Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

120results about How to "High fixed carbon content" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Technology for processing pulverized lignite

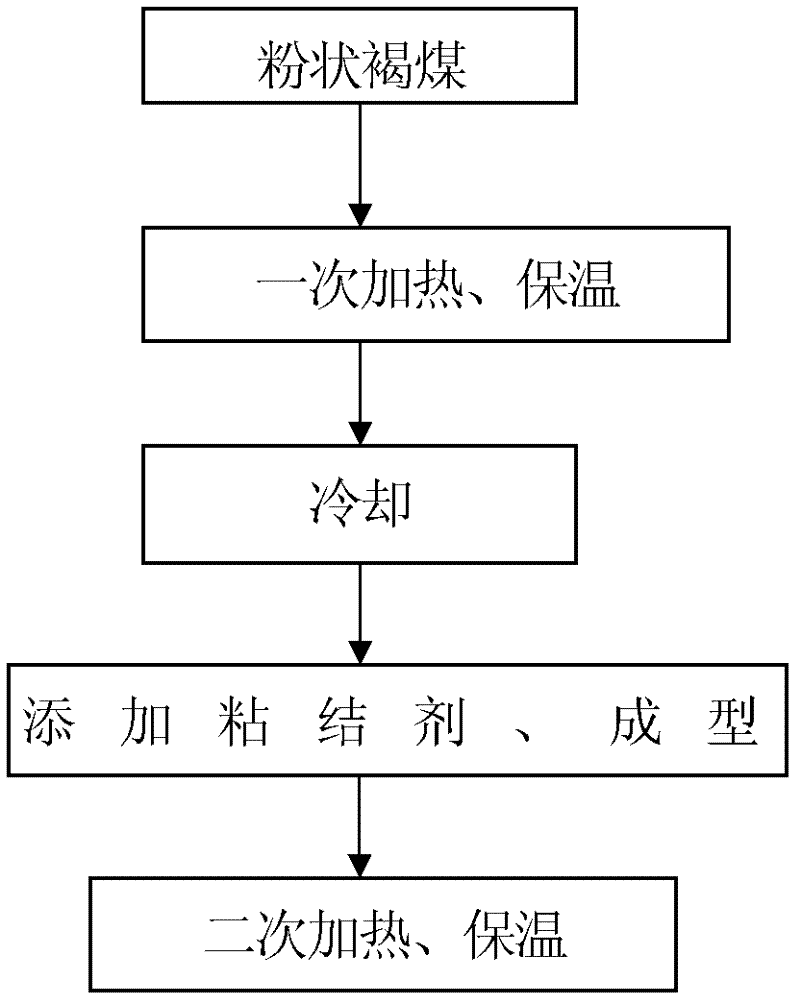

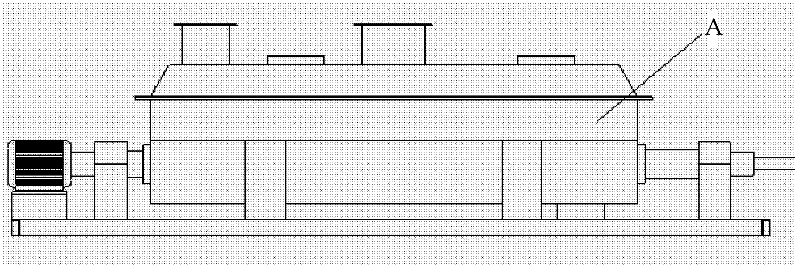

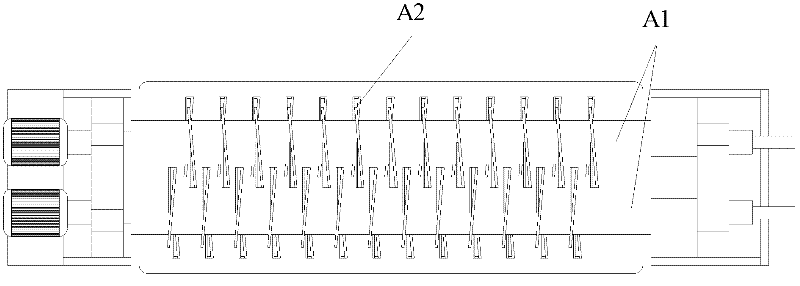

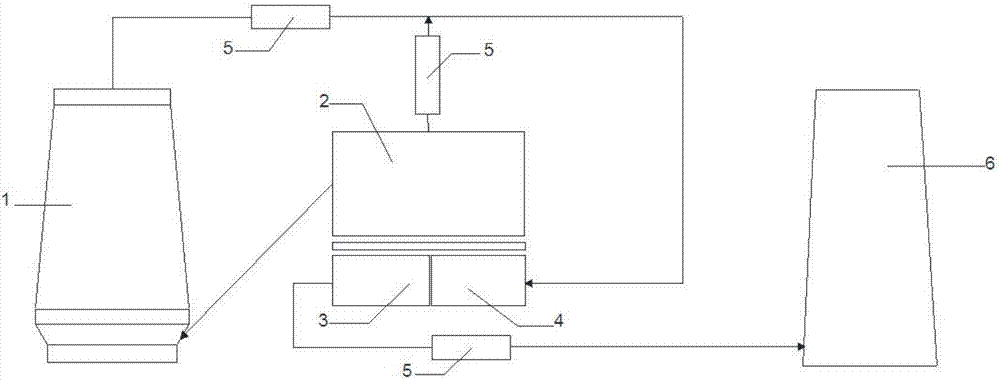

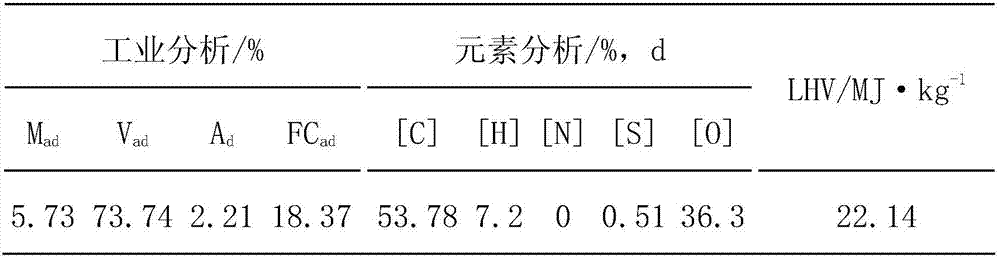

The invention discloses a technology for processing pulverized lignite. The technology comprises the followings steps of: firstly, heating pulverized lignite to 100-1000 DEG C, and then heat-preserving for 1-5h; secondly, cooling the lignite processed and obtained in the first step below 100; thirdly, then adding a binding agent, and uniformly stirring to form; fourthly, heating the formed lignite to 100-1000 DEG C and heat-preserving for 1-5h. According to the technology for processing the pulverized lignite disclosed by the invention, the lower calorific value of finally obtained products is greatly increased compared with that of the raw coal and is increased by more than 2 times compared with that of the raw coal before modification; all water is nearly completely removed, volatile components are greatly reduced, the content of solid carbon is greatly improved, and yield of condensed water is greater; and compared with the prior art, the technology for processing the pulverized lignite disclosed by the invention has lower cost, and the obtained products can be convenient to transport and has high calorific value.

Owner:QIANQIU ENERGY SHANGHAI

Method for manufacturing machine processed charcoal by utilizing Chinese medicinal or herbal drug to extract solid waste

InactiveCN1803981AReduce energy consumptionReduce manufacturing costBiofuelsSpecial form destructive distillationCombustion chamberThree stage

The disclosed preparation method for charcoal comprising: crushing the solid waste from extracted traditional drug or plant to extrude into bar-form; loading the product into retort for charring reaction with three stages for 10-30min at 120Deg, 200-400min at 120-350Deg and 100-300min at 350-450Deg, respectively. Wherein, firing the exhaust gas in combustion chamber to provide heat source. This invention has yield rate as 40-55% with low energy consumption and little pollution.

Owner:NORTHEAST FORESTRY UNIVERSITY +1

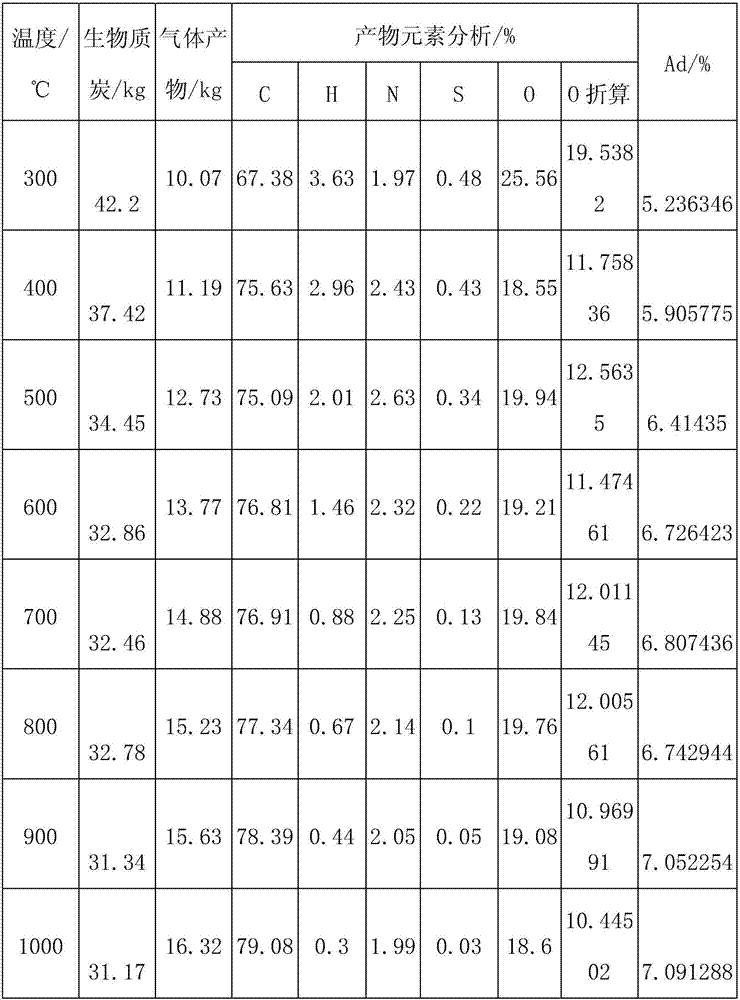

Method for biomass carbonization instead of pulverized coal injection in blast furnace

InactiveCN108003959AExpand the range of optionsIncrease production capacityBiofuelsSolid fuelsCombustion chamberCarbonization

The invention provides a method for biomass carbonization instead of pulverized coal injection in a blast furnace. Dried straw and other biomass raw materials are extruded to obtain a machine-made rod, and the machine-made rod is carbonized by a carbonization furnace to obtain carbon powder at a temperature of 300 to 1000 DEG C. The carbon powder obtained by the furnace is mixed with pulverized coal and injected into the blast furnace to greatly reduce a coal ratio and flux usage amount and improve production efficiency; latent heat of flue gas is fully utilized to reduce emission of exhaust gas; the exhaust gas discharged from a combustion chamber is filtered and discharged into air through a microporous ceramic tube. Biomass resources and sensible heat of the flue gas, and oxygen and carbon monoxide in the flue gas are used in ironmaking production. In addition, the biomass resources can also be used as a substitute for the pulverized coal or coke powder used in iron ore sintering machines. The method comprehensively utilizes existing equipment to treat waste materials such as biomass raw materials and the flue gas, saves coking coal resources, fully exerts potential advantages of biomass energy, protects environment, and reduces costs.

Owner:UNIV OF SCI & TECH BEIJING

Combined carbonaceous reducing agent for smelting metal silicon and preparation method thereof

ActiveCN102976330AMeet physical and chemical performance requirementsPoor improvementSilicon compoundsPetroleumPetroleum coke

The invention discloses a combined carbonaceous reducing agent for smelting metal silicon and a preparation method thereof. The combined carbonaceous reducing agent comprises refined pulverized coal and petroleum coke powder, wherein the refined pulverized coal accounts for 70-80% of the total weight; the refined pulverized coal is prepared from the raw material soft coal by oil agglomeration selective flocculation de-ashing treatment; the refined pulverized coal contains 75-80% of fixed carbon, 3.5-4.5% of ash content and 16-21% of volatile content by weight; and 2-3% of binder is added into the mixture of the refined pulverized coal and the petroleum coke powder, and then a combined carbonaceous reducing agent pellet is prepared by cold press molding briquetting and drying treatment. According to the invention, the ash content and impurities in the soft coal are removed by a flotation method, the petroleum coke powder serves as supplement of the fixed carbon, and the two are combined to obtain a combined carbonaceous reducing agent with high content of fixed carbon, low ash content and low content of impurities. Through the invention, the problem that the reducing effect is unsatisfactory by using the soft coal only is solved, the smelting efficiency and the product quality are improved, and the added value of the soft coal is increased.

