production, flame-retarding floor production, wooden fireproof door production, ship and vehicle furnishings and the like, and has good economical and social benefits.

Owner:北京盛大华源科技有限公司 +1

Coal tar hydrogenation system and coal tar hydrogenation method

ActiveCN103571533AExtend your lifeReduce adverse effectsTreatment with hydrotreatment processesHydrogenGas phase

The invention provides a coal tar hydrogenation system and a coal tar hydrogenation method. The method comprises a hydrogenation refining reactor, a separation unit and a hydrogenation cracking reactor, wherein the hydrogenation refining reactor is an up-flow fixed bed reactor, the hydrogenation cracking reactor is a down-flow fixed bed reactor, and the separation unit is a middle liquid separation tank; gas-liquid separation is performed on raw oil and hydrogen after a hydrogenation refining reaction, a part of liquid-phase heavy fractions is separated, one path is used as circulating oil and returned to perform the hydrogenation refining reaction again, and the other path is used as quenching oil after being cooled and added between catalyst bed layers for the hydrogenation refining reaction to play a role of cooling; and the other part of the liquid-phase heavy fractions is used as refined generated oil and mixed with hydrogen to perform a hydrogenation cracking reaction, and the obtained reaction product is combined with gas-phase light fractions after the gas-liquid separation to form the final product. The system and the method provided by the invention are low in equipment cost, simple to operate, capable of prolonging the life of the catalysts of the hydrogenation refining reactor and the hydrogenation cracking reactor, and suitable for raw oil with worse conditions.

Owner:CHINA PETROCHEMICAL CORP +1

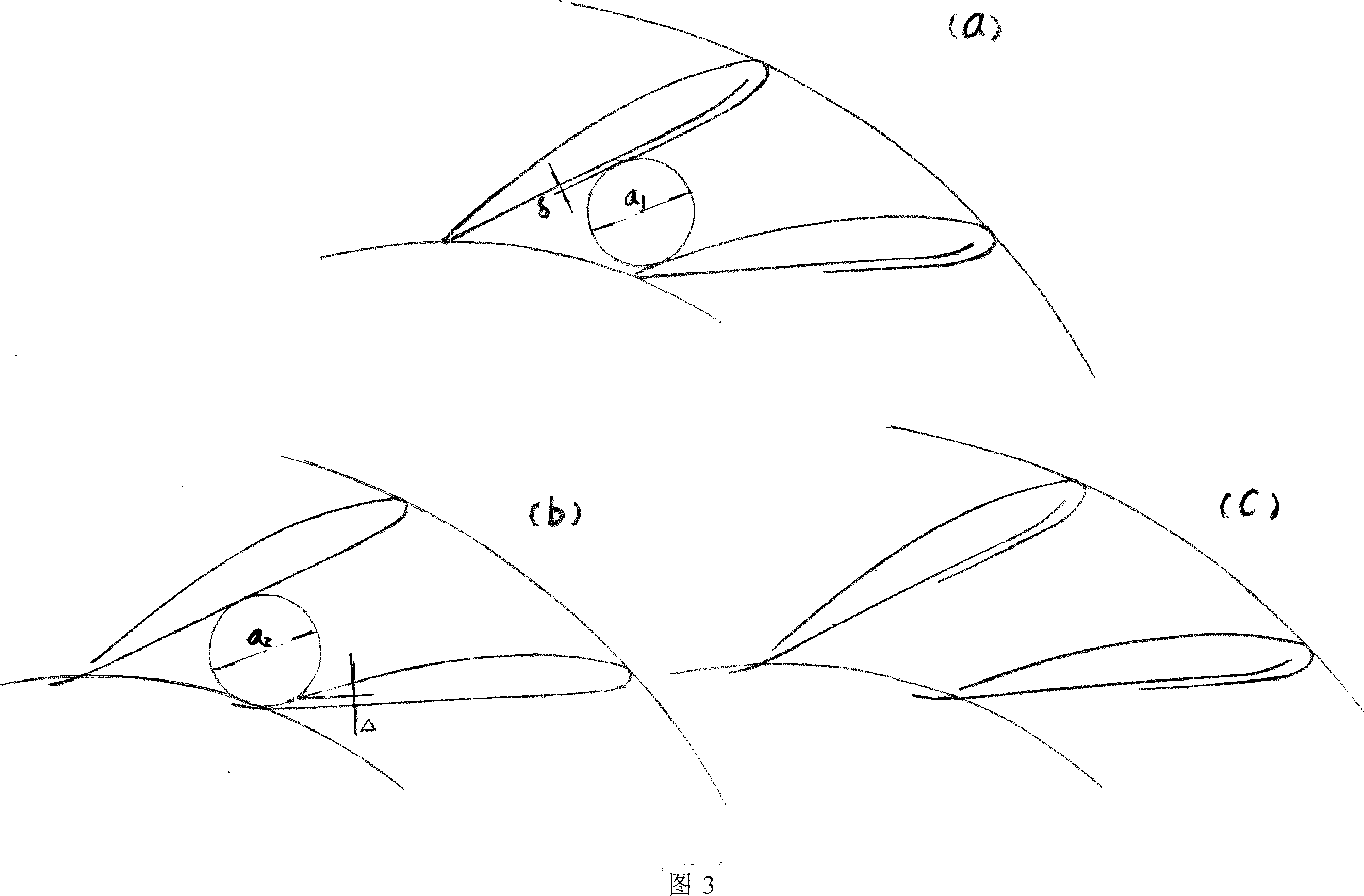

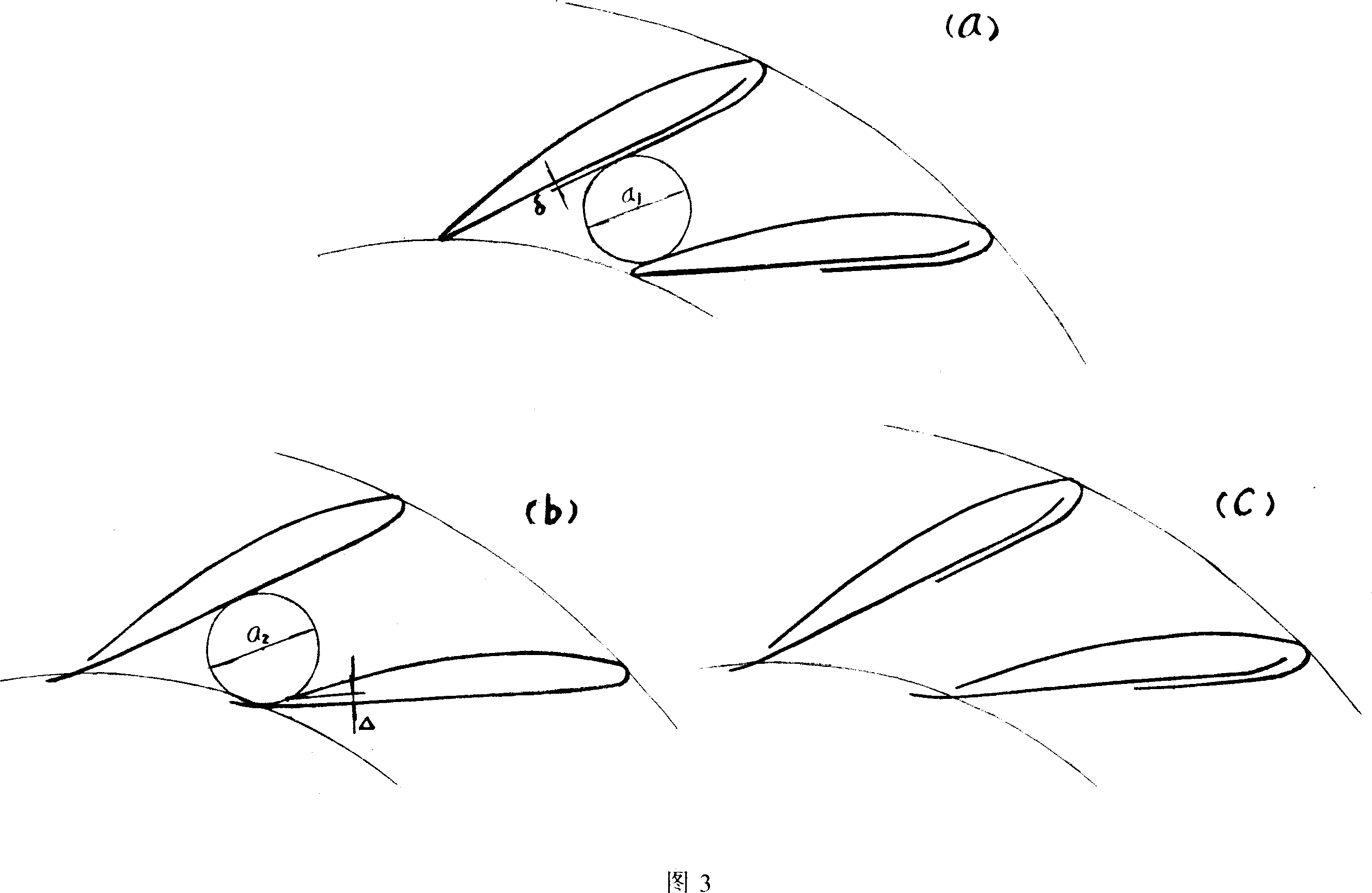

Outlet flowing intersecting surface changing adjustable turbo nozzle ring

InactiveCN101113678ALow efficiencyLarge leak lossInternal combustion piston enginesEngine componentsExternal energyTurbocharger

