Top corner gas extraction device for coal mine coal-mining working face

A coal mining face and gas drainage technology, which is applied in the direction of pump devices, gas discharge, safety devices, etc., can solve the problems of gas accumulation, high gas concentration, high temperature and humidity, and achieve energy saving, increase safety factor, and reduce gas The effect of the probability of explosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

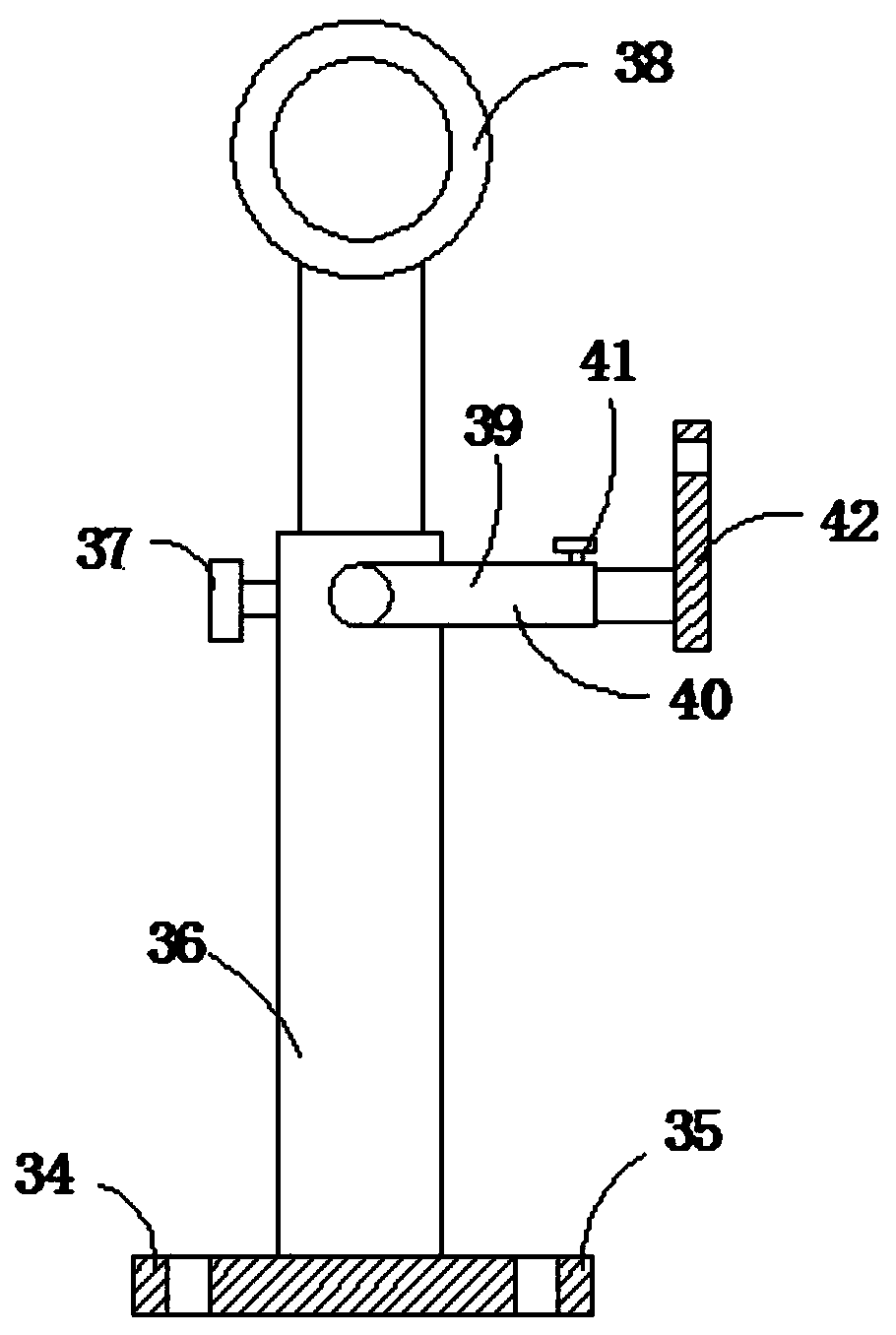

[0021] like Figure 1-3 As shown, a gas extraction device at the upper corner of a coal mining working face in a coal mine includes a casing 1, and a first cavity 2 and a second cavity 3 are arranged in the casing 1, and a discharge row is arranged in the first cavity 2. The air fan 4, the second cavity 3 is provided with an air intake fan 5, the central axis of the exhaust fan 4 and the air intake fan 5 both pass through the housing 1 and extend to the outside, and the outer wall of the housing 1 is fixedly connected with a double-axis motor 6. One output end of the biaxial motor 6 is connected to the exhaust fan 4 and the intake fan 5 through the transmission mechanism 14. The biaxial motor 6 can drive the exhaust fan 4 and the intake fan 5 to rotate. The drive shaft 16 that is coaxially fixedly connected with the output end of the biaxial motor 6, the end of the drive shaft 16 away from the biaxial motor 6 is coaxially fixedly connected with a first pulley 17, and the centr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com