Owner:KUNMING METALLURGY INST

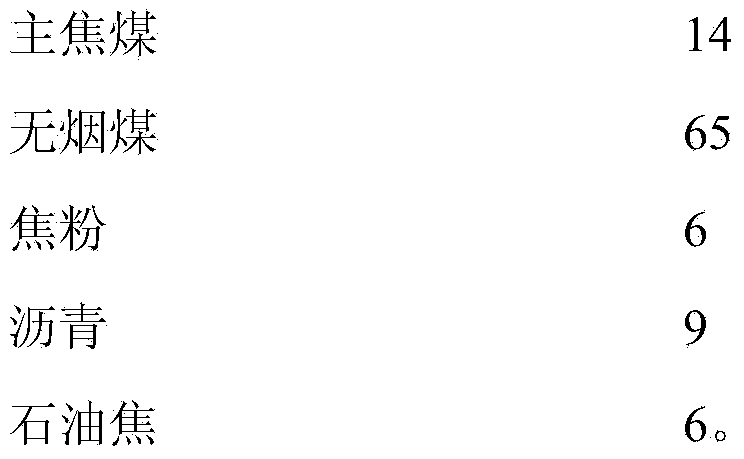

Method for preparing coke

ActiveCN104194813AQuality improvementHigh strengthSpecial form destructive distillationPorosityCoke oven

The invention provides a method for preparing coke. The invention provides a preparation method of formed coke in a vertical coke oven. The method comprises the step of carrying out dry distillation on the raw materials including coking coal, anthracite, coke powder, asphalt and petroleum coke. The formed coke is prepared by stirring blending coal at high temperature and high pressure according to a certain proportion and carrying out forming, charging and carbonizing processes. The method has the beneficial effects that a formula effectively solves the problem of impacts of plastic mass change under the conditions of high temperature and rapid heating; the coke quality reaches the A-level rate, which is above 95%, in the national standard; the coke has the characteristics of uniform product specification, high lumpiness, high strength, lower porosity and reactivity and low ash content and sulfur content.

Owner:SHANDONG JUMING ENERGY

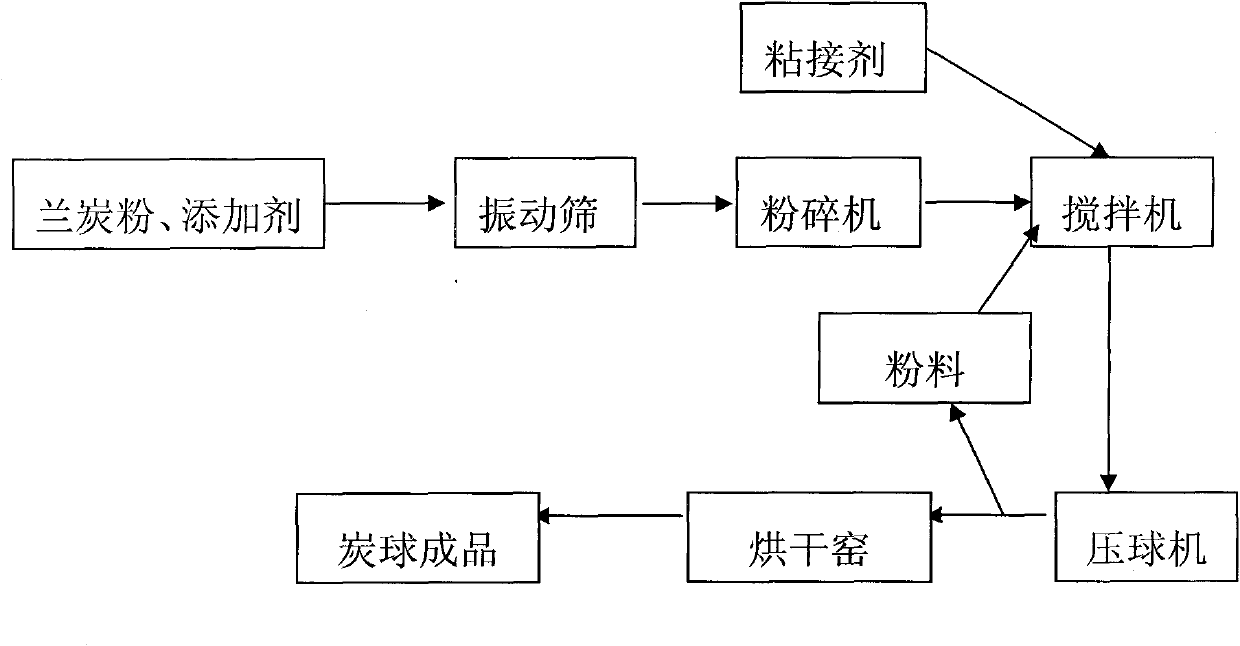

Method for pressing semicoke powder used for producing calcium carbide

InactiveCN101792685AHigh fixed carbon contentHigh strengthSolid fuelsResource utilizationRoom temperature

The invention discloses a method for pressing semicoke powder used for producing calcium carbide, which comprise: mixing 82 to 91 weight percent of semicoke powder, 7 to 9 weight percent of additive and 2 to11 weight percent of binder, adding the mixture into a stirrer to stir the mixture at room temperature for 2 to 5 minutes, processing and forming the mixture, drying the formed product to obtained the finished product, wherein the additive is rich coal; the binder for forming the semicoke powder is prepared by mixing 20 to 30 weight percent of solution of sodium hydroxide, 20 to 30 weight percent of solution of urea and 40 to 60 weight percent of corn starch and by adding hot water at 60 to 80 DEG C during mixing; and the concentration of the solution of sodium hydroxide is 0.1 to 5 percent and the concentration of the solution of urea is 0.1 to 5 percent. The product of the invention has high cold strength, can be fed in a furnace in batch in place of semicoke, avoids the yield and quality of smelted calcium carbide, reduces the production cost of the calcium carbide, improves resources utilization rate and has high use and promotion values.

Owner:丹江口福安运输有限责任公司

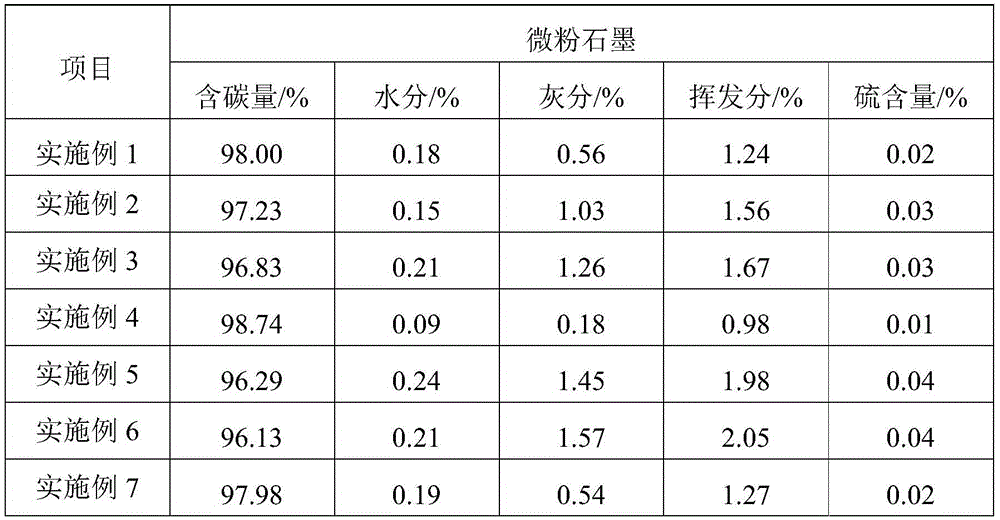

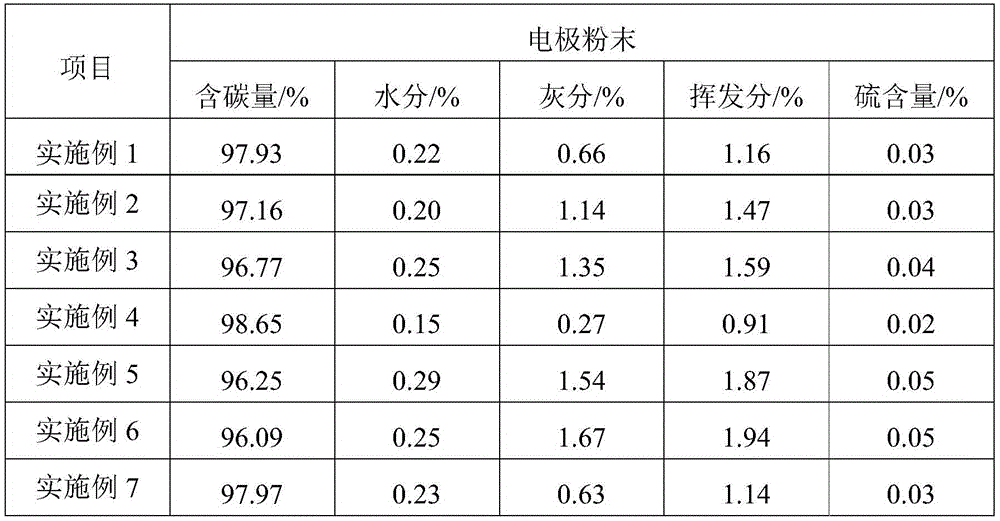

Carburant and preparation method thereof

InactiveCN105543444AHigh fixed carbon contentHigh granulation molding rateProcess efficiency improvementStress concentrationAbsorption capacity

The invention discloses a carburant and a preparation method thereof, and the technical problem to be solved is to improve the quality of the carburant. The carburant is composed of a graphite material and a bonding agent, wherein the graphite material is obtained by mixing micro-powder graphite and electrode powder, and the bonding agent is composed of an inorganic bonding agent and an organic bonding agent. The preparation method for the carburant comprises the following steps: uniformly mixing the micro-powder graphite with the electrode powder to obtain a mixture; carrying out thermal treatment on the mixture; mixing the inorganic bonding agent with the organic bonding agent; and adding the bonding agent into the graphite raw material to carry out pelletizing, thereby obtaining the carburant. Compared with the prior art, the fixed carbon content of the carburant is high, and the carburant is high in volumetric absorption capacity with iron parts and steel parts in a molten iron casting process, so that the quality of castings is improved, and the problems that the steel parts are easily cracked as a result of poor anti-impact toughness and low cracking energy absorption due to the fact that local stress concentration is caused by a great number of pores and crazes generated on the surfaces of the castings are overcome. The carburant prepared by the preparation method is high in pelletizing and molding ratio, and is low in production cost.