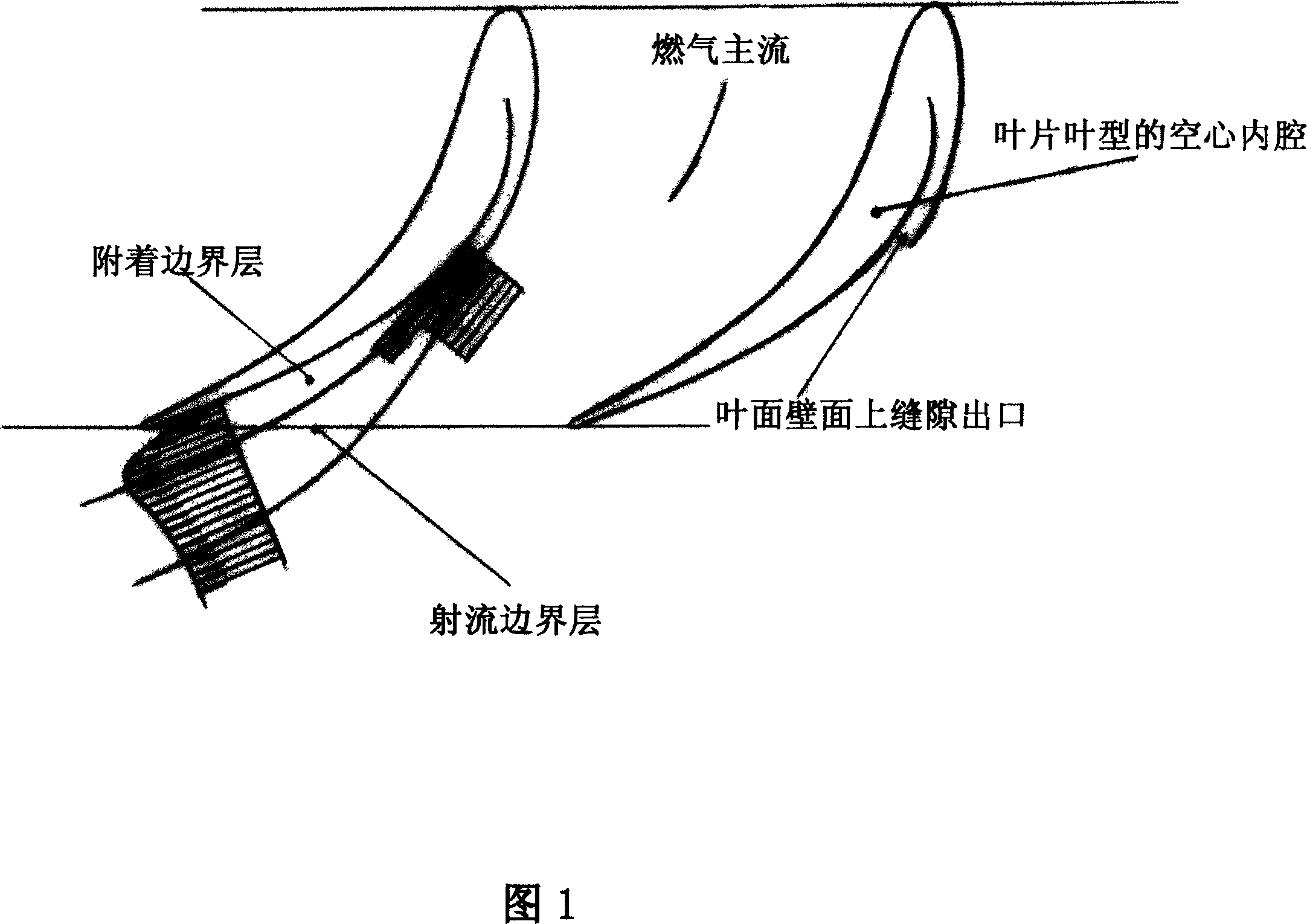

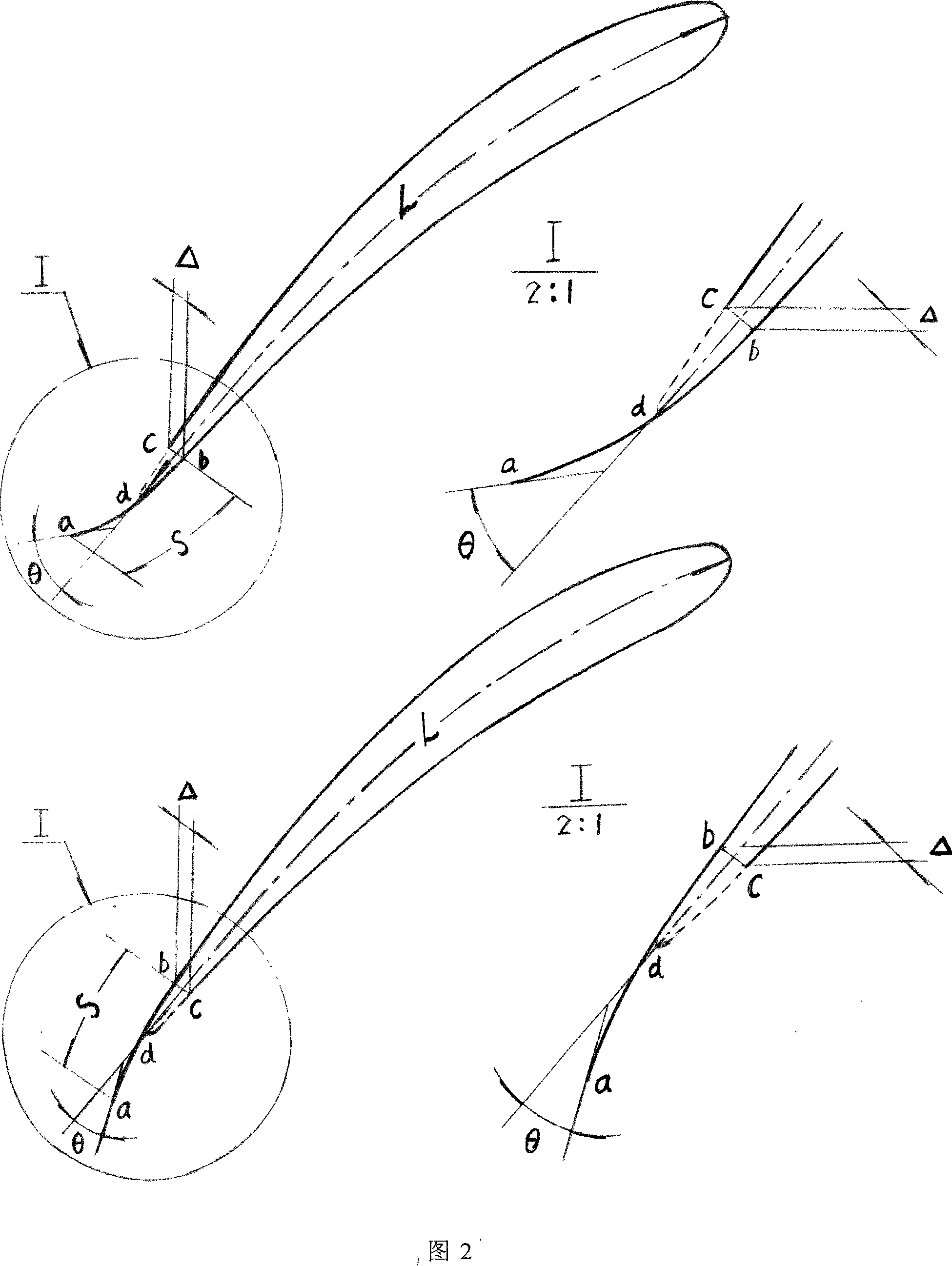

The invention relates to a turbine nozzle ring used in turbochargers. Compressed air from an outlet of an air compressor of the turbocharger and / or an external source goes through a hollow internal cavity of the nozzle vanes or a hollow sandwich near the internal wall of an intake pipe of a vane-less spiral case and blows directly to the nozzle vane ring or main burning gas flow at a flow passage and / or an outlet of the vane-less spiral case through a ventilation groove gap cut between a vane-shaped back side (or front side) and / or a rear margin part or through circular arc-shaped ventilation gap of the outlet of the hollow sandwich near the zero-degree section of the tip of the vane-less spiral case, making the mixed air of blowing flow from the gaps and the main flow change the flow direction at the outlet of the nozzle ring and causing the change of the flow angle (namely flow section) at the outlet. The invention has the advantages of wide range of control simple structure, low cost, safety and reliability, high efficiency, straightforward control and being applicable for turbochargers and being capable of making use of external air, additional pressure and external energy to supply auxiliary power.

Owner:孙敏超 +1

Changeable outlet flow section turbine jet nozzle ring

InactiveCN101050722ASmall footprintReduce manufacturing costInternal combustion piston enginesAirflowExternal combustion engine

The present invention belongs to the field of internal combustion engine turbocharging technology, in particular, it relates to a turbine nozzle ring used in turbocharger. Said invention provides the working principle of said turbine nozzle ring, and also provides the concrete structure of said turbine nozzle ring and its manufacture method.

Owner:孙敏超

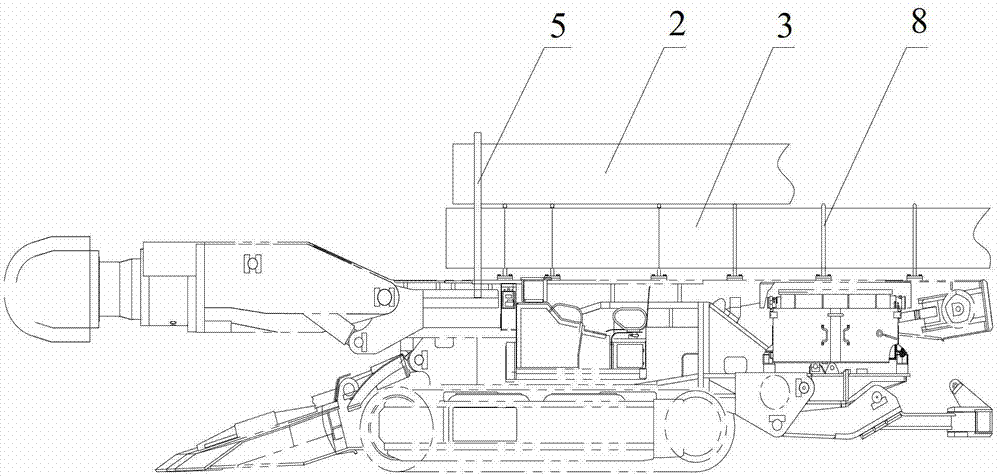

Roadway construction equipment and dust removing device thereof

ActiveCN102966367ADilution concentrationAvoid safety issues such as explosionsDust removalFire preventionAir currentGas concentration

The invention discloses roadway construction equipment and a dust removing device thereof. The dust removing device comprises a negative-pressure wind-cone, a dust removing fan, a dust remover, an air curtain mechanism and a positive-pressure wind-cone, wherein the air curtain mechanism is arranged on the roadway construction equipment or the roadway inner wall of roadway construction equipment operation; the air curtain mechanism is used for ejecting air current into a roadway to form a dust-blocking air curtain for isolating the control chamber of the roadway construction equipment from a tunneling work surface; the positive-pressure wind-cone is arranged on the roadway construction equipment or the roadway inner wall; the exhaust end of the positive-pressure wind-cone is arranged between the dust-blocking air curtain and the tunneling work surface; the exhaust end of the positive-pressure wind-cone points to the tunneling work surface; and the air sucking end of the negative-pressure wind-cone is arranged between the dust-blocking air curtain and the tunneling work surface. According to the dust removing device disclosed by the invention, air is supplied to the tunneling work surface through the positive-pressure wind-cone for blowing gas near the tunneling work surface away and lowering the gas concentration on the tunneling work surface, so that safety problems of explosion and the like possibly caused by the accumulation of gas on the tunneling work surface to a certain degree are avoided.

Owner:SANY HEAVY EQUIP

Turbine nozzle ring with adjustable and variable outlet flowing angle

InactiveCN102094705ASmall footprintReduce manufacturing costInternal combustion piston enginesStatorsJet flowTurbocharger

The invention relates to a turbine nozzle ring in a turbocharger. Pressurized air flowing out from an outlet manifold bypass of an air compressor of the turbocharger per se and / or compressed air of an external air source (or exhaust fuel gas flowing out from an outlet manifold bypass of an exhaust pipe of an internal-combustion engine) passes through the hollow cavity of a nozzle blade or a hollow interlayer nearby the inner wall of a bladeless volute inlet pipe, and jets and blows a nozzle blade ring or the interior of a bladeless volute runner and / or a main fuel gas flow in a downstream way from a blade profile back (or ventral face) and / or a through-flow slit cut at the tail edge part (a jet deflection arc guide plate is connected to the back of the tail edge slit) or an annular arc through-flow gap at a hollow interlayer outlet nearby the zero-degree section of a bladeless volute tongue tip and the jet deflection arc guide plate connected thereafter, so that the air flow formed by mixing the gap jet flow and the main flow generates flow direction deflection at the outlet of the nozzle ring to cause the change of an outlet airflow angle (namely outlet flowing section area). The turbine nozzle ring has the advantages of high control strength, simple structure, low cost, safety, reliability, high efficiency, convenience for control and applicability for the gasoline engine turbocharger, and the additional air has the functions of additional pressurization and auxiliary energy application.

Owner:孙敏超 +1

Preparation method for solid freshener

ActiveCN106860898AGood air purification effectReduce releaseBiocideDead animal preservationChlorine dioxideAir purifier

The invention belongs to the field of an air freshener and especially relates to a preparation method for a solid freshener. The method comprises the following steps: (1) preparing a stable chlorine dioxide solution; (2) preparing a colloid activating agent; (3) preparing microcapsule essence particles; (4) preparing the solid freshener. The solid freshener prepared according to the preparation method provided by the invention has an excellent air purifying effect; the essence powder is prepared from natural green plants and is green and safe; a microcapsule technique is cooperatively used for slowly releasing the fragrant active materials at a constant speed, so that the purpose of improving air quality can be achieved.

