Fluoride-free additive easy to degrade and preparing method and application thereof

An easy-to-degrade, additive-based technology, applied in fire prevention equipment, etc., can solve the problems of damage to precision instruments and other metal equipment at the fire extinguishing site, damage to the environment, and easy pollution of organic additives, etc., to achieve high production efficiency, simple process, and stable system Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0046] Correspondingly, the embodiment of the present invention also provides a preparation method of the above-mentioned fluorine-free easily degradable additive. In one embodiment, the preparation method of the above-mentioned fluorine-free easily degradable additive comprises the following steps:

[0047] Step S01, respectively weighing the surfactant, organic solvent, anti-scalding agent, alkali metal salt and water according to the above formula;

[0048] Step S02, performing mixing treatment on the weighed surfactant, the organic solvent and the anti-scalding agent to obtain component A;

[0049] Step S03, mixing the weighed alkali metal salt and the water to obtain component B;

[0050] In step S04, the component A and the component B respectively obtained in step S02 and step S03 are mixed.

[0051] Specifically, steps S01-S04 only need to be performed at normal temperature.

[0052] Specifically, in the mixing process of steps S02-S04, each component needs to be fu...

Embodiment 1

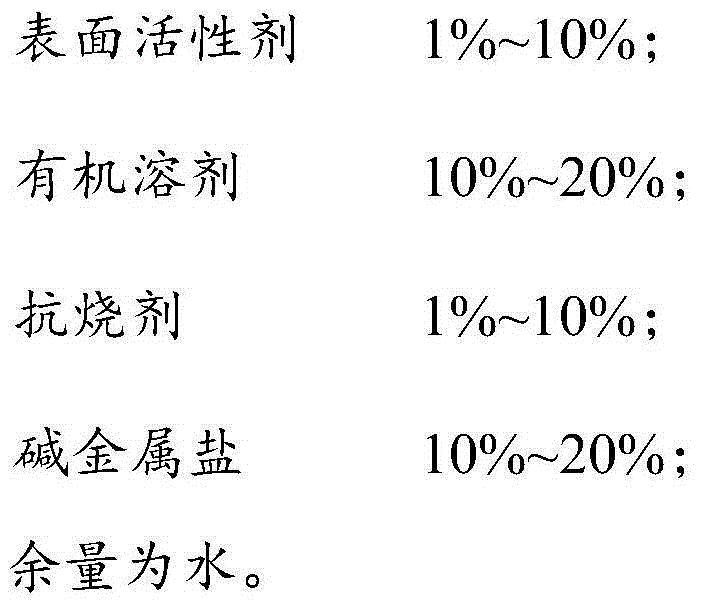

[0059] A fluorine-free easily degradable additive and a preparation method thereof, wherein the fluorine-free easily degradable additive consists of the following formula components:

[0060]

[0061]