Owner:NINGXIA KOCEL ENERGY CO LTD

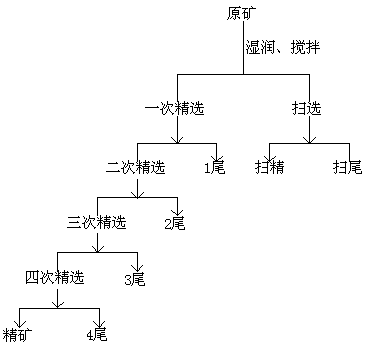

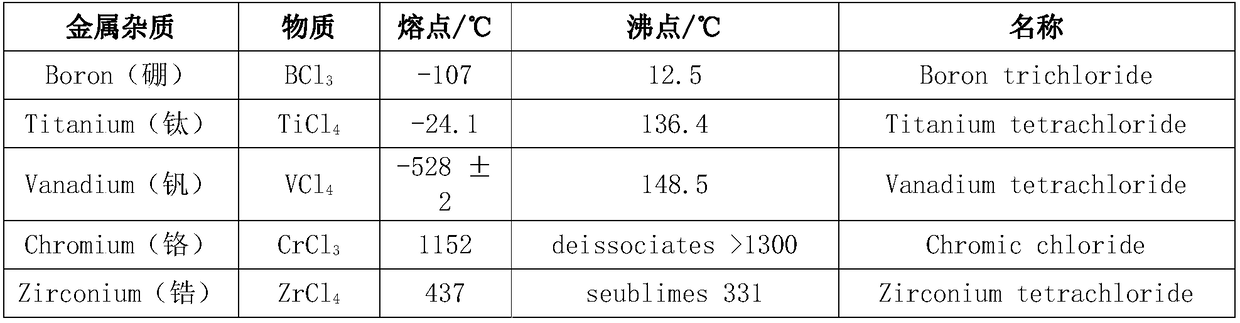

A process for preparing high-purity microcrystalline graphite with low energy consumption and in a large scale, and the high-purity microcrystalline graphite

InactiveCN107555426ALarge specific surface areaHigh purityCarbon compoundsPurification methodsGraphite

The invention relates to the technical field of microcrystalline graphite purification, and discloses a process for preparing high-purity microcrystalline graphite with low energy consumption and in alarge scale, and the high-purity microcrystalline graphite. According to the process, microcrystalline graphite raw ore is firstly crushed and ground, and flotation including one time of roughing, four times of cleaning and one time of scavenging is performed in match to increase the purity of the raw ore to the utmost through a physical method; an improved acid leaching purification method is adopted, the alkali leaching efficiency is increased, energy consumption is reduced, and the graphite recovery yield is increased; and finally a high-temperature purification method adopting a step-by-step heating manner is utilized to further reduce energy consumption for graphite purification, and the high-purity microcrystalline graphite the fixed carbon content of which is 99.993% or above can be finally obtained. The process overcomes a problem that microcrystalline graphite in the prior art is not high in purity, high in energy consumption and high in cost. Through improvements on the prior art, the process achieves an objective of reducing energy consumption and the cost, and achieves industrial production.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

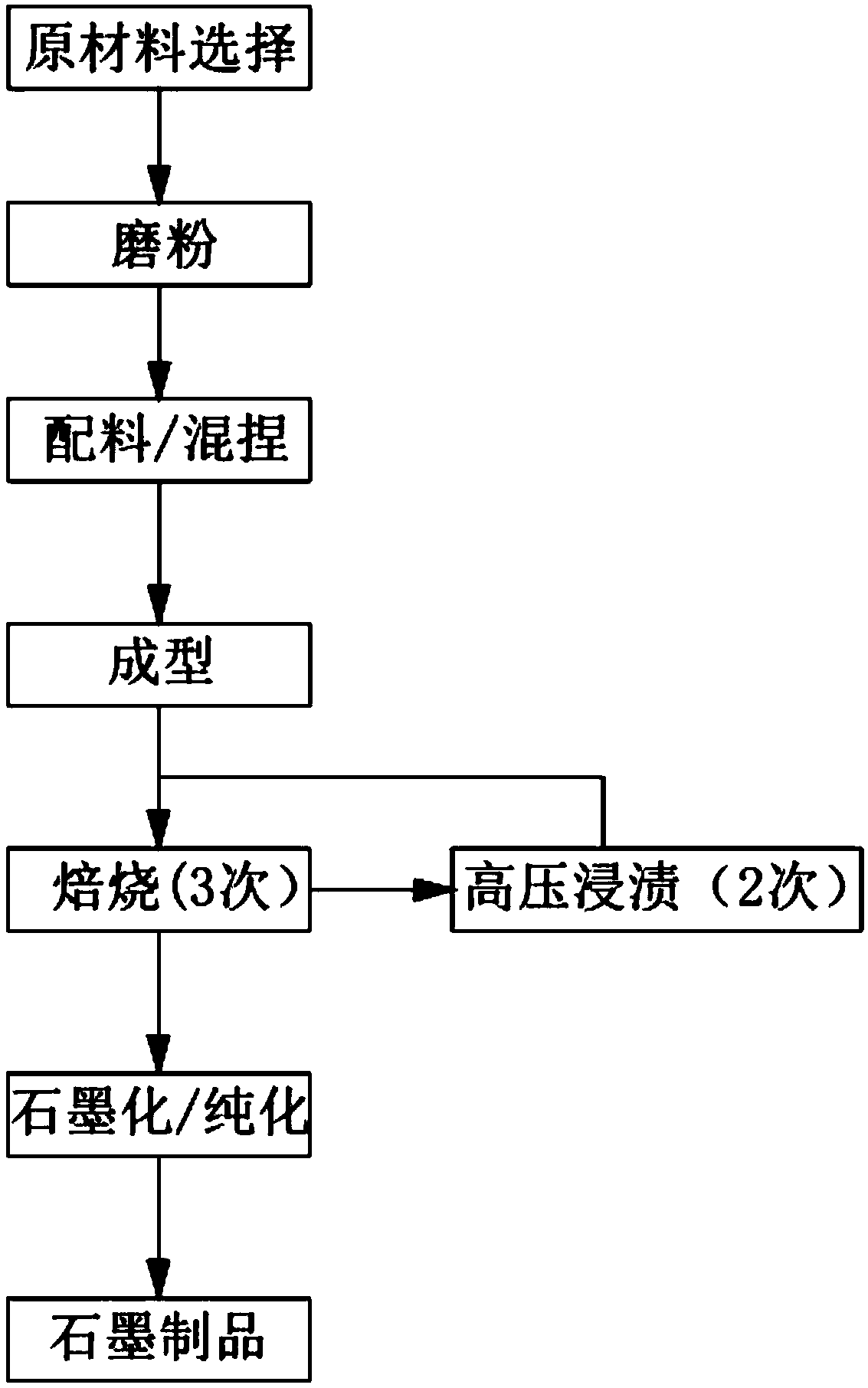

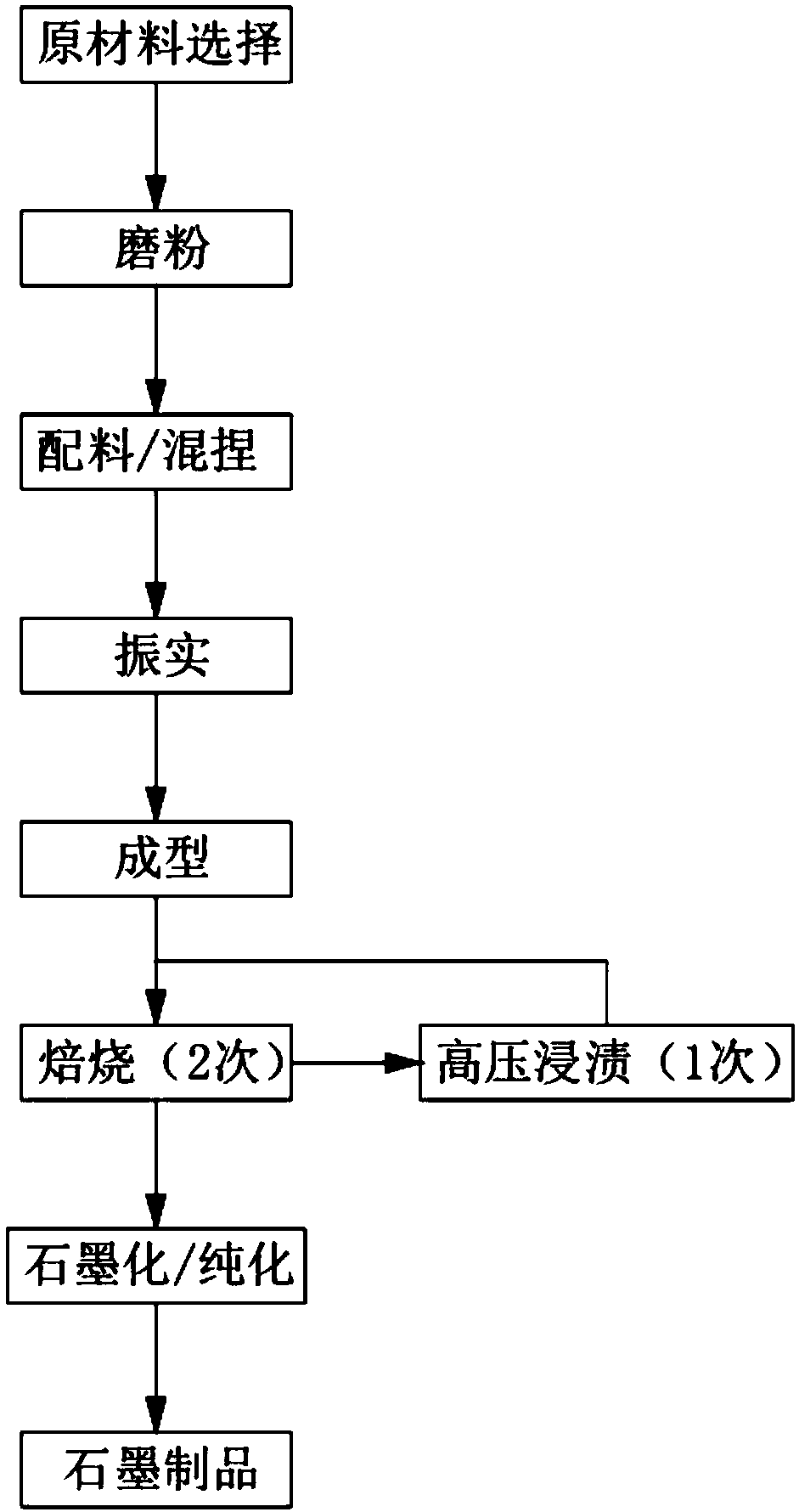

Preparation method of high-density ultrafine-aperture graphite

The invention provides a preparation method of high-density ultrafine-aperture graphite. The preparation method comprises the following steps: rotation of a raw material, stirring and hybrid kneading,compression molding, primary roasting, primary impregnation, secondary roasting, secondary impregnation, roasting for the third time and graphitization. A coke aggregate having an average particle size of 10 to 100 [mu]m and an adhesive are subjected to hybrid kneading, compression molding and roasting, and large pores of a product are blocked with an impregnant through two-times high-pressure impregnation, so that the large pores are turned into small pores, and the technical problem that large-particle aggregates cannot be used for preparing small-aperture graphite is solved; therefore, thelarge-particle aggregates can be used for preparing a small-aperture graphite material, and the aperture of the graphite material is less than or equal to 1 [mu]m; the particle specific surface areaand the surface energy of the graphite material are reduced; and furthermore, in the graphitization process, the purity of a graphite product is improved through purification.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

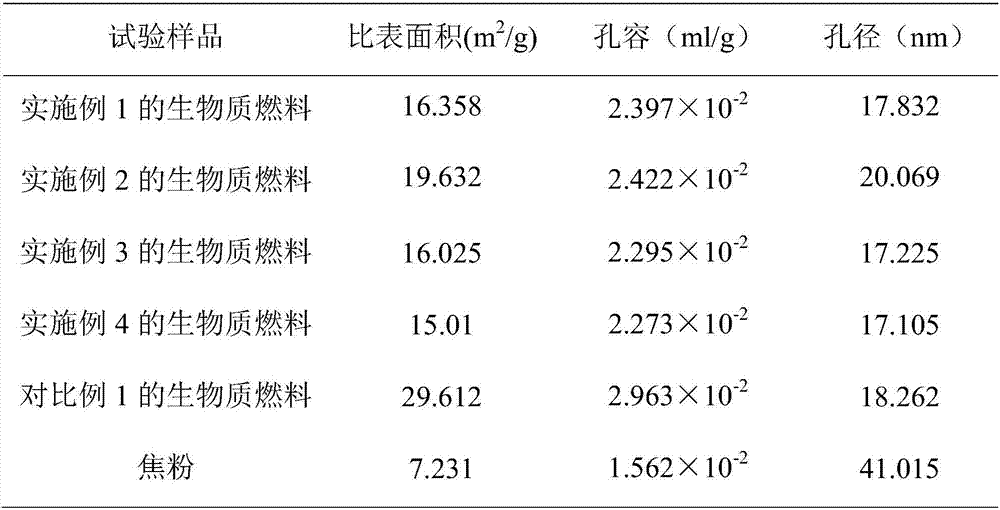

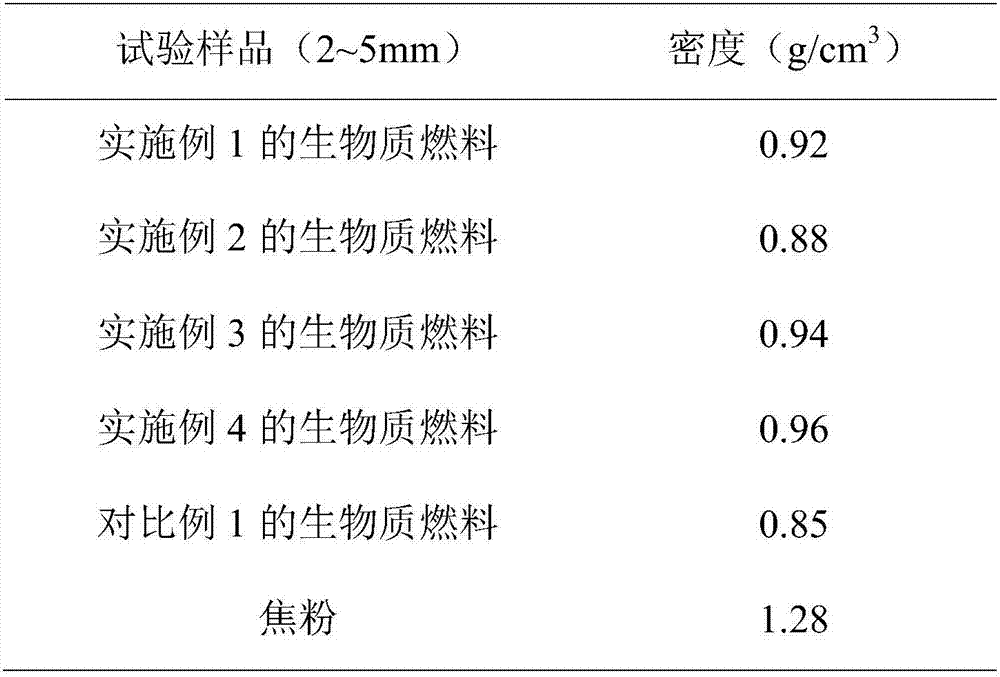

Biomass fuel for iron ore sintering and preparation method and application of biomass fuel