Owner:宁波宝和日化有限公司

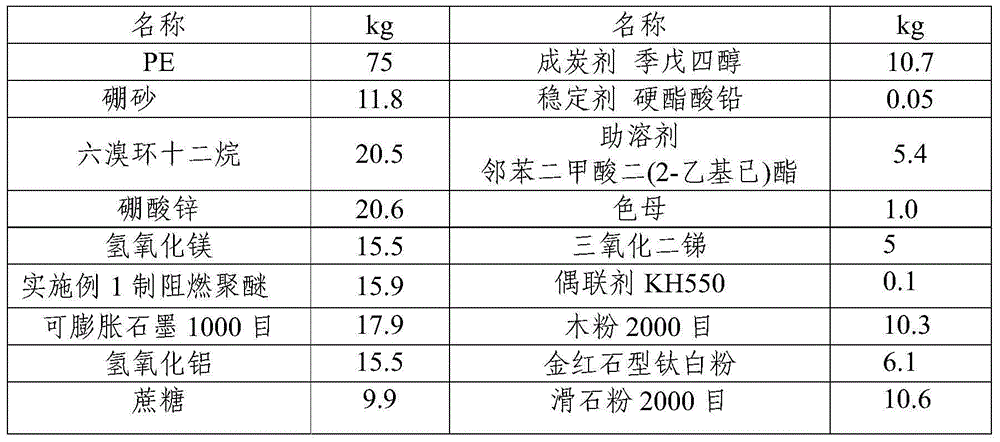

Polyethene flame resistant material and preparation method thereof

InactiveCN104610629ASlow down decompositionAvoid conductionBulk chemical productionGas phaseAntimony trioxide

The invention provides a polyethene flame resistant material. The polyethene flame resistant material is prepared from the following components in parts by weight: 70-100 parts of polyethene, 10-15 parts of a char forming agent, 10-15 parts of sodium borate, 0.01-0.5 part of a stabilizing agent, 10-30 parts of hexabromocyclododecane, 8-12 parts of talcum powder, 4-10 parts of a solubilizer, 15-25 parts of zinc borate, 0.1-3 parts of color masterbatch, 20-40 parts of hydroxide, 1-10 parts of antimony trioxide, 15-20 parts of flame resistant polyether, 0.05-0.5 part of a coupling agent, 10-20 parts of inflatable graphite, 8-15 parts of wood powder, 5-10 parts of titanium dioxide, 5-10 parts of cane sugar, and 1-5 parts of molybdenum trioxide. According to the invention, an expansion method, a gas phase method, a physical phase method and a chemical method are combined to prepare flame resistant PE high polymer which achieves an A-class fire-proof material, the operation is simple, and the mechanical property and the fire-proof property of products are both excellent.

Owner:SHENDUN FIREPROOF TECH

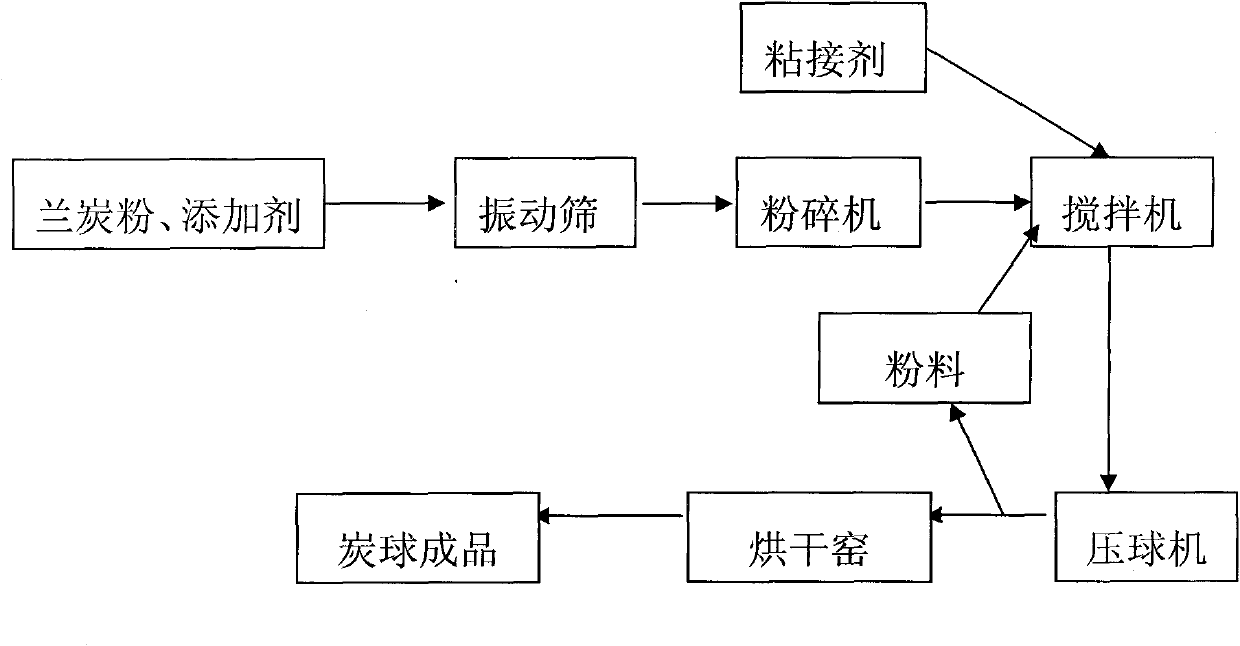

Method for pressing semicoke powder used for producing calcium carbide

InactiveCN101792685AHigh fixed carbon contentHigh strengthSolid fuelsResource utilizationRoom temperature

The invention discloses a method for pressing semicoke powder used for producing calcium carbide, which comprise: mixing 82 to 91 weight percent of semicoke powder, 7 to 9 weight percent of additive and 2 to11 weight percent of binder, adding the mixture into a stirrer to stir the mixture at room temperature for 2 to 5 minutes, processing and forming the mixture, drying the formed product to obtained the finished product, wherein the additive is rich coal; the binder for forming the semicoke powder is prepared by mixing 20 to 30 weight percent of solution of sodium hydroxide, 20 to 30 weight percent of solution of urea and 40 to 60 weight percent of corn starch and by adding hot water at 60 to 80 DEG C during mixing; and the concentration of the solution of sodium hydroxide is 0.1 to 5 percent and the concentration of the solution of urea is 0.1 to 5 percent. The product of the invention has high cold strength, can be fed in a furnace in batch in place of semicoke, avoids the yield and quality of smelted calcium carbide, reduces the production cost of the calcium carbide, improves resources utilization rate and has high use and promotion values.

Owner:丹江口福安运输有限责任公司

Polyvinyl chloride A-grade fire-retardant interior decoration material

The invention provides a polyvinyl chloride A-grade fire-retardant interior decoration material. The polyvinyl chloride A-grade fire-retardant interior decoration material is prepared from the following raw materials in parts by weight: 60-80 parts of polyvinyl chloride, 3-5 parts of melamine, 15-25 parts of wood powder, 1.1-2.2 parts of molybdenum trioxide, 8-11 parts of tetrabromo-bisphenol-A, 0.5-1.0 part of dicyclopentadienyl iron, 13-27 parts of hexabromocyclododecane, 2-5 parts of a plasticizer, 10-22 parts of zinc borate, 2-5 parts of a cosolvent, 20-40 parts of hydroxide, 0.6-1.8 parts of colour masterbatch, 10-15 parts of flame-retardant polyether, 30-60 parts of calcium carbonate, 5-10 parts of sodium carbonate, 5-9 parts of ammonium polyphosphate, 5-9 parts of brominated epoxy resin and 10-15 parts of expanded graphite. The polyvinyl chloride A-grade fire-retardant interior decoration material is environment-friendly and energy-saving, does not absorb water and is non-combustible and wear-resistant, the process is simple, the dimensional stability is good, and anti-compression creep property is good; meanwhile, the A-grade fire prevention standard in the national standard, Code for Fire Prevention in Design of Interior Decoration of Buildings, of the People's Republic of China GB 50222-95 can be met.

Owner:SHENDUN FIREPROOF TECH

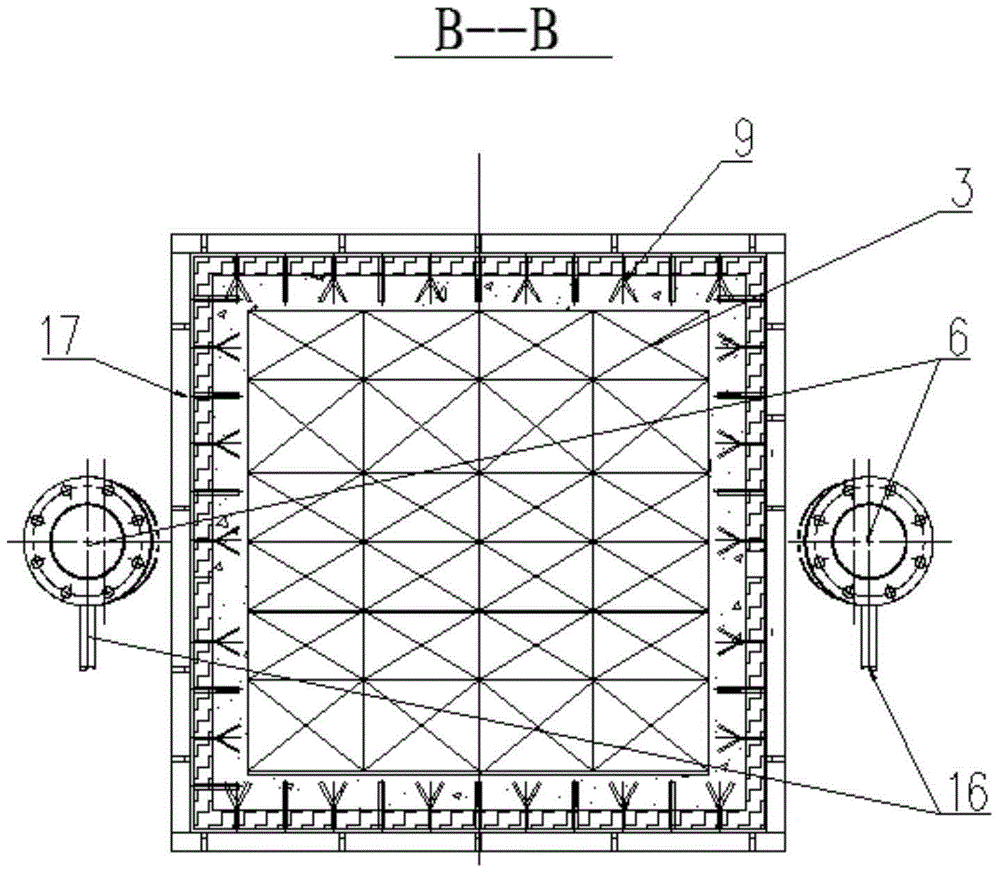

Multi-stream, high-temperature and low-oxygen and low NOx horizontally combined type single heat storage burner

InactiveCN105202543AReduce burning rateExtend the flame lengthIndirect carbon-dioxide mitigationGaseous fuel burnerSteel platesEngineering

The invention provides a multi-stream, high-temperature and low-oxygen and low NOx horizontally combined type single heat storage burner and belongs to the technical field of single heat storage combustion devices on heating furnaces and heat treatment furnaces. The burner comprises a porous burner block, an air heat storage box, a heat storage body and a coal gas spray pipe; the porous burner block and a furnace wall are formed by pouring the same refractory castable integrally; the porous burner block is mounted at the front end of the air heat storage box; the heat storage body is mounted in the air heat storage box; the coal gas spray pipe is mounted in the air heat storage box; the front end of the air heat storage box extends into the furnace wall for 150 mm and is welded to a furnace wall steel plate. The burner has the advantages as follows: combustion air can be preheated to 1000 DEG C or above, preheating efficient recycling is realized and fuel consumption is reduced. Meanwhile, a lean oxygen combustion mechanism is adopted, so that lean oxygen combustion of fuel in the furnace is realized, generation of NOx is effectively restrained in the combustion process and pollutant discharge is reduced greatly.