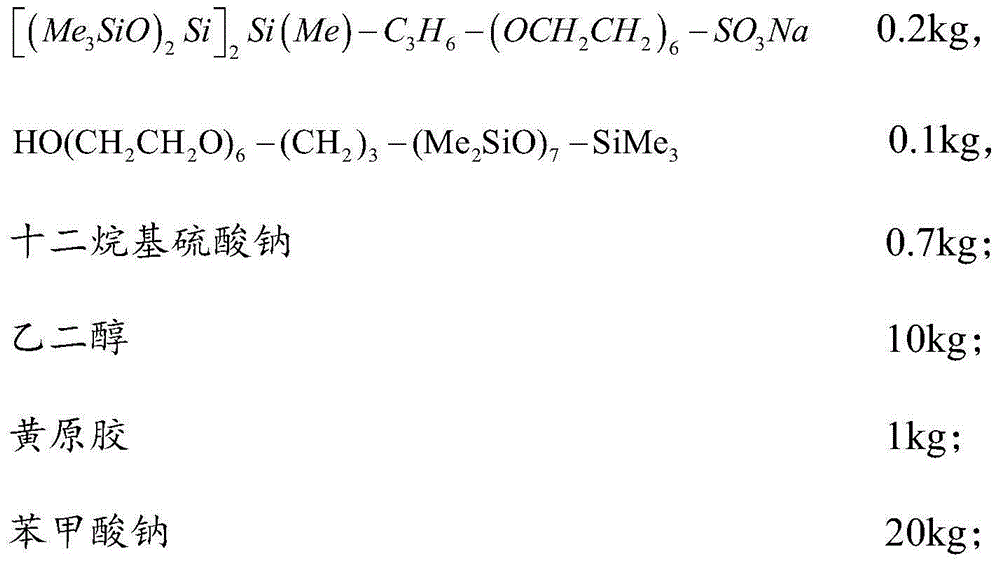

[0062] The preparation method of this fluorine-free easily degradable additive is as follows:

[0063] First, weigh the formulation components provided in the above-mentioned Example 1 respectively.

[0064] Secondly, 0.2kg [(Me 3 SiO) 2 Si] 2 Si(Me)-C 3 h 6 -(OCH 2 CH 2 ) 6 -SO 3 Na, 0.1kgHO(CH 2 CH 2 O) 6 -(CH 2 ) 3 -(Me 2 SiO) 7 -SiMe 3 , 0.7kg sodium lauryl sulfate and 1kg xanthan gum are dissolved and mixed with 10kg ethylene glycol to form component A.

[0065] Again, 20kg of sodium benzoate is dissolved and mixed with 68kg of water to form component B evenly.

[0066] Finally, mix A component and B component evenly.

Embodiment 2

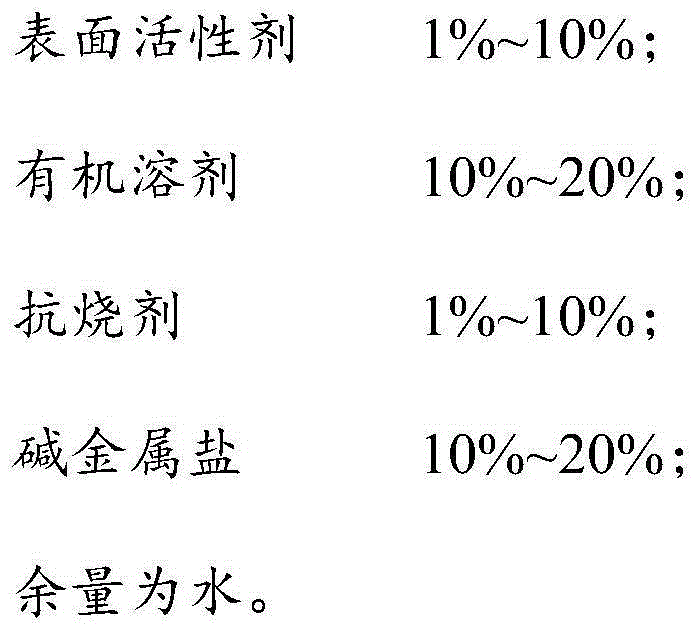

[0068] A fluorine-free easily degradable additive and a preparation method thereof, wherein the fluorine-free easily degradable additive consists of the following formula components:

[0069]

[0070] The preparation method of this fluorine-free easily degradable additive is as follows:

[0071] First, weigh the formulation components provided in the above-mentioned Example 2 respectively.

[0072] Secondly, 3kg[(Me 3 SiO) 2 Si] 2 Si(Me)-C 3 h 6 -(OCH 2 CH 2 ) 7 -O-SO 3 Na, 2kg sodium dodecylbenzenesulfonate and 5kg flame retardant urea are dissolved and mixed with 10kg ethylene glycol and 5kg glycerol to form component A.

[0073] Again, 15kg of potassium sorbate was dissolved and mixed with 60kg of water to evenly form component B.

[0074] Finally, mix A component and B component evenly.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com