The invention discloses biomass fuel for iron ore sintering and a preparation method and application of the biomass fuel. The biomass fuel is prepared through the steps that molding and carbonizing are conducted on the biomass fuel, and then filling and packing are conducted on the biomass fuel by means of a urea solution and CaO powder according to the requirements of iron ore sintered fuel. Theproblems that biomass is loose, porous, large in specific surface area, low in fixed carbon content, too fast in reaction and the like are solved, the performance index of the prepared biomass fuel isclose to that of coke powder, part of the coke powder can be replaced to conduct sintering production, and meanwhile the discharge amount of pollutant in the iron ore sintering production process canbe effectively inhibited.

Owner:NORTH CHINA UNIVERSITY OF SCIENCE AND TECHNOLOGY

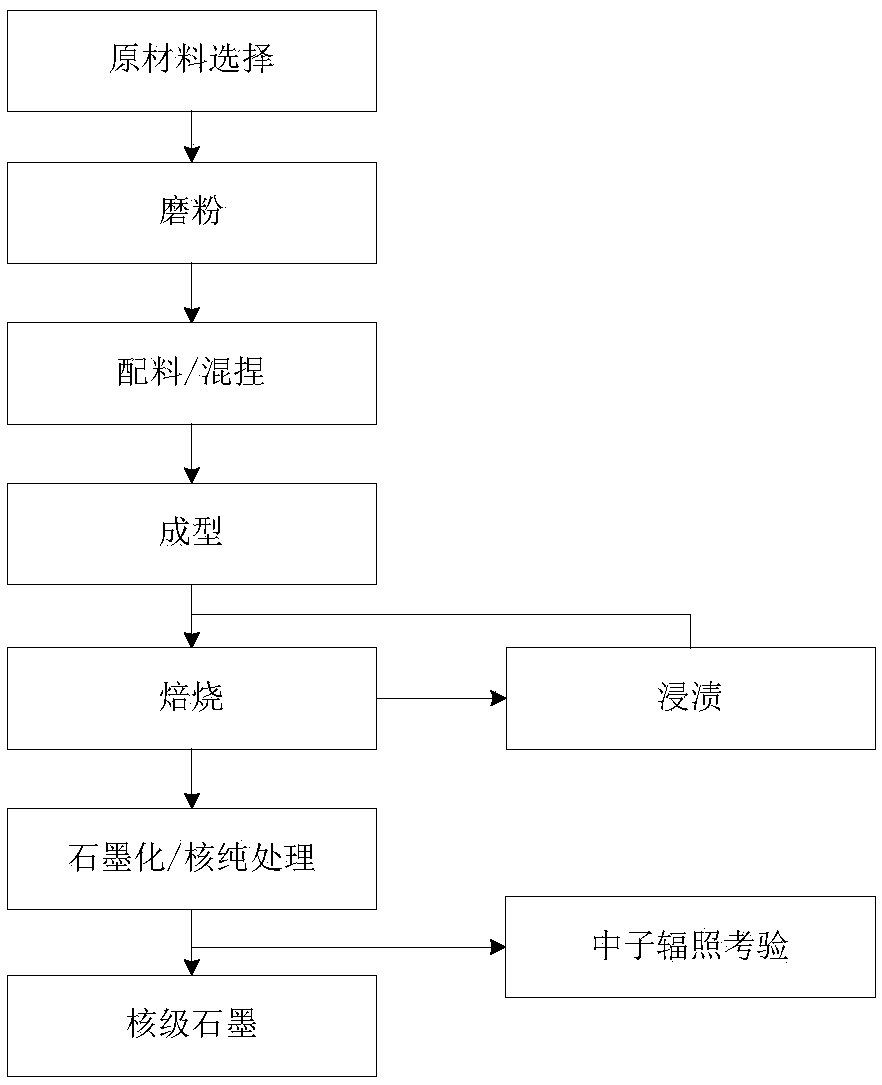

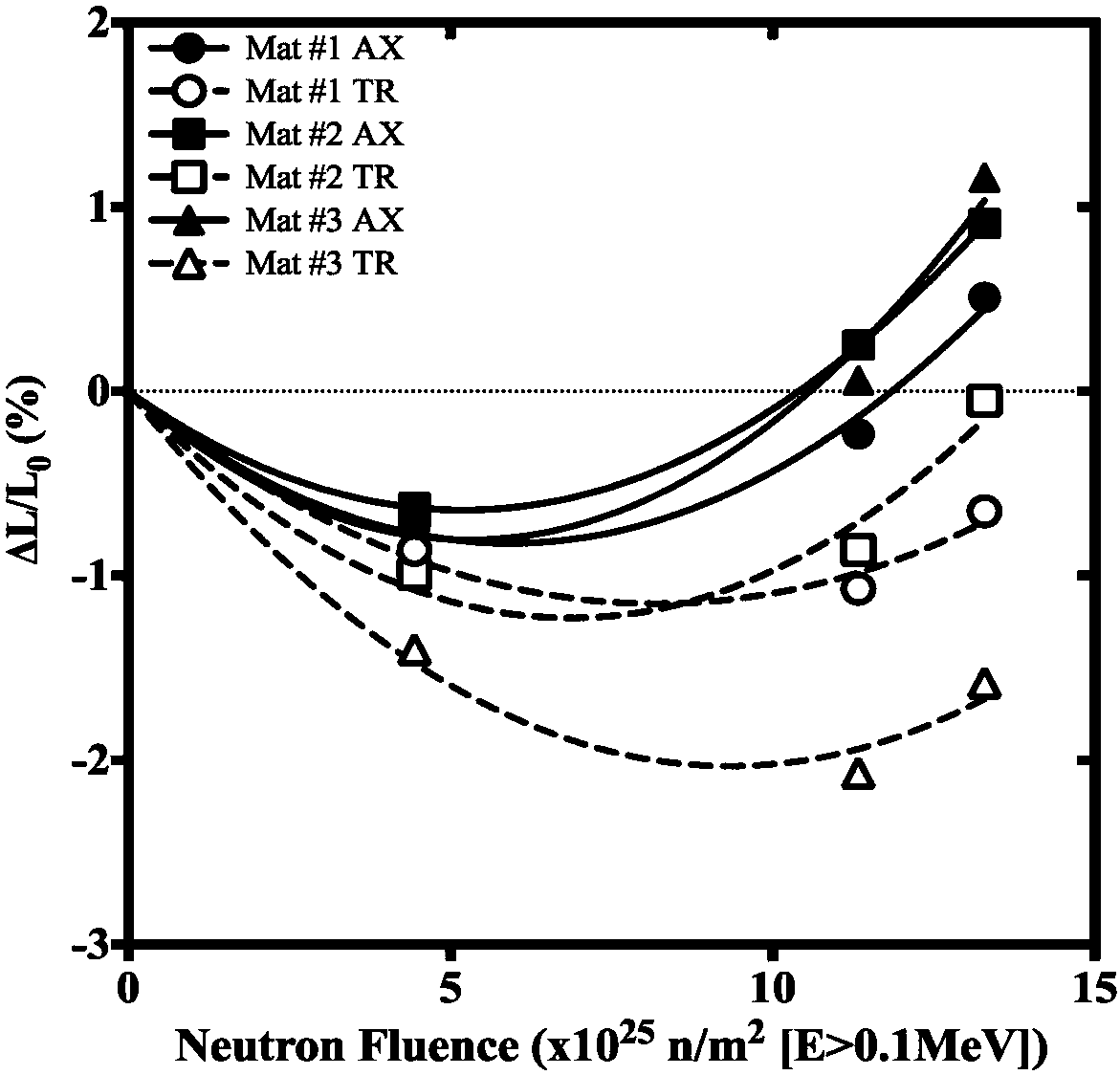

Large-dimension nuclear graphite material for reactor internal of high-temperature gas cooled reactor and preparation method

The invention relates to a large-dimension nuclear graphite material for a reactor internal of a high-temperature gas cooled reactor and a preparation method. The method comprises the following stepsof: raw material selection, grinding, mixing-kneading, forming, roasting, 0 to 1 time of impregnation, and graphitization / nuclear-pure processing. The large-dimension nuclear graphite material is simple in process and convenient to operate and adopts little production equipment, so that cost is further reduced; the large-dimension nuclear graphite material is convenient to popularize and apply andis applicable to large-scale production; compared with the prior art, the provided product has a large scale and has neutron irradiation performance data.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Reducing agent used for producing industrial silicon

The invention relates to a reducing agent used for producing industrial silicon, which has the advantages of being high in fixed carbon content, less in dosage, low in cost, good in reaction activity and capable of completely replacing wood charcoal to serve as the base or the main reducing agent of the industrial silicon. The reducing agent comprises the following agent by weight: 30 to 50 parts of washed coal, 20 to 30 parts of high-purity carbon powder and 30 to 40 parts of petroleum coke, wherein the washed coal comprises less than 8% of ash and more than 65% of fixed carbon by mass, the high-purity carbon powder comprises less than 8% of ash and more than 80% of fixed carbon by mass, and the petroleum coke comprises less than 5% of ash and more than 90% of fixed carbon by mass. A preparation method of the reducing agent is further disclosed and includes the following steps 1) mixing the washed coal, the high-purity carbon powder and petroleum coke according to the proportion and crushing the mixture to less than 200 meshes; 2) adding adhesive into the mixture evenly in stirring mode and conducting pelleting and drying; and 3) conducting screening to obtain a bonding product with the granularity as 10mm-30mm.

Owner:登封电厂集团铝合金有限公司

Microcrystalline graphite high temperature pretreatment-alkaline acid method purification method

InactiveCN107555425AHigh fixed carbon contentHigh recovery rateCarbon compoundsPurification methodsGraphite

The invention belongs to the technical field of microcrystalline graphite purification, and more specifically relates to a microcrystalline graphite high temperature pretreatment-alkaline acid methodpurification method. The microcrystalline graphite high temperature pretreatment-alkaline acid method purification method comprises following steps: microcrystalline graphite ore is subjected to smashing and grinding to a certain particle size; high temperature heat treatment is adopted; after heat treatment, the obtained microcrystalline graphite is subjected to pressurization alkaline leaching and normal pressure acid leaching so as to obtain microcrystalline graphite finished products. According to the microcrystalline graphite high temperature pretreatment-alkaline acid method purificationmethod, pressurization alkaline leaching is adopted to replace high temperature calcining, after heat treatment, alkaline leaching temperature in alkaline acid method purification process of microcrystalline graphite can be reduced, alkaline leaching efficiency is increased, energy consumption is reduced, and graphite recovery rate is increased. The microcrystalline graphite high temperature pretreatment-alkaline acid method purification method is capable of increasing microcrystalline graphite fixed carbon content to be 98% or higher.