Owner:BEIJING SHOUGANG INT ENG TECH

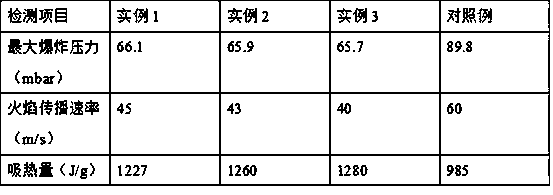

Preparation method of hydrotalcite-like compound-based powder explosion suppressant

InactiveCN108843378AHigh adsorption activityDilution concentrationDust removalFire preventionCompound matrixHydrotalcite

The invention relates to a preparation method of a hydrotalcite-like compound-based powder explosion suppressant, and belongs to the technical field of explosion suppressant preparation. The preparation method comprises the following steps: taking silkworm cocoons as a raw material; putting the silkworm cocoons into a grinder to carry out grinding and soaking the grinded silkworm cocoons by usingdopamine solution; mixing the soaked silkworm cocoons with a metal sale solution; adding a complexing agent to carry out a hydrothermal reaction; calcining a product obtained via the hydrothermal reaction to obtain a hydrotalcite-like compound matrix; and finally mixing the hydrotalcite-like compound matrix with metallothionein and urea so as to finally obtain the powder explosion suppressant. Theobtained powder explosion suppressant is good in explosion suppression performance and extremely strong in explosion energy adsorption capability, and has a wide application prospect.

Owner:FOSHAN LINGCHAO NEW MATERIAL CO LTD

Preparation method for modified magnesium-aluminium hydrotalcite cable fillers

InactiveCN108314821AImprove corrosion resistanceImprove high temperature resistancePlastic/resin/waxes insulatorsHeat resistanceHydrotalcite

The invention discloses a preparation method for modified magnesium-aluminium hydrotalcite cable fillers and belongs to the technical field of preparation of cable fillers. The preparation method disclosed by the invention has the beneficial effects that firstly a tetraethoxysilane hydrolysis method is utilized for preparing silica sol, and since the silica sol contains silicon dioxide, oxygen inthe air can be effectively isolated from a base material to prevent contact; in addition, bismaleimide resin has heat resistance, and is easily cured on the polyethylene surface to form a triazine-ring structure, so that the compatibility of self-made magnesium-aluminium hydrotalcite with the base material is improved; meanwhile, the self-made magnesium-aluminium hydrotalcite particles are uniformly dispersed on the surface of the base material, so that the surface temperature of the base material is reduced and the flame-retardant effect is achieved; furthermore, in the heat-absorbing and decomposing process of the self-made magnesium-aluminium hydrotalcite, an alkali porous composite oxide is obtained, and can be combined with a carbonized product on the surface of the base material to form a protective film, so that the invasion of heat and oxygen can be effectively prevented, the flame retardance of the cable fillers can be further improved and the application prospect is wide.

Owner:谢新昇

Method for preparing low-phosphorus and low-titanium molten iron by mixed-smelting high-phosphorus iron ore and ilmenite by oxygen-rich top-blowing smelting reduction technology

InactiveCN102051427ASolve problems that are difficult to smeltLow costProcess efficiency improvementDolomiteCoal

The invention discloses a method for producing molten iron under oxygen-rich top-blowing condition by taking mixed high-phosphorus iron ore and ilmenite as raw materials, coal dust as a reducing agent and lime stone or dolomite as a fluxing agent, which comprises the following process steps of: crushing charging materials which are the high-phosphorus iron ore, the ilmenite, the dolomite, lime and reduction coal; proportioning and uniformly mixing the charging materials according to process parameters comprising the alkalinity R of 1.0 to 2.0 and the inner C / O mole ratio of 0.9 to 1.3, and preheating the charging materials; and feeding the charging materials into a smelting reduction furnace from a furnace side, producing the molten iron with relatively lower phosphorus content and relatively lower titanium content under the oxygen-rich top-blowing condition, and periodically discharging the molten iron and slag from a tap hole and a bleed hole. In the invention, the high-phosphorus iron ore and the ilmenite difficult to smelt in a conventional method are treated. The mixed smelting reduces a phosphorus load in the smelting of the high-phosphorus iron ore, can obtain the molten iron with lower phosphorus content, reduces the amount of foamed slag in the smelting of the ilmenite, and is favorable for stabilizing furnace conditions. The method is favorable for developing a great number of high-phosphorus iron ore and ilmenite resources stored in China and enhancing the international competitive power of steel enterprises of China.

Owner:KUNMING UNIV OF SCI & TECH

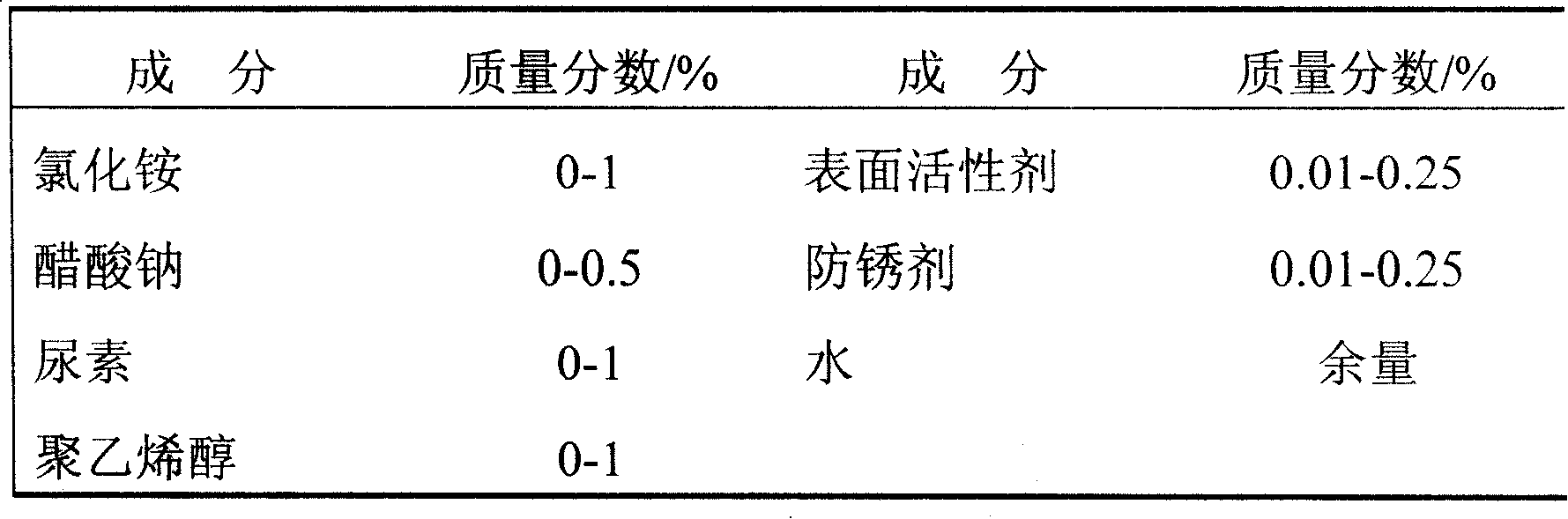

Water solution containing fine spray extinguishment additive agent and preparation and application

InactiveCN101214411AReduce the temperatureStrong penetrating powerFire rescueFire extinguisherSodium acetateCombustion

The invention relates to aqueous solution with fine water mist fire extinguishment additive, with the quality percentage of all components as below: ammonium chloride 0 percent to 1 percent, polyvinyl alcohol 0 percent to 1 percent, sodium acetate 0 percent to 0.5 percent, surface active agent 0.01 percent to 0.25 percent, urea 0 percent to 1 percent, rust preventive 0.01 percent to 0.25 percent, and the rest is water. The aqueous solution can improve the fire extinguishing efficiency of the fine water mist and effectively prevent after-combustion of inflamers; has little corrosion to equipments and instruments; basically has no pollution to fire scenes; is high-efficiency, stable and clean; the raw materials of all components are easy to be obtained; has stable performance; is basically nontoxic and low in cost; and has low consumption.

Owner:HENAN POLYTECHNIC UNIV

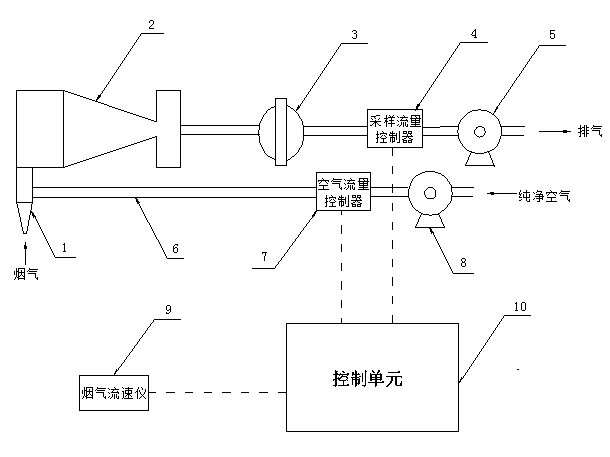

Smoke constant speed constant current sampling device and method

InactiveCN104390818ADilution concentrationAvoid corrosionWithdrawing sample devicesCurrent meterParticulates

The invention provides a smoke constant speed constant current sampling device. The sampling device comprises a sampling unit, an air supplementing unit and a speed measuring unit; the sampling unit comprises a sampling nozzle, a particulate matter cutter, a filter membrane clamp, a sampling flow rate controller and a sucking pump; the air supplementing unit comprises an air inlet pipe, an air flow rate controller and an air pump; the speed measuring unit comprises a smoke current meter. The invention also provides a method for sampling smoke at constant speed and constant current by utilizing the smoke constant speed constant current sampling device. By adopting the smoke constant speed constant current sampling device and method, the requirements of constant speed sampling and constant current sampling can be simultaneously met, the particulate matters such as PM10 or PM2.5 in the smoke of a fixed pollution source can be collected, the sampling nozzle does not need to be replaced in the sampling process, and automatic continuous sampling can be realized. By supplementing pure air, the concentration of the smoke can be diluted, the sampling device is prevented from being corroded by the smoke, accumulated dust in the sampling nozzle and pipelines can be cleaned by the pure air, and the sampling nozzle and the pipelines can be prevented from being blocked.