Owner:HUNAN GUOSHENG GRAPHITE TECH CO LTD

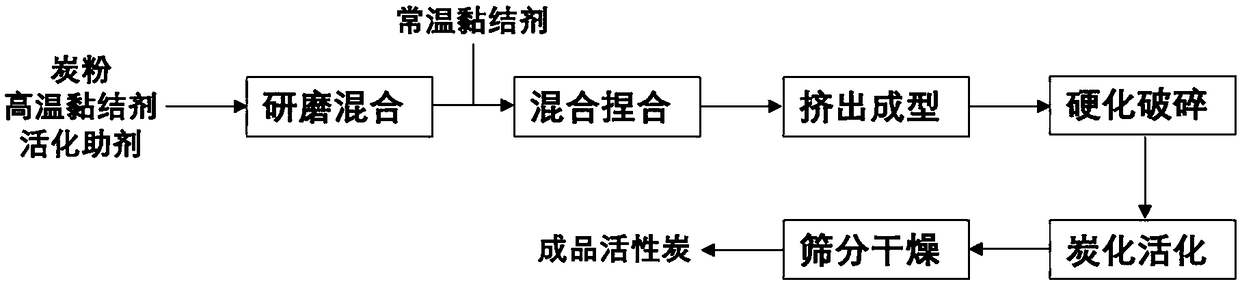

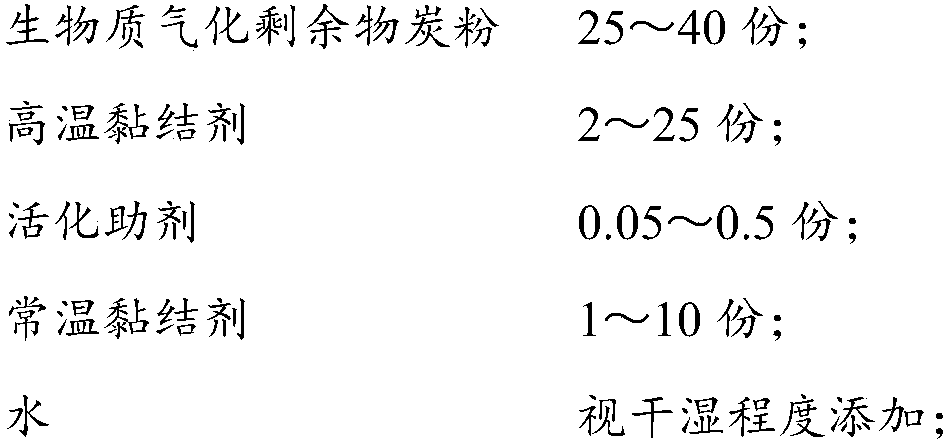

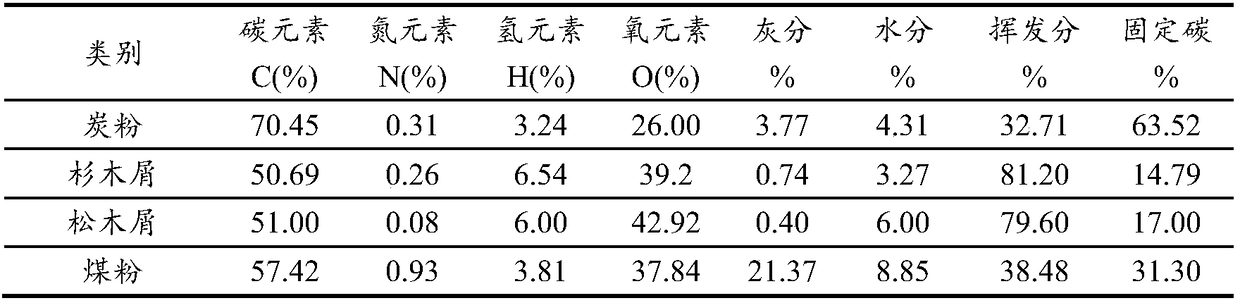

Biomass gasification residue formed activated carbon and preparation method thereof

ActiveCN109160512ARealize high-value utilizationSimple and fast operationCarbon compoundsActivated carbonAdhesive

The invention discloses biomass gasification residue formed activated carbon and a preparation method thereof. The preparation method comprises the following steps: uniformly mixing a raw material with a high-temperature adhesive, activation aids and a normal-temperature adhesive, carrying out extrusion molding in a molding machine, carrying out drying hardening, and carbonizing and activating ina high-temperature furnace, thereby obtaining a finished product of activation carbon, wherein biomass gasification residue carbon powder is used as the raw material. After the normal-temperature adhesive is mixed with the carbon powder and the high-temperature adhesive, a molding function is achieved, and convenience can be brought to extrusion molding or shaping of the raw material; in the high-temperature carbonization and activation process, the normal-temperature adhesive is burnt to generate pores, and the high-temperature adhesive is heated and molten to achieve an adhesion effect at the moment; due to addition of the activation aids, the reaction activity of gasification residues can be improved; the strength of the activated carbon is up to 99%, the iodine sorption value of the activated carbon is up to 900 mg / g, and the methylene blue adsorption value of the activated carbon is up to 180 mg / g.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

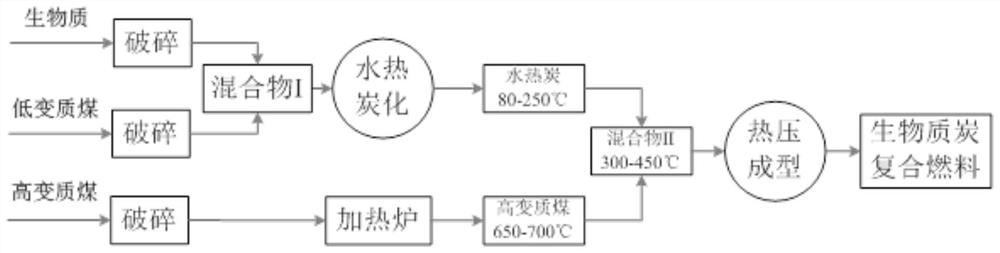

Preparation method of biomass charcoal composite fuel for blast furnace injection

The invention provides a preparation method of a biomass charcoal composite fuel for blast furnace injection, which comprises the following steps: mixing crushed biomass raw materials and low metamorphic coal, carrying out hydrothermal carbonization treatment, then mixing with preheated high metamorphic coal, carrying out heat preservation, and finally carrying out hot pressing treatment. According to the method, the yield of biomass hydrothermal carbonization is increased by utilizing mineral substances in the low-rank coal, and meanwhile, ash, volatile components and water in the low-rank coal can be partially removed, so that the caking property is improved. And then the mixture is mixed with the preheated high-metamorphic coal, so that the ignition point of the mixture can be improved, the explosiveness of the mixture is reduced, and the ash fusion point of the composite fuel can be further improved by utilizing the characteristic of high ash fusion point of the high-metamorphic coal. The biomass charcoal composite fuel can completely replace fossil fuel to be used for blast furnace injection, the emission amount of carbon dioxide and pollutants in the ironmaking production process is reduced, and in addition, the fuel formed through hot pressing has the advantages of being large in volume density and high in compressive strength and is suitable for long-distance transportation and long-term storage.

Owner:BAOSHAN IRON & STEEL CO LTD +1

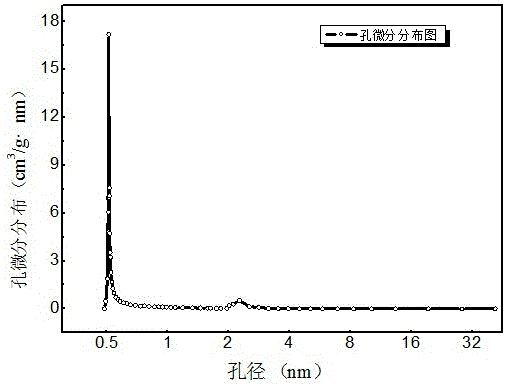

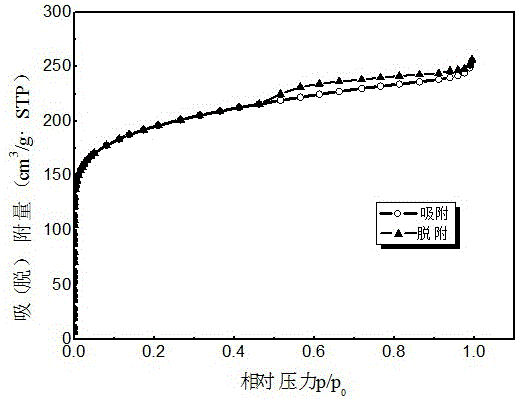

Uniform ultra-microporous activated carbon for gas separation and preparation method of uniform ultra-microporous activated carbon

InactiveCN106517189AReduce dosageReduce corrosionHydrogen separation by selective and reversible uptakeCarbon compoundsActivation methodMass ratio

The invention relates to uniform ultra-microporous activated carbon for gas separation and a preparation method of the uniform ultra-microporous activated carbon. According to the technical scheme of the preparation method, mixing semi-coke with KOH in a mass ratio being 1: (0.01-0.2), adding water and an activating aid to impregnate the mixture for 1-36 h; increasing the temperature to 800-950 DEG C in a programmed manner under N2 protection, controlling thermal decomposition, and introducing water for activation of part of steam for 0.5h-1.5h; finally, washing the mixture with acid and water until the mixture is neutral to obtain the uniform ultra-microporous activated carbon. The pore size is distributed centrally between 0.45 and 0.55 nm, the pores belong to ultra-micropores and have microporosity of 70% or more, and the adsorption capacity of hydrogen is 77cm<3> / g or higher. The semi-coke is taken as a raw material, low in price and low in energy consumption and needs not to be carbonized; an activation method integrates KOH impregnation pretreatment and activation of part of steam, little KOH is consumed, and the activation method has the characteristics of being low in cost and pollution, helpful for reducing corrosion of equipment and the like. The activated carbon prepared with the method has the characteristics of uniform pore size distribution, extremely rich ultra-microporous structure and the like, and can be used in gas separation fields such as pressure swing adsorption hydrogen making or hydrogen storage and the like.

Owner:WUHAN UNIV OF SCI & TECH

Technology for preparing high efficiency biomass fuel which is formed after charred

InactiveCN103509621ASolve the complete process technologyAchieve self-sufficiencyBiofuelsSolid fuelsCombustionCarbonization

The invention relates to a technology for preparing a high efficiency biomass fuel which is formed after charred, and relates to biomass carbonization and formation, and energy fields. The preparation technology comprises: 1. crushing and charring the biomass firstly; 2. after coarsely crushing the biomass waste by a shredder and finely crushing the biomass waste by a three-rotor hammer planer, removing ferruginous metals, and then removing heavy pollutants such as sand and stones which do not accord with production of the biomass fuel by pneumatic separation; 3. charring the materials satisfying specification in a charring device; 4. burning volatile gases and the biomass waste generated in the charring process in a combustion furnace, sending a high temperature gas into the charring device by a blower fan so as to provide heat demand for drying and material carbonization in the production process; 5. finely crushing or grinding the biomass again after charred, and then cooling; and 6. sending the charred finely particles into a granulator for granulation and formation. The technology implements continuous automation production of biomass formation, fuel carbonization and granulation formation.

Owner:北京泛欧瑞得科技有限公司

Preparation method for high-density, large-size, ultra-fine-pore nuclear graphite materials for fused salt piles

The invention provides a preparation method for high-density, large-size and ultra-fine-pore nuclear graphite materials for fused salt piles from coke aggregates 1-5 micrometers in size. The preparation method has the advantages that in the forming process, paste is compacted through vibration and ramming, calcination as well as temperature rise speeds and in-furnace temperature differences in thegraphitization process are controlled, and the shrinkage rate of graphite green bodies is further controlled, so that the technical problems that the smaller the average particle size of conventionalaggregates is, the larger the specific surface area and the surface energy of particles are, and the large-size nuclear graphite materials cannot be prepared are solved; multiple halogen gases are introduced as purification gases, and simultaneous purification in the graphitization process is realized; the method is clear in procedure, technically reliable and feasible, and suitable for large-scale production.