Owner:深圳睿境环保科技有限公司

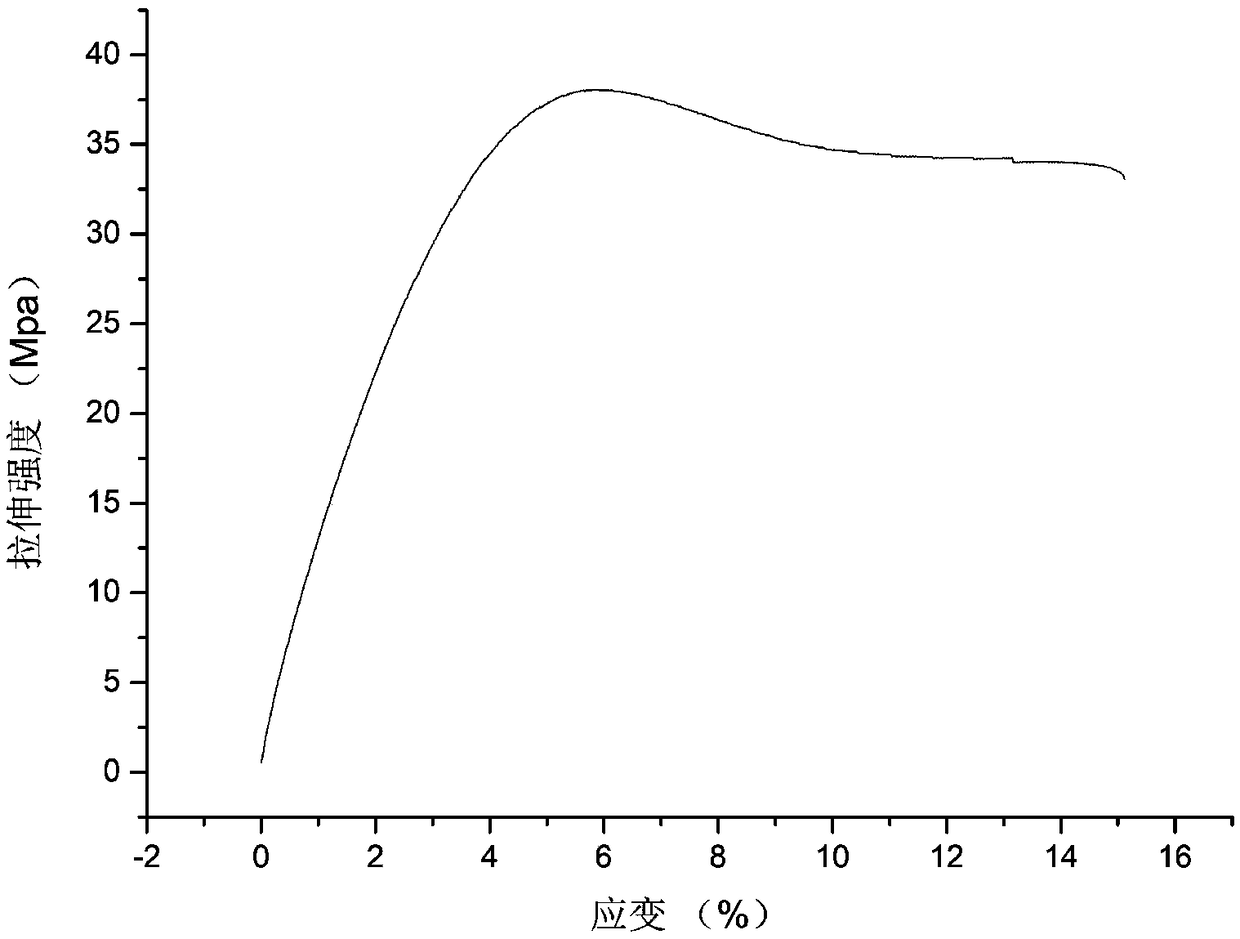

Self-toughened benzoxazine thermosetting resin and method for preparing same

The invention provides self-toughened benzoxazine thermosetting resin with structures shown as a formula I. The self-toughened benzoxazine thermosetting resin has the advantages that long alkyl chainsare led into chemical structures of benzoxazine, accordingly, toughening effects can be realized, and the self-toughened benzoxazine thermosetting resin has self-toughened characteristics; the long alkyl chains are led into the chemical structures of the benzoxazine in chemical bond forms, and accordingly the problem that the traditional added toughening agents are dissolved out due to poor compatibility can be effectively solved; the long alkyl chains are added into the self-toughened benzoxazine thermosetting resin, the concentration of oxazine rings can be diluted, and accordingly the curing temperature of the self-toughened benzoxazine thermosetting resin can be obviously lowered; the long alkyl chains are led into the structures of the benzoxazine, good internal plasticization effects can be realized, and accordingly the toughness of self-toughened benzoxazine thermosetting resin cured substances can be greatly improved.

Owner:GUIZHOU INST OF TECH +1

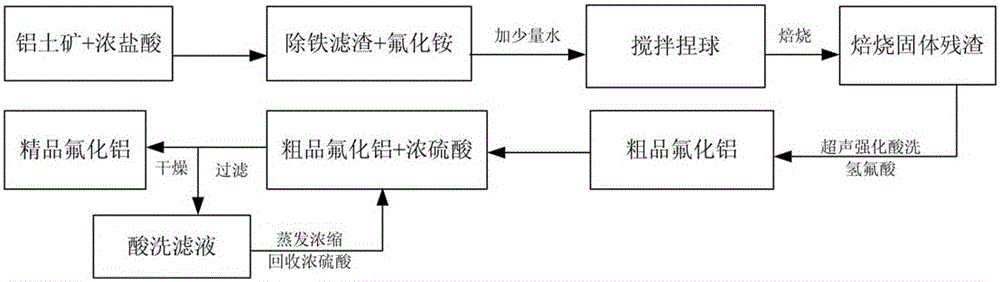

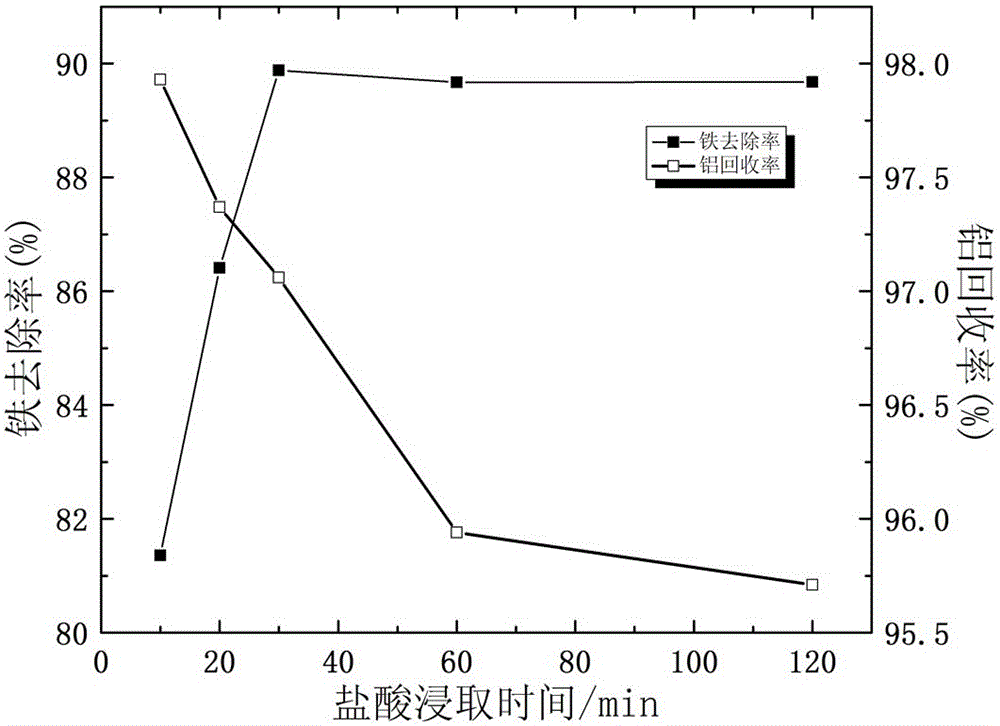

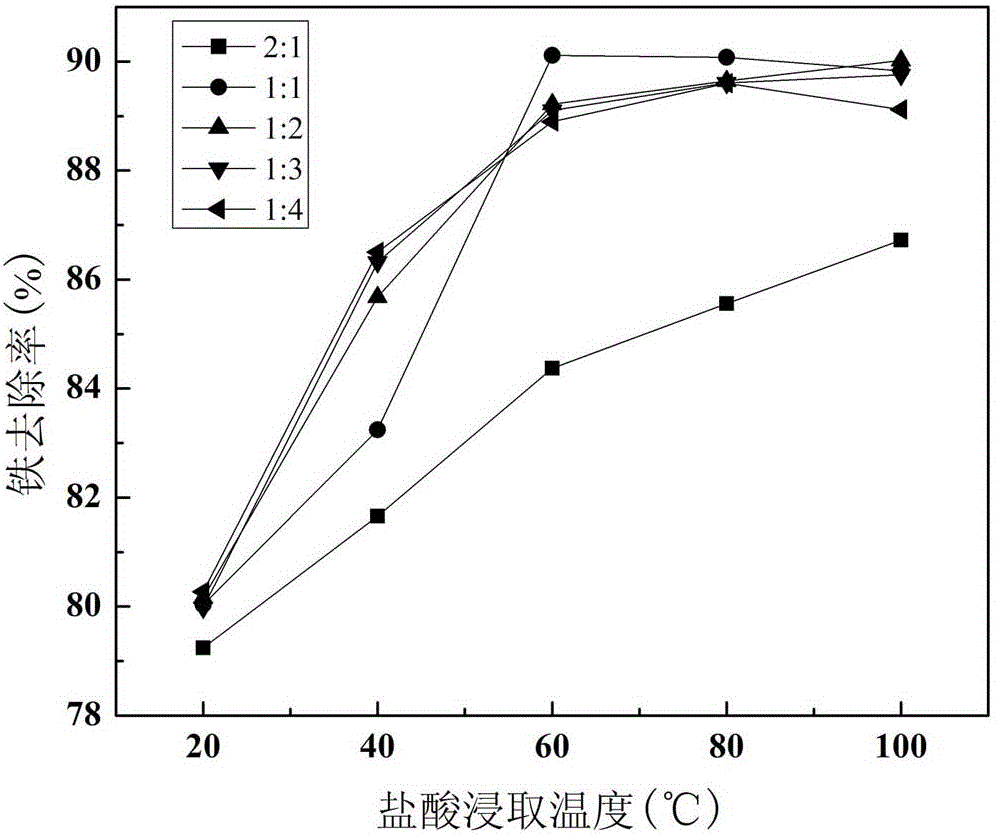

Method for preparing aluminium fluoride by utilizing low grade bauxite

The invention provides a method for preparing aluminium fluoride by utilizing low grade bauxite. The method mainly comprises the following steps: hydrochloric acid leaching to remove iron, stirring and ball kneading, high-temperature roasting to remove silicon, ultrasonic hydrofluoric acid washing and concentrated sulfuric acid washing to remove titanium. The method has the beneficial effects that the problem of how to effectively remove the impurities in the low grade bauxite, such as iron, silicon and titanium, to prepare fine aluminium fluoride is solved through the steps, so that the active ingredients in the low grade bauxite are fully utilized, thus improving the product quality and reducing the resource waste; and the method provided by the invention dispenses with pretreatment of the low grade bauxite, is mild in process conditions and is suitable for large-scale production.

Owner:洛阳国兴矿业有限公司

Method for producing hydroxypropyl methylcellulose

ActiveCN107098982AReduce energy consumptionImprove the mixing effectRotary stirring mixersTransportation and packagingCelluloseWater vapor

The invention relates to a method for producing hydroxypropyl methylcellulose. The method comprises the following steps: 1) performing pretreatment, namely preparing 60-100-mesh cotton powder from purified cotton; 2) alkalifying, namely reacting the powder with alkali to produce alkali cellulose in a mixed solvent; 3) etherification, namely carrying out an etherification reaction among the alkali cellulose, epoxypropane and chloromethane; 4) neutralizing, namely neutralizing the residual alkali with an acid; 5) desolventizing, namely discharging the mixed system into a desolventizing kettle, adding hot water to the top while stirring, introducing water vapor from the bottom of the desolventizing kettle so as to form a solid-liquid-gas three phase; discharging and recovering most of the liquid solvent from a pipeline in the middle of the desolventizing kettle; and 6) performing post-treatment, namely finally centrifuging, granulating, drying, packaging, thereby obtaining the product. According to the method disclosed by the invention, since the recovered reactants participate in the separation process due to the added hot water, compared with the hydroxypropyl methylcellulose (HPMC) prepared by the conventional technical method, the product prepared by the method disclosed by the invention has the advantages that the purity of the crude product is high, and the treatment difficulty of the HPMC at the later stage is reduced.