Owner:SINOSTEEL NEW MATERIAL ZHEJIANG

Method and device for preparing hydrogen-enriched fuel gas through sawdust charcoal gasification by high-temperature water vapor

InactiveCN106544057AIncrease useLow volatile contentEnergy inputGasification processes detailsWater vaporReaction temperature

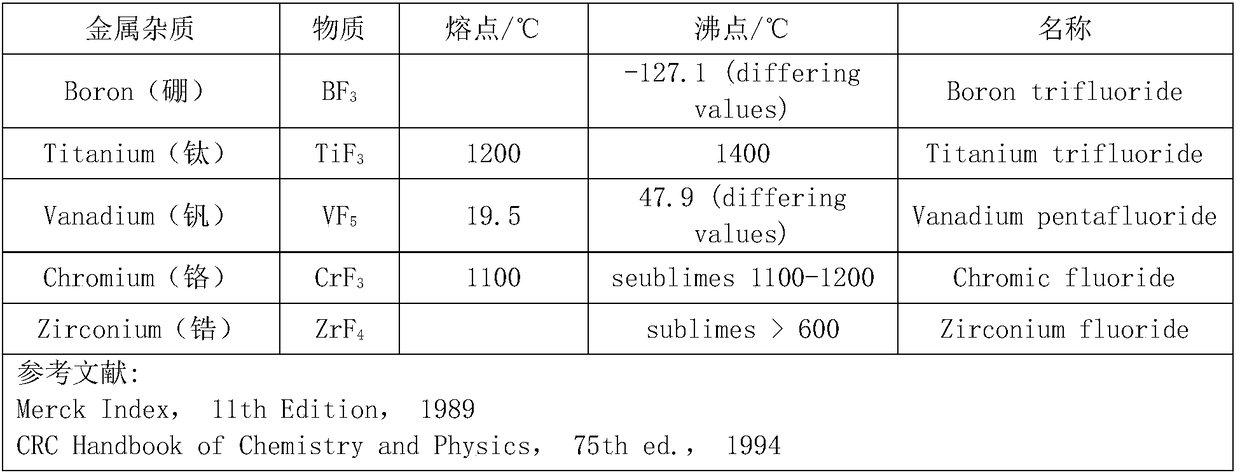

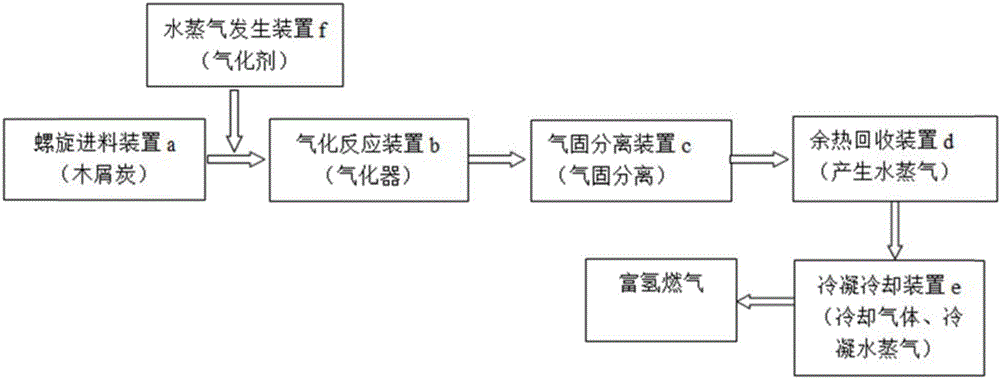

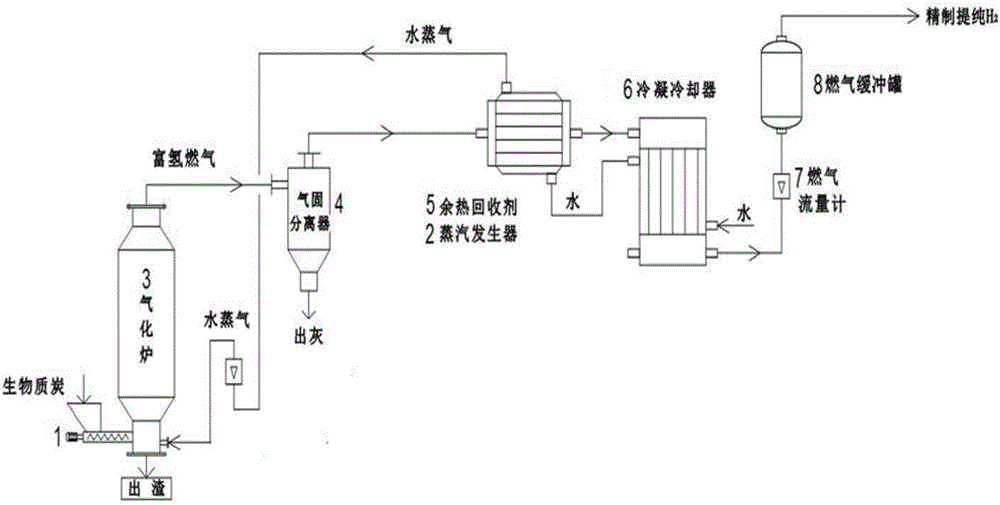

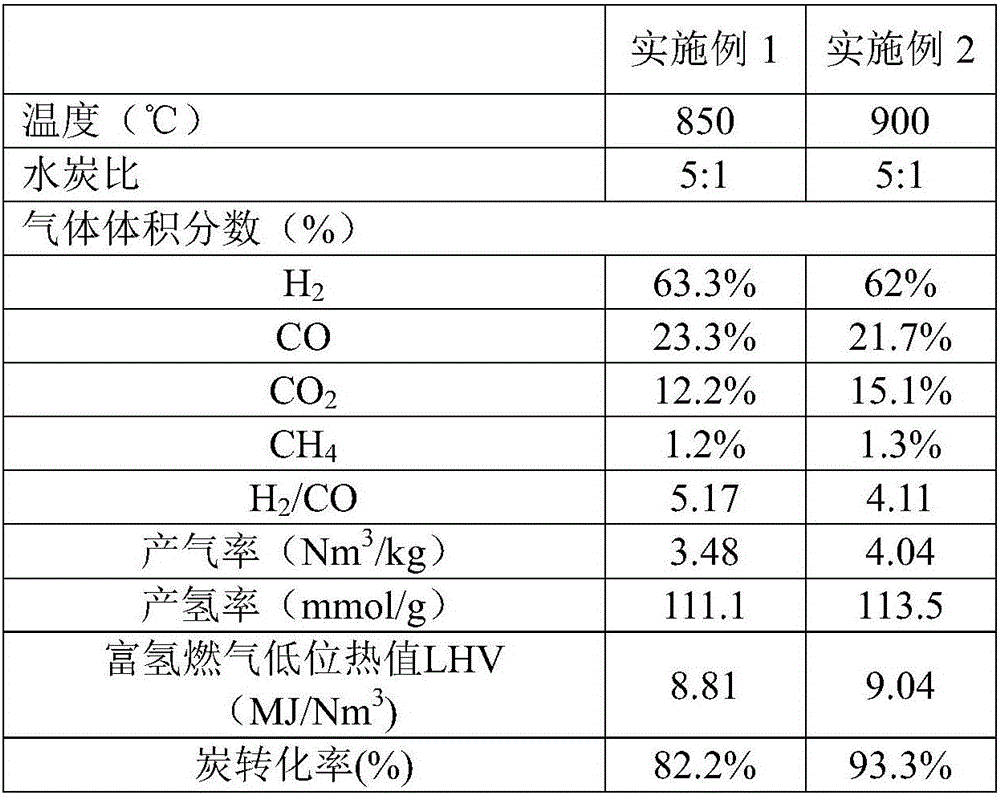

The invention discloses a method and a device for preparing hydrogen-enriched fuel gas through sawdust charcoal gasification by high-temperature water vapor. Sawdust charcoal is used as a raw material, and water vapor is used as a gasification medium, so as to prepare the hydrogen-enriched fuel gas. The method mainly comprises the following steps: helical feeding of sawdust charcoal, generation of water vapor, gasification of sawdust charcoal and cooling of hydrogen-enriched fuel gas. The water vapor is supplied by a water vapor generator in the early stage; after the system is stabilized, the water vapor is supplied by a waste heat recycling device; the temperature of a reactor is 800 to 950 DEG C; and the hydrogen-enriched fuel gas is prepared under technological conditions of proper reaction temperature, flow of the water vapor, particle size of the raw material, reaction time and the like. According to the method, the hydrogen-enriched fuel gas with the hydrogen volume percentage of 61.2 to 65.8 percent and the maximum hydrogen yield of 113.5 mmol / g can be prepared. The method has the advantages that the hydrogen volume percentage of the fuel gas is high, no tar is generated, and the gasification device is simple in structure; and the hydrogen-enriched fuel gas can be applied to preparation of high-purity hydrogen, synthesized natural gas, liquid fuel including methyl alcohol and dimethyl ether, and the like.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Method for marking active carbon by utilizing dyeing sludge

InactiveCN103318889ARealize resource utilizationSolve disposal problemsCarbon compoundsHigh carbonSludge

The invention discloses a method for making active carbon by utilizing dyeing sludge. The method comprises the following steps of: a, a pyrolyzing process: drying the sludge and pyrolyzing at the low temperature under the isolated air state; b, an oxidation pickling process; preparing a mixed aqueous solution mixture of potassium permanganate and sulfuric acid, wherein the potassium permanganate is 0.1mol / L-0.2mol / L, and the sulfuric acid is 1mol / L-1.8mol / L; soaking fixed carbon compound in a solid-liquid ratio of 1:(2-2.5), using the filtrate as aluminum ferric sulfate composite type purifying agent after removing heavy metal impurities; and drying the filter residue. According to the method for making active carbon by utilizing dyeing sludge disclosed by the invention, the sludge is used as the material to make the active carbon with low manufacturing cost and high carbon content through a pyrolyzing-oxidation pickling combination process. Moreover, the production process is almost free of pollution to the environment.

Owner:ZHEJIANG ZHUOJIA ENVIRONMENTAL ENG

Waste active carbon doped blending coal for coking, and coking method thereof

ActiveCN107011934AEfficient use ofAvoid pollutionSpecial form destructive distillationSocial benefitsActivated carbon

The invention discloses a waste active carbon doped blending coal for coking. The waste active carbon doped blending coal for coking is produced from feed coal, waste active carbon and a promoter according to a weight ratio of 100:(0.5-2):(0.5-1). The waste active carbon is used, so the effective use of resources is realized, the environment pollution caused by the stacking and the landfill of the waste active carbon is overcome, and disordered discharge of toxic volatile substances adsorbed by the waste active carbon, caused by improper regeneration, is overcome; and nonvolatile carbon and ash in the waste active carbon are coked by a coal coke oven to form coke, so the use amount of the feed coal is reduced, benzene series substances absorbed in the waste active carbon are fully recovered, environmental pollution is avoided, great economic and social benefits are realized. The promoter can promote the coking of the waste active carbon and the feed coal to form the coke, the fixed carbon content of the produced coke is increased to 88.1%or above, and the quality of the coke is greatly improved.