Owner:美信佳中维药业股份有限公司

Flame retardant CPVC-ABS (Chlorinated Polyvinyl Chloride-Acrylonitrile Butadiene Styrene) alloy material and preparation method thereof

ActiveCN103374191ADilution concentrationFlame retardantChlorinated polyvinyl chlorideCombustible gas

The invention discloses a flame retardant CPVC-ABS (Chlorinated Polyvinyl Chloride-Acrylonitrile Butadiene Styrene) alloy material which is prepared from the components in parts by weight: 40-80 parts of CPVC, 10-50 parts of ABS, 1-10 parts of a flame retardant and 1-8 parts of a processing agent. The invention further discloses a preparation method of the flame retardant CPVC-ABS alloy material. Compared with the prior art, CPVC in the alloy material disclosed by the invention combusts to generate HCl which can shield and dilute combustible gases. Antimonous oxide or (and) sodium antimonite in the initial combustion period is fused on the surface of the material to form a protective film to isolate air. In a high temperature state, antimonous oxide or (and) sodium antimonite is gasified to dilute oxygen concentration in air and is commonly used with CPVC to generate SbOCl and SbCl3, so as to have the flame retardant effect. The alloy material is less in use level and good in flame retardant effect.

Owner:滁州格美特科技有限公司

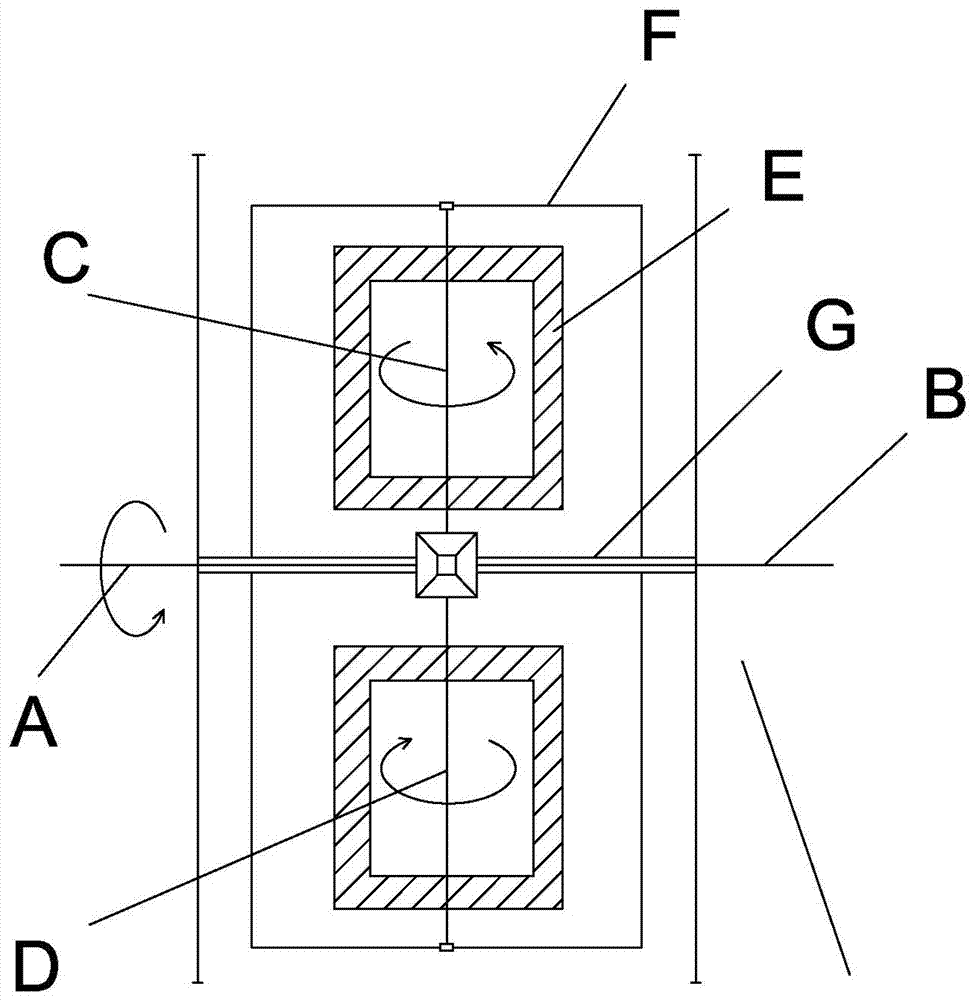

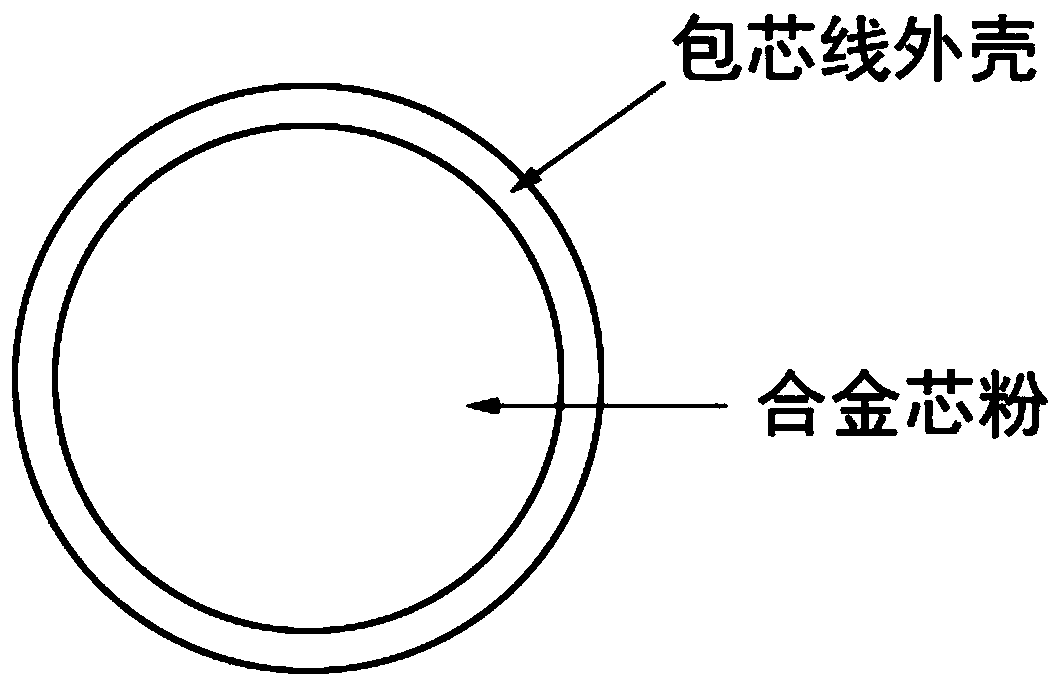

Composite core-spun yarn and large-line-energy welding steel preparing method

The invention discloses a composite core-spun yarn and a large-line-energy welding steel preparing method, and belongs to the technical field of steel metallurgy. Based on the oxide metallurgy basic principle, multiple alloy composite adding modes are selected in the core-spun yarn, and through reasonable core powder chemical component design, the functions of deep deoxygenation, deep desulfuration and inclusion harmless control in the steel smelting process are fused, the metallurgy process chemical reaction is sufficiently utilized, and fine, spheroidization, dispersion and composite controlof inclusions in the steel is achieved. According to a 60 mm EH36 ship making steel plate manufactured through the core-spun yarn, after EGW is conducted when the line energy is 460 kJ / cm, the -40 DEG C ballistic work value of the welding heat affected zone is larger than or equal to 170 J. After the core-spun yarn is used for replacing a Ni-Mg alloy commonly used during current large-line-energywelding steel production, the ton-steel alloy cost can be reduced to be smaller than or equal to 100 yuan from the cost higher than 300 yuan in the original technology, economic and social benefits are obvious, and very good popularization and application prospects are achieved.

Owner:李素坤

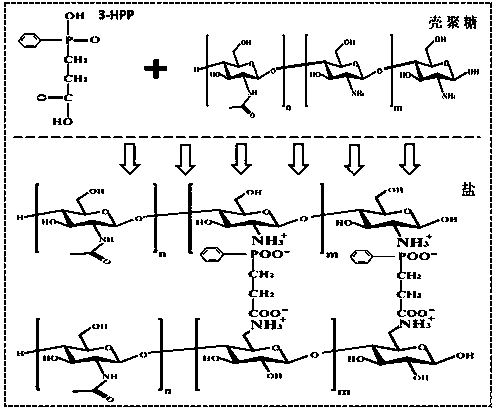

Intumescent flame retardant, flame-retardant polylactic acid material and preparation methods of intumescent flame retardant and flame-retardant polylactic acid material

The invention discloses an intumescent flame retardant, a flame-retardant polylactic acid material and preparation methods of the intumescent flame retardant and the flame-retardant polylactic acid material. The intumescent flame retardant consists of a chitosan salt and ZIF-8@GO in a mass ratio of (96-80):(4-20), the chitosan salt is prepared by reacting 2-carboxyethyl(phenyl)phosphinic acid withchitosan, and the ZIF-8@GO is prepared by loading a zeolite imidazate framework material ZIF-8 on graphene oxide; a chloroform solution of polylactic acid and a chloroform dispersion liquid of an intumescent flame retardant are blended according to a mass ratio of 95:5 by adopting a solution blending method, and coating is performed to prepare the flame-retardant polylactic acid material. The flame-retardant polylactic acid material is simple in formula, halogen-free and environment-friendly, the mechanical property and flame-retardant property of polylactic acid are remarkably improved, themolten drop phenomenon of the flame-retardant polylactic acid material is obviously weakened, a continuous and compact carbon layer is generated after combustion, and the effects of heat insulation and oxygen insulation are achieved.

Owner:南京塑煌新材料科技有限公司

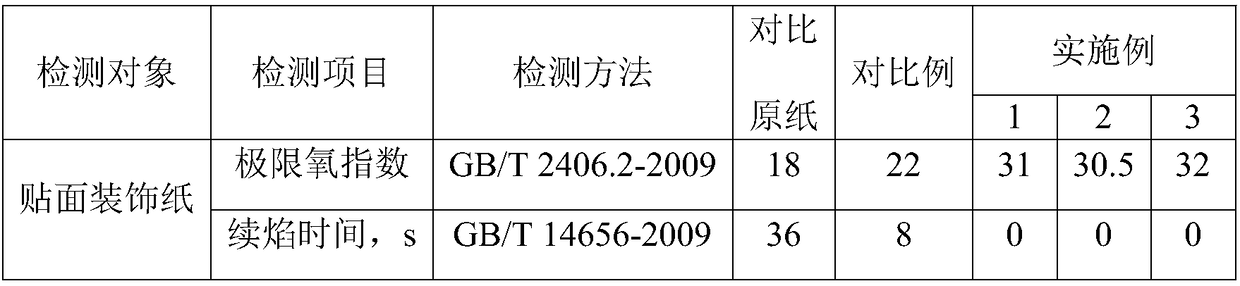

Veneering decorative paper having flame-retardant effect and flame-retardant veneering artificial board using same

ActiveCN108130808AFlame retardantIncrease temperatureSpecial paperWater-repelling agents additionLimiting oxygen indexPulp and paper industry

The invention relates to veneering decorative paper having a flame-retardant effect and a flame-retardant veneering artificial board using the same. The veneer decorative paper is prepared by the following method: 1) taking needle leaf wood pulp and broad leaf wood pulp, respectively beating, mixing and defibering, adding a titanium dioxide dispersion liquid, a retention aid, a wet strength agentand modified starch paste, to prepare original paper; 2) carrying out double-side coating on the obtained original paper with silica sol to obtain modified paper A; (3) carrying out impregnation treatment on the modified paper A with a borax solution to obtain modified paper B; and 4) carrying out double-side coating and gluing on the modified paper B with a soybean protein glue liquid with the gluing amount of 12-15 g / m<2>, and then carrying out press polishing with a press polishing machine. The obtained veneering decorative paper makes a flame-retardant agent added to the paper by using silica sol coating and borax solution impregnating, so the limit oxygen index of the decorative paper and the ignition time of the veneering artificial board are improved, and a good effect on preventingthe expansion and spreading of fire is achieved. The decorative paper does not contain formaldehyde, can greatly reduce the formaldehyde release amount of the veneering artificial board, and is suitable for promotion and use.

Owner:佛山市板缘装饰材料有限公司

Sintering flue gas SCR denitration and vapor removal system and technology

The invention relates to a sintering flue gas SCR denitration and vapor removal system. The system comprises a flue gas condensation vapor-removal defogging dedusting tower, a heat exchange device, ahot-blast stove, an ammonium hydroxide evaporator, a dilution fan, an ammonia injection grid, an SCR denitration reaction device and a flue gas exhaust device. The heat exchange device is arranged between the flue gas condensation vapor-removal defogging dedusting tower and the SCR denitration reaction device. The heat exchange device is used for heat exchange on flue gas to be denitrated or denitrated flue gas to change the temperature, an original flue gas outlet of the heat exchange device is connected with a gas inlet of the SCR denitration reaction device through a second main flue, the hot-blast stove and the ammonia injection grid are arranged in sequence in the flowing direction of the flue gas in the second main flue, and the ammonium hydroxide evaporator and the dilution fan arearranged between the ammonia injection grid and a gas outlet of the SCR denitration reaction device. The sintering flue gas SCR denitration and vapor removal system can carry out SCR denitration on desulfurated sintering flue gas while carrying out vapor removal treatment, the effect of purifying sintering flue gas desulfurated with a wet method is improved, and environmental pollution is reduced.

Owner:江苏朗润环保科技有限公司

Top corner gas extraction device for coal mine coal-mining working face

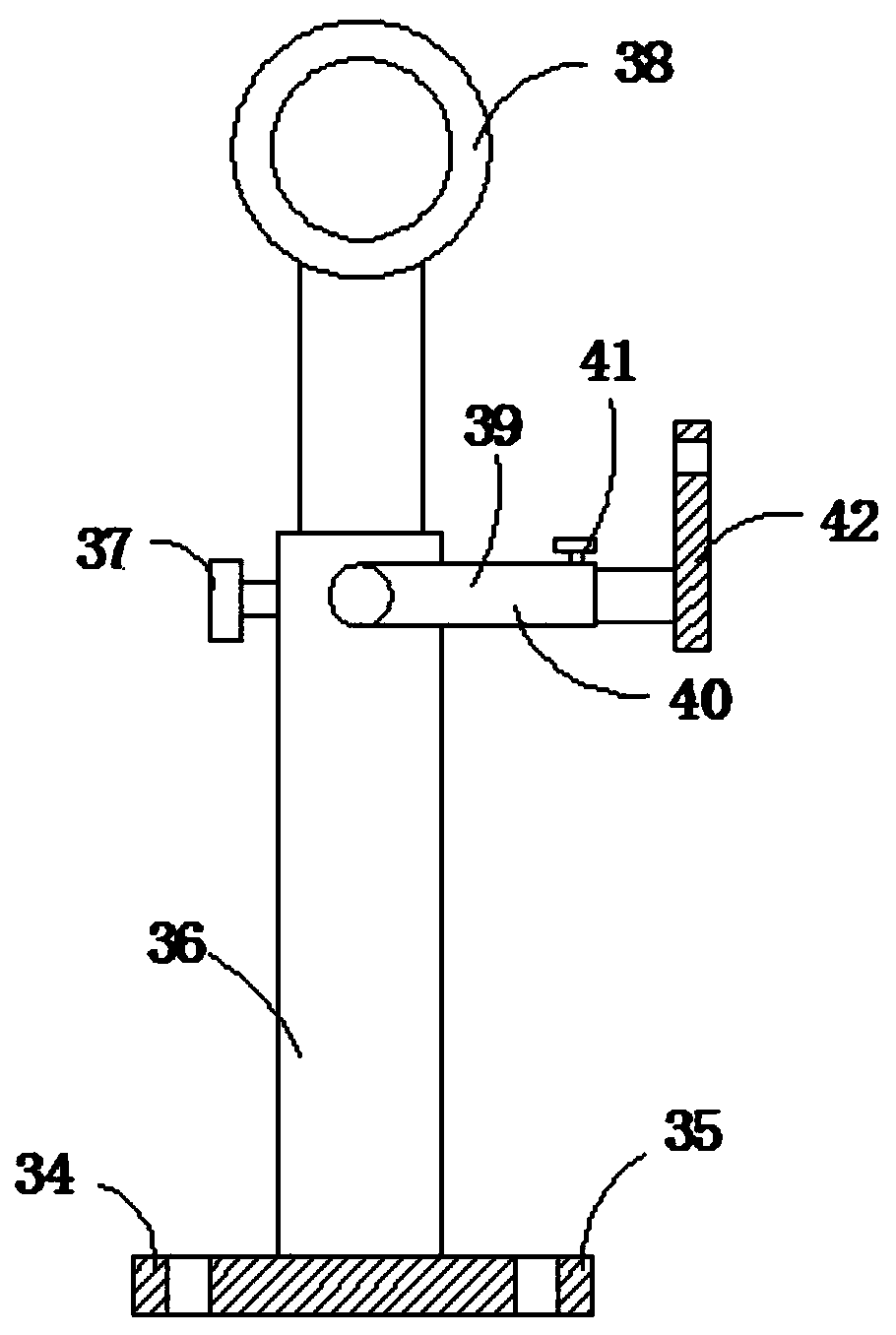

ActiveCN109113783ADilution concentrationIncrease humidityDust removalFire preventionDrive shaftFresh air

The invention belongs to the technical field of coal mines, and particularly relates to a top corner gas extraction device for a coal mine coal-mining working face. The top corner gas extraction device comprises a shell internally provided with a first cavity and a second cavity. An exhaust fan is arranged in the first cavity. The other output end of a double-axis motor is coaxially and fixedly connected with a transmission shaft. Two annular ventilating openings are formed in the side walls, away from a first opening and a second opening, of the shell. One end of a water pipe is fixedly connected with a spraying mechanism, and the other end of the water pipe is fixedly connected with a water pipe joint. A water pump is fixedly connected to the water pipe and fixedly connected with the shell. The input end of the water pump and the transmission shaft are coaxially and fixedly connected. The top corner gas extraction device has the advantages that top corner gas of the working face canbe extracted, meanwhile, fresh air can be delivered into a mine, water mist can be sprayed to increase humidity, and thus the danger of gas explosion is lowered; and one motor is adopted to drive multiple functions, and the energy saving effect is achieved.

Owner:湖南省煤业集团嘉禾矿业有限公司

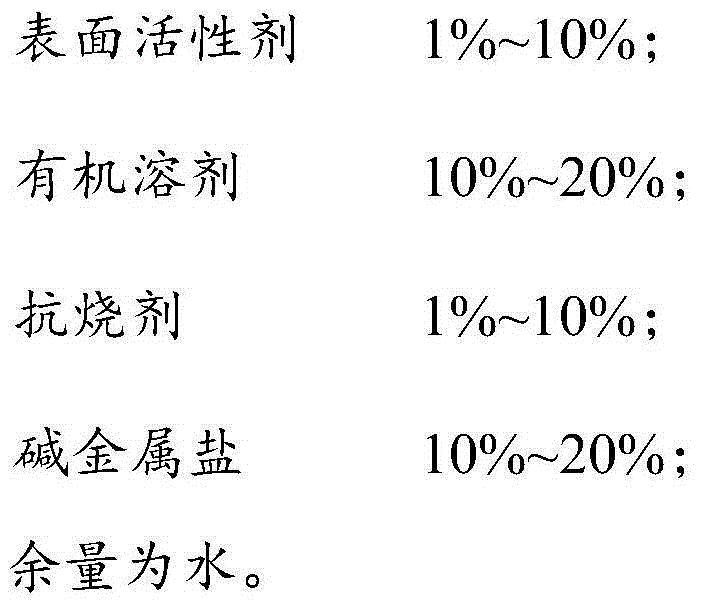

Fluoride-free additive easy to degrade and preparing method and application thereof

InactiveCN105126290ANo aggregationNo suspended solidsFire extinguisherOrganic solventSurface-active agents

The invention relates to the technical field of fire extinguishing and particularly discloses a fluoride-free additive easy to degrade and a preparing method and application thereof. The fluoride-free additive easy to degrade is composed of, by weight, 1%-10% of surface active agents, 10%-20% of organic solvent, 1%-10% of anti-burning agents, 10%-20% of alkali metal salt and the balance water. According to the fluoride-free additive easy to degrade, the surface active agents, the organic solvent, the anti-burning agents and the alkali metal salt serve as the important components of the fluoride-free additive easy to degrade, the four components cooperate with one another to improve a micro fine water mist fire extinguishing environment together, in this way, the fire extinguishing effect is improved, and the phenomenon of accelerated corrosion of metal products on a fire scene after a disaster can be avoided; in addition, the fluoride-free additive easy to degrade is nontoxic, harmless and environment-friendly and can be widely applied to fine water mist fire extinguishing systems on various occasions.

Owner:SHENZHEN HENG XING SECURITY TESTING TECH

Recycling method of LF scrap ladle slag inclusion

InactiveCN103045778AImprove the ability to adsorb silicate inclusionsImprove product qualityManufacturing convertersRecycling and recovery technologiesScrapMagnetic separation

The invention relates to a recycling method of an LF (ladle furnace) scrap ladle slag inclusion, and belongs to the technical field of steelmaking in the metallurgical industry. The method adopts the technical scheme that the method comprises the following process steps that (1), the LF scrap ladle slag inclusion is subjected to natural cooling, magnetic separation, crushing and screening, and then made into refining slag, with a particle size diameter of 5-30mm, and with the following chemical components by mass percentage: less than or equal to 10% of SiO2, greater than or equal to 40% of CaO, less than or equal to 12% of MgO, 18-45% of Al2O3, less than or equal to 3.0% of MnO, less than or equal to 3.0% of FeO, and less than or equal to 1.5% of S; (2), plain carbon steel is made in a converter, the refining slag is added to a ladle during tapping, 2-3Kg refining slag is added to molten steel per ton, all the refining slag is added before 1 / 3 of a tapping course, and argon blowing is conducted for 3-8min after tapping. The method has the positive effects that the method facilitates improving ladle slag adsorption silicate inclusion capacity, reducing oxidability of the molten steel, reducing consumption of iron and steel materials and alloys in the converter, and further improving the quality of the molten steel.