Owner:LINYI HENGCHANG COKING

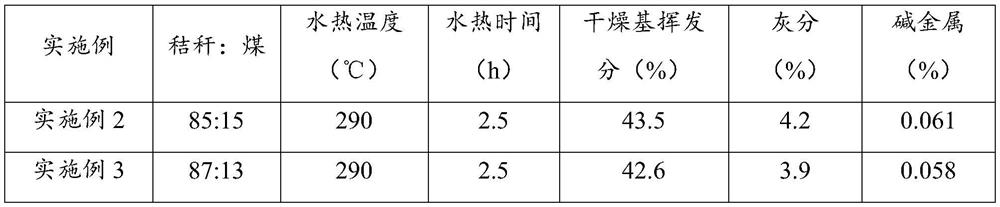

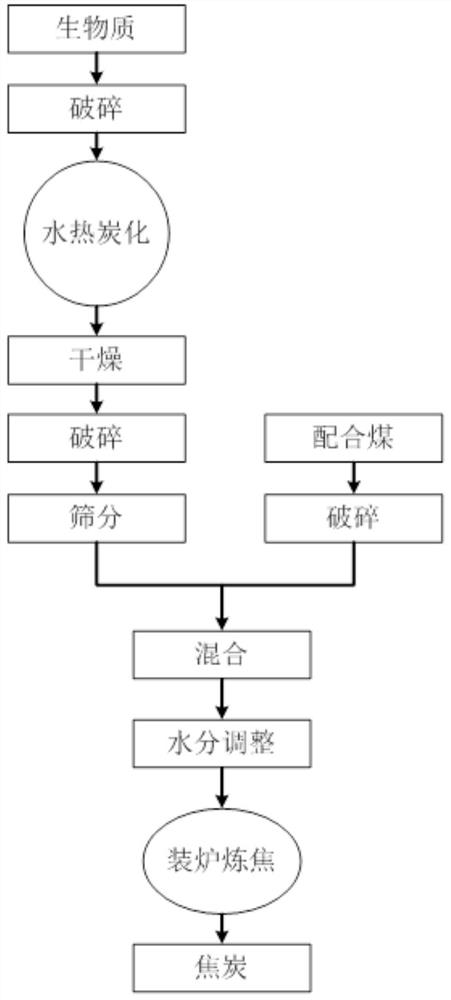

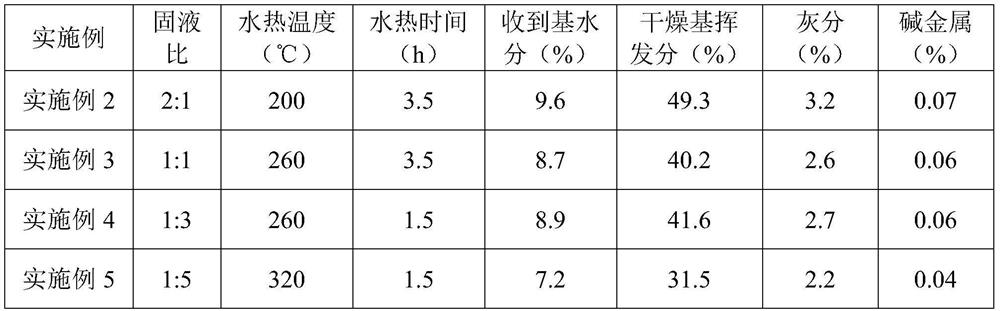

Method for preparing coking raw material through biomass hydrothermal carbonization treatment and application of coking raw material prepared by method to coking production

PendingCN111978970AAddressing Distribution Inconsistency BiasDistribution inconsistency deviation is smallBiofuelsSpecial form destructive distillationPollutant emissionsCoke

The invention provides a method for preparing a coking raw material through biomass hydrothermal carbonization treatment and application of the coking raw material prepared by the method to coking production. According to the method, firstly, crushed biomass is subjected to hydrothermal carbonization treatment; by controlling the hydrothermal carbonization temperature and time, high-quality biomass hydrothermal carbon with the low ash content, the low alkali metal content, the high fixed carbon content and the proper water content is obtained, so that the performance of the biomass hydrothermal carbon meets the quality requirement of coking production; then, the biomass hydrothermal carbon and base coal are mixed, a proper amount of water is added for uniform mixing, and the coking raw material is obtained; and the water content in the coking raw material is regulated and controlled to be 6 to 12 percent, and the coking production is performed. On the premise that the mechanical strength and the reaction performance of the produced coke are enabled to meet the blast furnace ironmaking requirement, the goals of realizing resource utilization of the biomass, reducing the coking cost,saving coking coal resources and reducing CO2 and pollutant emission are also achieved; and good environmental and economic benefits are achieved.

Owner:UNIV OF SCI & TECH BEIJING

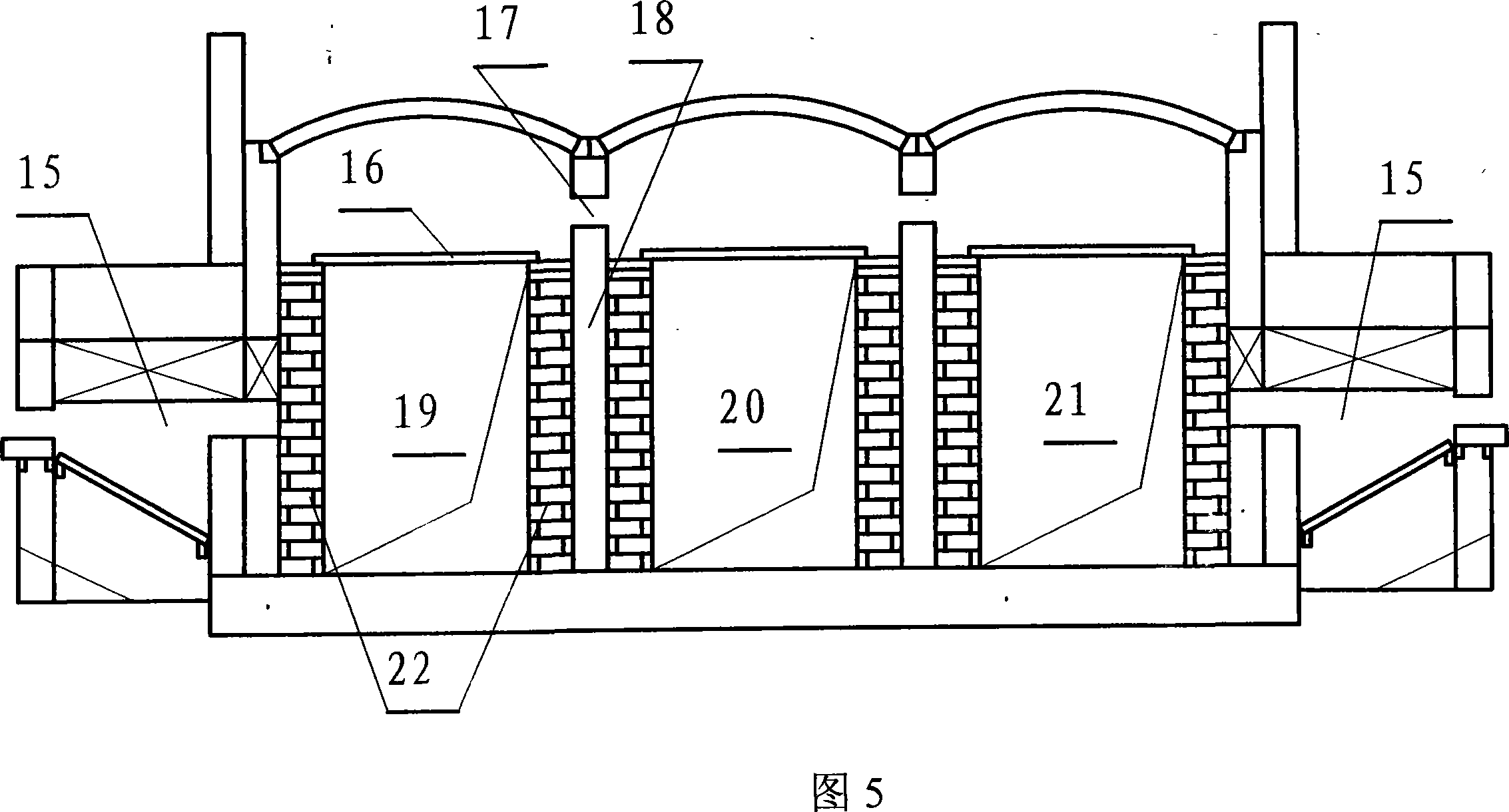

Formed coke clean production method and equipment

InactiveCN101225339AHigh fixed carbon contentHigh iron to coke ratioSolid fuelsContinuous operationSulfur content

The invention discloses a preparation method for formed coke and a piece of equipment, in particular to a method of using coke powder or anthracite, mill coal as primary material, adding powder normal temperature adhesive and coal tar powder, fully mixing, cold molding and performing, putting the coke adobe into a tunnel carbonization stove, giving a low temperature oxidation treatment to the coke adobe, to produce formed coke with a high quality. The forming equipment is over 24 times more efficient than the existing equipment by using multicavity composite mold and automatic feeding-ejection apparatus; the material needs no processing of drying and heat plasticizing; the elementary composition of the body can be adjusted freely; the formed coke has low sulfur content, low ash content, high fixed carbon content, no smoke in the combustion, high iron-coke ratio and good watertightness in the long time preservation. The investment scale with the same production capacity is only one twentieth of the heat seal - carbonization method; the working procedures of material drying, heat kneading, high temperature carbonization are saved, not only the production control becomes easy, but also the production process is more energy-saving; the tunnel type oxidation (or carbonization) stove realizes a continuous operation, has a large yield, and improves the productivity.

Owner:陈善堂

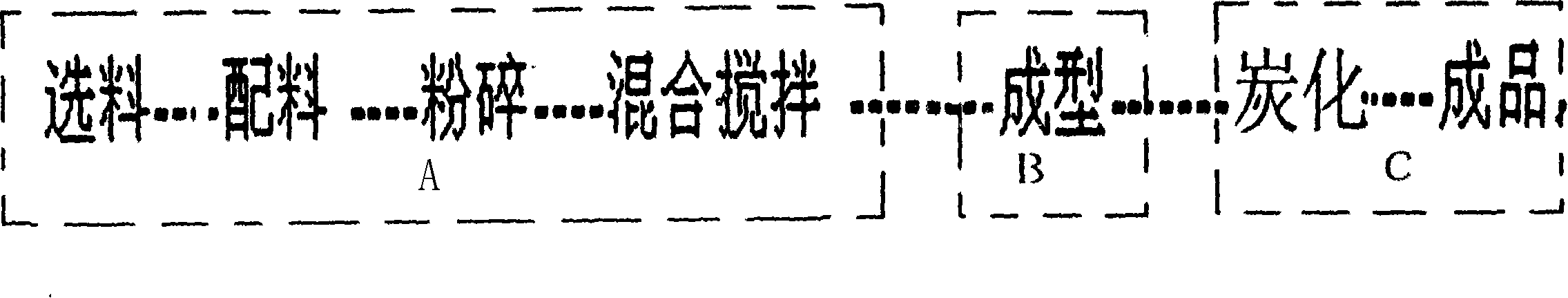

High-temperature casting molded coal and method for producing the same

InactiveCN101139537AActive reactionFacilitate active reactionCoke ovensSolid fuelsFertilizer plantAdhesive

The invention discloses a high-temperature casting coal and a production method for the coal. The product from the invention comprises 50-90% fine anthraciferous coal, 1-12% coke coal, 5-25% peacoke, 1-10% binder and 0.1-1% active agent. The production method of the invention comprises selecting material, blending materials, crushing, mixing and agitating, forming, carbonizing and getting finished product. The invention can reduce about 10% ash, so that the fixed carbon content of the product can be increased greatly, and the product is of very good water proofness and cold and hot strength, is easy to store and transport; meanwhile, a lot of microholes are produced during the carbonizing, this is good for active reaction during casting and production of chemical fertilizer plant, is both useful for gas making and casting, and can save about 50% coke.

Owner:赵宜文

Biomass coal briquette by use of anthracite coal and carbonized biomass fuel as base materials

InactiveCN105316057AHigh calorific valueResolve Insufficient CombustionSolid fuelsWaste based fuelCoal briquetteSorbent

The invention discloses a biomass coal briquette by use of anthracite coal and carbonized biomass fuel as base materials. The biomass coal briquette comprises the following raw materials in parts by weight: 49-59 parts of anthracite coal, 30-36 parts of carbonized biomass fuel powder, 0.5-12 parts of a combustion improver and 9-14 parts of a binding agent; the carbonized biomass fuel powder is obtained by carbonizing the following raw materials in parts by weight: 50-72 parts of eucalyptus bark, 15-20 parts of pine branches, 15-20 parts of straws, 5-8 parts of corncob, 15-20 parts of corn straws and 15-20 parts of soybean straws. The biomass coal briquette is prepared from anthracite coal and carbonized biomass fuel powder which are used in a combined manner, so that the content of volatile matters is low, the use of a sulfur fixation sorbent is eliminated, and energy conservation and environmental protection are realized.

Owner:GUANGXI KUONENGBA ENERGY TECH DEV CO LTD

Environment-friendly industrial briquette composite binder and preparation method thereof

The invention discloses an environment-friendly industrial briquette composite binder and a preparation method thereof. Humic acid, alumina, common seepweed herb seed cake meal, water and the like are used as raw materials; the preparation process is simple and convenient; the briquette prepared by the method has the advantages of little drop of the solid carbon content, good binding property, high pelletizing rate, high cold / hot strength, good thermal stability, low cost, short production cycle and the like.

Owner:GUANGXI LIUZHOU JUNYE TECH

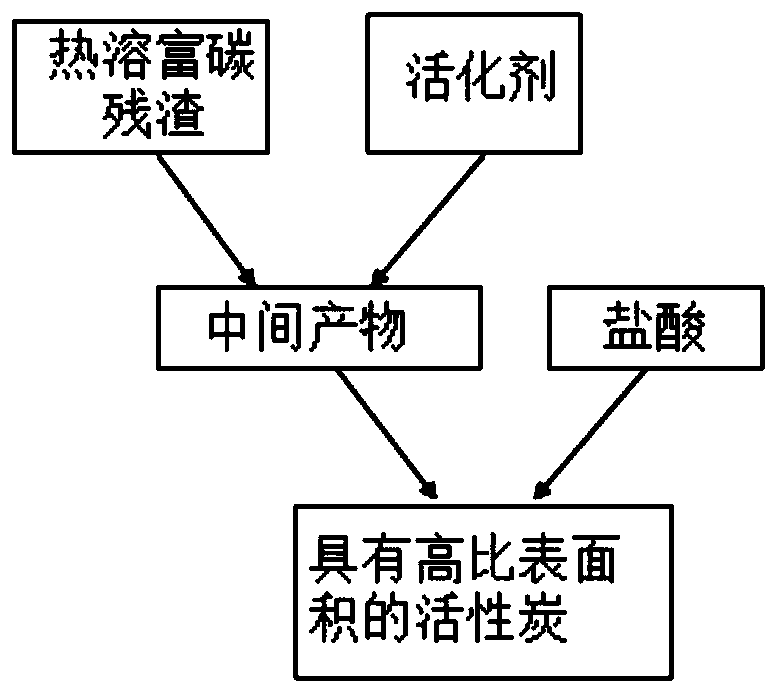

Activated carbon with high specific surface area and preparation method of activated carbon

The invention belongs to the field of renewable utilization of biomass and particularly discloses activated carbon with a high specific surface area and a preparation method of the activated carbon. The preparation method comprises steps as follows: thermally-dissolved carbon-enriched residues and an activator are sufficiently mixed, heated in the inert atmosphere, kept at the temperature for a period of time, and cooled to the room temperature, and an intermediate product is obtained; the intermediate product is washed with deionized water to be neutral after being subjected to acid pickling,finally, drying is performed, and the activated carbon with the high specific surface area is prepared. The activated carbon is prepared through sufficient use of waste produced in the thermally-dissolved carbon-enriched treatment process of the biomass, a new way is provided for high value-added utilization of biomass wastes, defects of a thermal-dissolving and carbon-enriching technology are made up, and comprehensive utilization of various solid wastes in the thermal-dissolving and carbon-enriching technology is realized.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing high-performance compound machine-made charcoal

The invention relates to a method for preparing high-performance compound machine-made charcoal, and belongs to the technical field of resource comprehensive utilization. The method comprises the following steps: respectively grinding a biomass raw material with a moisture content of lower than 5 percent and lignite into particles having granularity of less than 1cm; pyrolyzing the biomass raw material particles to obtain charcoal; uniformly mixing charcoal, lignite, an adhesive, a combustion improver and water to obtain a mixed material, and pressing the mixed material into charcoal rods with center holes; and heating the charcoal rods with center holes to 400-700 DEG C at a heating speed of 30-200 DEG C / min, carbonizing for 1-12 hours, and cooling to obtain the compound machine-made charcoal. The preparation process adopts biomass which is rich in source and low in price, is regenerative and can be easily ground and lignite with low price as carbon sources, has the potentials of low large-scale production price, high yield, high heat value and high porosity, and is well accepted by the market.

Owner:KUNMING UNIV OF SCI & TECH

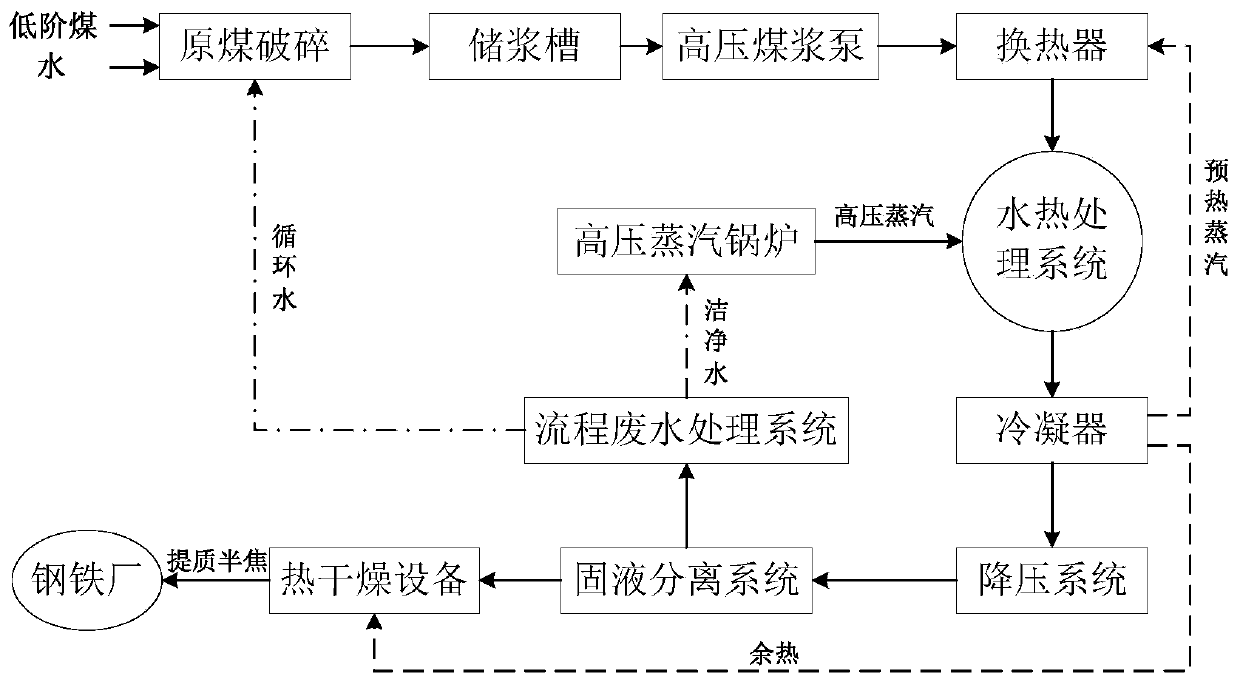

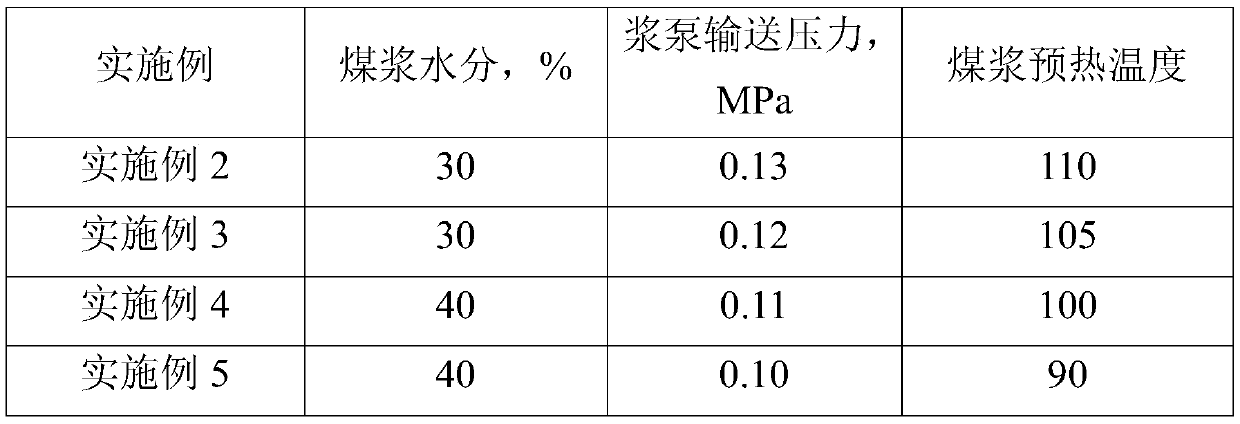

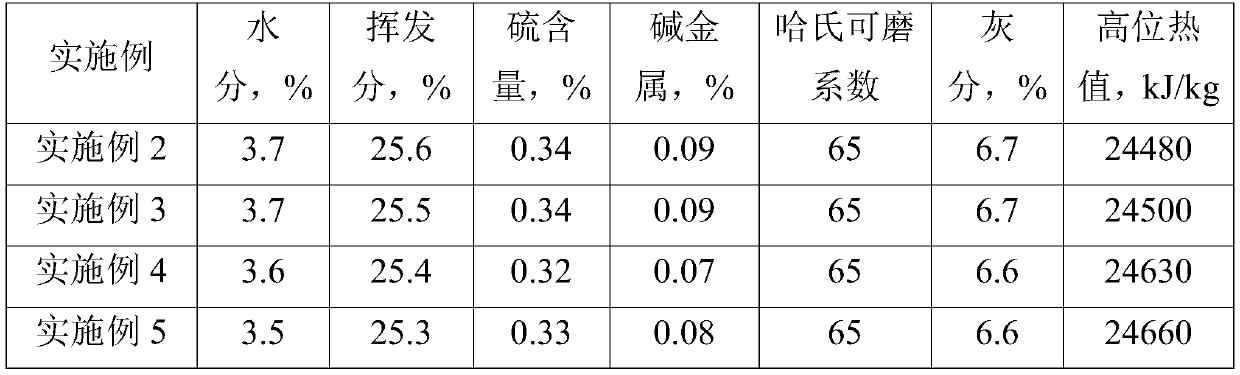

Method for preparing blast furnace blowing semicoke from low-rank coal based on high-pressure hydrothermal reaction

ActiveCN110982542ALow fixed carbon contentHigh fixed carbon contentEnergy inputSpecial form destructive distillationThermodynamicsProcess engineering

The invention relates to a treatment method for dehydrating and upgrading high-moisture and high-volatile low-rank coal, and discloses a method for preparing blast furnace blowing semicoke by upgrading low-rank coal based on a high-pressure hydrothermal reaction, wherein the method comprises four steps of low-rank coal pretreatment, high-pressure hydrothermal upgrading, waste heat recycling and upgraded semicoke dehydration and drying. According to the method, low-heat-value low-rank coal is converted into high-quality blast furnace blowing upgrading semicoke by utilizing a high-pressure hydrothermal reaction upgrading technology, wherein the moisture content of the semicoke air drying base is less than 6%, the volatile component content is less than 25%, the Hardgrove grind ability indexis greater than 60, the high-order heat generation value is greater than 24000 kJ / kg, soluble potassium salt, sodium salt and sulfate components in ash are dissolved out, the organic sulfur in coal iseffectively separated out, and the upgraded semicoke can meet the performance index requirements of coal for blast furnace blowing; and the method provided by the invention effectively solves the problems of high water content, high volatile component content, low heat value and high harmful element content of blast furnace blowing of low-rank coal, and provides a clean, efficient, low-energy-consumption and high-added-value low-rank coal upgrading utilization method.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing activated carbon through sludge fermentation residues

InactiveCN110171829ARealize resource utilizationHigh yieldCarbon compoundsActivated carbonPotassium hydroxide

The invention relates to a method for preparing activated carbon through sludge fermentation residues. The method comprises the following steps of 1, mixed strong base pretreatment on sludge, whereinthe remaining sludge is taken, the moisture content of the sludge is adjusted to be 95-98%, a mixed solution of potassium hydroxide and sodium hydroxide is added, and the sludge is subjected to mixedstrong base pretreatment after being heated to 90-95 DEG C; 2, sludge and water separation for a fermentation mixture, wherein the remaining sludge after strong base pretreatment in step 1 is subjected to anaerobic fermentation, and when fermentation is finished, agricultural and forest waste is put in the fermentation mixture to serve as a filter aid; 3, preparation of the activated carbon through the fermentation residues, wherein the fermentation residues after sludge and water separation in step 2 are slowly dried under a low-temperature condition, the dried residues are sent into a carbonizing furnace for high-temperature carbonizing, the carbonized residues are sent to an activator for pelleting activation, the activated residues are sent to an oven for drying, and after drying is finished, the sludge-based activated carbon is obtained. By means of the method, the situation that the agricultural and forest waste is left unused and wasted is reduced, and the problem that it is hard to dispose anaerobic fermentation sludge is solved.

Owner:南京河海环境研究院有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com