Owner:TANGSHAN GUOFENG IRON & STEEL

Method and system for preparation of glycerin alkyl ether

PendingCN108250053AShort stayLow selectivityLiquid carbonaceous fuelsEther preparation by compound additionGas phaseFixed bed

The invention provides a method for preparation of glycerin alkyl ether. The method includes: (1) adding a mixed solution of tert-butyl alcohol and glycerin and liquid isobutylene simultaneously intoa fixed bed reactor filled with an acidic resin catalyst to carry out glycerin etherification reaction on the system; (2) letting the material flowing out of the fixed bed reactor into a gas separation system to be separated into a gas phase and a liquid phase; (3) letting the liquid phase material enter a tert-butyl alcohol separation system to separate tert-butyl alcohol and (4) collecting the polyether product. The invention also provides a reaction system for preparation of glycerin alkyl ether. Under the reaction conditions of a temperature of 45-80DEG C and a glycerin residence time of 0.80-2.50h, the glycerin conversion rate can reach 100%, the polyether selectivity is up to 98.6% or more, and the selectivity of an isobutylene dimer is 1.7% or below. The method lowers the reaction temperature, greatly reduces the residence time of glycerin in the fixed bed, and well controls the selectivity of isobutylene dimer.

Owner:CHINA PETROLEUM & CHEM CORP +1

Ternary hybrid flame retardant, flame-retardant polylactic acid material and preparation methods thereof

The invention discloses a ternary hybrid flame retardant, a flame-retardant polylactic acid material and preparation methods thereof. The ternary hybrid flame retardant comprises graphene oxide, phenylphosphinic acid and a zeoliticimidazate framework material ZIF-8. The ternary hybrid flame retardant polylactic acid material comprises polylactic acid and the ternary hybrid flame retardant in the mass ratio of (97.5-98.0):(2.5-2.0). The preparation methods comprise the steps of grafting the phenylphosphinic acid onto the graphene oxide by utilizing an oxygen-containing functional group of the graphene oxide and loading the surface of the graphene oxide with ZIF-8 to obtain the ternary hybrid flame retardant; mixing a chloroform solution of the polylactic acid with a chloroform dispersion liquid of the ternary hybrid flame retardant in proportion by adopting a solution mixing method. and coating to obtain the ternary hybrid flame retardant polylactic acid material. The ternary hybrid flame-retardant polylactic acid material disclosed by the invention has the advantages that the material is simple in formula, free of halogen, friendly to environment and high in flame retardant efficiency; the mechanical properties are remarkably improved; the molten drop phenomenon is reduced; and a continuous and compact carbon layer is formed after combustion to play the roles of heat insulationand oxygen insulation.

Owner:NANJING UNIV OF SCI & TECH

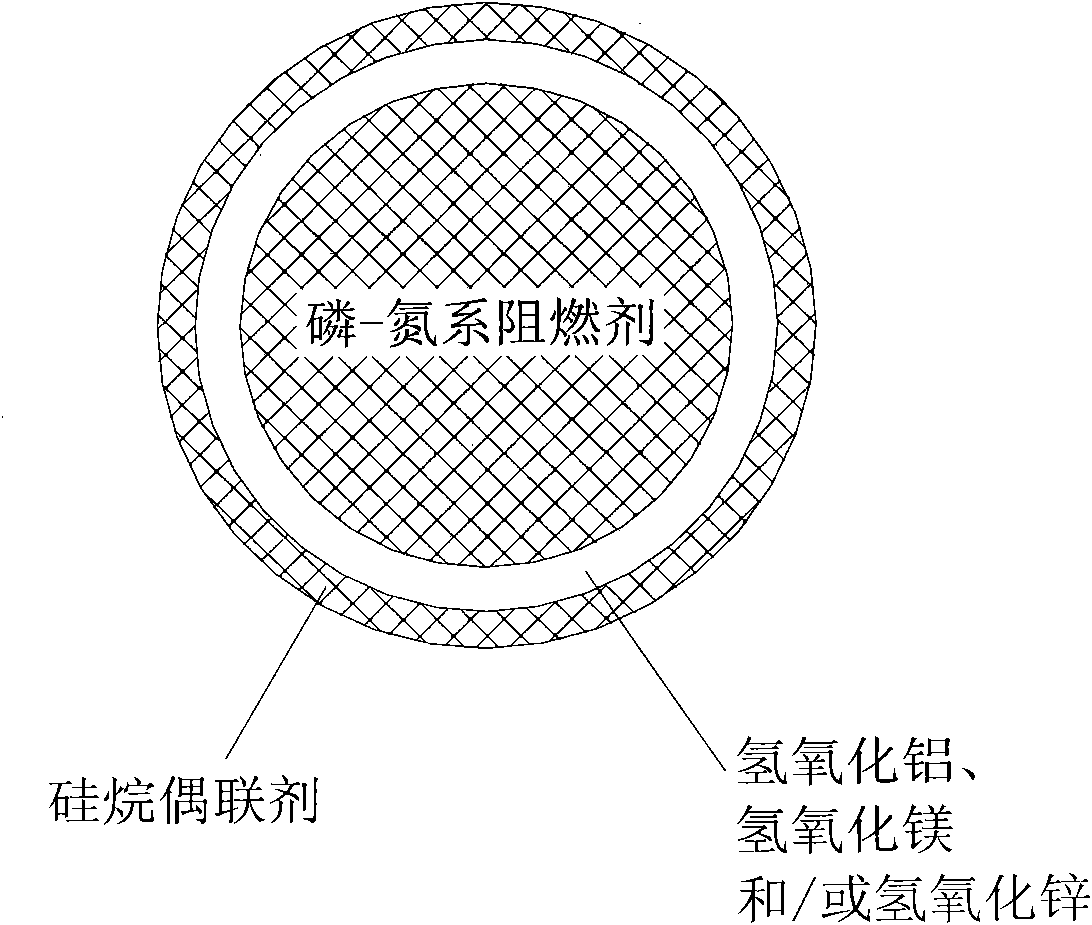

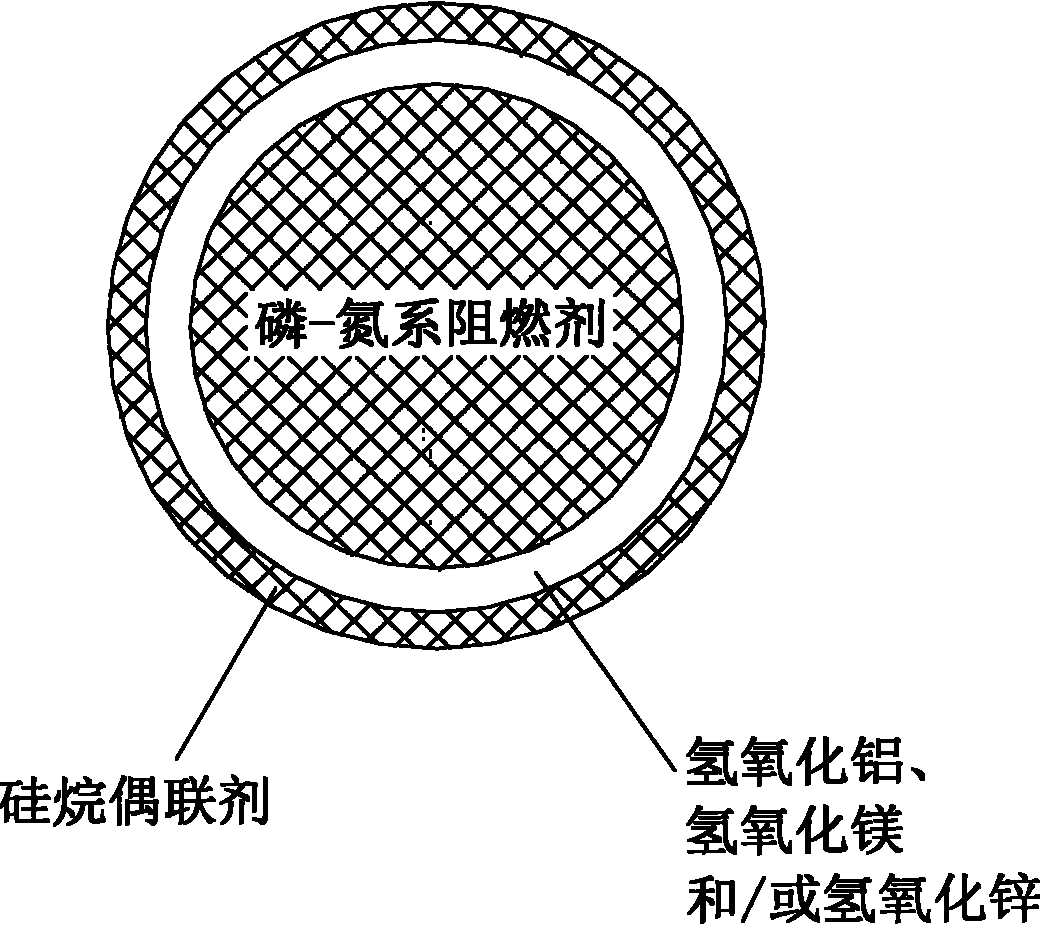

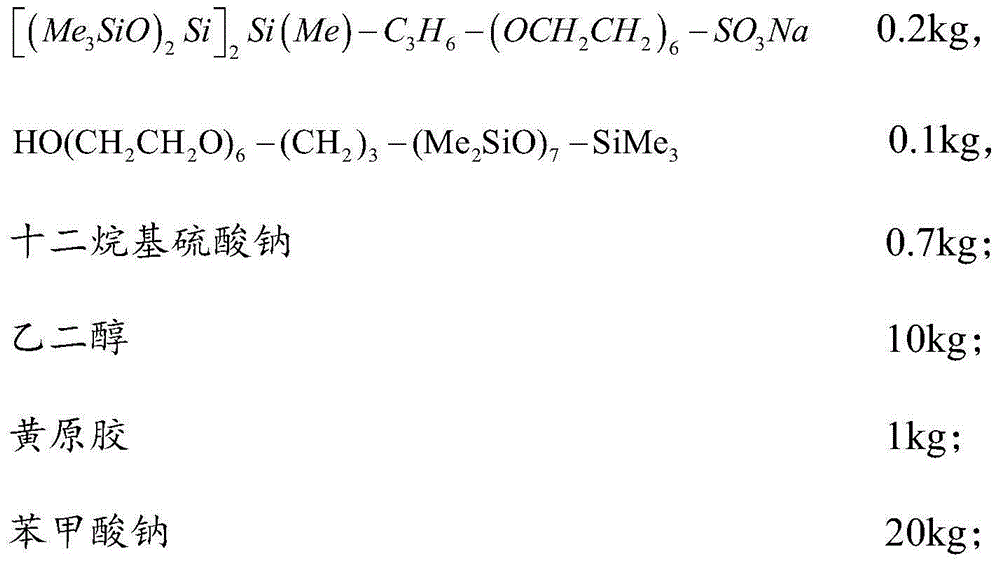

Composite intumescent flame retardant and preparation method thereof

The invention discloses a composite intumescent flame retardant and a preparation method thereof. The composite intumescent flame retardant is composed of 83.33-99.67 wt% of an intumescent flame retardant and 16.67-0.33 wt% of sodium oleate-modified lauryl sodium sulfate intercalated calcium magnesium aluminum hydrotalcite. According to the invention, Ca<2+>, Mg<2+>, Al<3+> and other cations are utilized to perform cation replacement modification on hydrotalcite, dodecyl sulfate and other anions are utilized to perform interlayer intercalation modification on hydrotalcite to expand interlayerspacing and improve the flame retardancy of the hydrotalcite flame retardant, and the hydrotalcite flame retardant is compounded with the intumescent flame retardant to form a synergistic flame-retardant system, so the flame retardancy of the composite flame retardant is improved, and the mechanical property of a polymer added with the flame retardant is also synergistically guaranteed.

Owner:OECHSLER PLASTIC PROD TAICANG +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com